Robust Direct Adaptive Controller Design for Photovoltaic Maximum Power Point Tracking Application

Abstract

1. Introduction

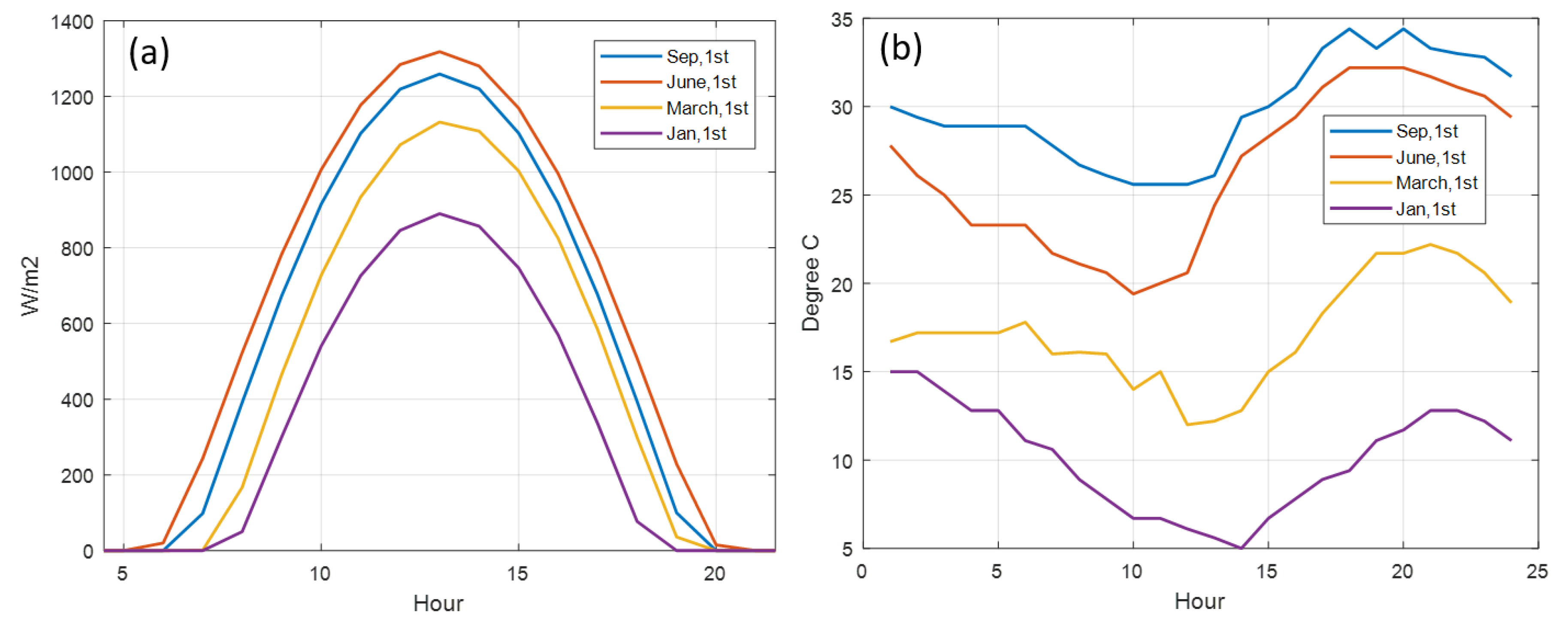

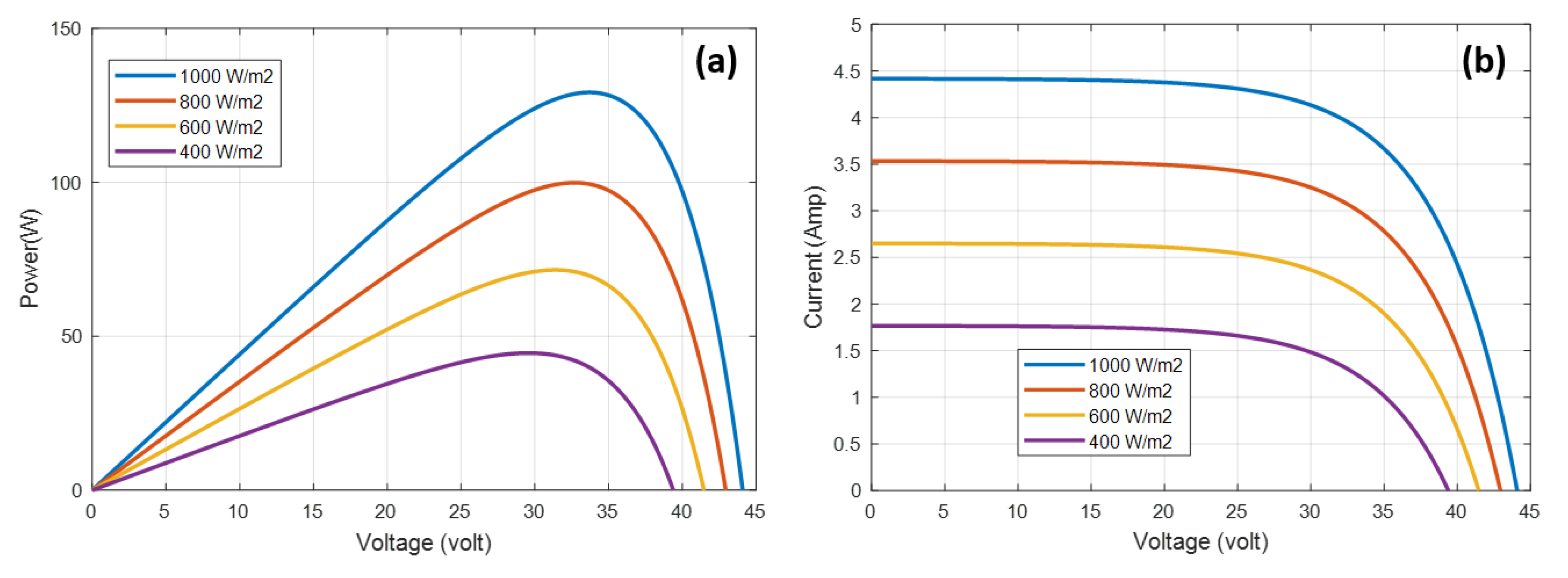

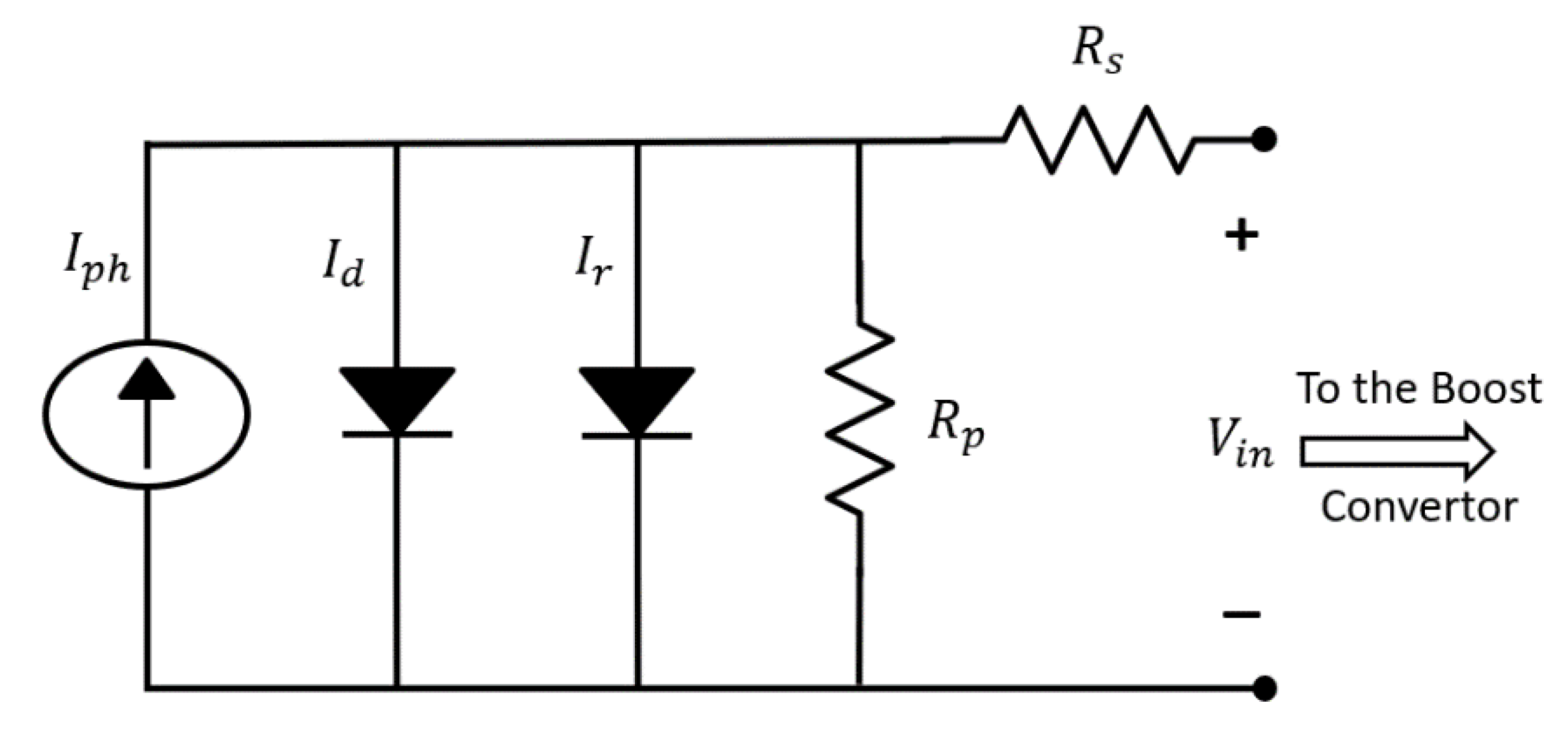

2. PV Mathematical Model

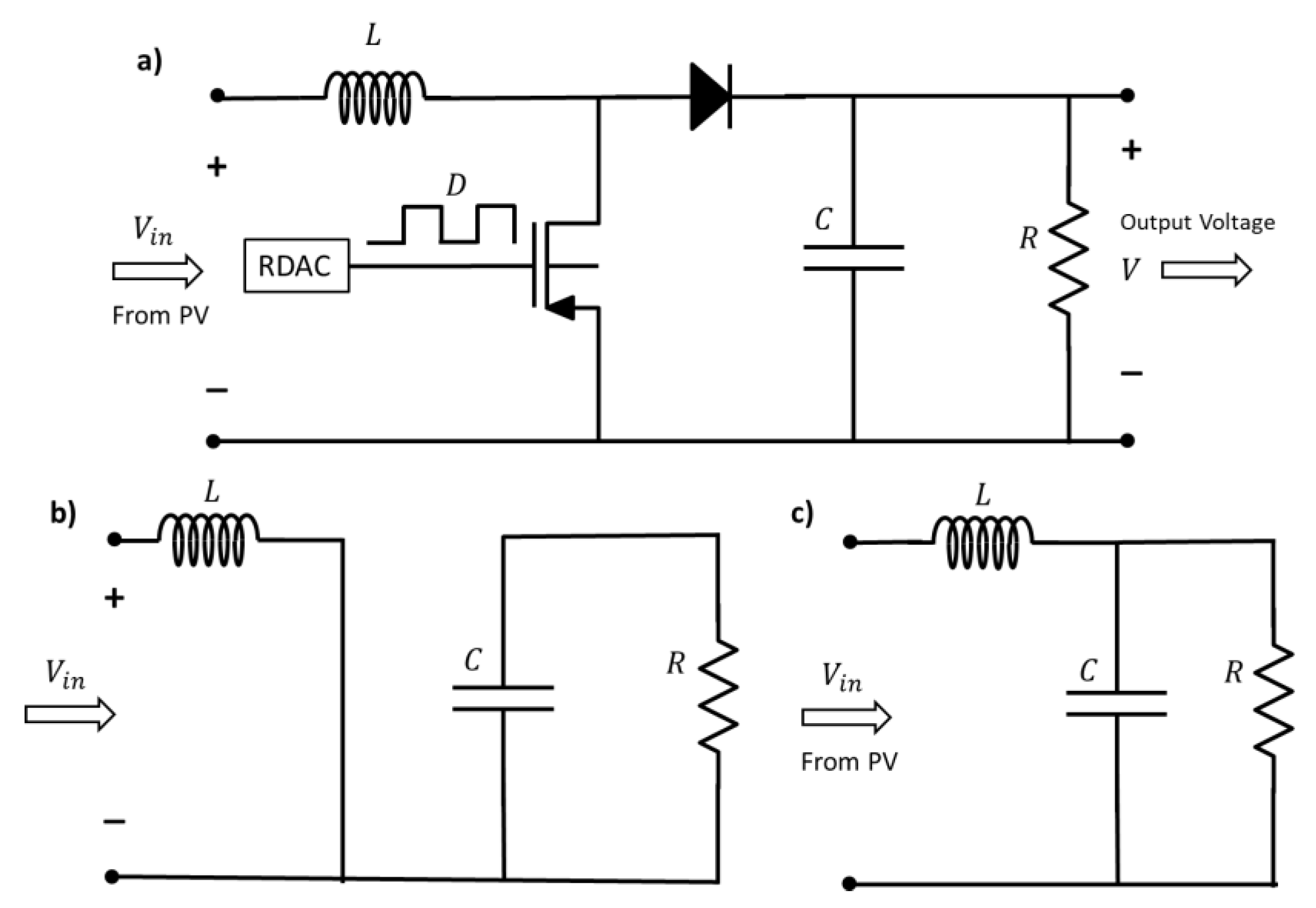

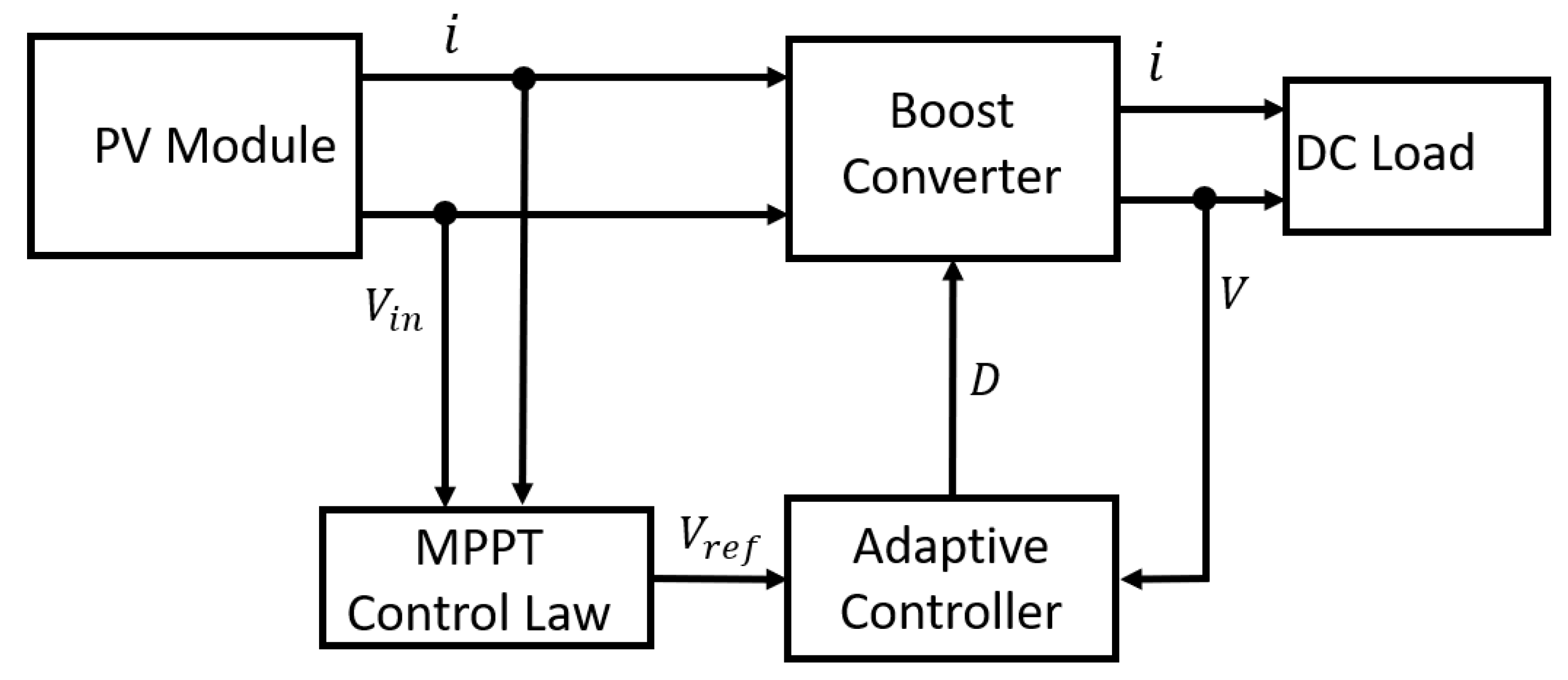

3. Boost Converter Model

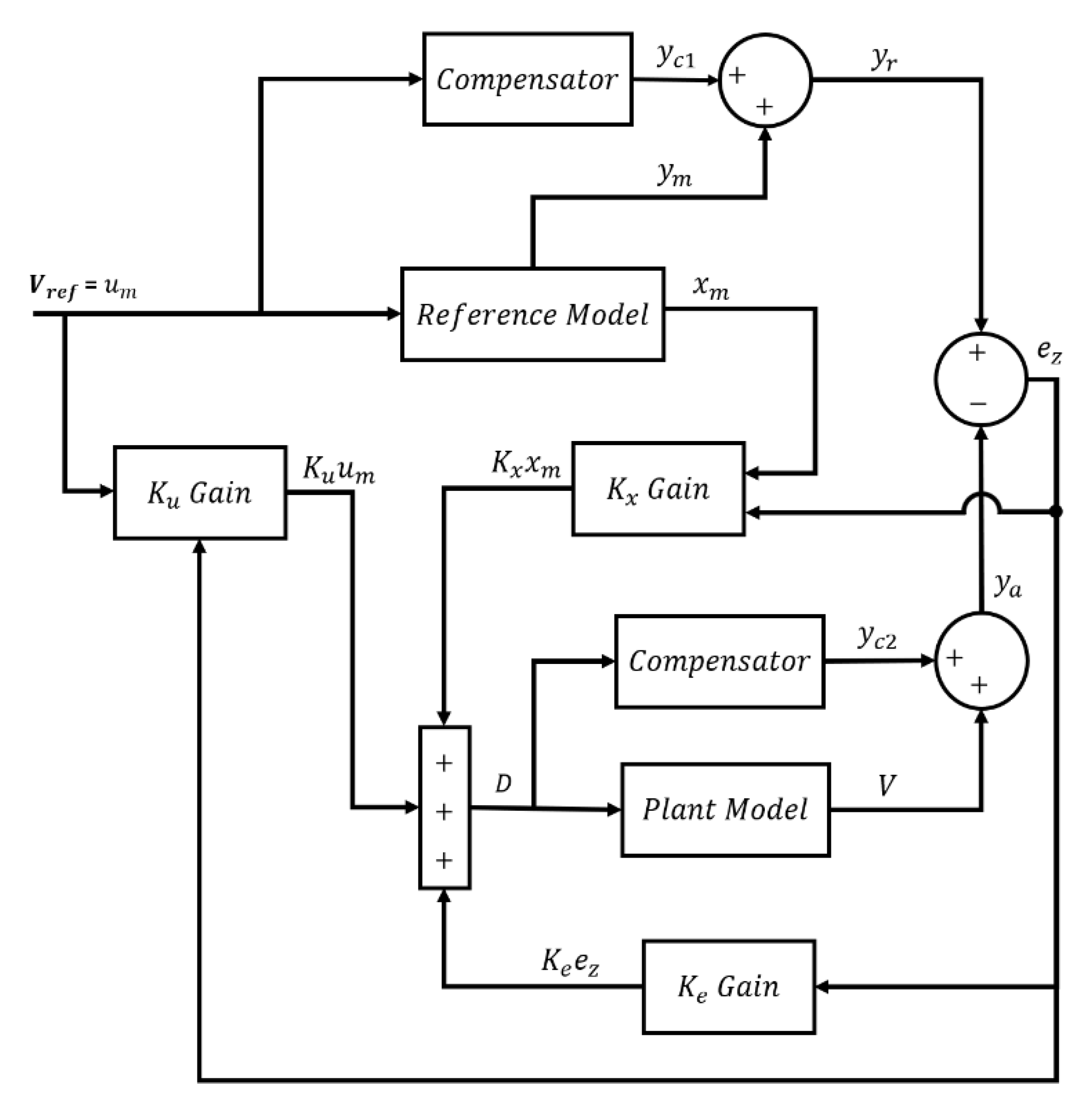

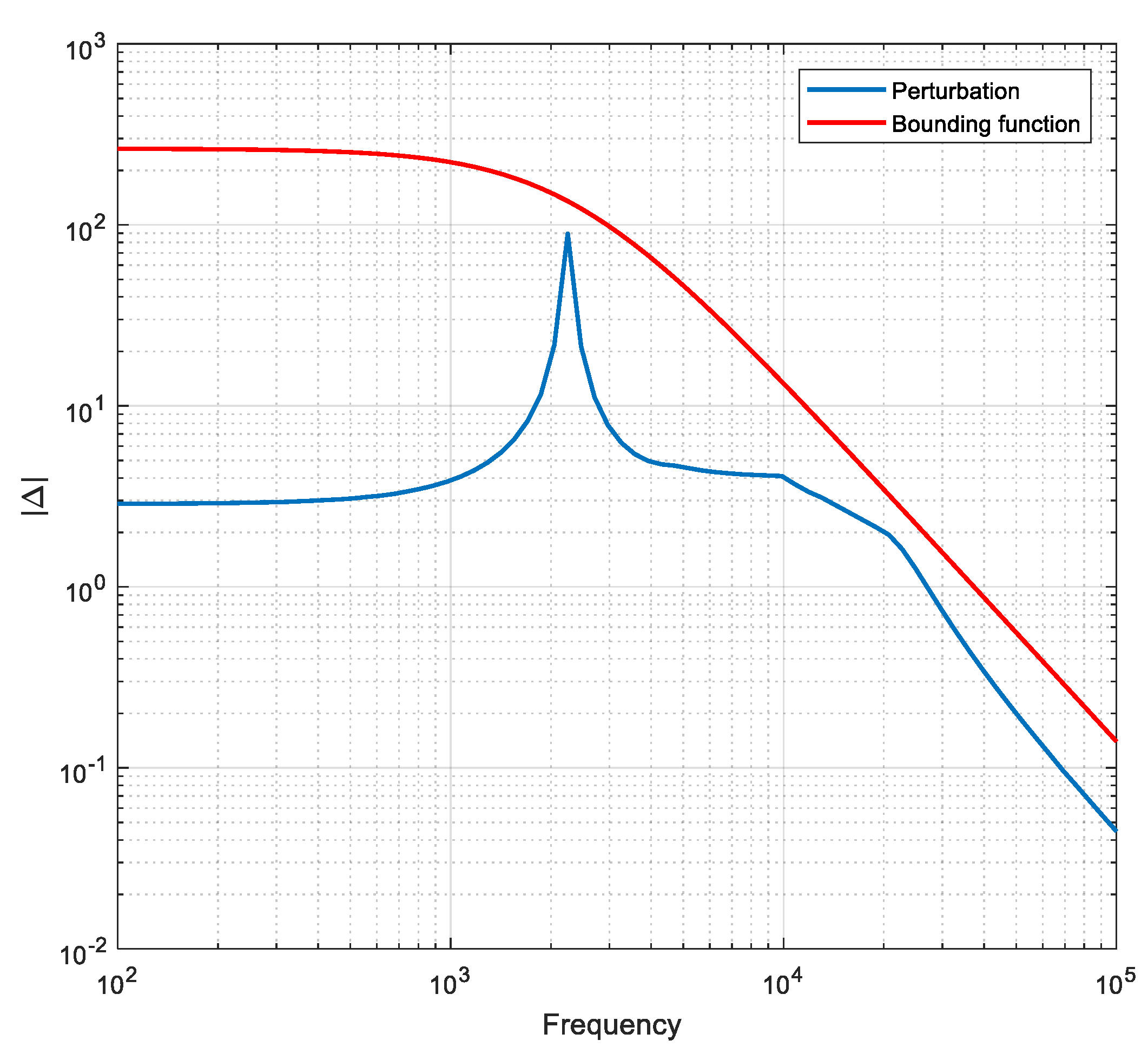

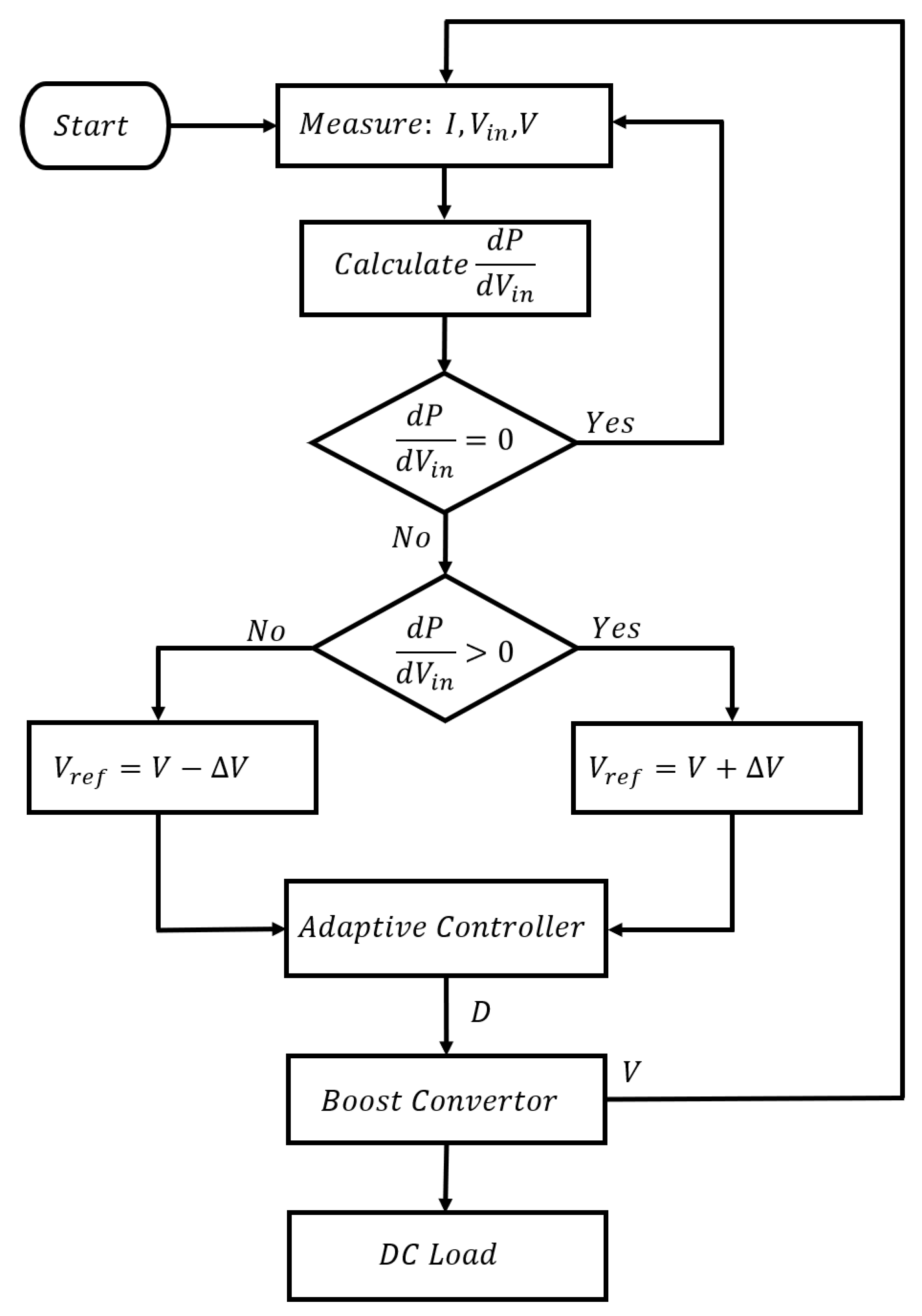

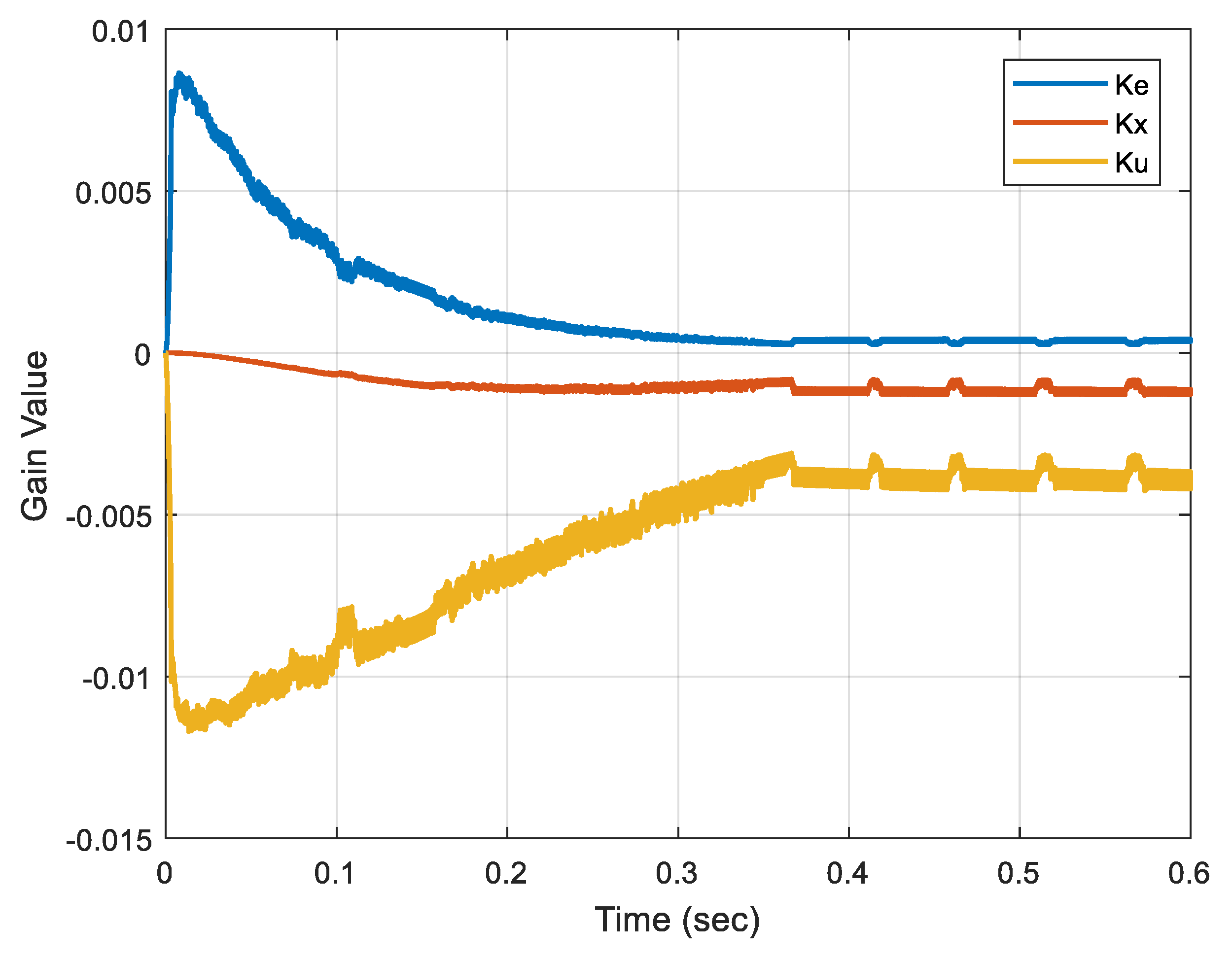

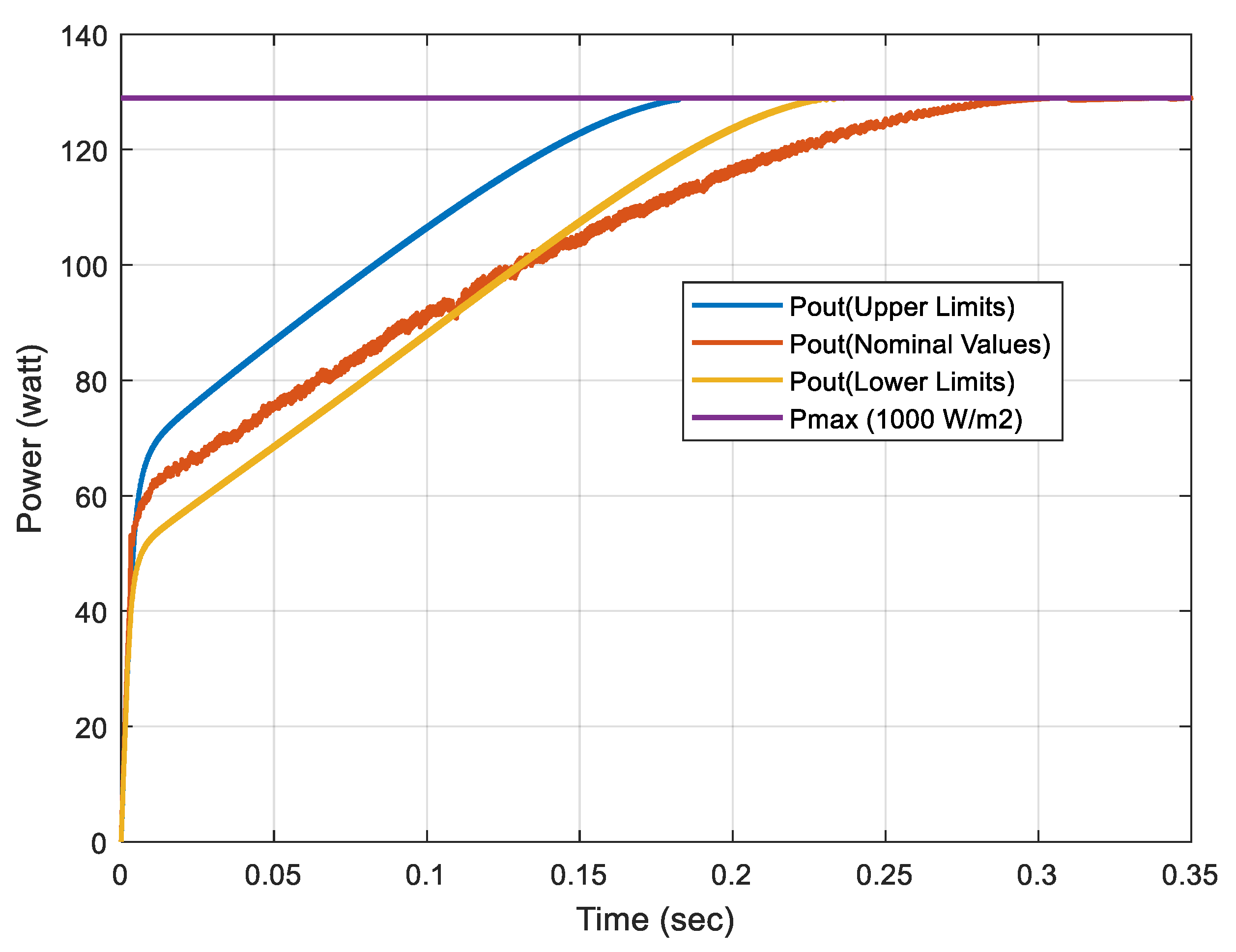

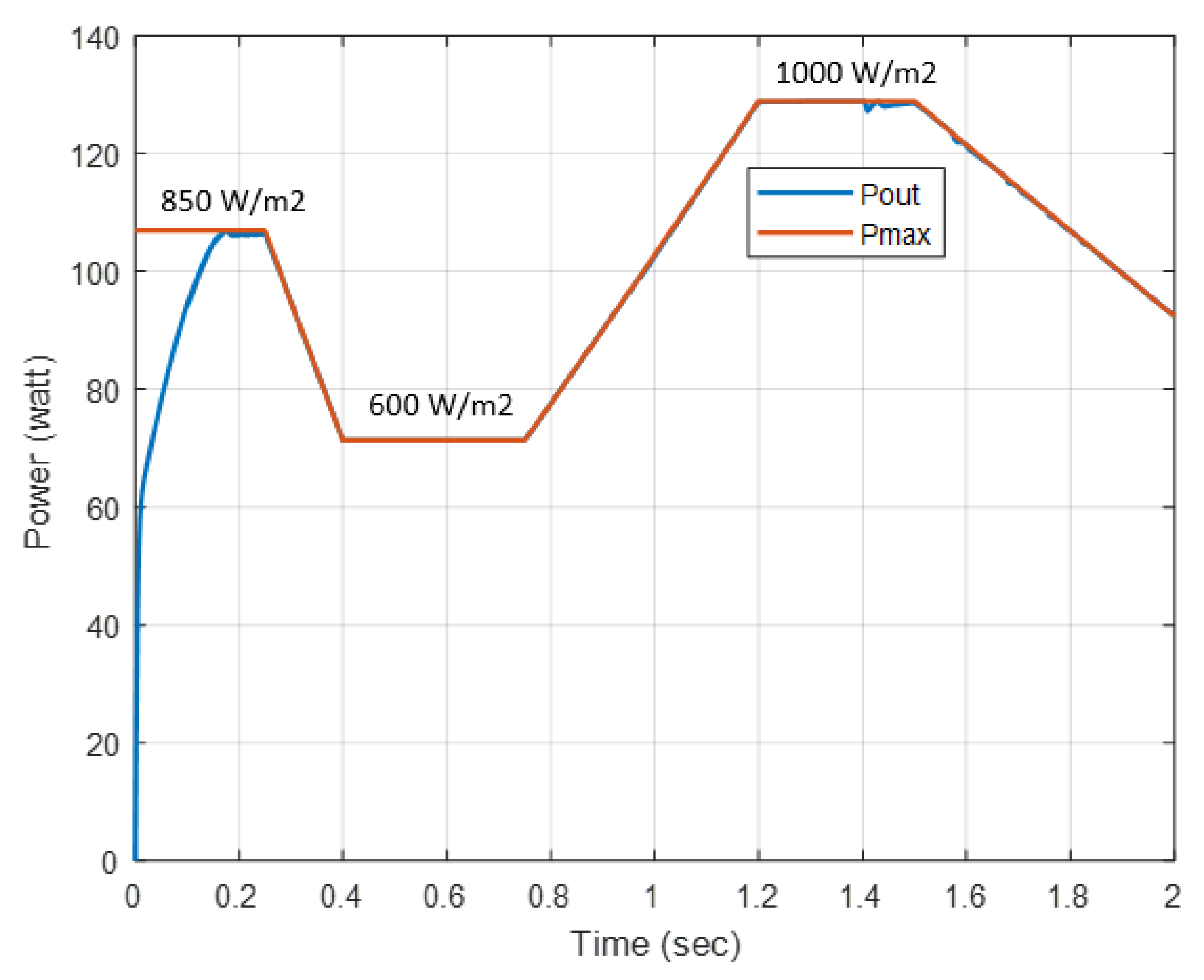

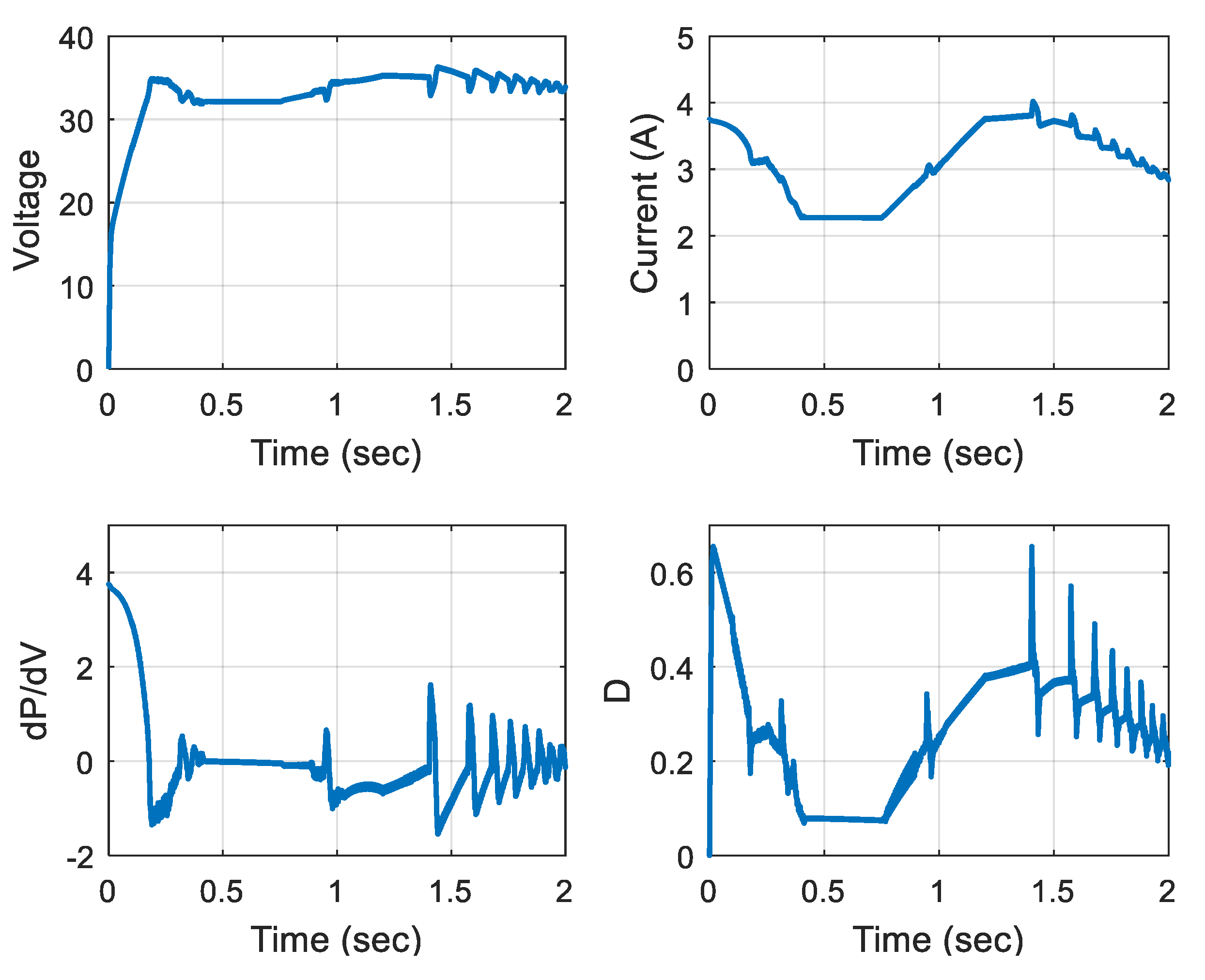

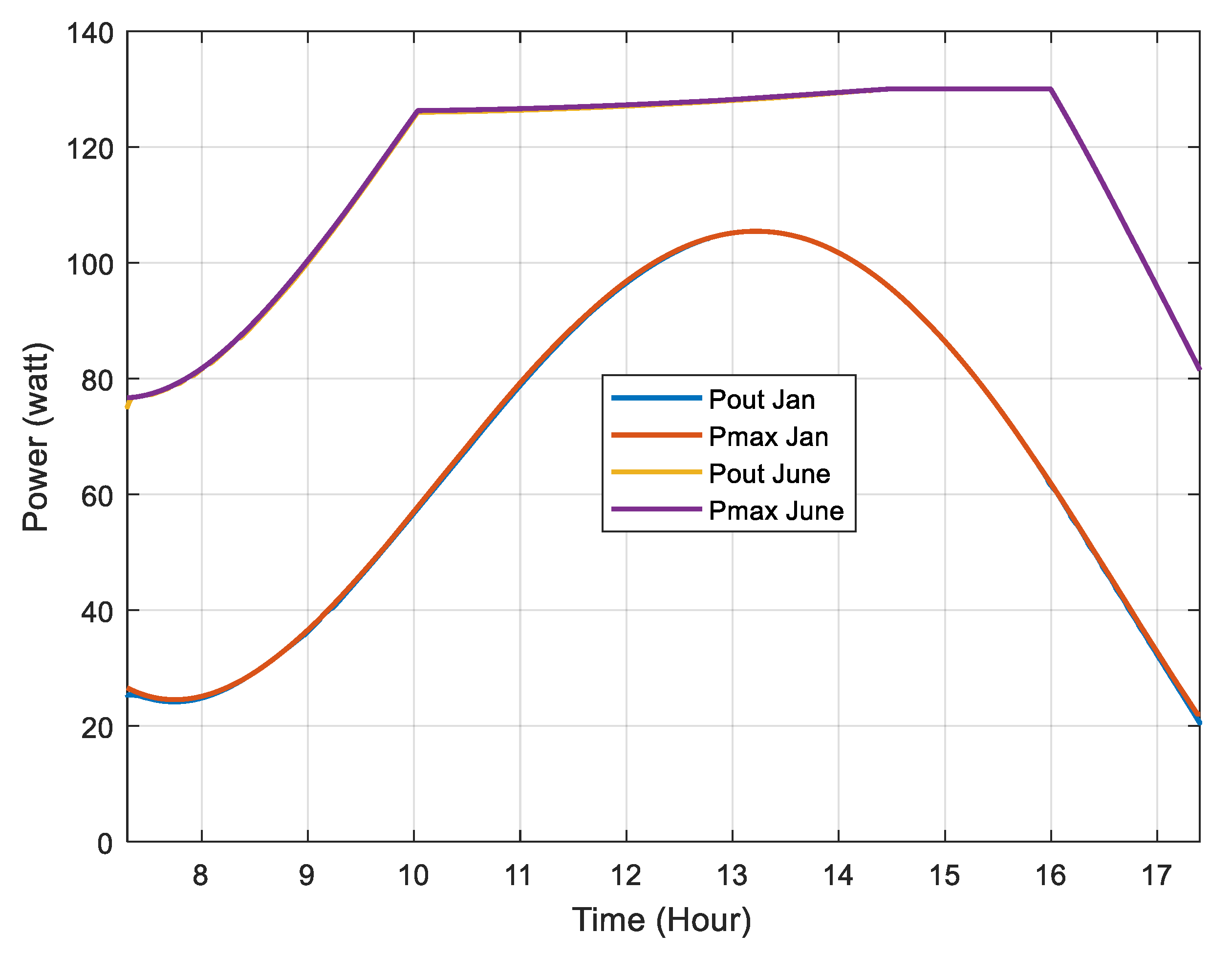

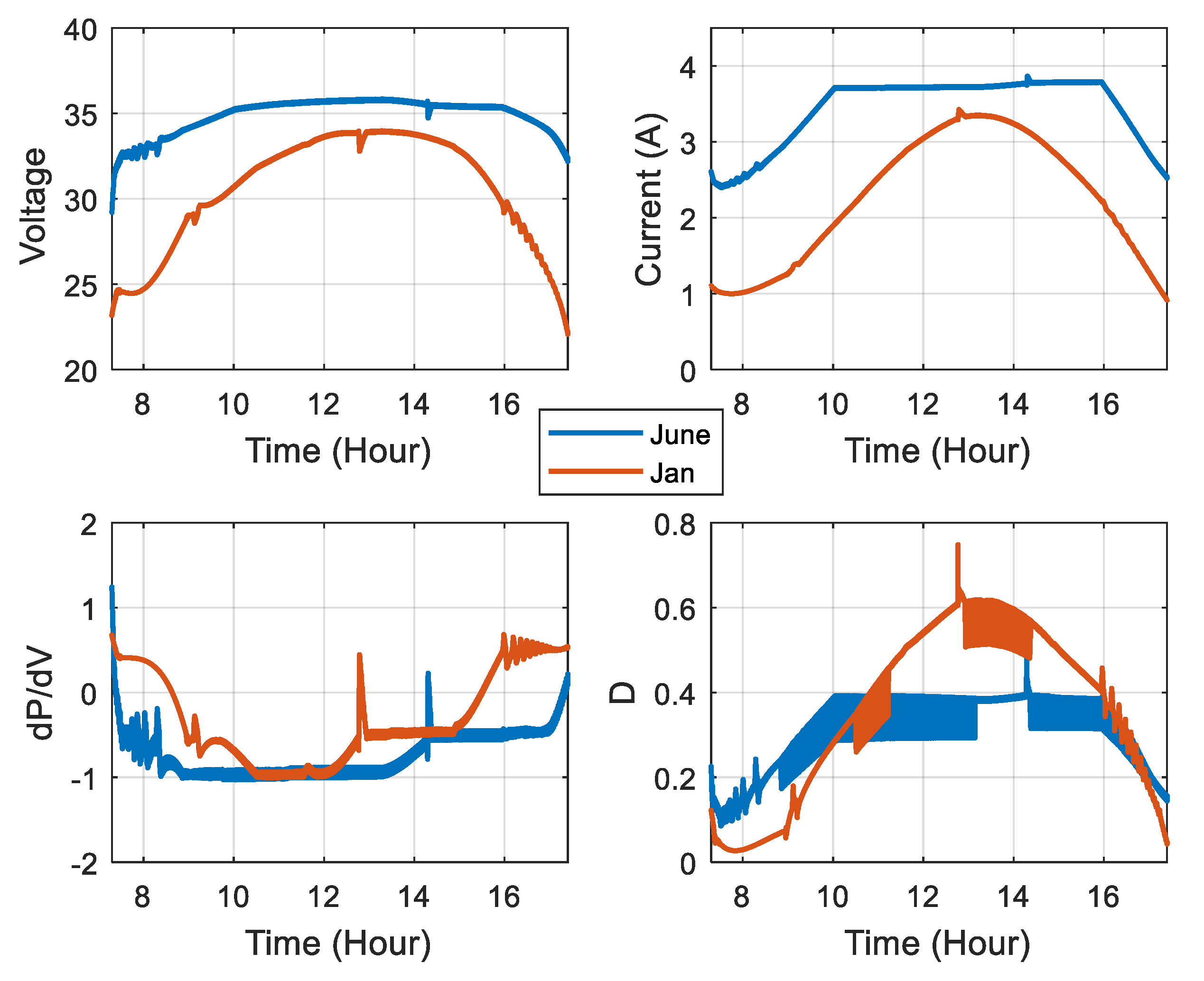

4. Robust Direct Adaptive Control

- The compensator transfer function must be stable with a desired relative degree of either 0 or 1.

- The closed-loop nominal plant transfer function of the system, must be stable as well.

- , where is given in the following

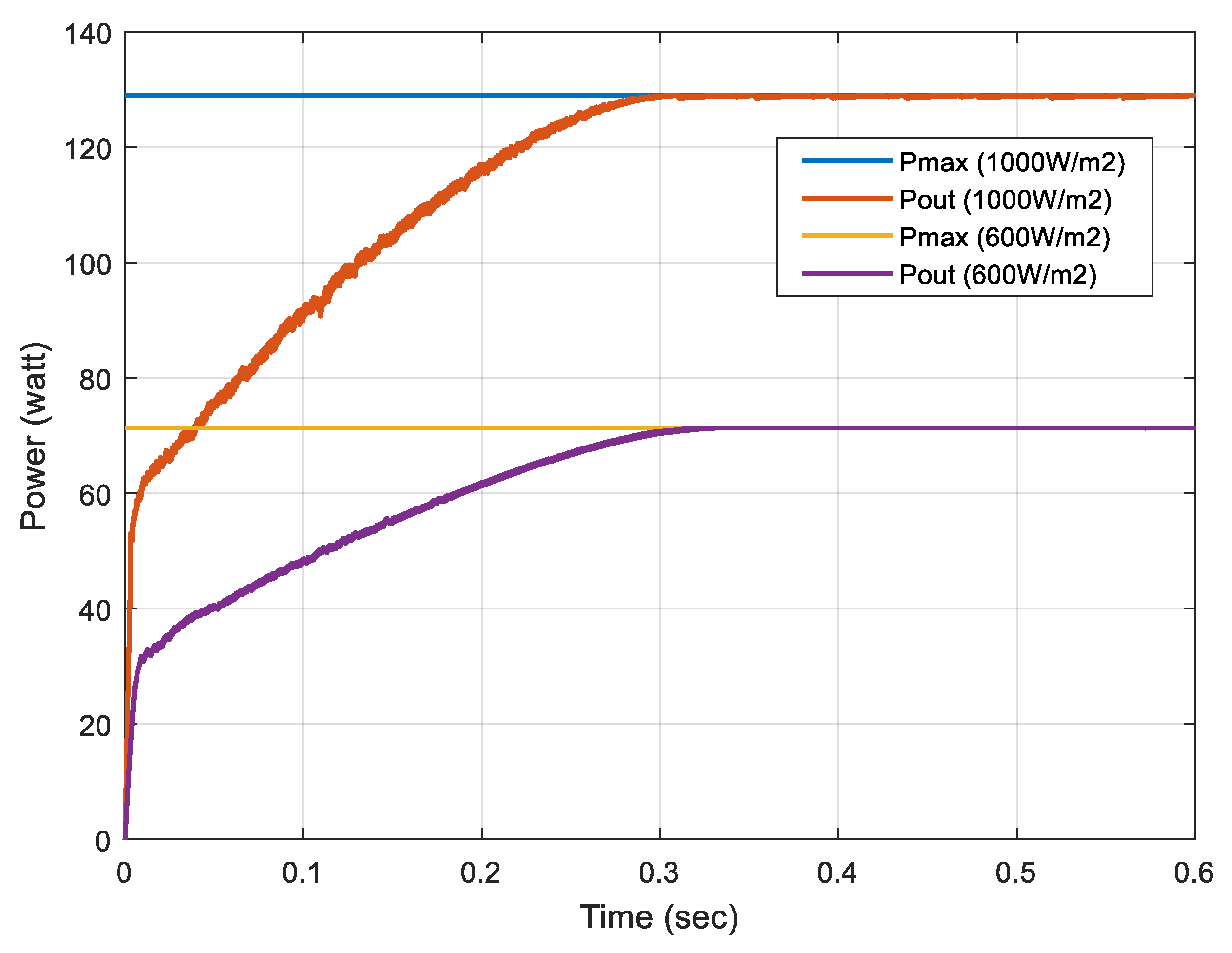

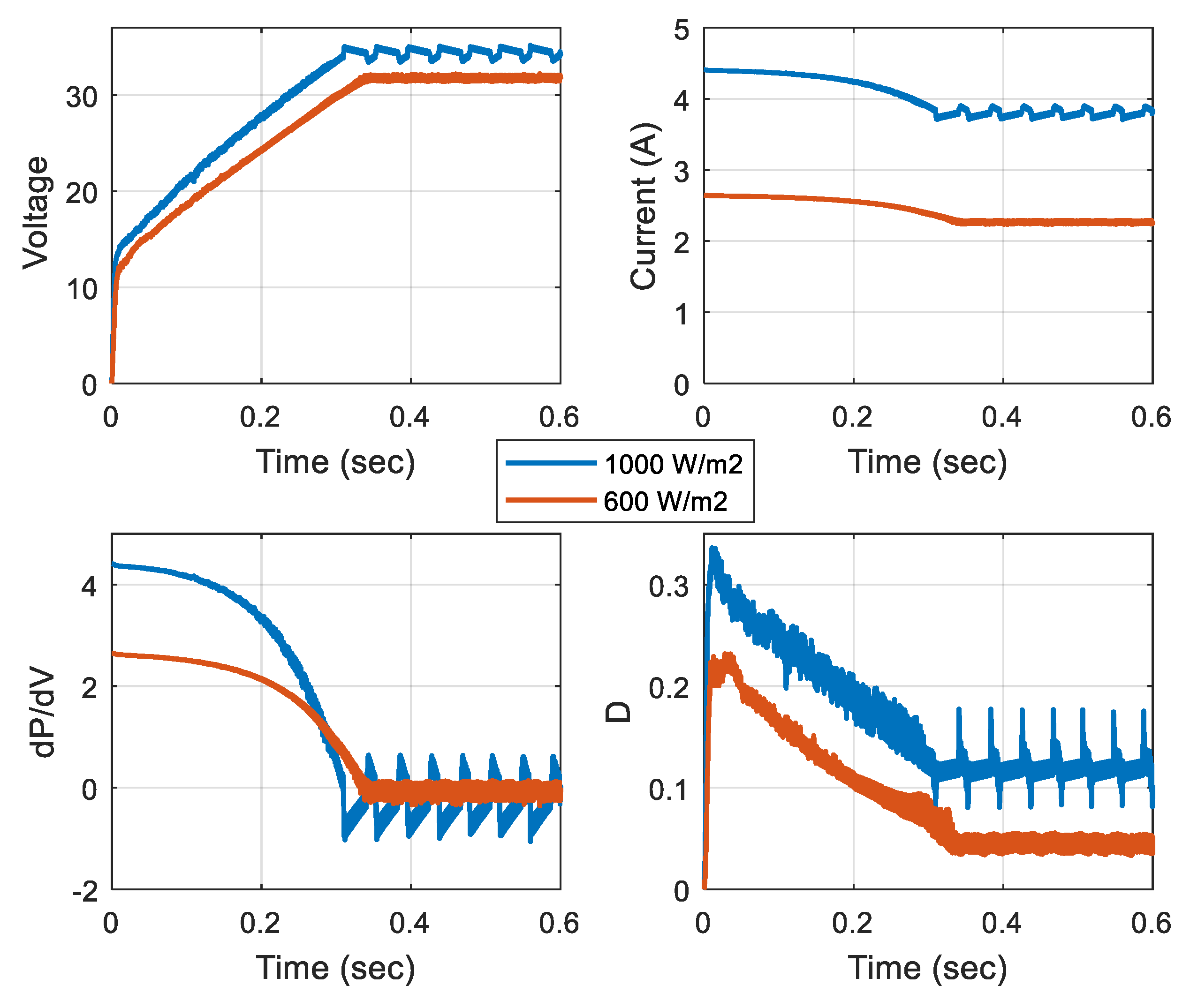

5. Results

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Knuth, S. ‘Breakthroughs’ for a green economy? Financialization and clean energy transition. Energy Res. Soc. Sci. 2018, 41, 220–229. [Google Scholar] [CrossRef]

- Ramanujam, J.; Verma, A.; González-Díaz, B.; Guerrero-Lemus, R.; del Cañizo, C.; García-Tabarés, E.; Rey-Stolle, I.; Granek, F.; Korte, L.; Tuccih, M.; et al. Inorganic photovoltaics—Planar and nanostructured devices. Prog. Mater. Sci. 2016, 82, 294–404. [Google Scholar] [CrossRef]

- Kumar, M.; Kumar, A. Performance assessment and degradation analysis of solar photovoltaic technologies: A review. Renew. Sustain. Energy Rev. 2017, 78, 554–587. [Google Scholar] [CrossRef]

- Creutzig, F.; Agoston, P.; Goldschmidt, J.C.; Luderer, G.; Nemet, G.; Pietzcker, R.C. The underestimated potential of solar energy to mitigate climate change. Nat. Energy 2017, 2, 17140. [Google Scholar] [CrossRef]

- Salim, M.B.; Demirocak, D.E.; Barakat, N. A Fuzzy Based Model for Standardized Sustainability Assessment of Photovoltaic Cells. Sustainability 2018, 10, 4787. [Google Scholar] [CrossRef]

- Fthenakis, V.M.; Kim, H.C. Photovoltaics: Life-cycle analyses. Sol. Energy 2011, 85, 1609–1628. [Google Scholar] [CrossRef]

- Shafeey, M.A.; Harb, A.M. Photovoltaic as a promising solution for peak demands and energy cost reduction in Jordan. In Proceedings of the 2018 9th International Renewable Energy Congress (IREC), Hamment, Tunisia, 20–22 March 2018; pp. 1–4. [Google Scholar]

- Gules, R.; Pacheco, J.D.P.; Hey, H.L.; Imhoff, J. A Maximum Power Point Tracking System with Parallel Connection for PV Stand-Alone Applications. IEEE Trans. Ind. Electron. 2008, 55, 2674–2683. [Google Scholar] [CrossRef]

- Jordan, D.C.; Silverman, T.J.; Wohlgemuth, J.H.; Kurtz, S.R.; VanSant, K.T. Photovoltaic failure and degradation modes. Prog. Photovolt. Res. Appl. 2017, 25, 318–326. [Google Scholar] [CrossRef]

- Li, L.; Wang, H.; Chen, X.; Bukhari, A.A.S.; Cao, W.; Chai, L.; Li, B. High Efficiency Solar Power Generation with Improved Discontinuous Pulse Width Modulation (DPWM) Overmodulation Algorithms. Energies 2019, 12, 1765. [Google Scholar] [CrossRef]

- Pathy, S.; Subramani, C.; Sridhar, R.; Thentral, T.M.T.; Padmanaban, S. Nature-Inspired MPPT Algorithms for Partially Shaded PV Systems: A Comparative Study. Energies 2019, 12, 1451. [Google Scholar] [CrossRef]

- Espi, J.M.; Castello, J. A Novel Fast MPPT Strategy for High Efficiency PV Battery Chargers. Energies 2019, 12, 1152. [Google Scholar] [CrossRef]

- Cortajarena, J.A.; Barambones, O.; Alkorta, P.; de Marcos, J. Sliding mode control of grid-tied single-phase inverter in a photovoltaic MPPT application. Sol. Energy 2017, 155, 793–804. [Google Scholar] [CrossRef]

- Kolsi, S.; Samet, H.; Amar, M.B. Design Analysis of DC-DC Converters Connected to a Photovoltaic Generator and Controlled by MPPT for Optimal Energy Transfer throughout a Clear Day. J. Power Energy Eng. 2014, 2, 27. [Google Scholar] [CrossRef]

- Tran, C.H.; Nollet, F.; Essounbouli, N.; Hamzaoui, A. Modeling and Simulation of Stand Alone Photovoltaic System using Three Level Boost Converter. In Proceedings of the 2017 International Renewable and Sustainable Energy Conference (IRSEC), Tangier, Morocco, 4–7 December 2017; pp. 1–6. [Google Scholar]

- Ahmed, M.E.; Mousa, M.; Orabi, M. Development of high gain and efficiency photovoltaic system using multilevel boost converter topology. In Proceedings of the 2nd International Symposium on Power Electronics for Distributed Generation Systems, Hefei, China, 16–18 June 2010; pp. 898–903. [Google Scholar]

- Anto, E.K.; Asumadu, J.A.; Okyere, P.Y. PID control for improving P amp; amp; O-MPPT performance of a grid-connected solar PV system with Ziegler-Nichols tuning method. In Proceedings of the 2016 IEEE 11th Conference on Industrial Electronics and Applications (ICIEA), Hefei, China, 5–7 June 2016; pp. 1847–1852. [Google Scholar]

- Kermadi, M.; Berkouk, E.M. Artificial intelligence-based maximum power point tracking controllers for Photovoltaic systems: Comparative study. Renew. Sustain. Energy Rev. 2017, 69, 369–386. [Google Scholar] [CrossRef]

- Hohm, D.P.; Ropp, M.E. Comparative study of maximum power point tracking algorithms. Prog. Photovolt. Res. Appl. 2003, 11, 47–62. [Google Scholar] [CrossRef]

- Dahmane, M.; Bosche, J.; El-Hajjaji, A.; Pierre, X. MPPT for photovoltaic conversion systems using genetic algorithm and robust control. In Proceedings of the American Control Conference, Washington, DC, USA, 17–19 June 2013; pp. 6595–6600. [Google Scholar]

- Wu, Z.; Yu, D. Application of improved bat algorithm for solar PV maximum power point tracking under partially shaded condition. Appl. Soft Comput. 2018, 62, 101–109. [Google Scholar] [CrossRef]

- The National Renewable Energy Laboratory. NSRDB: Alphabetical List by State. Available online: https://rredc.nrel.gov/solar/old_data/nsrdb/1991-2010/hourly/list_by_state.html (accessed on 8 December 2018).

- IOWA State University, IOWA environmental Mesonet. IEM: Download ASOS/AWOS/METAR Data. Available online: https://mesonet.agron.iastate.edu/request/download.phtml?network=TX_ASOS (accessed on 8 December 2018).

- Shabrina, H.N.; Setiawan, E.A.; Sabirin, C.R. Designing of new structure PID controller of boost converter for solar photovoltaic stability. In Proceedings of the International Tropical Renewable Energy Conference (i-TREC) 2016 on Renewable Energy Technology and Innovation for Sustainable Development, Bogor, Indonesia, 26–28 October 2017; p. 020026. [Google Scholar]

- Husna, A.W.N.; Siraj, S.F.; Muin, M.Z.A. Modeling of DC-DC converter for solar energy system applications. In Proceedings of the 2012 IEEE Symposium on Computers Informatics (ISCI), Penang, Malaysia, 18–20 March 2012; pp. 125–129. [Google Scholar]

- Priewasser, R.; Agostinelli, M.; Unterrieder, C.; Marsili, S.; Huemer, M. Modeling, Control, and Implementation of DC–DC Converters for Variable Frequency Operation. IEEE Trans. Power Electron. 2014, 29, 287–301. [Google Scholar] [CrossRef]

- Mira, M.C.; Knott, A.; Thomsen, O.C.; Andersen, M.A.E. Boost converter with combined control loop for a stand-alone photovoltaic battery charge system. In Proceedings of the 2013 IEEE 14th Workshop on Control and Modeling for Power Electronics (COMPEL), Salt Lake City, UT, USA, 23–26 June 2013; pp. 1–8. [Google Scholar]

- Zhang, W.; Tan, X.; Wang, K.; Li, T.; Chen, J. Design for boost DC-DC converter controller based on state-space average method. Integr. Ferroelectr. 2016, 172, 152–159. [Google Scholar] [CrossRef]

- Mohammed, S.S.; Devaraj, D. Simulation and analysis of stand-alone photovoltaic system with boost converter using MATLAB/Simulink. In Proceedings of the 2014 International Conference on Circuits, Power and Computing Technologies (ICCPCT-2014), Nagercoil, India, 20–21 March 2014; pp. 814–821. [Google Scholar]

- Landau, I.D.; Lozano, R.; M’Saad, M.; Karimi, A. Introduction to Adaptive Control. In Adaptive Control; Springer: London, UK, 2011; pp. 1–33. [Google Scholar]

- Tariba, N.; Haddou, A.; Omari, H.E.; Omari, H.E. Design and implementation an Adaptive Control for MPPT systems using Model Reference Adaptive Controller. In Proceedings of the 2016 International Renewable and Sustainable Energy Conference (IRSEC), Marrakech, Morocco, 14–17 November 2016; pp. 165–172. [Google Scholar]

- Ozcelik, S.; DeMarchi, J.; Kaufman, H.; Craig, K. Control of an Inverted Pendulum Using Direct Model Reference Adaptive Control. IFAC Proc. Volumes 1997, 30, 585–590. [Google Scholar] [CrossRef]

- Bar-Kana, I.; Kaufman, H. Global Stability and Performance of a Simplified Adaptive Algorithm. Int. J. Control 1985, 46, 1491–1505. [Google Scholar] [CrossRef]

- Livnch, R.; McLaren, M.D.; Slater, G.L. Some conditions for almost strict positive realness. In Proceedings of the 29th IEEE Conference on Decision and Control, Honolulu, HI, USA, 5–7 December 1990; pp. 2512–2517. [Google Scholar]

- Iwai, Z.; Mizumoto, I. Robust and simple adaptive control systems. Int. J. Control 1992, 55, 1453–1470. [Google Scholar] [CrossRef]

- Kaufman, H.; Barkana, I.; Sobel, K. Direct Adaptive Control Algorithms: Theory and Applications, 2nd ed.; Springer: New York, NY USA, 1998. [Google Scholar]

- MATLAB—MathWorks. Available online: https://www.mathworks.com/products/matlab.html (accessed on 25 May 2019).

- Koofigar, H.R. Adaptive robust maximum power point tracking control for perturbed photovoltaic systems with output voltage estimation. ISA Trans. 2016, 60, 285–293. [Google Scholar] [CrossRef]

- Hasanien, H.M. An Adaptive Control Strategy for Low Voltage Ride Through Capability Enhancement of Grid-Connected Photovoltaic Power Plants. IEEE Trans. Power Syst. 2016, 31, 3230–3237. [Google Scholar] [CrossRef]

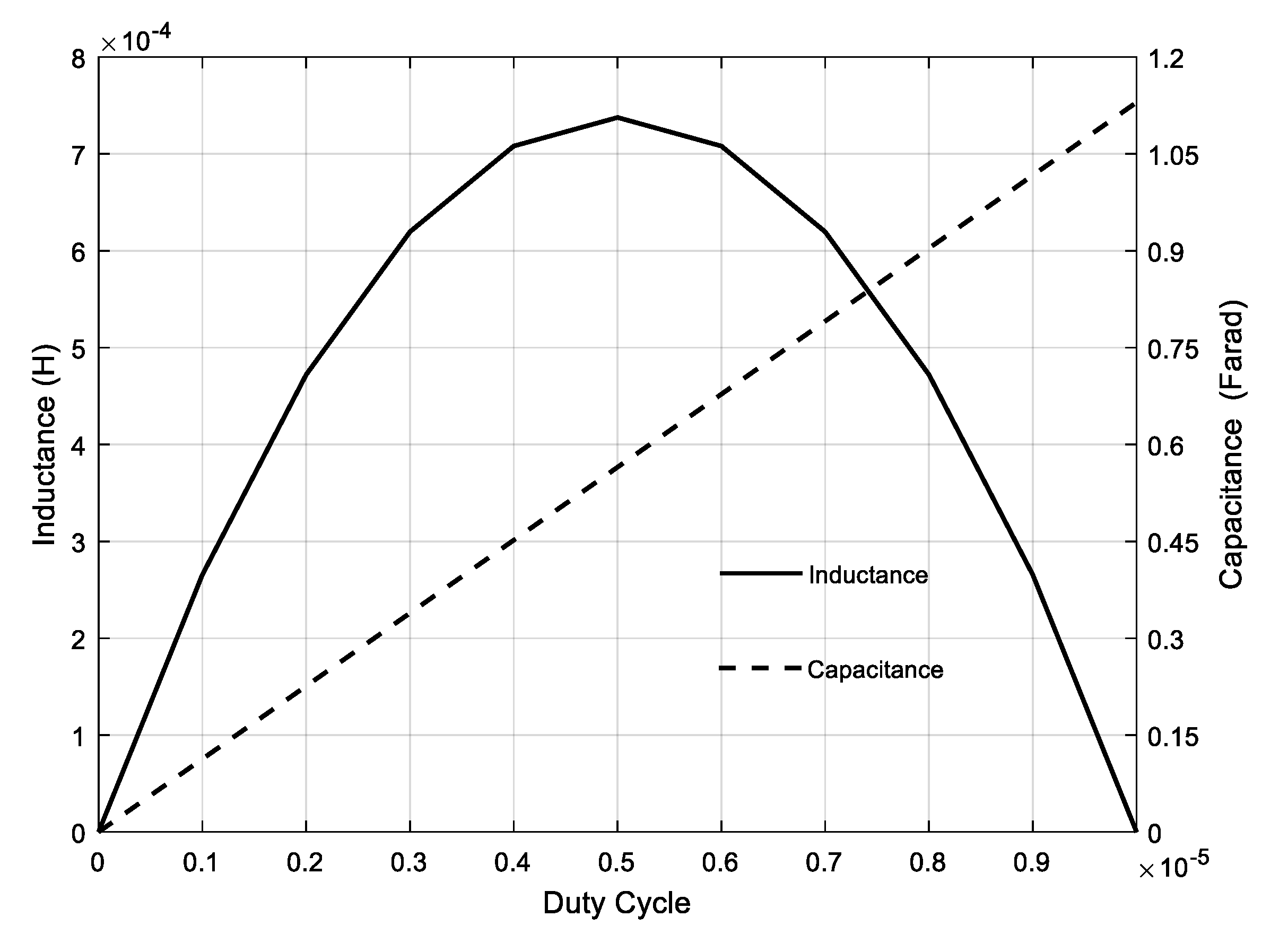

| L (Henry) | C (Farad) | ||

|---|---|---|---|

| Nominal | 15 | 0.8 × | 1.0 × |

| Minimum | 10 | 0.4 × | 0.8 × |

| Maximum | 18 | 1.2 × | 1.2 × |

| PV Model (at 25 C; 1000 W/m2) | Boost Converter | RDAC | |||

|---|---|---|---|---|---|

| 4.42 (A) | 30% | 5.0 × | |||

| 44.35 (V) | 5% | 1.0 × | |||

| 3.84 (A) | 1000 F | 5.0 × | |||

| 33.9 (V) | 0.8 mH | 5.0 × | |||

| 130 (W) | 15 | 1.0 × | |||

| Frequency | 10 kHz | 1.0 × | |||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bani Salim, M.; Hayajneh, H.S.; Mohammed, A.; Ozcelik, S. Robust Direct Adaptive Controller Design for Photovoltaic Maximum Power Point Tracking Application. Energies 2019, 12, 3182. https://doi.org/10.3390/en12163182

Bani Salim M, Hayajneh HS, Mohammed A, Ozcelik S. Robust Direct Adaptive Controller Design for Photovoltaic Maximum Power Point Tracking Application. Energies. 2019; 12(16):3182. https://doi.org/10.3390/en12163182

Chicago/Turabian StyleBani Salim, M., H. S. Hayajneh, A. Mohammed, and S. Ozcelik. 2019. "Robust Direct Adaptive Controller Design for Photovoltaic Maximum Power Point Tracking Application" Energies 12, no. 16: 3182. https://doi.org/10.3390/en12163182

APA StyleBani Salim, M., Hayajneh, H. S., Mohammed, A., & Ozcelik, S. (2019). Robust Direct Adaptive Controller Design for Photovoltaic Maximum Power Point Tracking Application. Energies, 12(16), 3182. https://doi.org/10.3390/en12163182