Modelling Energy Consumption and Energy-Saving in High-Quality Olive Oil Decanter Centrifuge: Numerical Study and Experimental Validation

Abstract

1. Introduction

- (1)

- (2)

- (3)

- More so than in the bulk of other plants, that the quality of the processed food has to be high in relation to the machine performance and energy requirements [13].

2. Materials and Methods

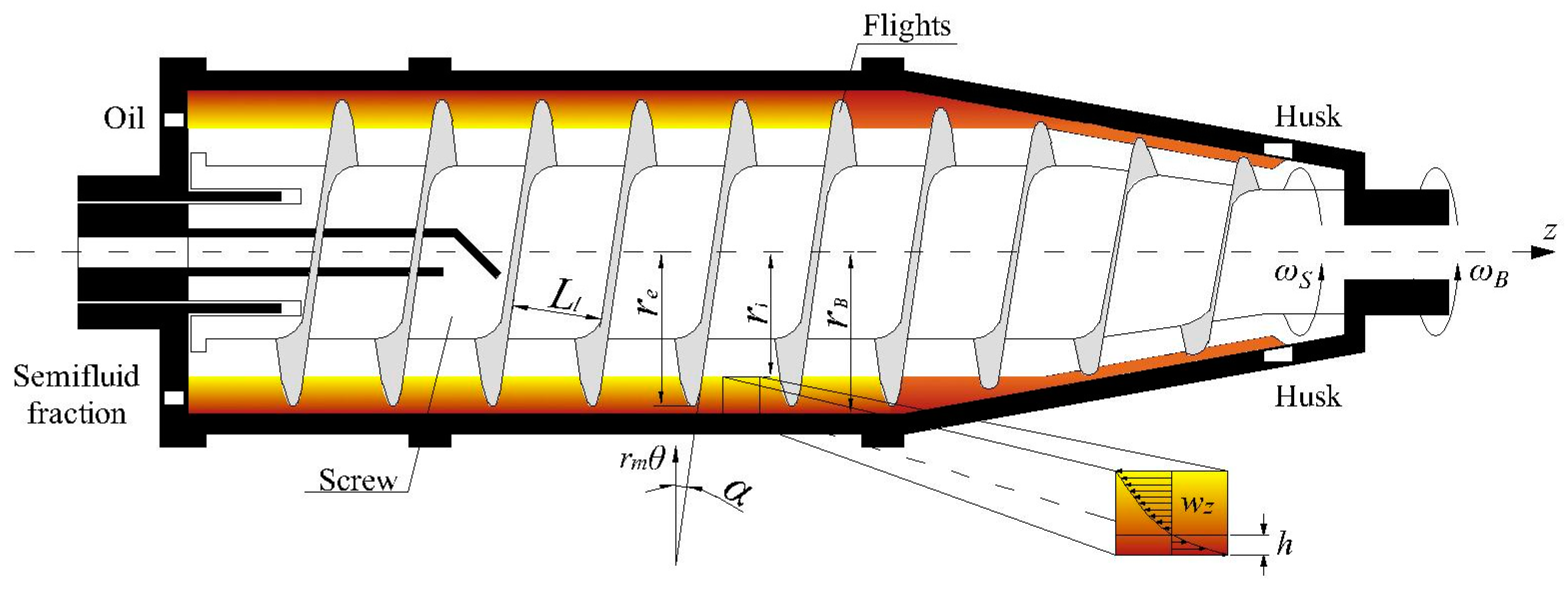

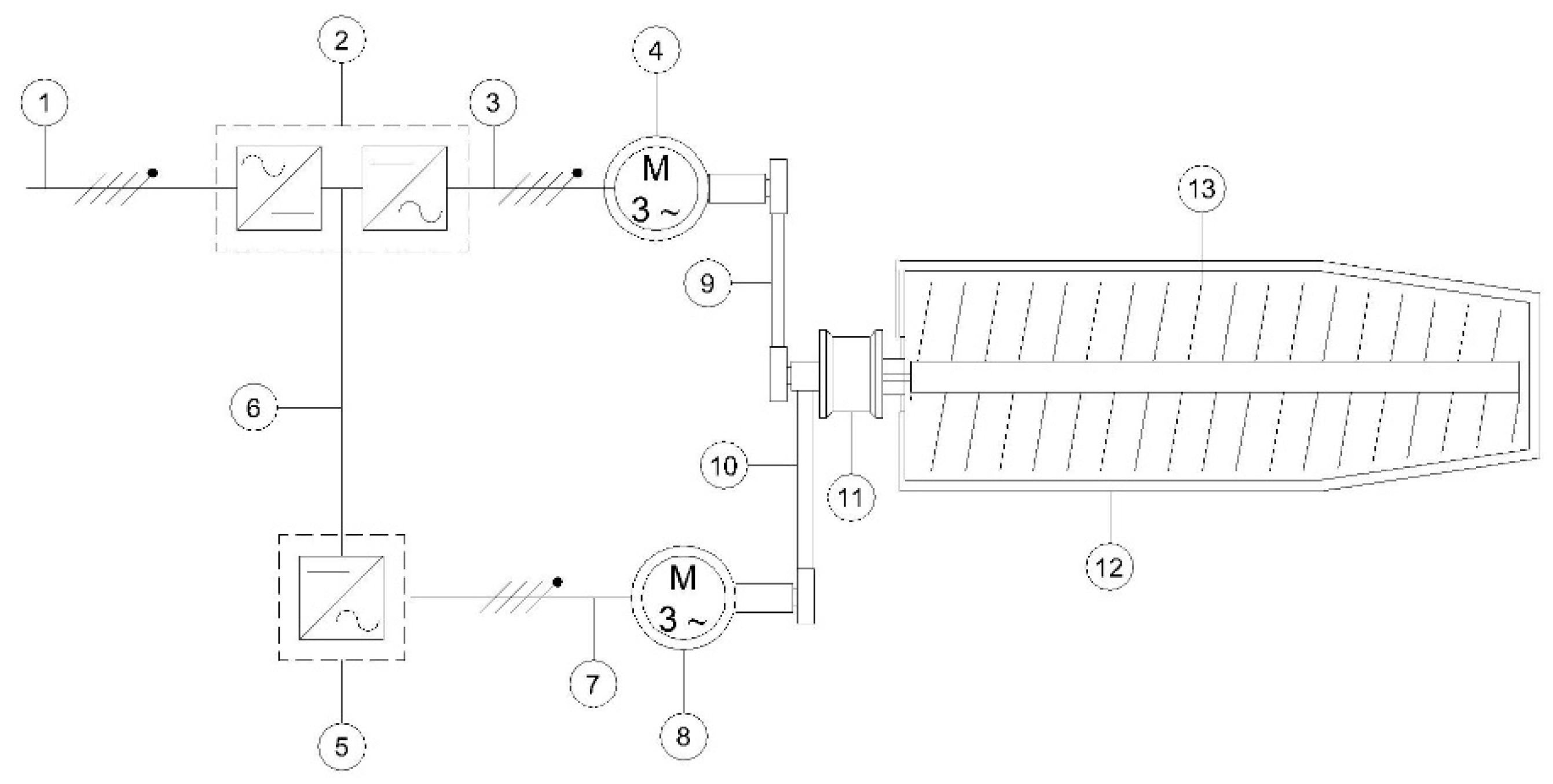

2.1. Decanter Machine Equipped with an Electro-Mechanical Recovery System

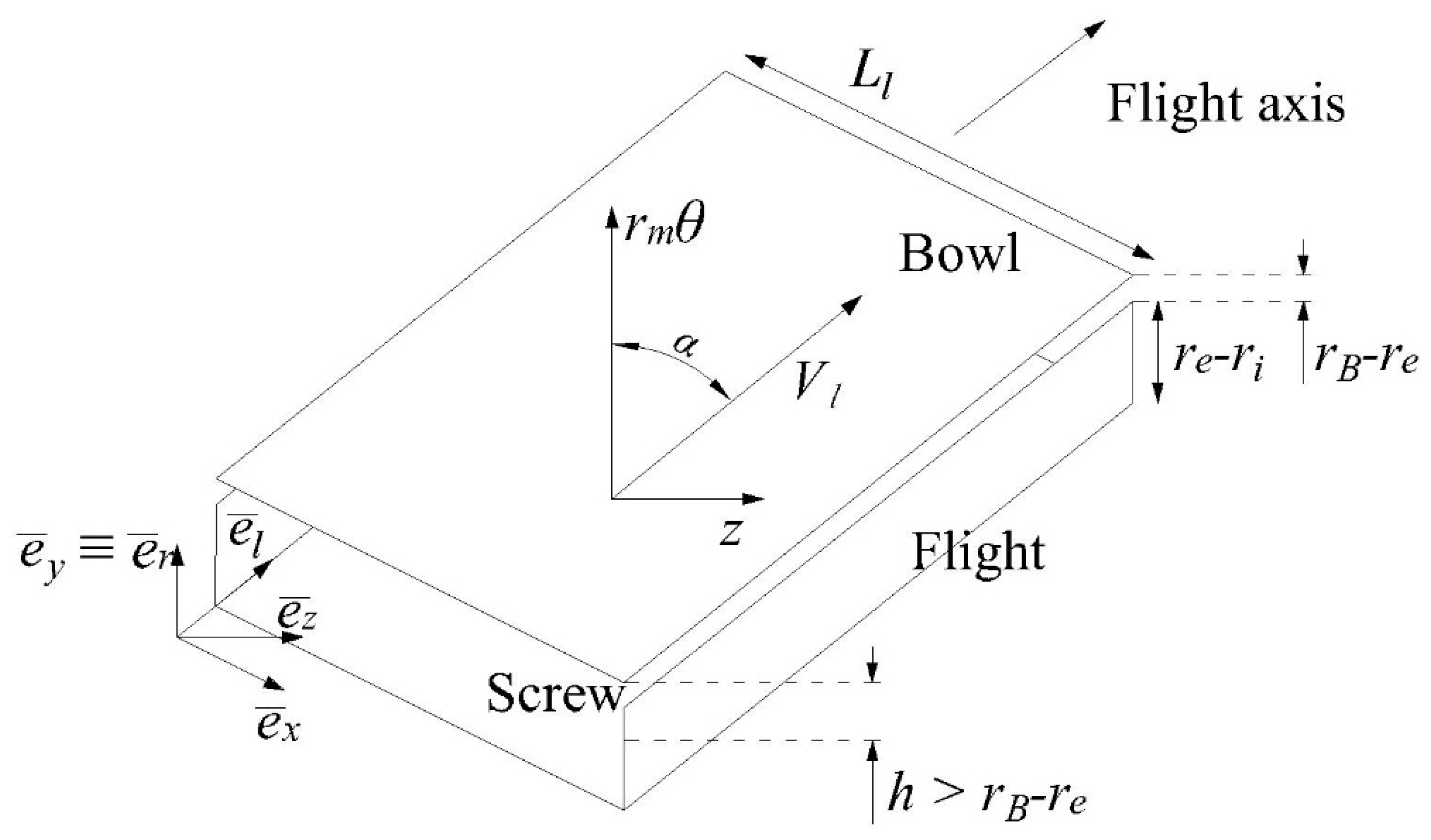

2.2. Decanter Basic Model

- even if the bulk of organic fluids are non-Newtonian, this has little influence on the velocity profile because of the high value of the apparent viscosity in any position in the decanter; in the screw coordinate system this also implies wx = wy = 0, as the secondary motions of high viscosity fluids are negligible;

- the viscosity depends on the concentration of the suspended solids, however, the bulk of the solids settle close to the olive paste inlet; this allows the assumption of small changes of with the position, and therefore, it can be taken as approximately constant.

2.3. Measurement Acquisition System

2.4. Experimental Design and Operative Parameters Set

2.5. VOO Analyses

3. Results

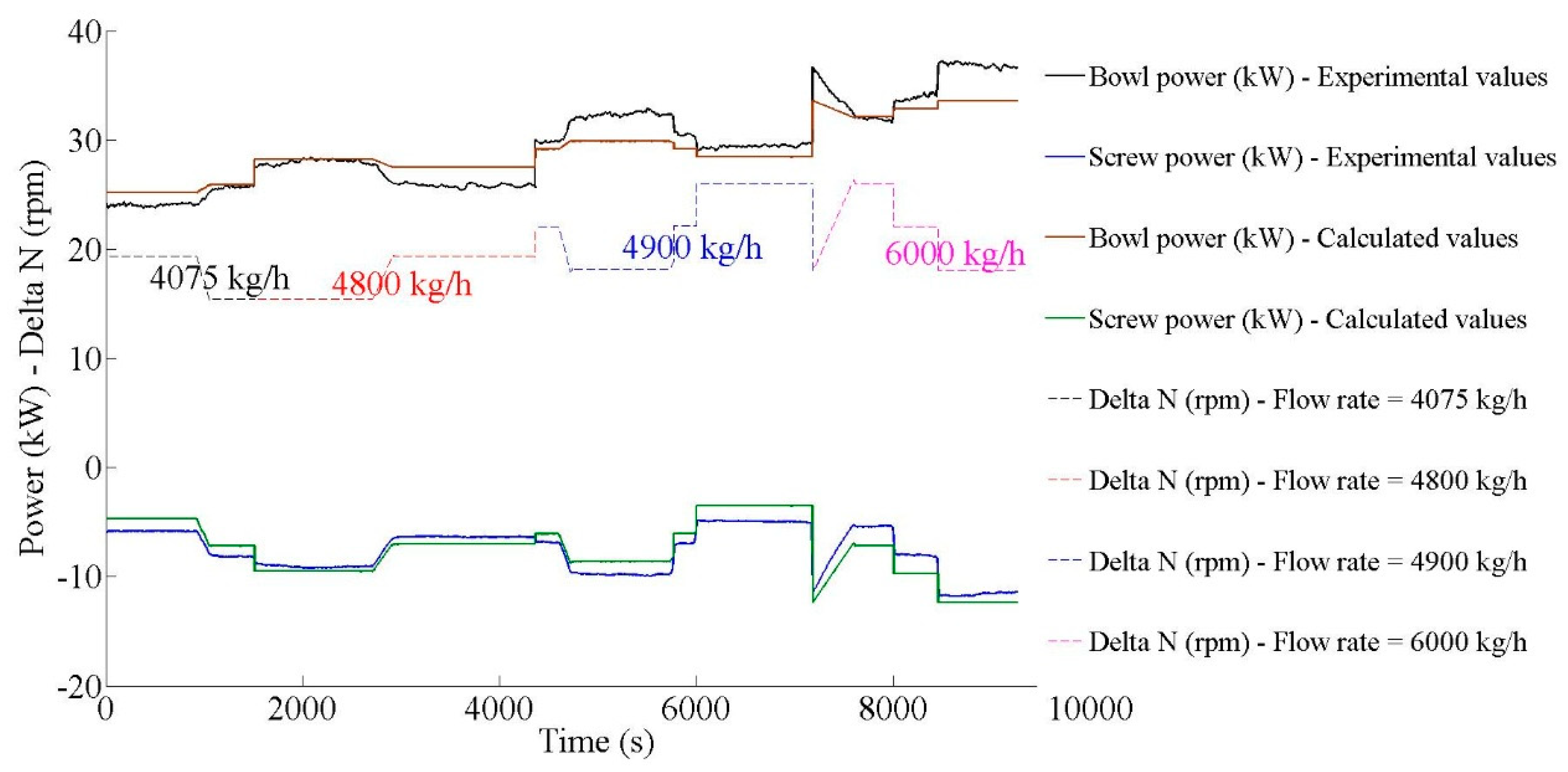

3.1. Model Validation

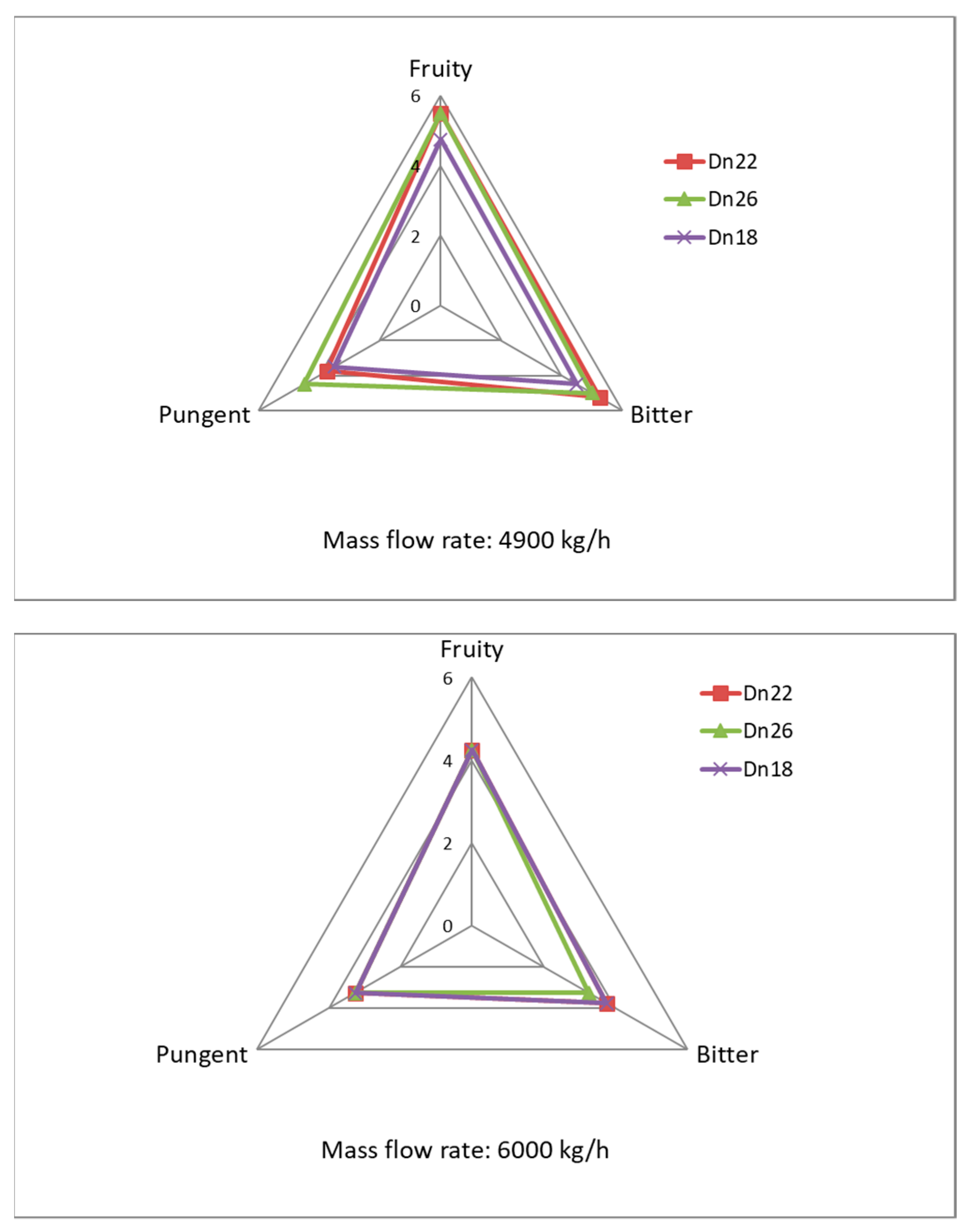

3.2. VOO Quality Assessment

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| unit vector | |

| , | functions depending on the ratio |

| height of the inversion surface of the flow field (m) | |

| J | moment of inertia (kg·m2) |

| K | various constants depending on subscript |

| l | helical coordinate (m) |

| L | distance between two consecutive flights (m) |

| n | angular velocity (rpm) |

| pressure (bar) | |

| P | power (W) |

| radial coordinate (m) | |

| t | time (s) |

| T | torque (Nm) |

| feed flow rate (kg/h) | |

| velocity vector (m·s−1) | |

| x coordinate (m) | |

| y coordinate (m) | |

| z coordinate (m) | |

| Greeks | |

| slope of screw flights with respect to decanter cross-section (rad) | |

| angular coordinate (rad) | |

| constant | |

| viscosity (Pa s) | |

| density (kg·m−3) | |

| τ | transmission ratio |

| stress tensor (N·m−2) | |

| angular velocity (rad·s−1) | |

| Subscripts | |

| B | bowl |

| C | cycloidal drive |

| e | external: tip of the screw flights |

| EM | electromagnetic |

| angular axis | |

| i | inner surface of the fluid ring (free surface) |

| l | helical axis |

| m | mean value |

| radial axis | |

| S, S1, S2 | screw conveyor |

| V | flow rate |

| y | y axis |

| z | z axis |

| Operators | |

| Nabla | |

| difference | |

References

- Yuan, C.; Zhai, Q.; Dornfeld, D.A. Three dimensional system approach for environmentally sustainable manufacturing. CIRP Ann. Manuf. Technol. 2012, 61, 39–42. [Google Scholar] [CrossRef]

- Bianchi, B.; Cavone, G.; Cice, G.; Tamborrino, A.; Amodio, M.; Capotorto, I.; Catalano, P. CO2 Employment as Refrigerant Fluid with a Low Environmental Impact. Experimental Tests on Arugula and Design Criteria for a Test Bench. Sustainability 2015, 7, 3734–3752. [Google Scholar] [CrossRef]

- Perone, C.; Catalano, F.; Tamborrino, A.; Giametta, F.; Bianchi, B.; Ayr, U. Study and Analysis of a Cogeneration System with Microturbines in a Food Farming of Dry Pasta. Chem. Eng. Trans. 2017, 58, 499–504. [Google Scholar] [CrossRef]

- Pusavec, F.; Krajnik, P.; Kopac, J. Transitioning to sustainable production e Part I: Application on machining technologies. J. Clean. Prod. 2010, 18, 174–184. [Google Scholar] [CrossRef]

- Bianchi, B.; Papajova, I.; Tamborrino, R.; Ventrella, D. Characterization of composting mixtures and compost of rabbit by-products to obtain a quality product and plant proposal for industrial production. Riv. Vet. Ital. 2015, 51, 51–61. [Google Scholar] [CrossRef]

- Morello, G.; Peri, G.; Planeta, A. Aspetti energetici dell’estrazione dell’olio di oliva in impianti a ciclo continuo. Aspetti Energ. Del. Sist. Agro-Ind. E Loro Influ. Sul. Territ. 1994, 1, 199–215. [Google Scholar]

- Özilgena, M.; Sorgüvenb, E. Energy and exergy utilization, and carbon dioxide emission in vegetable oil production. Energy 2011, 36, 5954–5967. [Google Scholar] [CrossRef]

- Cappelletti, G.M.; Ioppolo, G.; Nicoletti, G.M.; Russo, C. Energy Requirement of Extra Virgin Olive Oil Production. Sustainability 2014, 6, 4966–4974. [Google Scholar] [CrossRef]

- Alta, Z.D.; Ertekin, C. A review on exergy analysis of food production processes. In Proceedings of the International Conference of Agricultural Engineering, Zurich, Switzerland, 6–10 July 2014. [Google Scholar]

- Baptista, F.J.; Murcho, D.; Silva, L.L. Efficient Olive oil mills Handbook. TESLA project (Intelligent Energy Europe), IEE/12/758/SI2.644752. 2014. Available online: http://teslaproject.chil.me/download-doc/63246 (accessed on 1 February 2014).

- Ho, J.C.; Chandratilleke, T.T. Thermodynamic analysis applied to a food-processing plant. Appl. Energy 1987, 28, 35–46. [Google Scholar] [CrossRef]

- Miah, J.H.; Griffiths, A.; McNeill, R.; Poonaji, I.; Martin, R.; Yang, A.; Morse, S. Heat integration in processes with diverse production lines: A comprehensive framework and an application in food industry. Appl. Energy 2014, 132, 452–464. [Google Scholar] [CrossRef]

- Caponio, F.; Squeo, G.; Brunetti, L.; Pasqualone, A.; Summo, C.; Paradiso, V.M.; Catalano, P.; Bianchi, B. Influence of the feed pipe position of an industrial scale two-phase decanter on extraction efficiency and chemical-sensory characteristics of virgin olive oil. J. Food Eng. 2018. [CrossRef] [PubMed]

- Bianchi, B.; Tamborrino, A.; Santoro, F. Assessment of the energy and separation efficiency of the decanter centrifuge with regulation capability of oil water ring in the industrial process line using a continuous method. J. Agric. Eng. 2013, 278–282. [Google Scholar] [CrossRef]

- Tamborrino, A.; Leone, A.; Romaniello, R.; Catalano, P.; Bianchi, B. Comparative experiments to assess the performance of an innovative horizontal centrifuge working in a continuous olive oil plant. Biosyst. Eng. 2015, 129, 160–168. [Google Scholar] [CrossRef]

- Tamborrino, A.; Squeo, G.; Leone, A.; Paradiso, V.M.; Romaniello, R.; Summo, C.; Pasqualone, A.; Catalano, P.; Bianchi, B.; Caponio, F. Industrial trials on coadjutants in olive oil extraction process: Effect on rheological properties, energy consumption, oil yield and olive oil characteristics. J. Food Eng. 2017, 205, 34–46. [Google Scholar] [CrossRef]

- Leone, A.; Romaniello, R.; Peri, G.; Tamborrino, A. Development of a new model of olives destoner machine: Evaluation of electric consumption and kernel characterization. Biomass Bioenergy 2015, 81, 108–116. [Google Scholar] [CrossRef]

- Leone, A.; Romaniello, R.; Zagaria, R.; Tamborrino, A. Mathematical modelling of the performance parameters of a new decanter centrifuge generation. J. Food Eng. 2015, 166, 10–20. [Google Scholar] [CrossRef]

- Ayr, U.; Tamborrino, A.; Catalano, P.; Bianchi, B.; Leone, A. 3D computational fluid dynamics simulation and experimental validation for prediction of heat transfer in a new malaxer machine. J. Food Eng. 2015, 154, 30–38. [Google Scholar] [CrossRef]

- Leone, A.; Romaniello, R.; Tamborrino, A. Development of prototype for extra virgin olive oil storage, with online control system of the nitrogen injected. Trans. ASABE Am. Soc. Agric. Biol. Eng. 2013, 56, 1–8. [Google Scholar]

- Leone, A.; Romaniello, R.; Zagaria, R.; Sabella, E.; De Bellis, L.; Tamborrino, A. Machining effects of different mechanical crushers on pit particle size and oil drop distribution in olive paste. Eur. J. Lipid Sci. Technol. 2015, 117, 271–1279. [Google Scholar] [CrossRef]

- Leone, A.; Tamborrino, A.; Zagaria, R.; Sabella, E.; Romaniello, R. Plant innovation in the olive oil extraction process: A comparison of efficiency and energy consumption between microwave treatment and traditional malaxation of olive pastes. J. Food Eng. 2015, 146, 44–52. [Google Scholar] [CrossRef]

- Alburquerque, J.A.; Gonzálvez, J.; Garcıa, D.; Cegarra, J. Agrochemical characterisation of “alperujo”, a solid by-product of the two-phase centrifugation method for olive oil extraction. Bioresour. Technol. 2004, 91, 195–200. [Google Scholar] [CrossRef]

- Kalogeropoulos, N.; Kaliora, A.C.; Artemiou, A.; Giogios, I. Composition, volatile profiles and functional properties of virgin olive oils produced by two-phase vs three-phase centrifugal decanters. LWT Food Sci. Technol. 2014, 58, 272–279. [Google Scholar] [CrossRef]

- Altieri, G.; Di Renzo, G.C.; Genovese, F. Horizontal centrifuge with screw conveyor (decanter): Optimization of oil/water levels and differential speed during olive oil extraction. J. Food Eng. 2013, 119, 561–572. [Google Scholar] [CrossRef]

- Altieri, G.; Genovese, F.; Tauriello, A.; Di Renzo, G.C. Innovative plant for the separation of high quality virgin olive oil (VOO) at industrial scale. J. Food Eng. 2015, 166, 325–334. [Google Scholar] [CrossRef]

- Pugi, L.; Pagliai, M.; Nocentini, A.; Lutzemberger, G.; Pretto, A. Design of a hydraulic servo-actuation fed by a regenerative braking system. Appl. Energy 2017, 187, 96–115. [Google Scholar] [CrossRef]

- Li, L.; Li, X.; Wang, X.; Song, J.; He, K.; Li, C. Analysis of downshift’s improvement to energy efficiency of an electric vehicle during regenerative braking. Appl. Energy 2016, 176, 125–137. [Google Scholar] [CrossRef]

- Li, L.; Wang, X.; Xiong, R.; He, K.; Li, X. AMT downshifting strategy design of HEV during regenerative braking for process for energy conservation. Appl. Energy 2016, 183, 914–925. [Google Scholar] [CrossRef]

- Fard, S.M.; Khajepour, A. An optimal power management system for a regenerative auxiliary power system for delivery refrigerator trucks. Appl. Energy 2016, 169, 748–756. [Google Scholar] [CrossRef]

- Cooperstain, J.L. (Alfa Laval) Variable Frequency Centrifuge Control. U.S. Patent 5,203,762, 20 April 1993. [Google Scholar]

- Fiori, C.; Ahn, K.; Rakha, H.A. Power-based electric vehicle energy consumption model: Model development and validation. Appl. Energy 2016, 168, 257–268. [Google Scholar] [CrossRef]

- Hermeler, J.; Horstkötter, L.; Hartmann, T. New decanter generation with improved energy efficiency. FS Filtr. Sep. 2013, 13, 30–37. [Google Scholar]

- Larsen, J.A.; Alstrøm, P. Online Paramter Estimation for a Centrifugal Decanter System. In Proceedings of the 19th World Congress of the International Federation of Automatic Control, Cape Town, South Africa, 24–29 August 2014. [Google Scholar]

- Cheng, O.; Liu, H.; Tian, Y. An Analysis on the Velocity Field of Decanter Centrifuge on the Basis of Fluent. Int. J. Eng. Adv. Res. Technol. (IJEART) 2016, 2, 58–61. [Google Scholar]

- Amirante, R.; Catalano, P. Fluid Dynamic Analysis of the Solid-liquid Separation Process by Centrifugation. J. Agric. Engng Res. 2000, 77, 193–201. [Google Scholar] [CrossRef]

- Boncinelli, P.; Catalano, P.; Cini, E. Olive paste rheological analysis. Trans. ASABE 2013, 56, 237–243. [Google Scholar] [CrossRef]

- Bell, G.R.A.; Symons, D.D.; Pearse, J.R. Mathematical model for solids transport power in a decanter centrifuge. Chem. Eng. Sci. 2014, 107, 114–122. [Google Scholar] [CrossRef]

- Altieri, G.; Di Renzo, G.C.; Genovese, F. Preliminary Results about the Energy Saving Applied to the Decanter Centrifuge Used in Olive Oil Extraction. In Proceedings of the International Conference Ragusa SHWA2010, Ragusa, Italy, 16–18 September 2010. [Google Scholar]

- Balogun, V.A.; Mativenga, P.T. Modelling of direct energy requirements in mechanical machining processes. J. Clean. Prod. 2013, 41, 179–186. [Google Scholar] [CrossRef]

- Jiménez, A.; Beltrán, G.; Aguilera, M.P.; Uceda, M. A sensor-software based on artificial neural network for the optimization of olive oil elaboration process. Sens. Actuators B: Chem. 2008, 129, 985–990. [Google Scholar] [CrossRef]

- Sutherland, K. Filtration and separation technology: What’s new with centrifuges? Filtr. Sep. 2009, 46, 30–32. [Google Scholar] [CrossRef]

- Records, A.; Sutherland, K. Decanter Centrifuge Handbook, 1st ed.; Elsevier: Amsterdam, Netherlands, 2001. [Google Scholar]

- Caponio, F.; Summo, C.; Paradiso, V.M.; Pasqualone, A. Influence of decanter working parameters on the extra virgin olive oil quality. Eur. J. Lipid Sci. Technol. 2014, 116, 1626–1633. [Google Scholar] [CrossRef]

- Squeo, G.; Tamborrino, A.; Pasqualone, A.; Leone, A.; Paradiso, V.M.; Summo, C.; Caponio, F. Assessment of the influence of the decanter set-up during continuous processing of olives at different pigmentation index. Food Bioprocess Technol. 2017, 10, 592–602. [Google Scholar] [CrossRef]

- Di Giovacchino, L.; Costantini, N.; Ferrante, M.L.; Serraiocco, A. Influence of malaxation time of olive paste on oil extraction yields and chemical and organoleptic characteristics of virgin olive oil obtained by a centrifugal decanter at water saving. Grasas Y Aceites 2002, 53, 179–186. [Google Scholar] [CrossRef]

- Catalano, P.; Pipitone, F.; Calafatello, A.; Leone, A. Productive Efficiency of Decanters with Short and Variable Dynamic Pressure Cones. Biosyst. Eng. 2003, 86, 459–464. [Google Scholar] [CrossRef]

- Salem, A.I.; Okoth, G.; Thöming, J. An approach to improve the separation of solid-liquid suspensions in inclined plate settlers: CFD simulation and experimental validation. Water Res. 2011, 45, 3541–3549. [Google Scholar] [CrossRef] [PubMed]

- Ajayi, O.A. Newtonian flow in an inter-meshing counter-rotating twin screw extruder. J. Mater. Process. Technol. 2002, 128, 196–204. [Google Scholar]

- Yu, Q.; Hu, G.H. Development of a helical coordinate system and its application to analysis of polymer flow in screw extruders Part, I. The balance equations in a helical coordinate system. J. Non-Newton. Fluid Mech. 1997, 69, 155–167. [Google Scholar] [CrossRef]

- Singh, P.R.; Heldman, D.R. Introduction to Food Engineering, 4th ed.; Food Science and Technology, International Series; Academic Press, Elsevier: Amsterdam, The Netherlands, 2009. [Google Scholar]

- Kostic, M. Influence of viscosity function simplification on non-Newtonian velocity and shear rate profiles in rectangular ducts. Int. Commun. Heat Mass Transf. 1993, 20, 515–525. [Google Scholar] [CrossRef]

- Boncinelli, P.; Daou, M.; Cini, E.; Catalano, P. A simplified model for designing and regulating centrifugal decanters for olive oil production. Trans. ASABE Am. Soc. Agric. Biol. Eng. 2009, 52, 1961–1968. [Google Scholar] [CrossRef]

- Blagojevic, M.; Marjanovic, N.; Djordjevic, Z.; Stojanovic, B.; Disic, A. A New Design of a Two-Stage Cycloidal Speed Reducer. J. Mech. Des. 2011, 133. [Google Scholar] [CrossRef]

- Catalano, P.; Fucci, F.; Giametta, F.; La Fianza, G.; Bianchi, B. Vibration analysis using contatctless acquisition system. In Proceedings of the Sensing Technologies for Biomaterial, Food, and Agriculture 2013, Yokohama, Japan, 17 May 2013; pp. 1–7. [Google Scholar] [CrossRef]

- Official Journal of the European Communities. European Community Regulation No. 25,68/1991, N.L. 248 of September 5th; Publications Office of the European Union: Bruxelles, Belgique, 1991. [Google Scholar]

- Caponio, F.; Durante, V.; Varva, G.; Silletti, R.; Previtali, M.A.; Viggiani, I.; Squeo, G.; Summo, C.; Pasqualone, A.; Gomes, T.; et al. Effect of infusion of spices into the oil cs. Combined malaxation of olive paste and spices on quality of naturally flavoured virgin olive oils. Food Chem. 2016, 202, 211–228. [Google Scholar] [CrossRef] [PubMed]

- Squeo, G.; Silletti, R.; Summo, C.; Paradiso, V.M.; Pasqualone, A.; Caponio, F. Influence of calcium carbonate on extraction yield and quality of extra virgin oil from olive (Olea europaea L. cv. Coratina). Food Chem. 2016, 209, 65–71. [Google Scholar] [CrossRef]

| Parameter | Nominal Operating Conditions |

|---|---|

| Maximum work of throughput | 6500 kg/h |

| Main electric power | 75 kW |

| Supply voltage | 380 V 3-phases |

| Rated power asynchronous bowl electric motor | 45 kW |

| Rated current bowl electric motor | 80 A |

| cos ϕ bowl electric motor | 0.87 |

| Rotational speed of the bowl electric motor | 1475 rev·min−1 |

| Rated power asynchronous screw conveyor electric motor | 30 kW |

| Rated current screw conveyor electric motor | 54.4 A |

| cos ϕ screw conveyor electric motor | 0.87 |

| Rotational speed of the screw conveyor electric motor | 1470 rev·min−1 |

| Drive ratio of the planetary gear box | 1/87 |

| Mass Flow Rate (kg/h) | Harvest Season | Δn |

|---|---|---|

| 4800 | 1st | 19.50 |

| 4800 | 1st | 15.50 |

| 4075 | 1st | 19.50 |

| 4075 | 1st | 15.50 |

| 4900 | 2nd | 26 |

| 4900 | 2nd | 22 |

| 4900 | 2nd | 18 |

| 6000 | 2nd | 26 |

| 6000 | 2nd | 22 |

| 6000 | 2nd | 18 |

| Harvesting Season | ||||

|---|---|---|---|---|

| First | 0.0846 | −0.0022 | 0.1323 | −0.0012 |

| Second | 0.0883 | −0.0042 | 0.1065 | −0.0008 |

| 0.0866 | −0.0033 | 0.1336 | −0.0019 |

| Parameters | ∆n | = 6000 kg/h | |||||||

|---|---|---|---|---|---|---|---|---|---|

| p-Values | 18 | 22 | 26 | 18 | 22 | 26 | |||

| FFA (% oleic acid) | 1.000 | 0.964 | 0.870 | 0.35 ± 0.11 | 0.32 ± 0.08 | 0.31 ± 0.07 | 0.32 ± 0.08 | 0.32 ± 0.05 | 0.34 ± 0.08 |

| PV (meq O2 kg−1) | 0.018 | 0.684 | 0.893 | 2.31 ± 0.93 | 1.97 ± 0.21 | 2.07 ± 0.13 | 3.32 ± 0.22 | 2.94 ± 0.87 | 3.41 ± 0.64 |

| K232 | 0.001 | 0.231 | 0.118 | 1.650 ± 0.021ab | 1.694 ± 0.029a | 1.623 ± 0.066abc | 1.428 ± 0.084d | 1.506 ± 0.011cd | 1.564 ± 0.038bc |

| K270 | 0.221 | 0.813 | 0.589 | 0.161 ± 0.020 | 0.186 ± 0.018 | 0.170 ± 0.011 | 0.148 ± 0.049 | 0.140 ± 0.002 | 0.164 ± 0.035 |

| TPC (mg·kg−1) | 0.009 | 0.166 | 0.883 | 651 ± 28a | 598 ± 34ab | 649 ± 48a | 581 ± 5ab | 522 ± 59b | 554 ± 19b |

| Tocopherols (mg·kg−1) | 0.372 | 0.462 | 0.665 | 119.93 ± 13.82 | 132.28 ± 22.26 | 127.57 ± 9.70 | 134.17 ± 14.53 | 142.51 ± 6.30 | 125.12 ± 3.13 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tamborrino, A.; Perone, C.; Catalano, F.; Squeo, G.; Caponio, F.; Bianchi, B. Modelling Energy Consumption and Energy-Saving in High-Quality Olive Oil Decanter Centrifuge: Numerical Study and Experimental Validation. Energies 2019, 12, 2592. https://doi.org/10.3390/en12132592

Tamborrino A, Perone C, Catalano F, Squeo G, Caponio F, Bianchi B. Modelling Energy Consumption and Energy-Saving in High-Quality Olive Oil Decanter Centrifuge: Numerical Study and Experimental Validation. Energies. 2019; 12(13):2592. https://doi.org/10.3390/en12132592

Chicago/Turabian StyleTamborrino, Antonia, Claudio Perone, Filippo Catalano, Giacomo Squeo, Francesco Caponio, and Biagio Bianchi. 2019. "Modelling Energy Consumption and Energy-Saving in High-Quality Olive Oil Decanter Centrifuge: Numerical Study and Experimental Validation" Energies 12, no. 13: 2592. https://doi.org/10.3390/en12132592

APA StyleTamborrino, A., Perone, C., Catalano, F., Squeo, G., Caponio, F., & Bianchi, B. (2019). Modelling Energy Consumption and Energy-Saving in High-Quality Olive Oil Decanter Centrifuge: Numerical Study and Experimental Validation. Energies, 12(13), 2592. https://doi.org/10.3390/en12132592