Improving the Energy Efficiency of Petrochemical Plant Operations: A Measurement and Verification Case Study Using a Balanced Wave Optimizer

Abstract

:1. Introduction

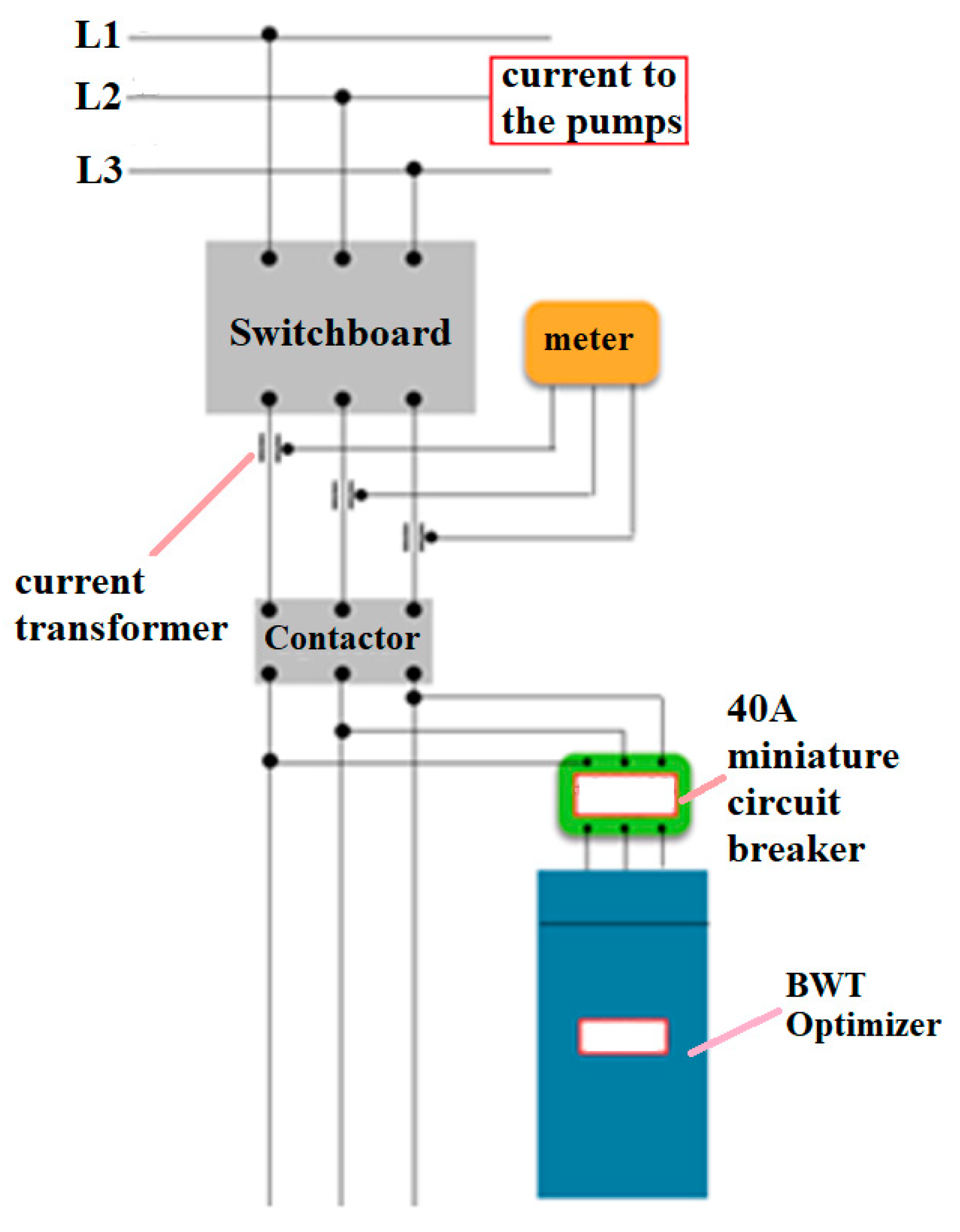

2. Methods

2.1. Balanced Wave Technology

2.2. The Auditing Procedure

2.3. Acquisition of Data

2.4. Data Manipulation

2.5. Option of Measurement and Verification Method

3. Results and Discussion

3.1. Baseline Energy Consumption

3.2. Initial Energy Savings

3.3. Overall Energy Savings

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Day | Active Power (kWh) | Reactive Power (kvarh) | Flow Rate (t/h) | Pressure (MPa) | Temperature (°C) | ||||

|---|---|---|---|---|---|---|---|---|---|

| P1601/1 | P1601/2 | P1601/1 | P1601/2 | FI701 | TI427 | PI411 | TI427 | TI426 | |

| 1 | 43.84 | 43.02 | 24.74 | 25.23 | 166.1810 | 78.2952 | 0.3262 | 55.5095 | 97.9048 |

| 2 | 43.89 | 43.04 | 25.42 | 25.95 | 166.1810 | 78.5333 | 0.3300 | 55.5286 | 98.1000 |

| 3 | 43.94 | 42.94 | 25.63 | 25.48 | 166.4238 | 78.5667 | 0.3300 | 55.5095 | 97.7667 |

| 4 | 43.91 | 42.83 | 25.52 | 25.03 | 164.5238 | 78.3333 | 0.3300 | 55.5333 | 98.6143 |

| 5 | 44.00 | 43.96 | 25.86 | 25.33 | 166.5357 | 78.5929 | 0.3200 | 55.3714 | 94.0143 |

| 6 | 44.17 | 43.10 | 25.64 | 25.12 | 166.4095 | 79.8619 | 0.3233 | 55.5000 | 93.6000 |

| 7 | 44.21 | 43.17 | 25.97 | 25.67 | 165.7381 | 79.4381 | 0.3300 | 55.5000 | 96.1667 |

| Average | 43.99 | 43.01 | 25.54 | 25.40 | 165.9990 | 78.8031 | 0.3271 | 55.4932 | 96.5952 |

| Total | 87.0 | 50.94 | 244.8020 | ||||||

References

- Hadhri, M. Facts & Figures 2017 of the European Chemical Industry; Cefic’s Facts & Figures Publications: Brussels, Belgium, 2017; pp. 6–7. [Google Scholar]

- Graham, L. Chinese Petchem Exports upset World Markets; ChinaOil: Hong Kong, China, 2017; pp. 1–18. [Google Scholar]

- International Energy Agency. Tracking Clean Energy Progress 2017; International Energy Agency: Paris, France, 2017; pp. 1–116. [Google Scholar]

- NRDC. The Road from Paris: China’s Progress toward Its Climate Pledge; NRDC: New York, NY, USA, 2017; pp. 1–5. [Google Scholar]

- China Government. China to Improve Petrochemical Industry; China Government: Beijing, China, 2016.

- International Energy Agency. Energy Efficiency 2017; International Energy Agency: Paris, France, 2017; pp. 1–143. [Google Scholar]

- International Energy Agency. Global Energy & CO2 Status Report 2017; International Energy Agency: Paris, France, 2018; pp. 1–15. [Google Scholar]

- Lotsu, S.; Yoshida, Y.; Fukuda, K.; He, B. Effectiveness of a Power Factor Correction Policy in Improving the Energy Efficiency of Large-Scale Electricity Users in Ghana. Energies 2019, 12, 2582. [Google Scholar] [CrossRef]

- Costantini, V.; Crespi, F.; Paglialunga, E. The employment impact of private and public actions for energy efficiency: Evidence from European industries. Energy Policy 2018, 119, 250–267. [Google Scholar] [CrossRef]

- Adefarati, T.; Oluwole, A.S.; Olusuyi, O.; Sanusi, M.A. Economic and industrial application of power factor improvement. Int. J. Eng. Res. Technol. 2013, 2, 1945–1955. [Google Scholar]

- No leakage pump into the mainstream of petrochemical pumps. In Enterprise News; Ningbo Zhenguan Electrical Co. Ltd.: Ningbo, China, 2015.

- Fleiter, T.; Eichhammer, W. Energy Efficiency in Electric Motor Systems: Technology, Saving Potentials and Policy Options for Developing Countries; United Nations Industrial Development Organization: Vienna, Austria, 2012; pp. 1–49. [Google Scholar]

- U.S. Department of Energy. Energy Use, Loss and Opportunities Analysis: U.S. Manufacturing & Mining; U.S. Department of Energy, E3M Incorporated: Washington, DC, USA, 2004; pp. 1–169.

- United States Department of Energy. Improving Pumping System Performance—A Sourcebook for Industry; United States Department of Energy: Washington, DC, USA, 2006.

- Hebri, S. Variable frequency drive importance in an LPG plant: Case study. Electr. Electron. Syst. 2012, 1, 1–4. [Google Scholar] [CrossRef]

- Variable Speed Pumping—A Guide to Successful Applications, Executive Summary; Hydraulic Institute, Europump, U.S. Department of Energy: Washington, DC, USA, 2004; pp. 1–22.

- Murray, M. Total System Efficiency. In Power Transmission Engineering; Randall Publications LLC: Elk Grove Village, IL, USA, 2010; pp. 16–23. [Google Scholar]

- Punwassi, V. Energy Savings through Pipe Header Optimization on a Cooling Tower Pumping Station. Energy Eng. 2016, 114, 63–76. [Google Scholar] [CrossRef]

- Bredin, M.S. Optimization of Building and Agricultural Pumping System Energy Efficiency for Maximum Return on Investment. Energy Eng. 2017, 114, 11–32. [Google Scholar] [CrossRef]

- Johnson, T.M. Developing Market-Based Energy Efficiency Program in China; World Bank: Washington, DC, USA, 2017. [Google Scholar]

- Energy Efficiency Measurement and Verification Issues and Options—An Overview of International Measurement and Verification Experience; World Bank: Washington, DC, USA, 2013.

- Kwon, Y.-D. Electric Power Saving Apparatus Comprising Semi-Conductor Device to Pass Energy of Infrared Ray Synthetic Wavelength into Electric Cable Using Output Pulse Signal, Electric Circuit Board Structure for Implementing the Apparatus, and Electric Power Saving Method. US Patent 7,373,535 B2, 13 May 2008. [Google Scholar]

- Cho, S.-H.; Choi, M.-H.; Kwon, Y.-D.; Kim, C.-D. A study on improving electric energy result by using composition wavelength. In Proceedings of the 3rd IEEE International Conference on Industral Informatics (INDIN’05), Perth, WA, Australia, 19 December 2005; pp. 566–571. [Google Scholar]

- Lee, F.Y.; Jo, H.R.; Lynch, C.S.; Pilon, L. Pyroelectric energy conversion using PLZT ceramics and the ferroelectric–ergodic relaxor phase transition. Smart Mater. Struct. 2013, 22, 1–16. [Google Scholar] [CrossRef]

- Yuan, H.T. Application of Energy Optimizer in Motor Energy Saving, China. 2013. Available online: www.chinaqking.com (accessed on 5 September 2019).

- Power Optimizer Case Study in Montreal, Canada. Power Optimizer. Available online: http://www.poweroptimizer.com (accessed on 5 September 2019).

- Power Optimizer Case Study in the Siam Center, Thailand. Power Optimizer. Available online: http://www.poweroptimizer.com (accessed on 5 September 2019).

- Anumaka, M.C. Analysis of technical losses in electrical power system (nigerian 330 kv network as a case study). IJRRAS 2012, 12, 320–327. [Google Scholar]

- Comparison between E-Clean Energy Saver and Conventional Energy Controller Installation Method; One Energy Holdings Pte Ltd.: Singapore, 2013.

- National Energy Administration. The measuring for energy conservation effect of energy conservation products in petroleum enterprise. In Oil and Gas Industry Standard of the People’s Republic of China; National Development and Reform Commission: Beijing, China, 2008; pp. 1–7. [Google Scholar]

- International Performance Measurement and Verification Protocol, Concepts and Options for Determining Energy and Water Savings; U.S. Department of Energy Office of Scientific and Technical Information: Oak Ridge, TN, USA, 2016; Volume 1.

- Overview of Different Measurement and Verification (M&V) Protocols; Natural Resources Canada’s CanmetENERGY: Québec, Canada, March 2018; pp. 1–20.

- Harding, A.C.; Nutter, D.W. Measurement and verification of industrial equipment: Sampling interval and data logger considerations. Energy Eng. 2016, 113, 7–33. [Google Scholar] [CrossRef]

- Pollitt, M.G.; Yang, C.H.; Chen, H. Reforming the Chinese Electricity Supply Sector: Lessons from International Experience; Energy Policy Research Group, University of Cambridge: Cambridge, UK, 2017; pp. 1–70. [Google Scholar]

- Brander, M.; Sood, A.; Wylie, C.; Haughton, A.; Lovel, J. Electricity-Specific Emission Factors for Grid Electricity; Ecometrica: Edinburgh, UK, 2011; pp. 1–22. [Google Scholar]

| Company | Hebei Datang International Zhangjiakou Thermal Power Co. Ltd. | Siam Centre | SNC-Lavalin |

|---|---|---|---|

| Function | Industry | Shopping Complex | Office |

| Retrofit System | A closed loop water circulation system with 2 water pumps in parallel | Five 35 kW chilled water pumps | 25 Hp water chiller pump motor |

| System Features | 2 × 185 kW, fixed load | 3–4 pumps run in rotation | 600 V, 1770 rpm, 60 Hz, fixed load |

| BWT Model | 2 × 200 kVA | 135 kVA | 25 kVA |

| Operating Hours/Day | - | 12.5 hours | 24 hours |

| Operating Days/Year | 7 days | 7 days | 7 days |

| Performance Period | 12 weeks | 8 weeks | Over 16 weeks |

| Baseline kWh Used | 302.70 kWh | 5446 kWh per 5 days | 22.21 kWh per hour |

| Post Retrofit kWh | 276.76 kWh | 4864 kWh per 5 days | 19.55 kWh per hour |

| Energy Savings (%) | 8.57% | 10.69% | 12.0% |

| Week | W1 (kWh/m³) | W2 (kWh/m³) | Q1 (kvarh/m³) | Q2 (kvarh/m³) | ξb (%) |

|---|---|---|---|---|---|

| 1 | 0.1162 | 0.1161 | 0.0681 | 0.0372 | 0.87 |

| 2 | 0.1171 | 0.0373 | 0.04 | ||

| 3 | 0.1166 | 0.0367 | 0.48 | ||

| 4 | 0.1164 | 0.0363 | 0.64 | ||

| 5 | 0.1166 | 0.0361 | 0.55 | ||

| 6 | 0.1165 | 0.0375 | 0.55 | ||

| 7 | 0.1162 | 0.0365 | 0.85 | ||

| 8 | 0.1162 | 0.0347 | 0.88 | ||

| 9 | 0.1159 | 0.0343 | 1.14 | ||

| 10 | 0.1106 | 0.0323 | 5.70 |

| Report Week | W1 (kWh/m³) | W2 (kWh/m³) | Q1 (kvarh/m³) | Q2 (kvarh/m³) | ξb (%) |

|---|---|---|---|---|---|

| 1 | 0.1162 | 0.1053 | 0.0681 | 0.0320 | 10.15 |

| 2 | 0.1053 | 0.0365 | 10.08 | ||

| 3 | 0.1043 | 0.0446 | 10.66 | ||

| 4 | 0.1038 | 0.0452 | 11.10 | ||

| 5 | 0.1047 | 0.0457 | 10.34 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chan, M.H.E.; Chu, K.-K.; Chow, H.-F.; Tsang, C.-W.; Ho, C.K.D.; Ho, S.-K. Improving the Energy Efficiency of Petrochemical Plant Operations: A Measurement and Verification Case Study Using a Balanced Wave Optimizer. Energies 2019, 12, 4136. https://doi.org/10.3390/en12214136

Chan MHE, Chu K-K, Chow H-F, Tsang C-W, Ho CKD, Ho S-K. Improving the Energy Efficiency of Petrochemical Plant Operations: A Measurement and Verification Case Study Using a Balanced Wave Optimizer. Energies. 2019; 12(21):4136. https://doi.org/10.3390/en12214136

Chicago/Turabian StyleChan, Man Hin Eve, Kar-Kit Chu, Hin-Fung Chow, Chi-Wing Tsang, Chi Kuen Danny Ho, and Shuk-Kei Ho. 2019. "Improving the Energy Efficiency of Petrochemical Plant Operations: A Measurement and Verification Case Study Using a Balanced Wave Optimizer" Energies 12, no. 21: 4136. https://doi.org/10.3390/en12214136

APA StyleChan, M. H. E., Chu, K.-K., Chow, H.-F., Tsang, C.-W., Ho, C. K. D., & Ho, S.-K. (2019). Improving the Energy Efficiency of Petrochemical Plant Operations: A Measurement and Verification Case Study Using a Balanced Wave Optimizer. Energies, 12(21), 4136. https://doi.org/10.3390/en12214136