Consequential Life Cycle Assessment of Swine Manure Management within a Thermal Gasification Scenario

Abstract

1. Introduction

2. Methods

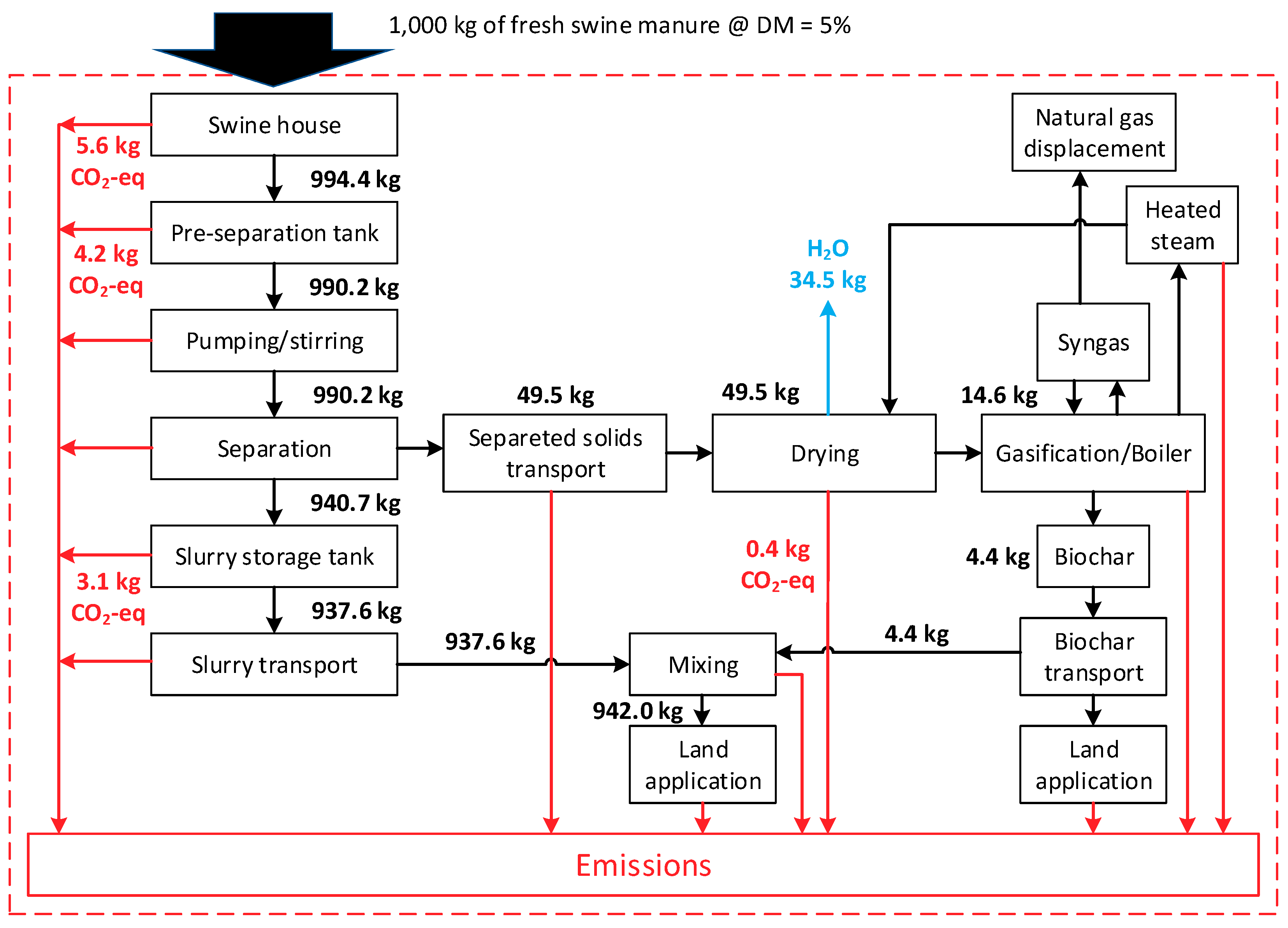

2.1. LCA Goal and Scope

2.2. Life-Cycle Inventory Assessment

2.2.1. Swine House

2.2.2. Pre-Separation Tank/Stirring and Mixing

2.2.3. Mechanical Separation and Separated Solids Transport

2.2.4. Drying

2.2.5. Gasification/Boiler

2.2.6. Biochar Transport and Land Application

2.2.7. Post-Separation Tank (Liquid-Fraction)

2.2.8. Liquid Fraction Transport, Mixing with Biochar, and Land Application

3. Results and Discussions

3.1. Impact Assessment

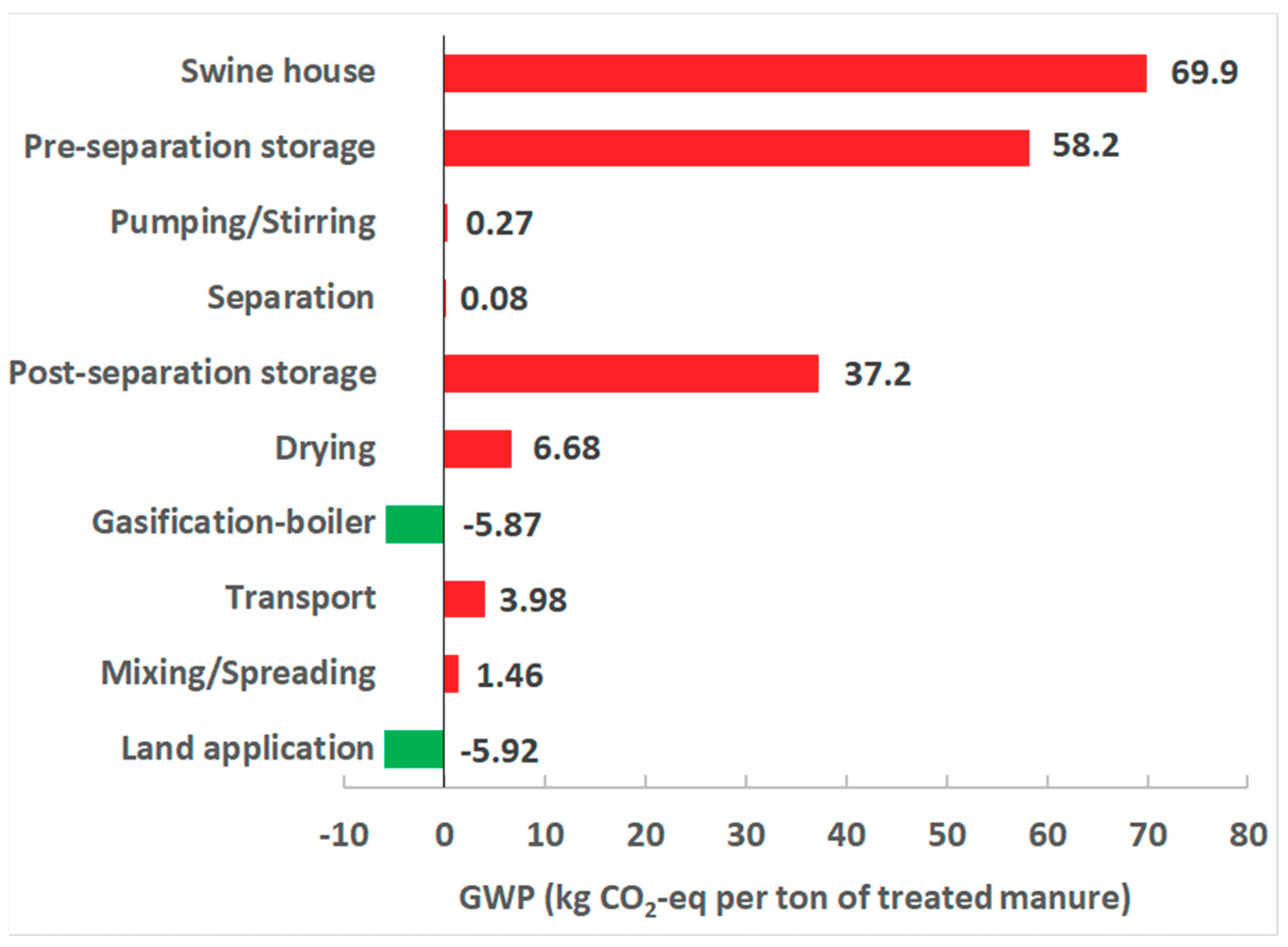

3.2. Global Warming Potential (GWP)

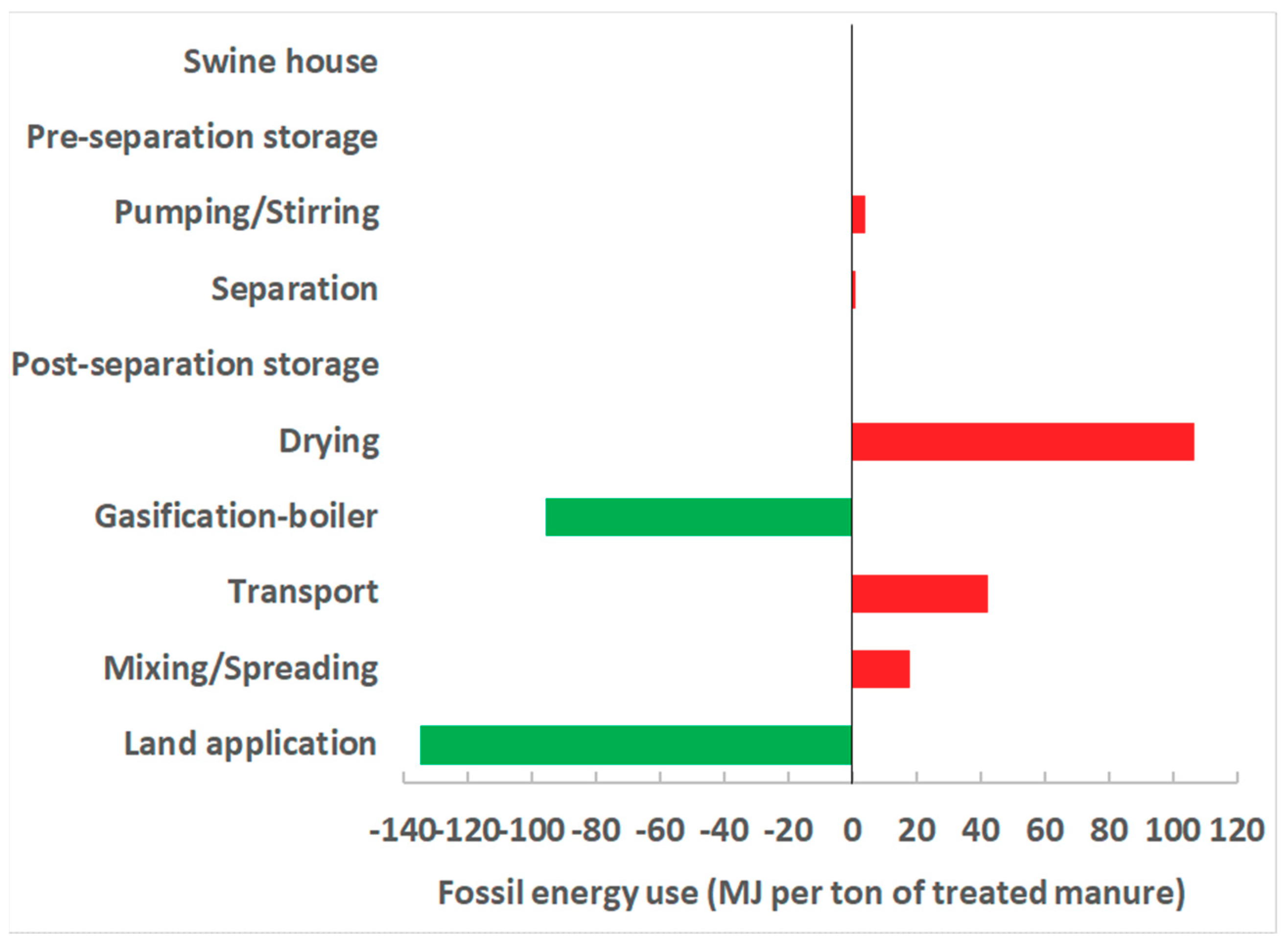

3.3. Fossil Fuel Use

3.4. Water Depletion

3.5. Marine Eutrophication

3.6. Freshwater Eutrophication

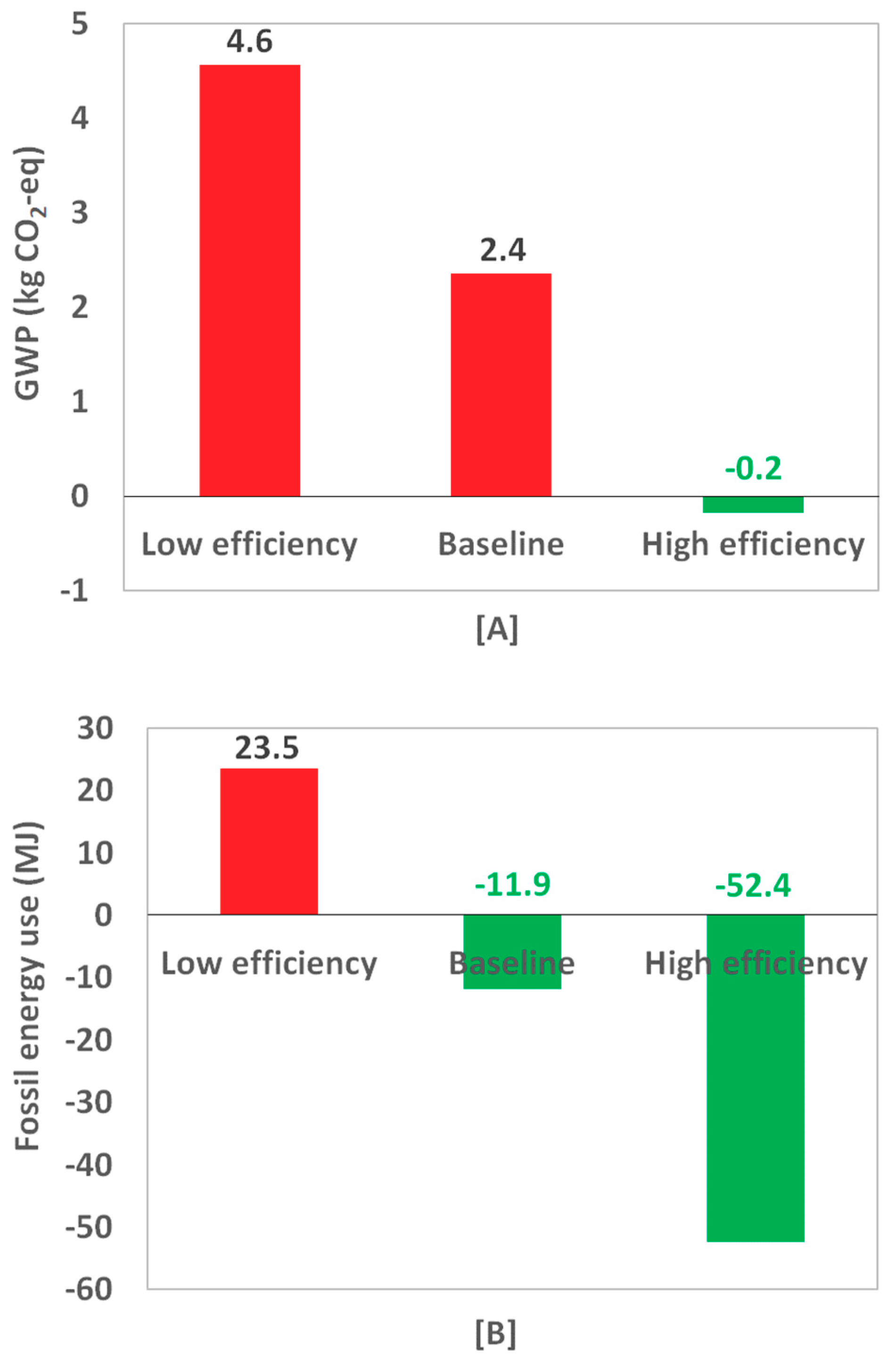

3.7. Model Sensitivity to Thermochemical Conversion Parameters

4. Implications of the Study

5. Conclusions

- Swine manure liquid storage (before and after solid-liquid separation) contributed 57.5% of the GHG emissions for the entire proposed manure management scenario.

- Swine manure solids separation, drying, and gasification resulted in a net energy expenditure of 12.3 MJ for each functional unit (treatment of 1 metric ton of manure slurry).

- The high energy demand associated with manure drying represented greater energy requirement than the energy produced from the gasification/boiler stage.

- Land application of slurry-biochar mixture is credited with 5.9 kg CO2-eq in avoided GHG emissions, and 135 MJ of avoided fossil fuel energy use resulting from avoided synthetic fertilizer production.

- Improvements to drying and thermochemical conversion efficiencies may further significantly reduce fossil fuel use in thermochemical manure management.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Dong, H.; Mangino, J.; McAllister, T.; Have, D. Emissions from livestock and manure management. In IPCC Guidelines for National Greenhouse Gas Inventories 4; 2006; Available online: https://www.alice.cnptia.embrapa.br/handle/doc/1024926 (accessed on 17 October 2019).

- Bockstaller, C.; Vertès, F.; Fiorelli, J.; Rochette, P.; Aarts, H. Tools for evaluating and regulating nitrogen impacts in livestock farming systems. Adv. Anim. Biosci. 2014, 5, 49–54. [Google Scholar] [CrossRef]

- Reddy, P.P. Agriculture as a Source of GHGs. In Climate Resilient Agriculture for Ensuring Food Security; Springer: New Delhi, India, 2015; pp. 27–42. [Google Scholar]

- Kurukulasuriya, P.; Rosenthal, S. Climate change and agriculture: A review of impacts and adaptations. World Bank 2013, 1, 91. Available online: https://openknowledge.worldbank.org/bitstream/handle/10986/16616/787390WP0Clima0ure0377348B00PUBLIC0.pdf?sequence=1&isAllowed=y (accessed on 17 October 2019).

- EPA 430-R-14-003. Inventory of U.S. Greenhouse Gas Emissions and Sinks: 1990-2012; Environmental Protection Agency (EPA): Washington, DC, USA, 2014.

- Fangueiro, D.; Coutinho, J.; Chadwick, D.; Moreira, N.; Trindade, H. Effect of Cattle Slurry Separation on Greenhouse Gas and Ammonia Emissions during Storage. J. Environ. Qual. 2008, 37, 2322–2331. [Google Scholar] [CrossRef] [PubMed]

- Fitzgerald, S.; Kolar, P.; Classen, J.; Boyette, M.; Das, L. Swine manure char as an adsorbent for mitigation of p cresol. Environ. Prog. Sustain. Energy 2015, 34, 125–131. [Google Scholar] [CrossRef]

- Lentz, Z.A.; Classen, J.; Kolar, P. Thermochemical Conversion: A Prospective Swine Manure Solution for North Carolina. Trans. ASABE 2017, 60, 591–600. [Google Scholar] [CrossRef]

- ISO 14040 Environmental Management–Life Cycle Assessment–Principles and Framework; International Organization for Standardization: London, UK; British Standards Institution: Hutchings, UK, 2006.

- Wu, H.; Hanna, M.A.; Jones, D.D. Life cycle assessment of greenhouse gas emissions of feedlot manure management practices: Land application versus gasification. Biomass Bioenergy 2013, 54, 260–266. [Google Scholar] [CrossRef]

- Lijó, L.; González-García, S.; Bacenetti, J.; Fiala, M.; Feijoo, G.; Lema, J.M.; Moreira, M.T. Life Cycle Assessment of electricity production in Italy from anaerobic co-digestion of pig slurry and energy crops. Renew. Energy 2014, 68, 625–635. [Google Scholar] [CrossRef]

- Rodriguez-Verde, I.; Regueiro, L.; Carballa, M.; Hospido, A.; Lema, J.M. Assessing anaerobic co-digestion of pig manure with agroindustrial wastes: The link between environmental impacts and operational parameters. Sci. Total Environ. 2014, 497, 475–483. [Google Scholar] [CrossRef]

- Pehme, S.; Veromann, E.; Hamelin, L. Environmental performance of manure co-digestion with natural and cultivated grass—A consequential life cycle assessment. J. Clean. Prod. 2017, 162, 1135–1143. [Google Scholar] [CrossRef]

- Roberts, K.G.; Gloy, B.A.; Joseph, S.; Scott, N.R.; Lehmann, J. Life cycle assessment of biochar systems: Estimating the energetic, economic, and climate change potential. Environ. Sci. Technol. 2010, 44, 827–833. [Google Scholar] [CrossRef]

- Sharara, M.A.; Sadaka, S.S. Opportunities and Barriers to Bioenergy Conversion Techniques and Their Potential Implementation on Swine Manure. Energies 2018, 11, 957. [Google Scholar] [CrossRef]

- Ecoinvent Centre. The Ecoinvent Database. Available online: https://www.ecoinvent.org/database/database.html (accessed on 11 October 2019).

- Bulle, C.; Margni, M.; Patouillard, L.; Boulay, A.; Bourgault, G.; De Bruille, V.; Cao, V.; Hauschild, M.; Henderson, A.; Humbert, S.; et al. IMPACT World+: A globally regionalized life cycle impact assessment method. Int. J. Life Cycle Assess. 2019, 24, 1653–1674. [Google Scholar] [CrossRef]

- IPCC. Climate Change 2013: The Physical Science Basis. Contribution of Working Group I to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Stocker, T.F., Qin, D., Plattner, G., Allen, S.K., Xia, Y., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2013; p. 1535. Available online: http://www.climatechange2013.org/images/report/WG1AR5_Frontmatter_FINAL.pdf (accessed on 17 October 2019).

- ASABE ASAE D384.2. Manure Production and Characteristics; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2005. [Google Scholar]

- Mikkelsen, M.; Gyldenkærne, S.; Poulsen, H.; Olesen, J.; Sommer, S. Emissions of Ammonia, Nitrous Oxide and Methane from Danish Agriculture 1985–2002: Methodology and Estimates (no. 231); National Environmental Research Institute (NERI), Ministry of Environment: Frontlinien, Denmark, 2006.

- Wesnaes, M.; Wenzel, H.; Petersen, B.M. Life Cycle Assessment of Slurry Management Technologies; Danish Ministry of the Environment/Danish Environmental Protection Agency: Copenhagen, Denmark, 2009. [Google Scholar]

- Nguyen, T.L.T.; Hermansen, J.E.; Mogensen, L. Fossil energy and GHG saving potentials of pig farming in the EU. Energy Policy 2010, 38, 2561–2571. [Google Scholar] [CrossRef]

- Moller, H.B.; Lund, I.; Sommer, S.G. Solid–liquid separation of livestock slurry: Efficiency and cost. Bioresour. Technol. 2000, 74, 223–229. [Google Scholar] [CrossRef]

- Day, D.; Funk, T.; Hatfield, J.; Stewart, B. Processing Manure: Physical, Chemical and Biological Treatment, in Animal Waste Utilization: Effective Use of Manure as a Soil Resource; CRC Press: Boca Raton, FL, USA, 1998. [Google Scholar]

- Sadaka, S.; Ahn, H. Evaluation of a biodrying process for beef, swine, and poultry manures mixed separately with corn stover. Appl. Eng. Agric. 2012, 28, 457–463. [Google Scholar] [CrossRef]

- Hjorth, M.; Christensen, K.V.; Christensen, M.L.; Sommer, S.G. Solid–liquid separation of animal slurry in theory and practice. A review. Agron. Sustain. Dev. 2010, 30, 153–180. [Google Scholar] [CrossRef]

- Sharara, M.A.; Sadaka, S.; Costello, T.A.; VanDevender, K. Influence of aeration rate on the physio-chemical characteristics of biodried dairy manure-wheat straw mixture. Appl. Eng. Agric. 2012, 28, 407–415. [Google Scholar] [CrossRef]

- Hospido, A.; Teresa Moreira, M.; Fernandez-Couto, M.; Feijoo, G. Environmental Performance of a Municipal Wastewater Treatment Plant. Int. J. Life Cycle Assess. 2004, 9, 261–271. [Google Scholar] [CrossRef]

- Jensen, L.S. Animal Manure Residue Upgrading and Nutrient Recovery in Biofertilisers. Animal Manure Recycling: Treatment and Management, 271–294. Available online: https://openknowledge.worldbank.org/handle/10986/16616 (accessed on 27 January 2015).

- Ro, K.S.; Cantrell, K.B.; Hunt, P.G. High-temperature pyrolysis of blended animal manures for producing renewable energy and value-added biochar. Ind. Eng. Chem. Res. 2010, 49, 10125–10131. [Google Scholar] [CrossRef]

- Wnetrzak, R.; Kwapinski, W.; Peters, K.; Sommer, S.G.; Jensen, L.S.; Leahy, J.J. The influence of the pig manure separation system on the energy production potentials. Bioresour. Technol. 2013, 136, 502–508. [Google Scholar] [CrossRef]

- Arena, U. Process and technological aspects of municipal solid waste gasification. A review. Waste Manag. 2012, 32, 625–639. [Google Scholar] [CrossRef] [PubMed]

- Pa, A.; Bi, X.T.; Sokhansanj, S. A life cycle evaluation of wood pellet gasification for district heating in British Columbia. Bioresour. Technol. 2011, 102, 6167–6177. [Google Scholar] [CrossRef] [PubMed]

- Zaman, A.U. Life cycle assessment of pyrolysis–gasification as an emerging municipal solid waste treatment technology. Int. J. Environ. Sci. Technol. 2013, 10, 1029–1038. [Google Scholar] [CrossRef]

- Daugaard, D.E.; Brown, R.C. Enthalpy for pyrolysis for several types of biomass. Energy Fuels 2003, 17, 934–939. [Google Scholar] [CrossRef]

- Evans, M.R.; Jackson, B.E.; Popp, M.; Sadaka, S. Chemical Properties of Biochar Materials Manufactured from Agricultural Products Common to the Southeast United States. HortTechnology 2017, 27, 16–23. [Google Scholar] [CrossRef]

- Laboski, C.A.; Peters, J.B.; Bundy, L.G. Nutrient Application Guidelines for Field, Vegetable, and Fruit Crops in Wisconsin; Division of Cooperative Extension of the University of Wisconsin-Extension: Madison, WI, USA, 2006. [Google Scholar]

- Pehme, S. Life Cycle Inventory & Assessment Report: Dairy Cow Slurry Biogas with Grass as an External C Source; Baltic Manure Report; Estonia, 2013; Available online: http://www.balticmanure.eu/download/Reports/wp5_report_estonia_web.pdf (accessed on 17 October 2019).

- Delin, S.; Stenberg, B.; Nyberg, A.; Brohede, L. Potential methods for estimating nitrogen fertilizer value of organic residues. Soil Use Manag. 2012, 28, 283–291. [Google Scholar] [CrossRef]

- Misselbrook, T.H.; Nicholson, F.A.; Chambers, B.J. Predicting ammonia losses following the application of livestock manure to land. Bioresour. Technol. 2005, 96, 159–168. [Google Scholar] [CrossRef]

- Sommer, S.G.; Hutchings, N.J. Ammonia emission from field applied manure and its reduction. Eur. J. Agron. 2001, 15, 1–15. [Google Scholar] [CrossRef]

- Hutchings, N.J.; ten Hoeve, M.; Jensen, R.; Bruun, S.; Søtoft, L.F. Modelling the potential of slurry management technologies to reduce the constraints of environmental legislation on pig production. J. Environ. Manag. 2013, 130, 447–456. [Google Scholar] [CrossRef]

- Buckley, K.E.; Mohr, R.M.; Therrien, M.C. Yield and quality of oat in response to varying rates of swine slurry. Can. J. Plant Sci. 2010, 90, 645–653. [Google Scholar] [CrossRef]

- Rochette, P.; Angers, D.A.; Chantigny, M.H.; Bertrand, N.; Côté, D. Carbon dioxide and nitrous oxide emissions following fall and spring applications of pig slurry to an agricultural soil. Soil Sci. Soc. Am. J. 2004, 68, 1410–1420. [Google Scholar] [CrossRef]

| Characteristics | Value | Units | Characteristics | Value | Units |

|---|---|---|---|---|---|

| Dry matter (DM) | 5.0 | % | P (Ash) | 20.9 | % |

| Volatile matter (DM) | 81.6 | % | K (Ash) | 21.1 | % |

| Ash (DM) | 18.4 | % | Na (Ash) | 10.3 | % |

| C (DM) | 50.8 | % | Ca (Ash) | 20.5 | % |

| Total-N (DM) | 4.3 | % | Mg (Ash) | 12.1 | % |

| O (DM) | 21.0 | % | Cu (Ash) | 0.01 | % |

| H (DM) | 6.9 | % | Zn (Ash) | 0.04 | % |

| S (DM) | 1.3 | % |

| Raw Pig Slurry | Separation Index (%) | ||||

|---|---|---|---|---|---|

| DM (%) | Volume | Dry Matter | N-Total | P-Total | |

| Mean 1 | 4.7 | 5.75 | 35 | 11 | 20.3 |

| Standard Deviation | (2.01) | (1.50) | (16) | (10) | (16.5) |

| Parameters | Values | Source |

|---|---|---|

| Air requirements (kgair kg−1) | 2.54 | Calculated from composition, ER = 0.20 |

| Manure solids HHV † (MJ kg−1) | 19–20 | [30,31] |

| Cold-gas efficiency (%) | 50–80 | [32] |

| Boiler thermal efficiency (%) | 78 | [33] |

| Char yield (g kg−1) | 300–490 | [32,33] |

| Electricity req. (kWh kg−1) | 0.339 | [34] |

| Thermal energy req. (MJ kg−1) | 1.2 | [35] |

| Substance | Value (g) | Substance | Value (g) |

|---|---|---|---|

| CO2 | 1458.5 | VOCs | 0.016 |

| NOx | 1.1400 | HF | 0.0005 |

| CO | 0.1460 | Hg | 0.0001 |

| SO2 | 0.076 | As | 0.0001 |

| HCl | 0.047 | Ni | 0.0000 |

| PM | 0.018 | Cd | 0.0000 |

| 1. Swine house | |||

| NH3 emissions (kg) | 0.418 | CO2 emissions, biogenic (kg) | 2.82 |

| N2O emissions (kg) | 0.017 | CH4 emissions (kg) | 2.36 |

| 2. Pre-separation storage tank | |||

| NH3 emissions (kg) | 0.052 | CO2 emissions, biogenic (kg) | 2.14 |

| N2O emissions (kg) | 0.017 | CH4 emissions (kg) | 1.94 |

| 3. Stirring and pumping | |||

| Electrical power requirements (kWh) | 1.7 | ||

| 4. Mechanical separation | |||

| Electrical power requirement (kWh) | 0.5 | ||

| 5. Solids transportation | |||

| Transportation (tkm) | 0.025 | ||

| 6. Drying (solid fraction) | |||

| Heat requirements (MJ) | 86.1 | VOC emissions (kg) | 0.00064 |

| Electricity requirements (kWh) | 1.72 | NH3 emissions (kg) | 0.43 |

| Water requirement (m3) | 0.222 | ||

| 7. Gasification-Boiler (solid fraction) | |||

| Electricity requirements (kWh) | 4.94 | HCl emissions (g) | 0.47 |

| Air needed (kg) | 37.05 | PM emissions (g) | 0.18 |

| Thermal energy requirement (MJ) | 17.5 | ||

| Generated heat (MJ) | 140.7 | VOCs emissions (g) | 0.16 |

| Char Produced (kg) | 4.38 | HF emissions (g) | 0.005 |

| CO2 emissions (kg) | 1.458 | Hg emissions (g) | 0.001 |

| NOx emissions (g) | 11.38 | As emissions (g) | 0.0009 |

| CO emissions (g) | 1.46 | Ni emissions (g) | 0.0006 |

| SO2 emissions (g) | 0.76 | Cd emissions (g) | 0.0001 |

| 8. biochar transportation (solid fraction) | |||

| Transportation (tkm) | 0.044 | ||

| 9. Post-land application for the biochar (solid fraction) | |||

| Avoided P2O5 (kg) | 0.71 | P leaching (kg) | 0.039 |

| Avoided K2O (kg) | 0.66 | ||

| 10. Post-separation storage tank (liquid fraction) | |||

| NH3 emissions (kg) | 0.033 | CO2 emissions, biogenic (kg) | 1.78 |

| N2O emissions (kg) | 0.011 | CH4 emissions (kg) | 1.24 |

| 11. Slurry transportation (liquid fraction) | |||

| Transportation (tkm) | 9.395 | ||

| 12. Mixing and land application (solid and liquid fractions) | |||

| Mixing (kWh) | 1.2 | ||

| 13. Post-land application for the slurry (liquid fraction) | |||

| NH3 emissions (kg) | 0.204 | Avoided P2O5 (kg) | 2.62 |

| N2O emissions (kg) | 0.021 | Avoided K2O (kg) | 1.13 |

| CO2 emissions, biogenic (kg) | 27.2 | NO3 leaching (kg) | 1.8 |

| Avoided N fertilizer (kg) | 0.398 | P leaching (kg) | 0.15 |

| Impact Category | Unit | Proposed Swine Manure Management |

|---|---|---|

| Global warming (GWP 100-year) | kg CO2-eq * | 166 |

| Fossil energy use | MJ | −57.9 |

| Water use | m3 | −0.015 |

| Marine eutrophication | kg N-eq | 0.470 |

| Aquatic eutrophication | kg PO4−-eq | 0.551 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sharara, M.; Kim, D.; Sadaka, S.; Thoma, G. Consequential Life Cycle Assessment of Swine Manure Management within a Thermal Gasification Scenario. Energies 2019, 12, 4081. https://doi.org/10.3390/en12214081

Sharara M, Kim D, Sadaka S, Thoma G. Consequential Life Cycle Assessment of Swine Manure Management within a Thermal Gasification Scenario. Energies. 2019; 12(21):4081. https://doi.org/10.3390/en12214081

Chicago/Turabian StyleSharara, Mahmoud, Daesoo Kim, Sammy Sadaka, and Greg Thoma. 2019. "Consequential Life Cycle Assessment of Swine Manure Management within a Thermal Gasification Scenario" Energies 12, no. 21: 4081. https://doi.org/10.3390/en12214081

APA StyleSharara, M., Kim, D., Sadaka, S., & Thoma, G. (2019). Consequential Life Cycle Assessment of Swine Manure Management within a Thermal Gasification Scenario. Energies, 12(21), 4081. https://doi.org/10.3390/en12214081