1. Introduction

Buildings account for around 40% of the total energy consumption and about 36% of CO2 emissions in Europe [

1]. The main factors of building energy consumption are the properties and design of the building envelope, the operation of building services, the occupants’ behavior and the climate/location [

2,

3,

4,

5]. Most of this energy, ranging from nearly 50% [

6] up to 60% [

7] depending on climate, design, use type and occupational patterns, is used by air-conditioning systems to achieve thermal comfort inside the buildings. Energy in the form of heat is dissipated to the environment at different rates according to the ventilation and building elements’ characteristics (e.g., thermal transmittance

-value). The rate of these losses/gains is important because it directly affects the operation and maintenance costs of mechanically ventilated and/or air conditioned buildings [

8].

Usually a wall element is composed of several layers, such as internal and external cladding (e.g., cement mortar), one or two supporting panes (e.g., ceramic brick masonry), air cavity, and thermal and acoustic insulation (e.g., expanded polystyrene (EPS) or mineral wool). Typically lightweight steel framed (LSF) walls are made of the following main types of materials [

9]: (1) supporting steel frame, which is constituted of cold formed profiles; (2) sheathing panels, such as inner gypsum plasterboard and outer oriented strand board (OSB), and; (3) insulation materials, such as mineral wool filling the air cavity between steel studs (which besides thermal insulation, has also an important acoustic insulation role [

10]) and the exterior thermal insulation composite system (ETICS), where the thermal insulation material could be EPS (expanded polystyrene), XPS (extruded polystyrene), mineral wool or other.

The

-value of an opaque building element (e.g., facade LSF wall) depends on several factors, such as the thickness of each layer, the number of layers, the thermal conductivity of each layer material, the existence of thermal bridges due to the presence of an inhomogeneous thermal layer (e.g., a steel stud), the existence of air voids in the insulation, and the external and internal surface thermal resistances [

11]. Perhaps the most relevant parameters regarding the thermal transmittance of a LSF building element are the level of insulation (i.e., its thickness), material properties (e.g., thermal conductivity) and positioning of insulation, and the amount of steel frame material [

7,

12].

In colder climates to reduce the

-value, and consequently the heat transmission losses, the level of thermal insulation is increased to diminish the heating energy demand [

13]. While in warmer climates this level of thermal insulation could be reduced, reducing energy consumption for space heating/cooling as well as the embodied energy related with the insulation materials [

14]. In these warmer climates the outdoor temperatures are often higher than the indoor temperatures, which could significantly increase the heat gains. Thus, the use of passive cooling strategies, such as natural ventilation [

15], phase change materials [

16], free cooling [

17] and ground ventilation using an earth-to-air heat exchanger [

18] becomes more relevant. In order to predict the energy consumption it is usual to perform advanced dynamic simulations of the entire building [

19,

20] or make use of more simplified approaches [

21].

Apart from the level of thermal insulation (i.e., the thickness of thermal insulation layer(s)), in LSF elements, the position in the building element influences the effectiveness of this insulation (i.e., its

-value or thermal transmittance), and is thus very relevant [

12]. Notice, that the thermal insulation positioning is also relevant to the effective thermal inertia/mass of the building, but this was not evaluated in the present paper, neither in reference [

12] work. Moreover, this insulation, mainly the LSF batt insulation (e.g., mineral wool), is relevant not only for thermal purposes but also for acoustic insulation [

10]. A typical interior partition and exterior facade LSF wall cross-sections will be studied in this paper, as presented later in

Section 2.1 and

Section 3.1, respectively.

At the design stage there are several ways to compute the

-value of a building element [

11]. The detailed calculation method based on numerical simulations (e.g., finite element method (FEM)) should be performed using the modeling rules prescribed in standard ISO 10211 [

22]. The most simple approach, applicable for homogeneous thermal layers, which may contain air layers up to 300 mm thick, is to consider the thermal resistance of each layer (depending on the thickness of the layer and on the thermal conductivity of the material) and to compute the reciprocal of the sum of all these thermal resistances, including both internal and external surface resistances [

23]. Notice that the external thermal surface resistance mainly depends on the wind direction and velocity, as well as on the surface roughness [

24].

The standard ISO 6946 [

11] also prescribes an approximate method, known as the ‘Combined Method’, for building elements containing homogenous and inhomogeneous layers, including the effect of metal fasteners, by means of a

-value correction term. However, this methodology is not applicable for LSF elements, where the thermal insulation is bridged by metal (cold and hybrid frame construction), making this type of construction even more challenging in order to obtain an accurate and reliable

-value [

23].

Several researchers devoted their attention to the thermal behavior and energy efficiency of LSF construction [

5,

9,

23,

25,

26]. Soares et al. [

26] performed a scientific bibliographic review about this kind of research. The first main driving research topic identified in the previous cited work was: “the development of single and combined strategies to reduce thermal bridges and to improve the thermal resistance of LSF envelope elements”. The present work deals with this suggested main research issue. Recently Santos et al. [

23] accomplished a comparison between experimental measurements in LSF walls’ thermal transmittance and numerical simulations (2D and 3D FEM models) and analytical approach (ISO 6946 combined method). It was concluded that for the LSF wall with a simpler frame (i.e., only vertical steel studs) the analytical ISO 6946 and the 2D FEM numerical approaches provide quite good accuracy in the

-value estimation.

Since the ISO 6946 combined method is not applicable for LSF elements where the thermal insulation is bridged by the steel frames, some researchers developed some alternative analytical methods for this type of structure, such as Gorgolewsky [

27] who developed a simplified analytical method for calculating

-values in LSF cold and hybrid construction. This method was based on the principles provided by ISO 6946, but adapted to consider the increased thermal effect of the steel frame, increasing the accuracy of the proposed methodology.

Given the high level of heterogeneity regarding the thermal conductivities of the materials composing the LSF elements, namely the steel frame and the thermal insulation, it is very challenging not only to accurately compute its thermal transmittance, but also to perform accurate and reliable measurements, both in-situ and in laboratory [

8]. Regarding the experimental approach there are several methods for the thermal characterization of building elements, such as the heat flow meter (HFM) method, the guarded hot plate (GHP) method, the hot box (HB) method (which could be calibrated (CHB) or guarded (GHB)) and the infrared thermography (IRT) method. For LSF elements the most suitable experimental method, given its large heterogeneity in its component materials’ thermal conductivity (e.g., steel and thermal insulation), is the hot box apparatus, since the measurements are not local, but instead in a representative wall area [

28].

Recently, Atsonios et al. [

29] developed two experimental methods for in-situ measurement of the overall thermal transmittance of cold frame LSF walls, namely the representative points method (RPM) and weighted area method (WAM). These methods make use of the analysis of the examined wall using thermal IR images with the recording and processing of indoor/outdoor air temperature and heat flux.

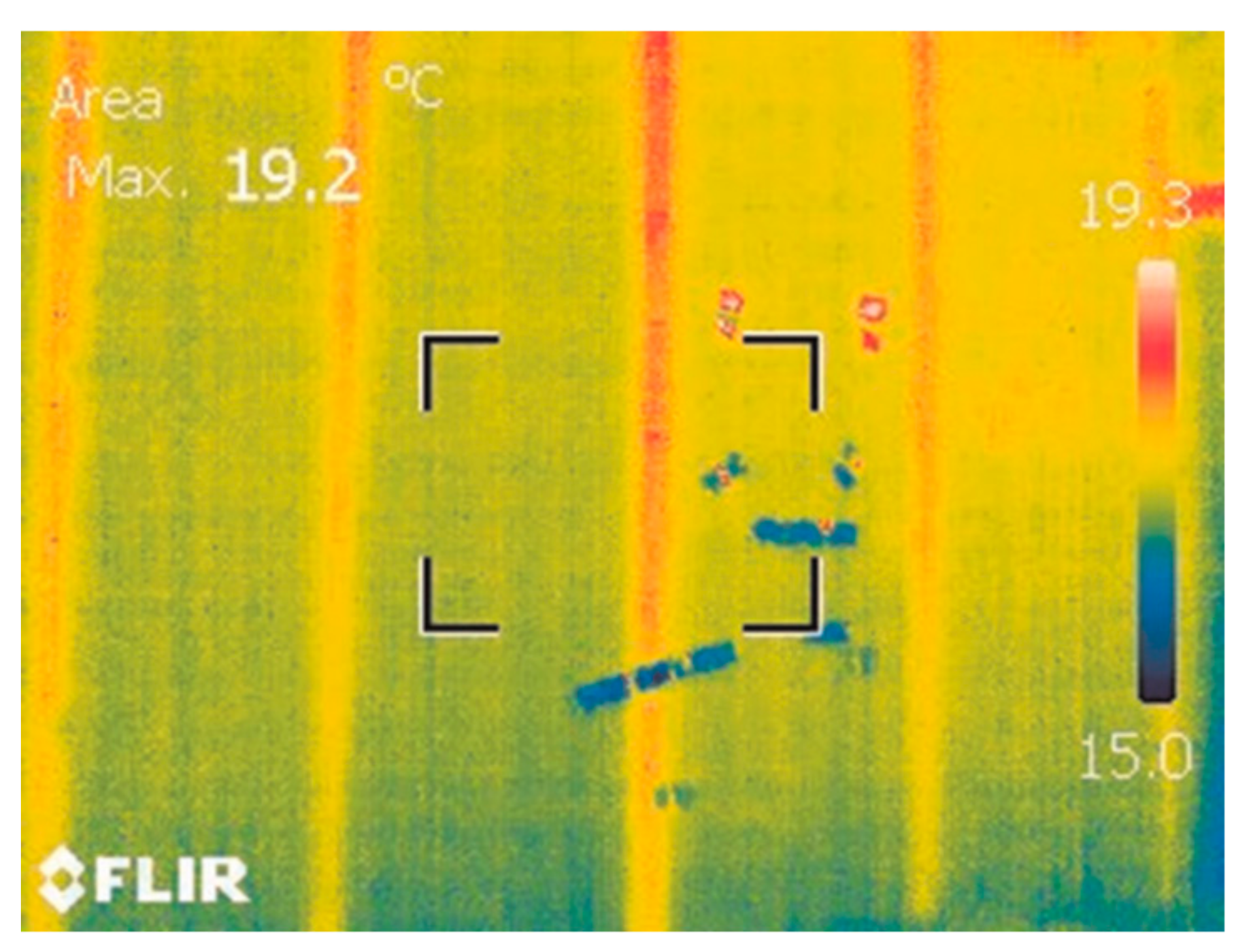

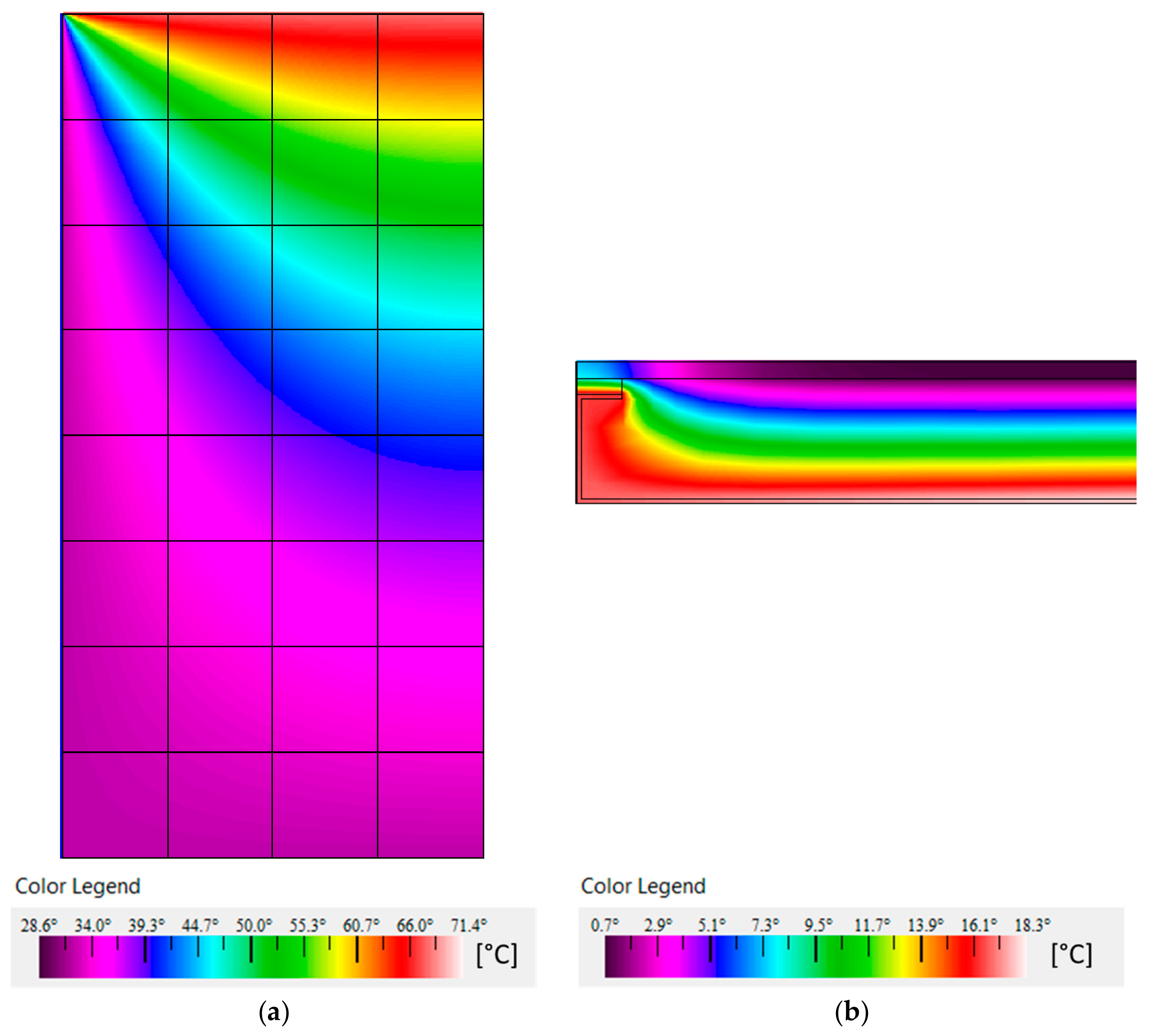

Figure 1 displays an infrared thermal image of an LSF wall, where the thermal bridge’s effect due to the high thermal conductivity of the vertical steel studs is quite visible. The vertical red lines denote higher surface temperatures due to an increased heat flow in the vicinity of each vertical steel profile, clearly identifying the position of them in the exterior colder surface of the LSF wall.

In fact, due to high thermal conductivity of steel in LSF structures, thermal bridges inspired many researchers to investigate the related thermal performance issues. De Angelis and Serra [

31] evaluated the thermal insulation performance of metal framed lightweight walls and concluded that the correct evaluation of LSF walls’ thermal performance requires more complex and detailed analysis than the ones necessary for traditional reinforced concrete and masonry constructions.

Also in 2014, Santos et al. [

30] evaluated the importance of flanking thermal losses of LSF walls using a 3D FEM model validated by comparison with experimental laboratory measurements. They found heat flux variations from −22% (external surface) to +50% (internal surface) when flanking heat loss was set to zero as a reference case for a LSF wall with a thermal transmittance equal to 0.30 W/(m

2.K). Later, in 2016, Martins et al. [

32] performed a parametric study in order to evaluate the effectiveness of some thermal bridges mitigation strategies in LSF walls, allowing the improvement of thermal performance and reducing energy consumption by air-conditioning systems. A reduction of 8.3% in the

-value was found, comparatively to the reference LSF wall, due to these thermal bridges’ mitigation strategies. Additionally, the use of new insulation materials (e.g., aerogel and vacuum insulation panels (VIPs)), which were combined with the mitigation approaches, led to a 68% decrease in the

-value.

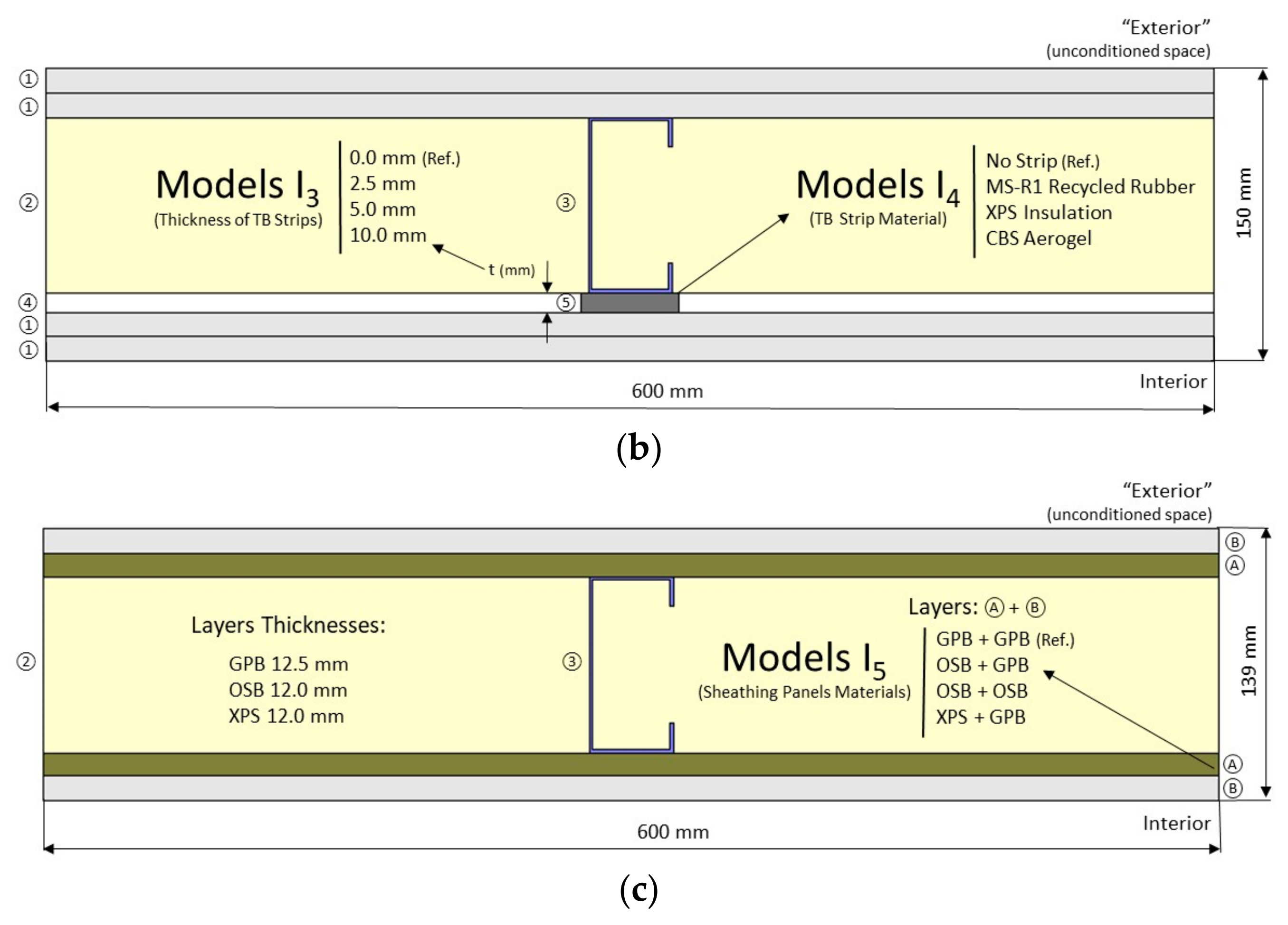

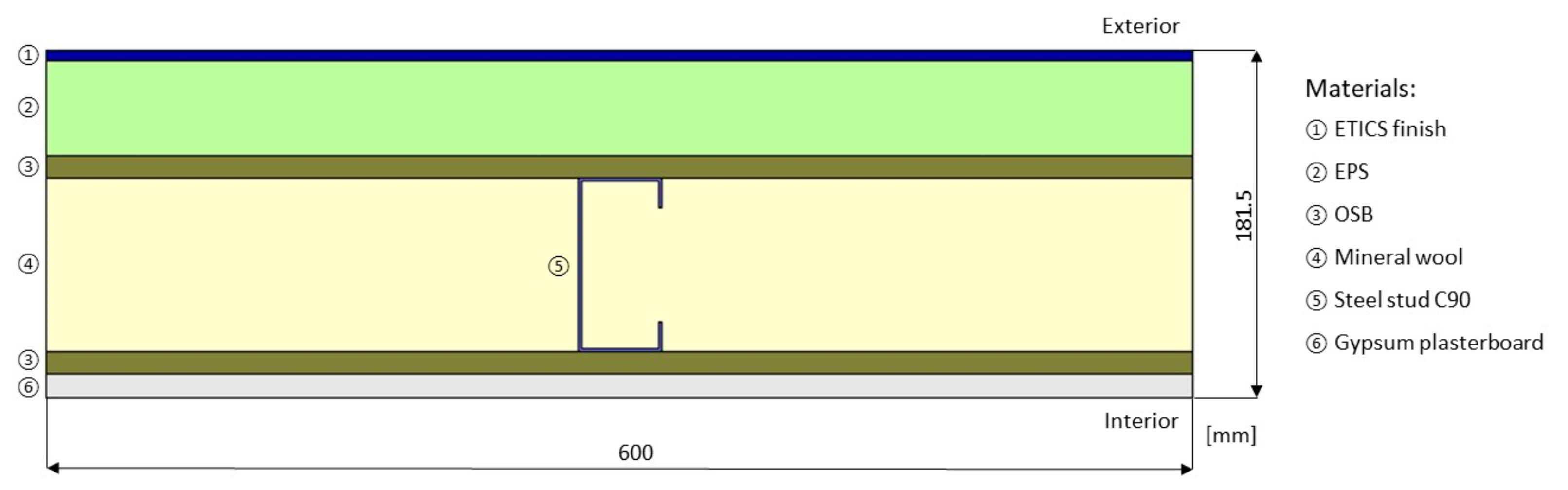

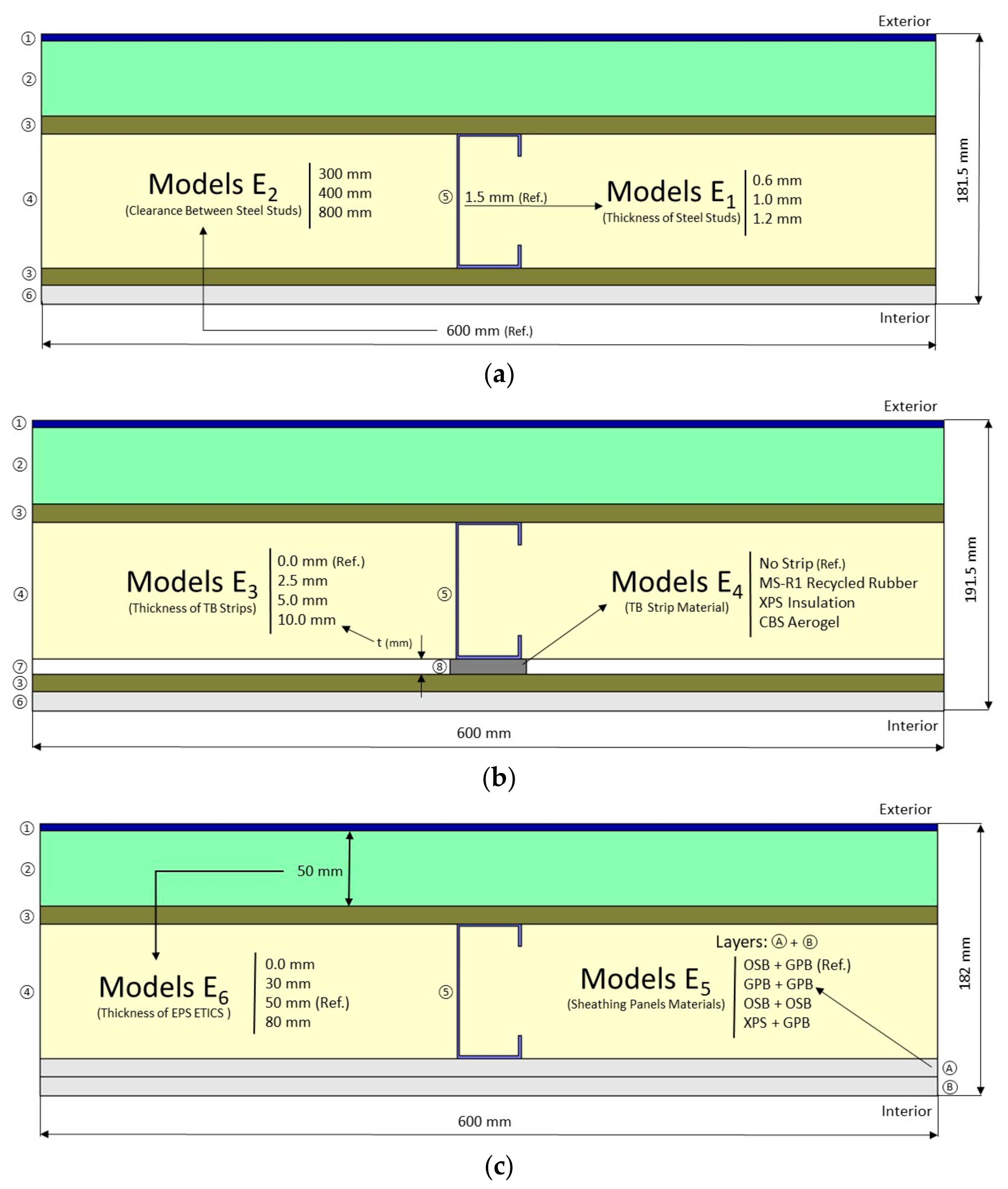

In previous research works there was a lack of research on both interior partitions and exterior facade LSF walls, as well as the thermal performance comparison between them. In this work the thermal transmittance (-value) of LSF walls is evaluated by means of a parametric study related with the wall typology (internal partition and external facade) and its composition. The main objective of this study is to quantify the relevance of several parameters in the -value of LSF partition and facade walls. The evaluated parameters were selected among the most relevant ones and could be easily implemented in practice with used materials available in the market (e.g., recycled rubber, extruded polystyrene (XPS) and aerogel thermal break strips). Moreover, the analyzed LSF wall configurations were newly implemented for this study (i.e., are different from the ones evaluated before by other researchers).

The simulations were performed bi-dimensionally, and the results could be of interest to building developers and researchers, helping them to mitigate thermal bridges and achieving energy savings, whenever an LSF construction system is used. In Portugal (but probably also in other countries) most of the building designers neglect the effect of repetitive thermal bridges due to the steel frame on the thermal transmittance calculations of LSF elements, leading to lower and erroneous -values. Consequently, the real building energy consumption will be higher than the predicted one in these cases and there is a higher probability of building pathologies related with the occurrence of interstitial condensations.

After this introduction, the evaluated interior and exterior LSF walls are presented, including the reference partition and facade LSF walls and the parameters used in the sensitivity analysis are described. Next, the accuracy of the used 2D FEM algorithm is verified by means of a comparison with ISO 10211 [

22] test cases and with the analytical approach, defined in ISO 6946 [

11], for a simplified model assuming no steel frame and homogeneous layers. Then, the 2D FEM simulations are explained, including the used boundary conditions and how the air layers were addressed in these simulations. After, the obtained results are presented and discussed for the two LSF wall typologies evaluated. Finally, the main conclusions of this work are presented.

7. Conclusions

In this work, a sensitivity analysis regarding the thermal transmittance (-value) was performed for two different types of lightweight steel framed (LSF) walls: interior partition and exterior facade. The numerical results were obtained by using 2D finite element method (FEM) models. The accuracy of these models was verified by comparison with ISO 10211 test cases and with ISO 6946 analytical approach.

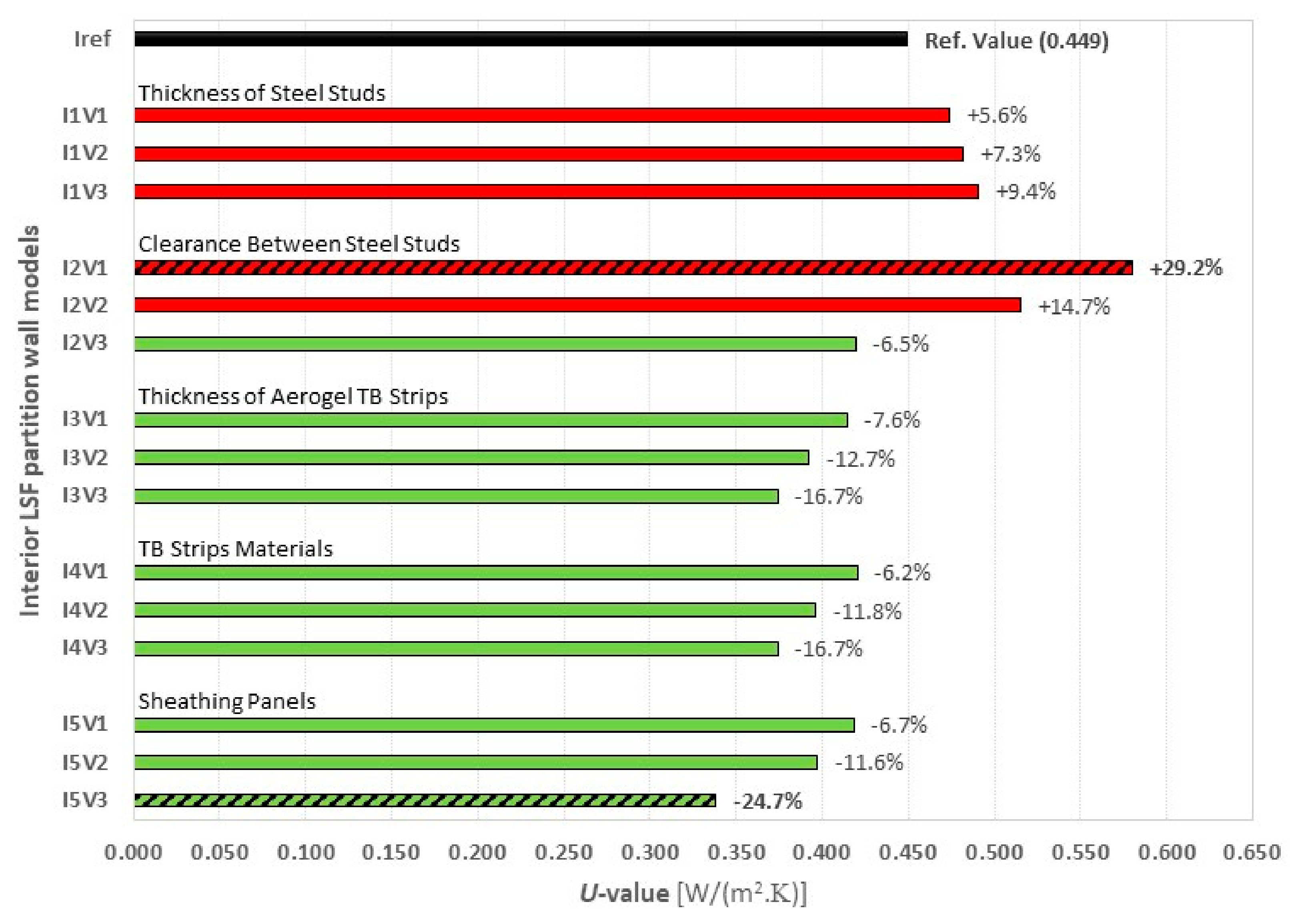

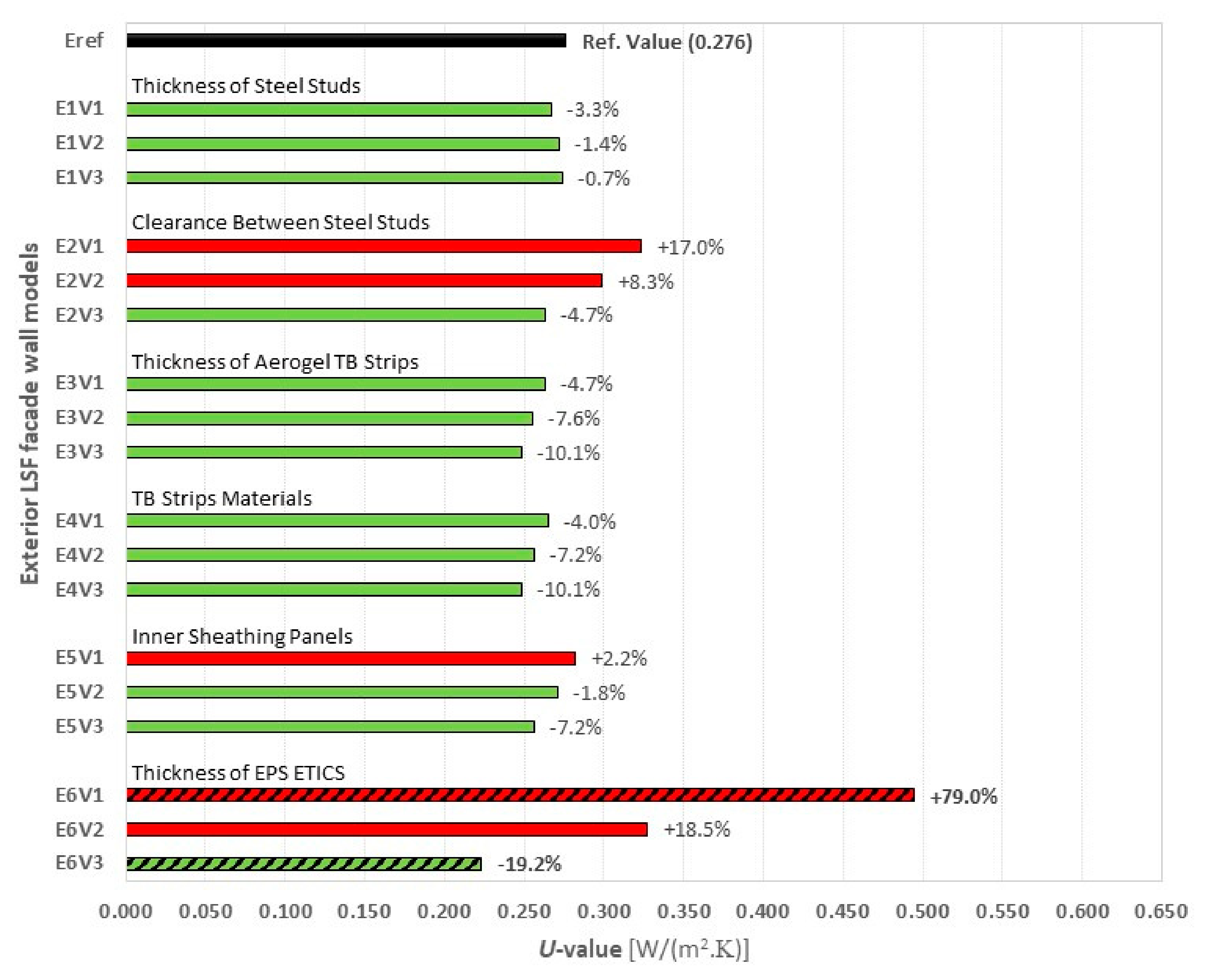

The assessed parameters were: (1) thickness of steel studs; (2) clearance between studs; (3) thermal break strips thickness and (4) material; (5) configuration of internal sheathings panels, and; (6) thickness of EPS external thermal insulation composite system (ETICS), only for the external facade wall. The results of this parametric study were compared to a reference interior partition LSF wall, with a -value equal to 0.449 W/(m2.K) and to a reference exterior facade LSF wall, with a -value equal to 0.276 W/(m2.K). Regarding the obtained results, notice that the percentages of -value change are high, but the absolute differences are rather small in most cases.

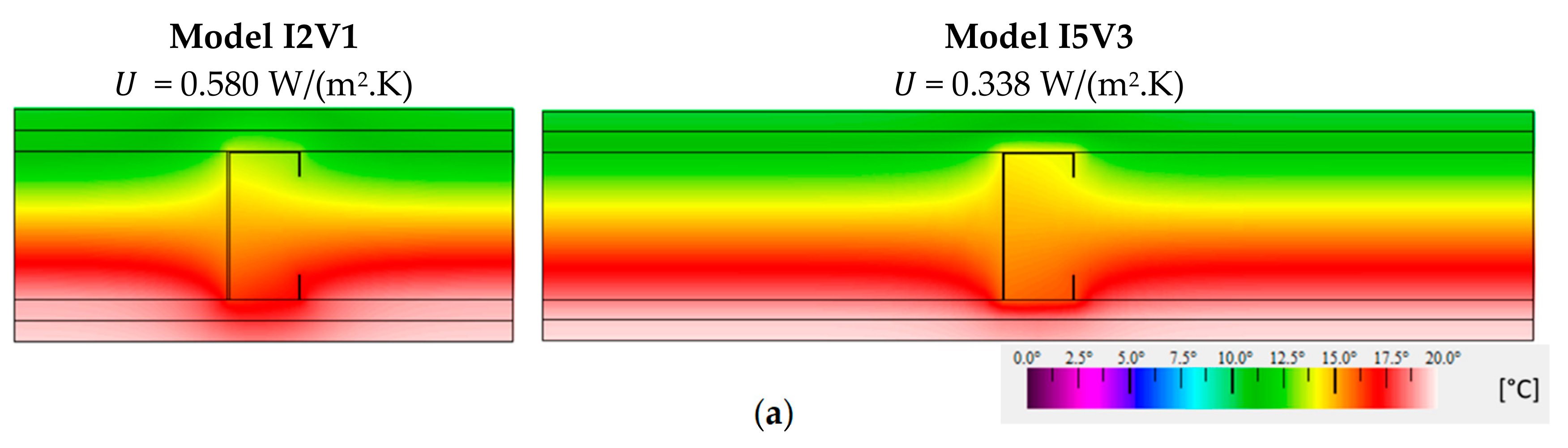

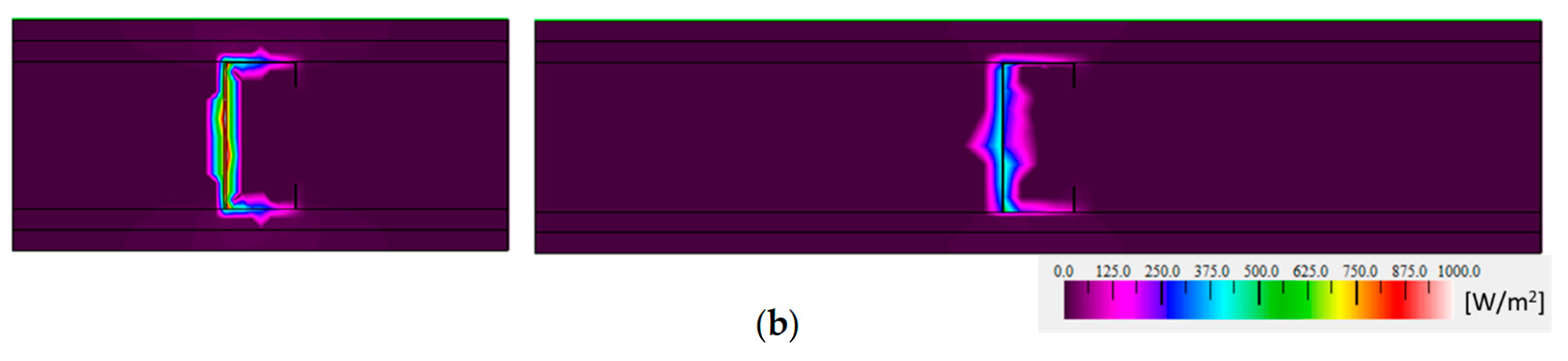

The interior partition LSF wall showed higher -values and a greater influence of the internal steel structure on the wall thermal transmittance. This was expected given the high thermal conductivity of steel and the absence of a continuous thermal insulation on interior partition walls potentiates the thermal bridges’ effects on the LSF structure, resulting in higher -values. Nevertheless, higher heat flux through the interior walls enables other evaluated parameters to have a greater influence on wall thermal transmittance (e.g., clearance between steel studs (up to +29.2%) and XPS sheathing panel (down to −24.7%)).

The thickness augment of the metallic structure increased the thermal transmittance of the interior wall up to +9.4% (1.5 mm thick). The use of thermal break (TB) strips reduced the -value of the interior wall down to −16.7% (10 mm thick aerogel strip). The use of different materials in the TB strip was also assessed. The -value reduction depends on the thermal conductivity of the material used in the TB strip: −6.2% for recycled rubber, −11.8% for XPS and −16.7% for aerogel.

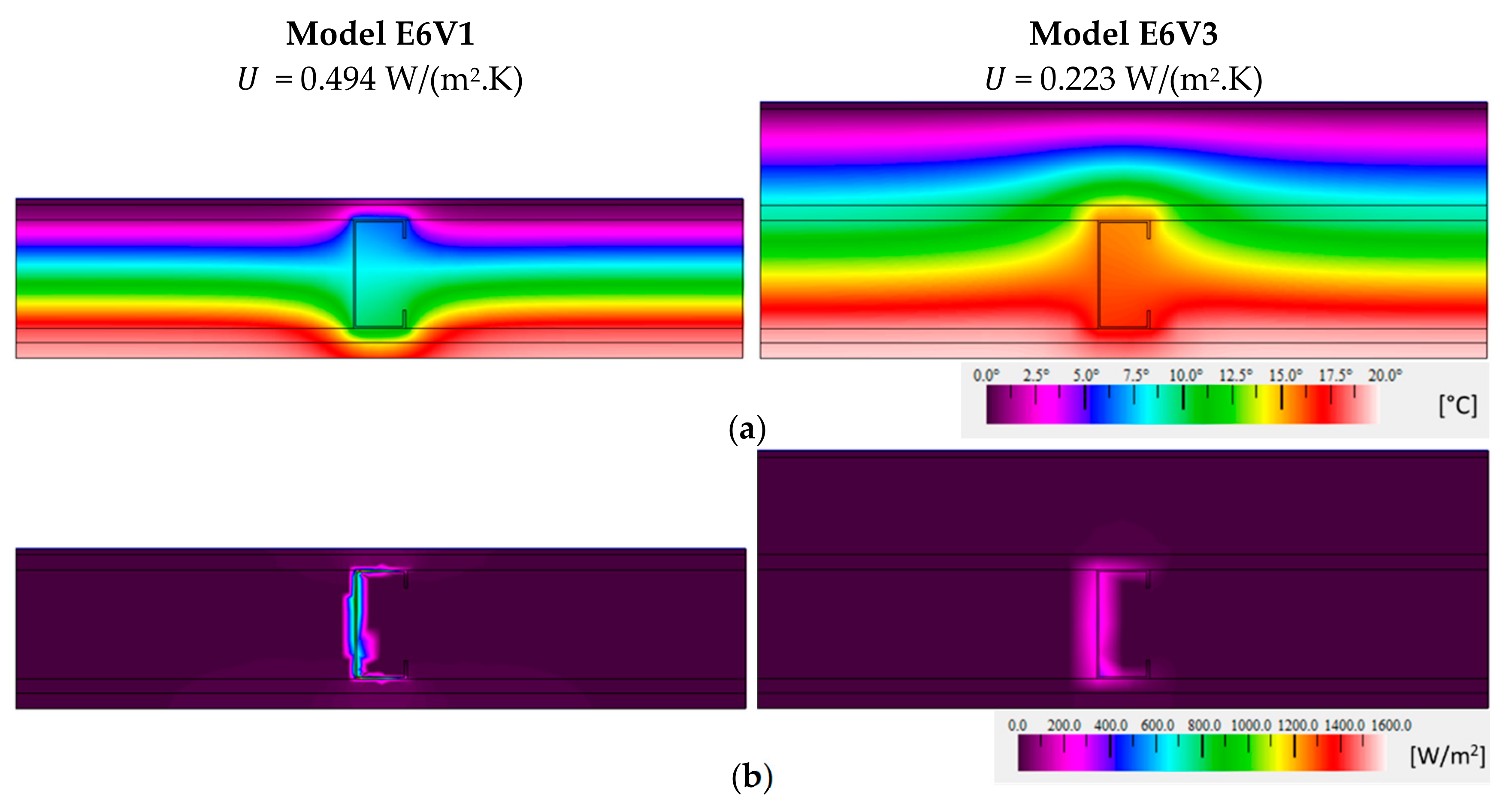

For the exterior facade LSF walls, the existence of an ETICS continuous thermal insulation on the outer side reduces the heat flux through the wall, particularly through the steel frame, resulting in a lower wall -value and decreasing the importance of other evaluated parameters. In fact, the major and the minor -value increment changed the thickness of the EPS insulation ETICS layer (i.e., an augment of +79.0% when there is no EPS (0.0 mm thick) and a decrease of −19.2% for 80 mm EPS thickness). Notice that the reference wall has 50 mm of EPS ETICS.

Decreasing the steel thickness (1.5 mm) to 0.6 mm reduced the -value to only −3.3% (−0.009 W/(m2.K)). Notice that in the interior partition wall the absolute -value increased, when the steel thickness changed from 0.6 mm up to 1.5 mm, and was more than four times higher (i.e., +0.042 W/(m2.K), showing the lower importance of the steel structure in this exterior facade LSF wall.

When changing the distance between the vertical studs from 600 mm to half (300 mm) and doubling the amount of steel, the -value increased only +17.0% (+0.047 W/(m2.K)). Notice that in the interior partition wall the absolute -value increase was almost the triple (i.e., +0.131 W/(m2.K)).

The use of aerogel thermal break strips with different thicknesses (up to 10 mm) reduced the -value down to −10.1% (−0.028 W/(m2.K)). Notice that in the interior wall this absolute -value reduction was more than double (i.e., −0.075 W/(m2.K)). Using a 10 mm thick TB strip with different materials (rubber, XPS and aerogel) decreased the -value to about −4.0% (−0.011 W/(m2.K)), −7.2% (−0.020 W/(m2.K)) and −10.1% (−0.028 W/(m2.K)), respectively. Notice that in the interior wall these -value reductions were quite higher: −6.2% (−0.028 W/(m2.K)), −11.8% (−0.053 W/(m2.K)) and −16.7% (−0.075 W/(m2.K)), respectively.

The use of different inner sheathing panels (GPB, OSB and XPS) led to a -value variation down to −7.2% (−0.020 W/(m2.K)) for the XPS/GPB panels. Notice that in the interior LSF wall this absolute -value reduction was much more relevant [i.e., more than five times higher (−0.111 W/(m2.K))]. This was due not only to the absence of any continuous thermal insulation in the reference interior LSF wall, but also to the fact that in this case the two wall sides were updated with an XPS sheathing panel (one in each side), while in the exterior facade only the inner wall surface was updated with an XPS sheathing panel.

For further related research work, the authors intend to perform laboratorial experimental measurements in similar interior and exterior LSF walls. These measurements will be useful to ensure the reliability of the numerical simulations and validate the numerical models. In order to consider and evaluate the relevance of some three-dimensional (3D) effects in the thermal performance of these interior and exterior LSF walls, the authors also intend to perform some 3D FEM simulations in a complementary future research work. Another predicted future work is to evaluate the cost-benefit of these thermal performance improvement measures and the provided energy efficiency benefits for an LSF building.