Viscosity–Temperature–Pressure Relationship of Extra-Heavy Oil (Bitumen): Empirical Modelling versus Artificial Neural Network (ANN)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methodology

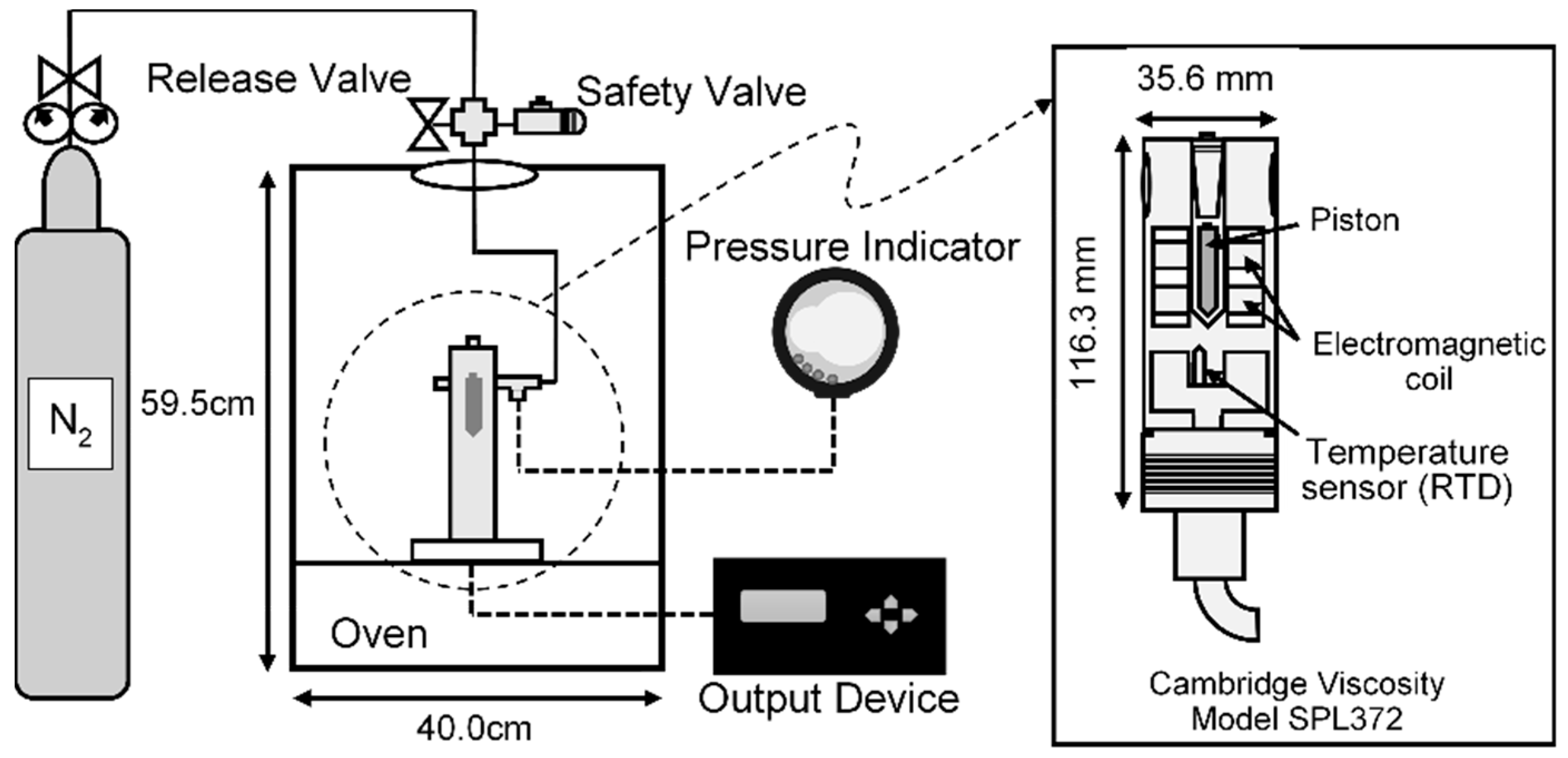

2.2.1. Measurement of Viscosity

2.2.2. Viscosity Modeling

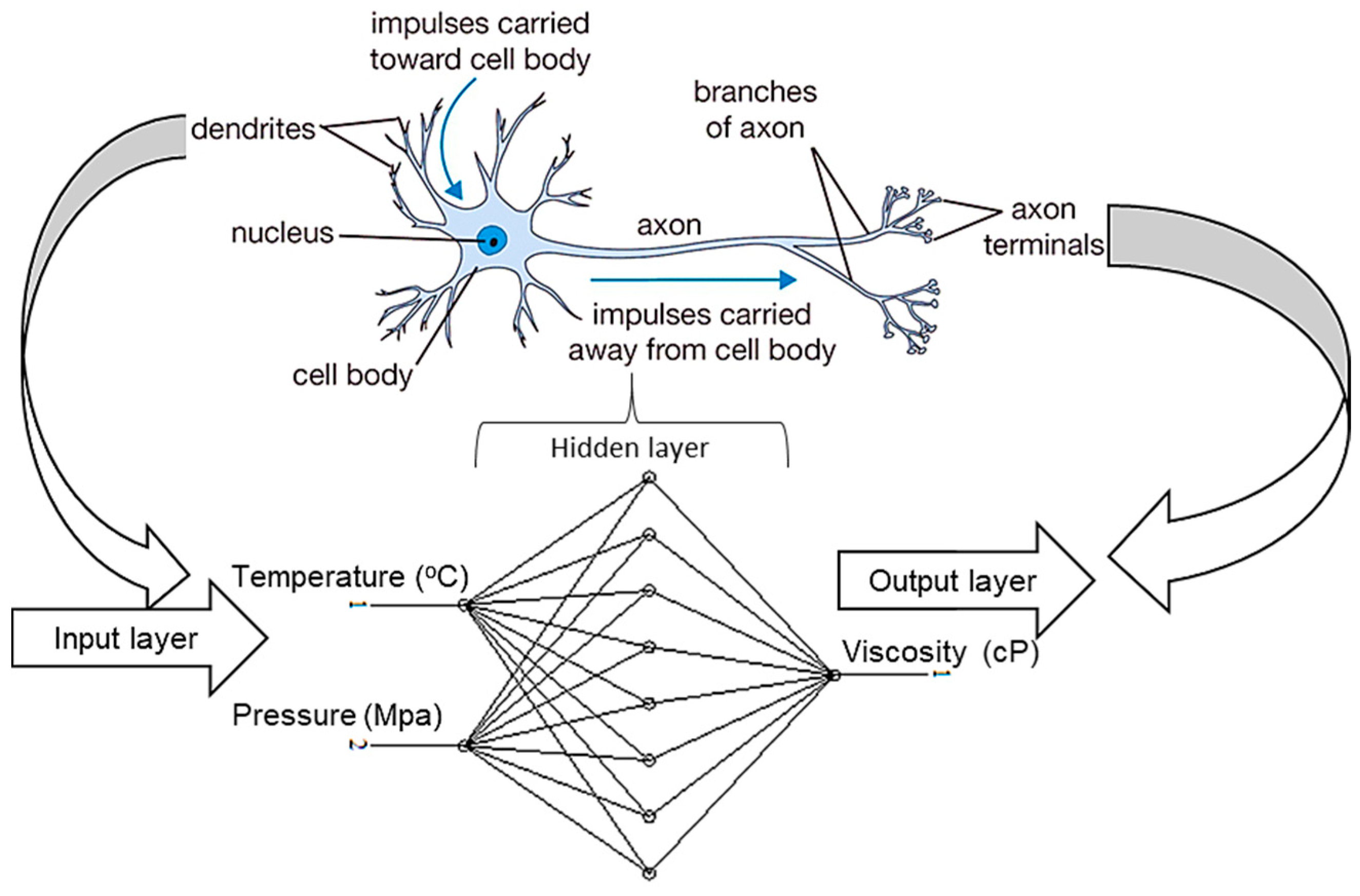

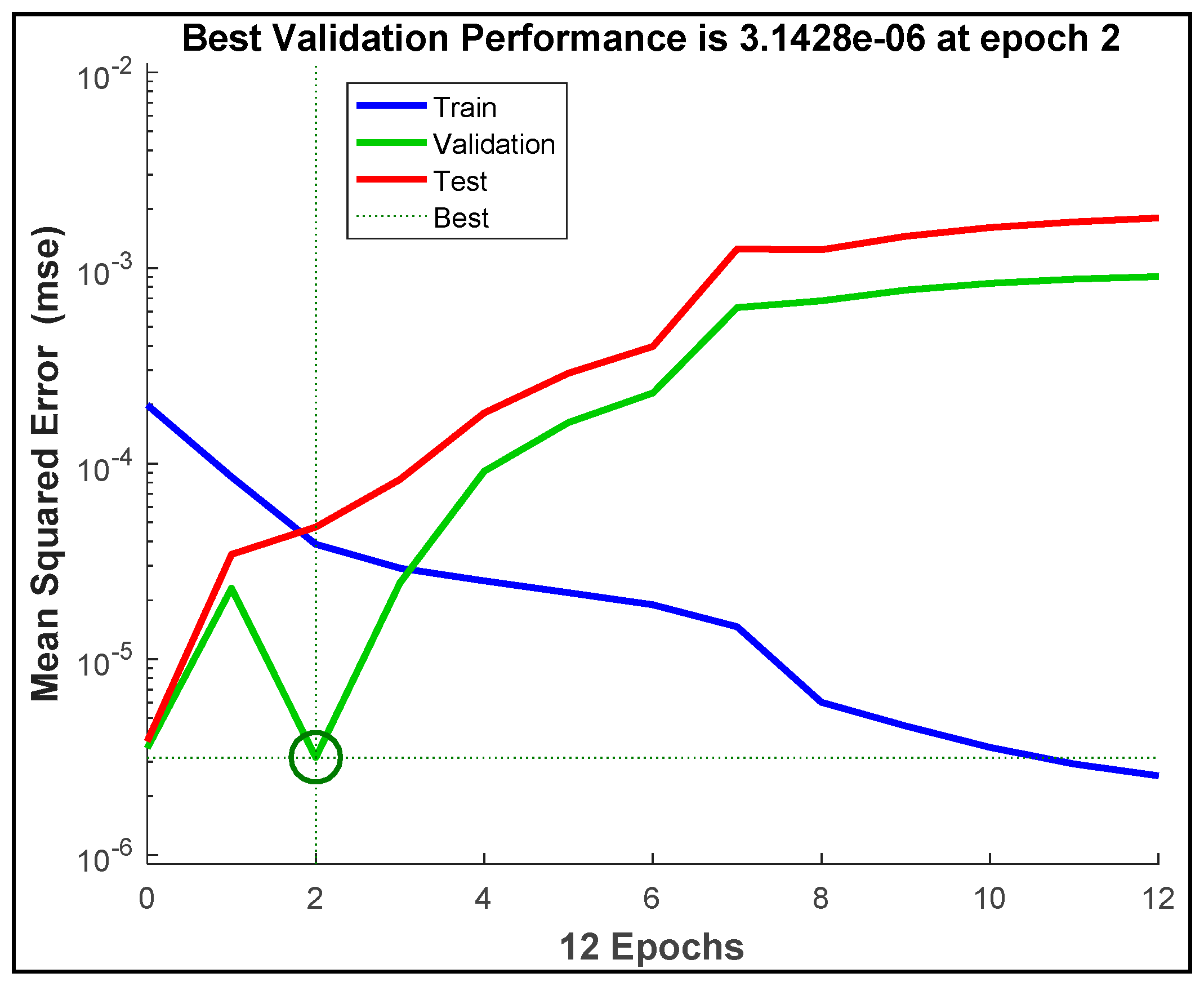

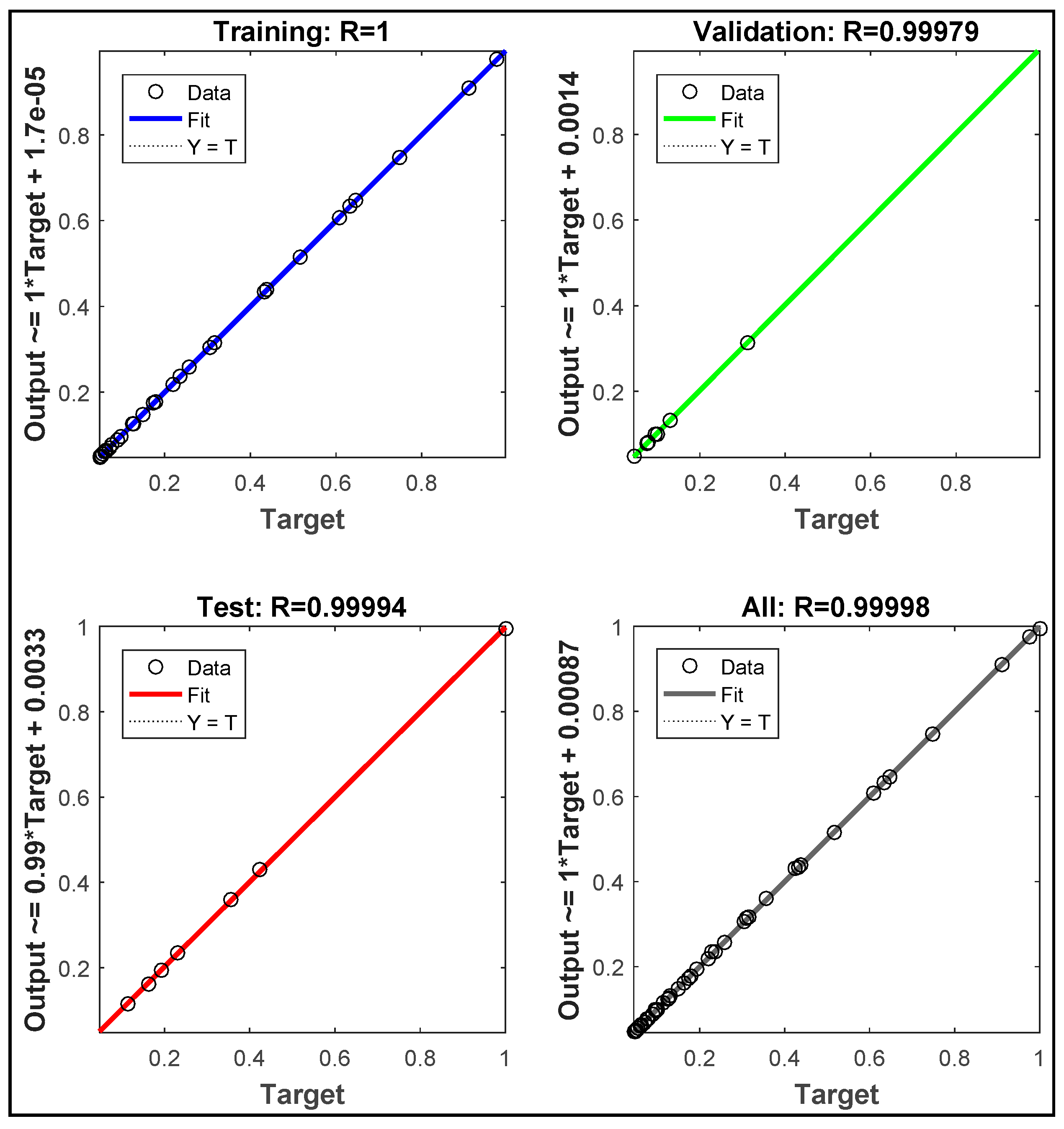

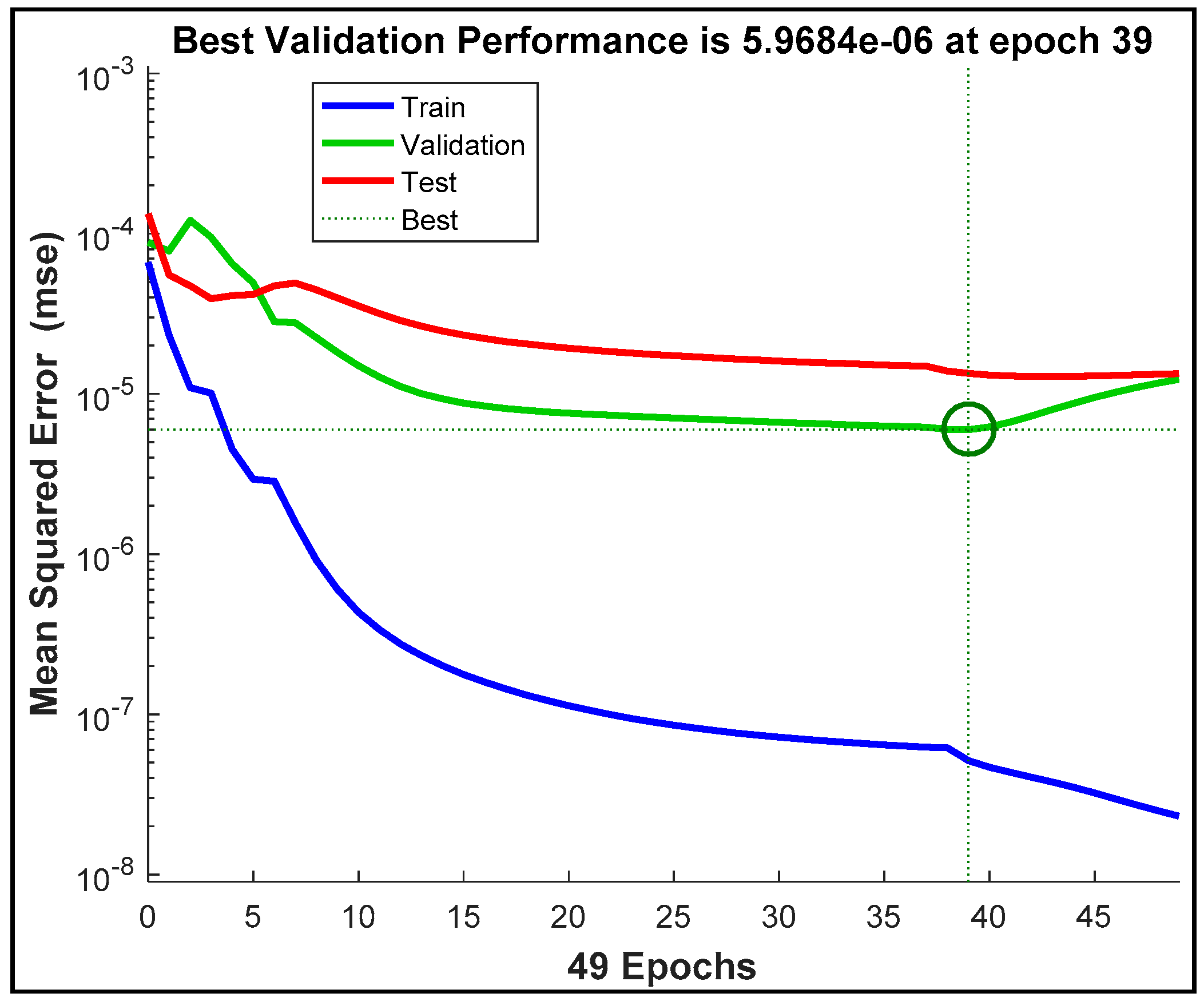

2.2.3. Development of the ANN Model

2.2.4. Statistical Error Analysis

3. Results and Discussion

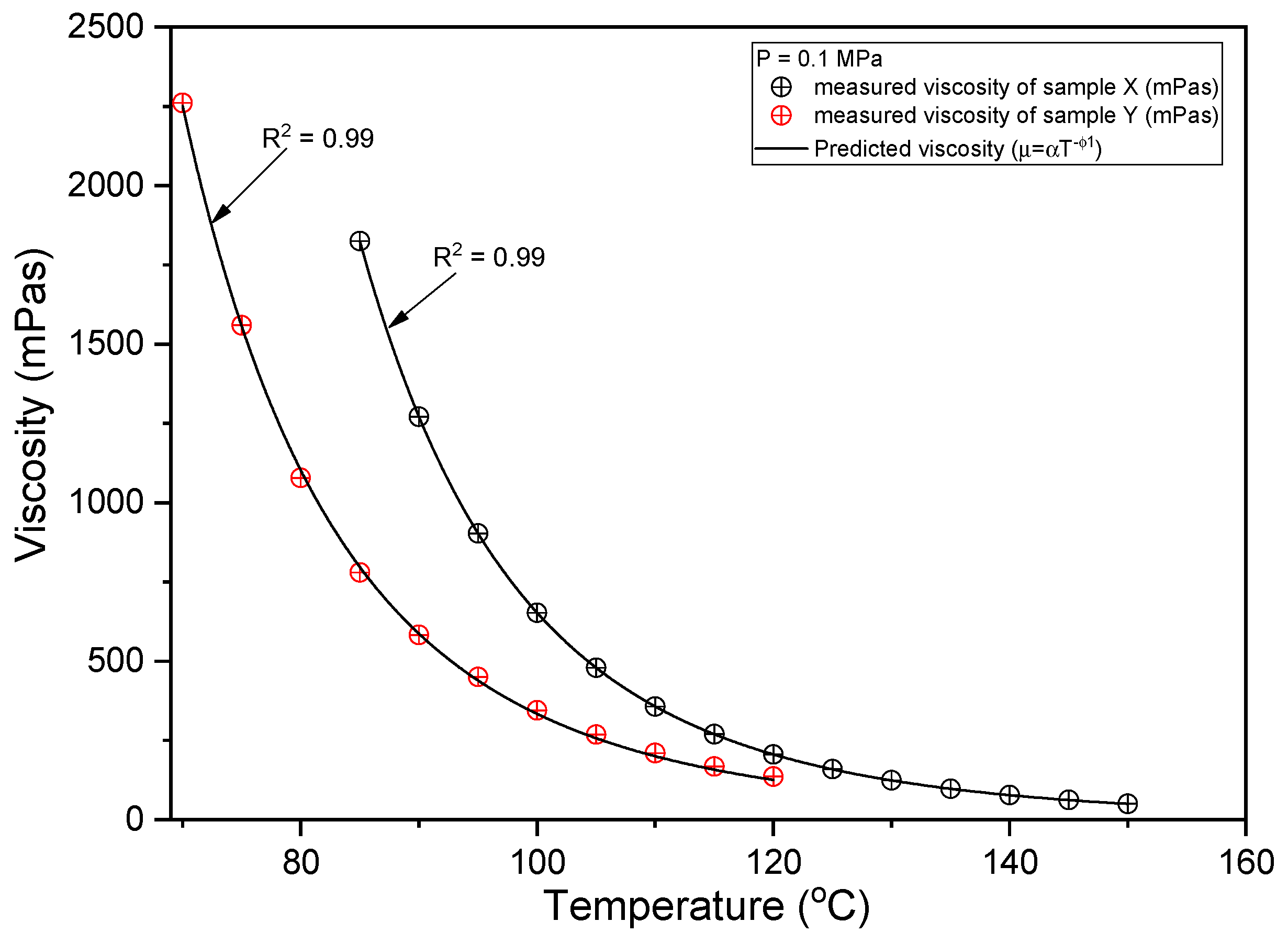

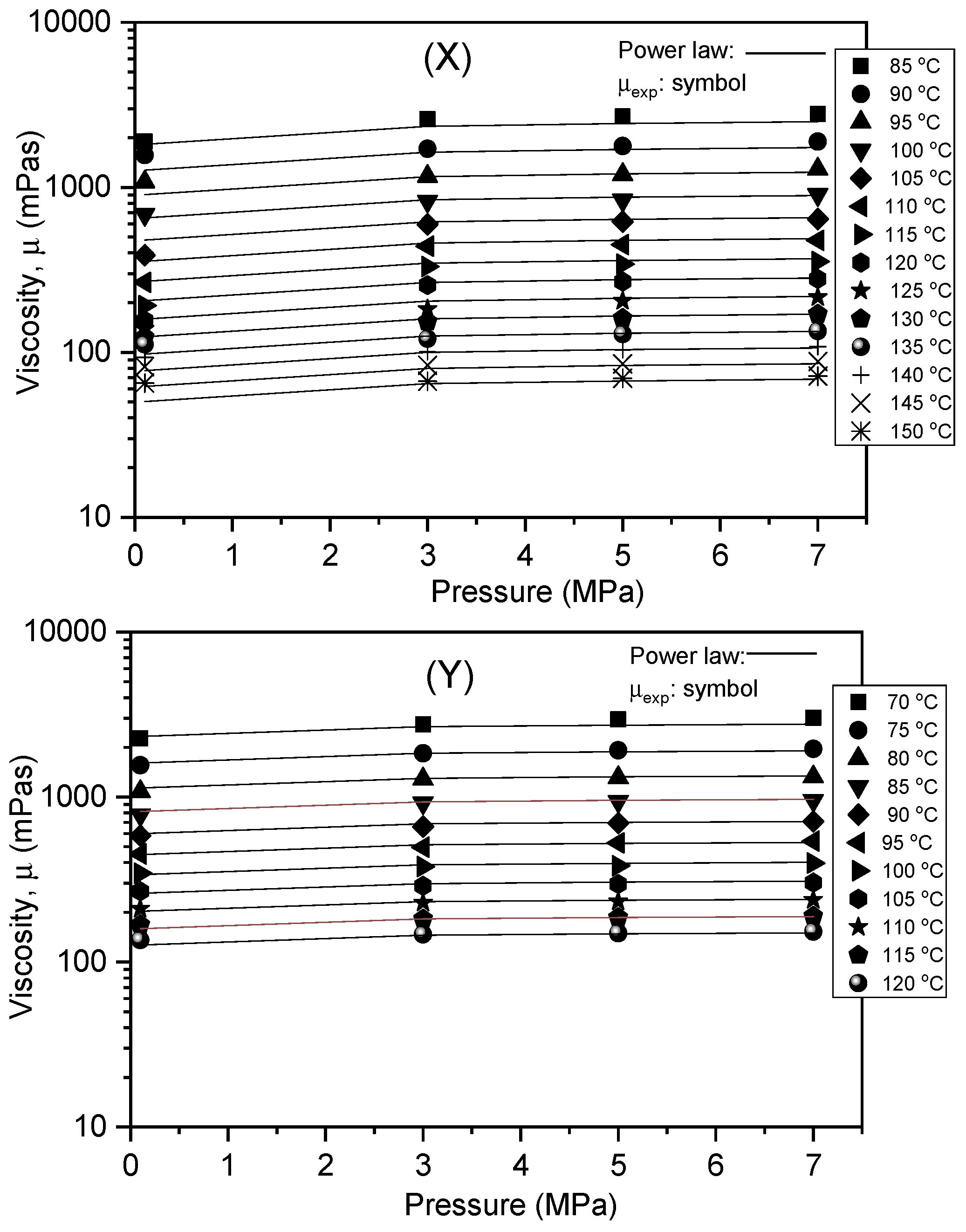

3.1. Viscosity Data of the Oil Samples

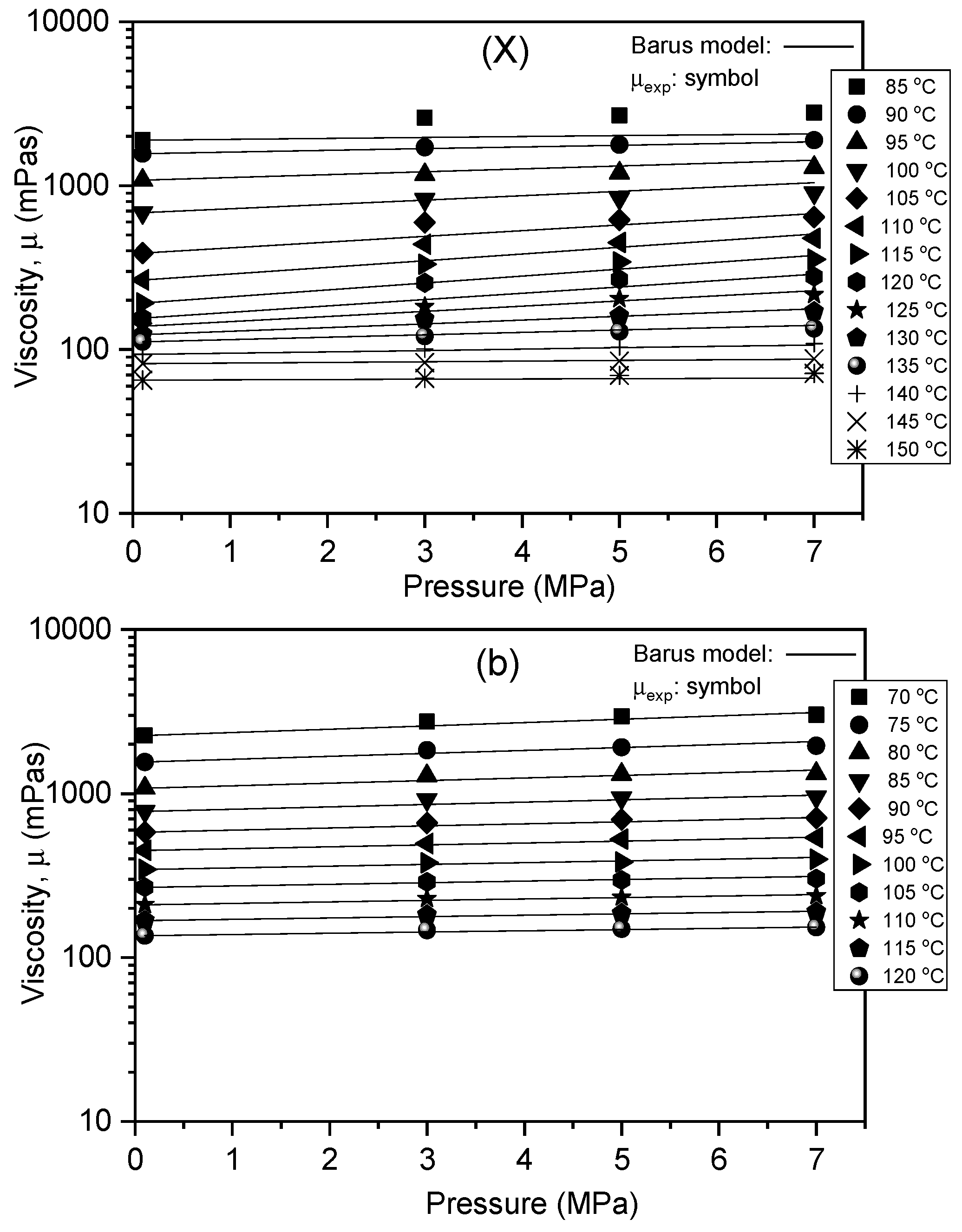

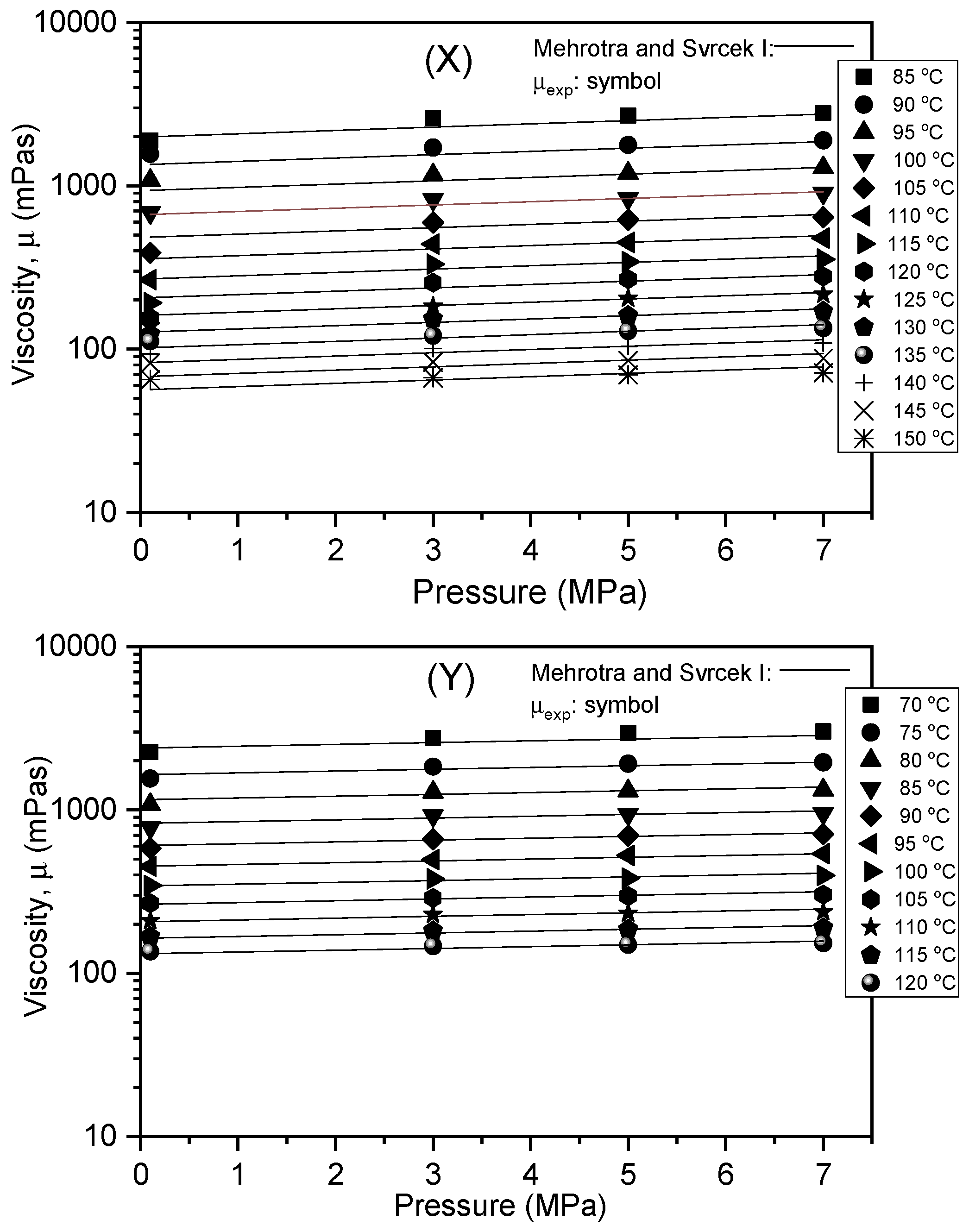

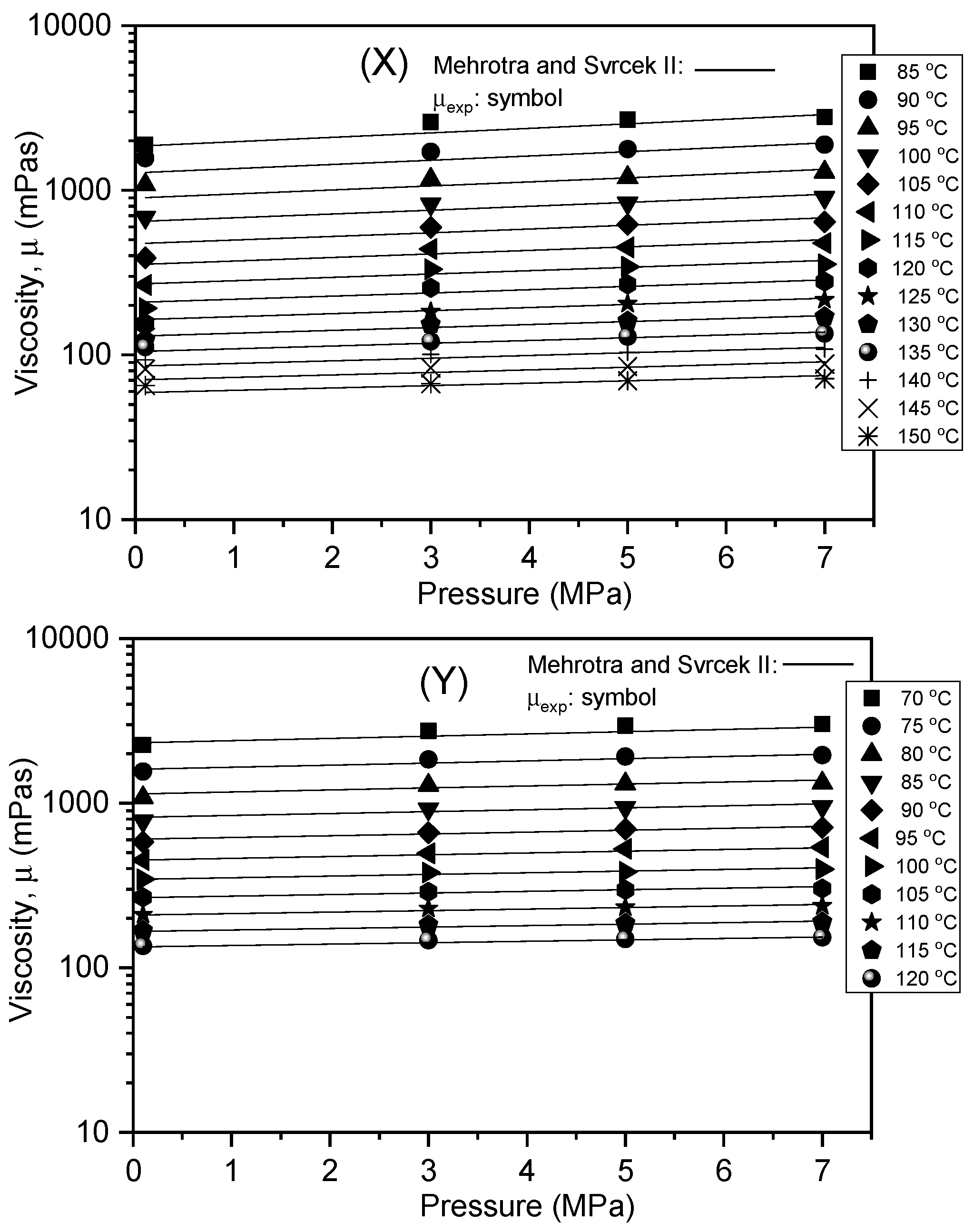

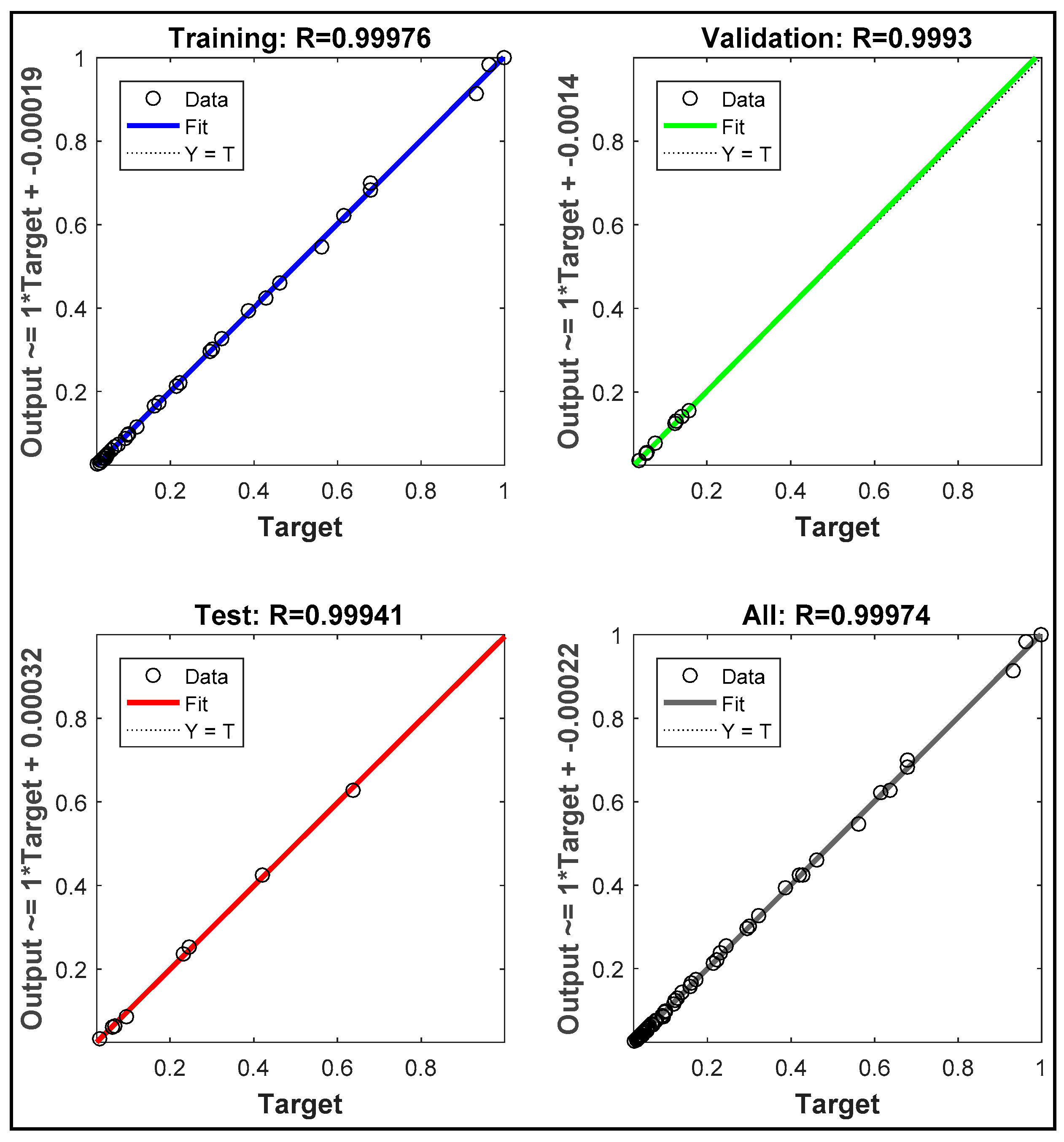

3.2. Viscosity–Temperature–Pressure (V-T-P) Modelling

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Alade, O.S.; Sasaki, K.; Sugai, Y.; Ademodi, B.; Nakano, M. Bitumen emulsification using a hydrophilic polymeric surfactant: Performance evaluation in the presence of salinity. J. Pet. Sci. Eng. 2016, 138, 66–76. [Google Scholar] [CrossRef]

- Nourozieh, H.; Kariznovi, M.; Abedi, J. Density and viscosity of Athabasca bitumen samples at temperatures up to 200 °C and pressures up to 10 MPa. SPE Reserv. Eval. Eng. 2015, 18, 375–386. [Google Scholar] [CrossRef]

- Kariznovi, M.; Nourozieh, H.; Guan, J.G.; Abedi, J. Measurement and modelling of density and viscosity for mixtures of Athabasca bitumen and heavy n-alkane. Fuel 2013, 112, 83–95. [Google Scholar] [CrossRef]

- Zirrahi, M.; Hassanzadeh, H.; Abedi, J. Prediction of bitumen and solvent mixture viscosity using thermodynamic perturbation theory. J. Can. Pet. Technol. 2014, 53, 48–54. [Google Scholar] [CrossRef]

- Bryan, J.; Mirotchnik, K.; Kantzas, A. Viscosity Determination of Heavy Oil and Bitumen Using NMR Relaxometry. J. Can. Pet. Technol. 2003, 42, 29–34. [Google Scholar] [CrossRef]

- Mehrotra, A.K.; Svrcek, W.Y. Viscosity of compressed Athabasca bitumen. Can. J. Chem. Eng. 1986, 64, 844–847. [Google Scholar] [CrossRef]

- Mehrotra, A.K.; Svrcek, W.Y. Viscosity of compressed Cold Lake bitumen. Can. J. Chem. Eng. 1987, 65, 672–675. [Google Scholar] [CrossRef]

- Puttagunta, V.R.; Singh, B.; Miadonye, A. Correlation of bitumen viscosity with temperature and pressure. Can. J. Chem. Eng. 1993, 71, 447–450. [Google Scholar] [CrossRef]

- Xin, X.; Li, Y.; Yu, G.; Wang, W.; Zhang, Z.; Zhang, M.; Ke, W.; Kong, D.; Wu, K.; Chen, Z. Non-Newtonian Flow Characteristics of Heavy Oil in the Bohai Bay Oilfield: Experimental and Simulation Studies. Energies 2017, 10, 1698. [Google Scholar] [CrossRef]

- Abukhalifeh, H.; Lohi, A.; Upreti, S.R. A Novel Technique to Determine Concentration-Dependent Solvent Dispersion in Vapex. Energies 2009, 2, 851–872. [Google Scholar] [CrossRef] [Green Version]

- Chen, Z.; Li, X.; Yang, D. Quantification of Viscosity for Solvents−Heavy Oil/Bitumen Systems in the Presence of Water at High Pressures and Elevated Temperatures. Ind. Eng. Chem. Res. 2019, 58, 1044–1054. [Google Scholar] [CrossRef]

- Eleyedath, A.; Swamy, K.A. Prediction of density and viscosity of bitumen. Pet. Sci. Technol. 2018, 36, 1779–1786. [Google Scholar] [CrossRef]

- Radhakrishnan, V.; Chowdari, S.G.; Reddy, K.S.; Chattaraj, R. A predictive model for estimating the viscosity of short-term-aged bitumen. Road Mater. Pavement Des. 2018, 19, 605–623. [Google Scholar] [CrossRef]

- Alade, O.S.; Ademodi, B.; Sasaki, K.; Sugai, Y.; Kumasaka, J.; Ogunlaja, A.S. Development of models to predict the viscosity of a compressed Nigerian bitumen and rheological property of its emulsions. J. Pet. Sci. Eng. 2016, 145, 711–722. [Google Scholar] [CrossRef]

- Behzadfar, E.; Hatzikiriakos, S.G. Rheology of bitumen: Effects of temperature, pressure, CO2 concentration and shear rate. Fuel 2014, 116, 578–587. [Google Scholar] [CrossRef]

- Martın-Alfonso, M.J.; Martinez-Boza, F.J.; Navarro, F.J.; Fernandez, M.; Crispulo, G. Pressure–temperature–viscosity relationship for heavy petroleum fractions. Fuel 2007, 86, 227–233. [Google Scholar] [CrossRef]

- Appeldorn, J.K. A simplified viscosity-pressure-temperature equation. SAE Tech. Pap. 1963. [Google Scholar] [CrossRef]

- Farobie, O.; Hasanah, N.; Matsumura, Y. Artificial neural network modelling to predict biodiesel production in supercritical methanol and ethanol using spiral reactor. Procedia Environ. Sci. 2015, 28, 214–223. [Google Scholar] [CrossRef]

- Barus, S. Isothermals, isopiestics, and isometrics relatives to viscosity. Am. J. Sci. 1963, 45, 87–96. [Google Scholar] [CrossRef]

- Sunphorka, S.; Chalermsinsuwan, B.; Piumsomboon, P. Artificial neural network model for the prediction of kinetic parameters of biomass pyrolysis from its constituents. Fuel 2017, 193, 142–158. [Google Scholar] [CrossRef]

- Meng, X.; Jia, M.; Wang, T. Neural network prediction of biodiesel kinematic viscosity at 313 K. Fuel 2014, 121, 133–140. [Google Scholar] [CrossRef]

- Deosarkar, M.P.; Sathe, V.S. Predicting effective viscosity of magnetite ore slurries by using artificial neural network. Powder Technol. 2012, 219, 264–270. [Google Scholar] [CrossRef]

- Ramadhas, A.S.; Jayaraj, S.; Muraleedharan, C.; Padmakumari, K. Artificial neural networks used for the prediction of the cetane number of biodiesel. Renew. Energy 2006, 31, 2524–2533. [Google Scholar] [CrossRef]

- Kalogirou, S.A. Artificial neural networks in renewable energy systems applications: A review. Renew. Sustain. Energy Rev. 2001, 5, 373–401. [Google Scholar] [CrossRef]

- Hosseini, S.M.; Pierantozzi, M.; Moghadasi, J. Viscosities of some fatty acid esters and biodiesel fuels from a rough hardsphere-chain model and artificial neural network. Fuel 2019, 235, 1083–1091. [Google Scholar] [CrossRef]

- Li, F.; Zhang, J.; Oko, E.; Wang, M. Modelling of a post-combustion CO2 capture process using neural networks. Fuel 2015, 151, 156–163. [Google Scholar] [CrossRef]

- Betiku, E.; Omilakin, R.O.; Ajala, O.S.; Okeleye, A.A.; Taiwo, A.E.; Solomon, B.O. Mathematical modeling and process parameters optimization studies by artificial neural network and response surface methodology: A case of non-edible neem (Azadirachta indica) seed oil biodiesel synthesis. Energy 2014, 72, 266–273. [Google Scholar] [CrossRef]

- Agwu, O.E.; Akpabio, J.U.; Alabi, S.B.; Dosunmu, A. Artificial Intelligence Techniques and their Applications in Drilling Fluid Engineering: A Review. J. Pet. Sci. Eng. 2018. [Google Scholar] [CrossRef]

- Kiss, A.; Fruhwirth, K.R.; Leoben, M.; Pongratz, R.; Maier, R. Formation breakdown pressure prediction with artificial neural networks. In Proceedings of the SPE International Hydraulic Fracturing Technology Conference and Exhibition, Muscat, Oman, 16–18 October 2018. SPE-191391-18IHFT-MS. [Google Scholar]

- Adeeyo, Y.A.; Saaid, M.I. Artificial Neural Network modeling of viscosity at bubblepoint pressure and dead oil viscosity of Nigerian crude oil. In Proceedings of the SPE NAICE Conference, Lagos, Nigeria, 31 July–2 August 2017. SPE-189142-MS. [Google Scholar]

- Ebaga-Ololo, J.; Chon, B.H. Prediction of Polymer Flooding Performance with an Artificial Neural Network: A Two-Polymer-Slug Case. Energies 2017, 10, 844. [Google Scholar] [CrossRef]

- Elkatatny, S.; Tariq, Z.; Mahmoud, M. Real time prediction of drilling fluid rheological properties using artificial neural networks visible mathematical model (white box). J. Pet. Sci. Eng. 2016, 146, 1202–1210. [Google Scholar] [CrossRef]

- Ghaffarian, N.; Eslamloueyan, R.; Vaferi, B. Model identification for gas condensate reservoirs by using ANN method based on well test data. J. Pet. Sci. Eng. 2014. [Google Scholar] [CrossRef]

- Li, X.; Miskimins, J.L.; Hoffman, B.T. A combined bottom-hole pressure calculation procedure using multiphase correlations and artificial neural network models. In Proceedings of the SPE Annual Technical Conference and Exhibition, Amsterdam, The Netherlands, 27–29 October 2014. SPE-170683-MS. [Google Scholar]

- Al-Fattah, S.M.; Startzman, R.A. Predicting natural gas production using artificial neural network. In Proceedings of the SPE Hydrocarbon Economics and Evaluation Symposium, Dallas, TX, USA, 2–3 April 2001. SPE-68593. [Google Scholar]

- Lopez, R.; Perez, J.R.; Dassori, C.G.; Ranson, A. Artificial Neural Networks Applied to the Operation of VGO Hydrotreaters. In Proceedings of the SPE Latin American and Caribbean Petroleum Engineering Conference, Buenos Aires, Argentina, 25–28 March 2001. SPE 69500. [Google Scholar]

- Adebiyi, F.M.; Omode, A.A. Organic, Chemical and Elemental Characterization of Components of Nigerian Bituminous Sands Bitumen. Energy Sources Part A Recovery Util. Environ. Eff. 2007, 29, 669–676. [Google Scholar] [CrossRef]

| Properties | X | Y |

|---|---|---|

| Bitumen content (% w/w) | 83.42 | 45.75 |

| Water content (% w/w) | 15.14 | 33.48 |

| Mineral matter (% w/w) | 1.44 | 20.76 |

| Asphaltene (% w/w) | 24.83 | 18.50 |

| Molecular mass (kg/mol) | 748 | - |

| Specific gravity (S.G. 25 °C/25 °C) | 1.02 | 1.01 |

| API gravity | 7.2 | 8.6 |

| Bitumen Samples | X | Y | ||||

|---|---|---|---|---|---|---|

| a1 | a2 | a3 | a1 | a2 | a3 | |

| Mehrotra and Svrcek I | 24.359 | −3.797 | 0.047 | 22.074 | −3.430 | 0.025 |

| Mehrotra and Svrcek II | 23.651 | −3.678 | 0.008 | 21.759 | −3.376 | 0.004 |

| v | θ | ∅ | v | θ | ∅ | |

| Power law | 3.47 × 1015 | −6.326 | 0.074 | 2.3942 × 1013 | −5.404 | 0.039 |

| x1 | x2 | x3 | x1 | x2 | x3 | |

| Barus (1893) | −33.7638 | 0.55163 | −0.00242 | −0.72303 | −0.04151 | 0.000116 |

| Model | Mehrotra and Svrcek I | Mehrotra and Svrcek II | Power Function | Barus Function | ANN Model | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Bitumen Sample | X | Y | X | Y | X | Y | X | Y | X | Y |

| R2 | 0.9886 | 0.9937 | 0.9855 | 0.9942 | 0.9830 | 0.9943 | 0.9331 | 0.9968 | 0.9995 | 0.9999 |

| RMSE | 71.6074 | 60.1350 | 81.2810 | 57.7763 | 84.3289 | 57.3053 | 161.3737 | 44.5842 | 16.4611 | 5.3377 |

| %AAD | 7.1712 | 2.7183 | 7.0783 | 1.8713 | 7.5396 | 1.8898 | 7.6811 | 2.5827 | 2.4385 | 0.6609 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alade, O.; Al Shehri, D.; Mahmoud, M.; Sasaki, K. Viscosity–Temperature–Pressure Relationship of Extra-Heavy Oil (Bitumen): Empirical Modelling versus Artificial Neural Network (ANN). Energies 2019, 12, 2390. https://doi.org/10.3390/en12122390

Alade O, Al Shehri D, Mahmoud M, Sasaki K. Viscosity–Temperature–Pressure Relationship of Extra-Heavy Oil (Bitumen): Empirical Modelling versus Artificial Neural Network (ANN). Energies. 2019; 12(12):2390. https://doi.org/10.3390/en12122390

Chicago/Turabian StyleAlade, Olalekan, Dhafer Al Shehri, Mohamed Mahmoud, and Kyuro Sasaki. 2019. "Viscosity–Temperature–Pressure Relationship of Extra-Heavy Oil (Bitumen): Empirical Modelling versus Artificial Neural Network (ANN)" Energies 12, no. 12: 2390. https://doi.org/10.3390/en12122390

APA StyleAlade, O., Al Shehri, D., Mahmoud, M., & Sasaki, K. (2019). Viscosity–Temperature–Pressure Relationship of Extra-Heavy Oil (Bitumen): Empirical Modelling versus Artificial Neural Network (ANN). Energies, 12(12), 2390. https://doi.org/10.3390/en12122390