Preliminary Assessment of a Biogas-Based Power Plant from Organic Waste in the North Netherlands

Abstract

1. Introduction

2. Materials and Methods

2.1. Feedstocks

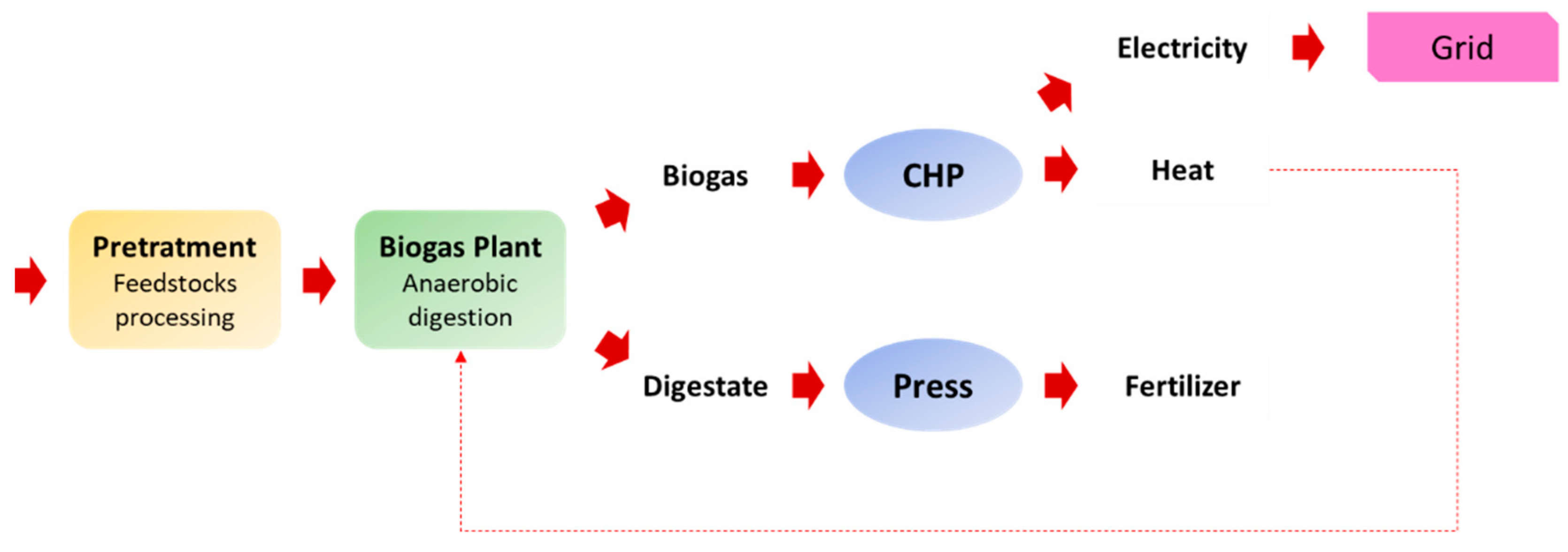

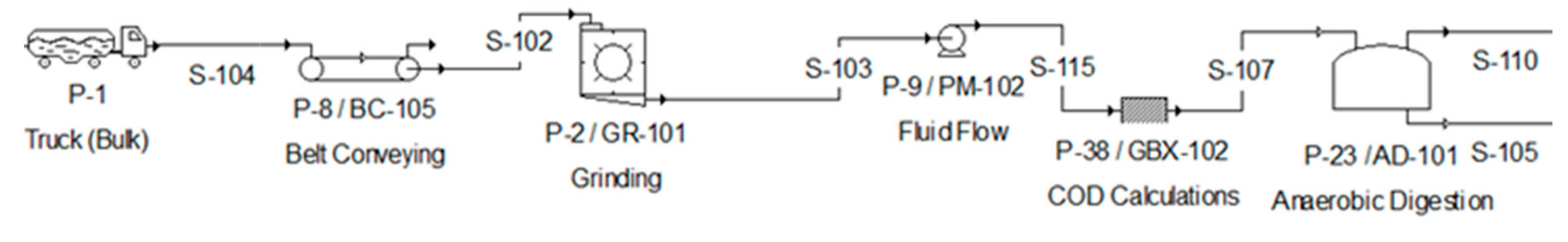

2.2. Process Design

2.2.1. Biogas Production

2.2.2. CHP unit

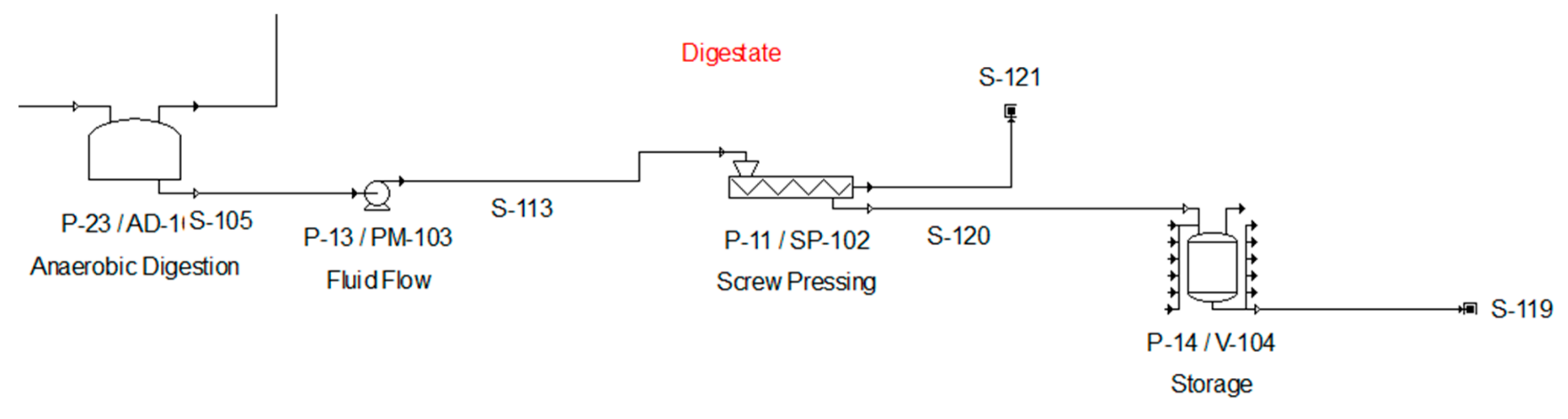

2.2.3. Digestate Treatment

2.3. Economic Evaluation

3. Results

3.1. Equipment Costs

3.2. Fixed Capital Costs

3.3. Labor Costs

3.4. Annual utility and operating costs

3.5. Revenues

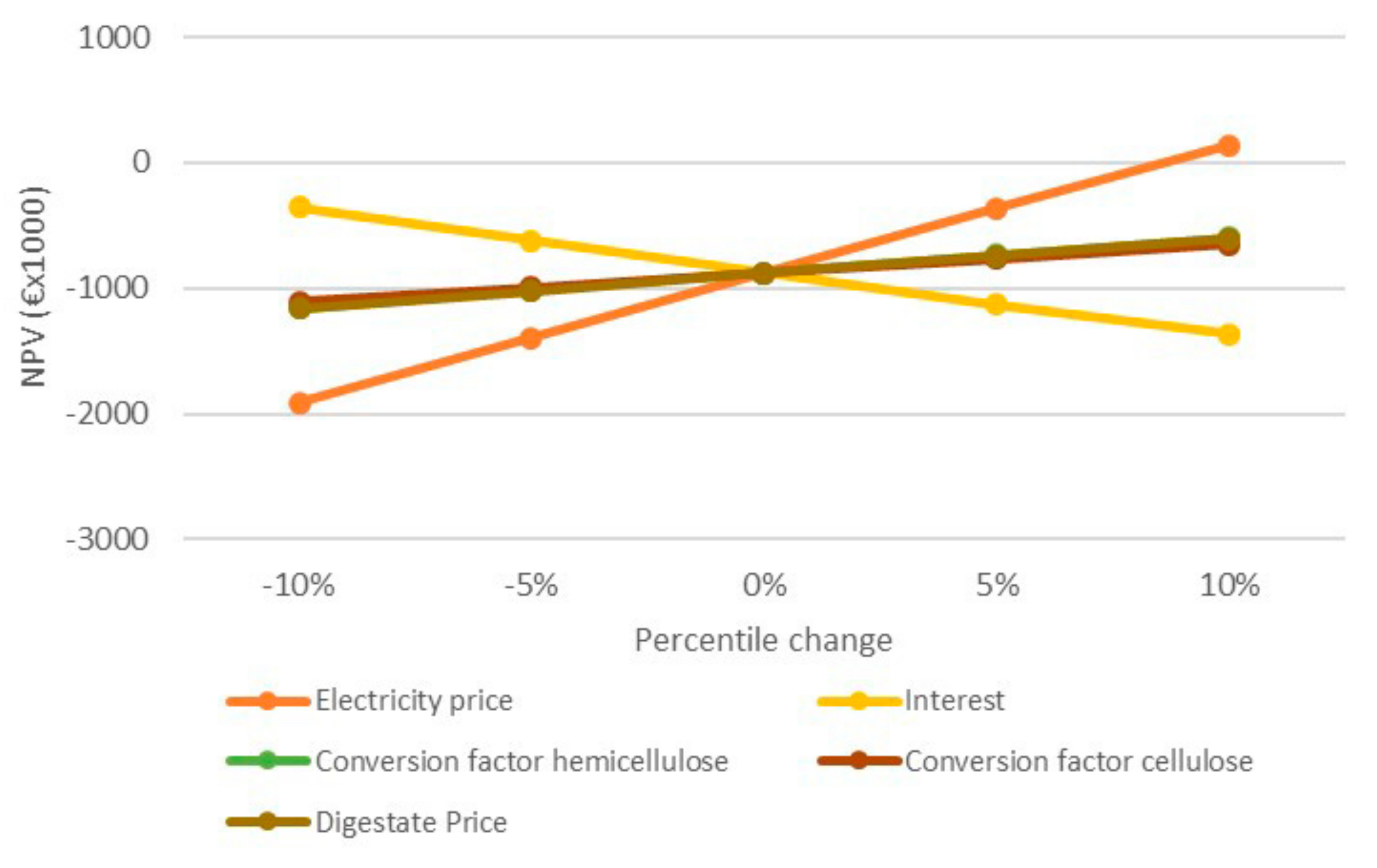

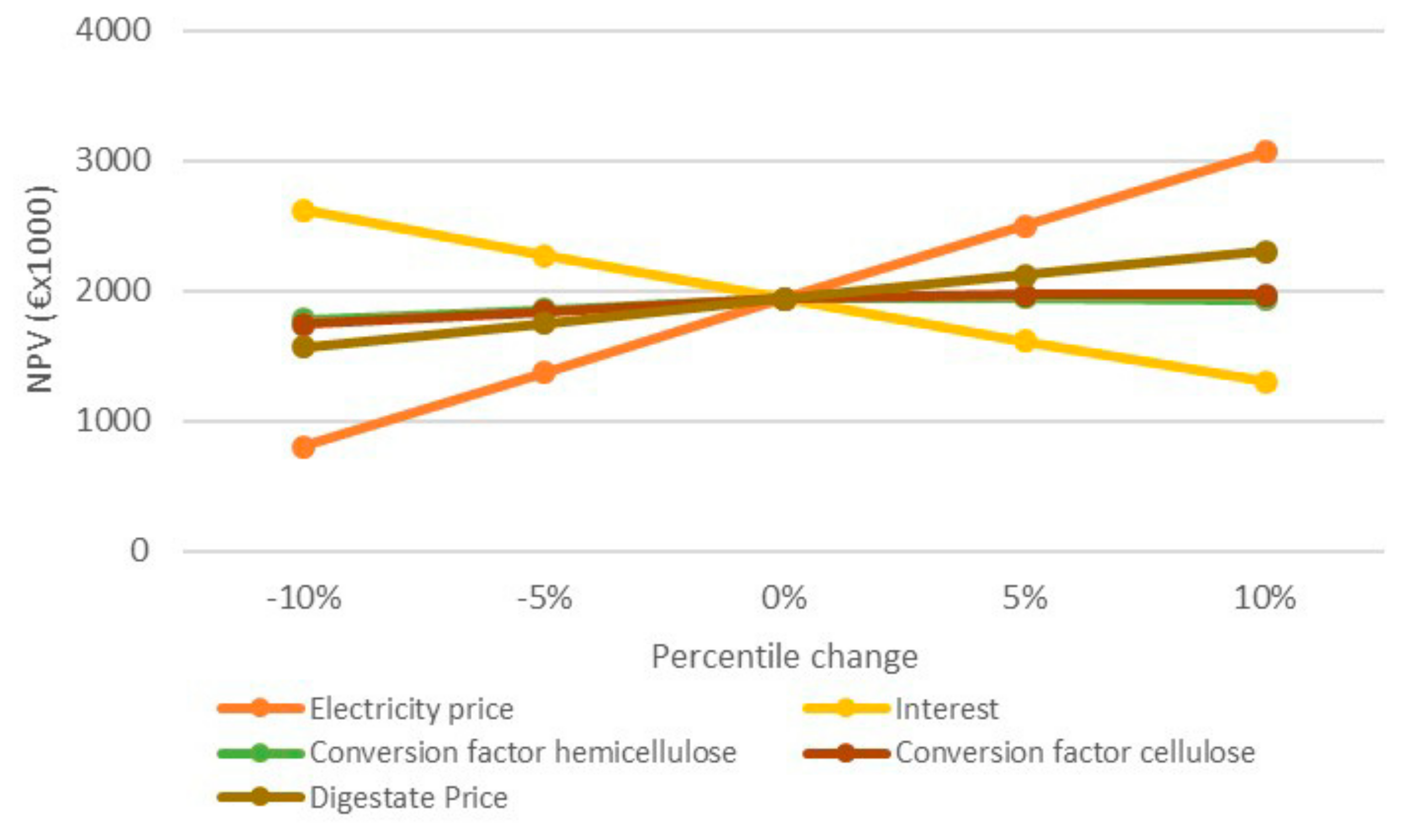

3.6. Viability

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| AD | anaerobic digestion |

| CFC | contractor’s fee and contingency |

| CHP | combined heat and power |

| CM | cow manure |

| EU | European Union |

| GHG | greenhouse gases |

| GS | grass straw |

| IRR | internal rate of return |

| NPV | net present value |

| MT | mega ton |

| PC | plant cost |

| SBP | Sugar beet pulp |

| TPDC | total plant direct cost |

| TPIC | total plant indirect cost |

References

- Cook, P.J. CCS research development and deployment in a clean energy future: Lessons from Australia over the past two decades. Engineering 2017, 3, 477–484. [Google Scholar] [CrossRef]

- Dalmo, F.C.; Simao, N.; Nebra, S.; Santana, P.D.M. Energy recovery from municipal solid waste of intermunicipal public consortia identified in São Paulo State. Waste Manag. Res. 2019, 37, 301–310. [Google Scholar] [CrossRef]

- RedCorn, R.; Fatemi, S.; Engelberth, A.S. Comparing end-use potential for industrial food-waste sources. Engineering 2018, 4, 371–380. [Google Scholar] [CrossRef]

- Macedonio, F.; Drioli, E. Membrane engineering for green process engineering. Engineering 2017, 3, 290–298. [Google Scholar] [CrossRef]

- Wang, J.; Wang, H.; Fan, Y. Techno-economic challenges of fuel cell commercialization. Engineering 2018, 4, 352–360. [Google Scholar] [CrossRef]

- Chen, J.F. Green chemical engineering. Engineering 2017, 3, 283–284. [Google Scholar] [CrossRef]

- Llewellyn, D. Does global agriculture need another green revolution? Engineering 2018, 4, 449–451. [Google Scholar] [CrossRef]

- Bezama, A.; Agamuthu, P. Addressing the big issues in waste management. Waste Manag. Res. 2019, 37, 1–3. [Google Scholar] [CrossRef]

- Hildebrandt, J.; Bezama, A. Cross-fertilisation of ideas for a more sustainable fertiliser market: The need to incubate business concepts for harnessing organic residues and fertilisers on biotechnological conversion platforms in a circular bioeconomy. Waste Manag. Res. 2018, 36, 1125–1126. [Google Scholar] [CrossRef] [PubMed]

- Davis, L.A. The shale oil and gas revolution. Engineering 2018, 4, 438–439. [Google Scholar] [CrossRef]

- Chen, J.F. Green chemical engineering for a better life. Engineering 2017, 3, 279. [Google Scholar] [CrossRef]

- Koçer, A.T.; Özçimen, D. Investigation of the biogas production potential from algal wastes. Waste Manag. Res. 2018, 36, 1100–1105. [Google Scholar] [CrossRef] [PubMed]

- Nelson, M.J.; Nakhla, G.; Zhu, J. Fluidized-bed bioreactor applications for biological wastewater treatment: A review of research and developments. Engineering 2017, 3, 330–342. [Google Scholar] [CrossRef]

- Huang, Q.; Jiang, F.; Wang, L.; Yang, C. Design of photobioreactors for mass cultivation of photosynthetic organisms. Engineering 2017, 3, 318–329. [Google Scholar] [CrossRef]

- European Commission. Energy Union: Secure, Sustainable, Competitive, Affordable Energy for Every European. 2015. Available online: https://ec.europa.eu/malta/news/energy-union-secure-sustainable-competitive-affordable-energy-every-european_en (accessed on 16 September 2019).

- Guo, X.; Kang, K.; Shang, G.; Yu, X.; Qiu, L.; Sun, G. Influence of mesophilic and thermophilic conditions on the anaerobic digestion of food waste: Focus on the microbial activity and removal of long chain fatty acids. Waste Manag. Res. 2018, 36, 1106–1112. [Google Scholar] [CrossRef]

- Smuga-Kogut, M.; Piskier, T.; Walendzik, B.; Szymanowska-Powałowska, D. Assessment of wasteland derived biomass for bioethanol production. Electron. J. Biotechnol. 2019, 41, 1–8. [Google Scholar] [CrossRef]

- Achinas, S.; Euverink, G.J.W. Elevated biogas production from the anaerobic co-digestion of farmhouse waste: Insight into the process performance and kinetics. Waste Manag. Res. 2019. [Google Scholar] [CrossRef]

- Borowski, S.; Kucner, M. The use of sugar beet pulp stillage for co-digestion with sewage sludge and poultry manure. Waste Manag. Res. 2019. [Google Scholar] [CrossRef]

- Teixeira Franco, R.; Coarita, H.; Bayard, R.; Buffière, P. An improved procedure to assess the organic biodegradability and the biomethane potential of organic wastes for anaerobic digestion. Waste Manag. Res. 2019, 37, 746–754. [Google Scholar] [CrossRef]

- Sahajwalla, V. Green processes: Transforming waste into valuable resources. Engineering 2018, 4, 309–310. [Google Scholar] [CrossRef]

- De Medina-Salas, L.; Castillo-González, E.; Giraldi-Díaz, M.R.; Jamed-Boza, L.O. Valorisation of the organic fraction of municipal solid waste. Waste Manag. Res. 2019, 37, 59–73. [Google Scholar] [CrossRef] [PubMed]

- Achinas, S.; Achinas, V.; Euverink, G.J.W. A technological overview of biogas production from biowaste. Engineering 2017, 3, 299–307. [Google Scholar] [CrossRef]

- Ruggero, F.; Gori, R.; Lubello, C. Methodologies to assess biodegradation of bioplastics during aerobic composting and anaerobic digestion: A review. Waste Manag. Res. 2019, 37, 959–975. [Google Scholar] [CrossRef] [PubMed]

- Efferth, T. Biotechnology applications of plant Callus cultures. Engineering 2019, 5, 50–59. [Google Scholar] [CrossRef]

- Reihani, S.F.S.; Khosravi-Darani, K. Influencing factors on single-cell protein production by submerged fermentation: A review. Electron. J. Biotechnol. 2019, 37, 34–40. [Google Scholar] [CrossRef]

- Önen, S.; Nsair, A.; Kuchta, K. Innovative operational strategies for biogas plant including temperature and stirring management. Waste Manag. Res. 2019, 37, 237–246. [Google Scholar] [CrossRef]

- Świątek, M.; Lewicki, A.; Szymanowska, D.; Kubiak, P. The effect of introduction of chicken manure on the biodiversity and performance of an anaerobic digester. Electron. J. Biotechnol. 2019, 37, 25–33. [Google Scholar] [CrossRef]

- Franchi, O.; Rosenkranz, F.; Chamy, R. Key microbial populations involved in anaerobic degradation of phenol and p-cresol using different inocula. Electron. J. Biotechnol. 2018, 35, 33–38. [Google Scholar] [CrossRef]

- Ghanimeh, S.; Abou Khalil, C.; Ibrahim, E. Anaerobic digestion of food waste with aerobic post-treatment: Effect of fruit and vegetable content. Waste Manag. Res. 2018, 36, 965–974. [Google Scholar] [CrossRef]

- Silva Lemões, J.; Lemons e Silva, C.F.; Peres Farias Avila, S.; Scherrer Montero, C.R.; Delmar dos Anjos e Silva, S.; Samios, D.; do Carmo Ruaro Peralba, M. Chemical pretreatment of Arundo donax L. for second-generation ethanol production. Electron. J. Biotechnol. 2018, 31, 67–74. [Google Scholar]

- Xu, J.; Ma, B.; Su, J.; Huang, S.; Xu, X.; Zhou, X.; Huang, X.E.; Knight, R. Emerging trends for microbiome analysis: From single-cell functional imaging to microbiome Big Data. Engineering 2017, 3, 66–70. [Google Scholar] [CrossRef]

- Rosero-Henao, J.C.; Bueno, B.E.; de Souza, R.; Ribeiro, R.; Lopes de Oliveira, A.; Gomide, C.A.; Gomes, T.M.; Tommaso, G. Potential benefits of near critical and supercritical pre-treatment of lignocellulosic biomass towards anaerobic digestion. Waste Manag. Res. 2019, 37, 74–82. [Google Scholar] [CrossRef] [PubMed]

- Luo, L.; Kaur, G.; Wong, J.W.C. A mini-review on the metabolic pathways of food waste two-phase anaerobic digestion system. Waste Manag. Res. 2019, 37, 333–346. [Google Scholar] [CrossRef] [PubMed]

- Huarachi-Olivera, R.; Dueñas-Gonza, A.; Yapo-Pari, U.; Vega, P.; Romero-Ugarte, M.; Tapia, J.; Molina, L.; Lazarte-Rivera, A.; Pacheco-Salazar, D.G.; Esparza, M. Bioelectrogenesis with microbial fuel cells (MFCs) using the microalga Chlorella vulgaris and bacterial communities. Electron. J. Biotechnol. 2018, 31, 34–43. [Google Scholar] [CrossRef]

- Chatzikonstantinou, D.; Tremouli, A.; Papadopoulou, K.; Kanellos, G.; Lampropoulos, I.; Lyberatos, G. Bioelectricity production from fermentable household waste in a dual-chamber microbial fuel cell. Waste Manag. Res. 2018, 36, 1037–1042. [Google Scholar] [CrossRef] [PubMed]

- Chen, P.; Anderson, E.; Addy, M.; Zhang, R.; Cheng, Y.; Peng, P.; Ma, Y.; Fan, L.; Zhang, Y.; Lu, Q.; et al. Breakthrough technologies for the biorefining of organic solid and liquid wastes. Engineering 2018, 4, 574–580. [Google Scholar] [CrossRef]

- Schmid, C.; Horschig, T.; Pfeiffer, A.; Szarka, N.; Thrän, D. Biogas Upgrading: A Review of National Biomethane Strategies and Support Policies in Selected Countries. Energies 2019, 12, 3803. [Google Scholar] [CrossRef]

- Matsakas, L.; Gao, Q.; Jansson, S.; Rova, U.; Christakopoulos, P. Green conversion of municipal solid wastes into fuels and chemicals. Electron. J. Biotechnol. 2017, 26, 69–83. [Google Scholar] [CrossRef]

- Wen-Wei, L.; Han-Qing, Y. Advances in energy-producing anaerobic biotechnologies for municipal wastewater treatment. Engineering 2016, 2, 438–446. [Google Scholar]

- Al Seadi, T. Biogas Handbook; University of Southern Denmark Esbjerg: Esbjerg, Denmark, 2008; pp. 1–126. [Google Scholar]

- Toselli, D.; Heberle, F.; Brüggemann, D. Techno-economic analysis of hybrid binary cycles with geothermal energy and biogas waste heat recovery. Energies 2019, 12, 1969. [Google Scholar] [CrossRef]

- van der Peet, G.; Leenstra, F.; Vermeij, I.; Bondt, N.; Puister, L.; van Os, J. Feiten en Cijfers over de Nederlandse Veehouderijsectoren; Technical Report for Wageningen Livestock Research; Wageningen University & Research: Wageningen, The Netherlands, 2018; Available online: https://www.wur.nl/nl/nieuws/Feiten-en-cijfers-over-de-Nederlandse-veehouderijsectoren-2018.htm (accessed on 3 August 2019).

- ‘welke provincie heeft’ Welke Provincie Heeft de Meeste Melkveebedrijven? 2018. Available online: https://www.boerenbusiness.nl/melk/artikel/10877043/welke-provincie-heeft-de-meeste-melkveebedrijven (accessed on 9 May 2019).

- CBS. Akkerbouwgewassen; Productie Naar Regio. 2019. Available online: https://statline.cbs.nl/Statweb/publication/?DM=SLNL&PA=7100oogs&D1=1-3&D2=25&D3=0,5-7&D4=6,22-24&HDR=G2,G3,T&STB=G1&VW=T (accessed on 23 October 2018).

- Ber lowska, J.; Pielech-Przybylska, K.; Balcerek, M.; Dziekonska-Kubczak, U.; Patelski, P.; Dziugan, P.; Krgiel, D. Simultaneous saccharification and fermentation of sugar beet pulp for efficient bioethanol production. BioMed Res. Int. 2016, 2016, 3154929. [Google Scholar]

- Van der Hilst, F.; Dornburg, V.; Sanders, J.; Elbersen, B.; Graves, A.; Turkenburg, W.; Elbersen, H.; Van Dam, J.; Faaij, A. Potential, spatial distribution and economic performance of regional biomass chains: The north of the netherlands as example. Agric. Syst. 2010, 103, 403–417. [Google Scholar] [CrossRef]

- CBS. Grasland; Oppervlakte en Opbrengst. 2018. Available online: https://statline.cbs.nl/Statweb/publication/?DM=SLNL&PA=7100oogs&D1=1-3&D2=25&D3=0,5-7&D4=6,22-24&HDR=G2,G3,T&STB=G1&VW=T (accessed on 3 August 2019).

- IRS. Sugar Beet Growing in the Netherlands; Technical Report for Institute of Sugar Beet Research; Sugar Beet Research: Bergen op Zoom, The Netherlands, June 2005; Available online: http://applicaties.irs.nl/ccmsupload/ccmsalg/sugar%20beet%20growing%20in%20the%20netherlands%20.pdf (accessed on 3 August 2019).

- Amon, T.; Amon, B.; Kryvoruchko, V.; Zollitsch, W.; Mayer, K.; Gruber, L. Biogas production from maize and dairy cattle manure influence of biomass composition on the methane yield. Agric. Ecosyst. Environ. 2007, 118, 173–182. [Google Scholar] [CrossRef]

- Zheng, Y.; Cheng, Y.S.; Yu, C.; Zhang, R.; Jenkins, B.M.; Van der Gheynst, J.S. Improving the efficiency of enzyme utilization for sugar beet pulp hydrolysis. Bioprocess Biosyst. Eng. 2012, 35, 1531–1539. [Google Scholar] [CrossRef]

- Intelligen USA. Available online: http://www.intelligen.com/superpro_overview.html (accessed on 3 July 2019).

- Kumar, D.; Murthy, G.S. Impact of pretreatment and downstream processing technologies on economics and energy in cellulosic ethanol production. Biotechnol. Biofuels 2011, 4, 27. [Google Scholar] [CrossRef]

- Solarte-Toro, J.C.; Chacón-Pérez, Y.; Cardona-Alzate, C.A. Evaluation of biogas and syngas as energy vectors for heat and power generation using lignocellulosic biomass as raw material. Electron. J. Biotechnol. 2018, 33, 52–62. [Google Scholar] [CrossRef]

- Zhang, L.; Li, F.; Sun, B.; Zhang, C. Integrated optimization design of combined cooling, heating, and power system coupled with solar and biomass energy. Energies 2019, 12, 687. [Google Scholar] [CrossRef]

- Lindkvist, E.; Karlsson, M.; Ivner, J. Systems analysis of biogas production—Part I research design. Energies 2019, 12, 926. [Google Scholar] [CrossRef]

- Goulding, D.; Power, N. Which is the preferable biogas utilisation technology for anaerobic digestion of agricultural crops in Ireland: Biogas to CHP or biomethane as a transport fuel? Renew. Energy 2013, 53, 121–131. [Google Scholar] [CrossRef]

- Zappa, W.; Junginger, M.; van den Broek, M. Is a 100% renewable European power system feasible by 2050? Appl. Energy 2019, 233, 1027–1050. [Google Scholar] [CrossRef]

- Hamzehkolaei, F.T.; Amjady, N. A techno-economic assessment for replacement of conventional fossil fuel based technologies in animal farms with biogas fueled CHP units. Renew. Energy 2018, 118, 602–614. [Google Scholar] [CrossRef]

- Akbulut, A. Techno-economic analysis of electricity and heat generation from farm-scale biogas plant: Çiçekda? case study. Energy 2012, 44, 381–390. [Google Scholar] [CrossRef]

- Clarke Energy. CHP Efficiency for Biogas. Available online: https://www.clarke-energy.com/2013/chp-cogen-efficiency-biogas/ (accessed on 26 September 2019).

- Cucchiella, F.; D’Adamo, I.; Gastaldi, M. An economic analysis of biogas-biomethane chain from animal residues in Italy. J. Clean. Prod. 2019, 230, 888–897. [Google Scholar] [CrossRef]

- Biomassa SDE+. Available online: https://www.rvo.nl/subsidies-regelingen/stimulering-duurzame-energieproductie/categorie%C3%ABn/biomassa-sde (accessed on 27 August 2019).

- Morero, B.; Vicentin, R.; Campanella, E.A. Assessment of biogas production in Argentina from co-digestion of sludge and municipal solid waste. Waste Manag. 2017, 61, 195–205. [Google Scholar] [CrossRef]

- Yang, M.; Rosentrater, K.A. Technoeconomic analysis of the production process of structural bio-adhesive derived from glycerol. J. Clean. Prod. 2019, 228, 388–398. [Google Scholar] [CrossRef]

| Ingredient | CM | SBP | GS |

|---|---|---|---|

| Mass % | Mass % | Mass % | |

| Ash | 2.3 | 5.1 | 8.9 |

| Cellulose | 4.8 | 15.1 | 28. |

| Hemicellulose | 4.1 | 18.2 | 18.80 |

| Lignin | 3.0 | 0.9 | 11.4 |

| Lignin soluble | - | - | 2.0 |

| Proteins | 2.3 | 10.3 | - |

| Protein soluble | - | - | 4.7 |

| Extractives | 3.8 | - | 18.0 |

| Water | 79.6 | 29.6 | 7.0 |

| Fats | 0.1 | - | - |

| Unit ID | Description | Details | CM | SBP | GS |

|---|---|---|---|---|---|

| P-8/BC-105 | Belt conveying | Length (m) | 20.0 | 20.0 | 20.0 |

| P-2/SP-101 | Screw press | Rated throughput (kg/h) | 1243.8 | - | - |

| P-2/GR-101 | Grinder | Rated throughput (kg/h) | - | 1243.8 | 1243.8 |

| P-9/PM-102 | Pump | Pump power (kW) | 0.02 | 0.05 | 0.04 |

| Vessel power (kW/m3) | 294.7 | 749.9 | 692.3 | ||

| P-23/AD-101 | Anaerobic reactor | Residence time (h) | 600 | 600 | 600 |

| Temperature (°C) | 35 | 35 | 35 |

| Unit ID | Input | Output | |||

|---|---|---|---|---|---|

| Feedstock | Unit ID | Volume (kg/h) | Products | Volume (kg/h) | |

| S-106 | CM | S-121 | 337.3 | Water | 193.8 |

| S-119 | Residues | 143.5 | |||

| S-106 | SBP | S-121 | 852.1 | Water | 266.3 |

| S-119 | Residues | 585.7 | |||

| S-106 | GS | S-121 | 800.9 | Water | 4.5 |

| S-119 | Residues | 798.5 | |||

| Unit ID | Description | Details | CM | SBP | GS |

|---|---|---|---|---|---|

| P-17/G-101 | Gas compressor | Compressor power (kW) | 13.1 | 32.8 | 37.1 |

| P-3/GT-101 | Gas turbine-generator | Electrical power (kW) | 441.2 | 1105.2 | 1249.5 |

| P-6/SG-101 | Steam generator | Throughput (kg/h) | 540.3 | 1239.7 | 1401.8 |

| P-10/ET-101 | Extraction steam turbine-generator | Turbine delivered shaft power (kW) | 27.0 | 85.7 | 100.4 |

| Unit ID | Input | Volume (kg/h) | ||

|---|---|---|---|---|

| CM | SBP | GS | ||

| S-111 | Biogas | 156.4 | 391.8 | 442.8 |

| S-108 | Water | 640.3 | 1293.7 | 1401.8 |

| S-101 | Air | 4191.7 | 10,500.7 | 11,872.3 |

| Output | ||||

| S-124 | Steam | 520.3 | 1239.7 | 1401.8 |

| S-110 | Residues | 4348.1 | 10,892.4 | 12,315.0 |

| Ingredient | CM | SBP | GS |

|---|---|---|---|

| Mass % | Mass % | Mass % | |

| Ash | 2.38 | 5.83 | 10.77 |

| Cellulose | 1.48 | 8.70 | 18.15 |

| Hemicellulose | 1.09 | 10.45 | 15.50 |

| Lignin | 1.23 | 0.49 | 13.86 |

| Lignin soluble | 2.18 | ||

| Proteins | 0.25 | 5.92 | - |

| Extractives | 2.21 | 12.05 | |

| Water | 90.85 | 43.35 | 24.44 |

| COD eq. | 0.12 | 0.33 | 0.48 |

| Sludge | 0.34 | 0.98 | 1.41 |

| Fats | 0.07 |

| Unit ID | Description | Details | CM | SBP | GS |

|---|---|---|---|---|---|

| P-13/PM-103 | Centrifugal pump | Power pump (kW) | 0.01 | 0.03 | 0.03 |

| P-11/SP-102 | Screw pressing | Throughput (kg/h) | 337.3 | 852.0 | 801.0 |

| P-14/V-104 | Receiver tank | Vessel volume (L) | 3105.9 | 14,324.5 | 17,686.5 |

| Unit ID | Input | Volume (kg/h) | ||

|---|---|---|---|---|

| CM | SBP | GS | ||

| S-106 | Digestate | 337.3 | 852.0 | 801.0 |

| Output | ||||

| S-121 | Water | 192.8 | 266.3 | 4.5 |

| S-129 | Residues | 143.5 | 585.7 | 796.5 |

| Parameters | Assumptions |

|---|---|

| Material costs | |

| Cow manure | 0 €/kg |

| Sugar beet pulp | 0.0105 €/kg |

| Grass straw | 0 €/kg |

| Utility costs | |

| Std power | 0.09 €/kWh |

| Steam | 11.28 €/MT |

| Steam for CHP | 0 €/MT |

| Cooling water | 0.05 €/MT |

| Chilled water | 0.38 €/MT |

| Labor costs | |

| Labor price | 29.90 €/h |

| Facility costs | |

| Maintenance | 0.02 × TPDC |

| Depreciation | Straight-line method |

| Insurance | 1.00 × TPDC |

| Tax | 0.02 × TPDC |

| Factory expense | 2.50 × TPDC |

| Type of Feedstock | Total eq. Costs (€ × 103) |

|---|---|

| CM | 1531 |

| SBP | 2425 |

| GS | 2486 |

| Type of Feedstock | TPDC (€ × 103) | TPIC (€ × 103) | CFC (€ × 103) | DFC (€ × 103) |

|---|---|---|---|---|

| CM | 4483 | 2690 | 1004 | 8177 |

| SBP | 7071 | 4243 | 1584 | 12,898 |

| GS | 7289 | 4373 | 1633 | 13,295 |

| Type of Feedstock | Annual Utility Costs (€ × 103) | Annual Operating Costs (€ × 103) |

|---|---|---|

| CM | 20,082 | 715 |

| SBP | 49,941 | 1162 |

| GS | 53,784 | 1086 |

| Stream | CM (€) | SBP (€) | GS (€) |

|---|---|---|---|

| Gas Turbine-Generator (P-3) | 390,180 | 977,419 | 1,105,044 |

| Steam Turbine-Generator (P-10) | 21,472 | 68,198 | 79,928 |

| Digestate (S-119) | 81,799 | 333,883 | 454,051 |

| Feedstock | 300,005 | ||

| Total | 793,456 | 1,379,500 | 1,639,024 |

| Stream | CM (€) | SBP (€) | GS (€) |

|---|---|---|---|

| Gas Turbine-Generator (P-3) | 461,122 | 1,155,131 | 1,305,962 |

| Steam Turbine-Generator (P-10) | 25,376 | 80,598 | 94,460 |

| Digestate (S-119) | 881,799 | 333,883 | 454,051 |

| Feedstock | 300,005 | ||

| Total | 868,302 | 1,569,612 | 1,854,473 |

| Stream | CM | SBP | GS |

|---|---|---|---|

| Total Capital Investment (€ × 103) | 8599 | 12,937 | 13,325 |

| Capital Investment Charged to this Project ((€ × 103) | 8599 | 12,937 | 13,325 |

| Operating Costs (€ × 103/yr) | 715 | 8599 | 1086 |

| Total Revenues (€ × 103/yr) | 793 | 8599 | 1693 |

| Gross Margin (%) | 9.85 | 15.77 | 33.76 |

| Return On Investment (%) | 5.06 | 5.75 | 7.23 |

| Payback Period (years) | 19.75 | 17.41 | 13.83 |

| IRR (%) | 1.80 | 2.58 | 5.23 |

| NPV (at 5.0% Interest) (€ × 103) | −2076 | −2467 | 192 |

| Stream | CM | SBP | GS |

|---|---|---|---|

| Total Capital Investment (€ × 103) | 8599 | 12,937 | 13,325 |

| Capital Investment Charged to this Project ((€ × 103) | 8599 | 12,937 | 13,325 |

| Operating Costs (€ × 103/yr) | 715 | 1165 | 1086 |

| Total Revenues (€ × 103/yr) | 868 | 1570 | 1854 |

| Gross Margin (%) | 17.62 | 25.98 | 41.45 |

| Return On Investment (%) | 5.58 | 6.63 | 8.20 |

| Payback Period (years) | 17.91 | 15.02 | 12.19 |

| IRR (%) | 2.89 | 4.14 | 6.64 |

| NPV (at 5.0% Interest) (€ × 103) | −1452 | −881 | 1935 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Achinas, S.; Martherus, D.; Krooneman, J.; Euverink, G.J.W. Preliminary Assessment of a Biogas-Based Power Plant from Organic Waste in the North Netherlands. Energies 2019, 12, 4034. https://doi.org/10.3390/en12214034

Achinas S, Martherus D, Krooneman J, Euverink GJW. Preliminary Assessment of a Biogas-Based Power Plant from Organic Waste in the North Netherlands. Energies. 2019; 12(21):4034. https://doi.org/10.3390/en12214034

Chicago/Turabian StyleAchinas, Spyridon, Demi Martherus, Janneke Krooneman, and Gerrit Jan Willem Euverink. 2019. "Preliminary Assessment of a Biogas-Based Power Plant from Organic Waste in the North Netherlands" Energies 12, no. 21: 4034. https://doi.org/10.3390/en12214034

APA StyleAchinas, S., Martherus, D., Krooneman, J., & Euverink, G. J. W. (2019). Preliminary Assessment of a Biogas-Based Power Plant from Organic Waste in the North Netherlands. Energies, 12(21), 4034. https://doi.org/10.3390/en12214034