Utilization of Food and Agricultural Residues for a Flexible Biogas Production: Process Stability and Effects on Needed Biogas Storage Capacities

Abstract

1. Introduction

2. Materials and Methods

2.1. Description of the Biogas Plant

2.2. Feedstock

2.2.1. Feedstock Analysis

2.2.2. Feedstock Characterization

2.3. Biological Methane Potential Test

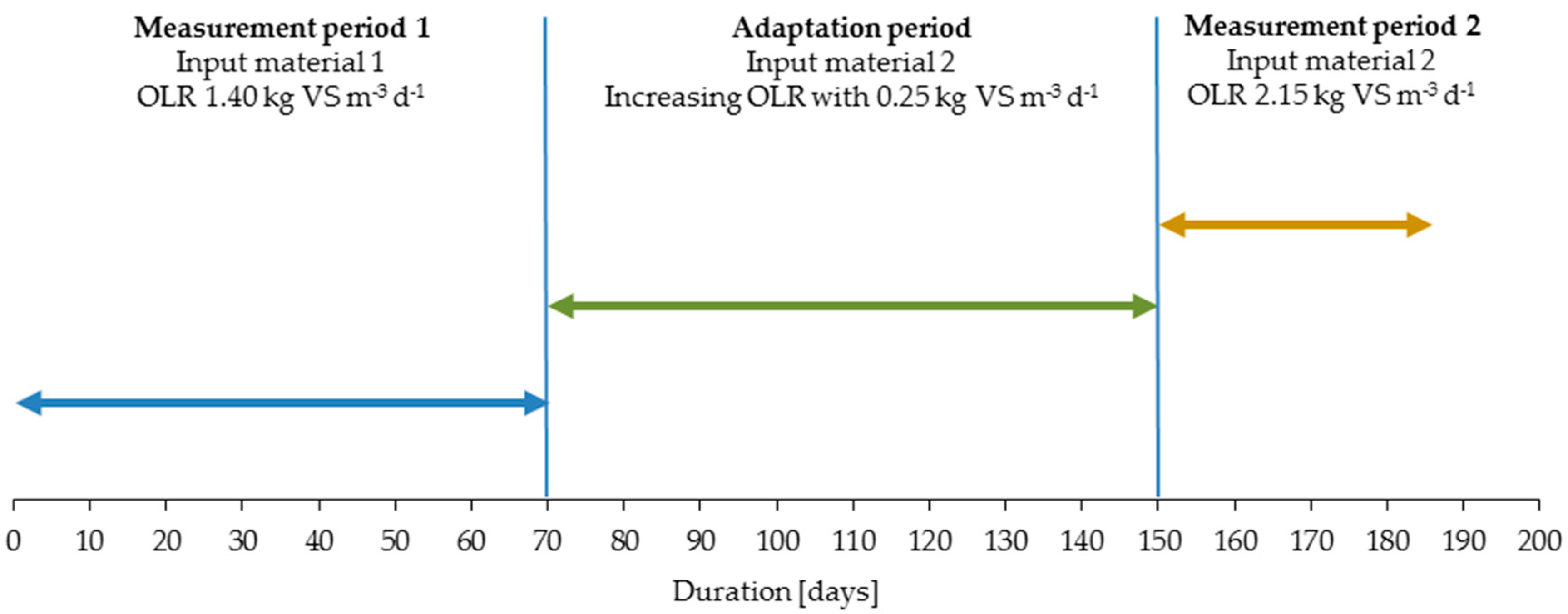

2.4. Semi-Continuous Flexible Biogas Production

2.5. Process Parameters

2.6. Molecular Biology Analyses

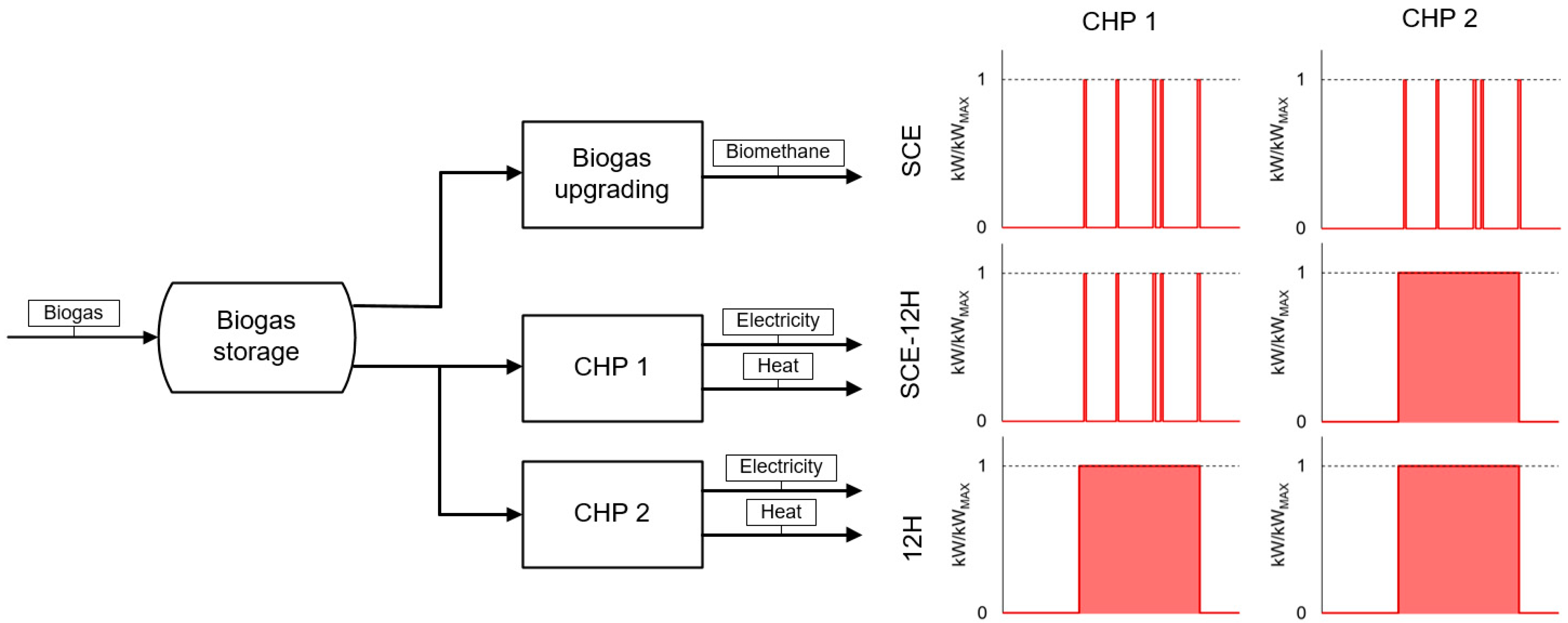

2.7. Process Simulation of Biogas Plant

3. Results

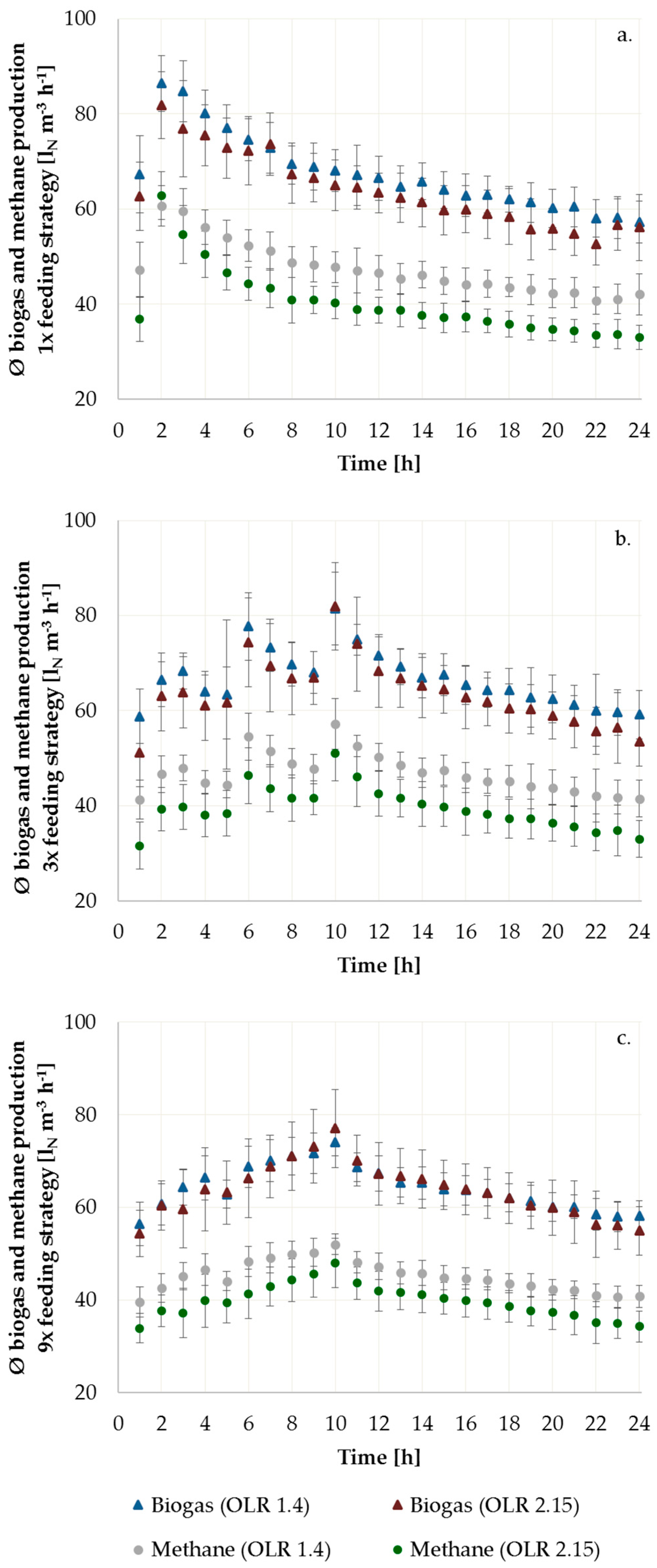

3.1. Semi-Continuous Flexible Biogas Production

3.2. Process Parameter

3.2.1. Short Chain Fatty Acids

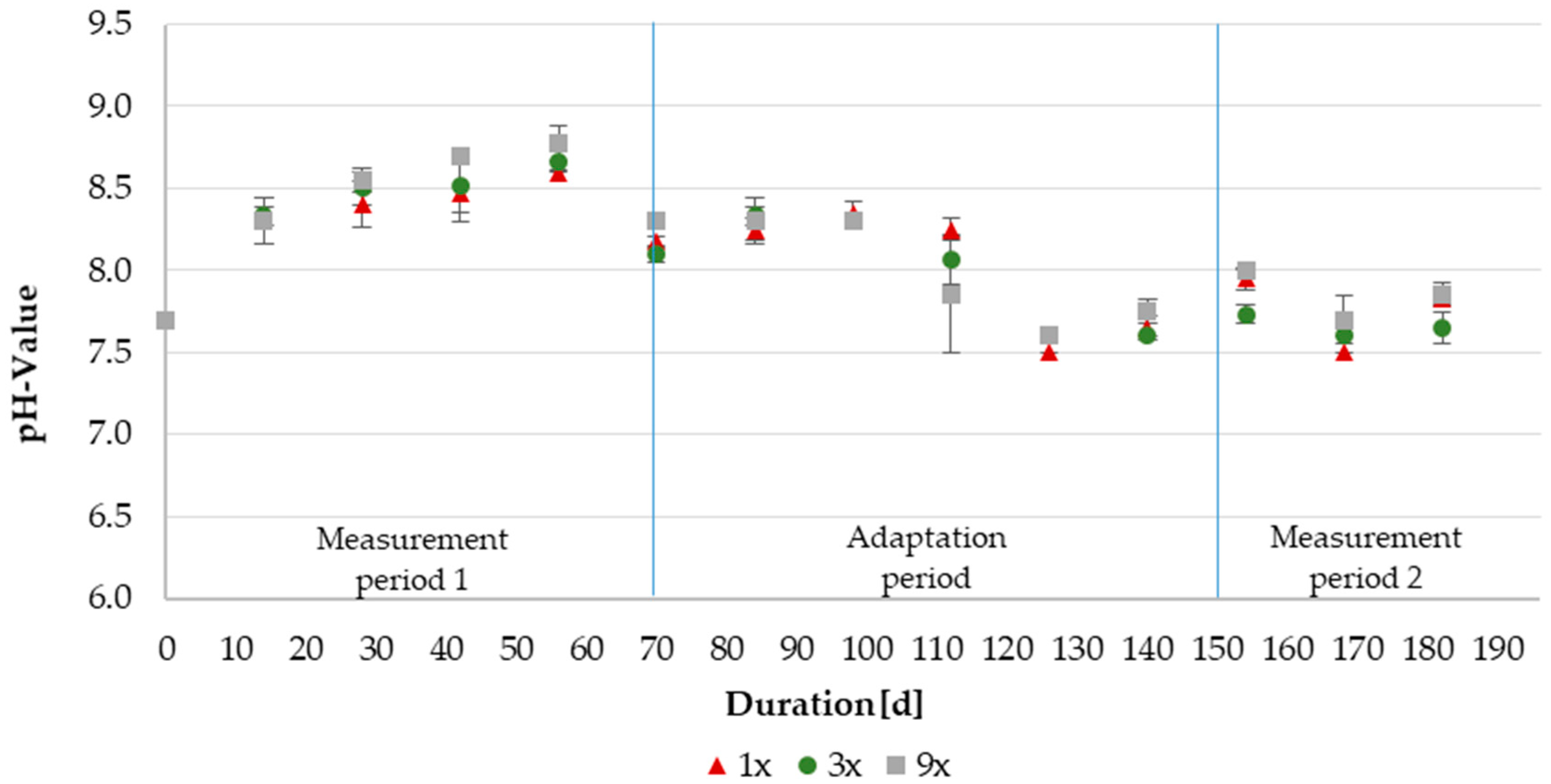

3.2.2. pH Value

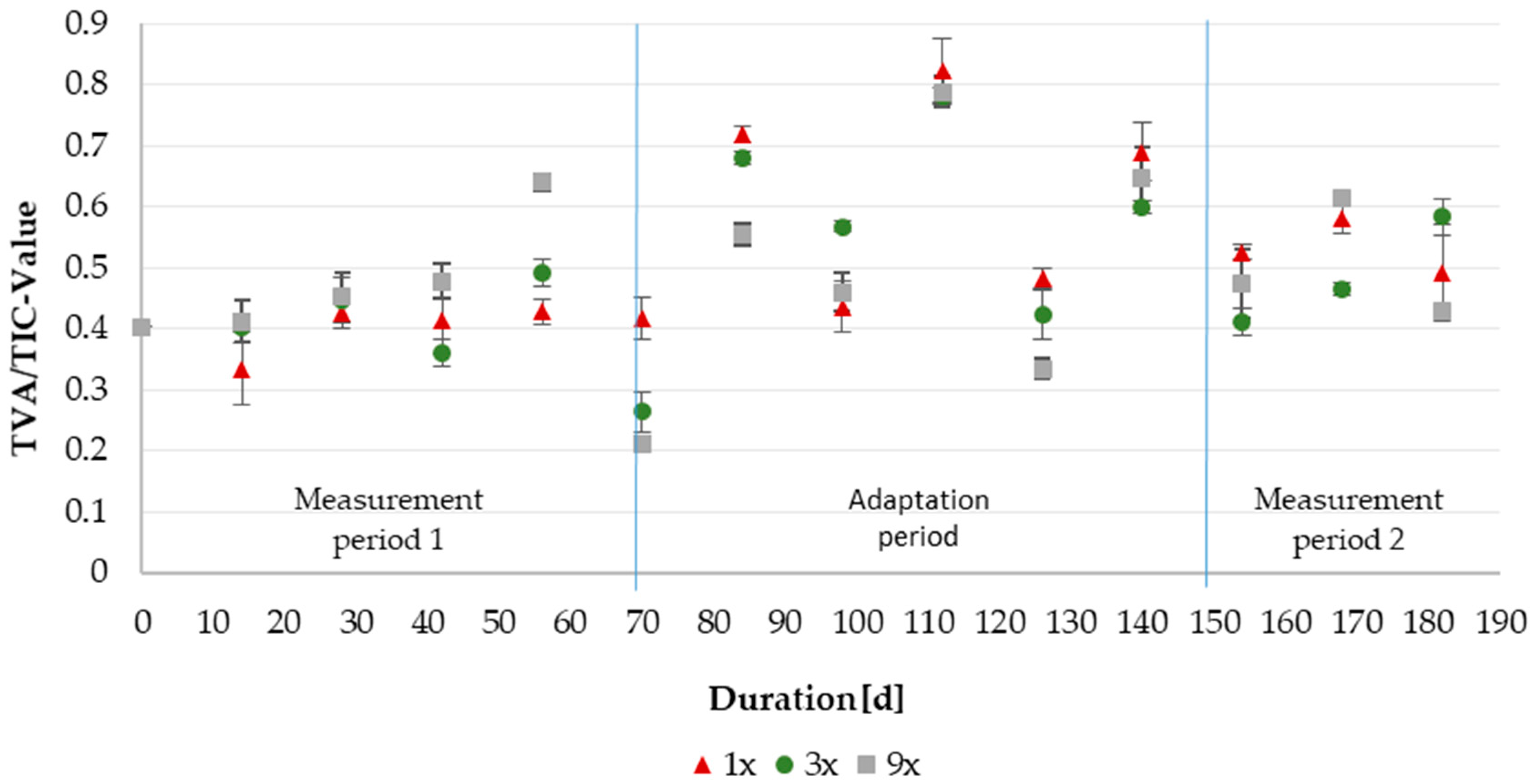

3.2.3. TVA/TIC Ratio

3.2.4. Total Ammonium-Nitrogen (NH4+-N) and Ammonia (NH3-N) Content

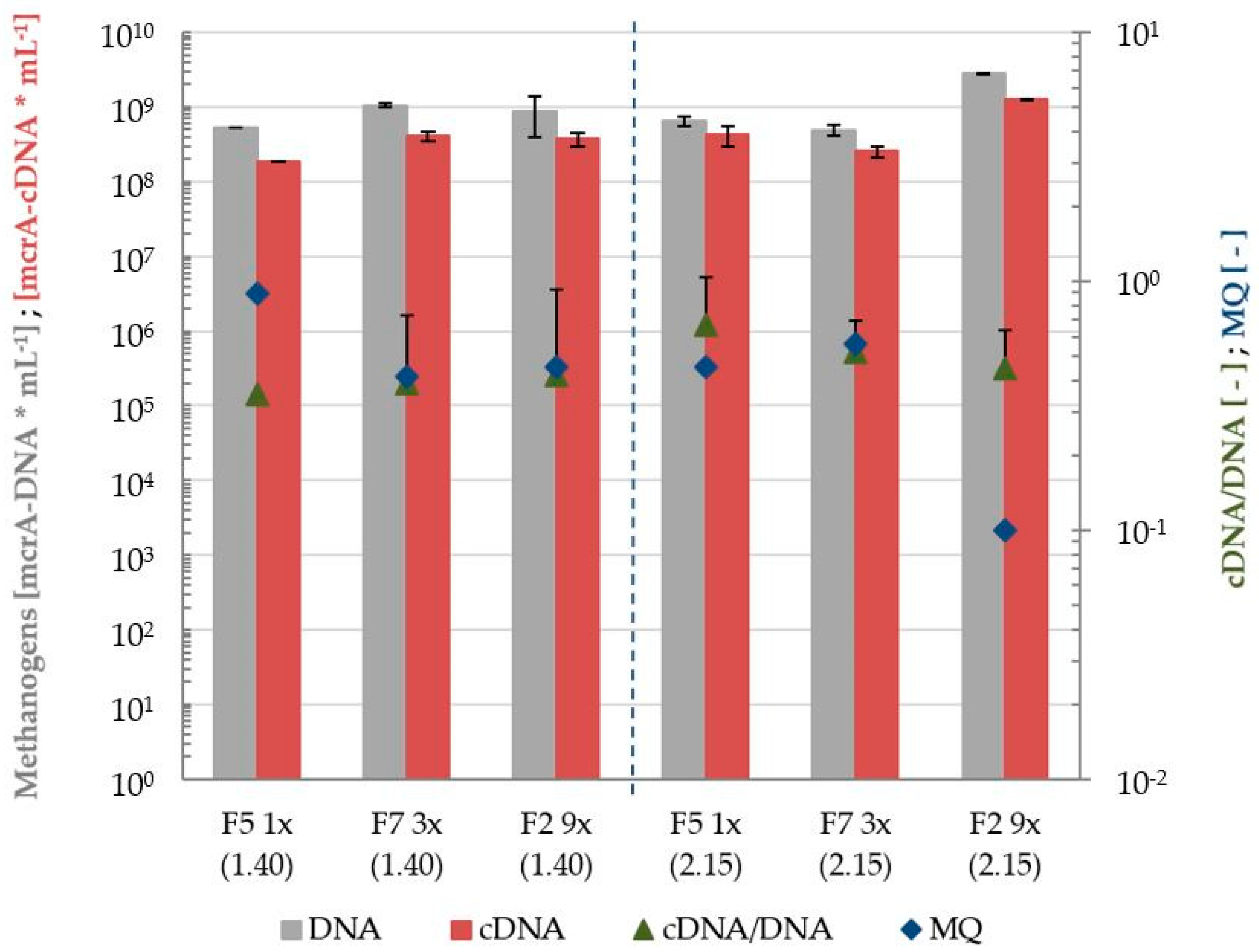

3.2.5. Molecular Biology Analyses

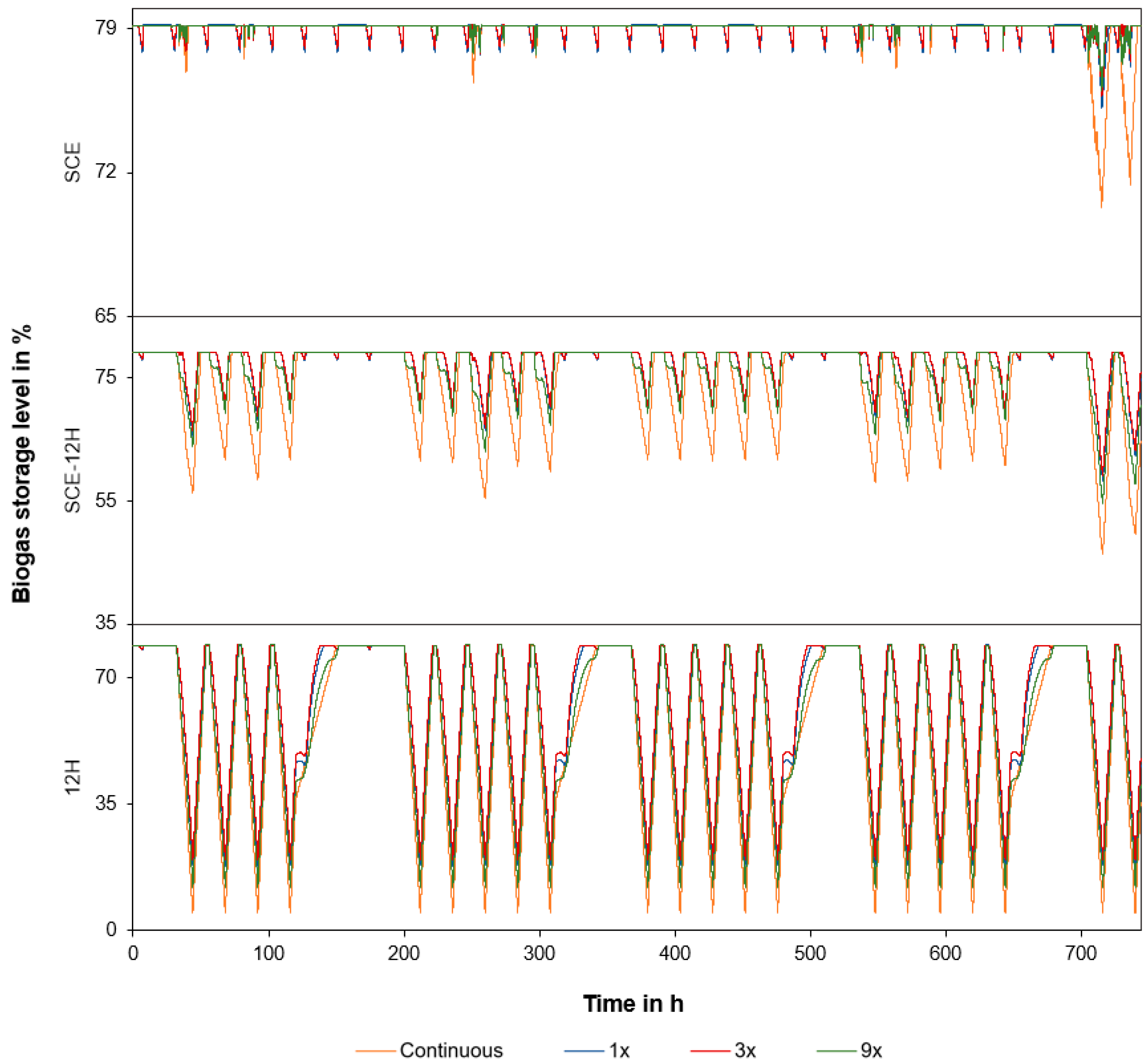

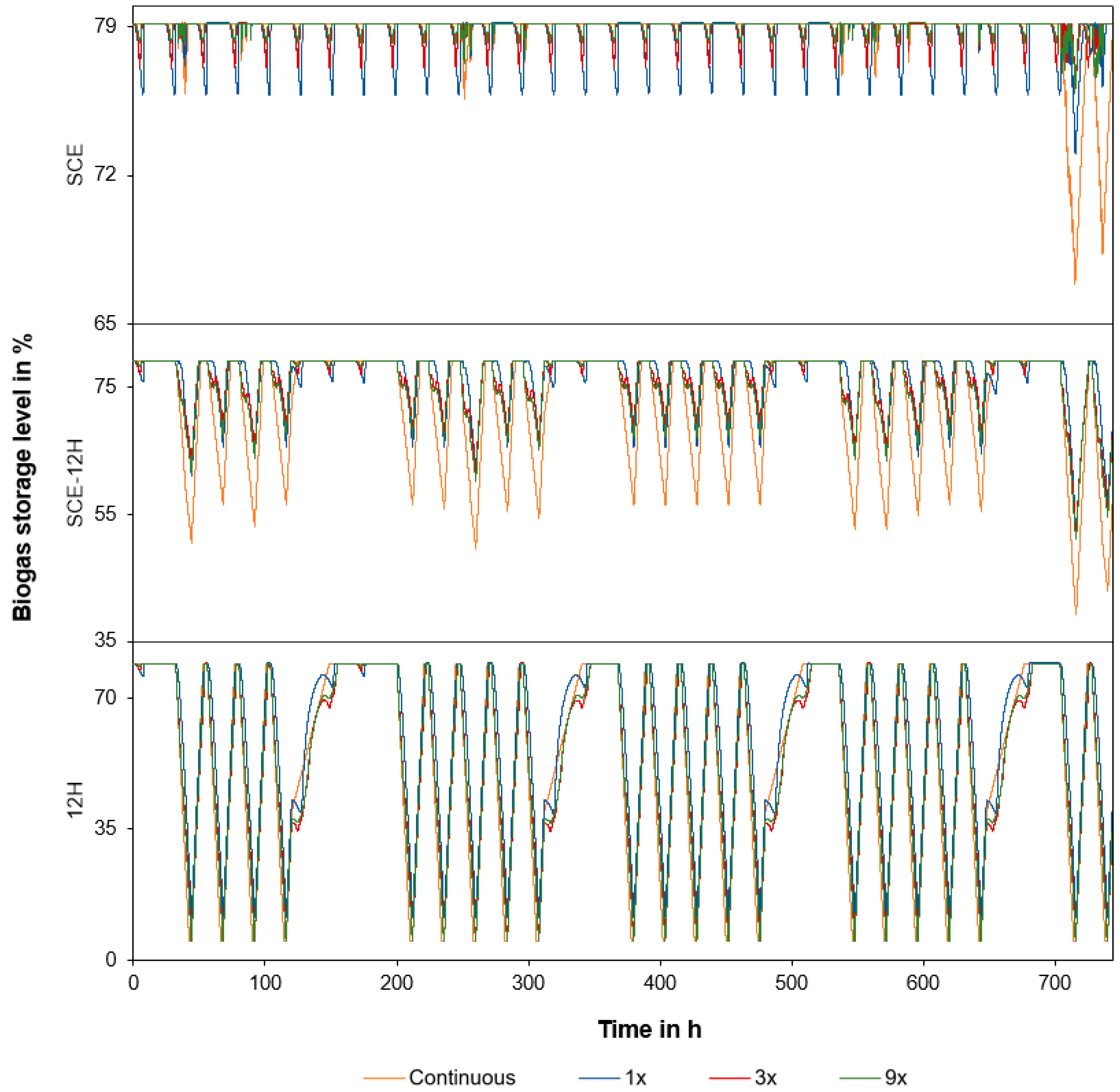

3.3. Effects on Biogas Storage Capacities

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Szarka, N.; Scholwin, F.; Trommler, M.; Fabian Jacobi, H.; Eichhorn, M.; Ortwein, A.; Thrän, D. A novel role for bioenergy: A flexible, demand-oriented power supply. Energy 2013, 61, 18–26. [Google Scholar] [CrossRef]

- Zacharias, F. Gasmotoren; Vogel Communications Group: Wels, Austria, 2001. [Google Scholar]

- Pablo-Romero, M.D.P.; Sánchez-Braza, A.; Salvador-Ponce, J.; Sánchez-Labrador, N. An overview of feed-in tariffs, premiums and tenders to promote electricity from biogas in the EU-28. Renew. Sustain. Energy Rev. 2017, 73, 1366–1379. [Google Scholar] [CrossRef]

- Hahn, H.; Krautkremer, B.; Hartmann, K.; Wachendorf, M. Review of concepts for a demand-driven biogas supply for flexible power generation. Renew. Sustain. Energy Rev. 2014, 29, 383–393. [Google Scholar] [CrossRef]

- Mauky, E.; Weinrich, S.; Jacobi, H.F.; Nägele, H.J.; Liebetrau, J.; Nelles, M. Demand-driven biogas production by flexible feeding in full-scale – Process stability and flexibility potentials. Anaerobe 2017, 46, 86–95. [Google Scholar] [CrossRef] [PubMed]

- Lv, Z.; Leite, A.F.; Harms, H.; Richnow, H.H.; Liebetrau, J.; Nikolausz, M. Influences of the substrate feeding regime on methanogenic activity in biogas reactors approached by molecular and stable isotope methods. Anaerobe 2014, 29, 91–99. [Google Scholar] [CrossRef] [PubMed]

- Mulat, D.G.; Fabian Jacobi, H.; Feilberg, A.; Adamsen, A.P.S.; Richnow, H.H.; Nikolausz, M. Changing feeding regimes to demonstrate flexible biogas production: Effects on process performance, microbial community structure, and methanogenesis pathways. Appl. Environ. Microbiol. 2016, 82, 438–449. [Google Scholar] [CrossRef] [PubMed]

- Mauky, E.; Jacobi, H.F.; Liebetrau, J.; Nelles, M. Flexible biogas production for demand-driven energy supply—Feeding strategies and types of substrates. Bioresour. Technol. 2015, 178, 262–269. [Google Scholar] [CrossRef]

- Lebuhn, M.; Munk, B.; Effenberger, M. Agricultural biogas production in Germany—From practice to microbiology basics. Energy Sustain. Soc. 2014, 4, 10. [Google Scholar] [CrossRef]

- Munk, B.; Bauer, C.; Gronauer, A.; Lebuhn, M. A metabolic quotient for methanogenic Archaea. Water Sci. Technol. 2012, 66, 2311–2317. [Google Scholar] [CrossRef][Green Version]

- Lyu, Z.; Shao, N.; Akinyemi, T.; Whitman, W.B. Methanogenesis. Curr. Biol. 2018, 28, 727–732. [Google Scholar] [CrossRef]

- Lebuhn, M.; Derenkó, J.; Rademacher, A.; Helbig, S.; Munk, B.; Pechtl, A.; Stolze, Y.; Prowe, S.; Schwarz, W.H.; Schlüter, A.; et al. DNA and RNA extraction and quantitative real-time PCR-based assays for biogas biocenoses in an interlaboratory comparison. Bioengineering 2016, 3, 7. [Google Scholar] [CrossRef] [PubMed]

- Grim, J.; Nilsson, D.; Hansson, P.A.; Nordberg, A. Demand-Orientated Power Production from Biogas: Modeling and Simulations under Swedish Conditions. Energy Fuels 2015, 29, 4066–4075. [Google Scholar] [CrossRef]

- Batstone, D.J.; Keller, J.; Angelidaki, I.; Kalyuzhnyi, S.V.; Pavlostathis, S.G.; Rozzi, A.; Sanders, W.T.; Siegrist, H.; Vavilin, V.A. The IWA anaerobic digestion model No 1 (ADM1). Water Sci. Technol. J. Int. Assoc. Water Pollut. Res. 2002, 45, 65–73. [Google Scholar] [CrossRef]

- O’Shea, R.; Wall, D.; Murphy, J.D. Modelling a demand driven biogas system for production of electricity at peak demand and for production of biomethane at other times. Bioresour. Technol. 2016, 216, 238–249. [Google Scholar] [CrossRef] [PubMed]

- Mauky, E.; Weinrich, S.; Nägele, H.J.; Jacobi, H.F.; Liebetrau, J.; Nelles, M. Model Predictive Control for Demand-Driven Biogas Production in Full Scale. Chem. Eng. Technol. 2016, 39, 652–664. [Google Scholar] [CrossRef]

- Barchmann, T.; Mauky, E.; Dotzauer, M.; Stur, M.; Weinrich, S.; Jakobi, H.F.; Liebetrau, J.; Nelles, M. Expanding the flexibility of Biogas plants—Substrate management, schedule synthesis and economic assessment. Landtechnik 2016, 71, 233–251. [Google Scholar] [CrossRef]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D.; Crocker, D. Determination of Structural Carbohydrates and Lignin in Biomass: Laboratory Analytical Procedure (LAP); National Renewable Energy Laboratory: Golden, CO, USA, 2008.

- Van Soest, P.J.; Wine, R.H. Use of detergents in the analysis of fibrous feeds. IV. Determination of plant cell-wall constituents. J. Assoc. Off. Anal. Chem. 1967, 50, 50–55. [Google Scholar]

- Eaton, A.D. Standard Methods for the Examination of Water and Wastewater; American Public Health Association: Washington, DC, USA, 1995. [Google Scholar]

- Hansen, K.H.; Angelidaki, I.; Ahring, B.K. Anaerobic digestion of swine manure: Inhibition by ammonia. Water Res. 1998, 32, 5–12. [Google Scholar] [CrossRef]

- Theiner, J. Elemental C/H/N/S Analysis; Microanalytical Laboratory, University of Vienna: Vienna, Austria, 2008. [Google Scholar]

- Boyle, W.C. Energy Recovery from Sanitary Landfills—A Review. In Microbial Energy Conversion, Proceedings of the a Seminar Sponsored by the UN Institute for Training and Research (UNITAR) and the Ministry for Research and Technology of the Federal Republic of Germany, Göttingen, Germany, October 1976; Schlegel, H.G., Barnea, J., Eds.; Elsevier: Amsterdam, Netherlands, 1977; pp. 119–138. [Google Scholar] [CrossRef]

- Li, Y.; Park, S.Y.; Zhu, J. Solid-state anaerobic digestion for methane production from organic waste. Renew. Sustain. Energy Rev. 2011, 15, 821–826. [Google Scholar] [CrossRef]

- Zeshan; Karthikeyan, O.P.; Visvanathan, C. Effect of C/N ratio and ammonia-N accumulation in a pilot-scale thermophilic dry anaerobic digester. Bioresour. Technol. 2012, 113, 294–302. [Google Scholar] [CrossRef]

- Kumar, M.; Ou, Y.-L.; Lin, J.-G. Co-composting of green waste and food waste at low C/N ratio. Waste Manag. 2010, 30, 602–609. [Google Scholar] [CrossRef] [PubMed]

- Zhong, W.; Chi, L.; Luo, Y.; Zhang, Z.; Zhang, Z.; Wu, W.-M. Enhanced methane production from Taihu Lake blue algae by anaerobic co-digestion with corn straw in continuous feed digesters. Bioresour. Technol. 2013, 134, 264–270. [Google Scholar] [CrossRef] [PubMed]

- Amon, T.; Amon, B.; Kryvoruchko, V.; Machmüller, A.; Hopfner-Sixt, K.; Bodiroza, V.; Hrbek, R.; Friedel, J.; Pötsch, E.; Wagentristl, H.; et al. Methane production through anaerobic digestion of various energy crops grown in sustainable crop rotations. Bioresour. Technol. 2007, 98, 3204–3212. [Google Scholar] [CrossRef] [PubMed]

- The Association of German Engineers. VDI 4630: Fermentation of Organic Materials—Characterisation of the Substrate, Sampling, Collection of Material data, Fermentation Tests; The Association of German Engineers: Duesseldorf, Germany, 2006; pp. 44–59. [Google Scholar]

- Sterling, M.C.; Lacey, R.E.; Engler, C.R.; Ricke, S.C. Effects of ammonia nitrogen on H2 and CH4 production during anaerobic digestion of dairy cattle manure. Bioresour. Technol. 2001, 77, 9–18. [Google Scholar] [CrossRef]

- Krapf, L.C.; Gronauer, A.; Schmidhalter, U.; Heuwinkel, H. Near infrared spectroscopy calibrations for the estimation of process parameters of anaerobic digestion of energy crops and livestock residues. J. Near Infrared Spectros. 2011, 19, 479–493. [Google Scholar] [CrossRef]

- Buchauer, K. A comparison of two simple titration procedures to determine volatile fatty acids in influents to waste-water and sludge treatment processes. Water SA 1998, 24, 49–56. [Google Scholar]

- Lebuhn, M.; Effenberger, M.; Gronauer, A.; Wilderer, P.A.; Wuertz, S. Using quantitative real-time PCR to determine the hygienic status of cattle manure. Water Sci. Technol. 2003, 48, 97–103. [Google Scholar] [CrossRef]

- Bauer, C.; Korthals, M.; Gronauer, A.; Lebuhn, M. Methanogens in biogas production from renewable resources—A novel molecular population analysis approach. Water Sci. Technol. 2008, 58, 1433–1439. [Google Scholar] [CrossRef]

- Munk, B.; Bauer, C.; Gronauer, A.; Lebuhn, M. Population dynamics of methanogens during acidification of biogas fermenters fed with maize silage. Eng. Life Sci. 2010, 10, 496–508. [Google Scholar] [CrossRef]

- Saracevic, E.; Woess, D.; Theuretzbacher, F.; Friedl, A.; Miltner, A. Techno-economic assessment of providing control energy reserves with a biogas plant. Front. Chem. Sci. Eng. 2018, 12, 763–771. [Google Scholar] [CrossRef]

- Wöss, D.; Pröll, T.; Hofbauer, H. Investigation of the start-up procedure of a circulating fluidized bed test unit using a commercial steady state simulation tool. In Proceedings of the European Combustion Meeting, Vienna, Austria, 14–17 April 2009. [Google Scholar]

- Konstantin, P. Praxisbuch Energiewirtschaft: Energieumwandlung, -Transport und -Beschaffung im Liberalisierten Markt, 3rd ed.; Springer: Berlin, Germany, 2007; ISBN 978-3-540-35377-5. [Google Scholar]

- Balancing Statistics in APG Control Area. Available online: https://www.apg.at/en/market/balancing/statistics (accessed on 30 April 2019).

- Internet Platform for Allocation of Control Energy Reserves. Available online: https://www.regelleistung.net/ext/ (accessed on 30 April 2019).

- Speicherung und flexible Betriebsmodi zur Schonung wertvoller Ressourcen und zum Ausgleich von Stromschwankungen bei hohen Anteil erneuerbarer Energien in Baden-Würtemberg (BioenergieFlex BW). Available online: http://fachdokumente.lubw.baden-wuerttemberg.de/servlet/is/119608/bwe13006_13008.pdf?command=downloadContent&filename=bwe13006_13008.pdf&FIS=203 (accessed on 30 April 2019).

- Drosg, B. Process monitoring in biogas plants. In Technical Brochure; IEA Bioenergy: Paris, France, 2013; ISBN 978-1-910154-03-8. [Google Scholar]

- Kaiser, F.; Metzner, T.; Effenberger, M.; Gronauer, A. Sicherung der Prozessstabilität in Landwirtschaftlichen Biogasanlagen, 2nd ed.; Bavarian State Research Center for Agriculture: Freising, Germany, 2008. [Google Scholar]

- Hansen, K.H.; Ahring, B.K.; Raskin, L. Quantification of syntrophic fatty acid-β-oxidizing bacteria in a mesophilic biogas reactor by oligonucleotide probe hybridization. Appl. Environ. Microbiol. 1999, 65, 4767–4774. [Google Scholar] [PubMed]

- Cirne, D.G.; Agbor, V.B.; Bjornsson, L. Enhanced solubilisation of the residual fraction of municipal solid waste. Water Sci. Technol. 2008, 57, 995–1000. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Speece, R.E. Anaerobic Biotechnology for Industrial Wastewaters; Archae Press: Nashville, TN, USA, 1996; ISBN 978-0965022606. [Google Scholar]

- Guštin, S.; Marinšek-Logar, R. Effect of pH, temperature and air flow rate on the continuous ammonia stripping of the anaerobic digestion effluent. Process Safety Environ. Prot. 2011, 89, 61–66. [Google Scholar] [CrossRef]

- Zhang, C.; Su, H.; Baeyens, J.; Tan, T. Reviewing the anaerobic digestion of food waste for biogas production. Renew. Sustain. Energy Rev. 2014, 38, 383–392. [Google Scholar] [CrossRef]

- Scherer, P. Operating Analytics of Biogas Plants to Improve Efficiency and to Ensure Process Stability. In Proceedings of Progress in Biogas; University Stuttgart-Hohenheim: Stuttgart, Germany; IBBK: Kirchberg, Germany, 2007; ISBN 387-3-940706-00-3. [Google Scholar]

- Jahan Imu, N.; Mann Samuel, D. Biogas production potential from municipalorganic wastes in Dhaka City, Bangladesh. Int. J. Res. Eng. Technol. 2014, 3, 453–460. [Google Scholar]

- Scano, E.A.; Asquer, C.; Pistis, A.; Ortu, L.; Demontis, V.; Cocco, D. Biogas from anaerobic digestion of fruit and vegetable wastes: Experimental results on pilot-scale and preliminary performance evaluation of a full-scale power plant. Energy Convers. Manag. 2014, 77, 22–30. [Google Scholar] [CrossRef]

- Van Velsen, A.F.M. Adaptation of methanogenic sludge to high ammonia-nitrogen concentrations. Water Res. 1979, 13, 995–999. [Google Scholar] [CrossRef]

- Melbinger, N.R.; Donnellon, J.; Zablatzky, H.R. Toxic effects of ammonia nitrogen in high rate digestion. Water Pollut. Control Federat. 1971, 43, 1658–1670. [Google Scholar]

- Munk, B.; Guebitz, G.M.; Lebuhn, M. Influence of nitrogen-rich substrates on biogas production and on the methanogenic community under mesophilic and thermophilic conditions. Anaerobe 2017, 46, 146–154. [Google Scholar] [CrossRef]

- Munk, B.; Lebuhn, M. Process diagnosis using methanogenic Archaea in maize-fed, trace element depleted fermenters. Anaerobe 2014, 29, 22–28. [Google Scholar] [CrossRef]

- De Francisci, D.; Kougias, P.G.; Treu, L.; Campanaro, S.; Angelidaki, I. Microbial diversity and dynamicity of biogas reactors due to radical changes of feedstock composition. Bioresour. Technol. 2015, 176, 56–64. [Google Scholar] [CrossRef] [PubMed]

- Ziganshin, A.M.; Liebetrau, J.; Pröter, J.; Kleinsteuber, S. Microbial community structure and dynamics during anaerobic digestion of various agricultural waste materials. Appl. Microbiol. Biotechnol. 2013, 97, 5161–5174. [Google Scholar] [CrossRef] [PubMed]

- Langer, S.G.; Gabris, C.; Einfalt, D.; Wemheuer, B.; Kazda, M.; Bengelsdorf, F.R. Different response of bacteria, archaea and fungi to process parameters in nine full-scale anaerobic digesters. Microb. Biotechnol. 2019. [Google Scholar] [CrossRef] [PubMed]

- Lauer, M.; Dotzauer, M.; Hennig, C.; Lehmann, M.; Nebel, E.; Postel, J.; Szarka, N.; Thrän, D. Flexible power generation scenarios for biogas plants operated in Germany: Impacts on economic viability and GHG emissions. Int. J. Energy Res. 2017, 41, 63–80. [Google Scholar] [CrossRef]

| Feedstock 1 | Feedstock 2 | ||

|---|---|---|---|

| OLR | [kg vs. m−3 d−1] | 1.4 | 2.15 |

| DM | [% FM] | 15.9 | 9.9 |

| VS | [% FM] | 15.1 | 8.8 |

| DM (KF) | [% FM] | 20.2 | 10.6 |

| Water | [% FM] | 79.8 | 89.4 |

| XA | [% VS] | 5.1 | 11.3 |

| XL | [% VS] | 73.5 | 33 |

| XP | [% VS] | 10.6 | 24.7 |

| CEL | [% VS] | 6.2 | 13.9 |

| H-CEL | [% VS] | 5.1 | 9.9 |

| ADL | [% VS] | 3.0 | 10.5 |

| C | [% VS] | 73.1 | 64.9 |

| H | [% VS] | 12.1 | 10.3 |

| N | [% VS] | 1.6 | 2.9 |

| O | [% VS] | 12.9 | 21.7 |

| S | [% VS] | 0.2 | 0.3 |

| Theoretical biogas potential | [lN kg−1VS] | 1.390 | 1.231 |

| Theoretical methane potential | [lN kg−1VS] | 963 | 796 |

| Sample | Biogas Production | Methane Production | ||||

|---|---|---|---|---|---|---|

| [lN m−3 d−1] | [lN m−3 d−1] | |||||

| 1x | 3x | 9x | 1x | 3x | 9x | |

| Feedstock 1 | 1623 ± 60 | 1590 ± 80 | 1542 ± 31 | 1138± 48 | 1114 ± 57 | 1080 ± 26 |

| Feedstock 2 | 1551 ± 95 | 1524 ± 137 | 1528 ± 118 | 966 ± 61 | 947 ± 95 | 952 ± 75 |

| Biogas plant Bruck an der Leitha (Ø 2015) | 1480 ± 273 | 932 ± 175 | ||||

| Sample | Feeding Strategy | CH4 | CO2 | H2 | H2S |

|---|---|---|---|---|---|

| [vol.-%] | [ppm] | ||||

| Feedstock 1 | 1x | 69.6 ± 0.6 | 30.4 ± 0.6 | 554 ± 127 | 93 ± 20 |

| 3x | 70.1 ± 0.9 | 29.9 ± 0.9 | 476 ± 67 | 92 ± 10 | |

| 9x | 69.9 ± 0.7 | 30.1 ± 0.7 | 214 ±167 | 45 ± 32 | |

| 1x | 64.2 ± 0.9 | 35.8 ± 0.9 | 359 ± 80 | 90 ± 9 | |

| Feedstock 2 | 3x | 64.3 ± 1.2 | 35.7 ± 1.2 | 138 ± 117 | 30. ± 30 |

| 9x | 64.8 ± 1.0 | 35.2 ± 1.0 | 242 ±122 | 55 ±29 | |

| Sample | Measurement Period | Acetic Acid | Propionic Acid | ||||

|---|---|---|---|---|---|---|---|

| [days] | [mg kg−1 FM] | [mg kg−1 FM] | |||||

| 1x | 3x | 9x | 1x | 3x | 9x | ||

| Feedstock 1 | 20 | 926 | 1002 | 1149 | 43.9 | 37.5 | 38.9 |

| 30 | 553 | 865 | 1373 | <0.03 | 11.1 | 53.6 | |

| 45 | 658 | 1642 | 741 | <0.03 | 64.9 | 31.1 | |

| 58 | 919 | 1118 | 1392 | 15.5 | 20.8 | 43.4 | |

| Feedstock 2 | 175 | 1307 | 1406 | 1817 | 11.1 | 50.1 | 43.2 |

| 180 | 1152 | 1314 | 1651 | 11.1 | 52.9 | 53.1 | |

| 186 | no value | 1038 | 1265 | <0.10 | 23.3 | 31.6 | |

| Sample | Measurement Period | Ammonium-Nitrogen (NH4+-N) | Ammonia-Nitrogen (NH3-N) | ||||

|---|---|---|---|---|---|---|---|

| [days] | [mg kg−1 FM] | [mg L−1 FM] | |||||

| 1x | 3x | 9x | 1x | 3x | 9x | ||

| Feedstock 1 | 0 | 1200 | 1200 | 1200 | 88 | 88 | 88 |

| 29 | 1230 | 1250 | 1300 | 170 | 211 | 220 | |

| 48 | 1330 | 1240 | 1230 | 225 | 255 | 305 | |

| Feedstock 2 | 158 | 1390 | 1240 | 1390 | 65 | 73 | 42 |

| 168 | 1340 | 1300 | 1280 | 26 | 32 | 39 | |

| 184 | 1330 | 1340 | 1360 | 40 | 64 | 41 | |

| Feedstock 1 | Feedstock 2 | ||||

|---|---|---|---|---|---|

| Scenario | Feeding Regime | Needed Biogas Storage Volume | Reduction Potential | Needed Biogas Storage Volume | Reduction Potential |

| [m3] | [%] | [m3] | [%] | ||

| SCE | Continuous | 425 | - | 591 | - |

| 1x | 194 | 54.3 | 299 | 49.5 | |

| 3x | 166 | 60.9 | 156 | 73.7 | |

| 9x | 155 | 63.7 | 161 | 72.8 | |

| SCE-12H | Continuous | 1579 | - | 1916 | - |

| 1x | 1004 | 36.4 | 1270 | 33.7 | |

| 3x | 964 | 38.9 | 1295 | 32.4 | |

| 9x | 1181 | 25.2 | 1353 | 29.4 | |

| 12H | Continuous | 3571 | - | 3571 | - |

| 1x | 2940 | 17.7 | 3266 | 8.5 | |

| 3x | 2865 | 19.8 | 3571 | - | |

| 9x | 3234 | 9.5 | 3571 | - | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saracevic, E.; Frühauf, S.; Miltner, A.; Karnpakdee, K.; Munk, B.; Lebuhn, M.; Wlcek, B.; Leber, J.; Lizasoain, J.; Friedl, A.; et al. Utilization of Food and Agricultural Residues for a Flexible Biogas Production: Process Stability and Effects on Needed Biogas Storage Capacities. Energies 2019, 12, 2678. https://doi.org/10.3390/en12142678

Saracevic E, Frühauf S, Miltner A, Karnpakdee K, Munk B, Lebuhn M, Wlcek B, Leber J, Lizasoain J, Friedl A, et al. Utilization of Food and Agricultural Residues for a Flexible Biogas Production: Process Stability and Effects on Needed Biogas Storage Capacities. Energies. 2019; 12(14):2678. https://doi.org/10.3390/en12142678

Chicago/Turabian StyleSaracevic, Ervin, Susanne Frühauf, Angela Miltner, Kwankao Karnpakdee, Bernhard Munk, Michael Lebuhn, Bernhard Wlcek, Jonas Leber, Javier Lizasoain, Anton Friedl, and et al. 2019. "Utilization of Food and Agricultural Residues for a Flexible Biogas Production: Process Stability and Effects on Needed Biogas Storage Capacities" Energies 12, no. 14: 2678. https://doi.org/10.3390/en12142678

APA StyleSaracevic, E., Frühauf, S., Miltner, A., Karnpakdee, K., Munk, B., Lebuhn, M., Wlcek, B., Leber, J., Lizasoain, J., Friedl, A., Gronauer, A., & Bauer, A. (2019). Utilization of Food and Agricultural Residues for a Flexible Biogas Production: Process Stability and Effects on Needed Biogas Storage Capacities. Energies, 12(14), 2678. https://doi.org/10.3390/en12142678