1. Introduction

Recently, electric vehicles (EVs) became more widespread, and thus, installing EV charger stations is substantial to satisfy the electrical energy demand of a large number of EVs [

1]. However, due to the extended electrical grids, fast EV charger stations, parking lots, and residential areas can supply the electrical energy desired to charge EVs. Energy management control strategies are required for the charger stations for designing and calculating an optimal contracted ability to promote performance and operation [

2,

3,

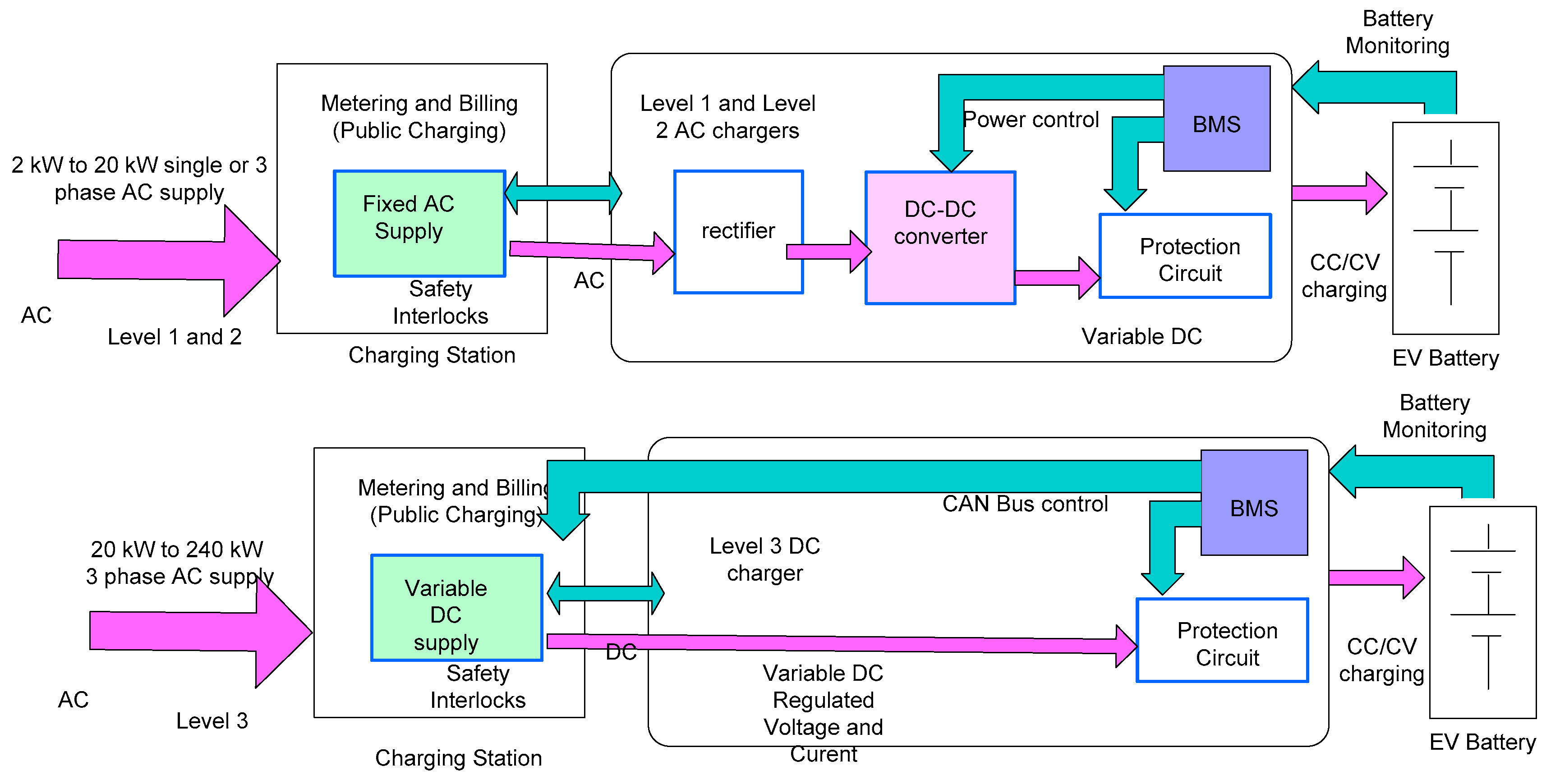

4]. Effective battery chargers represent a substantial role in the evolution of modern EVs. The characteristics of the battery charger affect the battery life and charging energy efficiency, as well as the charging time. EV battery chargers should have the key advantages of higher power density, higher efficiency, better reliability, smaller size, lighter weight, and cheaper cost. The operation of the charger circuit relies fundamentally on power circuit topology, power circuit passive and active devices, soft switching techniques and control schemes [

5]. Mostly, the EV-charger control techniques can be carried out by using analog/digital controllers, digital signal processors, microcontrollers, and some particular integrated circuits. However, this depends upon the complexity of the power circuit topology, cost, and the power rating of converters. Although plug-in electric vehicles (PEVs) are being promoted in the market with the objective of reducing the pollution from conventional automobiles, the energy demands for charging the EV batteries are still supplied by power generated by conventional fossil fuel sources. For this reason, many researchers have proposed the solution of charging PEVs using renewable energy sources like photovoltaic (PV) and wind. Numerous pilot projects are also carried out to charge PEVs from solar PV and wind energy systems [

4,

5,

6,

7,

8,

9]. These projects are still in the development stage [

10]. Moreover, due to the economic and social benefits, research work on charging stations powered by the PV system has engaged researchers worldwide. Generally, the use of solar energy charger is a dependable source for charging small scale electric vehicles, such as scooters, golf carts, and airport utility carriages [

11]. The use of photovoltaic powered chargers in a parking lot is analyzed in [

12]. A photovoltaic PV-based charging station that is connected with the utility grid is described in [

13,

14]. Solar PV parking lot chargers and other application models to supply PEVs with solar energy are explored in [

15]. Economic studies of PV powered charging stations have been done by [

16,

17]. Reference [

18] depicts how intelligent control algorithms can support PEVs and PV to integrate with the existing electrical power systems. PV system provides a potential source for PEV of median generation capacity, while PEVs represent a dispatchable load for low and extra PV generation during periods of light load demand.

For the stand-alone microgrid, energy management system (EMS) can control demand/supply balance and maximize the environmental or economic benefits. EMS is a key technology for stable microgrid operation. For the stand-alone wind-diesel microgrid in [

19], an optimal EMS strategy is proposed, which optimizes the charging/discharging cycles of storage system and system operation cost according to the prediction of wind turbine (WT) output and load demand. A novel EMS-based on a rolling horizon strategy for a renewable-based microgrid, which includes PV, WT generator, diesel generator, and energy storage system (ESS), is proposed in [

20]. In [

21], a control strategy to reduce power fluctuations is proposed, which utilizes the ESS to smooth the output power of the wind farm. DC microgrids have a less complex control strategy which only adopts P-V droop, mitigates the need for reactive power compensation, and reduce the circulating reactive power. Furthermore, elimination of frequency and phase angle would ease the resynchronization to the utility grid. Without reactive power and harmonics, DC microgrids could also offer a better quality of power [

22]. They can feed the DC loads directly by avoiding the conversion losses.

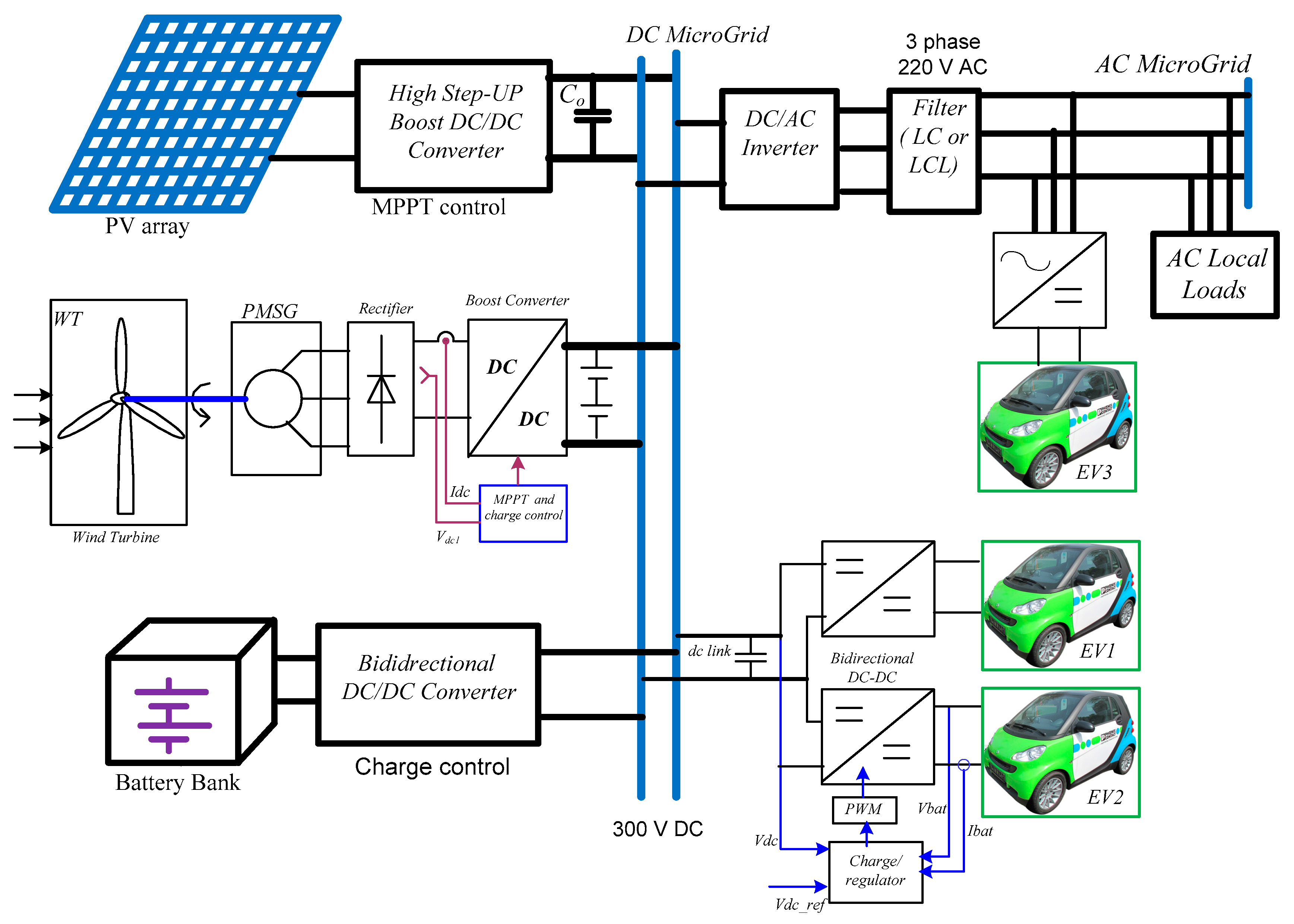

Renewable energy-based charging stations (wind and solar) are friendly EV charging that reduces fossil fuel exhaustion, optimizes investment cost and accommodates fluctuations of generated power by renewable sources. The evaluation objectives of charging stations include operational performance and customer acceptance of charging equipment; pricing criteria to encourage off-peak charging; and grid impacts [

23]. Hence, adopting a DC microgrid is presented for enhancing the resilience and optimum operation of microgrid, including distributed generation [

24]. The broad problem considered in this research is the optimization of energy flows in the DC microgrid. For this reason, a stable, robust and optimal supervisory control algorithm is substantial for the large scale hybrid dynamical system of PEV charging station. Since the system is subjected to random variations in solar power and the connected vehicles in the parking lot, the system operation must be robust against these disturbances. In a DC-microgrid, buses can be classified into four types: Generation bus, DC load bus, batteries energy storage system (BESS) bus, and connection bus to AC-microgrid using voltage-source converters (VSCs). Moreover, these types of buses can be divided into two groups according to their contribution to microgrid operation and control, which are power bus and slack bus. The power bus absorbs power from/to the microgrid on its own. Typical examples are variable DC-loads and variable (non-dispatchable) generation, such as photovoltaic and wind turbines generation systems. In contrast, slack buses are responsible for balancing the power surplus/deficit resulting from power buses and maintaining stable operation of the microgrid.

Generally, in the largely inhibited parking lot, interventions are focused on removing fully charged EVs, to give non-charged EVs a chance to be an effective to realize powerful utilization of the charging infrastructure [

25]. Specifically, two resilience measures are considered, the resilience related to the amount of energy delivered to EVs and the resilience related to the average charging time, are provided for the EV charging station. Resilience can be defined as the ability of the studied system to withstand disturbance state and return to a regular state quickly. It has become a new challenge facing the EV charging station design [

26]. A related key performance indicator (KPI) is the percent of sessions with a low charging time ratio to the total charging time divided by the amount of total connection time [

27,

28]. However, these sessions are often a burden during peak hours and daytime. To increase availability for other EV users, the fully charged EVs should be removed.

References [

29,

30] propose power management strategies for an autonomous DC-microgrid based on a PV source, a supercapacitor, electrochemical storage, and a diesel generator. However, these papers have difficulties in achieving power balance, while accounting for the slow start-up characteristic of the diesel generator, the self-discharge of an SC. Moreover, the economic operating mode of the diesel generator can increase the total energy cost of the DC-microgrid. References [

31,

32] has studied a test bed to investigate the dynamic response of a DC-microgrid to major disturbances, but it did not calculate the resilience of the studied DC-microgrid. References [

33,

34] have investigated the dynamic response of microgrids powered by renewable energy sources, but they did not define resilience of the studied systems.

This paper presents the control strategy of an isolated standalone EV chargers station incorporated in a DC microgrid. This control strategy is investigated using proportional-integral controllers (PI). This controller will regulate the charging of EVs. The proposed EMS is considered promising, due to its robustness and simplicity that makes this suitable for applications in the future smart DC microgrid. A new resilience measurement is defined as the ratio of the normalized system, integrated within its maximum permissible recovery time after the disturbance to the performance integral in the ordinary state. This measure enables the resilience of various systems to be compared on the same comparative scale. To estimate the resilience of DC microgrid, a resilience measurement scheme is developed.

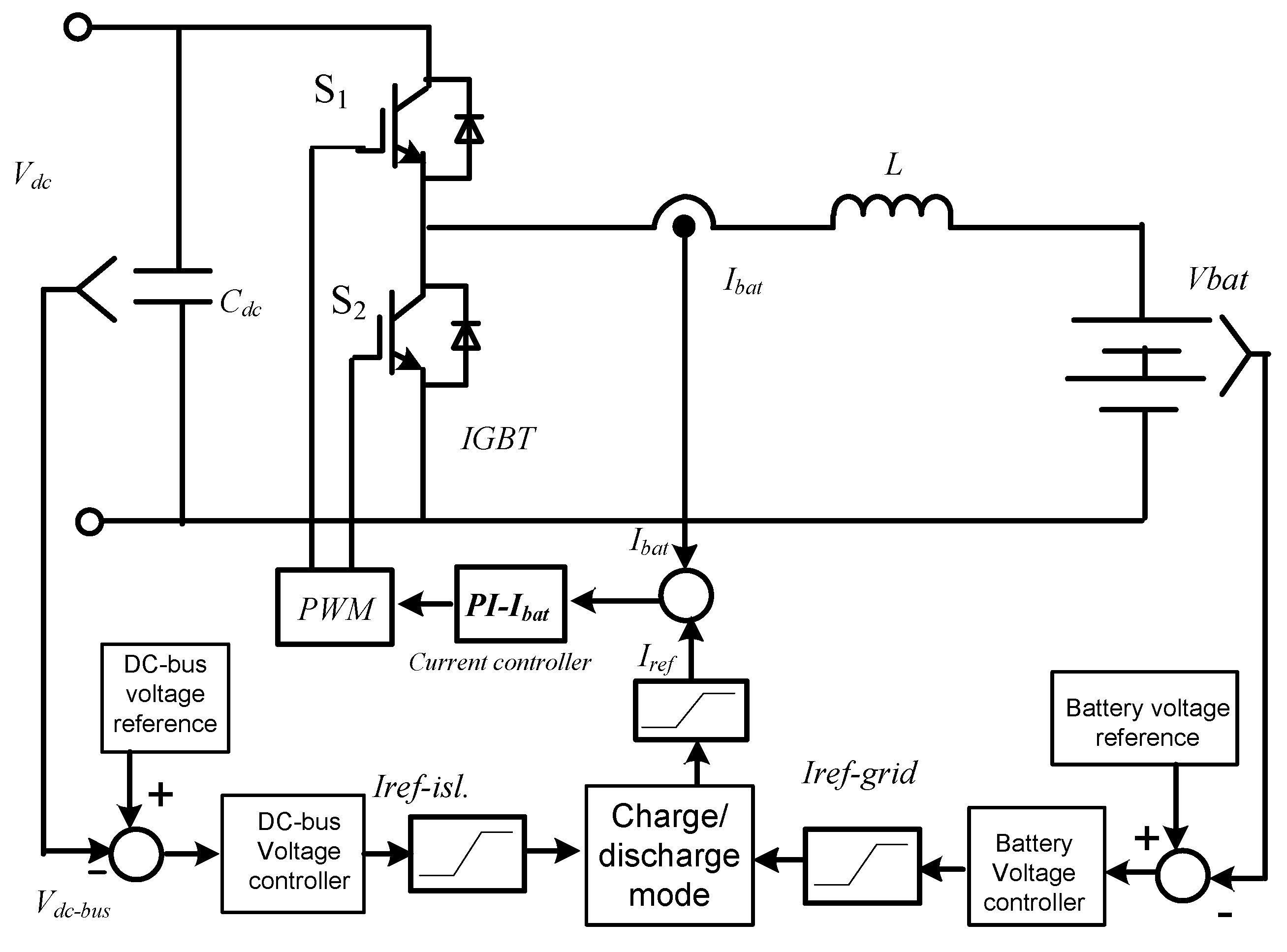

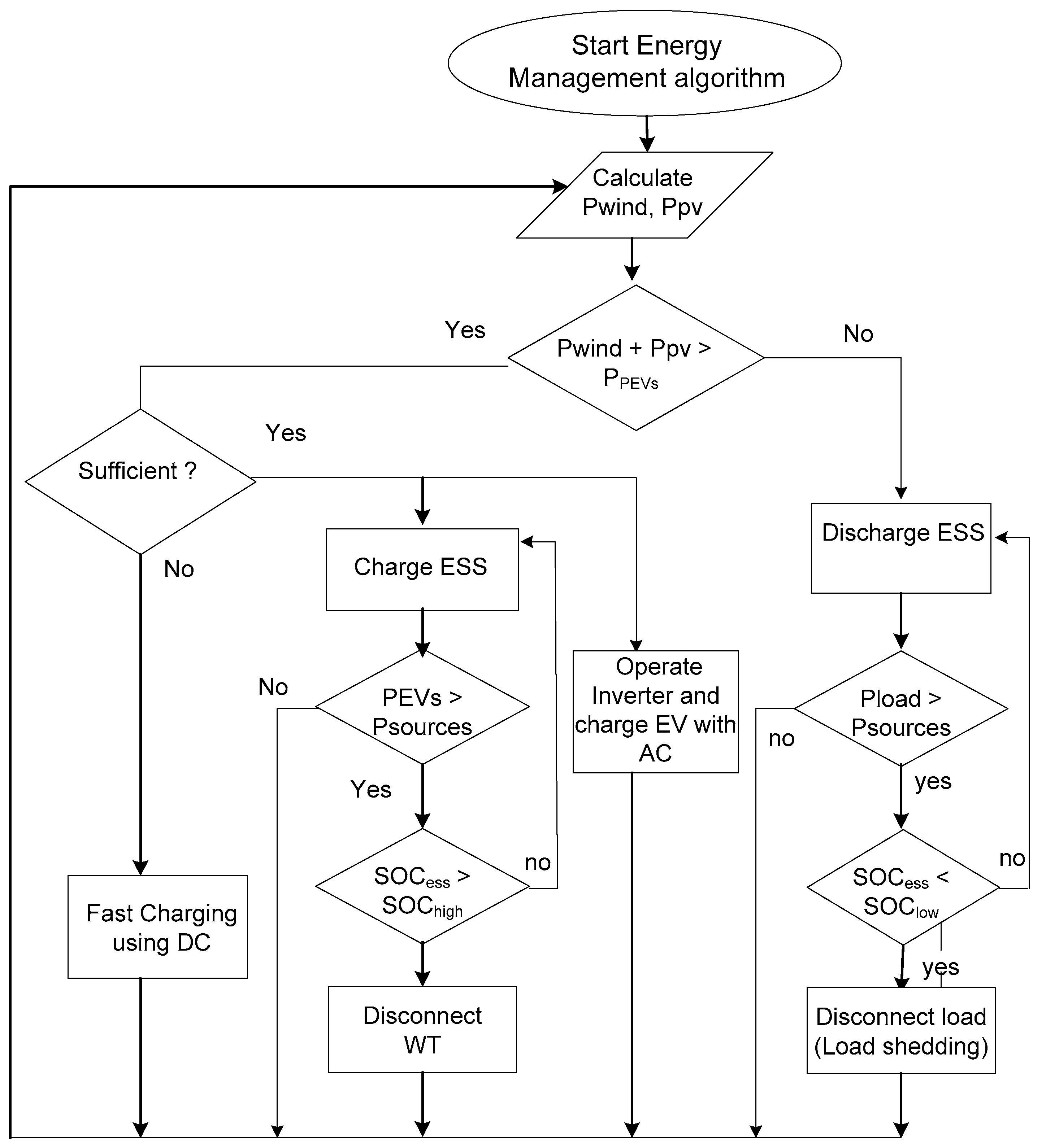

4. Energy Management Control Strategy

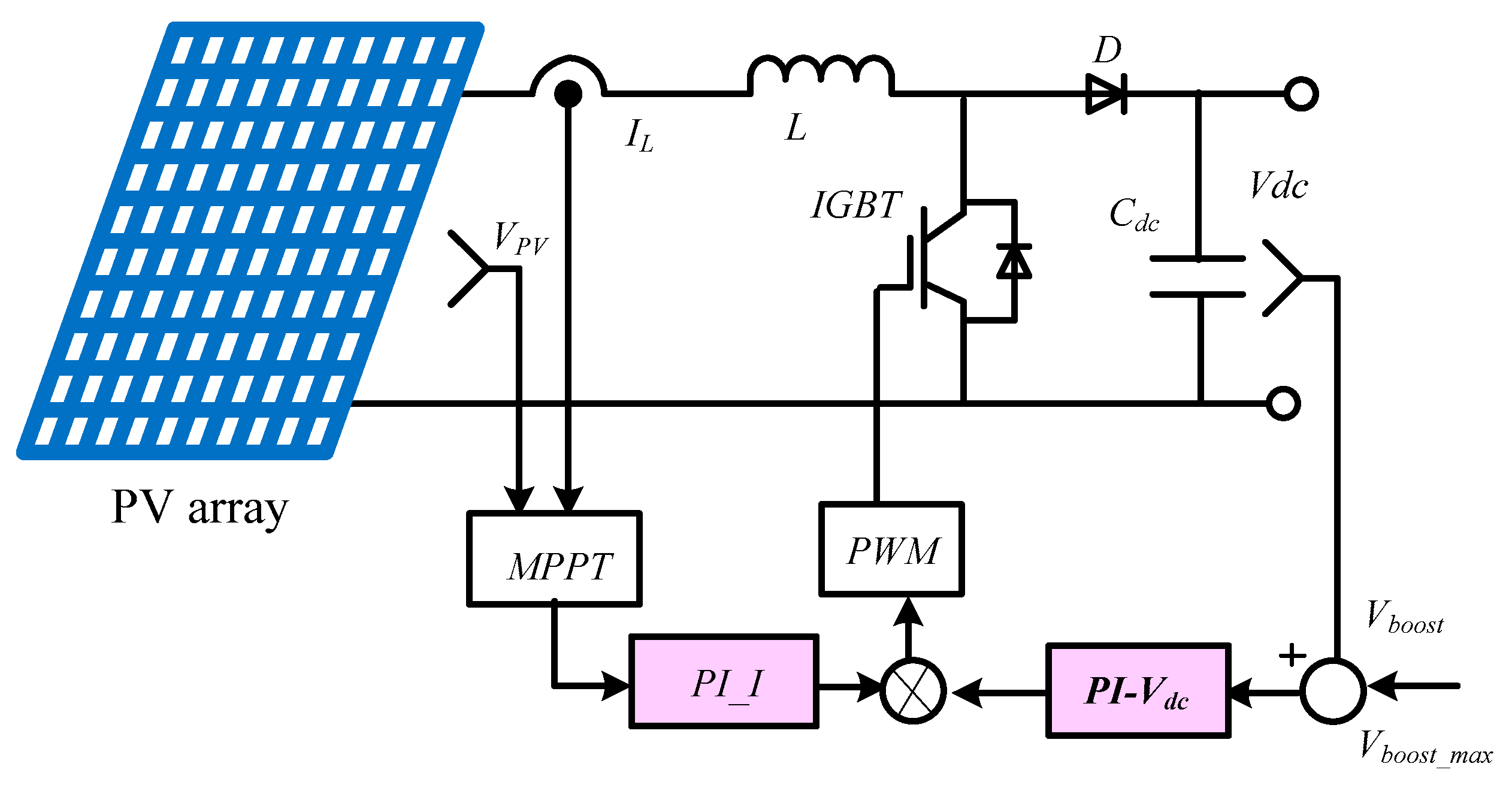

The amount of energy that can be produced by the PV or wind generator is calculated using the input data, such as hourly solar irradiance, wind speed, and ambient temperature. The total value of generated output power (Psources) is compared with the load demand energy (PPEVs) to estimate the energy flow distribution between the energy storage unit and the loads. Surplus energy is stored in the battery banks. The control strategy of the hybrid PV-wind charging station is described by the flowchart in

Figure 8. According to

Figure 8, the control strategy is applied according to four different cases as follows:

If Psourcs (Ppv + Pw) > PPEVs, then PESU = Psources − PPEVs. If the irradiance level and wind speed are high enough, the output power empowers the connected electric vehicles, and the exceeding power is stored in the battery bank.

If Psourcs·(Ppv + Pw) = PPEVs, then PESU = 0. That is, if the irradiance level and wind speed are just enough, to empowers the connected electric vehicles and no excess power to charge the battery bank.

If Psources < PPEVs and PPEVs − Psources ≤ PESU, then PPEVs − Psources = PESU. That is, if the PV and wind generators cannot supply the load, then the load is supplied directly from the DC-microgrid, and the battery converter is switched on.

If Psources < PEVS and PEVS − Psources > PESU, in this case, the energy stored in the battery bank is not enough to charge connected PEVs. Then the PEVS and battery bank are disconnected.

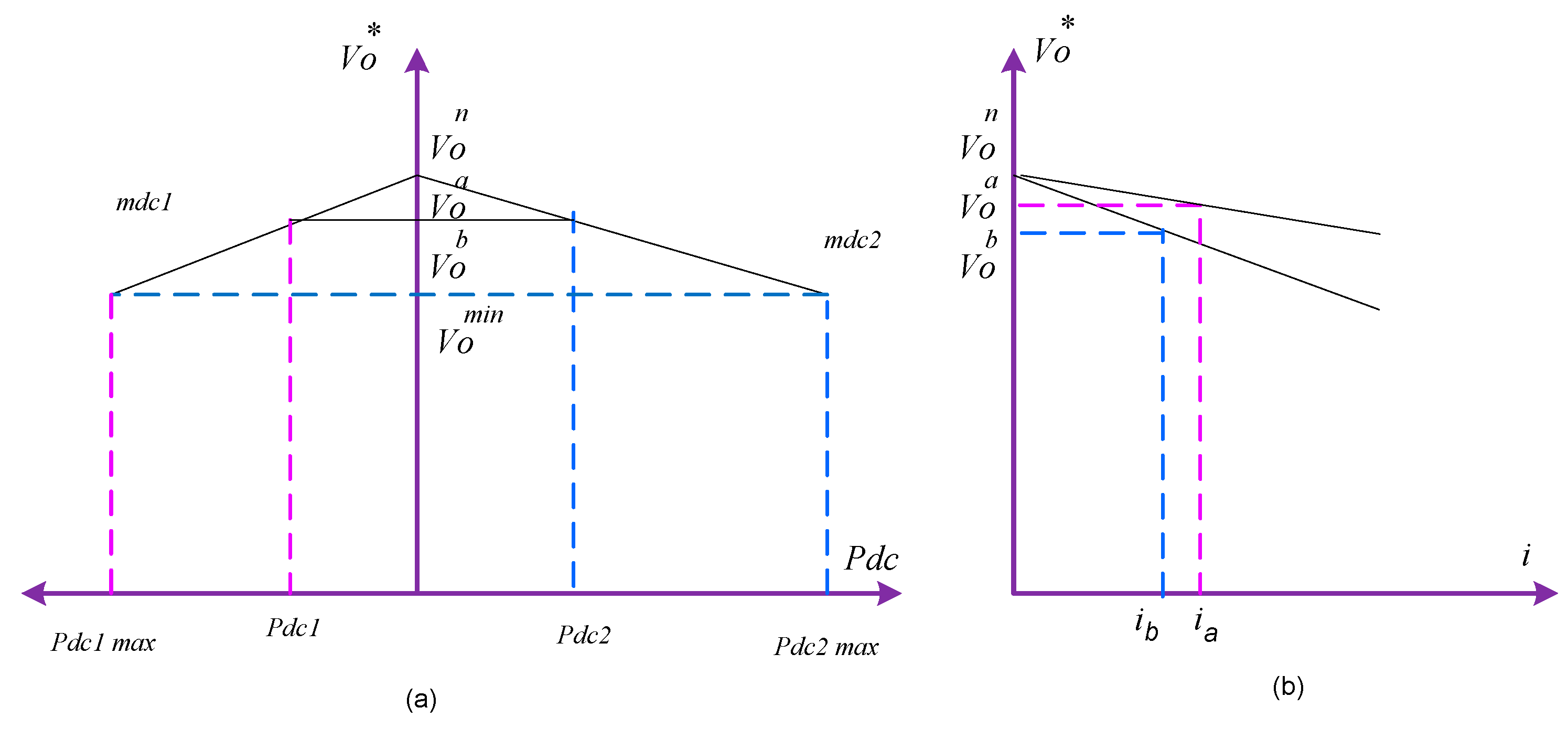

The supervisory controller is divided into two main functions. The first function identifies the mode of operation according to the conditions and situation of individual microgrid components. The second function is integrated into intelligent systems, such as converters and inverters that determine the performance of individual components in that mode of operation. The switch over in the battery charging mode takes place either when the state of charge of the battery is lower than the minimum SOClow or when there is a sudden decrease in the required power for load and state of charge of the battery is lower than maximum SOChigh. Therefore, when loading power decreases, the surplus power is utilized to charge the batteries if it is not fully charged. The individual components can be controlled easily using a built-in controller, such as the DC-DC converter controller. Thus, the energy management system (EMS) is responsible for achieving the optimal operation of the DC microgrid.

The energy management control algorithms overcome the unbalance between power produced from distributed generation (DG) units and load. This can be done when the SOCs of ESS are sufficient. In the case of ESS failure or an inappropriate SOC value, the master unit becomes the wind turbine. In case of that, the load is greater than the available energy production, and the controller of the DC-microgrid is not able to balance the power flow of the system, the solution will be the load shedding. In case that the power generated by the sources is bigger than the load consumption, one of the distributed generators will be disconnected from the microgrid.

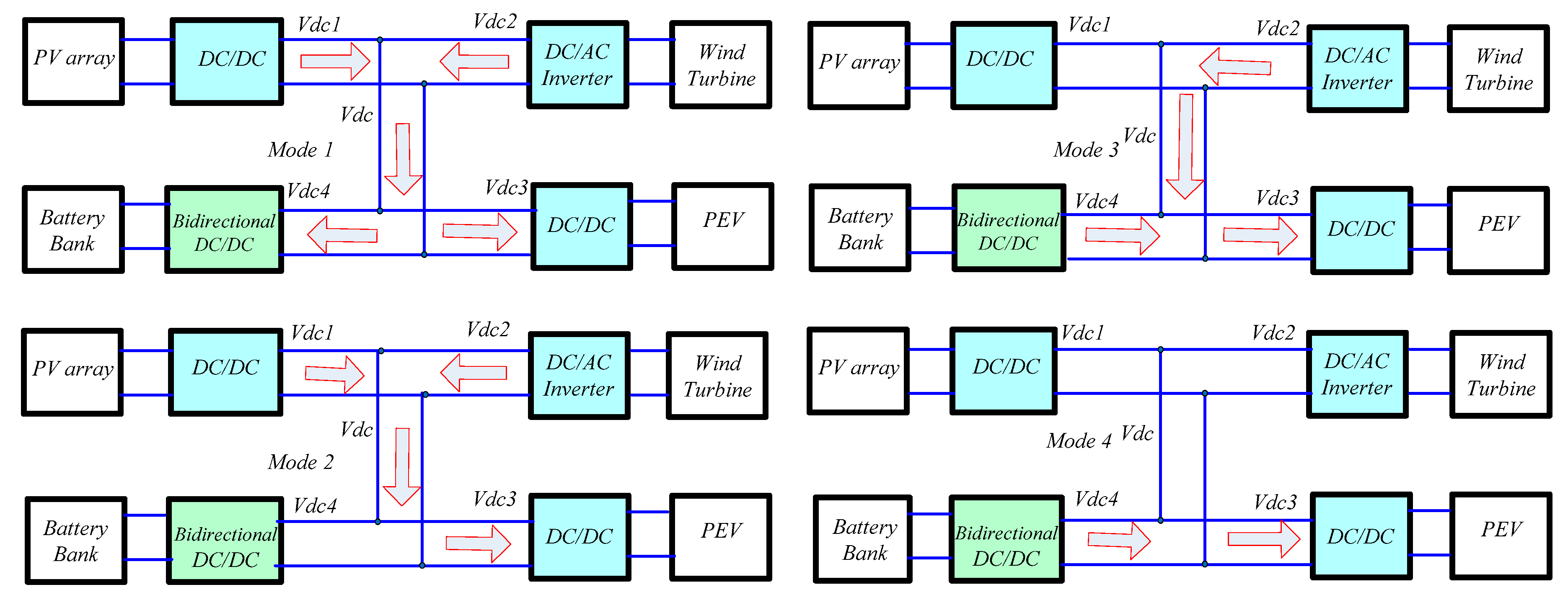

The operation of the charging station DC-microgrid can be divided into four operation modes. The power flow direction is changing during various operation modes of the DC-microgrid based charging station, as illustrated in

Figure 9. These modes of operation can be explained as follows:

Mode 1: VDC ≥ VDC3: PEV charging and battery bank charging mode

The PV panels produce enough power, and this appears in an increase of the DC-link voltage to be higher than VDC3. This additional energy produced by the PV panels and the wind turbine is supplied to the batteries through a bidirectional DC-DC converter. As soon as the PEVs are fully charged, all the power produced by the PV and wind sources is delivered to the battery banks.

Mode 2: VDC1 > VDC > VDC3: Charging by PV power

At this operating mode, the PEV is charged using the power generated by the PV system. In this case, the controller ensures that the PEV battery is not exceeding the over-charging limit. Thus, the controller terminates PEV charging when PEV voltage exceeds VBH (the voltage relating to 95 % state of charge of the PEV battery). This interval continues as long as the value of DC-link voltage is in a range between VDC1 and VDC3.

Mode 3: VDC3 ≤ VDC < VDC2: Wind turbine supplying power and battery bank discharging

During this mode, the power produced by the wind turbine is less than the required power for charging the PEV. Therefore, the whole power produced by the wind turbine is transferred to the PEV, and the additional amount is supplied by the battery bank. However, the DC-link voltage changes with the variation in solar irradiation and wind speed. Thus, any variation in the DC-link voltage at the DC-microgrid is monitored by the controller to produce a proper voltage at the output of the bidirectional DC-DC power converter. The renewable energy sources continue charging the PEV; whereas, the battery banks cover the peak load demand.

Mode 4: Case-1: VDC < VDC-1 and IDMD < IDMD-max

In this mode, the PV panels and wind turbines do not produce any power, due to inconvenient weather conditions. The boost DC-DC power converter is isolated, and the battery bank supplies the power required for charging PEVs. At any instant, during this mode, if the DC-link voltage VDC exceeds VDC-1, the controller moves the system to work in Mode 2. The bidirectional DC-DC power converter regulates the output current and voltage for charging the PEV battery. As the battery bank is at off-peak, it continues to supply energy until the vehicles are completely charged. The controller terminates the charging process of PEV by disabling the DC-DC converter when the battery voltage VBat exceeds its maximum value VBH.

Case-2: VDC < VDC-1 and IDMD ≥ IDMD-max

This case is similar to case 1, but local demand exceeds the maximum demand of the microgrid. During this period, the PEV can be charged using the stored energy in the BESS if it is enough to cater to the charging process of PEVs. This continues until the state of charge of BESS (battery bank) decreases below its minimum value (SOC < SOCmin). At this moment, the charging process of PEVs is stopped tentatively by de-activating the bidirectional DC-DC power converter. Once the renewable energy power is back to off-peak conditions (i.e., IDMD < IDMD-max) the charging process of the PEVs is restored, and the controller supervises charging parameters.

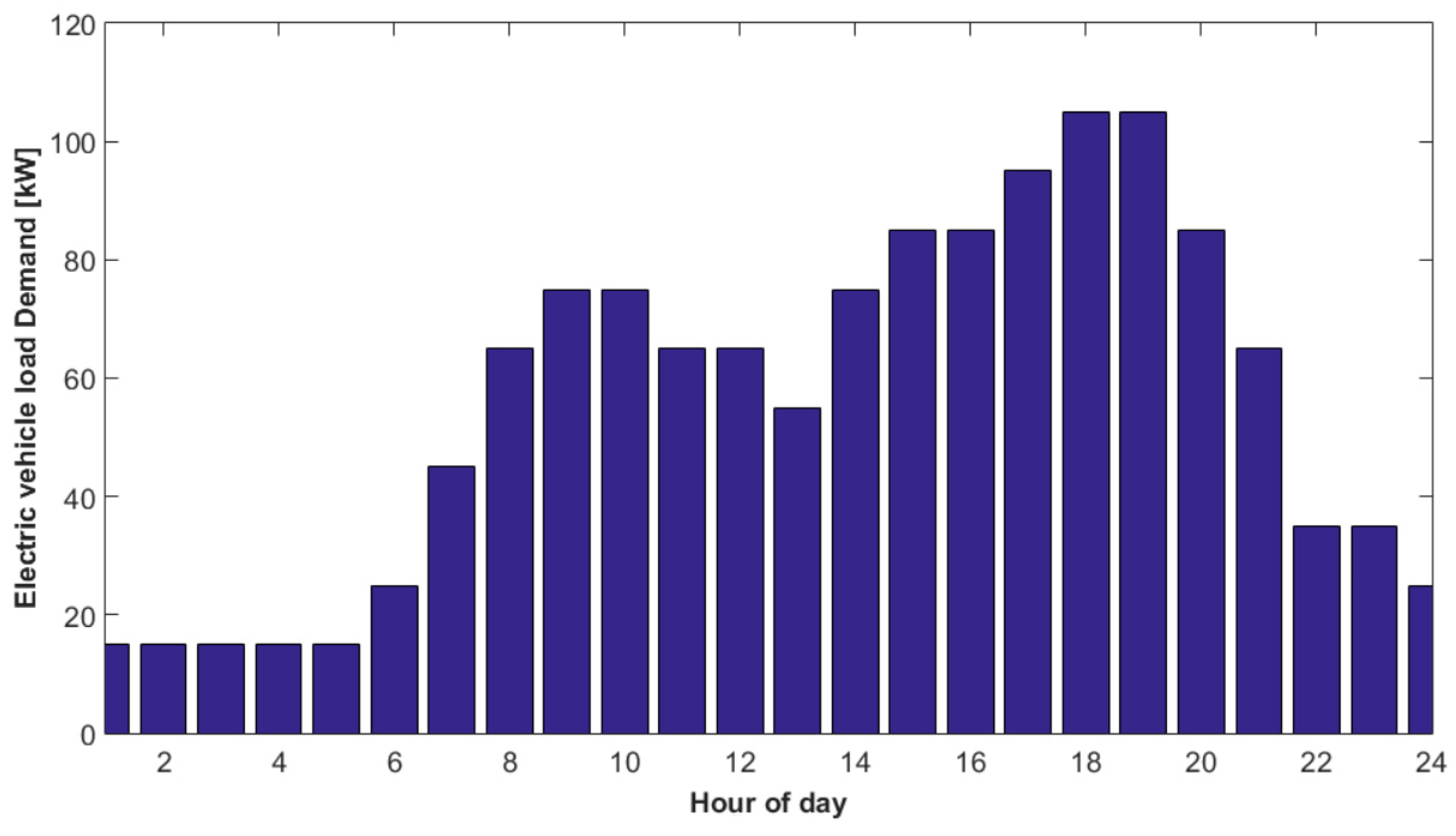

An example of the electric vehicle load supplied by the DC-microgrid is shown in

Figure 10 for one day period.

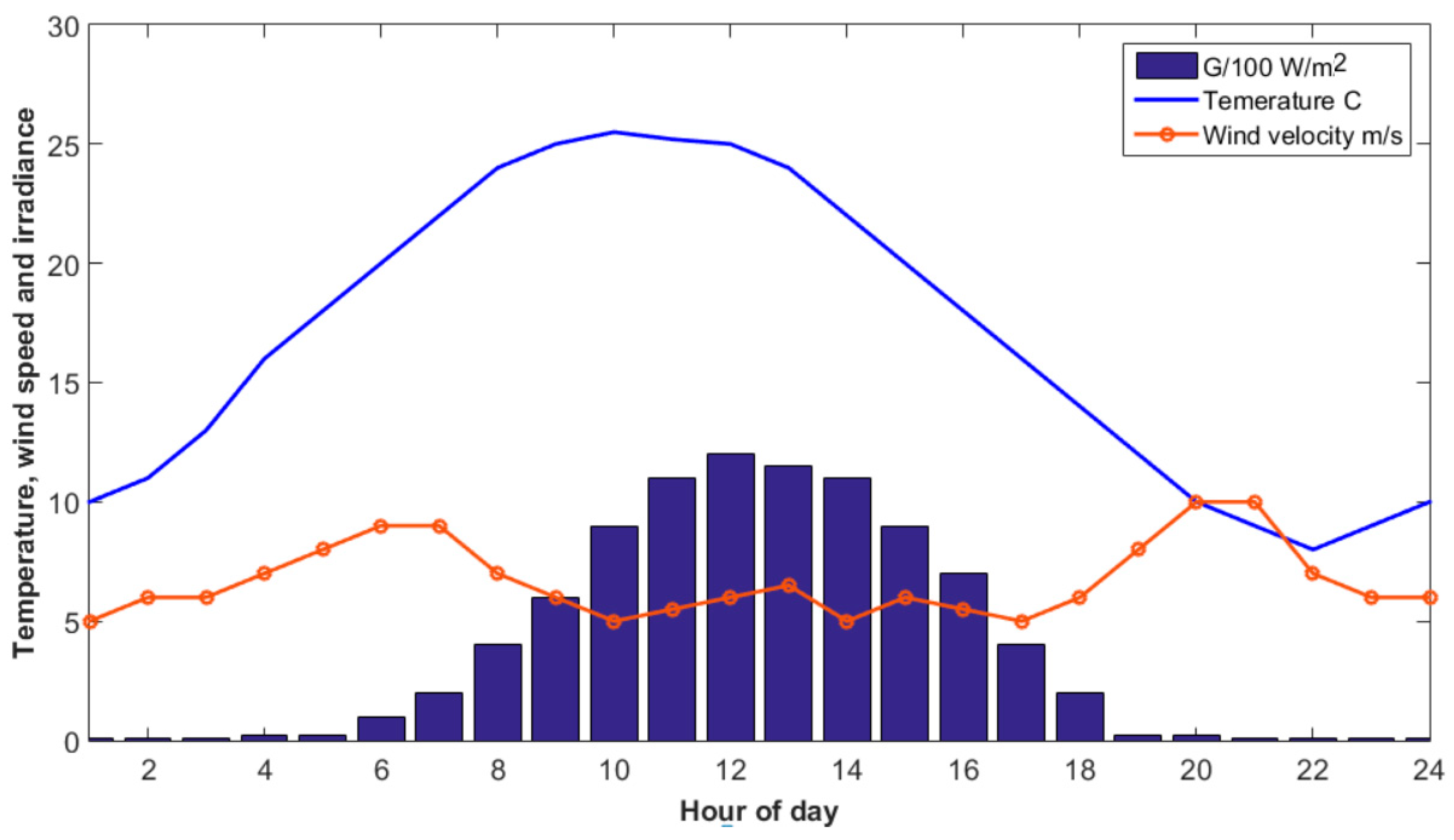

Figure 11 shows the solar irradiance, temperature and wind velocity profiles during a typical day in Sohag city, Egypt. The wind speed profile starts with 5 m/s at time 1 h, rises to 9 m/s at time 6 h, then falls down to 5 m/s at time 10 h, etc., as shown in

Figure 11. The generators meet the load during the night. In the morning when the sun comes up, and the PV starts generating, the PV charges the BESS until the PV generation and the BESS state of charge are high enough that they can meet the load on their own without the generators. The load is then transferred to the PV/BESS system, and the generators turn off. The BESS and PV power the load together from 7–8 a.m. when PV generation is not yet high enough to meet the load by itself. At 8 a.m., when PV can fully meet the load, the BESS stops discharging. Excess PV generation is used first to charge the BESS and then remaining excess is curtailed. In the evening, PV generation decreases, until the PV and BESS can no longer meet the full load. Some of the PV generation is curtailed because the BESS is already fully charged. At this point, the generators turn on again and supply the load overnight.

5. Simulation Results and Discussion

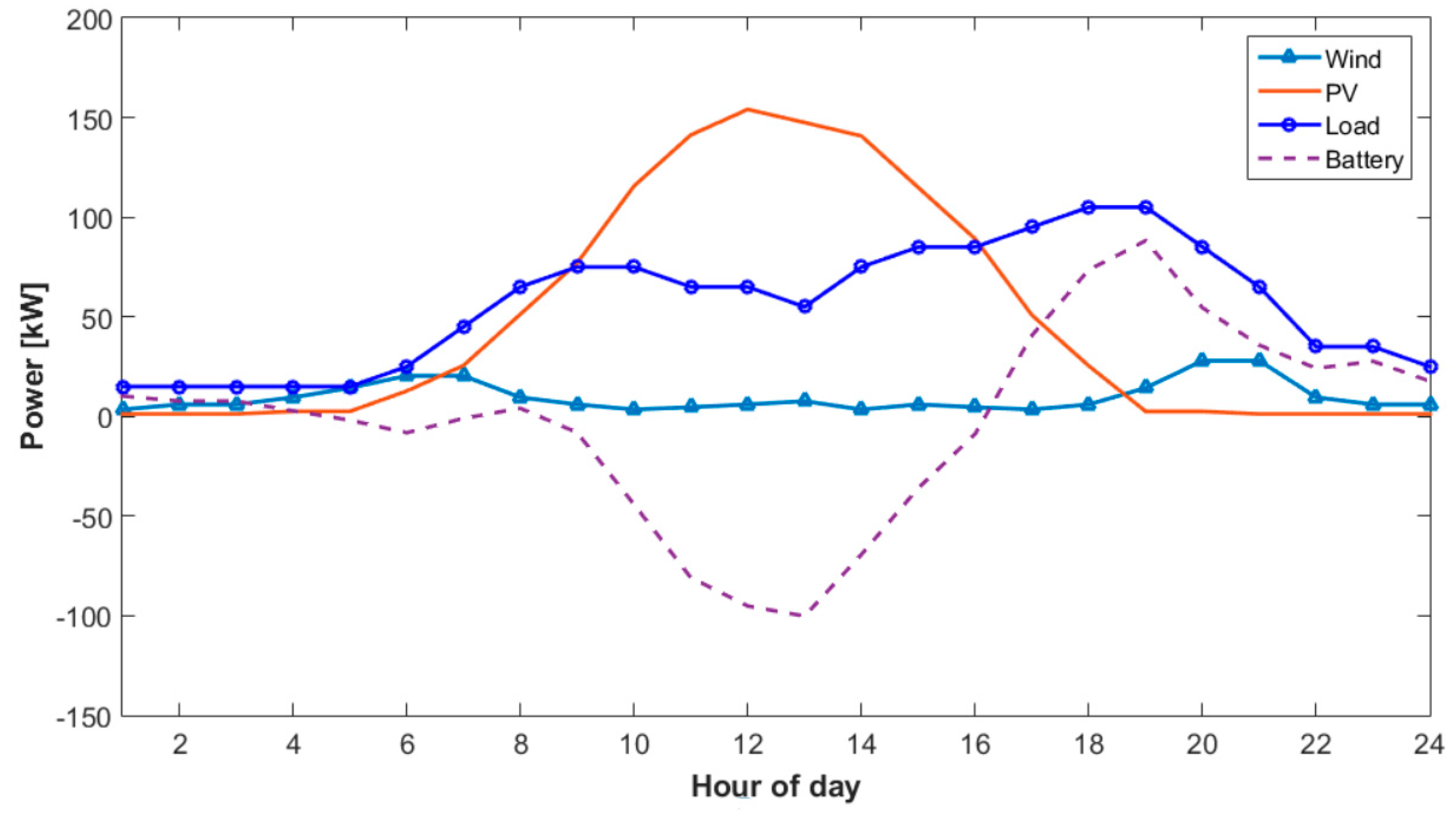

Simulation results are obtained based on the typical daily load profile of the studied EV presented in

Figure 11. The calculated produced renewable power and load during a typical day in the studied system is shown in

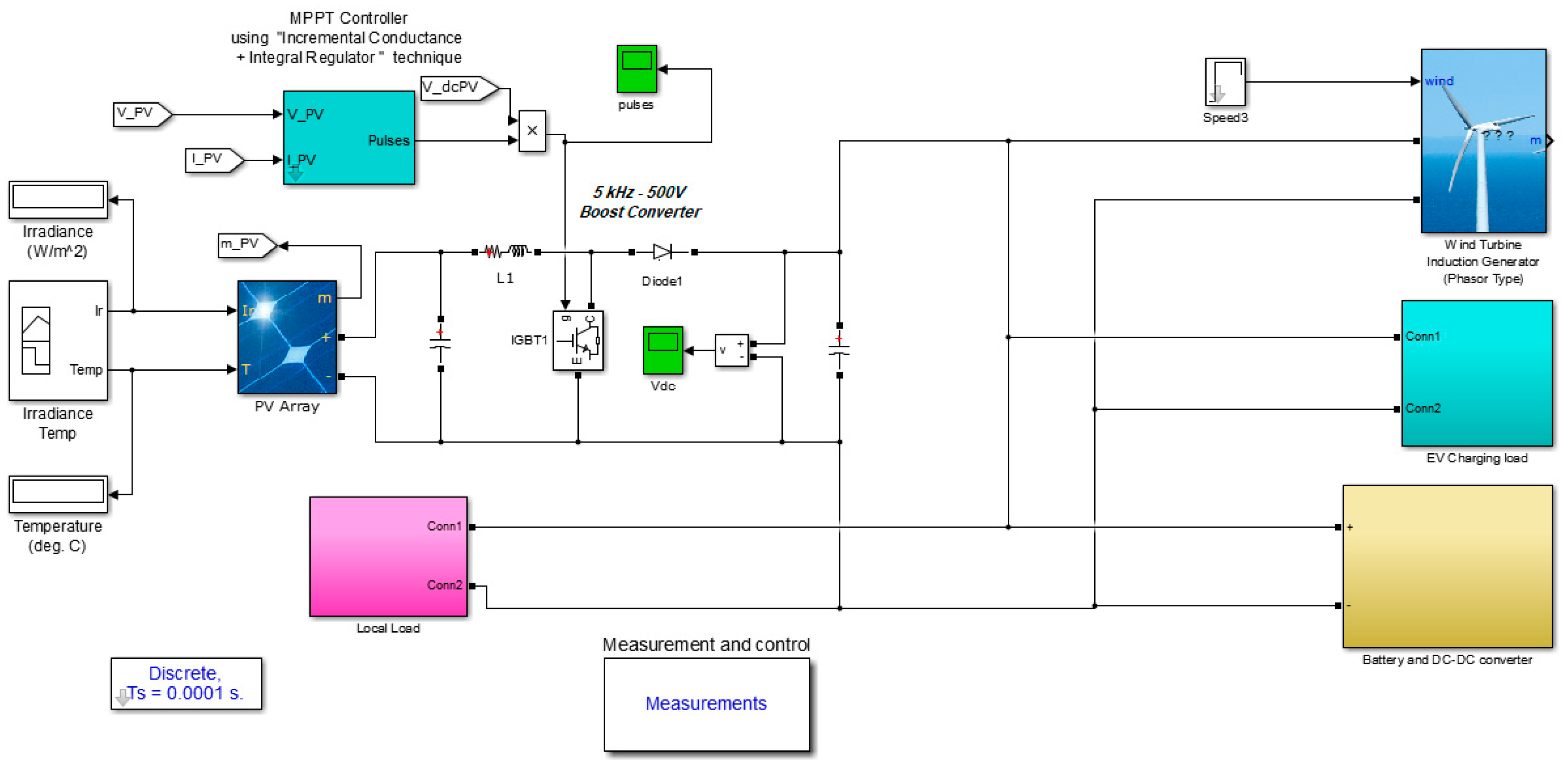

Figure 12. The hybrid system model is verified by implementing the detailed models in a MATLAB/ Simulink environment. This model presents an alternative emergency power system based on lithium-ion batteries. This model also features an energy management system for hybrid electric sources. The energy management system regulates the power between the energy sources and loads according to a predetermined control strategy. The Simulink model of the studied DC microgrid is shown in

Figure 13. The specifications of the studied DC-microgrid are shown in

Table 3:

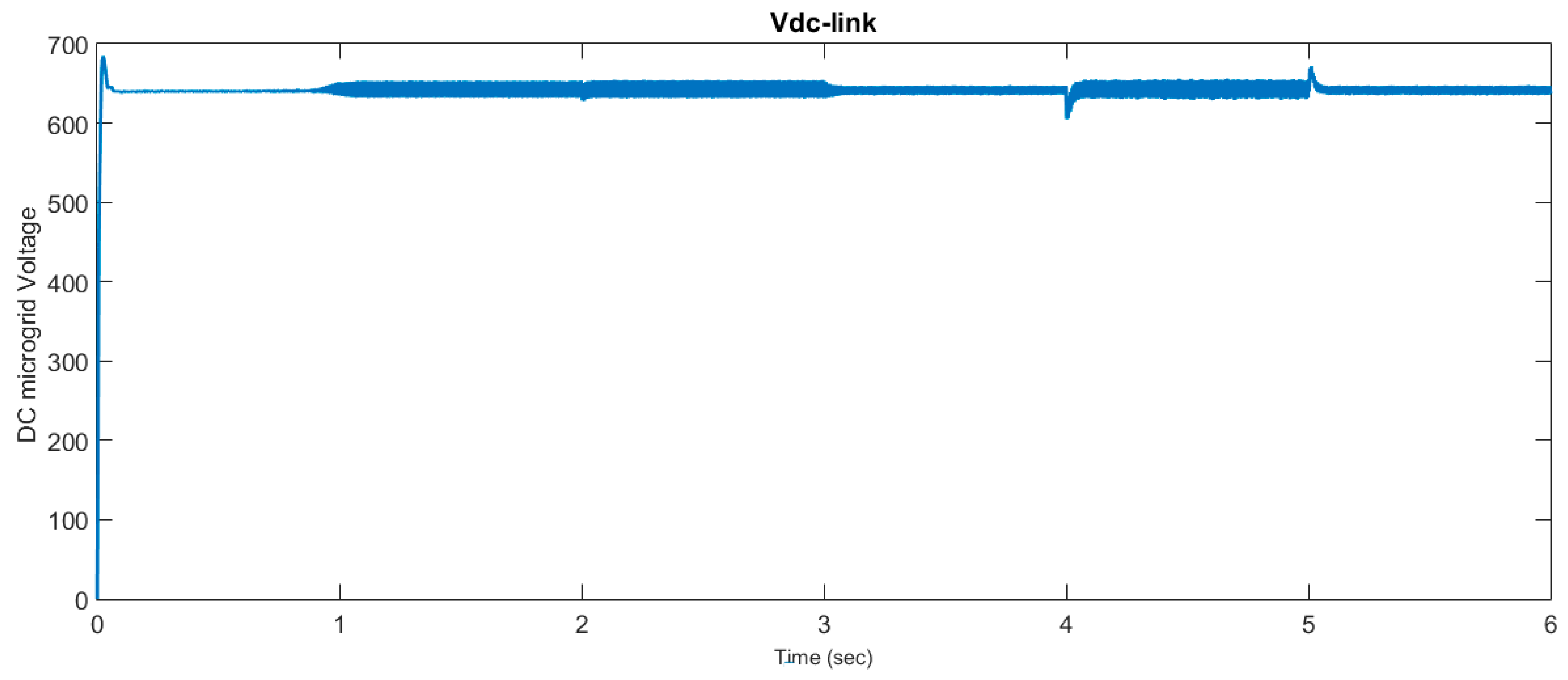

The DC microgrid voltage is shown in

Figure 14. The DC-link voltage is an indication for the DC generated power.

Figure 15 represents the output voltage and output current of PV panels. The photovoltaic power generation is set to the Maximal Power Point Tracking, which is proportional to the irradiance solar radiation and (W/m

2). These typical weather data at intervals of one hour are collected. There is much meteorological software can estimate the solar radiation and the ambient temperature. In this figure, the solar irradiation is reduced from 1000

to 850

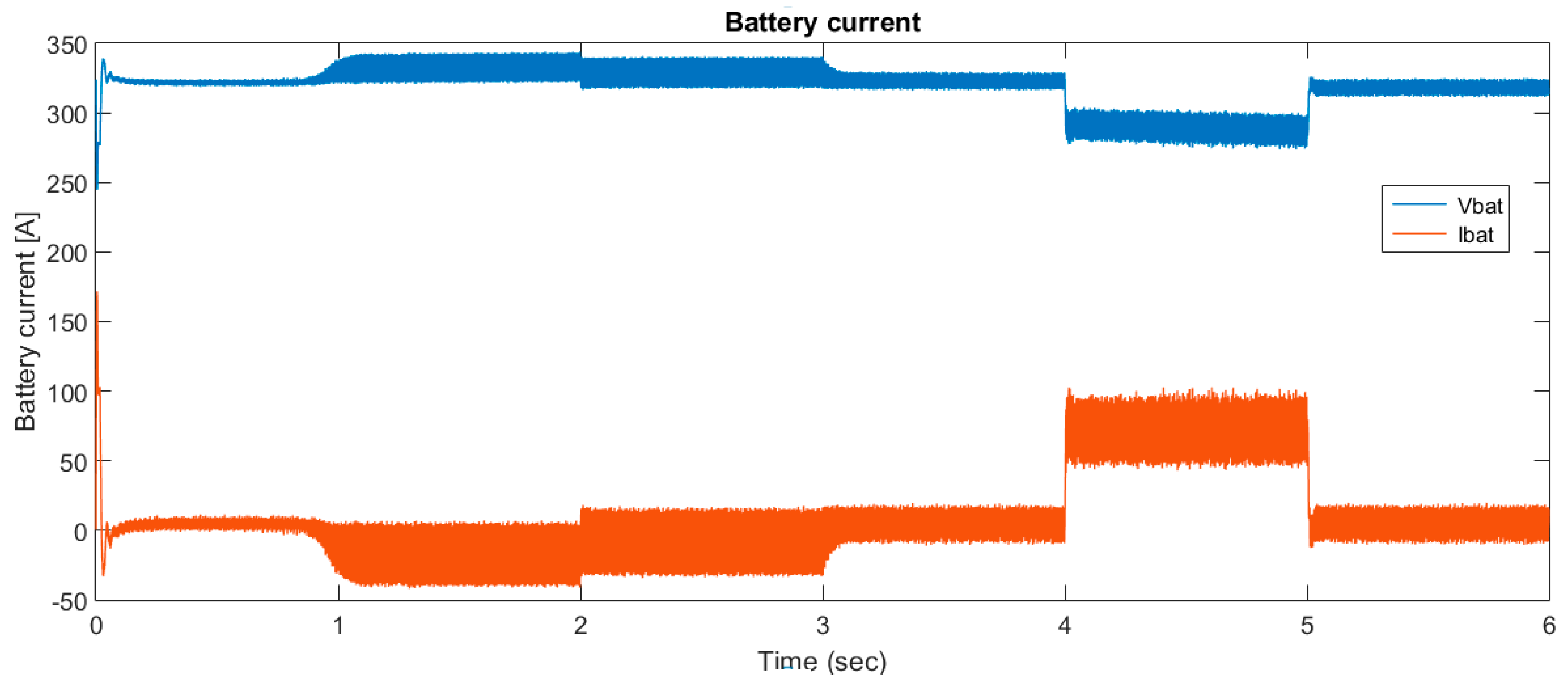

at time 2 s. Consequently, the total generated current from PV panels is reduced from 29.6 A to 25 A. The battery bank compensates the fluctuations of the difference between the microgrid reference power and all the passive power variations of the DC microgrid (PV/wind power and total loads). The battery bank voltage, charging and discharging current is shown in

Figure 16. The corresponding state of charge SOC of the battery bank is shown in

Figure 17.

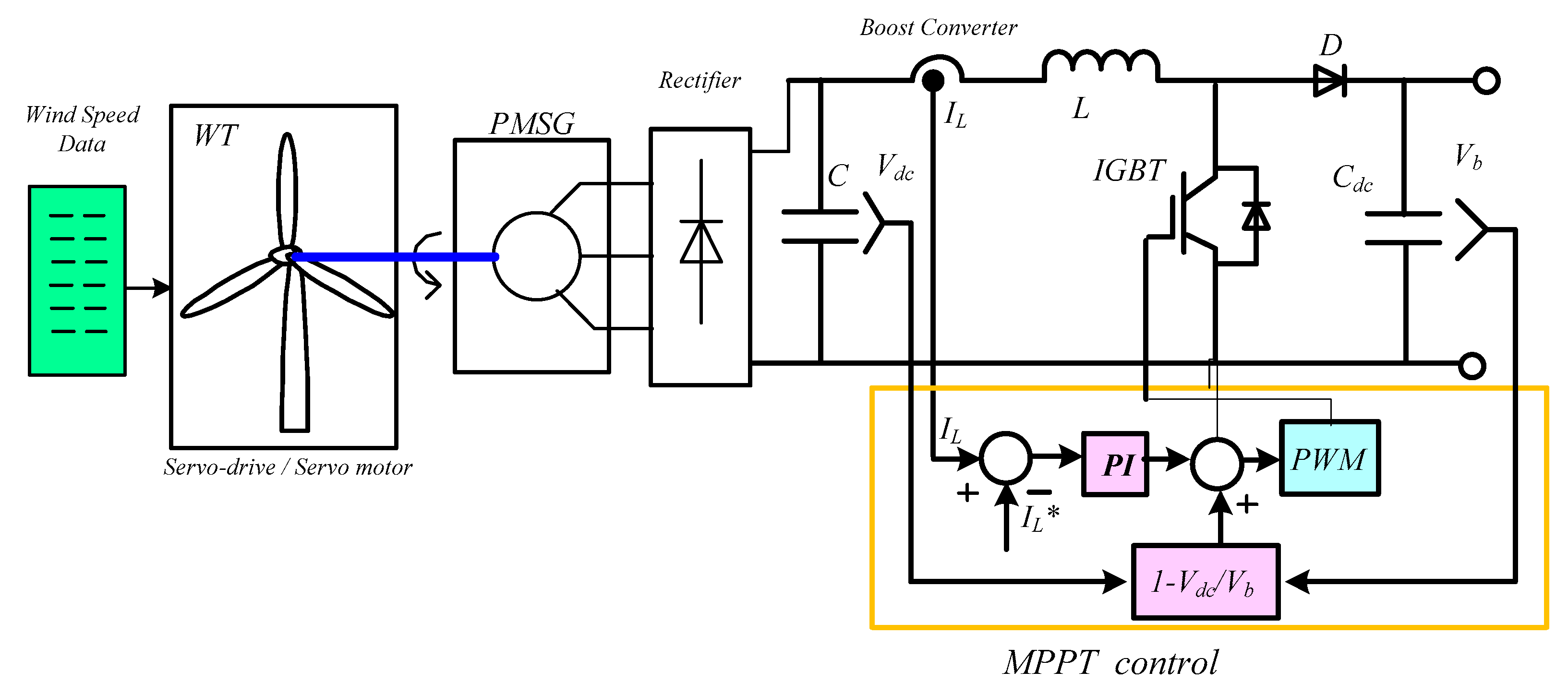

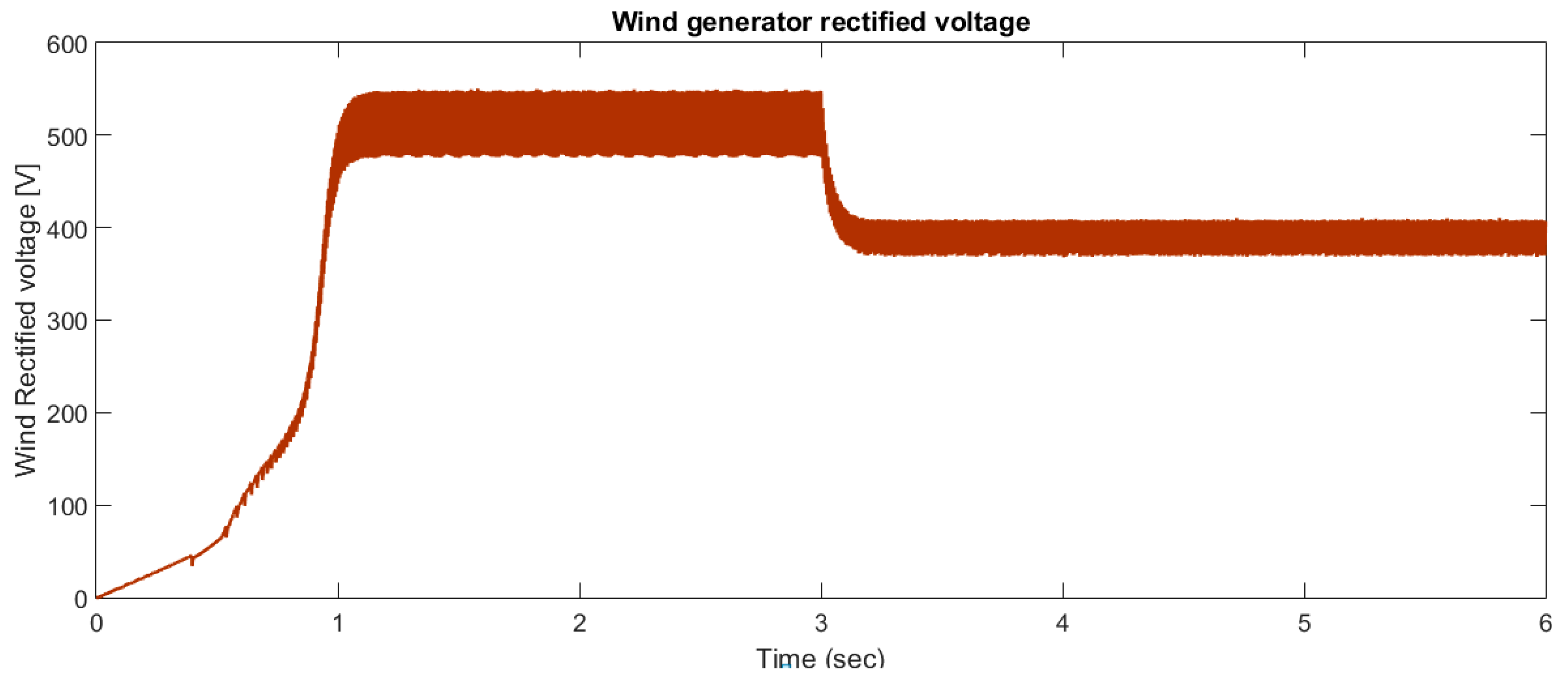

The wind turbine model comprises mathematical models of wind turbines and wind speed simulation.

Figure 18 shows how the voltage at generator terminals (instantaneous value) changes with time.

Figure 18 shows the corresponding generated current. The output power of the wind generator is proportional to the cube of the wind speed. A sudden variation of wind speed from 12 m/s to 9 m/s happens at a time of 3 s. However, the temporal variations of the PMSG rotational speed, torque, voltage, and output power follow that of the wind speed. The rectified output voltage of the wind generator is shown in

Figure 19.

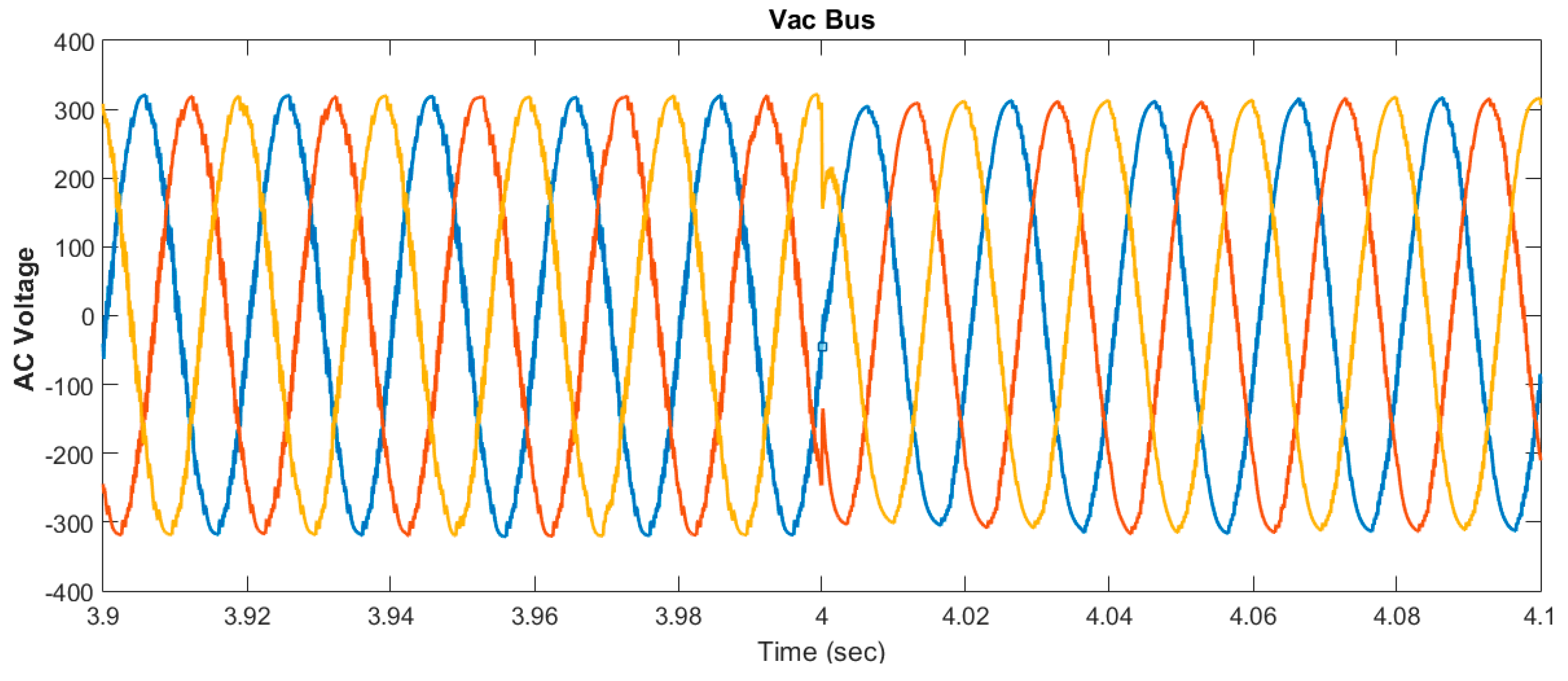

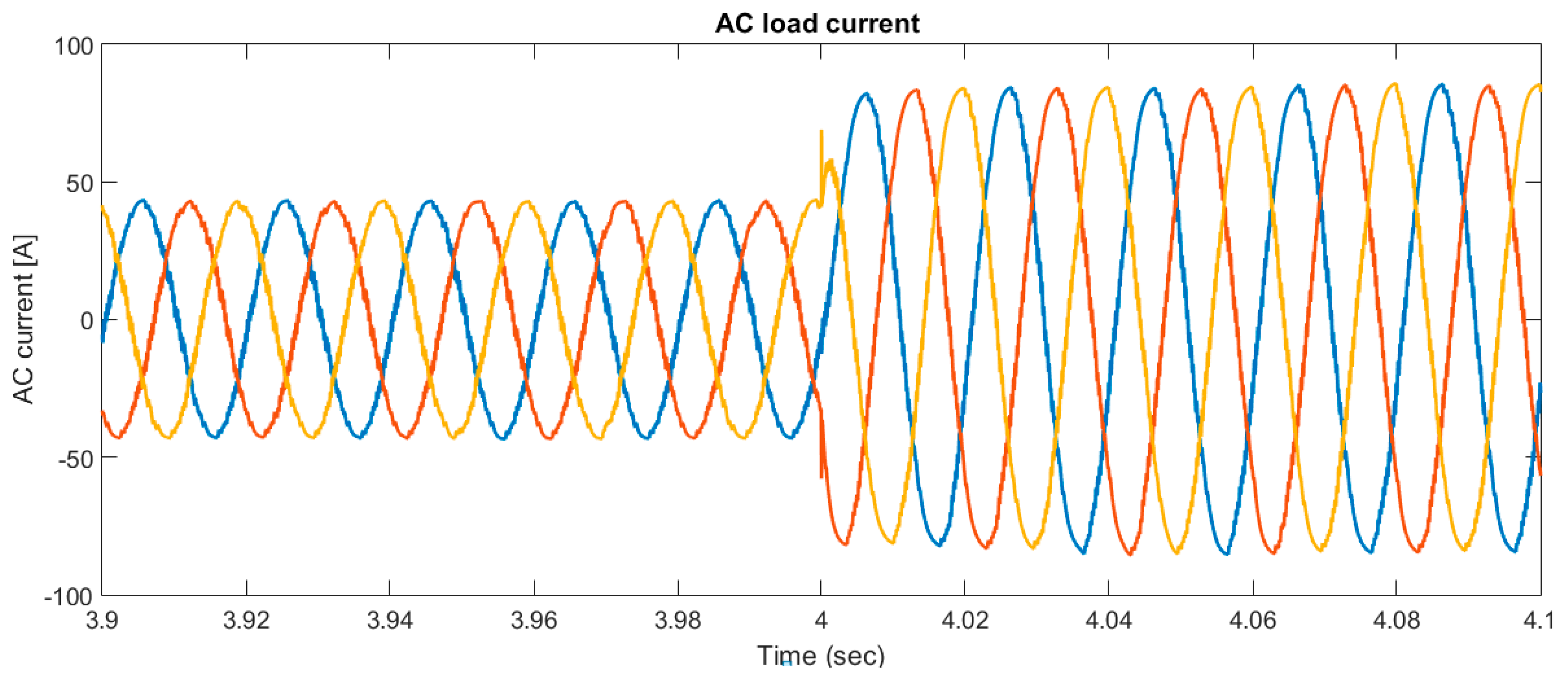

The voltage in the line and the current fed to the inverter for AC charging are shown in

Figure 20 and

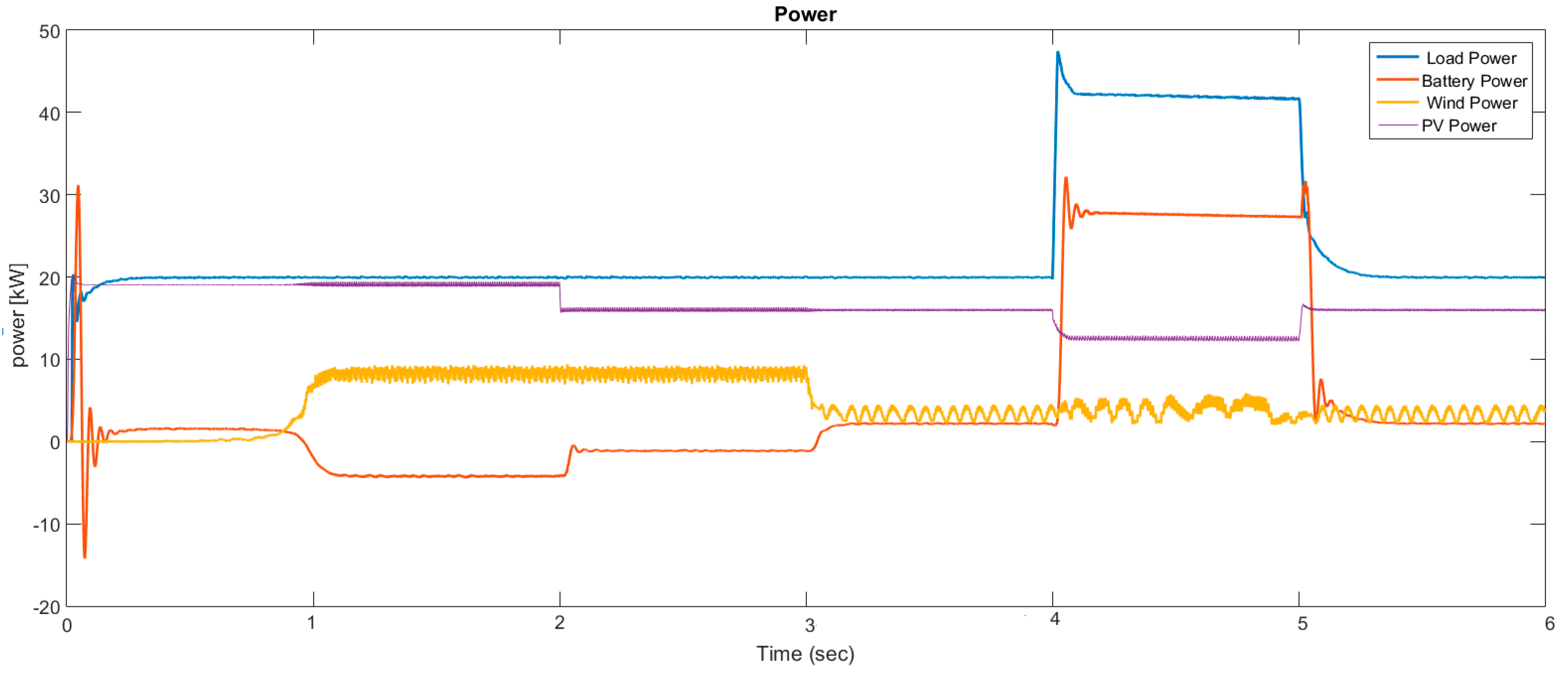

Figure 21, respectively. The current drawn from the AC system is sinusoidal, due to the AC filters employed. The lack of such AC filters will directly feed the harmonics into the grid source. A 3-phase AC load is used to emulate the EV charging load profile. The load profiles were generated using SIMULINK, and then the hourly energy results were configured into a suitable format. For each month, three day types were used to represent the annual load: Peak day, weekday, and weekend. The total powers from different sources and loads are shown in

Figure 22. A step change in load power occurs at time 4–5 s from 20 kW to 60 kW. During this period, the peak power is compensated from the battery bank. The electrical power performance, current-voltage characteristics and system response confirm that the system has satisfactory performance under conditions of a step changing power reference and loads disturbances.

6. Resilient DC-Microgrid

DC microgrid configurations are evaluated that can be used to integrate PV and wind generators alongside existing batteries’ energy storage systems (BESS) to increase resiliency at the site. The BESS units are sized to support the charging station load for one hour in this operation condition. There will be cloudy intervals or early morning/ late afternoon hours when PV and wind generators will not be capable of delivering the required charging load. During those times, the BESS is required to supply the EV loads until PV or wind generation supplies the charging station load. An integrated solution was proposed so that all energy sources operate in an integrated manner and are centrally controlled. Therefore, the BESS does not require to be sized for the full load in this operation scenario. The DC-bus Voltage of microgrid effects time of charging. Then the time of charging can be calculated according to the voltage and capacity of the battery. This measure takes into account the robustness of the system against disturbances and the quickness of the recovery [

27].

where

VDC-bus is the DC bus voltage.

R is the resiliency,

Ta is the recovery time.

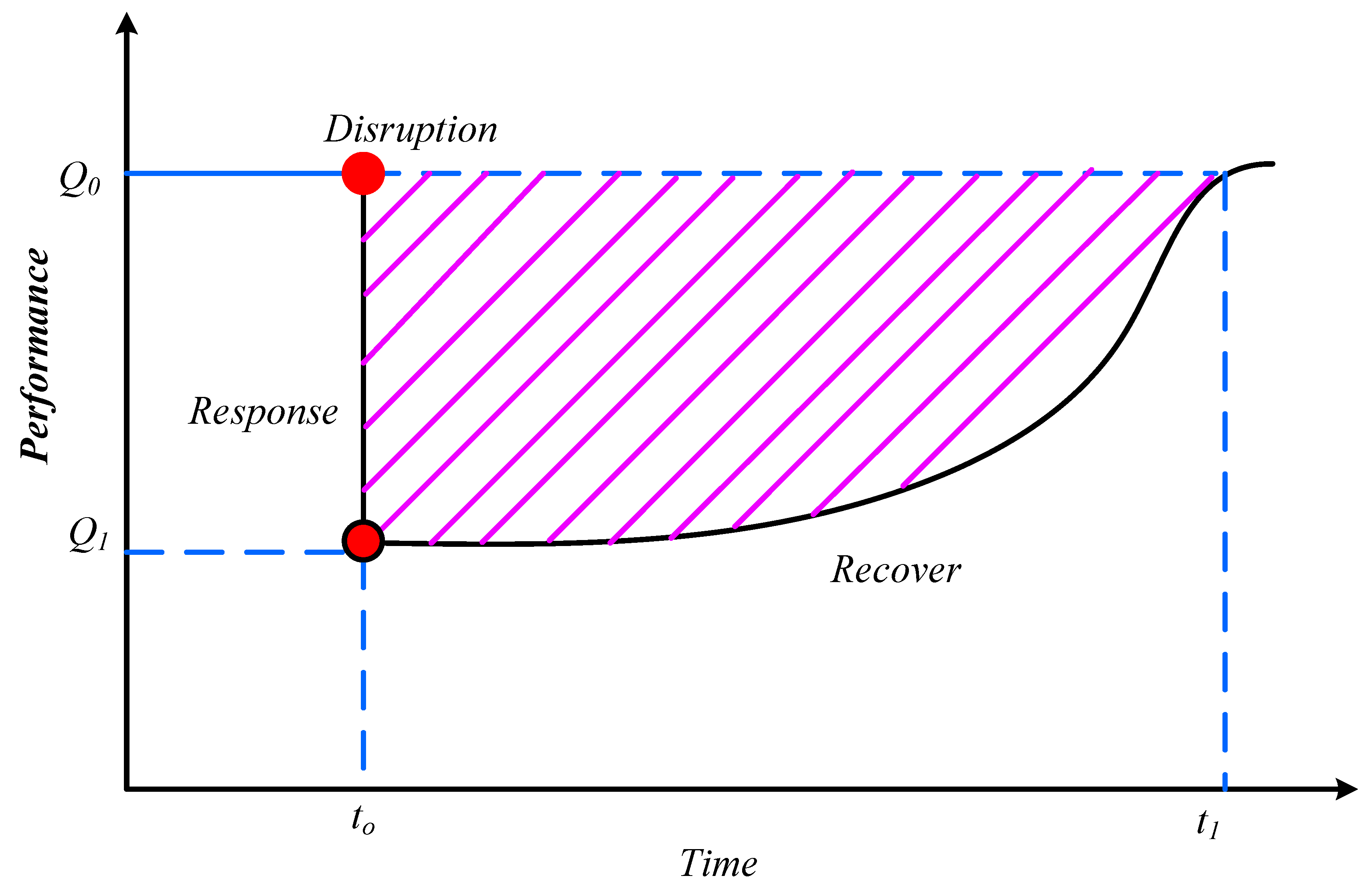

The resilience of an electrical microgrid can be defined as “the ability of the microgrid to sustain against disturbances and return to its normal state quickly”. This definition includes the two remarkable attributes, recovery and response, and is compatible with the definitions given in references [

27,

28]. The schematic diagram of the system’s resilience concept is illustrated in

Figure 10. However, disruption occurs at time

t0, as shown in this figure, and the system performance (DC bus voltage) falls from

Q0 to

Q1. By taking adequate action, the system returns finally to original DC-link voltage at time

t1.

As shown in Equation (6), the resilience measure is able to comprehensively represent the ability of the system to withstand the disruption and recover rapidly. Here, 0 < R< 1. Therefore, when R = 1, it means that the system has perfect resilience: Either its performance degradation is 0, or it can recover from disruption instantaneously. In case R = 0, it designates that the system is completely troubled immediately upon disruption and cannot recover within the maximum permissible recovery time. It is obvious that systems with higher values of R are more resilient.

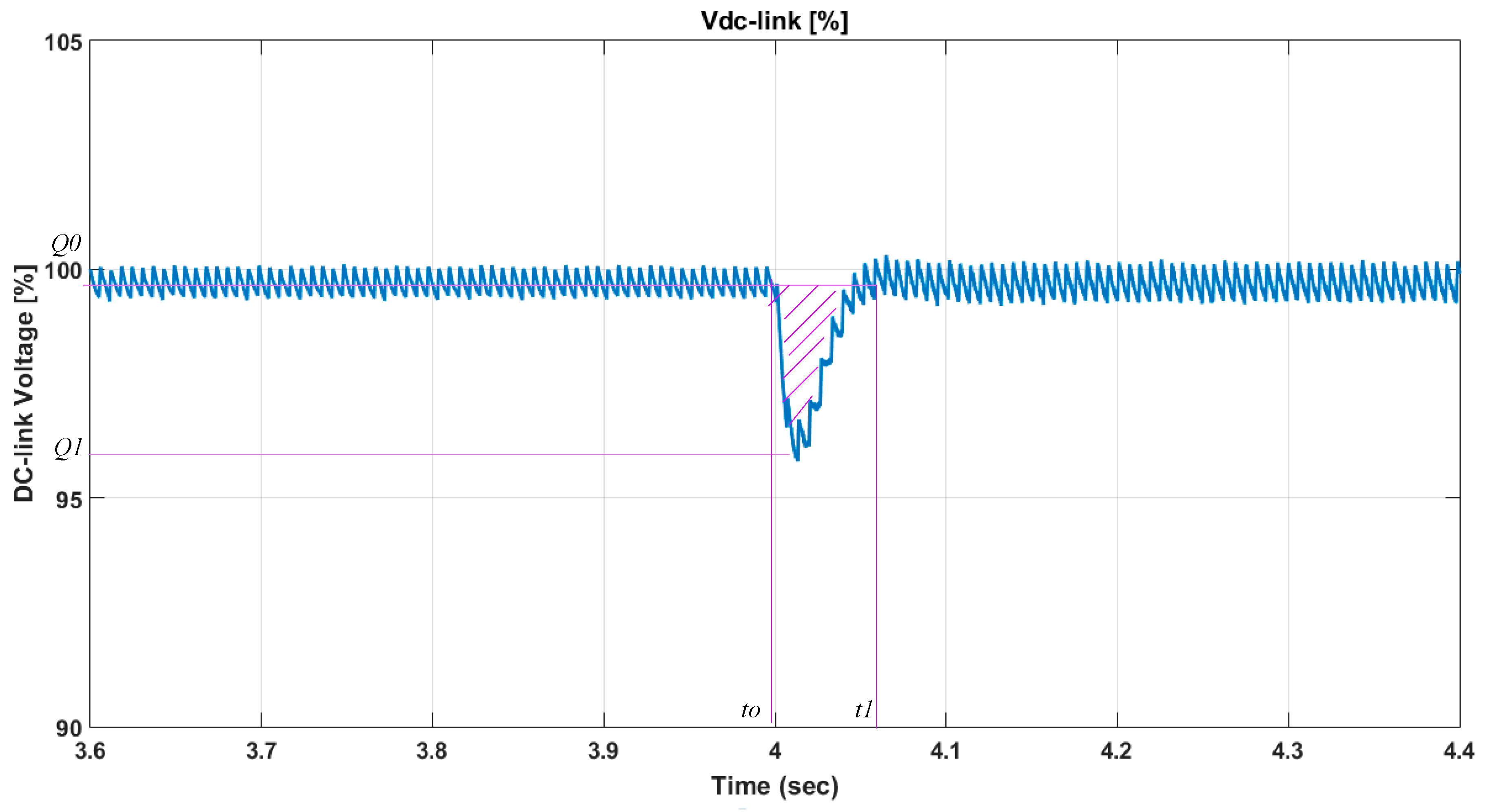

The performance curve

Q(t) is used to describe the system resilience of microgrid. The performance loss function from disruption is defined by the integral of the curve, followed by a gradual recovery (i.e., the shadowed area in

Figure 23). This measure achieves the robustness of the system versus disturbances (load disturbance and intermitted generated energy from renewable sources) and the quickness of the recovery action. By calculating the area under the curve of

Figure 24, the DC-bus voltage is recovered from

VDC = 96% to 100% and the time from 4 to 4.06 s and dividing this by time 0.06; then the resiliency will be 0.98. It means the system is near perfect resilient.

A new resilience measure is proposed in this paper for DC microgrid. It comprises using the maximum admissible recovery time as the considered time interval and enabling an estimation method. Resilience measurement scheme is used to estimate the resilience of different microgrid designs. It is also used to verify whether the resilience goal of microgrid can be satisfied, and choose a resilient method that can sustain the disruption and return the microgrid to the normal state as quickly as possible.