Sensitivity of Characterizing the Heat Loss Coefficient through On-Board Monitoring: A Case Study Analysis

Abstract

1. Introduction

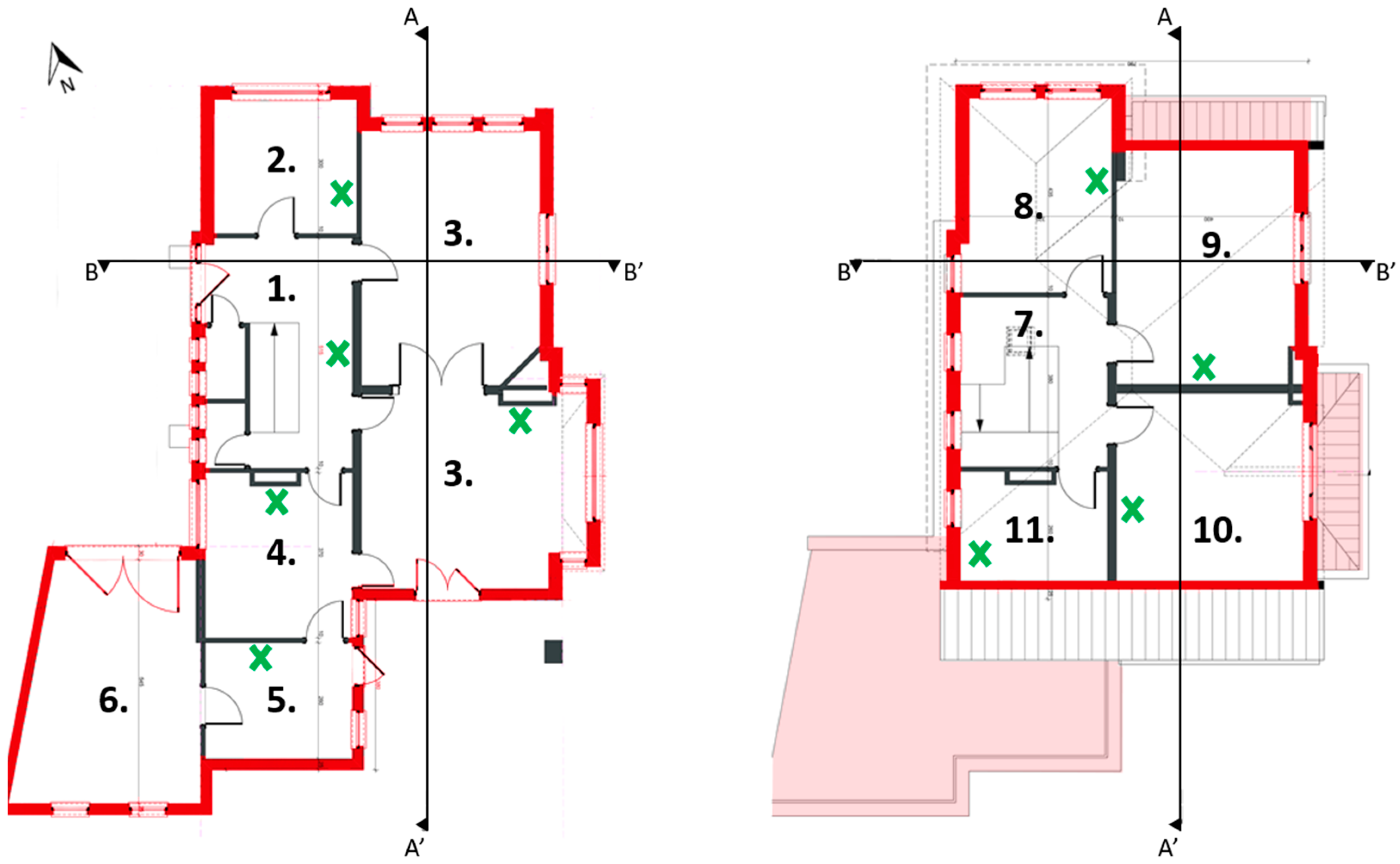

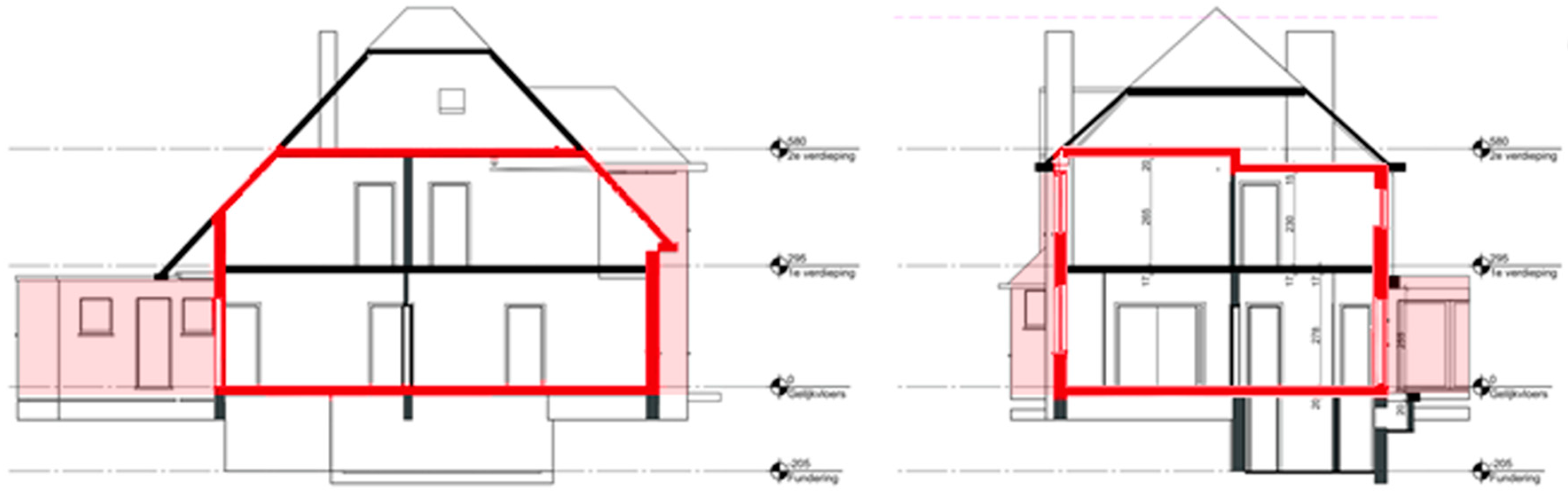

2. Description of Case Study

2.1. The Building

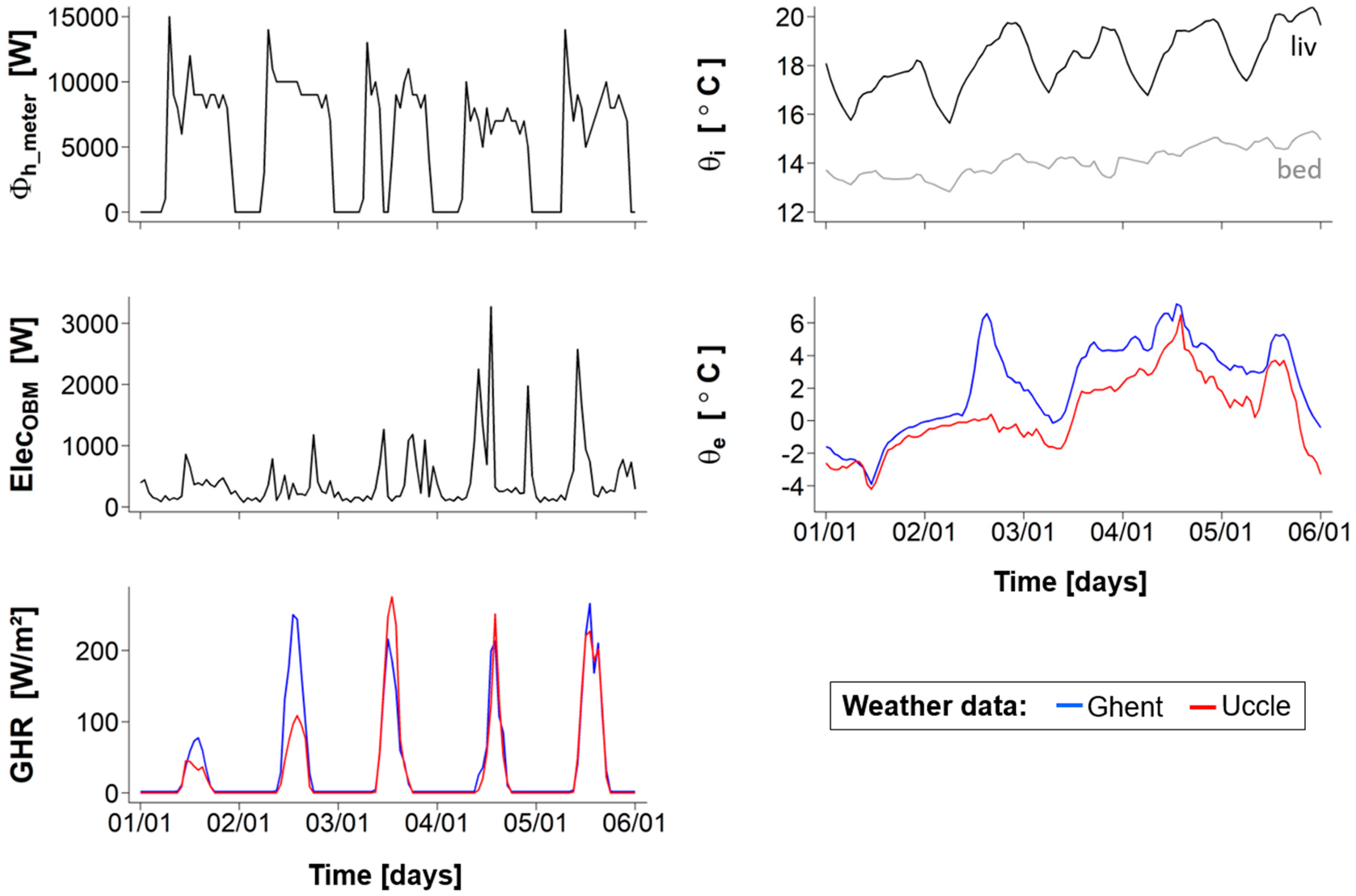

2.2. The Monitoring Campaign

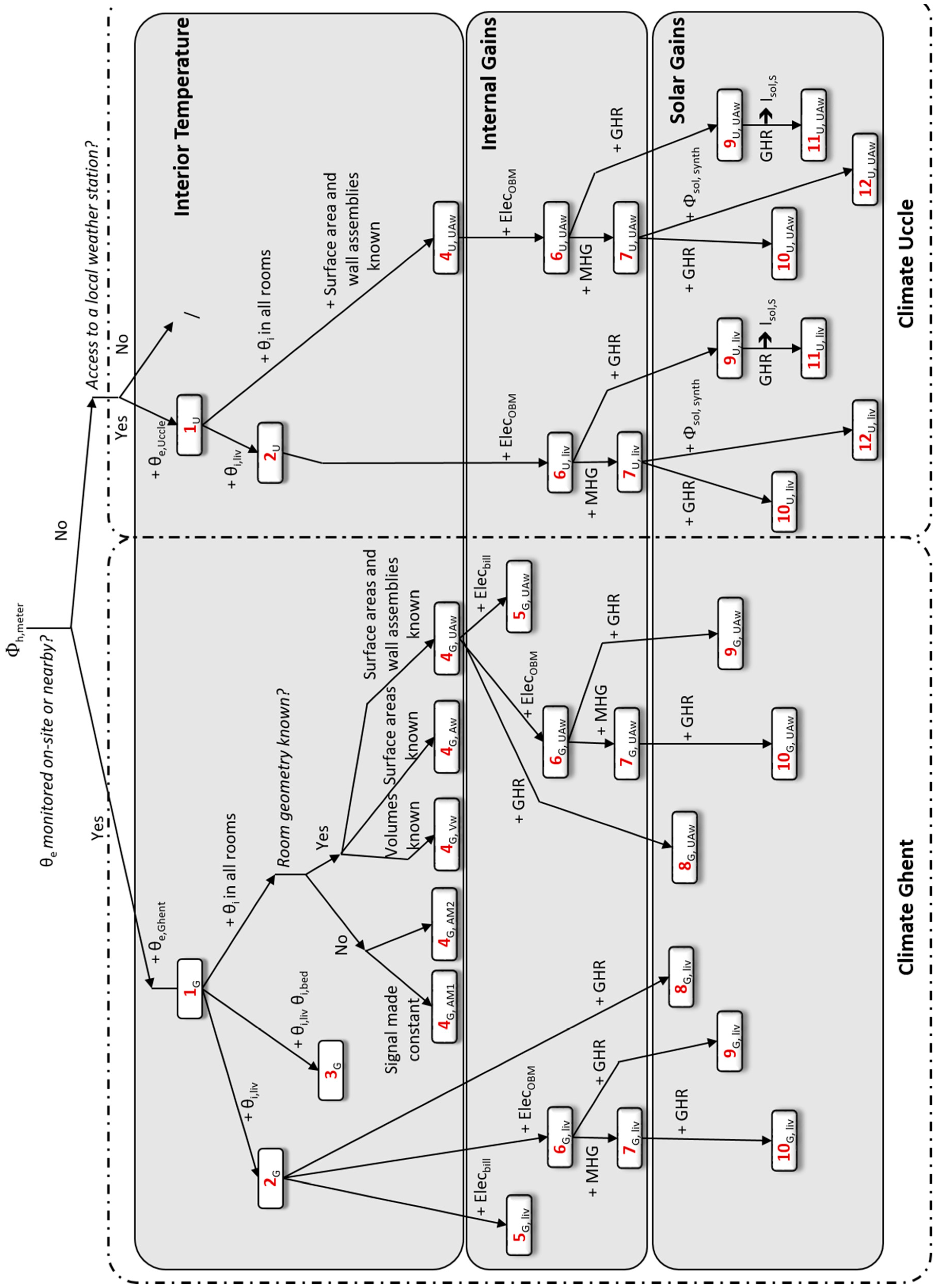

3. Research Methodology

3.1. Data Analysis Methods

3.2. Input Data Packages

- the arithmetic mean of all available interior temperature signals θi,AM (packages 4G,AM1 with θi = mean(θi,AM) and 4G,AM2 with θi = θi,AM);

- their (gross) room volume weighted average θi,Vw (package 4G,Vw);

- their heat loss area weighted average θi,Aw (package 4G,Aw);

- their UA-value weighted average θi,UAw (package 4G,UAw);

3.3. Model Fitting and Validation, Determination of HLC

- (a)

- All model coefficients should prove to be significantly different from zero in a marginal t-test (p-value < 0.05).

- (b)

- The residuals of the fitted model should resemble white noise, which is a sequence of uncorrelated zero mean random variables [18]. This property is examined in both the time and frequency domain, by inspecting the plots of the Autocorrelation Function (‘ACF’) and the cumulated periodogram (‘CP’), respectively. In the former plot, it is verified whether the conditions specified in the IEA Annex 58 statistical guidelines [44] are fulfilled. These state that not more than 5–10% of the lag correlations should be significantly different from zero (exceed above the 95% confidence bands). Especially the correlation for the shorter lags and the 24 h lag should be insignificant. The CP, on the other hand, should approximate a linearly increasing function, indicating that the residuals do not have excess of a certain frequency. Its plot should thus show a quasi-straight line, that barely (5%) exceeds the 95% confidence band.

- The model parametrization expressed in Equation (19), (20), or (21) is fitted to the data, allowing one lag for the autoregressive variable and 0 lags for the input variables (nφ = 1, nωx = 0).

- The insignificant model coefficients are systematically removed, starting with those of the highest order present. After each elimination, the model is refitted. This step is repeated until only significant model coefficients remain.

- If the model passes the white noise criterion specified in (b), it is accepted. Otherwise, another lag is added to each variable (lag x for the input polynomials and lag (x + 1) for the output polynomial, whereby lag x is the next lag that has not been added before: the same lag is never added again if it was eliminated before), increasing the model order, and step 2 is repeated.

4. Results and Discussion

4.1. Sensitivity Analysis

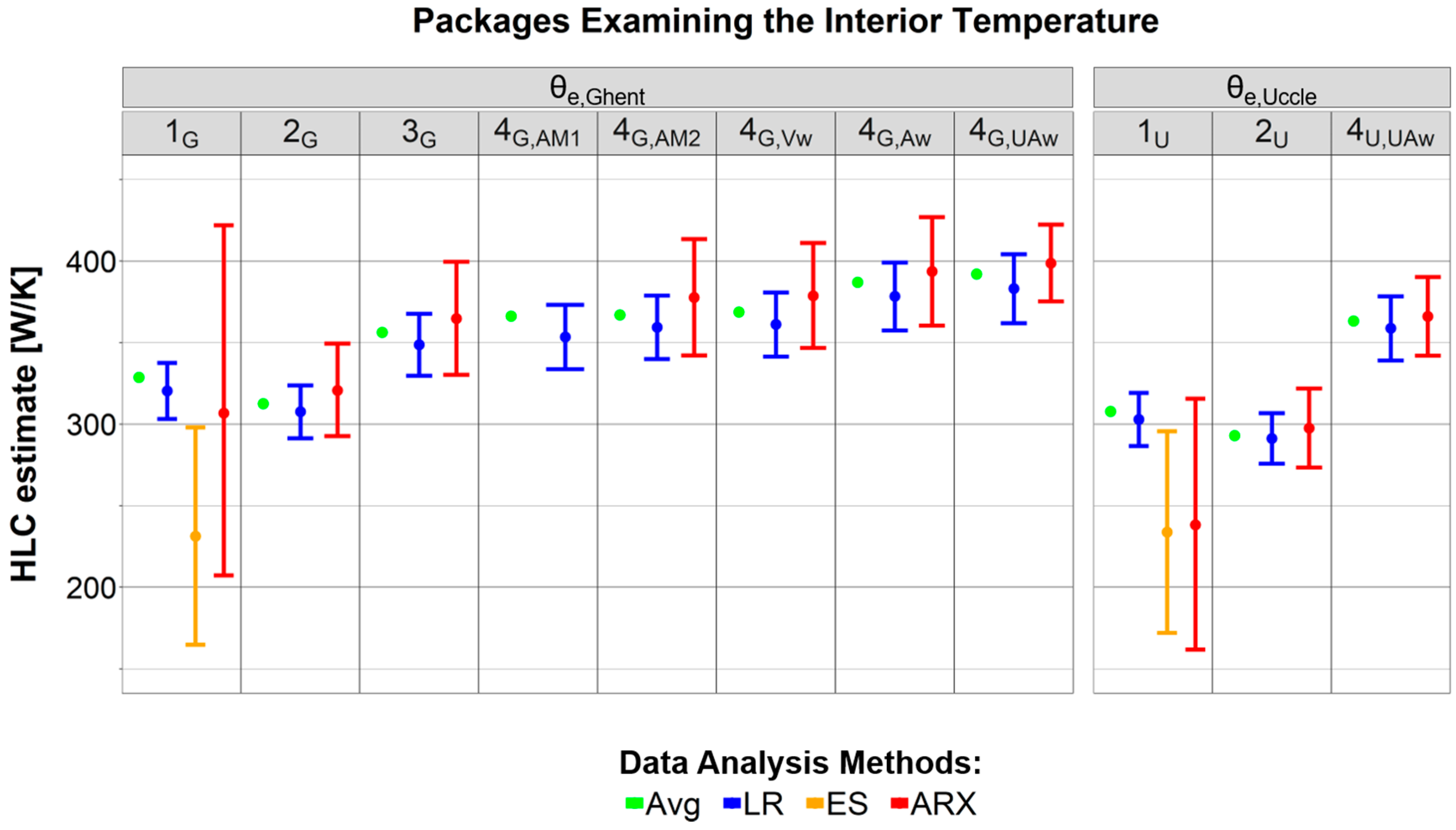

4.1.1. Impact of Representation of Exterior and Interior Temperature

Using a Default Value for the Interior Temperature

Installing One or More Interior Temperature Sensors

Using a Different Exterior Temperature Signal

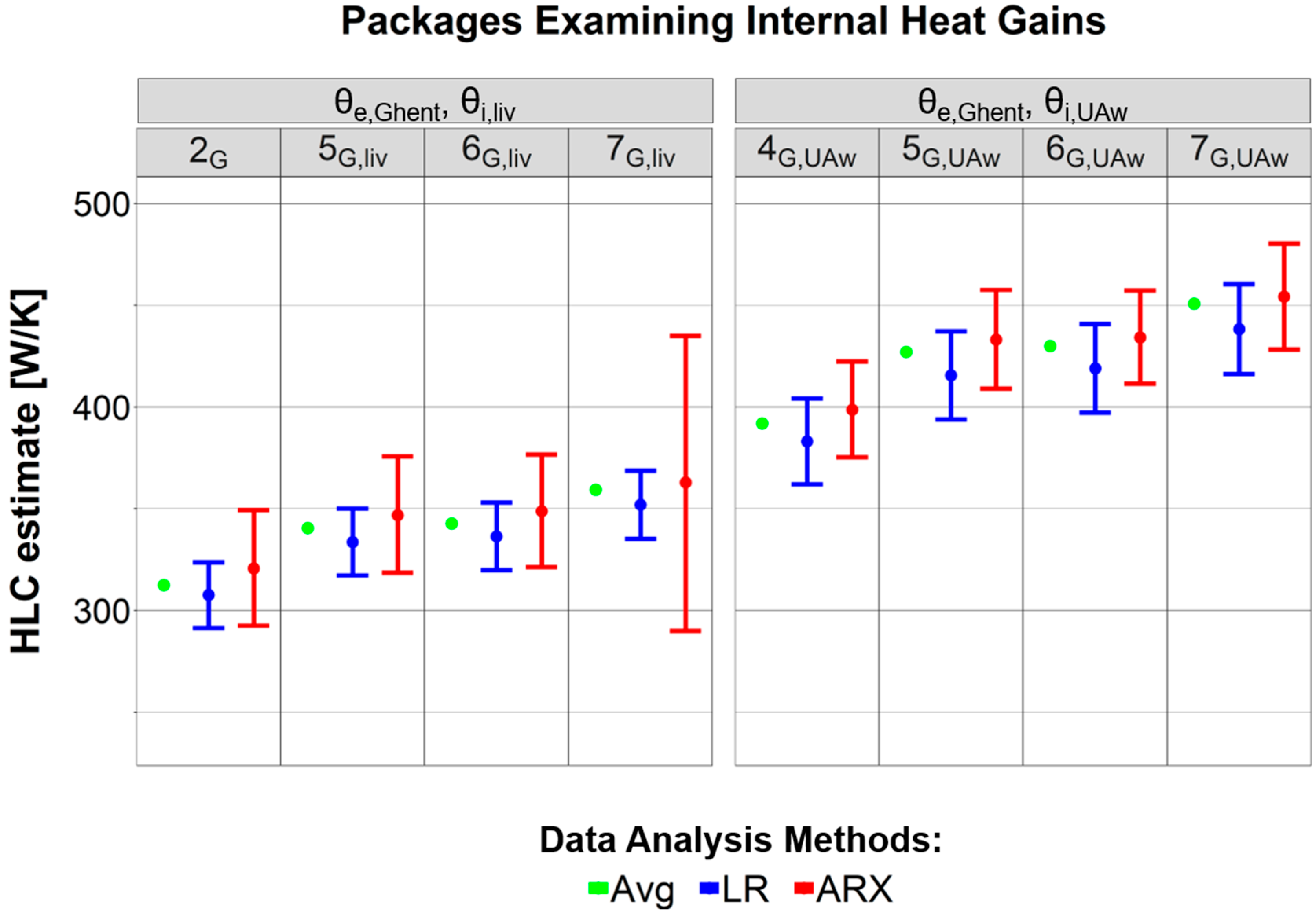

4.1.2. Impact of Representation of Internal Heat Gains

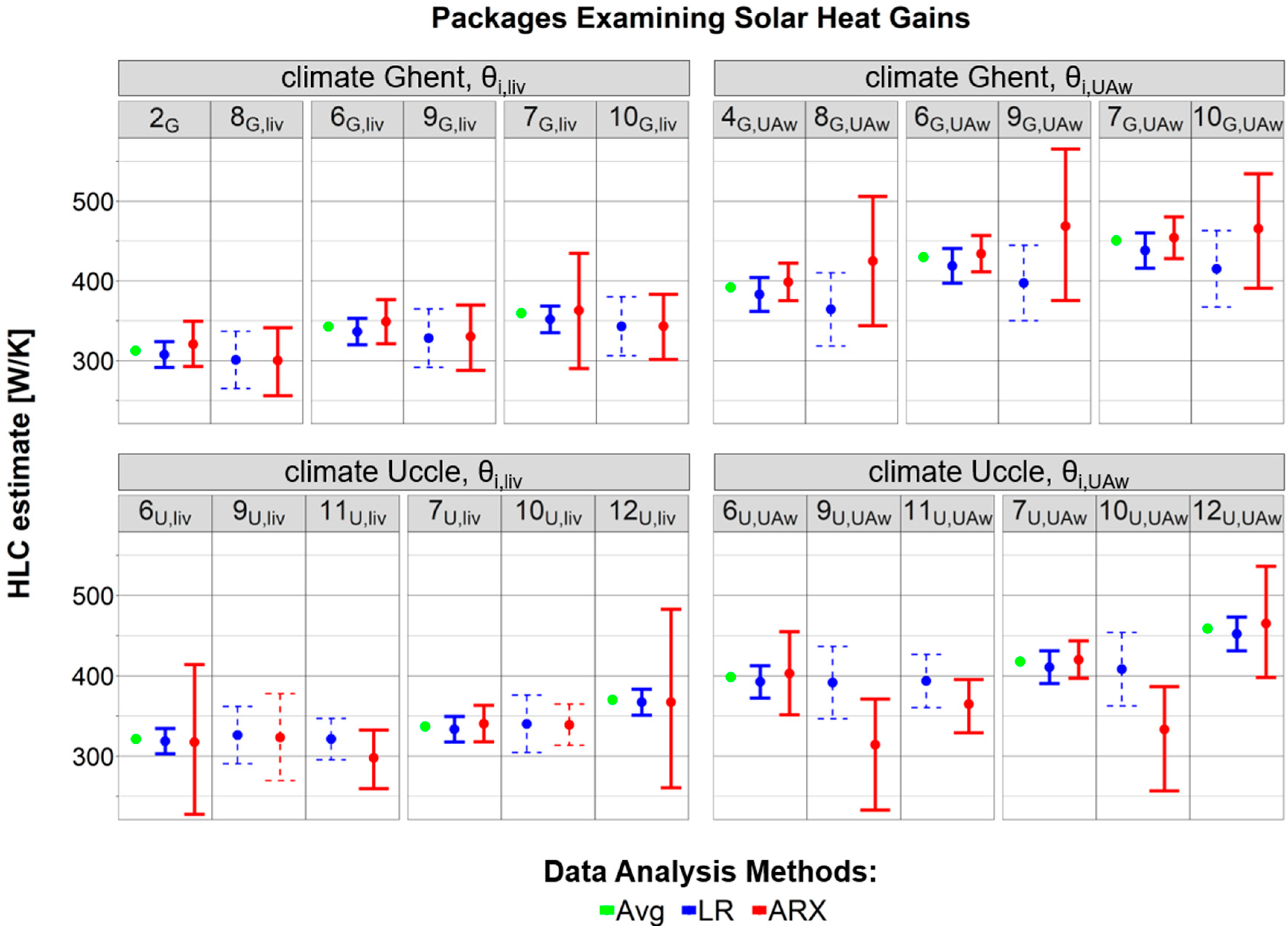

4.1.3. Impact of Representation of Solar Heat Gains

4.1.4. Overall Impact of Input Data and Analysis Method

4.2. Comparison with Theoretical Value and Assessment of Uncertainties

- (a)

- The U-values of the building components were determined based on assumed constructions, using default material properties. In reality, other materials than those specified in Table 1 could have been used, and the thermal conductivity and thickness of the material layers could be either higher or lower.

- (b)

- For the temperature ratios bT (Equations (3) and (4)) of the floor slab above the cellar and the attic floor, constant, default values of respectively 0.8 and 0.9 were used (see Table 1). However, in reality these ratios vary over time. With the aid of the temperature signals measured in the cellar and attic it could be established that especially the temperature ratio applied to the U-value of the slab above the cellar is not appropriate in this case. Over the training period, the actual bT values on average amount to 0.4 and 0.7 for respectively the floor slab to the cellar and the attic floor. Notably, in the calculations the variable θi was respectively represented by the temperature of the entrance hall and a ceiling area weighted average of the temperatures measured in the rooms on the first floor. Substituting these actual bT values in the theoretical calculation results in an HLC value of 678.6 W/K (compared to the original value of 697.1 W/K).

- (c)

- According to ISO 13370 [33,34] the thermal resistance of dense concrete slabs and thin floor coverings can be neglected when calculating the U-value of the slab-on-ground floor including the effect of the ground. In this particular case, this means that the thermal resistance of the floor slab is assumed to be zero. When this suggestion is ignored, and the thermal resistances of the tiles, sand bed, and concrete slab (see Table 1) are taken into account, the U-value of the slab on ground floor lowers to 0.7 W/m2·K and the theoretical HLC to 678.5 W/K.

- (d)

- The surface areas in Equation (3) are calculated from building plans, the accuracy of which is unknown.

- (e)

- Thermal bridges have not been accounted for (Ψ and Χ in Equation (3) are assumed to be zero). However, these would only further increase the observed gap.

- Inappropriate sensor placement. For example, issues were raised concerning the position of the heat meter and the temperature sensors.

- Measurement errors (e.g., missing observations and small anomalies in the GHR data collected in Ghent).

- Use of unrepresentative input variables in the model: e.g., the complex search for one interior temperature signal θi approximating the ‘equivalent homogenous temperature’ of a multizone building.In this context, it could for instance be noted that the above presented OBM characterization and sensitivity analysis relied on the assumption that the temperature registered in the utility room is also representative for the former garage, where no temperature sensor was installed. Since this room has a heat loss area of 133.6 m2 and is not actively heated according to the inhabitants, this assumption is questionable. To evaluate its impact on the HLC estimate, a synthetic, alternative room temperature signal is developed for the garage based on the formula expressed in Equation (31), where the subscripts ‘gar’, ‘ut’, and ‘kit’ stand for the garage, utility room and kitchen, respectively. ‘gar/ut’ indicates the building elements separating the garage from the utility room.Weighting this new temperature signal in θi,UAw and repeating the analysis of package 7G,UAw yields an estimate of 501.8 W/K (average for the three methods), which is 12.1% higher than the original estimate for 7G,UAw presented in Section 4.1. The discrepancy with the theoretical value reduces by 22%.

- Physical phenomena that are unaccounted for in the models. For packages 7 to 12 these include, for example, the opening of external doors and windows, radiative heat exchange with the sky, and latent heat gains. Other phenomena, such as the dynamic thermal loading of the building parts, internal heat gains, and solar gains, may not have been correctly incorporated.

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Variables | Symbol | Unit |

| Temperature | θ | °C |

| Temperature ratio | bT | - |

| Global Horizontal Radiation | GHR | W/m2 |

| Solar irradiance | Isol | W/m2 |

| Net heat input | Φh | W |

| Solar gains | Φsol | W |

| Internal heat gains | Φint | W |

| Heat transfer through transmission | Φtr | W |

| Heat transfer through infiltration | Φinf | W |

| Heat transfer through intended ventilation | Φv | W |

| Flow rate | Q | m³/s |

| Parameters | ||

| Heat transfer coefficient by transmission | Htr | W/K |

| Heat transfer coefficient by infiltration | Hinf | W/K |

| Heat loss coefficient | HLC | W/K |

| Thermal transmittance or U-value | U | W/m2·K |

| g-value | g | - |

| Surface area | A | m2 |

| Subscripts | ||

| Interior | i | |

| Exterior | e | |

| Ground | g | |

| Unconditioned | u | |

| Adjacent | a | |

| Arithmetic mean | AM | |

| Volume weighted average | Vw | |

| Heat loss area weighted average | Aw | |

| UA-value weighted average | UAw |

References

- Eurostat-Statistical Office of the European Union. Energy, Transport and Environment Indicators; Eurostat-Statistical Office of the European Union: Luxembourg, 2018. [Google Scholar] [CrossRef]

- ISO (International Organization for Standardization). ISO 52016-1: Energy Performance of Buildings: Energy Needs for Heating and Cooling, Internal Temperatures and Sensible and Latent Heat Loads: Part 1: Calculation Procedures; International Organization for Standardization: Geneva, Switzerland, 2017. [Google Scholar]

- Gupta, R.; Dantsiou, D. Understanding the gap between ‘as Designed’ and ‘as Built’ performance of a new low carbon housing development in UK. In Sustainability in Energy and Buildings; Hakansson, A., Höjer, M., Howlett, R.J., Jain, L.C., Eds.; Springer: Heidelberg, Germany, 2013; Volume 2, pp. 567–580. [Google Scholar]

- Wingfield, J.; Bell, M.; Miles-Shenton, D.; Seavers, J. Elm Tree Mews Field Trial–Evaluation and Monitory of Dwellings Performance, Final Technical Report. 2011. Available online: http://www.leedsmet.ac.uk/as/cebe/projects/elmtree/elmtree_finalreport.pdf (accessed on 31 July 2019).

- Wingfield, J.; Bell, M.; Miles-Shenton, D.; South, T.; Lowe, B. Evaluating the Impact of an Enhanced Energy Performance Standard on Load-Bearing Masonry Domestic Construction: Understanding the Gap Between Designed and Real Performance: Lessons from Stamford Brook; Leeds Beckett University: London, UK, 2011. [Google Scholar]

- Johnston, D.; Farmer, D.; Brooke, M.; Brooke-Peat, M.; Miles-Shenton, D. Bridging the domestic building fabric performance gap. Build. Res. Inf. 2016, 44, 147–159. [Google Scholar] [CrossRef]

- Johnston, D.; Miles-Shenton, D.; Wingfield, J.; Farmer, D.; Bell, M. Whole House Heat Loss Test Method (Coheating). 2013. Available online: https://www.leedsbeckett.ac.uk/as/cebe/projects/cebe_coheating_test_method_june2013.pdf (accessed on 31 July 2019).

- Bauwens, G. In Situ Testing of A Building’s Overall Heat Loss Coefficient. Ph.D. Thesis, KU Leuven, Leuven Belgium, 2015. [Google Scholar]

- Subbarao, K.; Burch, J.D.; Hancock, C.E.; Lekov, A.; Balcomb, J.D. Short-Term Energy Monitoring (STEM): Application of the PSTAR Method to a Residence in Fredericksburg, Virginia; SERI/TR-254-33 56; Solar Energy Research Institute: Golden, CO, USA, 1988. [Google Scholar]

- Palmer, J.; Pane, G.; Bell, M.; Wingfield, J. Comparing Primary and Secondary Terms Analysis and Re-Normalisation (PStar) Test. and Co-Heating Test. Results. Final Report: BD2702; DCLG Publications: London, UK, 2011. [Google Scholar]

- Alzetto, F.; Pandraud, G.; Fitton, R.; Heusler, I.; Sinnesbichler, H. QUB: A fast dynamic method for in-situ measurement of the whole building heat loss. Energy Build. 2018, 174, 124–133. [Google Scholar] [CrossRef]

- Ghiaus, C.; Alzetto, F. Design of experiments for Quick U-building method for building energy performance measurement. J. Build. Perform. Simul. 2019, 12, 465–479. [Google Scholar] [CrossRef]

- Bouchié, R.; Alzetto, F.; Brun, A.; Boisson, P.; Thebault, S. Short methodologies for in-situ assessment of the intrinsic thermal performance of the building envelope. In Proceedings of the Sustainable Places 2014 (SP2014), Nice, France, 1–3 October 2014. [Google Scholar]

- Boisson, P.; Bouchié, R. ISABELE method: In situ assessment of the building envelope performances. In Proceedings of the Ninth International Conference on System Simulation in Buildings (SSB2014), Liege, Belgium, 10–12 December 2014; pp. 302–320. [Google Scholar]

- Thébault, S.; Bouchié, R. Refinement of the ISABELE method regarding uncertainty quantification and thermal dynamics modelling. Energy Build. 2018, 178, 182–205. [Google Scholar] [CrossRef]

- Senave, M.; Reynders, G.; Verbeke, S.; Saelens, D. A simulation exercise to improve building energy performance characterization via on-board monitoring. Energy Procedia 2017, 132, 969–974. [Google Scholar] [CrossRef]

- Ljung, L. System Identification: Theory for the User, 2nd ed.; PTR Prentice Hall: Upper Saddle River, NJ, USA, 1999. [Google Scholar]

- Madsen, H. Time Series Analysis; Chapman & Hall/CRC: Boca Raton, FL, USA, 2008; ISBN 9781420059670. [Google Scholar]

- Jack, R.; Loveday, D.; Allinson, D.; Lomas, K. First evidence for the reliability of building co-heating tests. Build. Res. Inf. 2017, 46, 383–401. [Google Scholar] [CrossRef]

- Alzetto, F.; Farmer, D.; Fitton, R.; Hughes, T.; Swan, W. Comparison of whole house heat loss test methods under controlled conditions in six distinct retrofit scenarios. Energy Build. 2018, 168, 35–41. [Google Scholar] [CrossRef]

- European Commission. Benchmarking Smart Metering Deployment in the EU-27 with a Focus on Electricity; European Commission: Brussels, Belgium, 2014. [Google Scholar]

- Annex 71 of the programme ‘‘EBC” of the IEA on ‘‘Building Energy Performance Assessment Based on In-situ Measurements”. 2016–2021. Available online: http://www.iea-ebc.org/projects/project?AnnexID=71 (accessed on 31 July 2019).

- Castillo, L.; Enríquez, R.; Jiménez, M.J.; Heras, M.R. Dynamic integrated method based on regression and averages, applied to estimate the thermal parameters of a room in an occupied office building in Madrid. Energy Build. 2014, 81, 337–362. [Google Scholar] [CrossRef]

- Erkoreka, A.; Garcia, E.; Martin, K.; Teres-Zubiaga, J.; Del Portillo, L. In-use office building energy characterization through basic monitoring and modelling. Energy Build. 2016, 119, 256–266. [Google Scholar] [CrossRef]

- Uriarte, I.; Erkoreka, A.; Giraldo-Soto, C.; Martin, K.; Uriarte, A.; Eguia, P. Mathematical development of an average method for estimating the reduction of the Heat Loss Coefficient of an energetically retrofitted occupied office building. Energy Build. 2019, 192, 101–122. [Google Scholar] [CrossRef]

- Senave, M.; Reynders, G.; Bacher, P.; Roels, S.; Verbeke, S.; Saelens, D. Towards the characterization of the heat loss coefficient via on-board monitoring: Physical interpretation of ARX model coefficients. Energy Build. 2019, 195, 180–194. [Google Scholar] [CrossRef]

- Senave, M.; Reynders, G.; Sodagar, B.; Verbeke, S.; Saelens, D. Mapping the pitfalls in the characterisation of the heat loss coefficient from on-board monitoring data using ARX models. Energy Build. 2019, 197, 214–228. [Google Scholar] [CrossRef]

- Chambers, J.D.; Oreszczyn, T. Deconstruct: A scalable method of as-built heat power loss coefficient inference for UK dwellings using smart meter data. Energy Build. 2019, 183, 443–453. [Google Scholar] [CrossRef]

- De Dietrich. Modulens: Staande Hoog Rendement Ketel: AGC 15 BE-25 BE-35 BE. Available online: http://nl.dedietrich-heating.be/download/file?file=var/ddth/storage/original/application/ab3fd134254179a7081a4720c6d14a29.pdf&filename=NOT-300026053-06.pdf (accessed on 28 May 2015).

- Cuypers, D.; Birigt Vandevelde, B.; Marlies Van Holm, B.; Stijn Verbeke, B. Belgische Woningtypologie Nationale Brochure over de TABULA Woningtypologie, 2nd ed. 2014. Available online: http://episcope.eu/fileadmin/tabula/public/docs/brochure/BE_TABULA_TypologyBrochure_VITO.pdf (accessed on 31 July 2019). (In Dutch).

- Belgisch Staatsblad (Belgian Official Journal). Bijlage 4 bij het MB van 28 december: Transmissie Referentie Document. 2019. Available online: https://www.energiesparen.be/EPB-pedia/bijlagen-coordinatieMB#bijlage4 (accessed on 31 July 2019). (In Dutch).

- Belgian Bureau for Standardisation (NBN). NBN EN 12831: Heating Systems in Buildings: Method for Calculation of the Design Heat Load; Belgisch instituut voor normalisatie (BIN): Brussels, Belgium, 2003. [Google Scholar]

- ISO (International Organization for Standardization). ISO 13370: Thermal Performance of Buildings: Heat Transfer via the Ground: Calculation Methods; International Organization for Standardization: Geneva, Switzerland, 2017. [Google Scholar]

- Schietecat, J. Warmteoverdracht Door Wanden van Gebouwen in Contact Met. de Grond. Toepassing van de Rekenmethode Uit de Norm en ISO 13370; WTCB: Brussels, Belgium, 2002. (In Dutch) [Google Scholar]

- RENOSEEC -Collectief Renoveren, 2014–2018. Available online: http://www.renoseec.com/ (accessed on 31 July 2019).

- De Proeftuinen van Het IWT-Duurzame ontwikkeling. Available online: https://do.vlaanderen.be/de-proeftuinen-van-het-iwt (accessed on 31 July 2019).

- Senave, M.; Reynders, G.; Sodagar, B.; Saelens, D. Uncertainty in building energy performance characterization: Impact of gas consumption decomposition on estimated heat loss coefficient. In Proceedings of the 7th International Building Physics Conference. (IBPC 2018), Syracuse, NY, USA, 23–26 September 2018; pp. 1491–1496. [Google Scholar]

- Bureau for Standardisation (NBN). NBN EN ISO 9972: Thermische Eigenschappen van Gebouwen: Bepaling van de Luchtdoorlatendheid van Gebouwen: Overdrukmethode Met. Ventilator; Belgisch instituut voor normalisatie (BIN): Brussels, Belgium, 2015. (In Dutch) [Google Scholar]

- Senave, M.; Roels, S.; Reynders, G.; Verbeke, S.; Saelens, D. Assessment of data analysis methods to identify the heat loss coefficient from on-board monitoring data. Energy Build. 2019. submitted for publication. [Google Scholar]

- ISO (International Organization for Standardization). ISO 9869-1: Thermal Insulation: Building Elements: In-situ Measurement of Thermal Resistance and Thermal Transmittance: Part. 1: Heat Flow Meter Method; International Organization for Standardization: Geneva, Switzerland, 2014. [Google Scholar]

- Bauwens, G.; Roels, S. Co-heating test: A state-of-the-art. Energy Build. 2014, 82, 163–172. [Google Scholar] [CrossRef]

- Ghiaus, C. Experimental estimation of building energy performance by robust regression. Energy Build. 2006, 38, 582–587. [Google Scholar] [CrossRef]

- Janssens, A. IEA EBC Annex 58: Report of Subtask 1b: Overview of Methods to Analyse Dynamic Data; KU Leuven: Leuven, Belgium, 2016. [Google Scholar]

- Madsen, H.; Bacher, P.; Bauwens, G.; Deconinck, A.H.; Reynders, G.; Roels, S.; Himpe, E.; Lethé, G. IEA EBC Annex 58: Report of Subtask 3, part 2: Thermal Performance Characterisation Using Time Series Data–Statistical Guidelines; KU Leuven: Leuven, Belgium, 2016. [Google Scholar]

- Belgisch Staatsblad (Belgian Official Journal). Bijlage 5 bij het energiebesluit: Bepalingsmethode EPW: Bepalingsmethode van het peil van primair energieverbruik van residentiële eenheden. 2019. Available online: https://www.energiesparen.be/EPB-pedia/regelgeving/energiebesluit/bijlageV (accessed on 31 July 2019). (In Dutch).

- ISO (International Organization for Standardization). ISO 8996: Ergonomics of the Thermal Environment: Determination of Metabolic rate; International Organization for Standardization: Geneva, Switzerland, 2004. [Google Scholar]

- Klein, S.A.; Beckman, W.A.; Mitchell, J.W.; Duffie, J.A.; Duffie, N.A.; Freeman, T.L.; Kummer, J.P. TRNSYS 17: A Transient System Simulation Program; Solar Energy Laboratory, University of Wisconsin: Madison, WI, USA, 2009; Available online: http://sel.me.wisc.edu/trnsys (accessed on 31 July 2019).

- Klein, S.A.; Beckman, W.A.; Mitchell, J.W.; Duffie, J.A.; Duffie, N.A.; Freeman, T.L.; Mitchell, J.C.; Braun, J.E.; Evans, B.L.; Kunmmer, J.P.; et al. TRNSYS 17: A Transient System Simulation Program: Volume 4: Mathematical Reference; Solar Energy Laboratory, University of Wisconsin: Madison, WI, USA, 2014. [Google Scholar]

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2017; Available online: https://www.r-project.org/ (accessed on 31 July 2019).

- R-core. lm: Fitting Linear Models. Available online: https://www.rdocumentation.org/packages/stats/versions/3.4.3/topics/lm (accessed on 31 July 2019).

- Jiménez, M.J.; Madsen, H.; Andersen, K.K. Identification of the main thermal characteristics of building components using MATLAB. Build. Environ. 2008, 43, 170–180. [Google Scholar] [CrossRef]

- Efron, B.; Tibshirani, R. Bootstrap methods for standard errors, confidence intervals, and other measures of statistical accuracy. Stat. Sci. 1986, 1, 54–75. [Google Scholar] [CrossRef]

- Suszanowicz, D. Internal heat gain from different light sources in the building lighting systems. In E3S Web of Conferences; EDP Sciences: Yulis, France, 2017; Volume 19, p. 01024. [Google Scholar]

- Stamp, S.; Lowe, R.; Altamirano-Medina, H. Using simulated co-heating tests to understand weather driven sources of uncertainty within the co-heating test method. In Proceedings of the ECEEE 2013 Summer Study, Toulon/Hyères, France, 3–8 June 2013; pp. 2049–2055. [Google Scholar]

- Kronvall, J. Testing of houses for air leakage using a pressure method. ASHRAE Trans. 1978, 84, 72–79. [Google Scholar]

| Building Component | Composition (From Inside to Outside, Layer Thicknesses in (m)) | A (m2) | U (W/m2·K) | bT (-) | |

|---|---|---|---|---|---|

| External wall | type 1 | plaster finish (0.015), lightweight brick inner leaf (0.14), unfilled cavity (0.055), brick outer leaf (0.09) | 133.1 | 1.3 | 1.0 |

| type 2 | plaster finish (0.015), lightweight brick inner leaf (0.09), unfilled cavity (0.055), brick outer leaf (0.09) | 55.4 | 1.5 | 1.0 | |

| type 3 | lightweight brick inner leaf (0.14), unfilled cavity (0.045), wood cladding (0.015) | 16.5 | 1.4 | 1.0 | |

| Floor slab | on ground | tiles (0.01), sand bed (0.04), concrete slab (0.15) | 111.8 | 0.9 | 1.0 |

| above cellar | tiles (0.01), sand bed (0.04), hollow-core concrete slab (0.15) | 20.3 | 1.7 | 0.8 | |

| Attic floor | type 1 | hollow-core concrete slab (0.15), XPS insulation (0.10) | 38.1 | 0.3 | 0.9 |

| type 2 | hollow-core concrete slab (0.20), XPS insulation (0.10) | 33.8 | 0.3 | 0.9 | |

| Roof | pitched, type 1 | gypsum board (0.014), rafters (0.15), oriented strand board (OSB) (0.02), battens and counter battens, ceramic tiles | 22.8 | 1.6 | 1.0 |

| pitched, type 2 | gypsum board (0.014), mineral wool with aluminum foil facing between rafters (0.15), oriented strand board (OSB) (0.02), battens and counter battens, ceramic tiles | 15.0 | 0.4 | 1.0 | |

| flat | gypsum board (0.014), wood frame layer (0.27), oriented strand board (OSB) (0.02), bitumen roofing | 37.9 | 1.6 | 1.0 | |

| External doors | uninsulated polyvinyl chloride (PVC) door leaf | 3.0 | 4.0 | 1.0 | |

| Garage door | uninsulated PVC door leaf | 5.4 | 4.0 | 1.0 | |

| External Window | type 1 | aluminum-framed double glazing with selective coating | 22.7 | 1.8 | 1.0 |

| type 2 | PVC-framed double glazing with selective coating | 13.0 | 3.0 | 1.0 | |

| skylight | PVC-framed double glazing with selective coating | 1.5 | 1.6 | 1.0 | |

| Monitored Variable | Specifications of Instrumentation | ||||

|---|---|---|---|---|---|

| Description | Abbreviation | type | Sampling time | Resolution | Accuracy |

| Heat output of the boiler for space heating | Φh,meter | Flow: Micronics, U1000 Temperature: JUMO, Pt500 Integrator: Zenner, multidata | 10 min | 1 kW·h | 3% for flow, unspecified for temperature reading |

| Mains electricity consumption | ElecOBM | Fluksometer | 5 min | 1 W | 2–6% |

| Interior temperature in the attic, cellar, and all rooms except for the former garage and landing. | θi,<room> | Onset, HOBO UX100-003 | 10 min | 0.024 °C | 0.21 °C |

| Exterior temperature (Ghent) | θe,Ghent | Vaisala, HMS82 | 1 min | 0.00001 °C | 0.3 °C |

| Global horizontal radiation (Ghent) | GHRGhent | Kipp&Zonen, SP Lite2 | 1 min | 0.00001 W/m2 | <10 W/m2 |

| Exterior temperature (Uccle) | θe,Uccle | Thermibel, Pt100 | 1 h | 0.1 °C | 0.2 °C |

| Global horizontal radiation (Uccle) | GHRUccle | Kipp&Zonen, CNR1 | 1 h | 0.1 W/m2 | 10% |

| Method | Model Equation | |

|---|---|---|

| Avg | (13) | |

| LR | (14) | |

| (15) | ||

| ES | (16) | |

| (17) | ||

| (18) | ||

| ARX | (19) | |

| (20) | ||

| (21) | ||

| Data Package | Analysis Method | |||||||

|---|---|---|---|---|---|---|---|---|

| Name | Content | Avg. | LR | ES | ARX | |||

| OBM Data | Additional Knowledge | Assumptions (*) | ||||||

| Impact of representation of exterior and interior temperature | ||||||||

| 1 | 1G | Φh,meter, θe,Ghent | / | θi = 18°C, Φint = 0, Φsol = 0 | ✓ | ✓ | ✓ | ✓ |

| 1U | Φh,meter, θe,Uccle | / | θi = 18°C, Φint = 0, Φsol = 0, | ✓ | ✓ | ✓ | ✓ | |

| 2 | 2G | Φh,meter, θe,Ghent, θi,liv | / | θi = θi,living, Φint = 0, Φsol = 0 | ✓ | ✓ | ✓ | |

| 2U | Φh,meter, θe,Uccle, θi,liv | / | θi = θi,living, Φint = 0, Φsol = 0 | ✓ | ✓ | ✓ | ||

| 3G | Φh,meter, θe,Ghent, θi,liv, θi,bed | / | θi = θi,AM, Φint = 0, Φsol = 0 | ✓ | ✓ | ✓ | ||

| 4 | 4G,AM1 | Φh,meter, θe,Ghent, θi all rooms | / | θi = mean(θi,AM), Φint = 0, Φsol = 0 | ✓ | ✓ | ✓ | |

| 4G,AM2 | Φh,meter, θe,Ghent, θi all rooms | / | θi = θi,AM, Φint = 0, Φsol = 0 | ✓ | ✓ | ✓ | ||

| 4G,Vw | Φh,meter, θe,Ghent, θi all rooms | Vrooms | θi = θi,Vw, Φint = 0, Φsol = 0 | ✓ | ✓ | ✓ | ||

| 4G,Aw | Φh,meter, θe,Ghent, θi all rooms | Arooms | θi = θi,Aw, Φint = 0, Φsol = 0 | ✓ | ✓ | ✓ | ||

| 4G,UAw | Φh,meter, θe,Ghent, θi all rooms | Arooms, U-values | θi = θi,UAw, Φint = 0, Φsol = 0 | ✓ | ✓ | ✓ | ||

| 4U,UAw | Φh,meter, θe,Uccle, θi all rooms | Arooms, U-values | θi = θi,UAw, Φint = 0, Φsol = 0 | ✓ | v | v | ||

| Impact of representation of internal heat gains | ||||||||

| 5 | 5G,liv | Φh,meter, θe,Ghent, θi,liv | electricity bill | θi = θi,living, Φint = Elecbill, Φsol = 0 | ✓ | ✓ | ✓ | |

| 5G,UAw | Φh,meter, θe,Ghent, θi all rooms | Arooms, U-values, electricity bill | θi = θi,UAw, Φint = Elecbill, Φsol = 0 | ✓ | ✓ | ✓ | ||

| 6 | 6G,liv | Φh,meter, θe,Ghent, θi,liv, ElecOBM | / | θi = θi,living, Φint = ElecOBM, Φsol = 0 | ✓ | ✓ | ✓ | |

| 6G,UAw | Φh,meter, θe,Ghent, θi all rooms, ElecOBM | Arooms, U-values | θi = θi,UAw, Φint = ElecOBM, Φsol = 0 | ✓ | ✓ | ✓ | ||

| 6U,liv | Φh,meter, θe,Uccle, θi,liv, ElecOBM | / | θi = θi,living, Φnt = ElecOBM, Φsol = 0 | ✓ | ✓ | ✓ | ||

| 6U,UAw | Φh,meter, θe,Uccle, θi all rooms, ElecOBM | Arooms, U-values | θi = θi,UAw, Φint = ElecOBM, Φsol = 0 | ✓ | ✓ | ✓ | ||

| 7 | 7G,liv | Φh,meter, θe,Ghent, θi,liv, ElecOBM | occupancy | θi = θi,living, Φint = (ElecOBM+MHG), Φsol = 0 | ✓ | ✓ | ✓ | |

| 7G,UAw | Φh,meter, θe,Ghent, θi all rooms, ElecOBM | Arooms, U-values, occupancy | θi = θi,UAw, Φint = (ElecOBM+MHG), Φsol = 0 | ✓ | ✓ | ✓ | ||

| 7U,liv | Φh,meter, θe,Uccle, θi,liv, ElecOBM | occupancy | θi = θi,living, Φint = (ElecOBM+MHG), Φsol = 0 | ✓ | ✓ | ✓ | ||

| 7U,UAw | Φh,meter, θe,Uccle, θi all rooms, ElecOBM | Arooms, U-values, occupancy | θi = θi,UAw, Φint = (ElecOBM+MHG), Φsol = 0 | ✓ | ✓ | ✓ | ||

| Impact of representation of solar heat gains | ||||||||

| 8 | 8G,liv | Φh,meter, θe,Ghent, θi,liv, GHRGhent | / | θi = θi,living, Φint = 0, Φsol = gAl·GHRGhent (**) | ✓ | ✓ | ||

| 8G,UAw | Φh,meter, θe,Ghent, θi all rooms, GHRGhent | Arooms, U-values | θi = θi,UAw, Φint = 0, Φsol = gAl·GHRGhent (**) | ✓ | ✓ | |||

| 9 | 9G,liv | Φh,meter, θe,Ghent, θi,liv, ElecOBM, GHRGhent | / | θi = θi,living, Φint = ElecOBM, Φsol = gAl·GHRGhent (**) | ✓ | ✓ | ||

| 9G,UAw | Φh,meter, θe,Ghent, θi all rooms, ElecOBM, GHRGhent | Arooms, U-values | θi = θi,UAw, Φint = ElecOBM, Φsol = gAl·GHRGhent (**) | ✓ | ✓ | |||

| 9U,liv | Φh,meter, θe,Uccle, θi,liv, ElecOBM, GHRUccle | / | θi = θi,living, Φint = ElecOBM, Φsol = gAl·GHRUccle (**) | ✓ | ✓ | |||

| 9U,UAw | Φh,meter, θe,Uccle, θi all rooms, ElecOBM, GHRUccle | Arooms, U-values | θi = θi,UAw, Φint = ElecOBM, Φsol = gAl·GHRUccle (**) | ✓ | ✓ | |||

| 10 | 10G,liv | Φh,meter, θe,Ghent, θi,liv, ElecOBM, GHRGhent | occupancy | θi = θi,living, Φint = (ElecOBM+MHG), Φsol = gAl·GHRGhent (**) | ✓ | ✓ | ||

| 10G,UAw | Φh,meter, θe,Ghent, θi all rooms, ElecOBM, GHRGhent | Arooms, U-values, occupancy | θi = θi,UAw, Φint = (ElecOBM+MHG), Φsol = gAl·GHRGhent (**) | ✓ | ✓ | |||

| 10U,liv | Φh,meter, θe,Uccle, θi,liv, ElecOBM, GHRUccle | occupancy | θi = θi,living, Φint = (ElecOBM+MHG), Φsol = gAl·GHRUccle (**) | ✓ | ✓ | |||

| 10U,UAw | Φh,meter, θe,Uccle, θi all rooms, ElecOBM, GHRUccle | Arooms, U-values, occupancy | θi = θi,UAw, Φint = (ElecOBM+MHG), Φsol = gAl·GHRUccle (**) | ✓ | ✓ | |||

| 11 | 11U,liv | Φh,meter, θe,Uccle, θi,liv, ElecOBM, GHRUccle | solar radiation algorithm | θi = θi,living, Φint = ElecOBM, Φsol = gAl·Isol,S,Uccle (**) | ✓ | ✓ | ||

| 11U,UAw | Φh,meter, θe,Uccle, θi all rooms, ElecOBM, GHRUccle | Arooms, U-values, solar radiation algorithm | θi = θi,UAw, Φint = ElecOBM, Φsol = gAl·Isol,S,Uccle (**) | ✓ | ✓ | |||

| 12 | 12U,liv | Φh,meter, θe,Uccle, θi,liv, ElecOBM, GHRUccle | occupancy, window positioning, solar radiation algorithm | θi = θi,living, Φint = (ElecOBM+MHG), Φsol = Φsol,synth | ✓ | ✓ | ✓ | |

| 12U,UAw | Φh,meter, θe,Uccle, θi all rooms, ElecOBM, GHRUccle | Arooms, U-values, occupancy, window positioning, solar radiation algorithm | θi = θi,UAw, Φint = (ElecOBM+MHG), Φsol = Φsol,synth | ✓ | ✓ | ✓ | ||

| Time Period | 11 p.m.–7 a.m. | 7 a.m.–9 a.m. | 9 a.m.–5 p.m. | 5 p.m.–8 p.m. | 8 p.m.–11 p.m. |

|---|---|---|---|---|---|

| Number of persons, M/F | 1 M, 2 F | 1 M, 2 F | 0 | 1 M, 2 F | 1 M, 2 F |

| Activity | sleeping | standing, medium activity | - | standing, medium activity | sedentary activity |

| MHG (W) | 200 | 575 | 0 | 575 | 350 |

| Temperature Signal | θi,liv | θi,AM(bed, liv) | θi,AM(all) = θi,AM2 | θi,Vw | θi,Aw | θi,UAw | θe,Ghent | θe,Uccle |

|---|---|---|---|---|---|---|---|---|

| Mean (°C) | 18.7 | 17.0 | 16.6 | 16.6 | 16.0 | 15.9 | 4.47 | 3.94 |

| Sd (°C) | 1.00 | 0.93 | 1.13 | 1.07 | 1.14 | 1.16 | 3.70 | 4.03 |

| Input Data for Φint | Elecbill (Included in 5G) | ElecOBM (Included in 6G) | ElecOBM + MHG (Included in 7G) |

|---|---|---|---|

| Mean (± σ), six-hourly data (W) | 387.1 (± 0.0) | 418.8 (± 327.8) | 649.0 (± 337.0) |

| Mean (± σ), daily data (W) | 387.1 (± 0.0) | 418.8 (± 180.3) | 649.0 (± 180.3) |

| Total consumption (GJ) | 3.0 | 3.3 | 5.0 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Senave, M.; Roels, S.; Verbeke, S.; Lambie, E.; Saelens, D. Sensitivity of Characterizing the Heat Loss Coefficient through On-Board Monitoring: A Case Study Analysis. Energies 2019, 12, 3322. https://doi.org/10.3390/en12173322

Senave M, Roels S, Verbeke S, Lambie E, Saelens D. Sensitivity of Characterizing the Heat Loss Coefficient through On-Board Monitoring: A Case Study Analysis. Energies. 2019; 12(17):3322. https://doi.org/10.3390/en12173322

Chicago/Turabian StyleSenave, Marieline, Staf Roels, Stijn Verbeke, Evi Lambie, and Dirk Saelens. 2019. "Sensitivity of Characterizing the Heat Loss Coefficient through On-Board Monitoring: A Case Study Analysis" Energies 12, no. 17: 3322. https://doi.org/10.3390/en12173322

APA StyleSenave, M., Roels, S., Verbeke, S., Lambie, E., & Saelens, D. (2019). Sensitivity of Characterizing the Heat Loss Coefficient through On-Board Monitoring: A Case Study Analysis. Energies, 12(17), 3322. https://doi.org/10.3390/en12173322