Optimization of Air Distribution to Reduce NOx Emission and Unburned Carbon for the Retrofit of a 500 MWe Tangential-Firing Coal Boiler

Abstract

:1. Introduction

2. Target Boilers and Numerical Methods

2.1. Target Boiler and Operation Conditions

2.2. CFD Modeling

3. Results

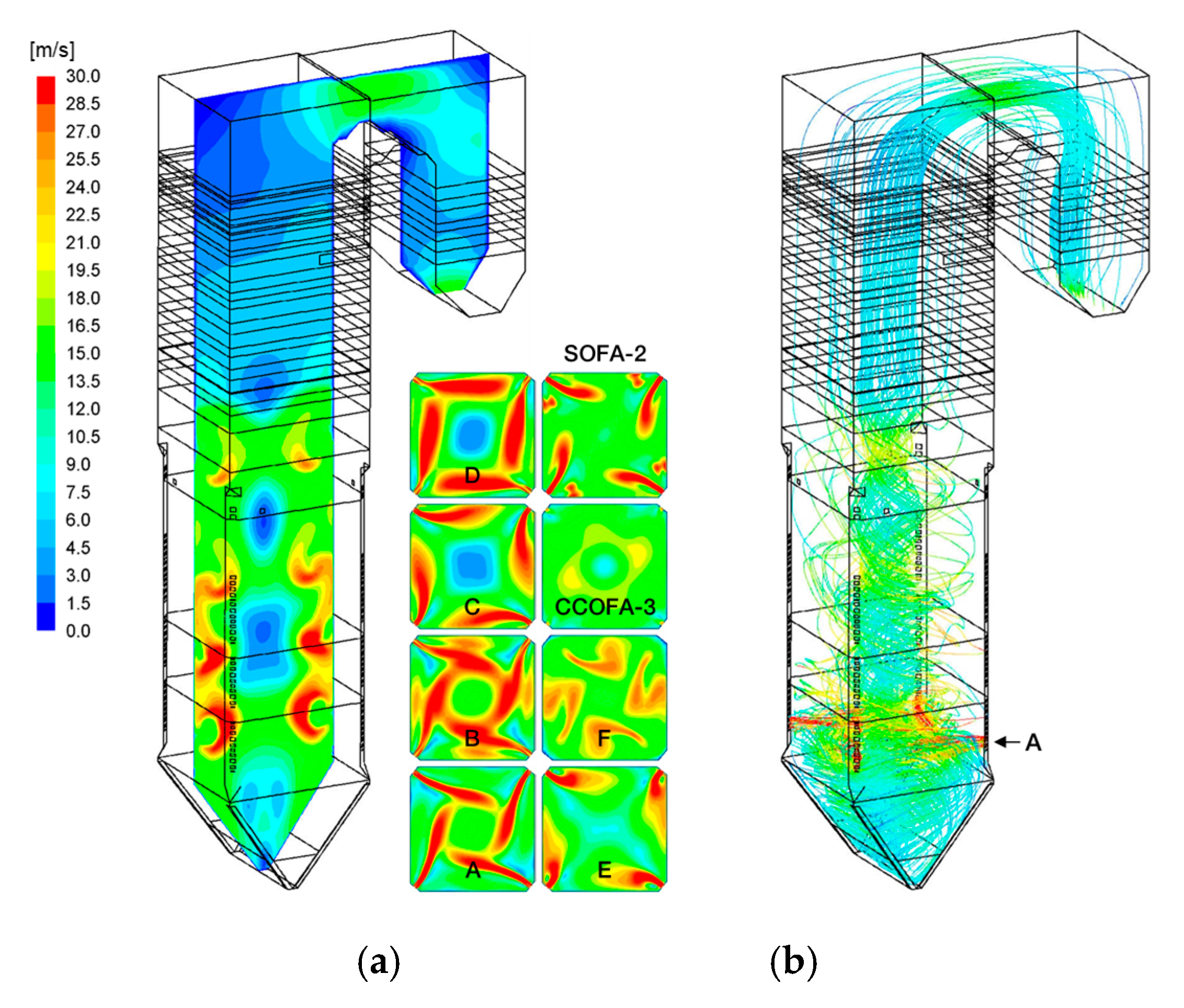

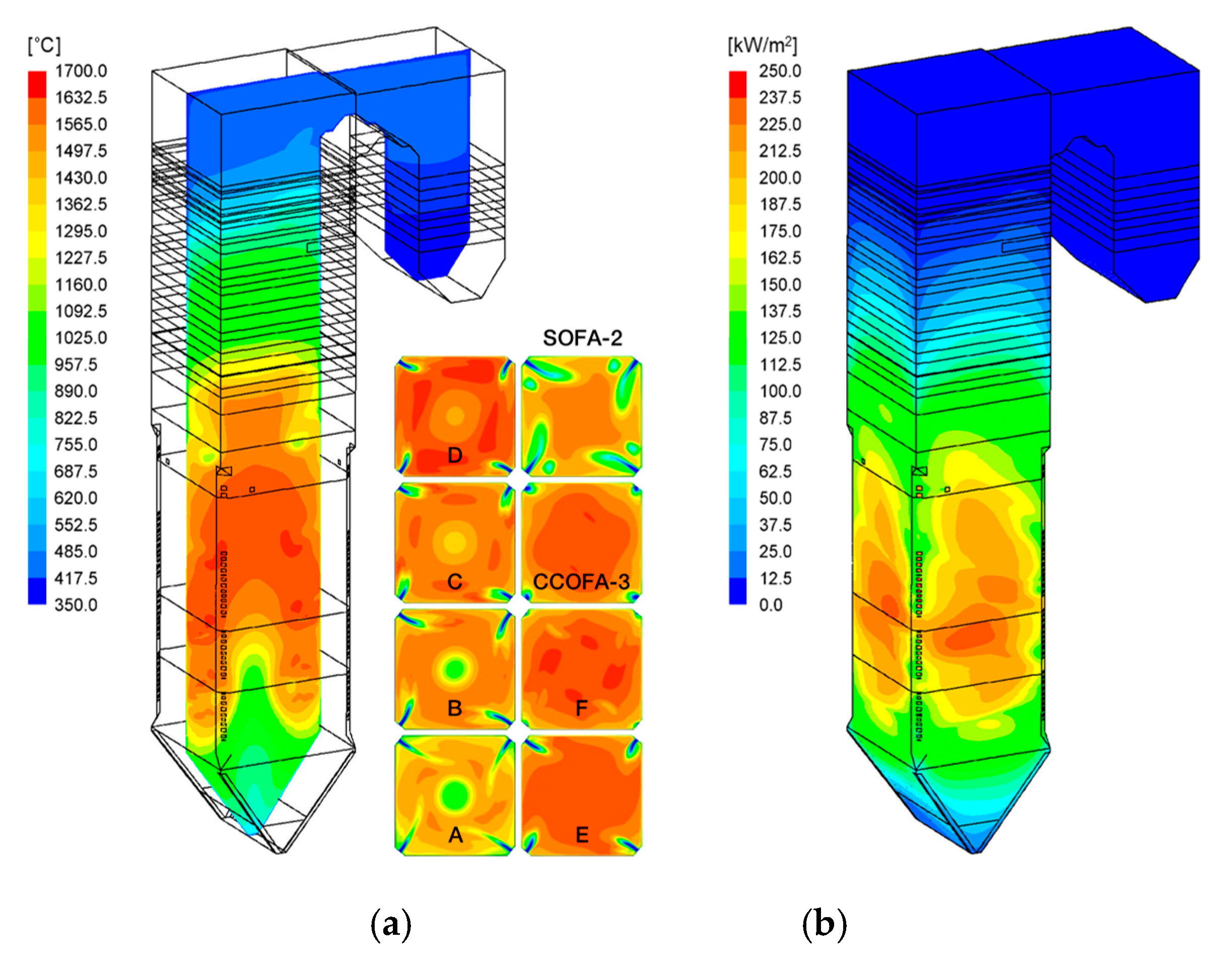

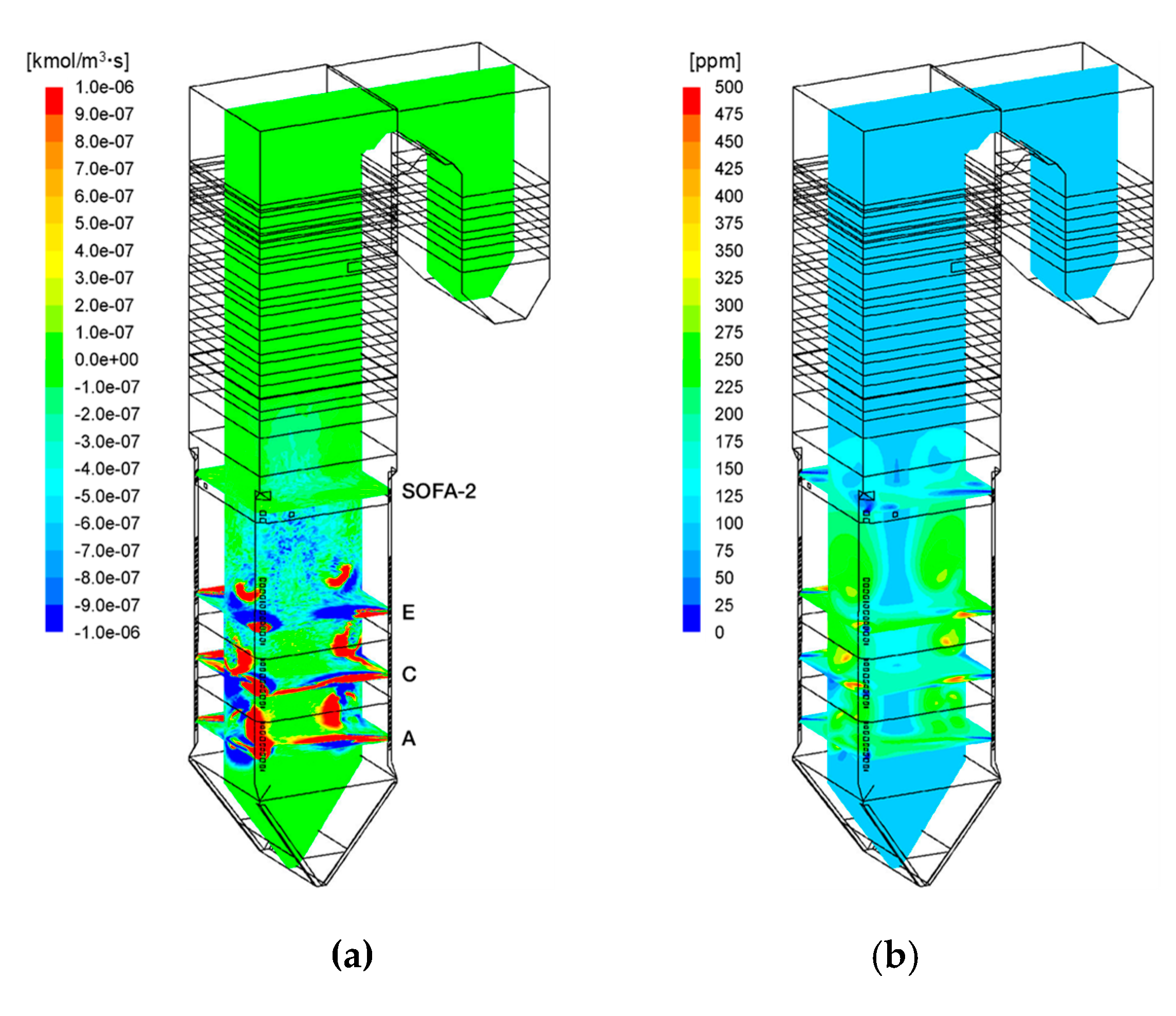

3.1. Reaction and Heat Transfer in the Reference Case

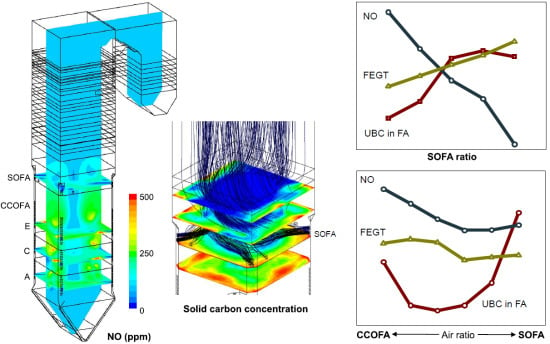

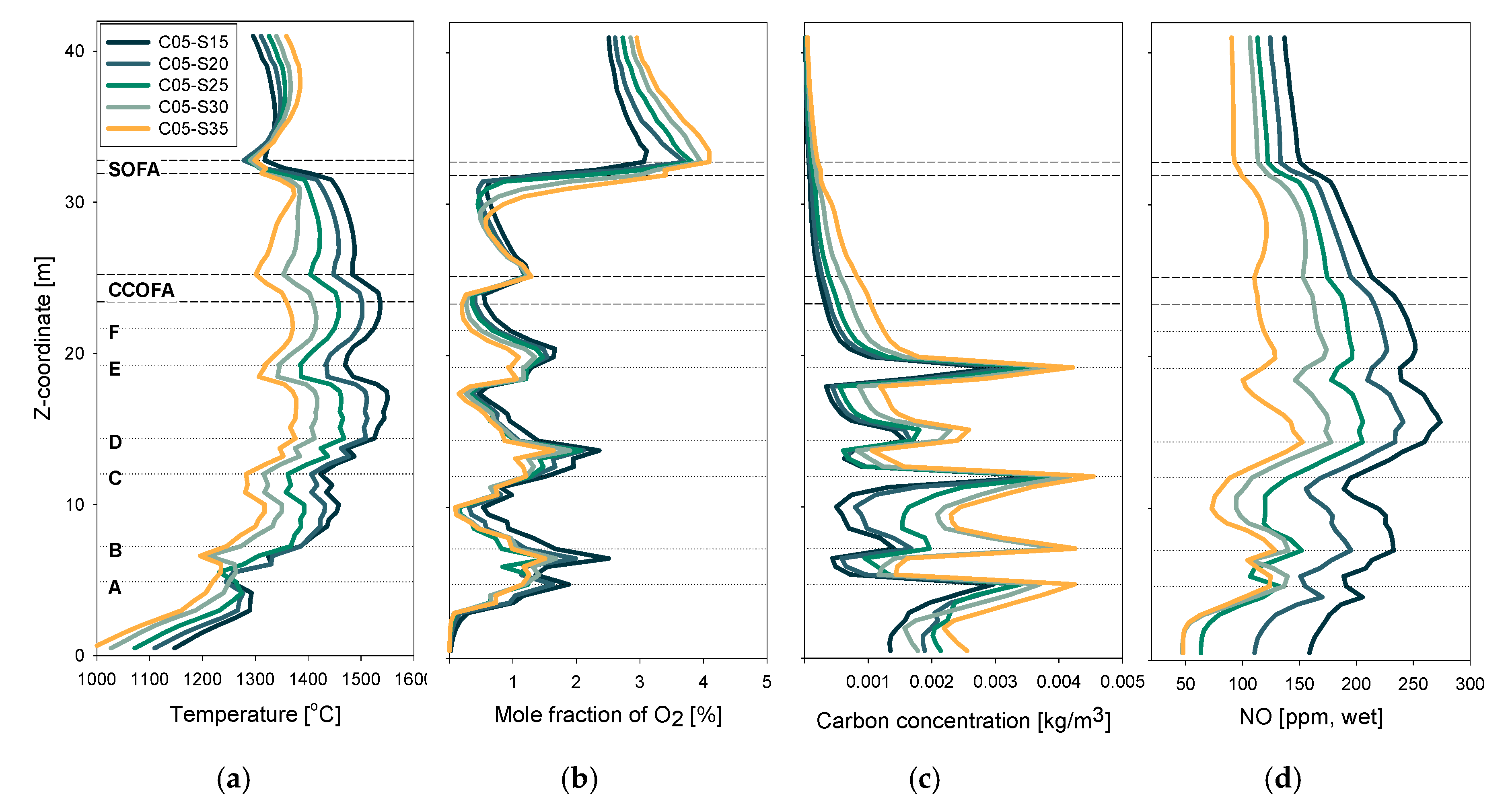

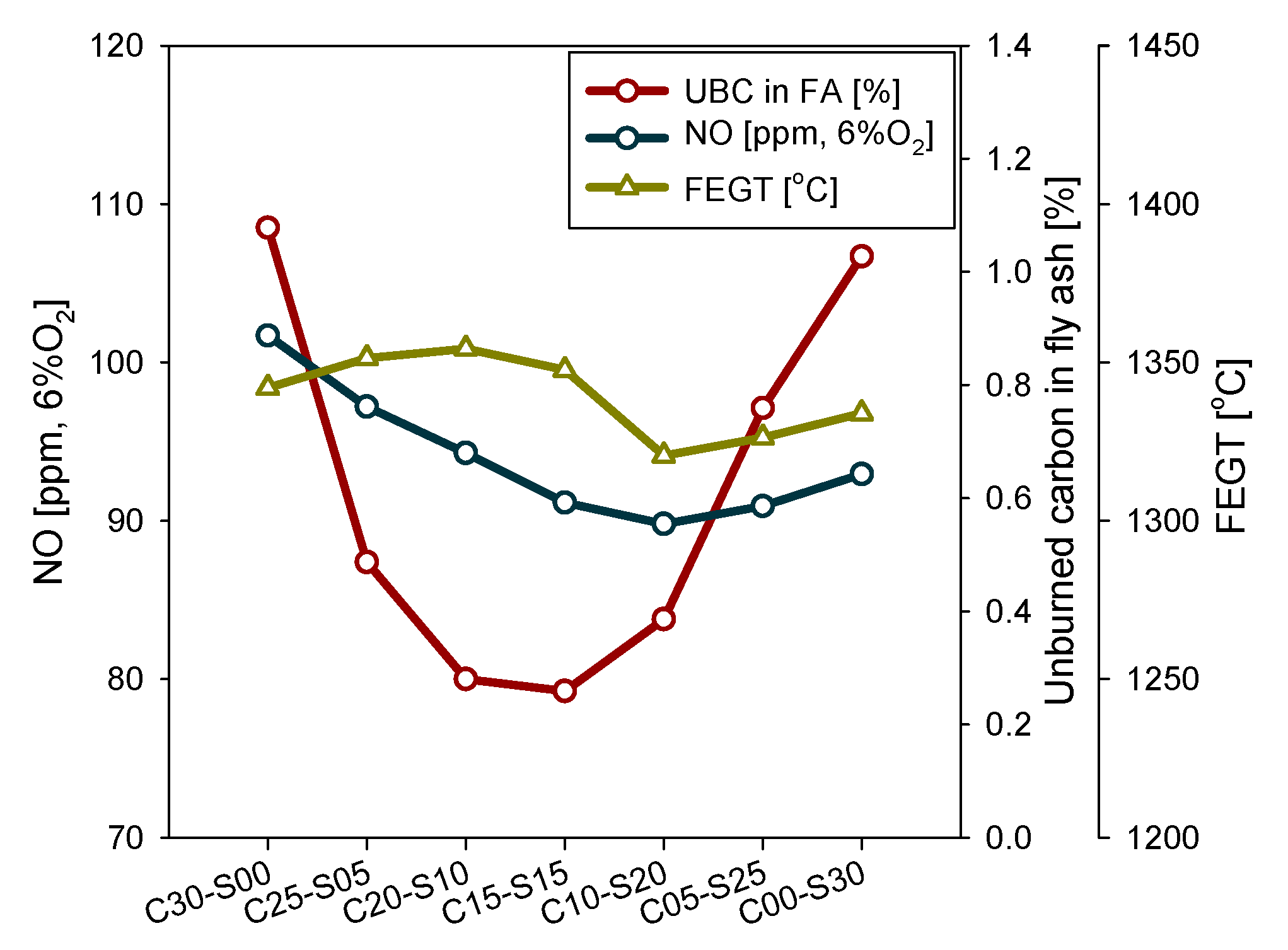

3.2. Influence of SOFA Ratios

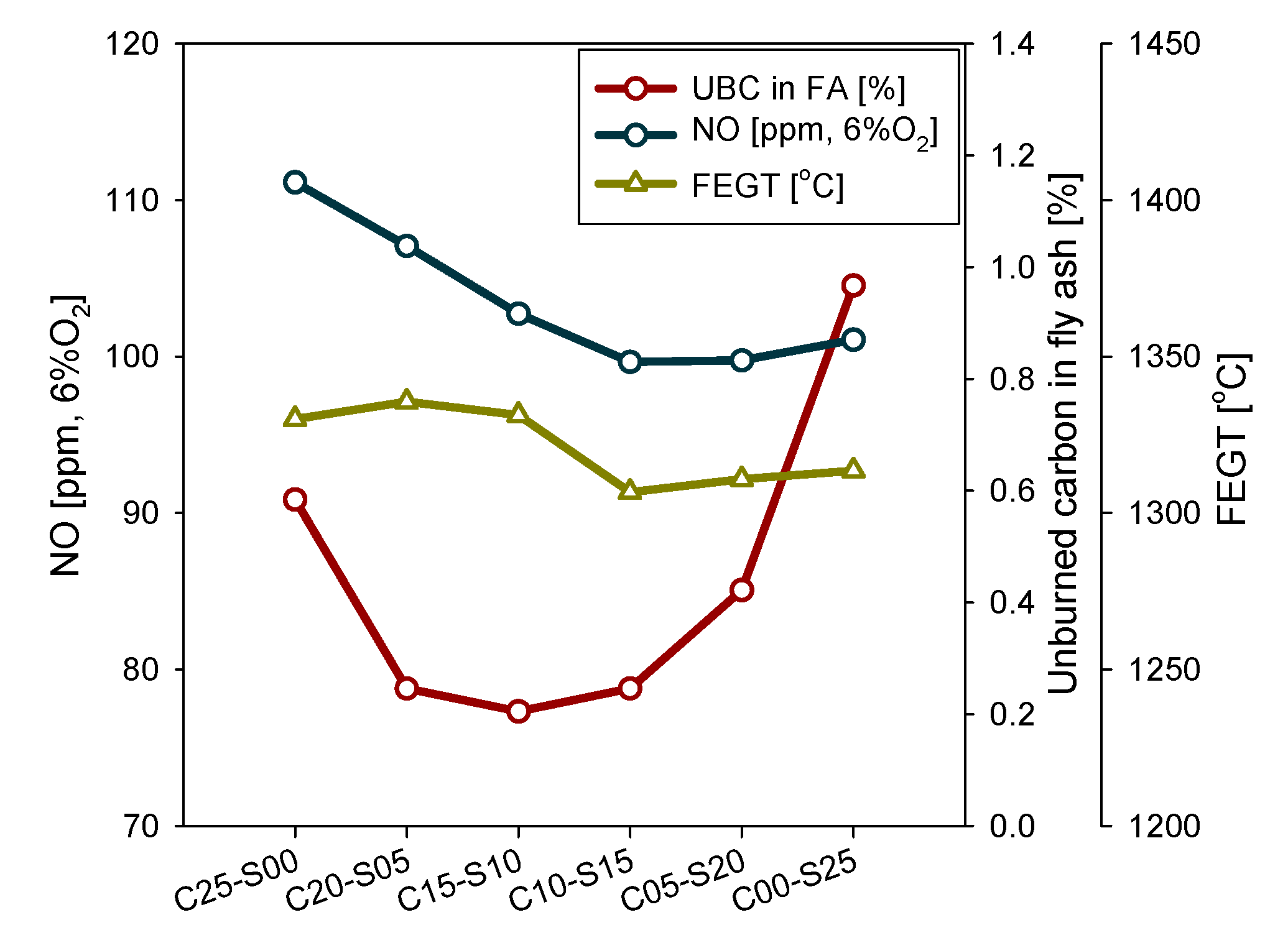

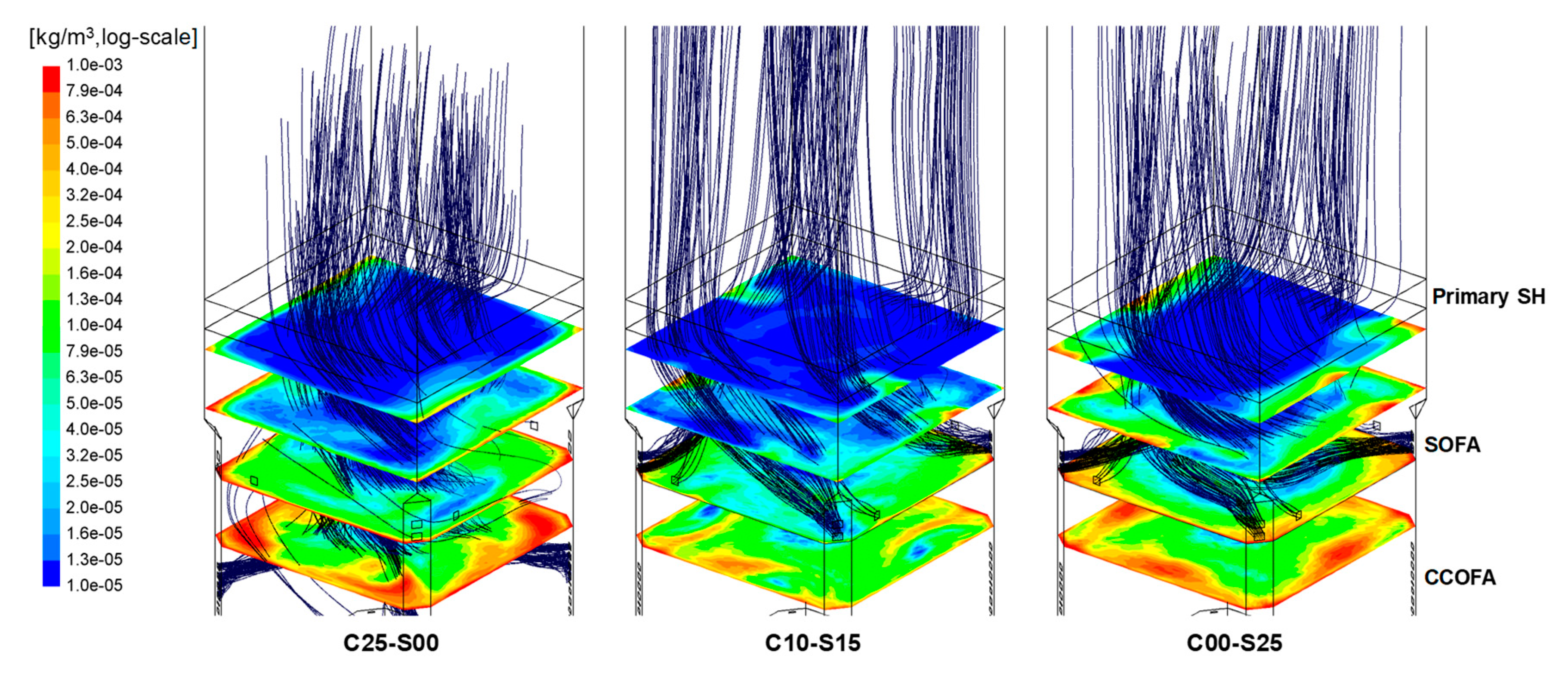

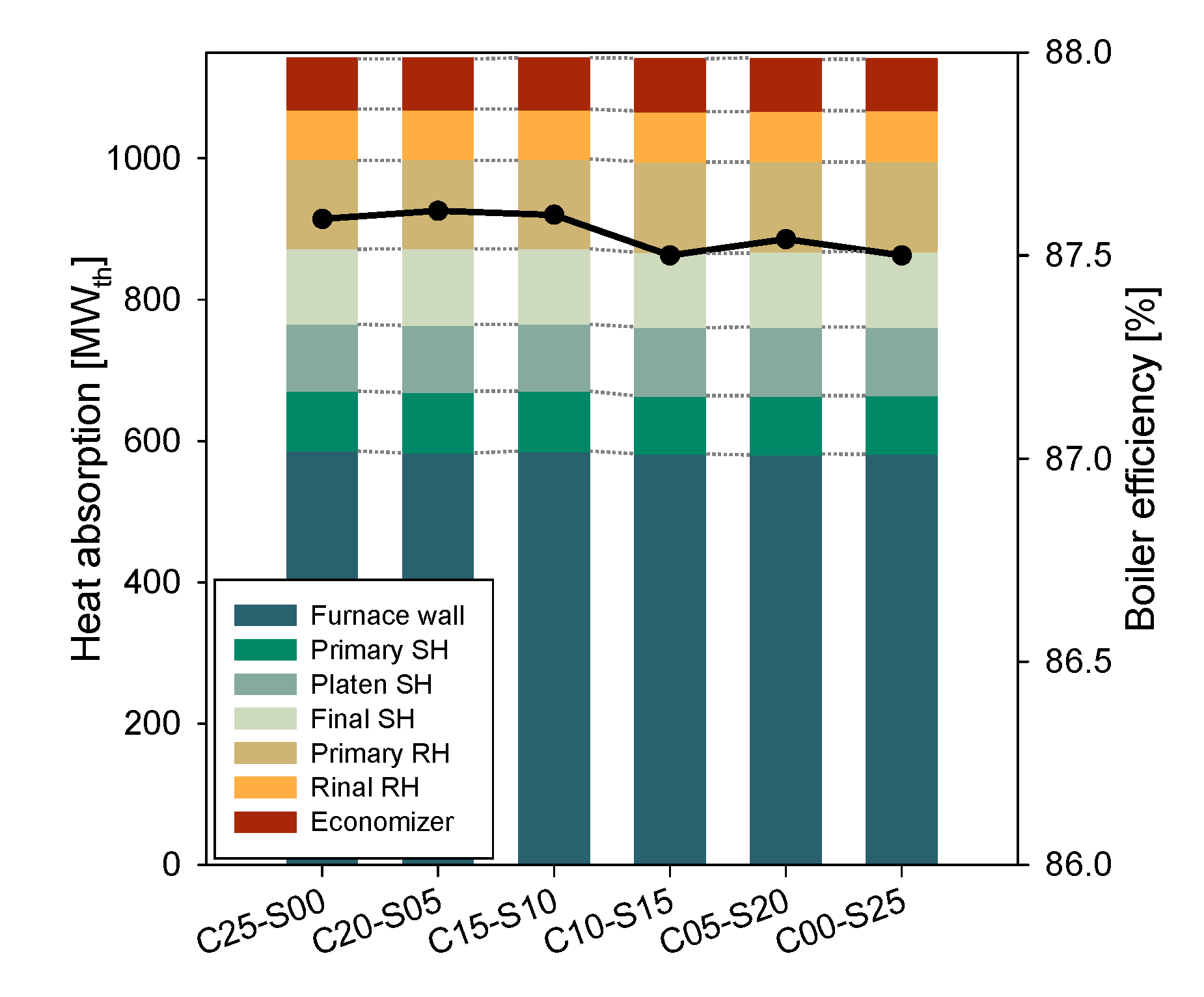

3.3. Influence of Different Air Distributions between SOFA and CCOFA

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Symbols | |

| A | Pre-exponential factor [s−1] |

| As | Specific tube surface area per unit volume [m2/m3] |

| d | Diameter [cm] |

| D | Tube diameter [cm] |

| E | Activation energy [kJ/kmol] |

| f | Correction factor |

| f’ | Friction factor |

| G | Mass velocity [kg/m2·s] |

| Keq | Chemical equilibrium constant |

| k | Reaction rate [g⋅cm−2⋅atm−1⋅s−1], Thermal conductivity [W/m·K] |

| N | Number of tube |

| Nu | Nusselt number |

| P | Pressure [atm] |

| Pr | Prandtl number |

| Δp | Pressure difference [atm] |

| Volumetric heat sink [W/m3] | |

| R | Universal gas constant, Reaction rate of char [g⋅cm−2⋅s−1] |

| Re | Reynolds number |

| S | Pitch [m] |

| T | Temperature [K] |

| V | Volatile matter [kg] |

| Y | Char core to particle diameter ratio |

| Greek Symbols | |

| ε | Porosity of the ash layer, Emissivity |

| ρ | Density [kg/m3] |

| μ | Viscosity [kg/m·s] |

| σ | Stefan-Boltzman constant (5.67 × 10−8 [W/m2·K4]) |

| Subscripts | |

| char | Unreacted char core |

| conv | Convection |

| diff | Diffusion rate |

| dash | Diffusion rate in the ash-layer |

| gas | Gas |

| i | Index of gasification reaction |

| L | Longitudinal |

| max | Maximum |

| o | Initial |

| p | Particle |

| rad | Radiation |

| s | Surface |

| t | Total pressure |

| T | Transverse |

References

- Kim, H.C.; Kim, S.; Kim, B.-U.; Jin, C.-S.; Hong, S.; Park, R.; Son, S.-W.; Bae, C.; Bae, M.; Song, C.-K.; et al. Recent increase of surface particulate matter concentrations in the Seoul Metropolitan Area, Korea. Sci. Rep. 2017, 7, 4710. [Google Scholar] [CrossRef] [PubMed]

- Choi, J.; Park, R.J.; Lee, H.-M.; Lee, S.; Jo, D.S.; Jeong, J.I.; Henze, D.K.; Woo, J.-H.; Ban, S.-J.; Lee, M.-D.; et al. Impacts of local vs. trans-boundary emissions from different sectors on PM2.5 exposure in South Korea during the KORUS-AQ campaign. Atmos. Environ. 2019, 203, 196–205. [Google Scholar] [CrossRef]

- Nalbandian, H. NOx Control for Coal-Fired Plant; CCC/157; IEA Clean Coal Centre: London, UK, 2009. [Google Scholar]

- Kang, K.; Ryu, C. Numerical simulation on the effects of air staging for pulverized coal combustion in a tangential-firing boiler. Korean Chem. Eng. Res. 2017, 55, 548–555. [Google Scholar]

- Sankar, G.; Kumar, D.S.; Balasubramanian, K.S. Computational modeling of pulverized coal fired boilers–a review on the current position. Fuel 2019, 236, 643–665. [Google Scholar] [CrossRef]

- Zhou, H.; Mo, G.; Si, D.; Cen, K. Numerical simulation of the NOx emissions in a 1000 MW tangentially fired pulverized-coal boiler: Influence of the multi-group arrangement of the separated over fire air. Energy Fuels 2011, 25, 2004–2012. [Google Scholar] [CrossRef]

- Ma, L.; Fang, Q.Y.; Lv, D.Z.; Zhang, C.; Chen, Y.P.; Chen, G.; Duan, X.N.; Wang, X.H. Reducing NOx emissions for a 600 MWe down-fired pulverized-coal utility boiler by applying a novel combustion system. Environ. Sci. Technol. 2015, 49, 13040–13049. [Google Scholar] [CrossRef] [PubMed]

- Ma, L.; Fang, Q.; Tan, P.; Zhang, C.; Chen, G.; Lv, D.; Duan, X.; Chen, Y. Effect of the separated overfire air location on the combustion optimization and NOx reduction of a 600 MWe FW down-fired utility boiler with a novel combustion system. Appl. Energy 2016, 180, 104–115. [Google Scholar] [CrossRef]

- Zha, Q.; Li, D.; Wang, C.A.; Che, D. Numerical evaluation of heat transfer and NOx emissions under deep-air-staging conditions within a 600 MWe tangentially fired pulverized-coal boiler. Appl. Therm. Eng. 2017, 116, 170–181. [Google Scholar] [CrossRef]

- Qi, X.; Yang, M.; Zhang, Y. Numerical analysis of NOx production under the air staged combustion. Front. Heat Mass Transf. 2017, 8, 1–8. [Google Scholar]

- Zheng, Y.; Gao, X.; Sheng, C. Impact of co-firing lean coal on NOx emission of a large-scale pulverized coal-fired utility boiler during partial load operation. Korean J. Chem. Eng. 2017, 34, 1273–1280. [Google Scholar] [CrossRef]

- Stupar, G.; Tucaković, D.; Živanović, T.; Stevanović, Ž.; Belošević, S. Predicting effects of air staging application on existing coal-fired power steam boiler. Appl. Therm. Eng. 2019, 149, 665–677. [Google Scholar] [CrossRef]

- Yang, W.; Wang, B.; Lei, S.; Wang, K.; Chen, T.; Song, Z.; Ma, C.; Zhou, Y.; Sun, L. Combustion optimization and NOx reduction of a 600 MWe downfired boiler by rearrangement of swirl burner and introduction of separated over-fire air. J. Clean Prod. 2019, 210, 1120–1130. [Google Scholar] [CrossRef]

- Li, S.; Xu, T.; Hui, S.; Wei, X. NOx emission and thermal efficiency of a 300 MWe utility boiler retrofitted by air staging. Appl. Energy 2009, 86, 1797–1803. [Google Scholar] [CrossRef]

- Wu, X.; Fan, W.; Liu, Y.; Bian, B. Numerical simulation research on the unique thermal deviation in a 1000 MW tower type boiler. Energy 2019, 173, 1006–1020. [Google Scholar] [CrossRef]

- Liu, Y.C.; Fan, W.D.; Wu, M.Z. Experimental and numerical studies on the gas velocity deviation in a 600 MWe tangentially fired boiler. Appl. Therm. Eng. 2017, 110, 553–563. [Google Scholar] [CrossRef]

- Park, H.Y.; Baek, S.H.; Kim, H.H.; Kim, Y.J.; Kim, T.H.; Lim, H.S.; Kang, D.S. Reduction of main steam temperature deviation in a tangentially coal-fired, two pass boiler. Fuel 2016, 166, 509–516. [Google Scholar] [CrossRef]

- Xu, L.; Huang, Y.; Zou, L.; Yue, J.; Wang, J.; Liu, C.; Liu, L.; Dong, L. Experimental research of mitigation strategy for high-temperature corrosion of waterwall fireside in a 630 MWe tangentially fired utility boiler based on combustion adjustments. Fuel Process. Tech. 2019, 188, 1–15. [Google Scholar] [CrossRef]

- Jo, H.; Kang, K.; Park, J.; Ryu, C.; Ahn, H.; Go, Y. Detailed assessment of mesh sensitivity and coupled iteration method for CFD simulation of coal combustion in a tangential-firing boiler. J. Mech. Sci. Technol. 2019. under review. [Google Scholar]

- ANSYS Inc. ANSYS Fluent User Guide; ANSYS Inc.: Cannonsburg, PA, USA, 2016. [Google Scholar]

- Niksa, S. PC Coal Lab Version 4.1: User Guide and Tutorial; Niksa Energy Associates LLC: Belmont, CA, USA, 1997. [Google Scholar]

- Wen, C.Y.; Chaung, T.Z. Entrainment coal Gasification Modeling. Ind. Eng. Chem. Process Des. Dev. 1979, 18, 684–695. [Google Scholar] [CrossRef]

- Jones, W.P.; Lindstedt, R.P. Global reaction schemes for hydrocarbon combustion. Combust. Flame 1988, 73, 233–249. [Google Scholar] [CrossRef]

- Smoot, L.D.; Smith, P.J. Coal Combustion and Gasification; Plenum Press: New York, NY, USA, 1985. [Google Scholar]

- Magnussen, B.F.; Hjertager, B.H. On mathematical models of turbulent combustion with special emphasis on soot formation and combustion. Proc. Combust. Inst. 1977, 16, 719–729. [Google Scholar] [CrossRef]

- Hanson, R.K.; Salimian, S. Survey of rate constants in H/N/O systems. In Combustion Chemistry; Gardiner, W.C., Ed.; Springer: New York, NY, USA, 1984; p. 361. [Google Scholar]

- De Soete, G.G. Overall reaction rates of NO and N2 formation from fuel nitrogen. Proc. Combust. Inst. 1975, 15, 1093–1102. [Google Scholar] [CrossRef]

- Smith, T.F.; Shen, Z.F.; Friedman, J.N. Evaluation of coefficients for the weighted sum of gray gases model. J. Heat Transf. 1982, 104, 602–608. [Google Scholar] [CrossRef]

- Park, H.Y.; Lee, J.E.; Kim, H.H.; Park, S.; Beak, S.H.; Ye, I.; Ryu, C. Thermal resistance by slagging and its relationship with ash properties for six coal blends in a commercial coal-fired boiler. Fuel 2019, 235, 1377–1386. [Google Scholar] [CrossRef]

- Park, J.K.; Park, S.; Kim, M.K.; Ryu, C.; Baek, S.H.; Kim, Y.J.; Kim, H.H.; Park, H.Y. CFD analysis of combustion characteristics for fuel switching to bioliquid in oil-fired power plant. Fuel 2015, 159, 324–333. [Google Scholar] [CrossRef]

- Jakob, M. Heat transfer and flow resistance in cross flow of gases over tube banks. Trans. ASME 1938, 60, 384–386. [Google Scholar]

- Zukauskas, A. Heat transfer from tubes in cross flow. In Advances in Heat Transfer; Hartnett, J.P., Irvine, T.F., Jr., Eds.; Academic Press: New York, NY, USA, 1972; Volume 8, pp. 93–160. [Google Scholar]

- Kung, S.C. Further understanding of furnace wall corrosion in coal-fired boilers. Corrosion 2014, 70, 749–763. [Google Scholar] [CrossRef]

| Input | Values |

|---|---|

| Coal properties | Proximate analysis (% wet): Total moisture 17, volatile matter 31.36, fixed carbon 43.89, ash 7.75 Ultimate analysis (% daf): C 76.95, H 5.34, O 16.01, N 1.19, S 0.51 Higher heating value (HHV): 5600 kcal/kg |

| Coal throughput | 55.583 kg/s (50.494 kg/s after drying/pulverization) |

| Primary air | 121.2 kg/s, 224 °C (126.3 kg/s, 77 °C after drying/pulverization) |

| Total secondary air | 355.1 kg/s, 326 °C |

| Excess air ratio | 12.94% |

| Case Set | Case Name | Ratio in Total Combustion Air (%) | Burner Zone SR | Note | ||

|---|---|---|---|---|---|---|

| CCOFA | SOFA | Total OFA | ||||

| Set #1 | C05-S15 | 5 | 15 | 20 | 0.904 | |

| C05-S20 | 20 | 25 | 0.847 | Reference case | ||

| C05-S25 | 25 | 30 | 0.791 | |||

| C05-S30 | 30 | 35 | 0.734 | |||

| C05-S35 | 35 | 40 | 0.678 | |||

| Set #2 | C25-S00 | 25 | 0 | 25 | 0.847 | |

| C20-S05 | 20 | 5 | ||||

| C15-S10 | 15 | 10 | ||||

| C10-S15 | 10 | 15 | ||||

| C05-S20 | 5 | 20 | Reference case | |||

| C00-S25 | 0 | 25 | ||||

| Set #3 | C30-S00 | 30 | 0 | 30 | 0.791 | |

| C25-S05 | 25 | 5 | ||||

| C20-S10 | 20 | 10 | ||||

| C15-S15 | 15 | 15 | ||||

| C10-S20 | 10 | 20 | ||||

| C05-S25 | 5 | 25 | ||||

| C00-S30 | 0 | 25 | ||||

| Category | Submodels |

|---|---|

| Coal combustion | -Devolatilization: FLASHCHAIN [21] Dry coal→58.56 wt% daf Volatiles + 32.91 wt% daf C(s)(Char) Composition of Volatiles: Tar 32.57, CO 3.31, CO2 3.89, H2O 14.35, H2 0.71, CH4 1.99, CxHy 1.73 wt% daf Devolatilization rate: ; E = 5.49 kcal/mol, A = 7.89 × 103 s−1 -Char combustion: Unreacted core shrinking model [22] , (R1) C(s) + 0.5 O2 → CO (R2) C(s) + H2O → CO+H2 (R3) C(s) + CO2 → 2 CO |

| Species, gas reaction | -Species: Tar, CO, CO2, H2, CH4, CxHy, H2, SO2, O2, N2 -Reaction mechanism [23,24] (R4) CxHyOz (tar) + a O2 → x CO + 0.5y H2 (R5) CnHm + 0.5n O2 → n CO + 0.5m H2 (R6) CnHm + 0.5n H2O → n CO + 0.5(m+n) H2 (R7) CH4 + 0.5 O2 → CO + 2 H2 (R8) CH4 + 0.5 H2O → CO + 2.5 H2 (R9) CO + H2O → CO2 + H2 (R10)H2 + 0.5 O2 → H2O -Reaction rate: kinetic rate/eddy dissipation rate model [25] |

| Discrete phase | -Lagrangian scheme with stochastic tracking for turbulence -Number of particles: 49,560 -Particle size: 5.88–204 μm |

| NOx | -Thermal NOx: Extended Zeldovich mechanism [26] -Fuel NOx: De Soete [27] -Fuel-N intermediate: HCN 83.33%, NH3 16.67% |

| Parameter | Design | CFD | |

|---|---|---|---|

| Exit O2 (% dry) | 2.45 | 2.47 | |

| Exit NO (ppm, 6% O2) | <150 | 99.75 | |

| Heat absorption | Furnace wall | 562.31 | 562.27 |

| (MWth) | Primary SH | 88.74 | 84.00 |

| Platen SH | 102.81 | 99.96 | |

| Final SH | 113.04 | 108.75 | |

| Primary RH | 128.86 | 129.59 | |

| Final RH | 75.36 | 71.05 | |

| Economizer | 72.92 | 73.29 | |

| Case | C05-S15 | C05-S20 | C05-S25 | C05-S30 | C05-S35 | |

|---|---|---|---|---|---|---|

| Mole fraction on the burner zone wall [%] | CO | 0.329 | 0.355 | 0.462 | 0.609 | 0.704 |

| O2 | 0.783 | 0.657 | 0.617 | 0.657 | 0.572 | |

| Wall area with CO > 0.5% in the burner zone | 16.0 | 18.7 | 21.9 | 35.5 | 42.1 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jo, H.; Kang, K.; Park, J.; Ryu, C.; Ahn, H.; Go, Y. Optimization of Air Distribution to Reduce NOx Emission and Unburned Carbon for the Retrofit of a 500 MWe Tangential-Firing Coal Boiler. Energies 2019, 12, 3281. https://doi.org/10.3390/en12173281

Jo H, Kang K, Park J, Ryu C, Ahn H, Go Y. Optimization of Air Distribution to Reduce NOx Emission and Unburned Carbon for the Retrofit of a 500 MWe Tangential-Firing Coal Boiler. Energies. 2019; 12(17):3281. https://doi.org/10.3390/en12173281

Chicago/Turabian StyleJo, Hyunbin, Kiseop Kang, Jongkeun Park, Changkook Ryu, Hyunsoo Ahn, and Younggun Go. 2019. "Optimization of Air Distribution to Reduce NOx Emission and Unburned Carbon for the Retrofit of a 500 MWe Tangential-Firing Coal Boiler" Energies 12, no. 17: 3281. https://doi.org/10.3390/en12173281

APA StyleJo, H., Kang, K., Park, J., Ryu, C., Ahn, H., & Go, Y. (2019). Optimization of Air Distribution to Reduce NOx Emission and Unburned Carbon for the Retrofit of a 500 MWe Tangential-Firing Coal Boiler. Energies, 12(17), 3281. https://doi.org/10.3390/en12173281