An Evaluation Method of Wind Power Integration in Power Systems with Flexible Combined Heat and Power Plant

Abstract

1. Introduction

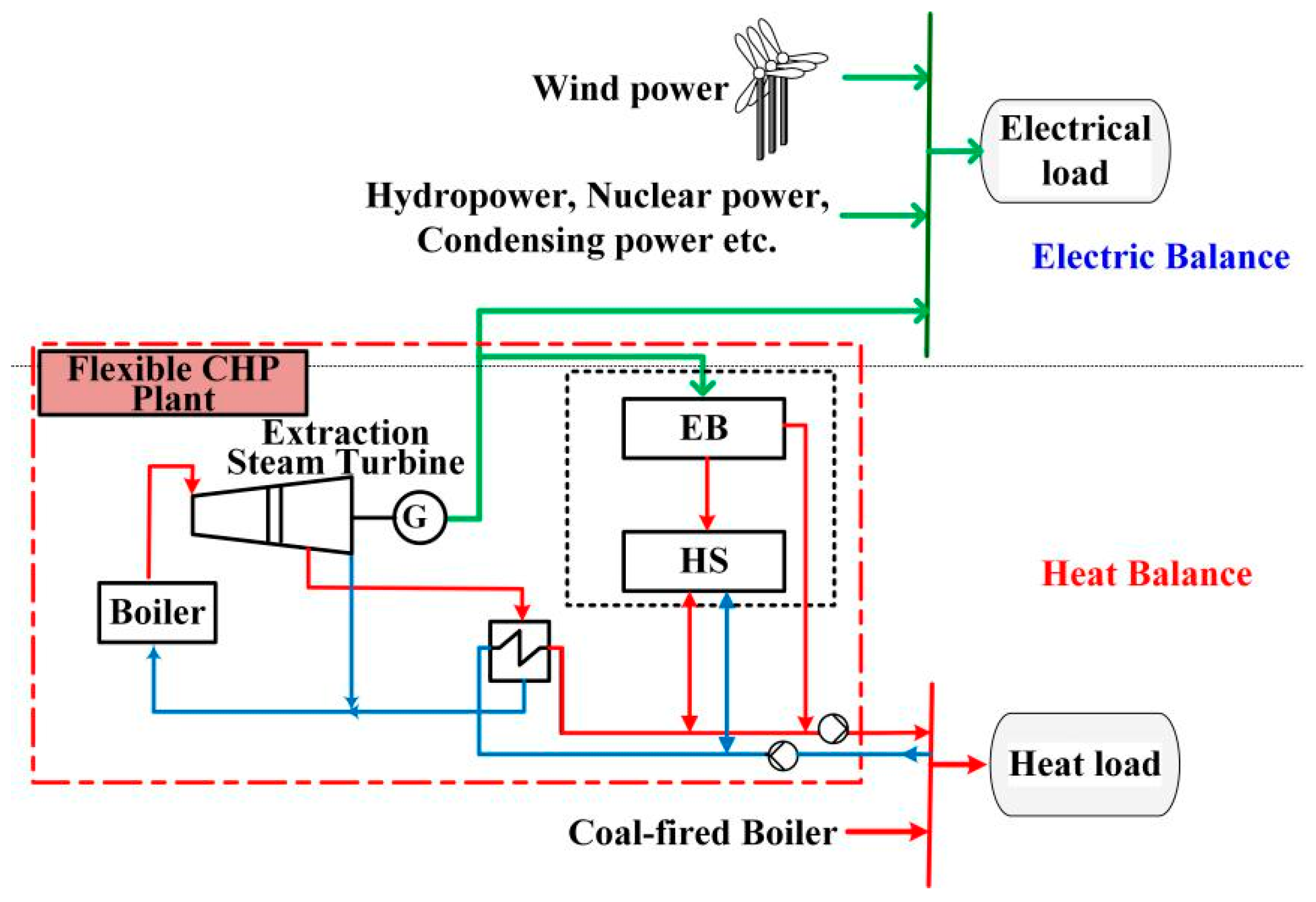

2. Flexible CHP Plant

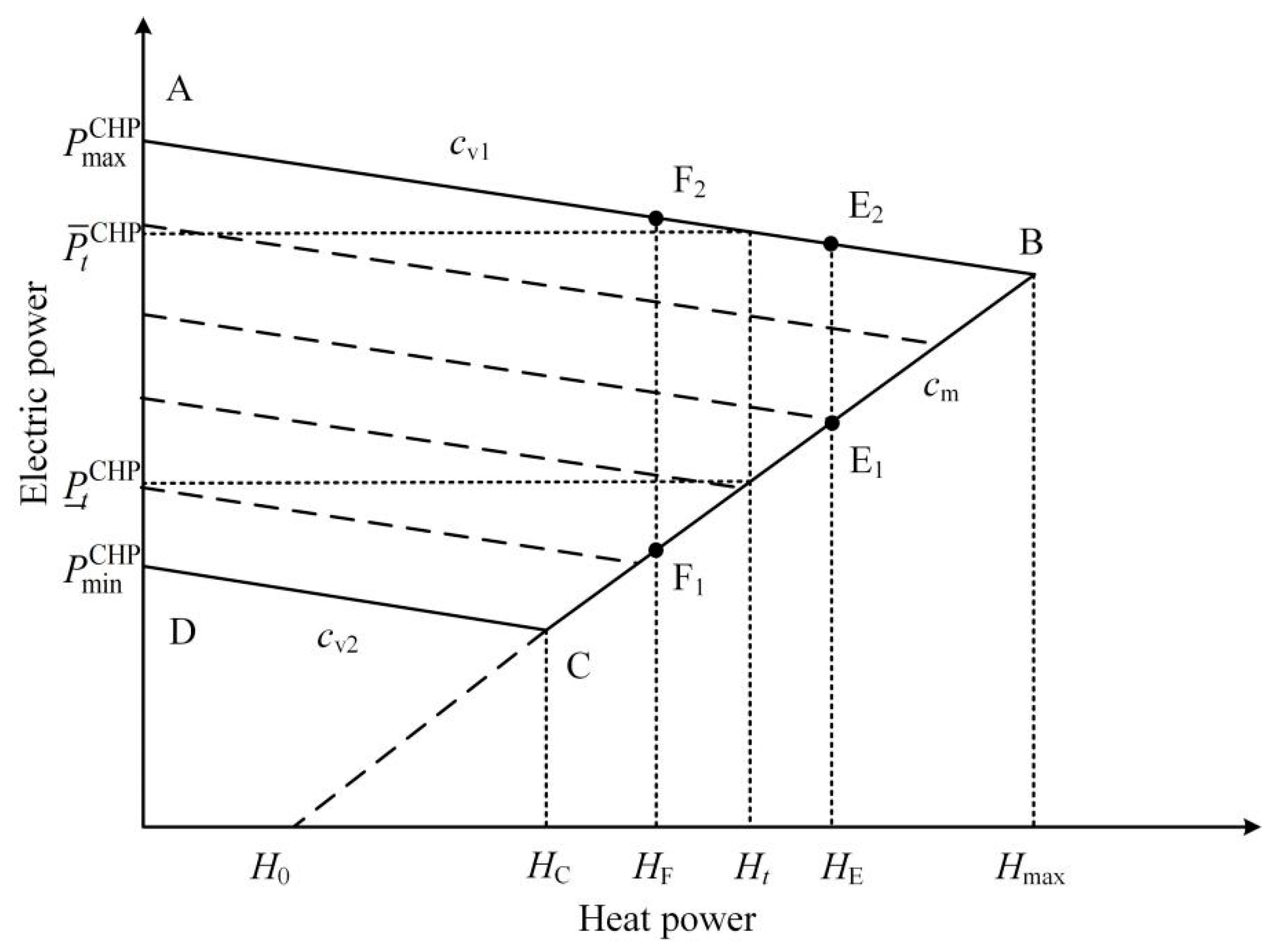

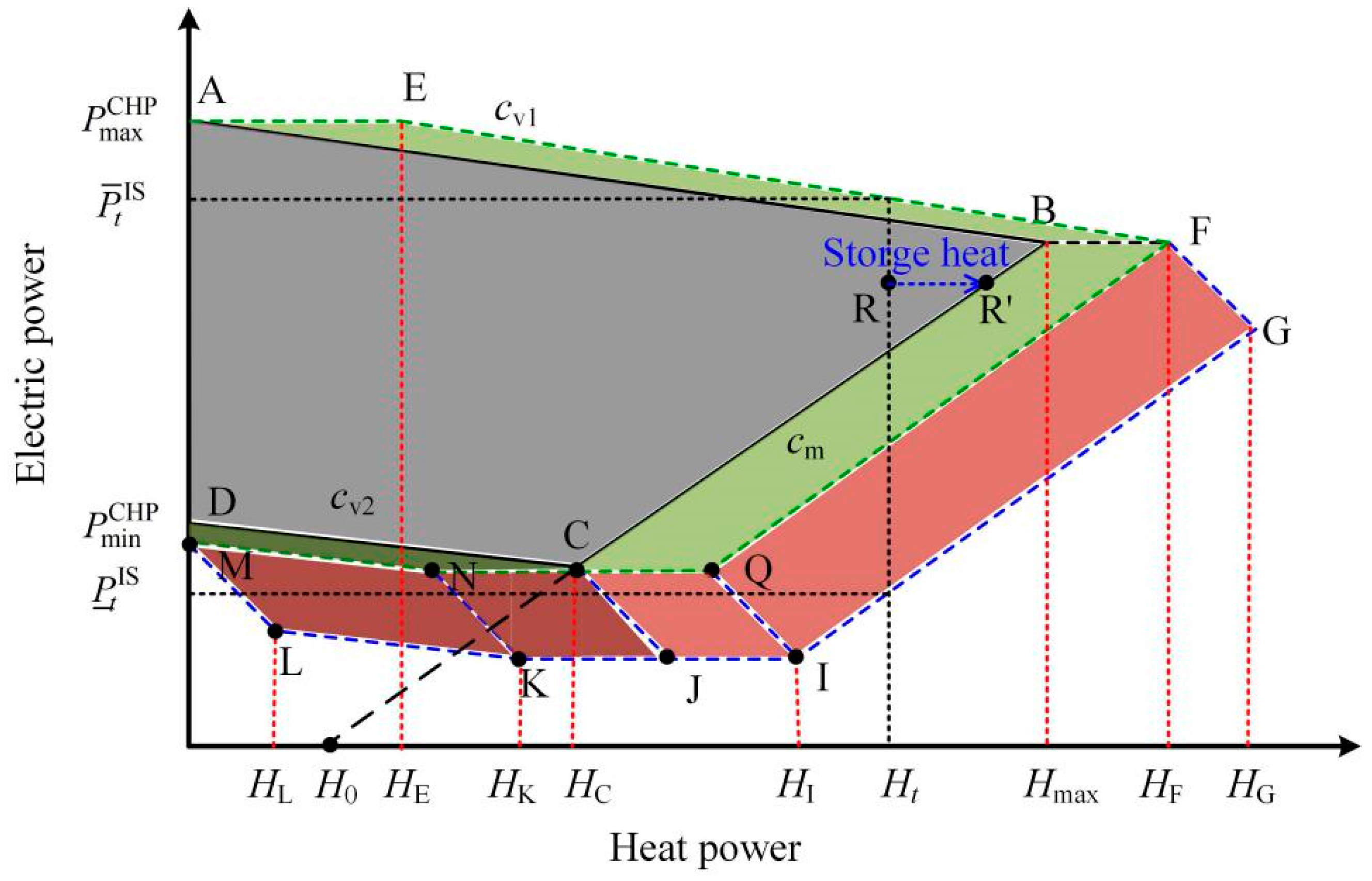

2.1. Feasible Operation Interval of Traditional CHP Units

2.2. Overall Feasible Operating Interval of Flexible CHP Units

2.3. The Internal Coordination Operation Model of a Flexible CHP Plant

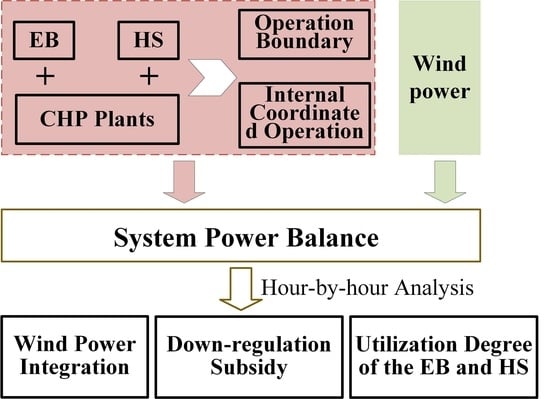

3. Wind Power Integration Evaluation for Power Systems with Flexible CHP Plants

3.1. Principle of Wind Power Integration Assessment

- Calculate the peak adjustable capacity required for the day based on the daily maximum load and spare capacity;

- Determine the operating capacity of each type of power supply according to the energy-saving scheduling or other scheduling principles;

- Calculate the minimum electric power output of each operating plant according to the regulation of the grid-connected power plant auxiliary service management method and their operational constraints (such as heating, water, etc.);

- Obtain the minimum electric power output of the system by adding the minimum electric power output of all the operating plants;

- Wind power curtailment occurs when the minimum electric power output of the system is greater than the equivalent load (electric power demand minus the wind power output).

3.2. Calculation of Minimum Electric Output of CHP Plants after Flexibility Transformation

3.2.1. Simplified Calculation of Minimum Electrical Power Output of the CHP Plants

3.2.2. Accurate Calculation of Minimum Electrical Power Output of the CHP Plants

- (1)

- Calculate the wind power curtailment of the system () before the CHP plants flexibility transformation according to the method described in Section 3.1. At this time, the minimum electric power output of CHP plants is determined by the current heat demand.

- (2)

- Calculate the minimum electric output of CHP plants after the flexibility transformation from the initial period, and the heat in the HS is assumed to be zero at the initial time.

4. Evaluation Indicators

4.1. The Wind Power Curtailment Indicator

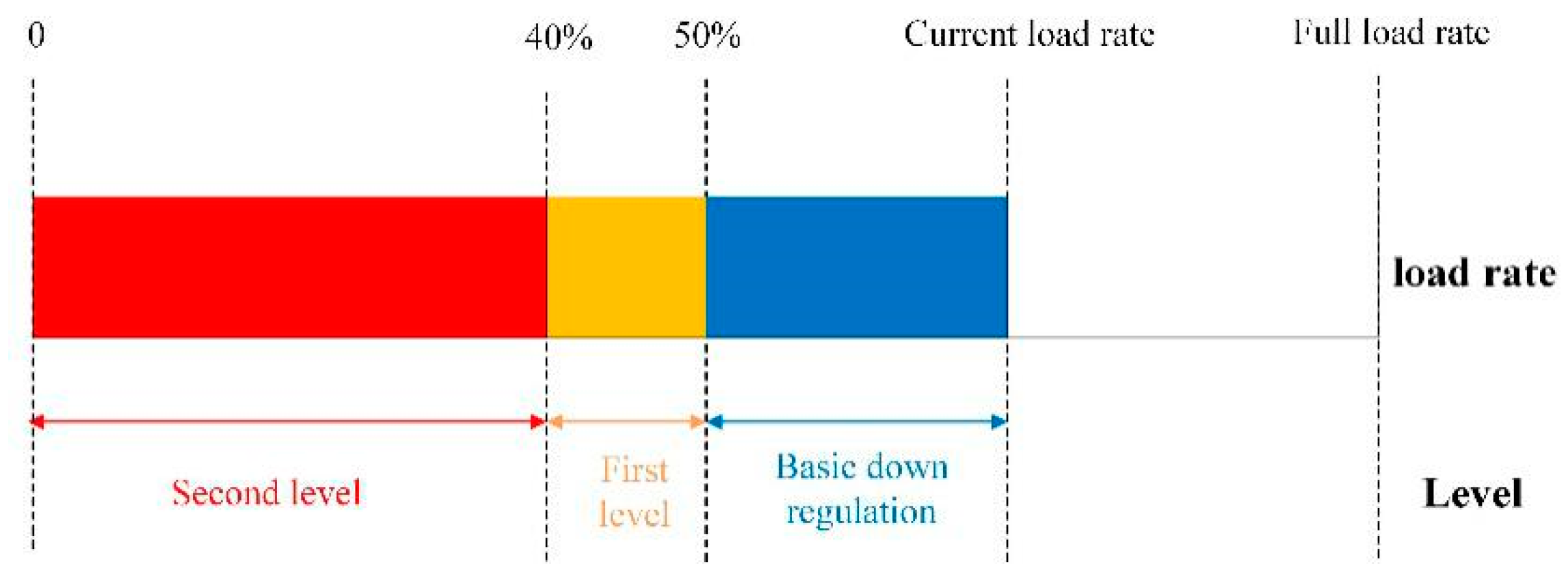

4.2. The Down-regulation Subsidy Indicator

5. Case Study

5.1. Basic Data

5.1.1. Electric Load Data

5.1.2. Power Source Structure

5.1.3. Heating Load of the CHP Plant

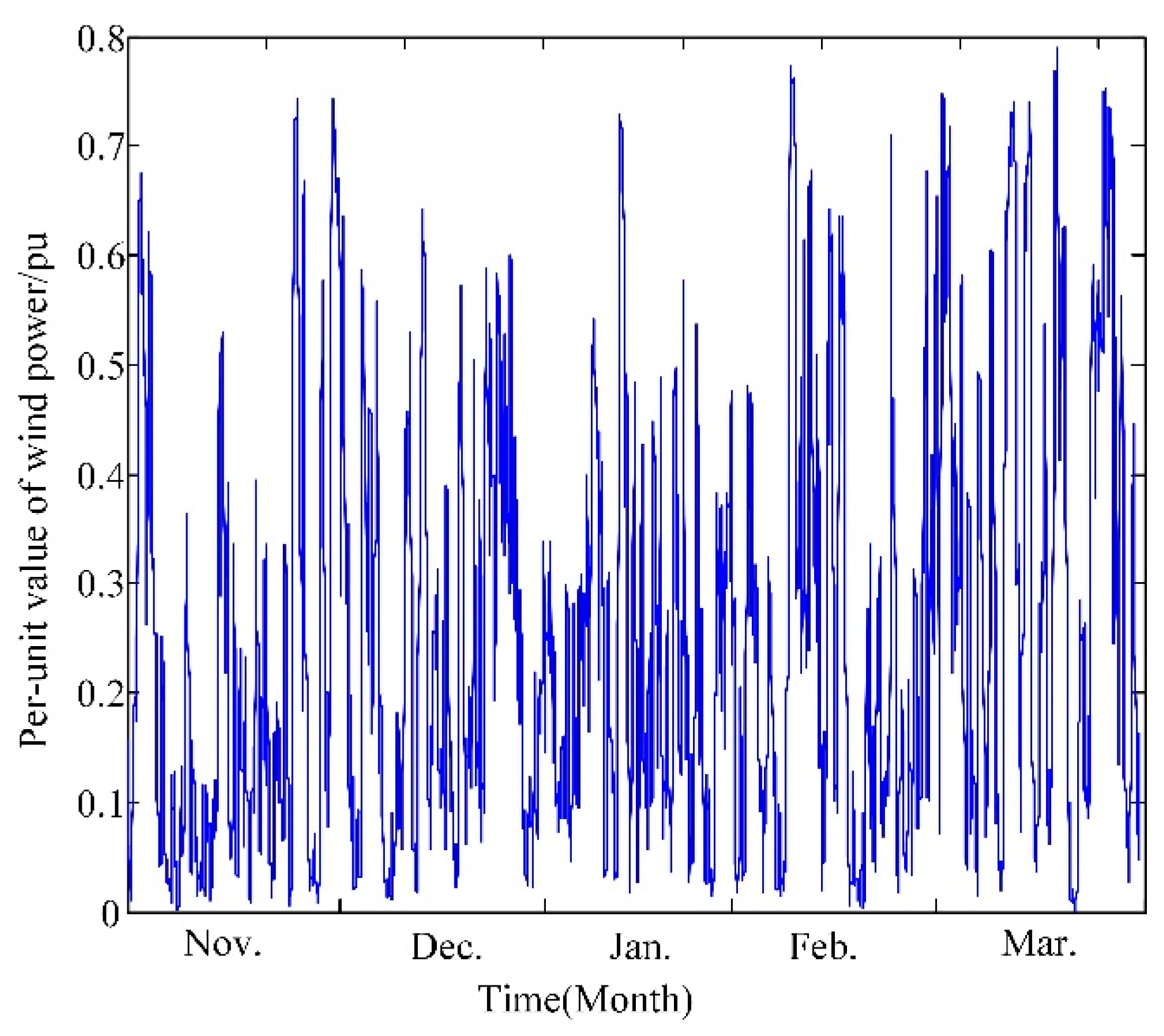

5.1.4. Wind Power Data

5.2. Evaluation Results

5.2.1. Analysis of Evaluation Results before Flexibility Transformation

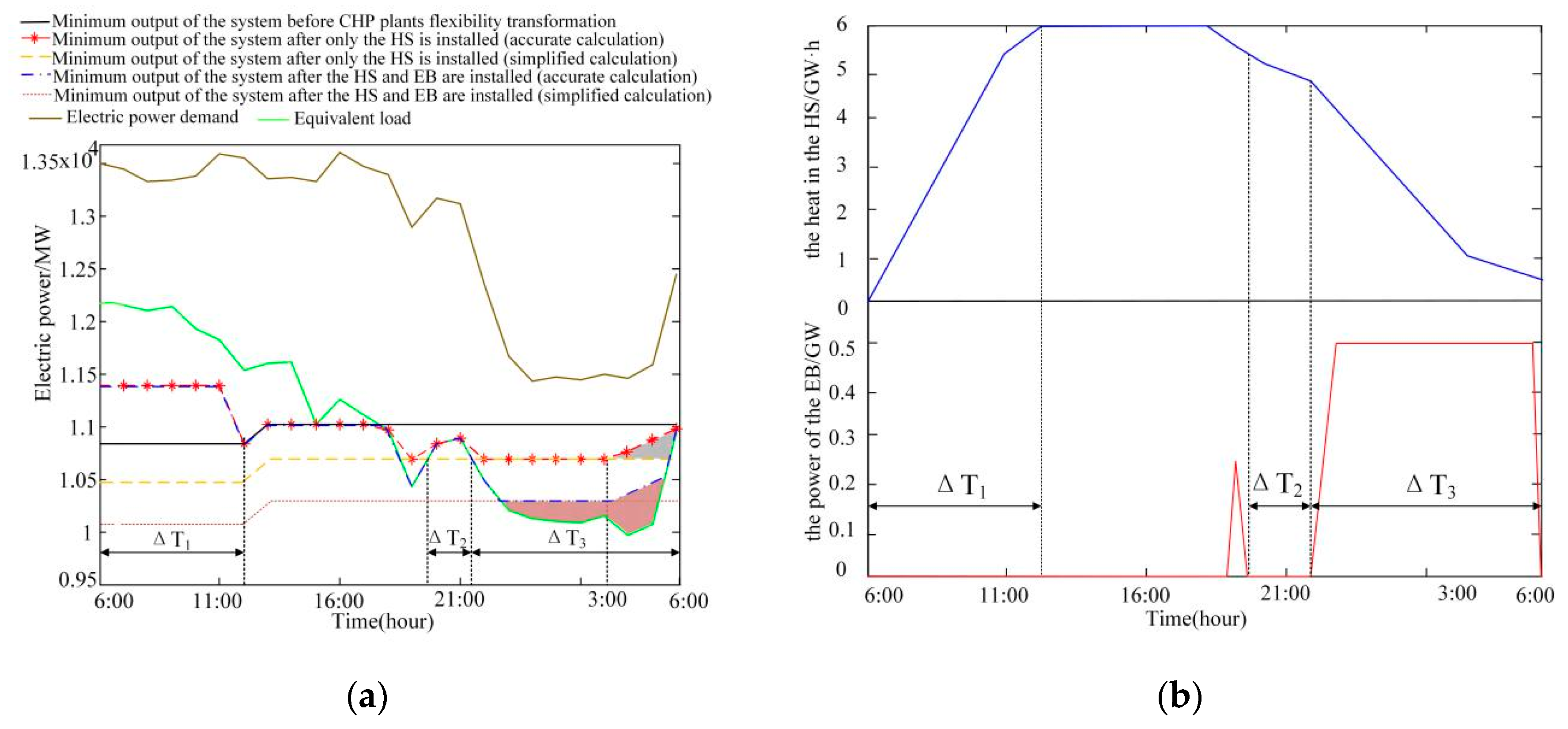

5.2.2. Comparisons between Simplified Calculation and Accurate Calculation

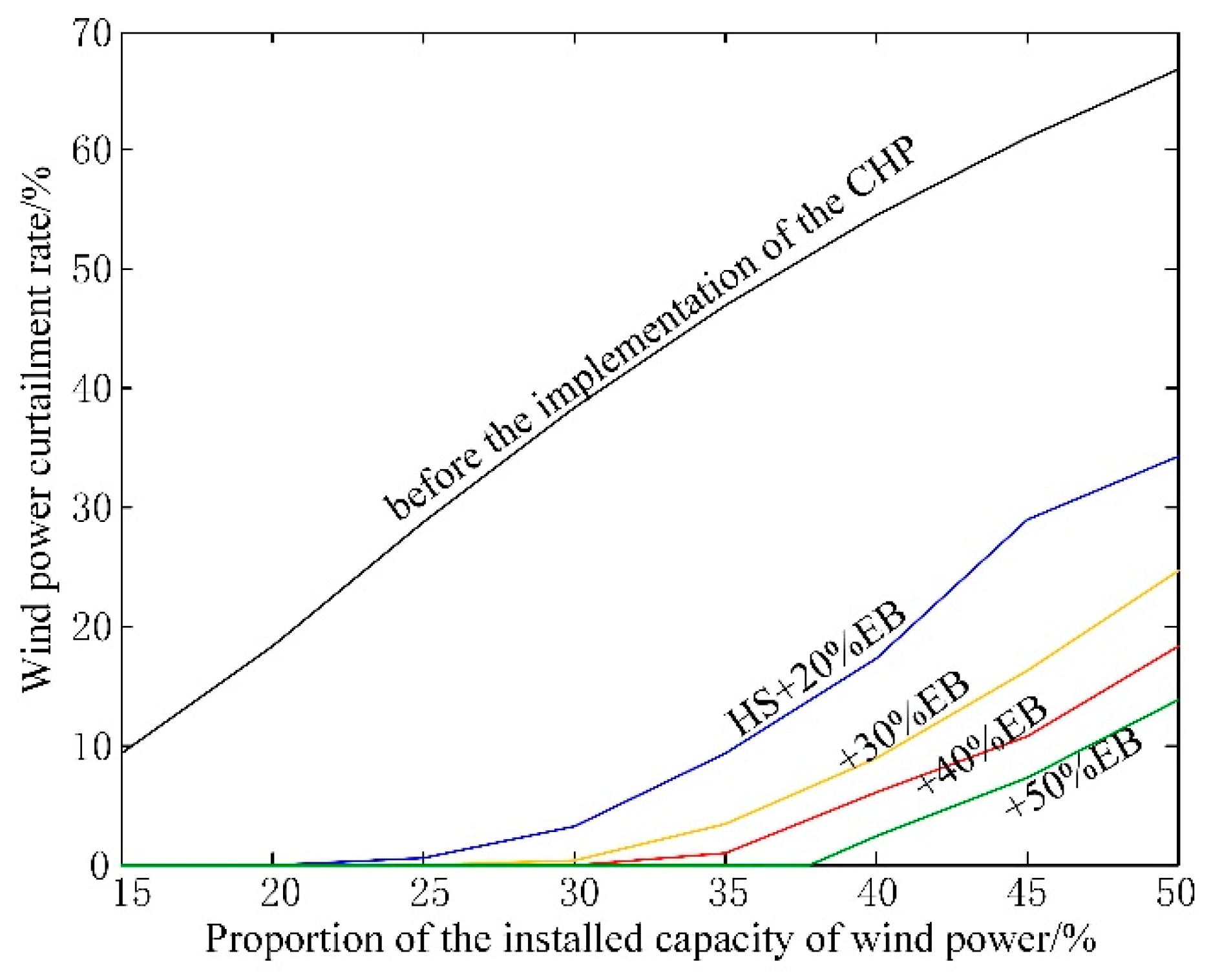

5.2.3. Wind Power integration of the System after Installation of HS and EB

5.2.4. Down-regulation Subsidy in the System

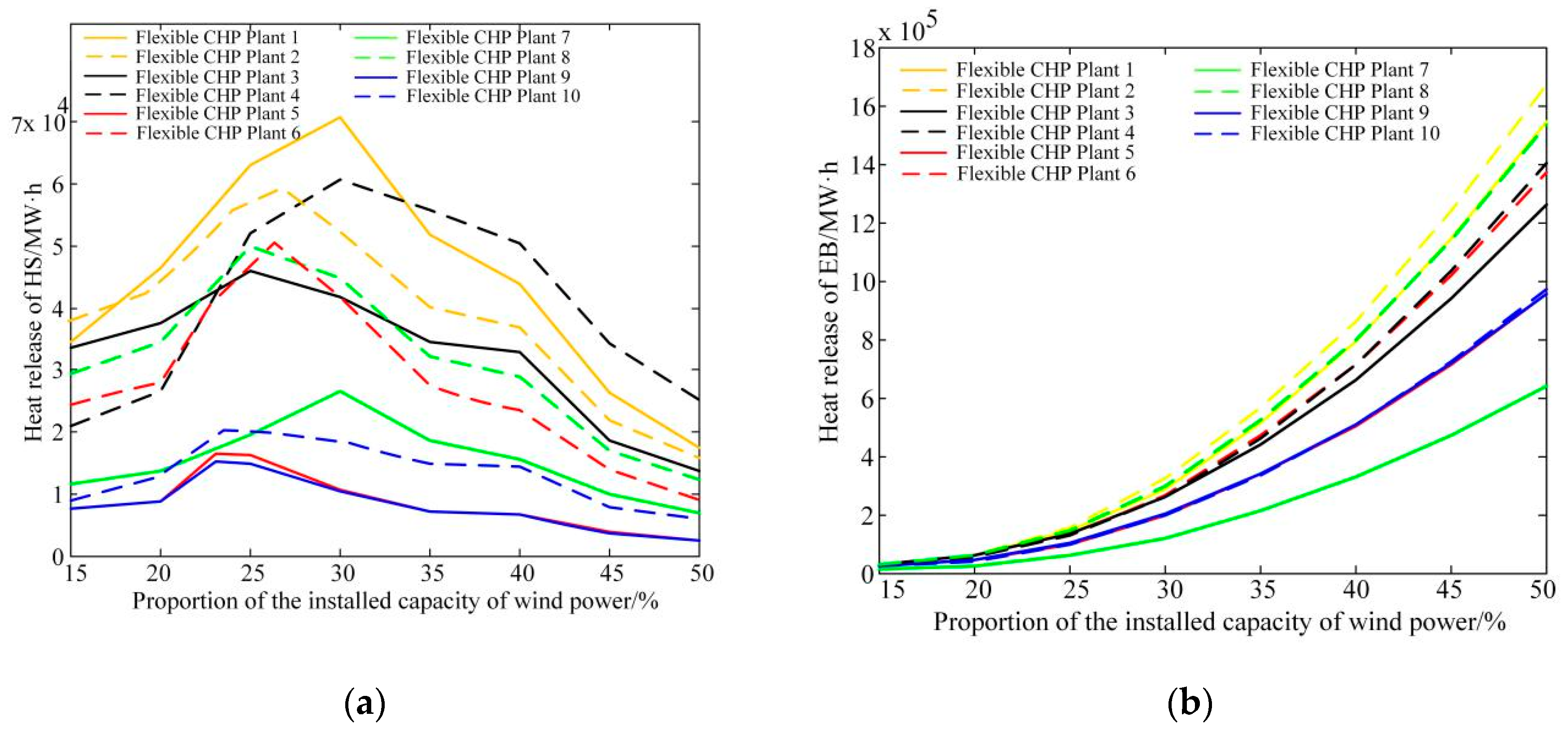

5.2.5. Influence of Wind Power Capacity on Utilization of HS and EB

5.2.6. Analysis of the Potential of Wind Power Integration in the Transformed CHP Plant

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| CHP | Combined heat and power |

| CON | Condensing power |

| HS | Heat storage |

| EB | Electric boilers |

Appendix A

| Unit | Max Electric Output (MW) | Min Electric Output (MW) | Max Heat Output/MW | a (t·MW−2·h−1) | b (t·MW−1·h−1) | c (t·h−1) | cv | cm | Upper Climbing Rate | Lower Climbing Rate |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 212 | 100 | 241 | 0.000254 | 0.242 | 10.339 | 0.21 | 0.44 | 80 | 100 |

| 2 | 323 | 150 | 357 | 0.000068 | 0.243 | 16.867 | 0.23 | 0.45 | 120 | 100 |

| Level | Load Rate | Subsidy (¥/kW·h) |

|---|---|---|

| First-level | 40–50% | 0.4 |

| Second-level | Less than 40% | 1.0 |

Appendix B

References

- The National Energy Administration. The Statistics of Wind Power in 2017. 2017. Available online: http://www.nea.gov.cn/2018-02/01/c_136942234.htm (accessed on 20 July 2019).

- The National Energy Administration. The Minimum Approval of Northeast Power Grid in 2018. Available online: http://www.nea.gov.cn/2017-04/25/c_136234299.htm (accessed on 20 July 2019).

- The National Energy Administration. The National Energy Administration Officially Launched the Pilot Project to Improve the Thermal Power Flexibility Transformation Demonstration. 2016. Available online: http://www.nea.gov.cn/2016-06/20/c_135451050.htm (accessed on 21 July 2019).

- Electric Power Planning & Engineering Institute. Thermal Power Plant Flexibility, a Publication under the Clean Energy Ministerial Campaign; Electric Power Planning & Engineering Institute: Beijing, China, 2018. [Google Scholar]

- The National Research Center of Thermal Power Engineering Technology. Brief Analysis on Flexibility Transformation of Thermal Power Units in Dandong Jinshan Thermal Power Co., Ltd.; The National Research Center of Thermal Power Engineering Technology: Beijing, China, 2017. [Google Scholar]

- Lin, J.; Li, J. Practice of Flexible Reformation of Direct Thermal Electric Boiler in Thermal Power Plant. Jilin Electr. Power 2017, 45, 11–14. (In Chinese) [Google Scholar]

- China Electricity Council. The Flexible Thermal Power Transformation Project of Datang Hayi Thermal Power Plant Has Been Approved by the Project. 2017. Available online: http://www.cec.org.cn/hangyeguangjiao/fadianxinxi/2017-07-12/170750.html (accessed on 24 July 2019).

- Chen, H.; Yu, Y.; Jiang, X. Optimal scheduling of combined heat and power units with heat storage for the improvement of wind power accommodation. In Proceedings of the 2016 IEEE PES Asia-Pacific Power and Energy Engineering Conference (APPEEC), Xi’an, China, 25–28 October 2016; pp. 1508–1512. [Google Scholar]

- Rong, S.; Li, Z.; Li, W. Investigation of the promotion of wind power consumption using the thermal-electric decoupling techniques. Energies 2015, 8, 8613–8629. [Google Scholar] [CrossRef]

- Chen, X.; Kang, C.; O’Malley, M.; Xia, Q.; Bai, J.; Liu, C.; Sun, R.; Wang, W.; Li, H. Increasing the flexibility of combined heat and power for wind power accommodation in China: Modeling and implications. IEEE Trans. Power Syst. 2015, 30, 1848–1857. [Google Scholar] [CrossRef]

- Zhang, N.; Lu, X.; McElroy, M.B.; Nielsen, C.P.; Chen, X.; Deng, Y.; Kang, C. Reducing curtailment of wind electricity in China by employing electric boilers for heat and pumped hydro for energy storage. Appl. Energy 2016, 184, 987–994. [Google Scholar] [CrossRef]

- Lv, Q.; Wang, W.; Han, S.; Yuan, S.; Zhang, J.; Li, W.D. A new evaluation method for wind power curtailment based on analysis of system regulation capacity. Power Syst. Technol. 2013, 37, 1887–1894. (In Chinese) [Google Scholar]

- Xiong, W.; Wang, Y.; Mathiesen, B.V.; Zhang, X. Case study of the constraints and potential contributions regarding wind curtailment in Northeast China. Energy 2016, 110, 55–64. [Google Scholar] [CrossRef]

- Liu, W.; Lund, H.; Mathiesen, B.V. Large-scale accommodation of wind power into the existing Chinese energy system. Energy 2011, 36, 4753–4760. [Google Scholar] [CrossRef]

- Liu, W.; Hu, W.; Lund, H.; Chen, Z. Electric vehicles and large-scale accommodation of wind power-The case of Inner Mongolia in China. Appl. Energy 2013, 104, 455–456. [Google Scholar] [CrossRef]

- Hedegaard, K.; Mathiesen, B.V.; Lund, H.; Heiselberg, P. Wind power accommodation using individual heat pumps-Analysis of different heat storage option. Energy 2012, 47, 284–293. [Google Scholar] [CrossRef]

- Lund, H. Renewable heating strategies and their consequences for storage and grid infrastructures comparing a smart grid to a smart energy systems approach. Energy 2018, 151, 94–102. [Google Scholar] [CrossRef]

- Jakob, Z.T.; Steffen, N.; Henrik, L. Implementing cleaner heating solutions towards a future low-carbon scenario in Ireland. J. Clean. Prod. 2019, 214, 377–388. [Google Scholar]

- Li, P.; Wang, H.; Lv, Q.; Li, W. Combined heat and power dispatch considering heat storage of both buildings and pipelines in district heating system for wind power accommodation. Energies 2017, 10, 893. [Google Scholar] [CrossRef]

- Northeast China Energy Regulatory Bureau of the National Energy Administration. Operation Rules of Northeast Electricity Auxiliary Service Market (Provisional); Northeast China Energy Regulatory Bureau of the National Energy Administration: Shenyang, China, 2018. [Google Scholar]

- Li, C. Research on Optimal Capacity of Heat Accumulators Installed to CHP Plants for the accommodation of the Abandoned Wind. Dalian Univ. Technol. 2016. (In Chinese) [Google Scholar]

| The Type of Unit | Installed Capacity (GW) |

|---|---|

| CHP Condensing Power (CP) | 8.2 |

| 13.665 | |

| WIND | 4.42 |

| Capacity of the HS (MWh) Cost of Down-Regulation Subsidy (Ten Thousand Yuan) Capacity of the EB (MW) | 0 | 20% of the Installed Capacity of Each CHP Plant | 30%of the Installed Capacity of Each CHP Plant | 40%of the Installed Capacity of Each CHP Plant | 50%of the Installed Capacity of Each CHP Plant |

|---|---|---|---|---|---|

| Heating medium-term compensation heating power × heat release time (6 h) | 0.184 | 10.459 | 15.827 | 18.294 | 19.374 |

| Heating medium-term compensation heating power × heat release time (8 h) | 0.471 | 10.559 | 15.892 | 18.319 | 19.387 |

| Heating medium-term compensation heating power × heat release time (10 h) | 0.931 | 10.677 | 15.914 | 18.353 | 19.427 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lyu, Q.; Gong, H.; Yang, N.; Xu, X.; Zhang, N.; Wang, H. An Evaluation Method of Wind Power Integration in Power Systems with Flexible Combined Heat and Power Plant. Energies 2019, 12, 4129. https://doi.org/10.3390/en12214129

Lyu Q, Gong H, Yang N, Xu X, Zhang N, Wang H. An Evaluation Method of Wind Power Integration in Power Systems with Flexible Combined Heat and Power Plant. Energies. 2019; 12(21):4129. https://doi.org/10.3390/en12214129

Chicago/Turabian StyleLyu, Quan, Haoyan Gong, Nan Yang, Xiandong Xu, Na Zhang, and Haixia Wang. 2019. "An Evaluation Method of Wind Power Integration in Power Systems with Flexible Combined Heat and Power Plant" Energies 12, no. 21: 4129. https://doi.org/10.3390/en12214129

APA StyleLyu, Q., Gong, H., Yang, N., Xu, X., Zhang, N., & Wang, H. (2019). An Evaluation Method of Wind Power Integration in Power Systems with Flexible Combined Heat and Power Plant. Energies, 12(21), 4129. https://doi.org/10.3390/en12214129