The Impact of Power Source Performance Decrease in a PV/WT/FC Hybrid Power Generation System on the Result of a Multi-Criteria Analysis of Load Distribution

Abstract

1. Introduction

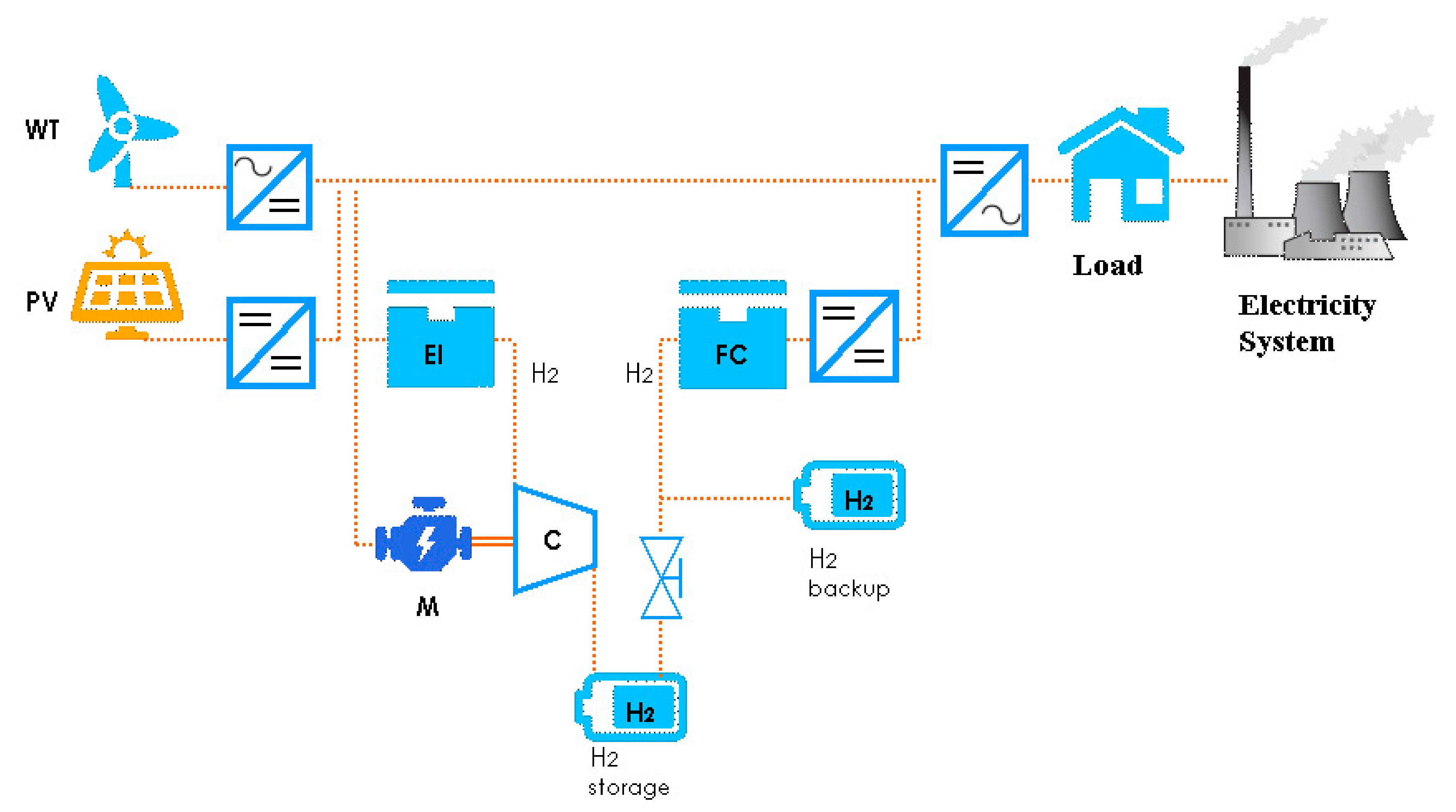

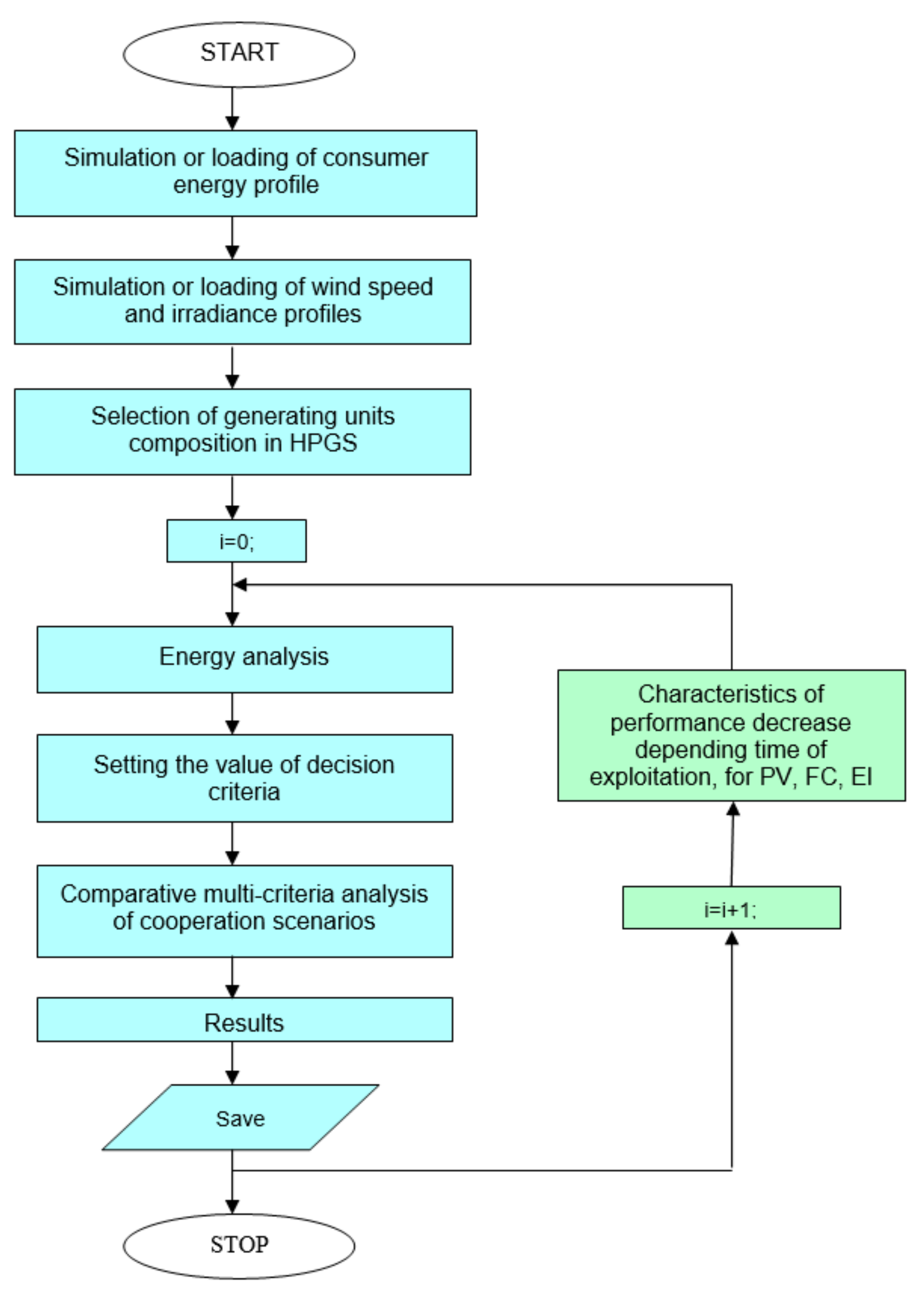

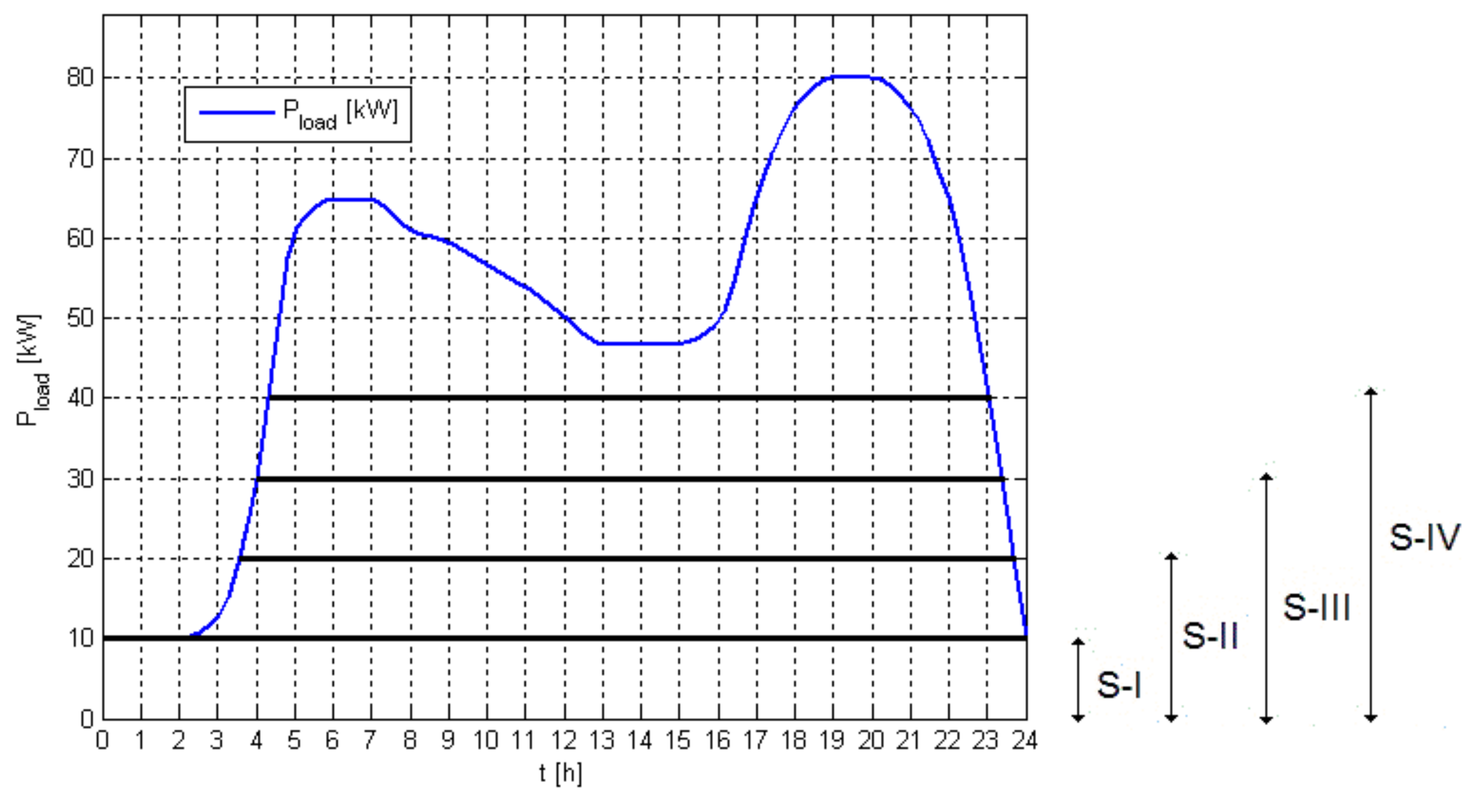

2. Problem Description

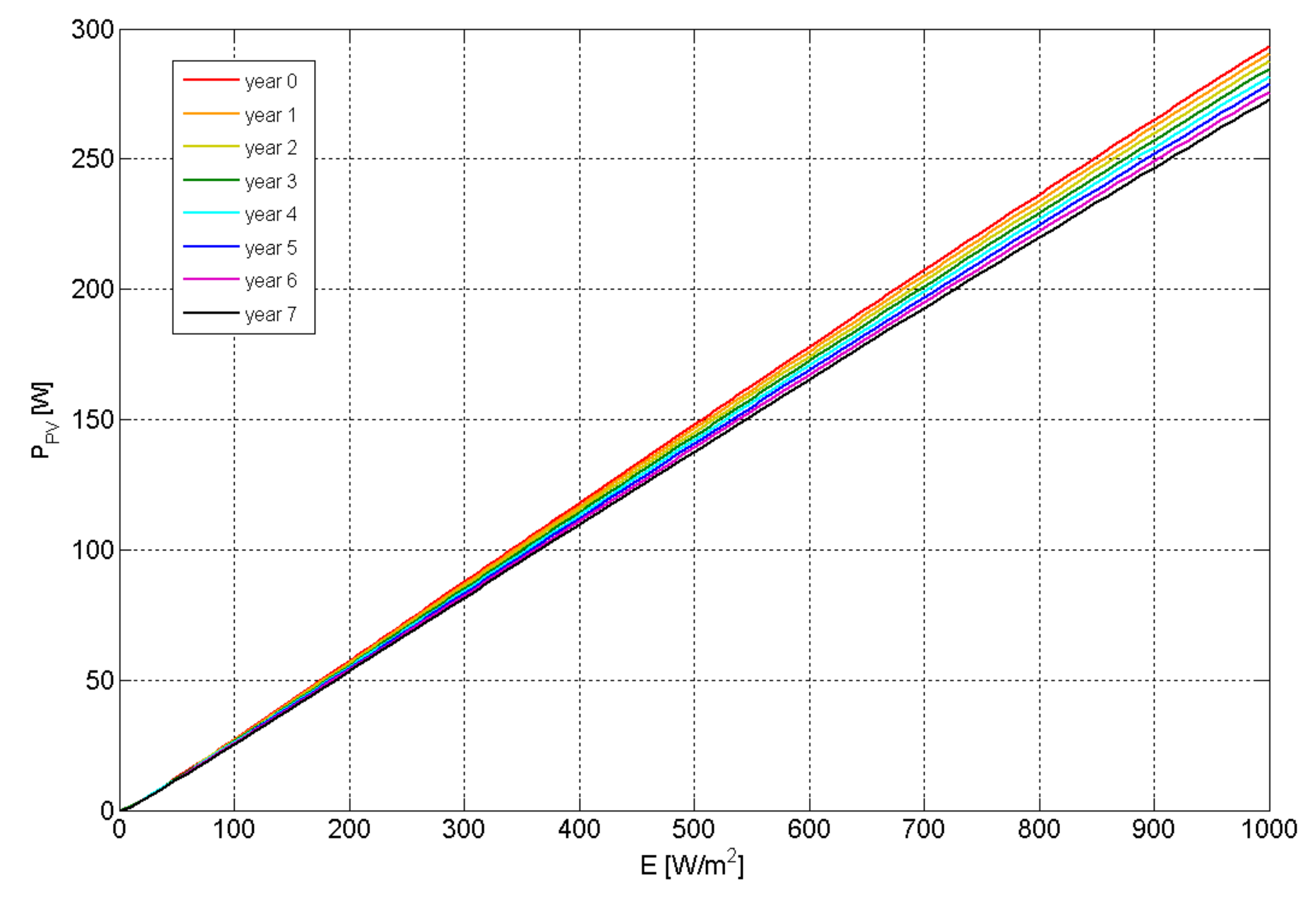

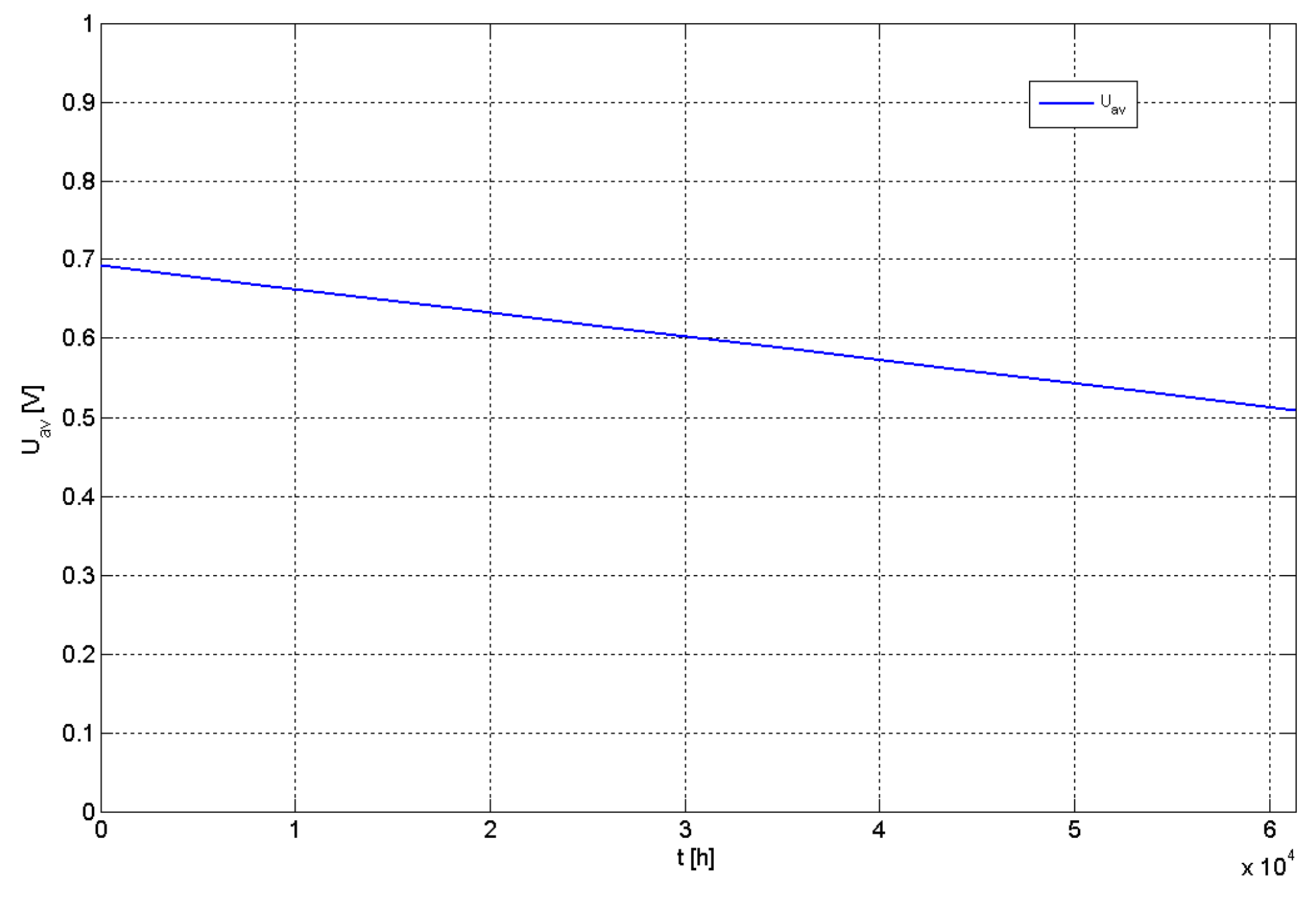

3. Model and Method Description

4. Results

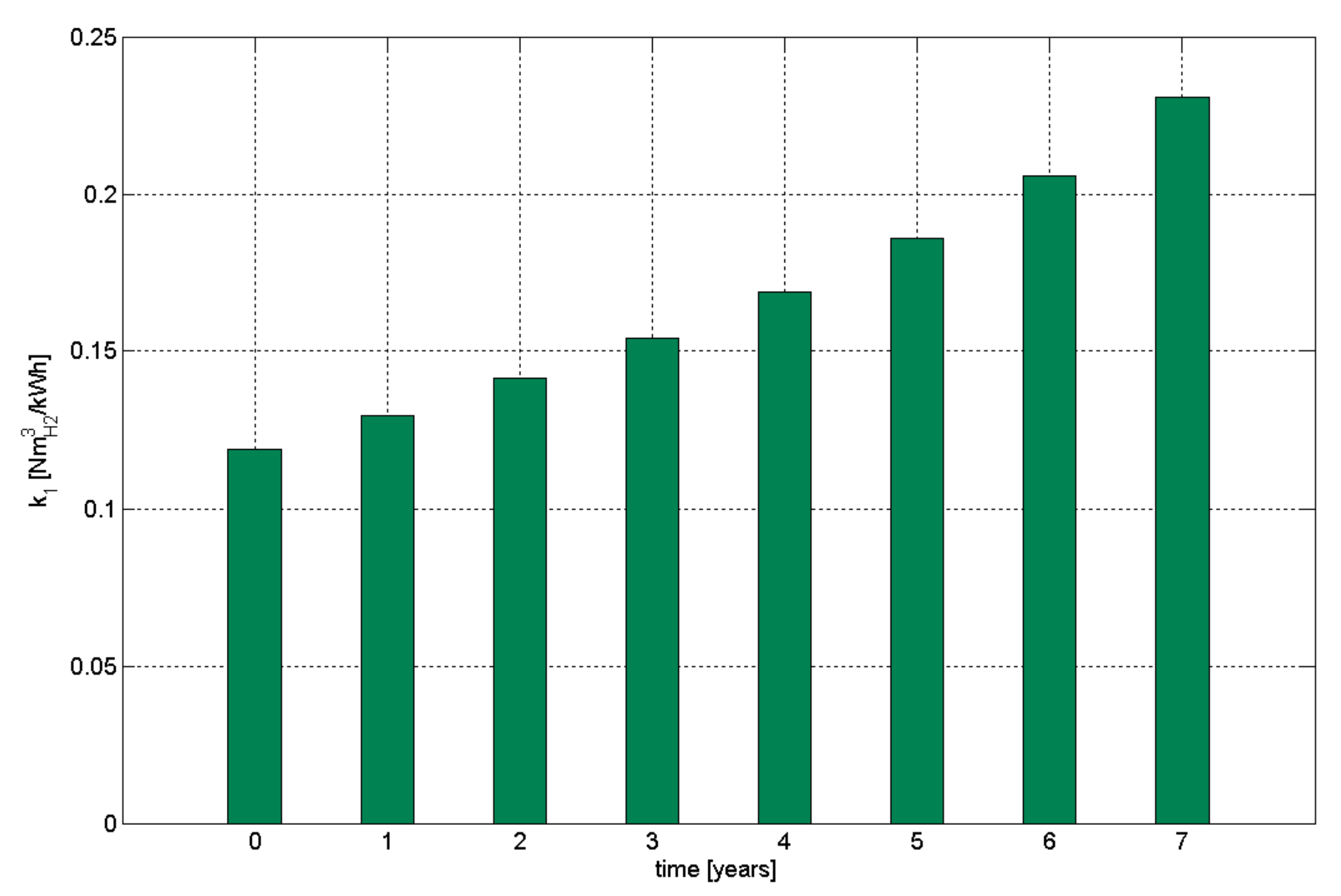

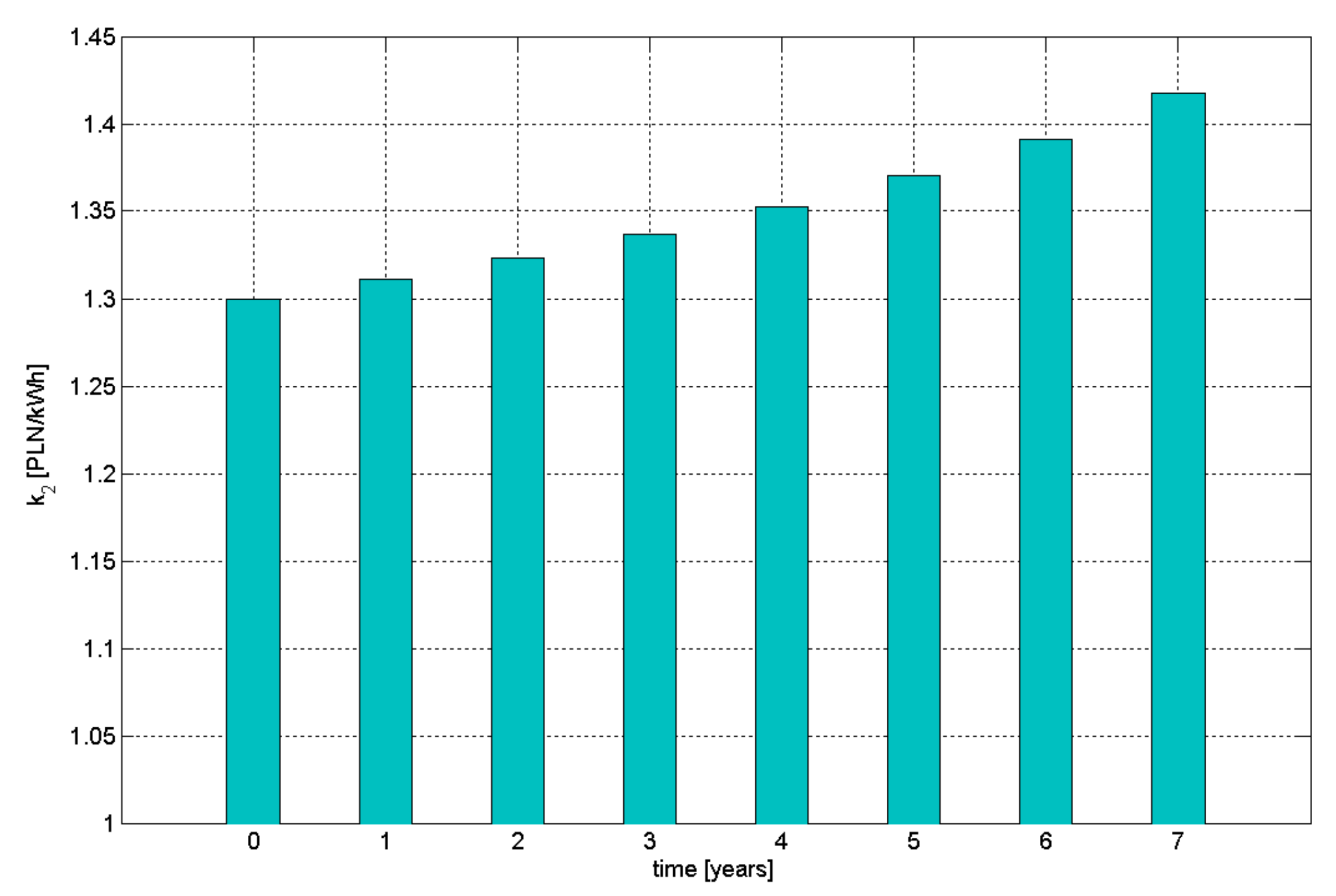

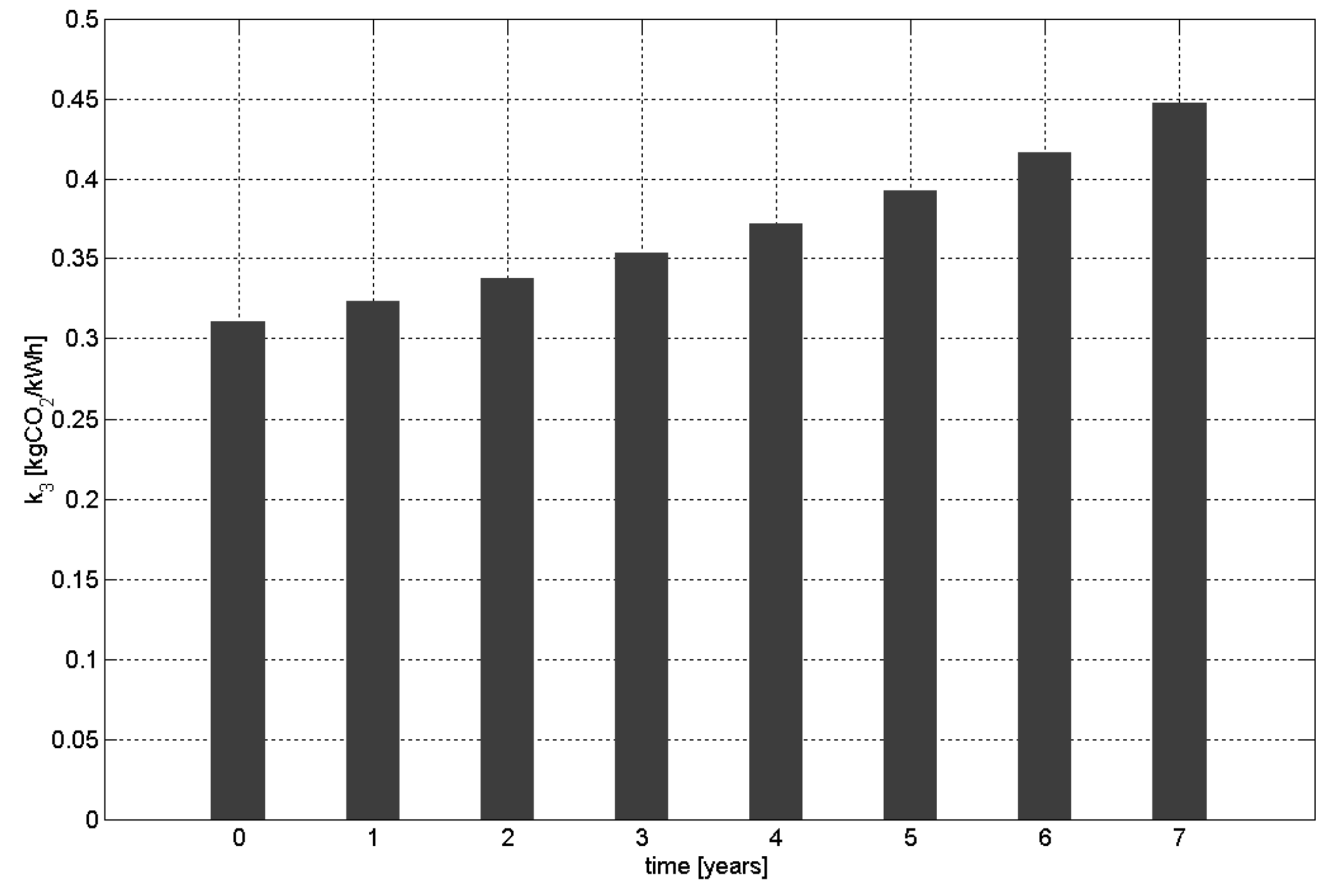

4.1. The Impact of a Decrease in the Performance of Generation Devices in HPGS (PV, FC, El) on the Value of Decision Criteria

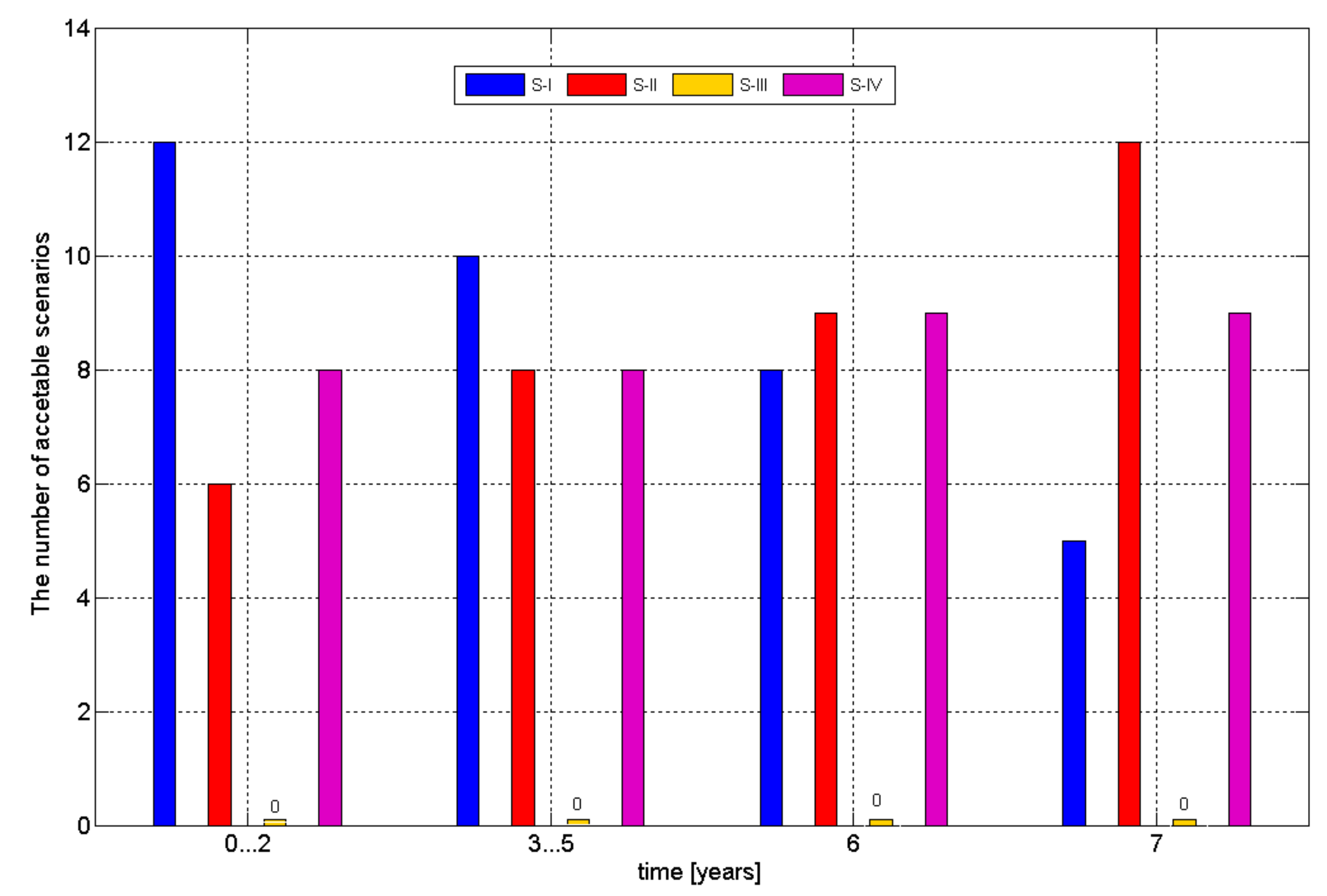

4.2. Impact of a Decrease in the Performance of Generation Devices in HPGS (PV, FC, El) on the Results of the Multi-Criteria Analysis of Load Distribution

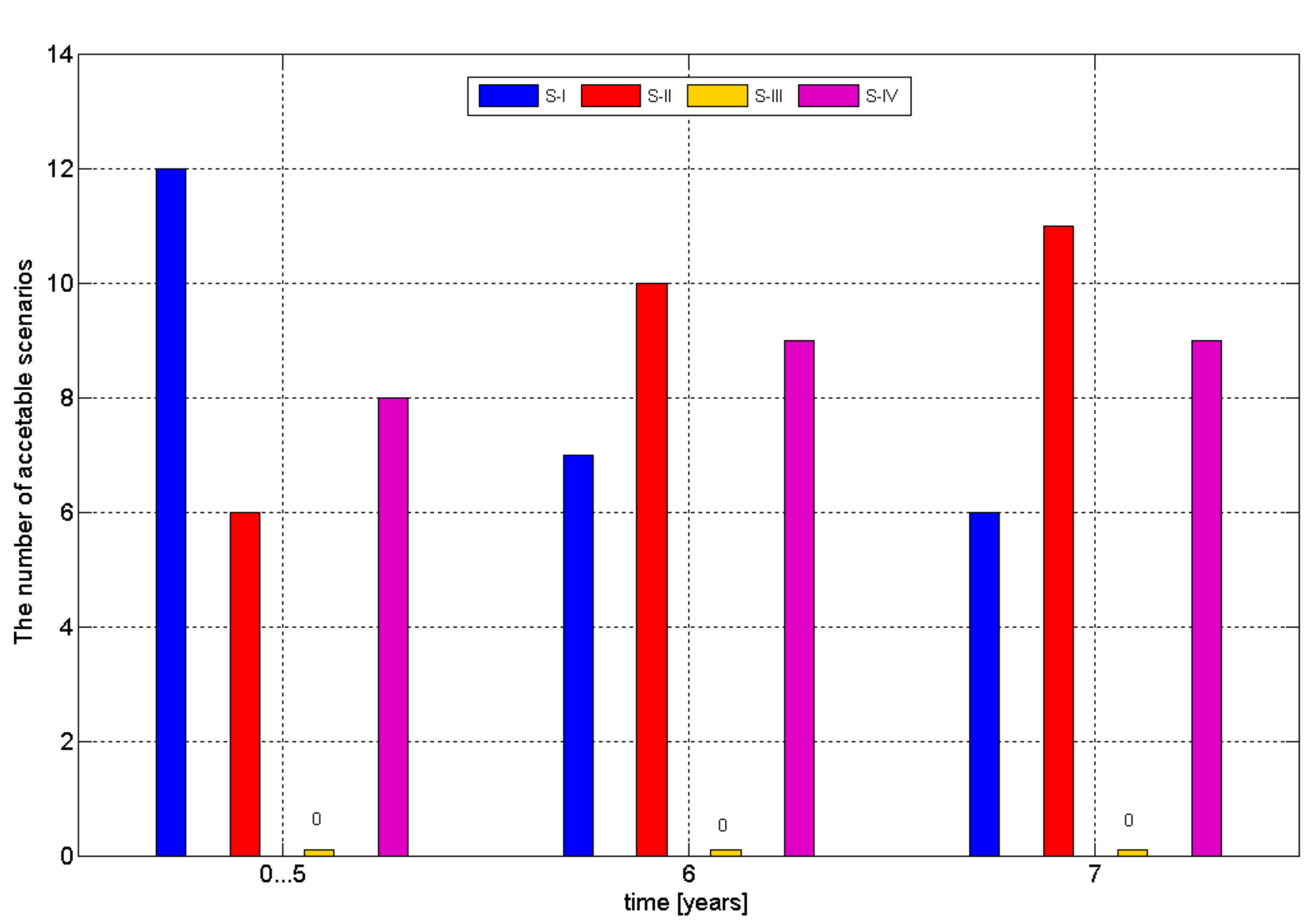

4.3. Analysis of the Impact of a Decrease in the Performance of Specific HPGS Components on the Results of the Multi-Criteria Analysis of Load Distribution

4.3.1. Impact of the Degradation of PV Installation Alone on the Results of the Multi-Criteria Analysis of Load Distribution

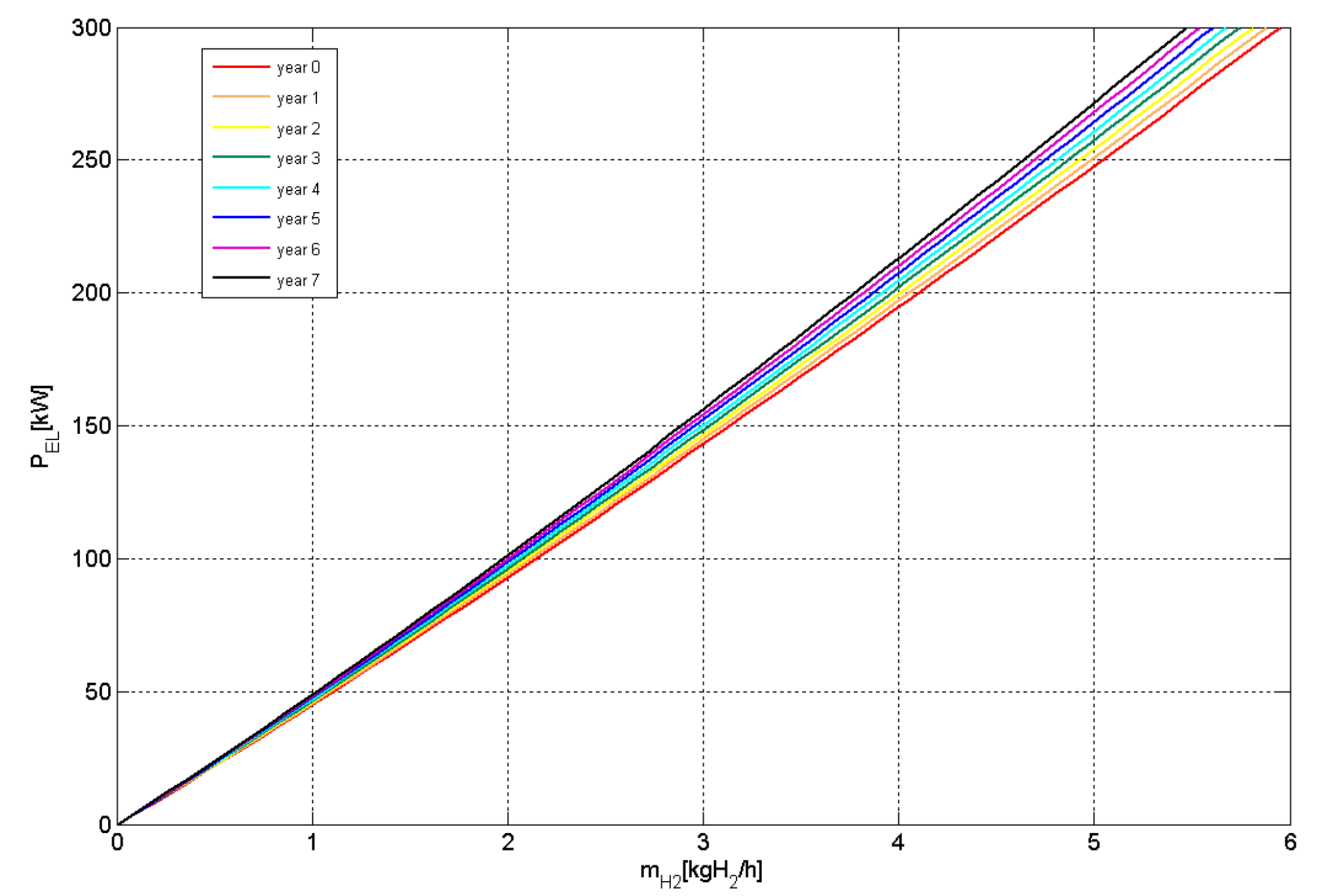

4.3.2. Impact of a Degradation of the Electrolyzer Alone on the Results of the Multi-Criteria Analysis of Load Distribution

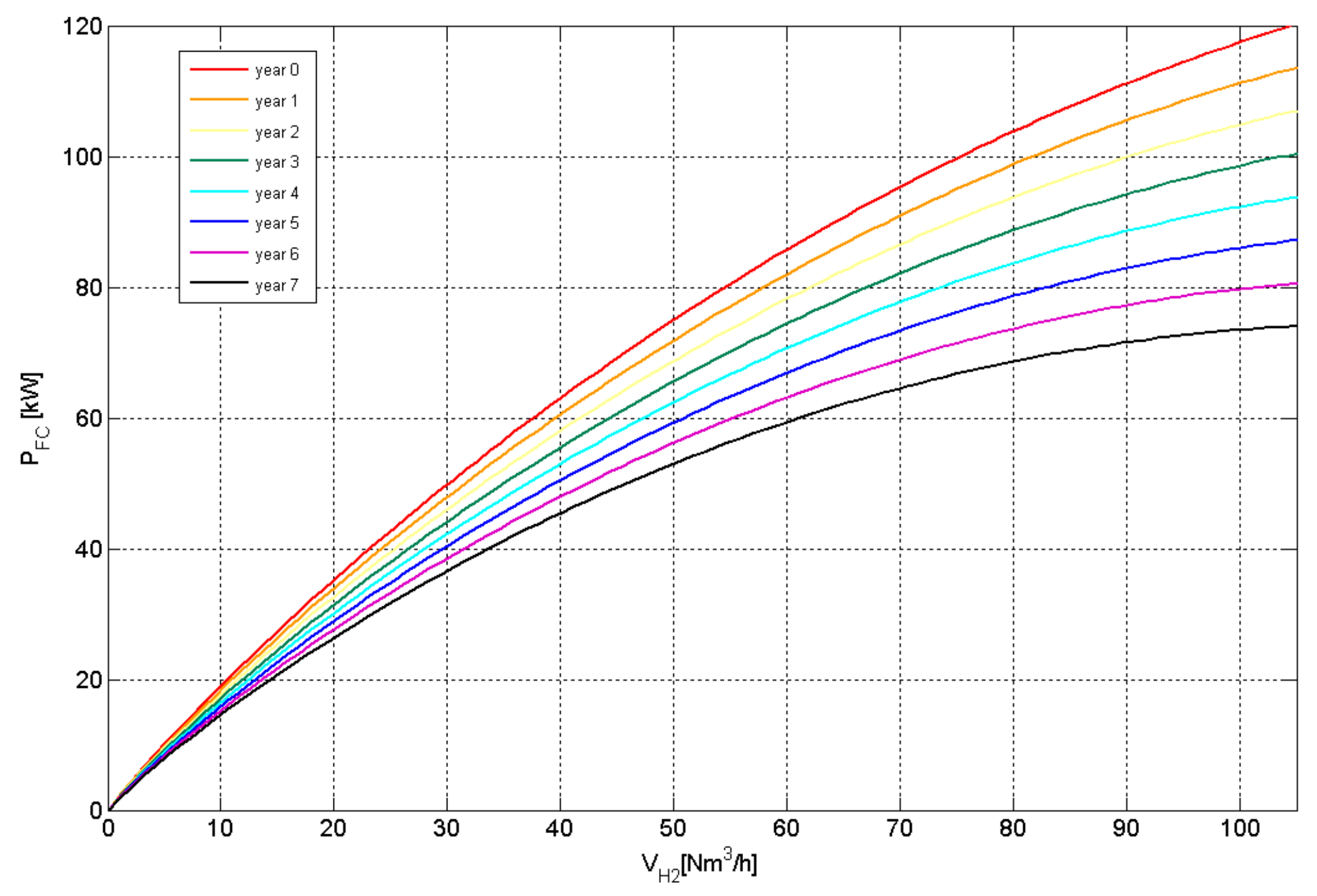

4.3.3. Impact of Degradation of the Fuel Cell Alone on the Results of the Multi-Criteria Analysis of Load Distribution

5. Discussion

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| m | number of scenarios in multi-criteria analysis |

| n | number of criteria in multi-criteria analysis |

| m | number of scenarios in multi-criteria analysis |

| n | number of criteria in multi-criteria analysis |

| dH2 | specific energy consumption by an electrolyzer for production of 1 kg of hydrogen [kWh/kgH2] |

| mH2 | mass stream of hydrogen produced by an electrolyzer [kgH2/h] |

| n | coefficient of simultaneous operation of photovoltaic installation and wind turbines |

| k | shape parameter (k > 0) |

| v | wind speed [m/s] |

| xm | m-th coordinate of ideal point |

| xnm | value of assessment criterion |

| x’nm | normalized value of assessment criterion |

| α | power exponent equal to 1, 2 or ∞ |

| λ | scale parameter (λ > 1) |

| ηEL | efficiency of electrolyzer |

| ηPV | efficiency of photovoltaic panels |

| ηFC | efficiency of fuel cell |

| wm | weight factor of m-th criterion |

| CO2/H2 | amount of CO2 connected with production 1 kg of H2 [kgCO2/kgH2] |

| E | solar irradiance [W/m2] |

| EHPGS | energy produced by hybrid power generation system [kWh] |

| Eload | energy consumption by consumer [kWh] |

| Esys | energy from electricity system [kWh] |

| Et | thermo-neutral voltage [V] |

| Kd | costs of depreciation [PLN] |

| Ke | hybrid system operating costs [PLN] |

| KO&M | HPGS operating costs [PLN] |

| KH2 | costs of hydrogen for backup purposes [PLN] |

| KH2O | cost of water for the electrolysis process [PLN] |

| Lα | measure of differences of the concerned Sn scenario from the ideal point |

| MH2 | mass of additional hydrogen consumption for backup purposes [kgH2] |

| Pav_PV | average value of power generated by PV panels [kW] |

| Pav_WT | average value of power generated by wind turbines [kW] |

| PFC | power rating of fuel cell stack [kW] |

| PEl | nominal power of electrolyzer [kW] |

| Pmax_WT | maximum power of wind turbine [kW] |

| Pmax_PV | maximum power of PV panels [kW] |

| Pmin_load | minimum load power [kW] |

| Pord | maximum input power from electricity system [kW] |

| PLN | currency in Poland |

| S | total photovoltaic panels area [m2] |

| Sn | n - scenario |

| Sn* | the best scenario |

| Ta | time of year [h] |

| Uav | average voltage value of one cell [V] |

| VH2 | volumetric additional hydrogen consumption for backup purposes [Nm3H2/h] |

| WECO2 | indicator of carbon dioxide emissions in the electricity system [kgCO2/MWh] |

| Wk | coefficient of performance |

| Ww | coefficient taking into account the inclination of PV installation |

| k1 | the unit use of additional hydrogen by HPGS [Nm3H2/kWh] |

| k2 | the unit cost of electricity production by HPGS [PLN/kWh] |

| k3 | the ratio of CO2 emission by HPGS and electricity system [kgCO2/kWh] |

| k4 | the degree of capacity utilization ordered from electricity system [kgCO2/kWh] |

| P(v) | operational characteristics of wind turbine |

| f(v) | Weibull distribution of wind speeds |

References

- Shayeghi, H.; Shahryari, E.; Moradzadeh, M.; Siano, P. A Survey on Microgrid Energy Management Considering Flexible Energy Sources. Energies 2019, 12, 2156. [Google Scholar] [CrossRef]

- Polish Power Networks (In Polish: Polskie Sieci Elektroenergetyczne). Available online: https://www.pse.pl/web/pse-eng (accessed on 15 July 2019).

- Marcos, J.; de la Perra, I.; Garcia, M.; Marroyo, L. Control Strategies to Smooth Short-Term Power Fluctuations in Large Photovoltaic Plants Using Battery Storage Systems. Energies 2014, 7, 6593–6619. [Google Scholar] [CrossRef]

- Wang, W.; Mao, C.; Lu, J.; Wang, D. An Energy Storage System Sizing Method for Wind Power Integration. Energies 2013, 6, 3392–3404. [Google Scholar] [CrossRef]

- Rezk, H.; Dousoky, G.M. Technical and economic analysis of different configurations of stand-alone hybrid renewable power systems–A case study. Renew. Sustain. Energy Rev. 2016, 62, 941–953. [Google Scholar] [CrossRef]

- Jurasz, J.; Beluco, A.; Canales, F.A. The impact of complementarity on power supply reliability of small scale hybrid energy systems. Energy 2018, 161, 737–743. [Google Scholar] [CrossRef]

- Maleki, A.; Askarzadeh, A. Artificial bee swarm optimization for optimum sizing of a stand-alone PV/WT/FC hybrid system considering LPSP concept. Sol. Energy 2014, 107, 227–235. [Google Scholar] [CrossRef]

- Fathy, A. A reliable methodology based on mine blast optimization algorithm for optimal sizing of hybrid PV-wind-FC system for remote area in Egypt. Renew. Energy 2016, 95, 367–380. [Google Scholar] [CrossRef]

- Hatata, A.Y.; Lafi, A. Clonal Selection Algorithm for Optimum Sizing of WT/PV/FC Hybrid Renewable Power System. In Proceedings of the 1st International Conference on Computer Applications & Information Security (ICCAIS), Riyadh, Saudi Arabia, 4–6 April 2018. [Google Scholar]

- Maleki, A.; Askarzdeh, A. Comparative study of artificial intelligence techniques for sizing of a hydrogen-based stand-alone photovoltaic/wind hybrid system. Int. J. Hydrogen Energy 2014, 19, 9973–9984. [Google Scholar] [CrossRef]

- Al-falahi, M.D.A.; Jayasinghe, S.D.G.; Enshaei, H. A review on recent size optimization methodologies for standalone solar and wind hybrid renewable energy system. Energy Convers. Manag. 2017, 143, 252–274. [Google Scholar] [CrossRef]

- Anoune, K.; Bouya, M.; Astito, A.; Abdellah, A.B. Sizing methods and optimization techniques for PV-wind based hybrid renewable energy system: A review. Renew. Sustain. Energy Rev. 2018, 93, 652–673. [Google Scholar] [CrossRef]

- Nieto, A.; Vita, V.; Ekonomou, L.; Mastorakis, N.E. Economic analysis of energy storage system integration with a grid connected intermittent power plant, for power quality purposes. WSEAS Trans. Power Syst. 2016, 11, 65–71. [Google Scholar]

- Nieto, A.; Vita, V.; Maris, T.I. Power quality improvement in power grids with the integration of energy storage systems. Int. J. Eng. Res. Technol. 2016, 5, 438–443. [Google Scholar]

- Al Ghaithi, H.M.; Fotis, G.P.; Vita, V. Techno-economic assessment of hybrid energy off-grid system—A case study for Masirah island in Oman. Int. J. Power Energy Res. 2017, 1, 103–116. [Google Scholar] [CrossRef]

- Wang, C.; Nehir, M.H. Power Management of a Stand-Alone Wind/Photovoltaic/Fuel Cell Energy System. IEEE Trans. Energy Convers. 2008, 23, 957–967. [Google Scholar] [CrossRef]

- Bizon, N.; Oproescu, M.; Raceanu, M. Efficient energy control strategies for a Standalone Renewable/Fuel Cell Hybrid Power Source. Energy Convers. Manag. 2015, 90, 93–110. [Google Scholar] [CrossRef]

- García-Triviñoa, P.; Llorens-Iborraa, F.; García-Vázqueza, C.A.; Gil-Menaa, A.J.; Fernández-Ramíreza, L.M.; Juradob, F. Long-term optimization based on PSO of a grid-connected renewable energy/battery/hydrogen hybrid system. Int. J. Hydrogen Energy 2014, 21, 10805–10816. [Google Scholar] [CrossRef]

- Moghaddam, M.J.H.M.; Kalam, A.; Nowdeh, S.A.; Ahmadi, A.; Babanezhad, M.; Saha, S. Optimal sizing and energy management of stand-alone hybrid photovoltaic/wind system based on hydrogen storage considering LOEE and LOLE reliability indices using flower pollination algorithm. Renew. Energy 2019, 135, 1412–1434. [Google Scholar] [CrossRef]

- Garcia, P.; Garcia, C.A.; Fernández, L.M.; Llorens, F.; Jurado, F. ANFIS-Based Control of a Grid-Connected Hybrid System Integrating Renewable Energies, Hydrogen and Batteries. IEEE Trans. Ind. Inform. 2014, 10, 1107–1117. [Google Scholar] [CrossRef]

- Bukar, A.L.; Tan, C.W. A review on stand-alone photovoltaic-wind energy system with fuel cell: System optimization and energy management strategy. J. Clean. Prod. 2019, 221, 73–88. [Google Scholar] [CrossRef]

- Omazic, A.; Oreski, G.; Halwachs, M.; Eder, G.C.; Hirschl, C.; Neumaier, L.; Pinter, G.; Erceg, M. Relation between degradation of polymeric components in crystalline silicon PV module and climatic conditions: A literature review. Sol. Energy Mater. Sol. Cells 2019, 192, 123–133. [Google Scholar] [CrossRef]

- Liu, Z.; Castillo, M.L.; Youssef, A.; Serdy, J.G.; Watts, A.; Schmid, C.; Kurtz, S.; Peters, I.M.; Buonassisi, T. Quantitative analysis of degradation mechanisms in 30-year-old PV modules. Sol. Energy Mater. Sol. Cells 2019, 20, 110019. [Google Scholar] [CrossRef]

- Višniakov, N.; Kilikevičius, A.; Novickij, J.; Grainys, A.; Novickij, V. Low-cost experimental facility for evaluation of the effect of dynamic mechanical loads on photovoltaic modules. Maint. Reliab. 2015, 17, 334–337. [Google Scholar]

- Kilikevičienė, K.; Matijošius, J.; Fursenko, A.; Kilikevičius, A. Tests of hail simulation and research of the resulting impact on the structural reliability of solar cells. Maint. Reliab. 2019, 21, 275–281. [Google Scholar] [CrossRef]

- Yousfi-Steiner, N.; Moçotéguy, P.; Candusso, D.; Hissel, D.; Hernandes, A.; Aslanides, A. A review on PEM voltage degradation associated with water management: Impacts, influent factors and characterization. J. Power Sources 2008, 183, 260–274. [Google Scholar] [CrossRef]

- Ceran, B. The concept of use of PV/WT/FC hybrid power generation system for smoothing the energy profile of the consumer. Energy 2019, 167, 853–865. [Google Scholar] [CrossRef]

- Chandesris, M.; Vincent, R.; Guatez, L.; Roch, J.-S.; Thoby, D.; Quinaud, M. Membrane degradation in PEM fuel cells: From experimental results to semi-empirical degradation laws. Int. J. Hydrogen Energy 2017, 42, 8139–8149. [Google Scholar] [CrossRef]

- Ceran, B.; Szczerbowski, R. Energy cost analysis by hybrid power generation system. IOP Conf. Ser. Earth Environ. Sci. 2019, 214, 012001. [Google Scholar] [CrossRef]

- Szczerbowski, R.; Ceran, B. Technical and Economic Analysis of a Hybrid Generation System of Wind Turbines, Photovoltaic Modules and a Fuel Cell. E3S Web Conf. 2016, 10, 00090. [Google Scholar] [CrossRef]

- Chmielniak, T.; Lepszy, S.; Mońka, P. Hydrogen energy–Main problems. Polityka Energetyczna Energy Policy J. 2017, 20–23, 55–66. [Google Scholar]

- Verhage, A.; Gerits, J.; Manders, T. Duration Tests of PEM Fuel Cells in a 50 kW Pilot Power Plant. In Proceedings of the 18th World Hydrogen Energy Conference (WHEC), Essen, Germany, 16–20 May 2010; pp. 63–67. [Google Scholar]

- Renewable Electrolysis Integrated Systems Development and Testing. Available online: https://www.hydrogen.energy.gov (accessed on 15 July 2019).

- Ceran, B. The use of multi-criteria analysis to compare the operating scenarios of the hybrid generation system of wind turbines, photovoltaic modules and a fuel cell. E3S Web Conf. 2017, 22, 00028. [Google Scholar] [CrossRef]

- Ceran, B. A comparative analysis of energy storage technologies. Polityka Energetyczna Energy Policy J. 2018, 21–23, 97–110. [Google Scholar]

- Ceran, B.; Bernstein, P.A. Operational characteristics of proton exchange membrane (PEM) fuel cells. Przegląd Elektrotechniczny 2014, 10, 102–105. [Google Scholar]

| Scenarios | ||||

|---|---|---|---|---|

| Devices in HPGS | S-I | S-II | S-III | S-IV |

| Wind turbines [kW] | 2 × 80 | 2 × 80 | 1 × 80 | 1 × 80 |

| PV panels 290 Wp | 467 × 290 | 240 × 290 | 328 × 290 | 119 × 290 |

| Fuel cell [kW] | 70 | 60 | 50 | 40 |

| Electrolyzer [kW] | 180 | 150 | 100 | 80 |

| Scenarios | ||||||||

|---|---|---|---|---|---|---|---|---|

| Devices in HPGS | SI | SII | SIII | SIV | ||||

| Year_0 | Year_7 | Year_0 | Year_7 | Year_0 | Year_7 | Year_0 | Year_7 | |

| k1 [Nm3/kWh] | 0.119 | 0.231 | 0.090 | 0.165 | 0.072 | 0.131 | 0.047 | 0.083 |

| Δk1[Nm3/kWh] | +0.112 | +0.075 | +0.059 | +0.036 | ||||

| k2 [PLN/kWh] | 1.300 | 1.417 | 1.320 | 1.420 | 1.331 | 1.437 | 1.454 | 1.549 |

| Δk2[PLN/kWh] | +0.117 | +0.100 | +0.106 | +0.095 | ||||

| k3 [kgCO2/kWh] | 0.310 | 0.447 | 0.415 | 0.508 | 0.528 | 0.601 | 0.627 | 0.671 |

| Δk3[kgCO2/kWh] | +0.137 | +0.093 | +0.073 | +0.044 | ||||

| k4 [kWh/kWh] | 1.000 | 1.079 | 1.125 | 1.159 | ||||

| Weight Ratios w1:w2:w3:w4 | Year 0,1,2 | Year 3 | Year 4 | Year 5 | Year 6 | Year 7 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| α = 1 | α = 2 | α = 1 | α = 2 | α = 1 | α = 2 | α = 1 | α = 2 | α = 1 | α = 2 | α = 1 | α = 2 | |

| 1:1:1:1 | SII | SII | SII | SII | SII | SII | SII | SII | SIV | SII | SIV | SII |

| 2:1:1:1 | SIV | SIV | SIV | SIV | SIV | SIV | SIV | SIV | SIV | SIV | SIV | SIV |

| 1:2:1:1 | SII | SII | SII | SII | SII | SII | SII | SII | SII | SII | SII | SII |

| 1:1:2:1 | SI | SI | SI | SI | SI | SI | SI | SI | SII | SI | SII | SII |

| 1:1:1:2 | SI | SI | SII | SII | SII | SII | SII | SII | SII | SII | SII | SII |

| 2:2:1:1 | SIV | SIV | SIV | SIV | SIV | SIV | SIV | SIV | SIV | SIV | SIV | SIV |

| 1:1:2:2 | SI | SI | SI | SI | SI | SI | SI | SI | SI | SI | SII | SI |

| 3:1:1:1 | SIV | SIV | SIV | SIV | SIV | SIV | SIV | SIV | SIV | SIV | SIV | SIV |

| 1:3:1:1 | SII | SII | SII | SII | SII | SII | SII | SII | SII | SII | SII | SII |

| 1:1:3:1 | SI | SI | SI | SI | SI | SI | SI | SI | SI | SI | SII | SI |

| 1:1:1:3 | SI | SI | SI | SI | SI | SI | SI | SI | SII | SI | SII | SI |

| 3:3:1:1 | SIV | SIV | SIV | SIV | SIV | SIV | SIV | SIV | SIV | SIV | SIV | SIV |

| 1:1:3:3 | SI | SI | SI | SI | SI | SI | SI | SI | SI | SI | SI | SI |

| Weight Ratios w1:w2:w3:w4 | Year 0…10 | Year 11…12 | Year 13…20 | |||

|---|---|---|---|---|---|---|

| α = 1 | α = 2 | α = 1 | α = 2 | α = 1 | α = 2 | |

| 1:1:1:1 | SII | SII | SII | SII | SII | SII |

| 2:1:1:1 | SIV | SIV | SIV | SIV | SIV | SIV |

| 1:2:1:1 | SII | SII | SII | SII | SII | SII |

| 1:1:2:1 | SI | SI | SI | SI | SI | SI |

| 1:1:1:2 | SI | SI | SII | SI | SII | SII |

| 2:2:1:1 | SIV | SIV | SIV | SIV | SIV | SIV |

| 1:1:2:2 | SI | SI | SI | SI | SI | SI |

| 3:1:1:1 | SIV | SIV | SIV | SIV | SIV | SIV |

| 1:3:1:1 | SII | SII | SII | SII | SII | SII |

| 1:1:3:1 | SI | SI | SI | SI | SI | SI |

| 1:1:1:3 | SI | SI | SI | SI | SI | SI |

| 3:3:1:1 | SIV | SIV | SIV | SIV | SIV | SIV |

| 1:1:3:3 | SI | SI | SI | SI | SI | SI |

| Weight Ratios w1:w2:w3:w4 | Year 0…6 | Year 7 | ||

|---|---|---|---|---|

| α = 1 | α = 2 | α = 1 | α = 2 | |

| 1:1:1:1 | SII | SII | SII | SII |

| 2:1:1:1 | SIV | SIV | SIV | SIV |

| 1:2:1:1 | SII | SII | SII | SII |

| 1:1:2:1 | SI | SI | SI | SI |

| 1:1:1:2 | SI | SI | SI | SI |

| 2:2:1:1 | SIV | SIV | SIV | SIV |

| 1:1:2:2 | SI | SI | SI | SI |

| 3:1:1:1 | SIV | SIV | SIV | SIV |

| 1:3:1:1 | SII | SII | SII | SII |

| 1:1:3:1 | SI | SI | SI | SI |

| 1:1:1:3 | SI | SI | SI | SI |

| 3:3:1:1 | SIV | SIV | SIV | SIV |

| 1:1:3:3 | SI | SI | SI | SI |

| Weight Ratios w1:w2:w3:w4 | Year 0…5 | Year 6 | Year 7 | |||

|---|---|---|---|---|---|---|

| α = 1 | α = 2 | α = 1 | α = 2 | α = 1 | α = 2 | |

| 1:1:1:1 | SII | SII | SIV | SII | SIV | SII |

| 2:1:1:1 | SIV | SIV | SIV | SIV | SIV | SIV |

| 1:2:1:1 | SII | SII | SII | SII | SII | SII |

| 1:1:2:1 | SI | SI | SII | SI | SII | SII |

| 1:1:1:2 | SI | SI | SII | SII | SII | SII |

| 2:2:1:1 | SIV | SIV | SIV | SIV | SIV | SIV |

| 1:1:2:2 | SI | SI | SII | SI | SII | SI |

| 3:1:1:1 | SIV | SIV | SIV | SIV | SIV | SIV |

| 1:3:1:1 | SII | SII | SII | SII | SII | SII |

| 1:1:3:1 | SI | SI | SI | SI | SII | SI |

| 1:1:1:3 | SI | SI | SII | SI | SII | SI |

| 3:3:1:1 | SIV | SIV | SIV | SIV | SIV | SIV |

| 1:1:3:3 | SI | SI | SI | SI | SI | SI |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ceran, B.; Orłowska, A. The Impact of Power Source Performance Decrease in a PV/WT/FC Hybrid Power Generation System on the Result of a Multi-Criteria Analysis of Load Distribution. Energies 2019, 12, 3453. https://doi.org/10.3390/en12183453

Ceran B, Orłowska A. The Impact of Power Source Performance Decrease in a PV/WT/FC Hybrid Power Generation System on the Result of a Multi-Criteria Analysis of Load Distribution. Energies. 2019; 12(18):3453. https://doi.org/10.3390/en12183453

Chicago/Turabian StyleCeran, Bartosz, and Agata Orłowska. 2019. "The Impact of Power Source Performance Decrease in a PV/WT/FC Hybrid Power Generation System on the Result of a Multi-Criteria Analysis of Load Distribution" Energies 12, no. 18: 3453. https://doi.org/10.3390/en12183453

APA StyleCeran, B., & Orłowska, A. (2019). The Impact of Power Source Performance Decrease in a PV/WT/FC Hybrid Power Generation System on the Result of a Multi-Criteria Analysis of Load Distribution. Energies, 12(18), 3453. https://doi.org/10.3390/en12183453