Life Cycle Assessment of Low-Rank Coal Utilization for Power Generation and Energy Transportation

Abstract

:1. Introduction

2. Cases Description

2.1. Systems Description

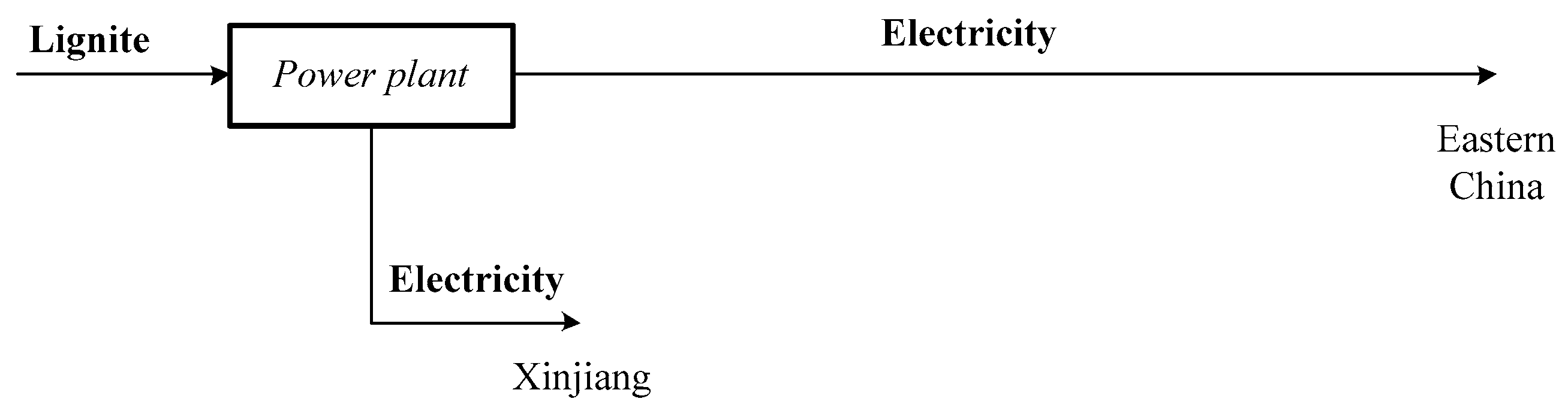

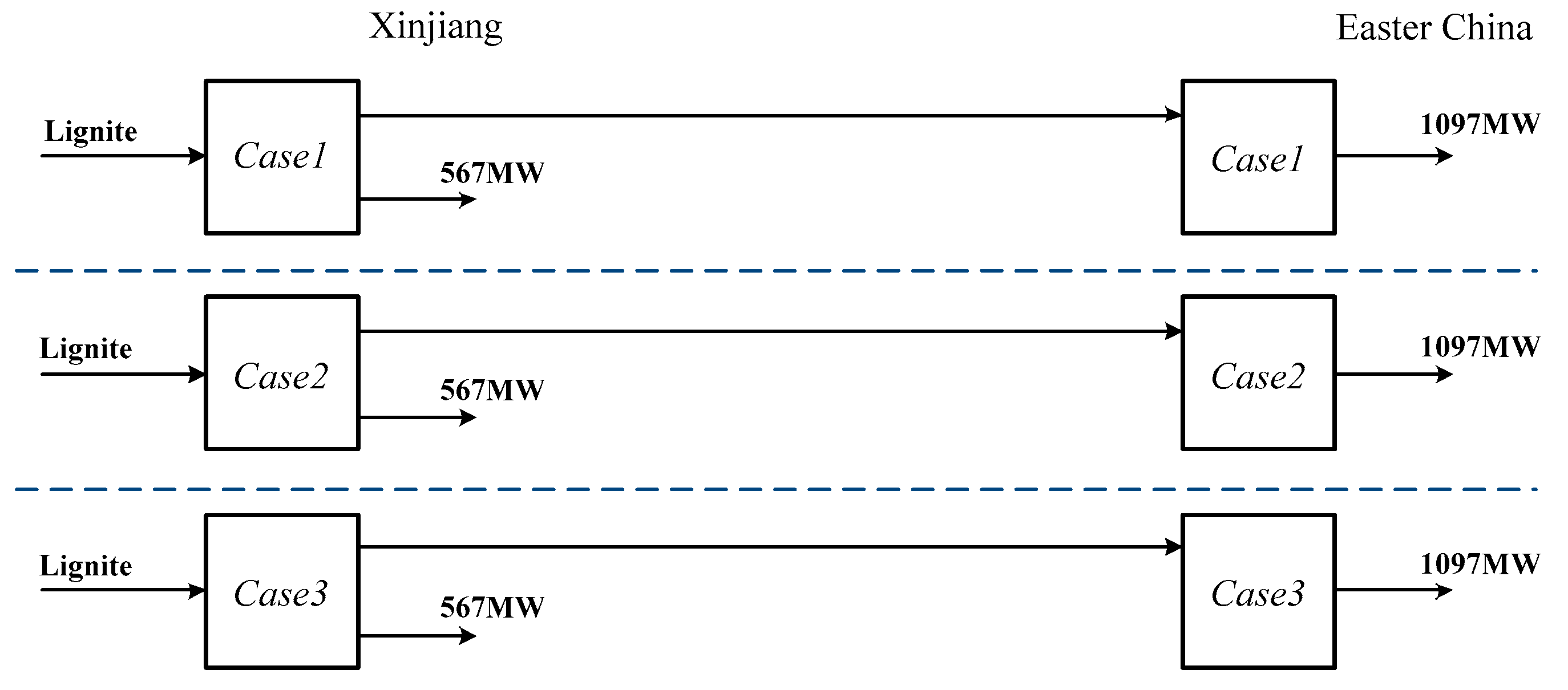

2.1.1. Case 1: Low-Rank Coal Fueled Power Generation and Electric Power Transmission

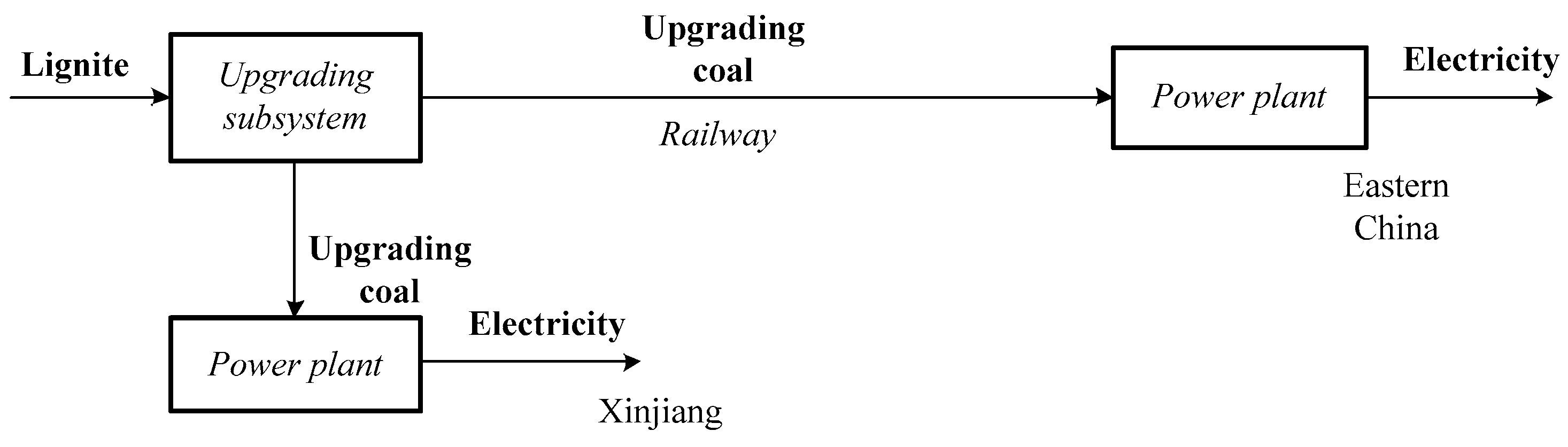

2.1.2. Case 2: Conventional Low-Rank Coal Upgrading and Upgraded Coal (UGC) Transportation

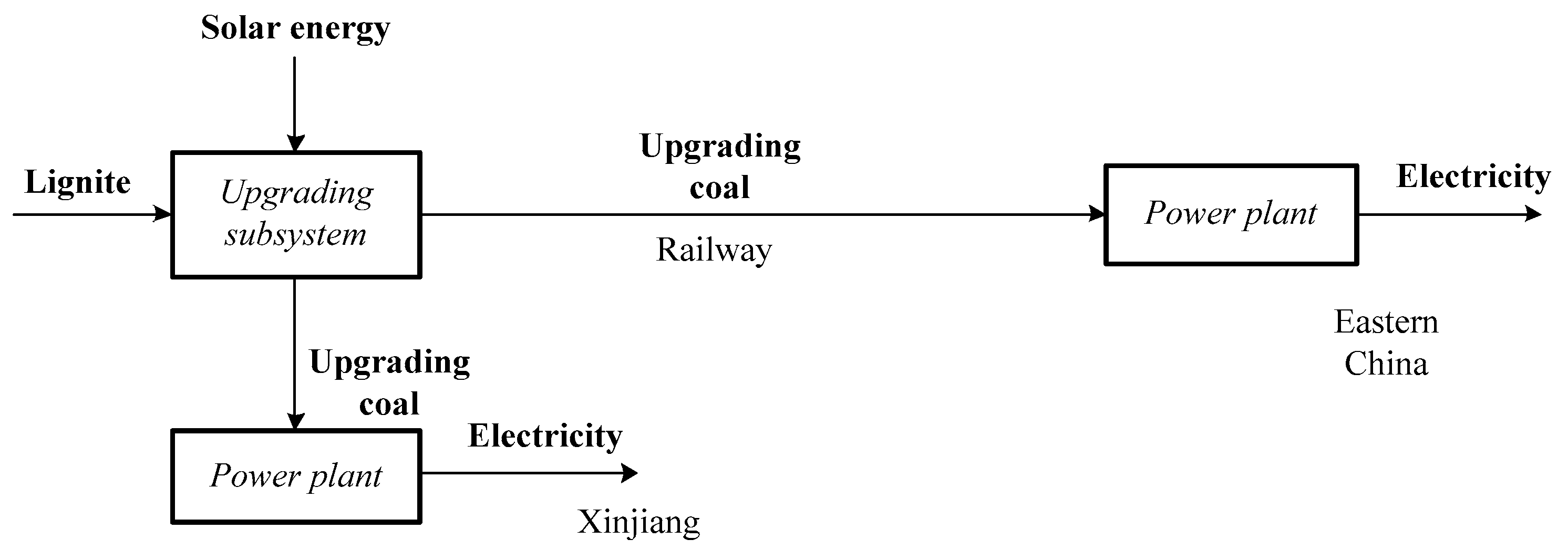

2.1.3. Case 3: Solar–Hybrid Coal Upgrading Power Generation and UGC Transportation

2.2. Initial Conditions and Assumptions

- (1)

- The operating hours for all power plants are calculated as 4500 hours per annum.

- (2)

- Both the electric power and upgraded coal transportation is 3000 km.

3. Life Cycle Assessment (LCA) Analysis

3.1. LCA Methodology

3.1.1. Goal and Scope

3.1.2. Life Cycle Inventory

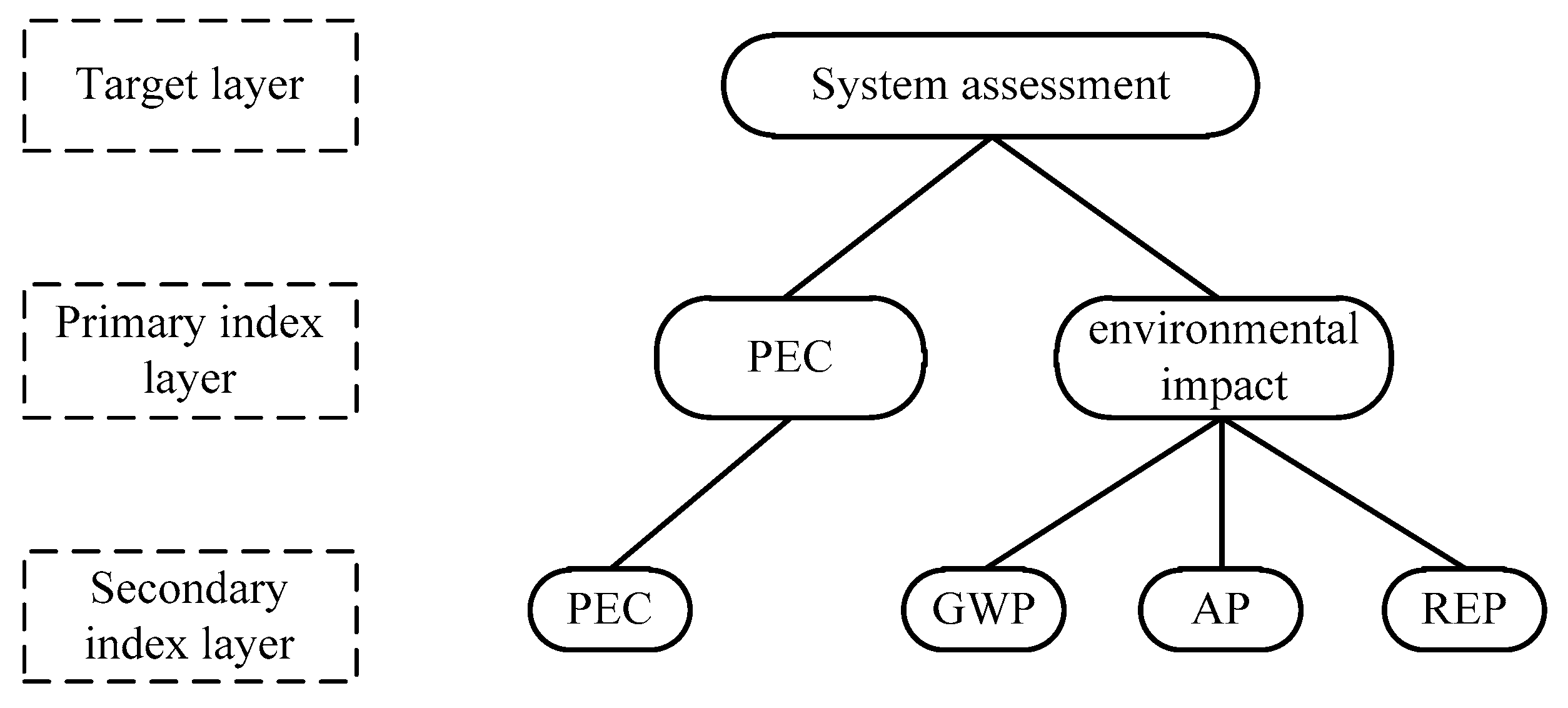

3.2. Analytic Hierarchy Process (AHP) Analysis

3.2.1. Hierarchical Model

3.2.2. Object Function

4. Case Study

4.1. Basic Data for LCA Analysis

4.2. Results and Discussion

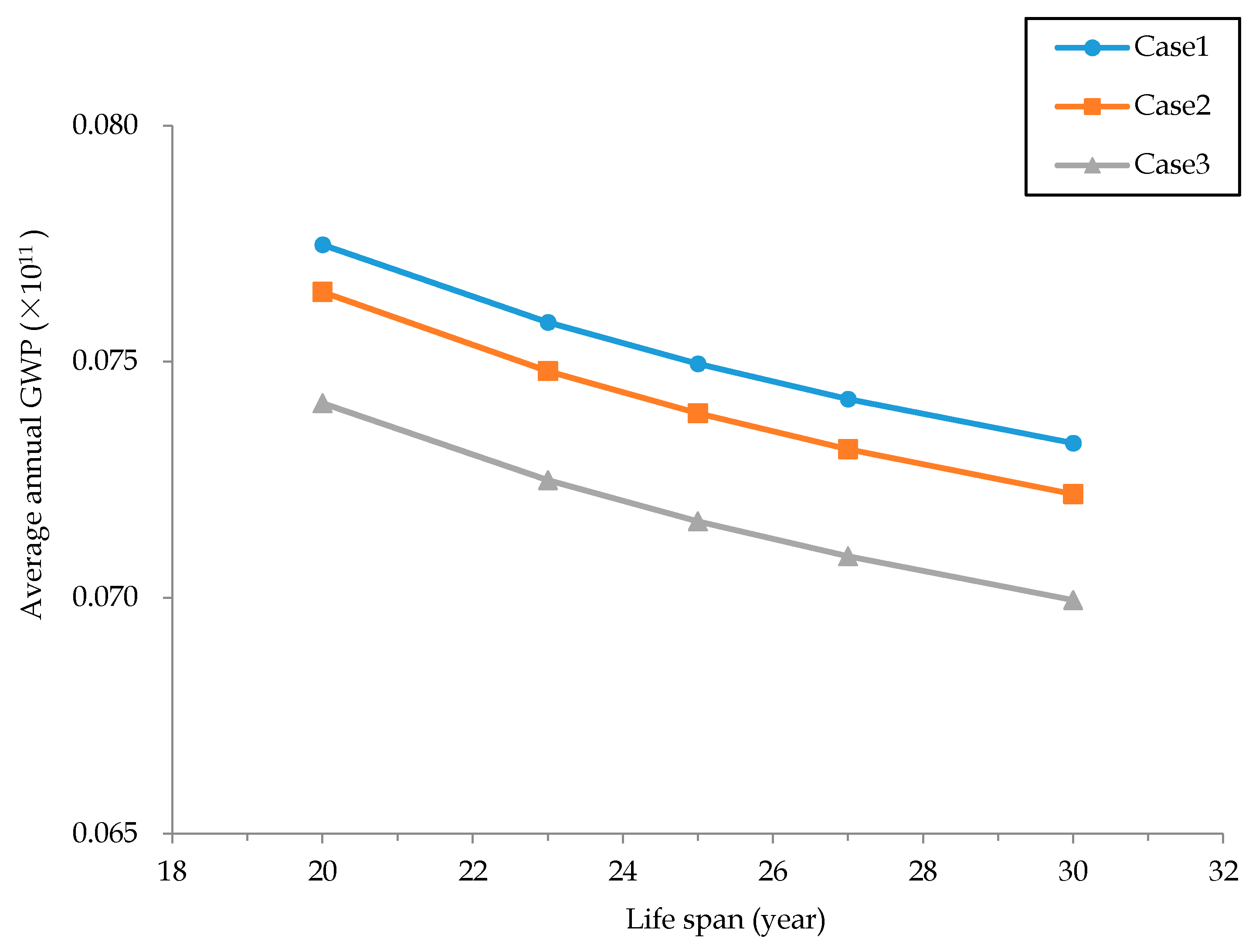

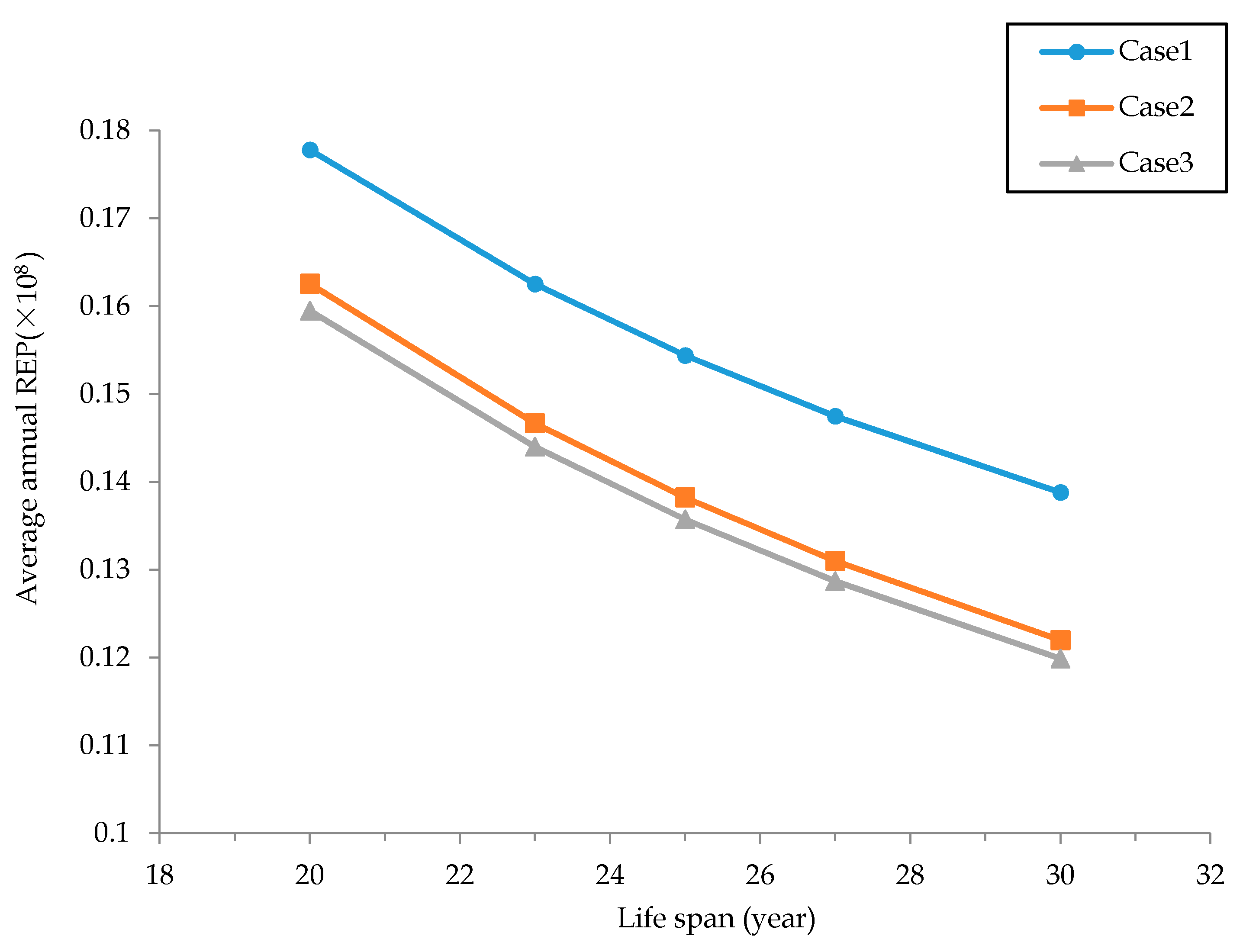

4.3. Sensitive Analysis

4.3.1. Effect of Life Span

4.3.2. Effect of Total Global Pollution Emissions

5. Conclusions

- (1)

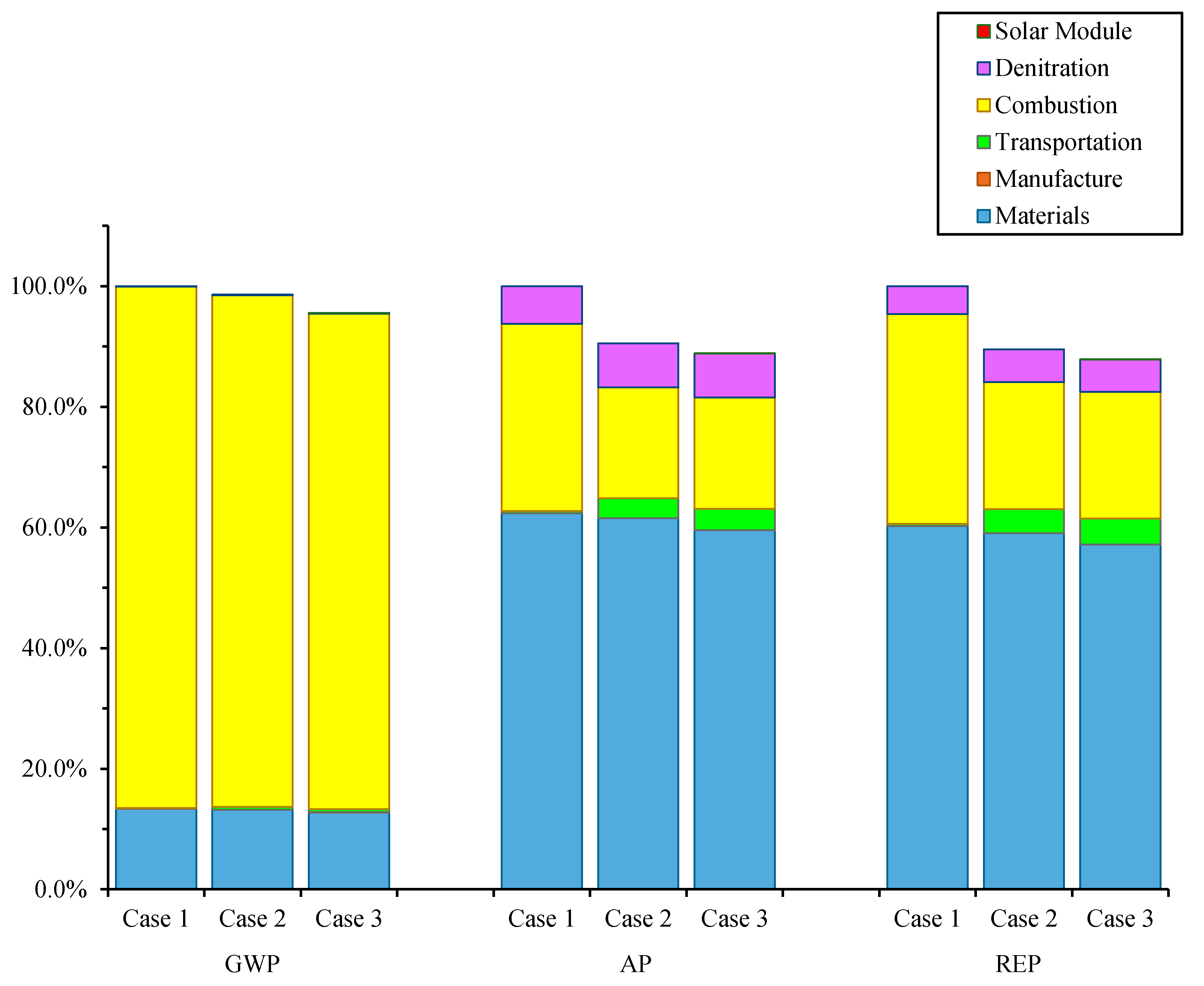

- From the perspective of the whole life cycle, upgrading the low-rank coal to power generation will help reduce pollution emissions and primary energy consumption. Whether it is solar upgrading or traditional nonsolar upgrading, it has a significant effect in reducing the acidification potential of the system and the potential of respiratory effects, but the traditional upgrading is not effective in reducing the greenhouse effect potential of the system, while the effect of the solar upgrading system is clear.

- (2)

- Pollution emissions and primary energy consumption are mainly concentrated in the operational phase, which produces more than 90% CO2 and consumes more than 90% primary energy of the life cycle. As a result the greenhouse effect potential of the system depends mainly on this stage. Emissions and consumption during coal transportation are only a small fraction of the total. Manufacturing coal upgrading equipment and solar energy collection equipment also account for a small percentage. This shows that it is feasible to carry out long-distance transportation after upgrading low-rank coal.

- (3)

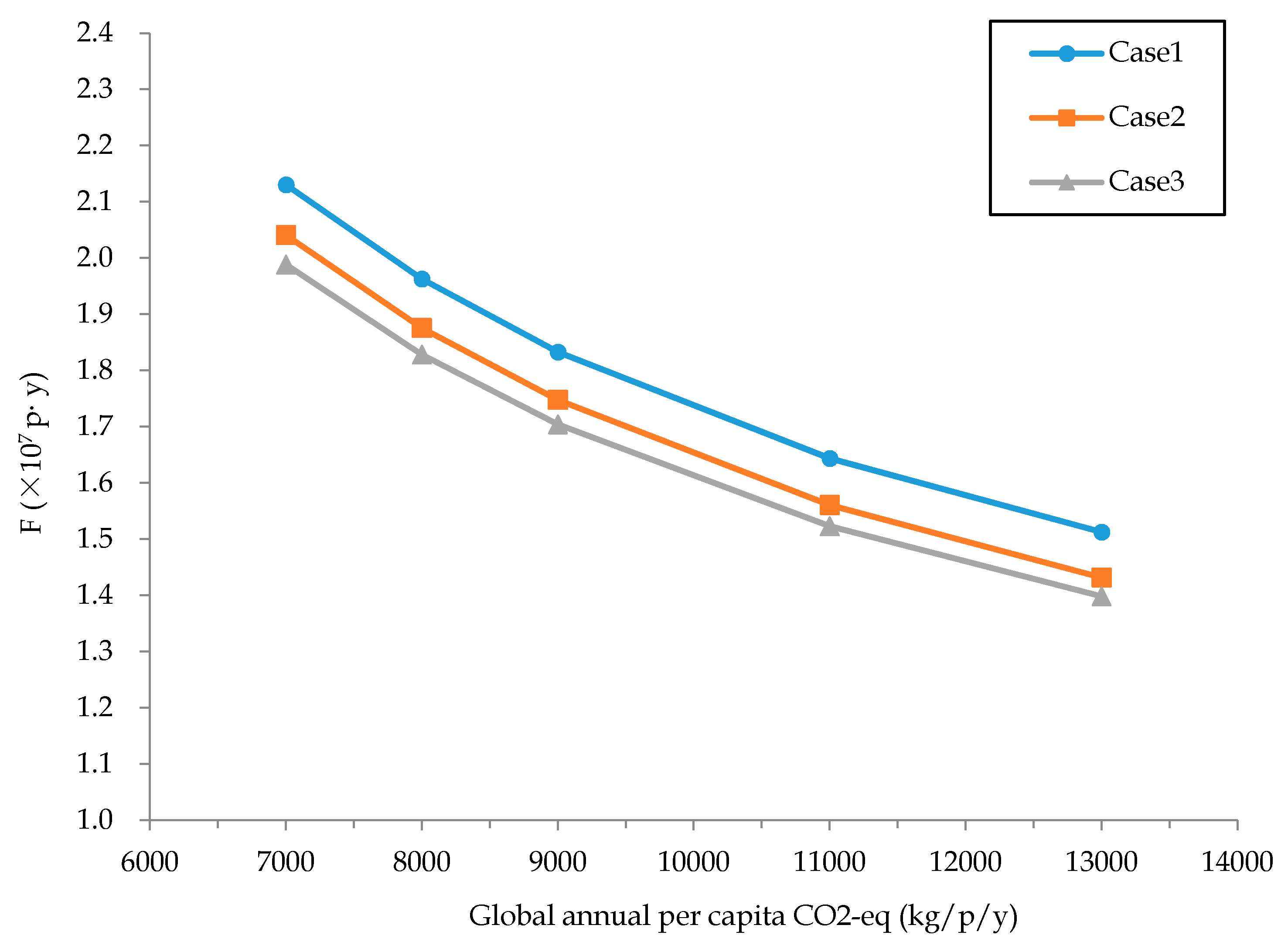

- Uncertainty analysis shows that system performance will vary with life cycle and global total pollution emissions. Specifically, as the life span increases, the proportion of fixed investment in the construction process will gradually decrease over the entire life cycle, resulting in an increase in the comprehensive performance of the system. In particular, the advantages of solar low-rank coal upgrading and power generation systems relative to the reference system will be further revealed. The impact of global pollution emissions on the system is mainly reflected in the cumulative effect of global pollution. Solar low-rank coal upgrading and power generation systems can effectively mitigate the trend of pollution and have good competitiveness.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature/Abbreviations

| GWP | global warming potential |

| AP | acidification potential |

| REP | respiratory potential |

| PEC | primary energy consumption |

| COE | gross cost of electricity |

| UGC | upgraded coal |

| GHG | greenhouse gas |

| LCA | life cycle assessment |

| AHP | analytic hierarchy process |

Appendix A

| Index | Case | Materials | Manufacture | Transportation | Operation | Ammonia Module | Solar Module | Total |

|---|---|---|---|---|---|---|---|---|

| CO2 (kg) | Case1 | 8646733800.00 | 10737445.97 | 59091692.52 | 162020801882.58 | 157546156.17 | 0.00 | 170894910977.24 |

| Case2 | 8454037875.00 | 10737445.97 | 748319280.60 | 158909125395.09 | 184425013.73 | 0.00 | 168306645010.40 | |

| Case3 | 8187875721.17 | 10737445.97 | 804187264.80 | 153870685416.47 | 183307384.49 | 30152062.08 | 163086945294.98 | |

| SO2 (kg) | Case1 | 82083106.98 | 2086.77 | 731311.99 | 55370663.45 | 1260025.66 | 0.00 | 139447194.84 |

| Case2 | 80676087.60 | 2086.77 | 7257975.18 | 30785924.01 | 1474997.90 | 0.00 | 120197071.46 | |

| Case3 | 78120930.92 | 2086.77 | 7794215.43 | 30836451.37 | 1466059.30 | 98815.42 | 118318559.22 | |

| NOX (kg) | Case1 | 133400264.10 | 2436.74 | 341331.13 | 55370663.45 | 25372873.13 | 0.00 | 214487568.54 |

| Case2 | 131932857.00 | 2436.74 | 3668316.04 | 35662927.16 | 29701724.18 | 0.00 | 200968261.12 | |

| Case3 | 127735099.60 | 2436.74 | 3940561.09 | 35735109.10 | 29521729.53 | 73072.83 | 197008008.89 | |

| PM2.5 (kg) | Case1 | 36467826.00 | 838.89 | 51684.60 | 12301771.26 | 7875160.12 | 0.00 | 56697280.88 |

| Case2 | 35126370.00 | 838.89 | 450325.63 | 12056929.98 | 9218736.58 | 0.00 | 56853201.08 | |

| Case3 | 34031302.85 | 838.89 | 483325.03 | 11674769.64 | 9162870.36 | 77231.50 | 55430338.27 | |

| CO (kg) | Case1 | 22704270.00 | 22909.48 | 499452.54 | 0.00 | 2172.89 | 0.00 | 23228804.91 |

| Case2 | 21506925.00 | 22909.48 | 4388210.68 | 0.00 | 2543.60 | 0.00 | 25920588.75 | |

| Case3 | 20862052.12 | 22909.48 | 4709954.83 | 0.00 | 2528.19 | 12448.49 | 25609893.11 | |

| CH4 (kg) | Case1 | 490195375.20 | 35.95 | 397220.70 | 0.00 | 252.66 | 0.00 | 490592884.52 |

| Case2 | 483792324.00 | 35.95 | 5070117.21 | 0.00 | 295.77 | 0.00 | 488862772.93 | |

| Case3 | 468461383.94 | 35.95 | 5449610.31 | 0.00 | 293.98 | 20515.77 | 473931839.95 | |

| N2O (kg) | Case1 | 19645200.00 | 119.84 | 135354.94 | 0.00 | 0.00 | 0.00 | 19780674.78 |

| Case2 | 19473075.00 | 119.84 | 285502.39 | 0.00 | 0.00 | 0.00 | 19758697.24 | |

| Case3 | 18852536.95 | 119.84 | 302002.09 | 0.00 | 0.00 | 484.92 | 19155143.81 | |

| PEC (kWh) | Case1 | 35454678.78 | 29959.06 | 557006.11 | 438072254.63 | 625321.27 | 0.00 | 474739219.85 |

| Case2 | 35023361.10 | 29959.06 | 6951011.49 | 431601376.28 | 732006.96 | 0.00 | 474337714.90 | |

| Case3 | 33910042.83 | 29959.06 | 7470752.04 | 431601376.28 | 727570.95 | 0.00 | 473739701.16 |

| Index | Case | Materials | Manufacture | Transportation | Operation | Ammonia Module | Solar Module | Summary |

|---|---|---|---|---|---|---|---|---|

| GWP | Case1 | 25098961489.20 | 10844080.61 | 110891715.12 | 162020801882.58 | 157557980.71 | 0.00 | 187399057148.22 |

| Case2 | 24714850704.00 | 10844080.61 | 956462116.28 | 158909125395.09 | 184438855.65 | 0.00 | 184775721151.64 | |

| Case3 | 23932437394.74 | 10844080.61 | 1026379595.03 | 153870685416.47 | 183321142.53 | 30770563.38 | 179054438192.76 | |

| AP | Case1 | 189214931.85 | 3876.38 | 1064992.23 | 94130127.86 | 19021036.85 | 0.00 | 303434965.17 |

| Case2 | 186660240.00 | 3876.38 | 10025648.09 | 55749973.03 | 22266204.82 | 0.00 | 274705942.31 | |

| Case3 | 180732276.51 | 3876.38 | 10764009.67 | 55851027.73 | 22131269.97 | 150305.85 | 269632766.10 | |

| REP | Case1 | 232445808.49 | 5534.78 | 1543576.72 | 134117230.85 | 17881070.81 | 0.00 | 385993221.64 |

| Case2 | 227990793.54 | 5534.78 | 15340973.29 | 81249063.75 | 20931749.84 | 0.00 | 345518115.19 | |

| Case3 | 220781601.49 | 5534.78 | 16474502.68 | 80984559.97 | 20804901.88 | 286902.66 | 339338003.45 |

References

- An, L. Analysis of low-rank coal upgrading technology on the present situation and development. J. Petrochem. Ind. Technol. 2018, 25, 281. [Google Scholar]

- Osman, H.; Jangam, S.V.; Lease, J.D. Drying of low-rank coal (LRC)da review of recent patents and innovations. Dry Technol. 2010, 29, 1763–1783. [Google Scholar] [CrossRef]

- Xu, C.; Bai, P.; Xin, T. A novel solar energy integrated low-rank coal fired power generation using coal pre-drying and an absorption heat pump. Appl. Energy 2017, 200, 170–179. [Google Scholar] [CrossRef]

- Li, C.Z. Advances in the Science of Victorian Brown Coal; Elsevier Ltd.: Oxford, UK, 2004. [Google Scholar]

- Robinson, P.J.; Luyben, W.L. Simple dynamic gasifier model that runs in aspen dynamics. Ind. Eng. Chem. Res. 2008, 47, 7784–7792. [Google Scholar] [CrossRef]

- Hayashi, J.I.; Miura, K. Advances in the Science of Victorian Brown Coal: Chapter 4: Pyrolysis of Victorian Brown Coal; Elsevier Ltd.: Oxford, UK, 2004. [Google Scholar]

- Kaji, R.; Muranaka, Y.; Otsuka, K. Water absorption by coals: Effects of pore structure and surface oxygen. Fuel 1986, 65, 288–291. [Google Scholar] [CrossRef]

- Ogunsola, O.I.; Mikula, R.J. Effect of thermal upgrading on spontaneous combustion characteristics of western Canadian low rank coals. Fuel 1992, 71, 3–8. [Google Scholar] [CrossRef]

- Xu, C.; Xu, G.; Zhao, S. A theoretical investigation of energy efficiency improvement by coal pre-drying in coal fired power plants. Energy 2012, 44, 720–731. [Google Scholar] [CrossRef]

- Guan, J.; He, D.; Song, B. Lignite thermal upgrading and its effect on surface properties. Adv. Mater. Res 2012, 524–527, 887–893. [Google Scholar] [CrossRef]

- Xu, C.; Xin, T.; Xu, G. Thermodynamic analysis of a novel solar-hybrid system for low-rank coal upgrading and power generation. Energy 2017, 141, 1737–1749. [Google Scholar] [CrossRef]

- Xu, C.; Xin, T.; Li, X. A thermodynamic analysis of a solar hybrid coal-based direct-fired supercritical carbon dioxide power cycle. Energy Convers. Manag. 2019, 196, 77–91. [Google Scholar] [CrossRef]

- Piatkowski, N.; Wieckert, C.; Steinfeld, A. Experimental investigation of a packed-bed solar reactor for the steam-gasification of carbonaceous feedstocks. Fuel Process. Technol. 2009, 90, 360–366. [Google Scholar] [CrossRef]

- Michael, B.W.; Garvin, A.H.; John, J.B.; Craig, S.T. Life cycle assessment of a power tower concentrating solar plant and the impacts of key design alternatives. J. Environ. Sci. Technol. 2013, 47, 5896–5903. [Google Scholar]

- Varun; Bhat, I.K.; Ravi, P. LCA of renewable energy for electricity generation systems—A review. Renew. Sustain. Energy Rev. 2009, 13, 1067–1073. [Google Scholar] [CrossRef]

- Hong, H.; Zhao, Y.; Jin, H. Proposed partial repowering of a coal-fired power plant using low-grade solar thermal energy. Int. J. Thermodyn. 2011, 14, 21–28. [Google Scholar]

- Wang, J.; Zhai, Z.J.; Zhang, C. Environmental impact analysis of BCHP system in different climate zones in China. Energy 2010, 35, 4208–4216. [Google Scholar] [CrossRef]

- Wang, J.; Yang, Y.; Mao, T. Life cycle assessment (LCA) optimization of solar-assisted hybrid CCHP system. Appl. Energy 2015, 146, 38–52. [Google Scholar] [CrossRef]

- Saaty, T.L. The Analytic Hierarchy Process; McGraw-Hill Company: New York, NY, USA, 1980. [Google Scholar]

- GB3059-2012. Available online: http://www.mee.gov.cn/hjzl/ (accessed on 17 June 2019).

- Shindina, T.; Streimikis, J.; Sukhareva, Y.; Nawrot, Ł. Social and Economic Properties of the Energy Markets. Econ. Sociol. 2018, 11, 334–344. [Google Scholar] [CrossRef]

- Nation environmental protection agency of China. Production and Emission of Industrial Pollutant Manual; China Environment Science Press: Beijing, China, 1996.

- Jing, Y.Y.; Bai, H.; Wang, J.J. Life cycle assessment of a solar combined cooling heating and power system in different operation strategies. Appl. Energy 2012, 92, 843–853. [Google Scholar] [CrossRef]

- Dong, W. Study on Multidimensional Analysis of Thermal Economy of Unit Thermal Power Unit Generation; Shanghai University of Electric Power: Shanghai, China, 2016. [Google Scholar]

- Wang, X.; Xu, Z.; Wei, B. The ash deposition mechanism in boilers burning Zhundong coal with high contents of sodium and calcium: A study from ash evaporating to condensing. Appl. Therm. Eng. 2015, 80, 150–159. [Google Scholar] [CrossRef] [Green Version]

- Gu, Y.Z.; Wang, S.M. Ammonia slip in denitration system of coal-fired power plant and emission characteristics of fine particulate matters derived from slipped ammonia. Mod. Chem. Ind. 2017, 37, 19–23. [Google Scholar]

- Tvaronavičienė, M.; Prakapienė, D.; Garškaitė-Milvydienė, K.; Prakapas, R.; Nawrot, Ł. Energy efficiency in the long run in the selected European countries. Econ. Sociol. 2018, 11, 245–254. [Google Scholar] [CrossRef] [PubMed]

- Leiden University. Institute of Environmental science (CML) 2012 [EB/OL]. Available online: http://cml.leiden.edu/research/industrialecology/ (accessed on 24 September 2012).

- Zhu, Y.; Zhai, R.R.; Zhao, M.M.; Yang, Y.P. Analysis of solar contribution evaluation method in solar aided coal-fired power plants. Energy Proc. 2014, 61, 1610–1613. [Google Scholar] [CrossRef]

- Makarenko, D.; Streimikiene, D. Quality of life and environmentally responsible behavior in energy sector. J. Int. Stud. 2014, 7, 179–192. [Google Scholar]

- Zhai, R.R.; Li, C. Life cycle assessment of solar aided coal-fired power system with and without heat storage. Energy Convers. Manag. 2016, 111, 453–465. [Google Scholar] [CrossRef]

| Item | Symbol | Unit | Value |

|---|---|---|---|

| boiler efficiency (Case 1) | η1 | % | 92.95 |

| boiler efficiency (Case 2) | η2 | % | 93.83 |

| boiler efficiency (Case 3) | η3 | % | 93.83 |

| steam turbine | ηt | % | 47.3 |

| generator efficiency | ηg | % | 99.0 |

| Item | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|---|---|---|---|---|---|---|---|

| i | Generators and their auxiliary equipment | Upgrading equipment | Trough heat exchanger | Power line | Pylon | - | - |

| j | Steel | Aluminum | Glass | - | - | - | - |

| k | CO2 | SO2 | NOX | PM2.5 | CO | CH4 | N2O |

| c | - | - | - | Raw lignite | UGC without solar energy | UGC with solar energy | - |

| r | Road | Railway | - | - | - | - | - |

| Pollutant | FGWP (g CO2-eq/g) | FAP (g SO2-eq/g) | FREP (g PM2.5-eq/g) |

|---|---|---|---|

| CO2 | 1 | 0 | 0 |

| SO2 | 0 | 1 | 1.9 |

| NOX | 0 | 0.7 | 0.3 |

| PM2.5 | 0 | 0 | 1 |

| CO | 3 | 0 | 0 |

| CH4 | 21 | 0 | 0 |

| N2O | 310 | 0.7 | 0 |

| Scale aij | Meaning |

|---|---|

| 1 | The effect of Ci and Cj is the same |

| 3 | The effect of Ci is slightly stronger than that of Cj |

| 5 | The effect of Ci is stronger than that of Cj |

| 7 | The effect of Ci is evidently stronger than that of Cj |

| 9 | The effect of Ci is overwhelmingly stronger than that of Cj |

| 2,4,6,8 | The effect ratio of Ci and Cj is between the 2 adjacent grades |

| 1, 1/2, …1/9 | The effect ratio of Ci and Cj is the reciprocal of the above |

| n | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| RI | 0 | 0 | 0.58 | 0.90 | 1.12 | 1.24 | 1.32 | 1.41 | 1.45 | 1.49 | 1.51 |

| Materials | CO2 (g) | SO2 (g) | NOx (g) | PM2.5 (g) | CO (g) | CH4 (g) | N2O (g) | PEC (kWh) |

|---|---|---|---|---|---|---|---|---|

| Steel (kg) | 2000.000 | 9.700 | 4.000 | 15.000 | 25.000 | 53.000 | 0.000 | 1.700 |

| Aluminum (kg) | 25800.000 | 205.500 | 94.700 | 290.000 | 14.000 | 24.000 | 0.000 | 36.100 |

| Glass (kg) | 132.300 | 1.100 | 3.700 | 7.000 | 0.000 | 0.000 | 0.000 | 0.600 |

| Coal (kWh) | 43.750 | 0.420 | 0.690 | 0.180 | 0.106 | 2.520 | 0.102 | 0.183 |

| NH3 (kg) | 2771.388 | 22.165 | 446.333 | 138.532 | 0.038 | 0.004 | 0.000 | 11.000 |

| Materials | Generators and Their Auxiliary Equipment | Upgrading Equipment | Trough Heat Exchanger | Power Line | Pylon |

|---|---|---|---|---|---|

| Steel (t) | 16936 | - | 116284 | 23904 | 375000 |

| Aluminum (t) | 0 | - | 0 | 15150 | 0 |

| Glass (t) | 0 | - | 62239 | 0 | 0 |

| Unit | CO2 (kW/kg) | SO2 (kW/kg) | NOX (kW/kg) | PM2.5 (kW/kg) | CO (kW/kg) | CH4 (kW/kg) | N2O (kW/kg) | PEC (kW/kWh) |

|---|---|---|---|---|---|---|---|---|

| Power unit | 4455.0631 | 0.8658 | 1.0110 | 0.3481 | 9.5053 | 0.0149 | 0.0497 | 12.4303 |

| Boiler unit | 110.0140 | 0.0214 | 0.0250 | 0.0086 | 0.2347 | 0.0004 | 0.0012 | 0.3070 |

| Equipment | Solar Panel | Trough Heat Exchanger |

|---|---|---|

| Area(m2) | 373014 | 183200 |

| Equipment | CO2 (kg/m2) | SO2 (kg/m2) | NOX (kg/m2) | PM2.5 (kg/m2) | CO (kg/m2) | CH4 (kg/m2) | N2O (kg/m2) | PEC (kWh) |

|---|---|---|---|---|---|---|---|---|

| Solar panel | 16.29 | 0.15 | 0.065 | 0 | 0.00305 | 0.055 | 0.0013 | 0 |

| Trough heat exchanger | 131.42 | 0.23 | 0.27 | 0.42 | 0.06 | 0.00 | 0.00 | 0.00 |

| Transportation | CO2 (g) | SO2 (g) | NOx (g) | PM2.5 (g) | CO (g) | CH4 (g) | N2O (g) | PEC (kWh) |

|---|---|---|---|---|---|---|---|---|

| Railway (103 kg)−1km−1 | 6.772 | 0.065 | 0.033 | 0.004 | 0.039 | 0.046 | 0.002 | 0.063 |

| Road (103 kg)−1km−1 | 209 | 9.421 | 3.159 | 0.942 | 8.942 | 0.143 | 6.409 | 0.9 |

| Item | Steel (km) | Glass (km) | Aluminum (km) | Equipment (km) | Lignite (km) | UGC (km) |

|---|---|---|---|---|---|---|

| Case 1 | 200 | 200 | 200 | 900 | 200 | 0 |

| Case 2, 3 | 200 | 200 | 200 | 100 | 200 | 3000 |

| Items | Ultimate Analysis | LHV | Proximate Analysis | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Cdaf | Hdaf | Odaf | Ndaf | Sdaf | (MJ/kg) | Ad | FCd | Vd | Mar | |

| Raw lignite | 79.78 | 3.45 | 15.48 | 0.69 | 0.60 | 19.33 | 7.39 | 64.21 | 28.39 | 26.40 |

| UGC without solar energy | 88.37 | 3.47 | 7.39 | 0.41 | 0.36 | 29.45 | 8.67 | 75,37 | 15.96 | 3.09 |

| UGC with solar energy | 81.85 | 3.50 | 13.48 | 0.63 | 0.55 | 27.18 | 7.69 | 66.79 | 25.53 | 2.75 |

| Pollutant | Non-disposition/Disposition/Difference Value | |

|---|---|---|

| SO2 (g/kWh) | NOX (g/kWh) | |

| Raw lignite | 2.772/0.332/2.440 | 1.459/0.332/1.127 |

| UGC with solar energy | 2.358/0.107/2,251 | 1.144/0.153/0.991 |

| UGC without solar energy | 1.404/0.107/1.297 | 0.828/0.153/0.675 |

| Coal | Ammonia (g/kWh) |

|---|---|

| Raw lignite | 0.442944444 |

| UGC without solar energy | 0.263196313 |

| UGC with solar energy | 0.382219877 |

| Materials | CO2 (kg) | SO2 (kg) | NOX (kg) | PM2.5 (kg) | CO (kg) | CH4 (kg) | N2O (kg) | PEC (kWh) |

|---|---|---|---|---|---|---|---|---|

| Ammonia (kg−1) | 2.771388 | 0.022165 | 0.446333 | 0.138532 | 0.000038 | 0.000004 | 2.771388 | 11.00 |

| Region | The Comparison Matrix of the Target |

|---|---|

| Developed region | |

| Moderately developed region | |

| Underdeveloped region |

| Perspective | The Comparison Matrix of Environmental Impact |

|---|---|

| Global | |

| regional | |

| Local |

| Item | Base Value | Unit |

|---|---|---|

| GWP | 9487.061 | kg CO2-eq·(p·y)−1 |

| AP | 35.70132 | kg SO2-eq·(p·y)−1 |

| REP | 14.05832 | kg PM2.5-eq·(p·y)−1 |

| PEC | 25.00 | kWh·(p·y)−1 |

| Perspective | Global | Regional | Local | ||

|---|---|---|---|---|---|

| Region | |||||

| α1 | 0.6667 | 0.5000 | 0.3333 | ||

| Developed region | α2 | 0.1898 | 0.2848 | 0.3797 | |

| α3 | 0.1110 | 0.1665 | 0.2220 | ||

| α4 | 0.0325 | 0.0487 | 0.0649 | ||

| α1 | 0.6667 | 0.5000 | 0.3333 | ||

| Moderately developed region | α2 | 0.0284 | 0.0426 | 0.0568 | |

| α3 | 0.2147 | 0.3221 | 0.4295 | ||

| α4 | 0.0902 | 0.1353 | 0.1804 | ||

| α1 | 0.6667 | 0.5000 | 0.3333 | ||

| Underdeveloped region | α2 | 0.0389 | 0.0584 | 0.0779 | |

| α3 | 0.0666 | 0.0999 | 0.1332 | ||

| α4 | 0.2278 | 0.3417 | 0.4556 | ||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, L.; Xu, C. Life Cycle Assessment of Low-Rank Coal Utilization for Power Generation and Energy Transportation. Energies 2019, 12, 2365. https://doi.org/10.3390/en12122365

Yuan L, Xu C. Life Cycle Assessment of Low-Rank Coal Utilization for Power Generation and Energy Transportation. Energies. 2019; 12(12):2365. https://doi.org/10.3390/en12122365

Chicago/Turabian StyleYuan, Leidong, and Cheng Xu. 2019. "Life Cycle Assessment of Low-Rank Coal Utilization for Power Generation and Energy Transportation" Energies 12, no. 12: 2365. https://doi.org/10.3390/en12122365

APA StyleYuan, L., & Xu, C. (2019). Life Cycle Assessment of Low-Rank Coal Utilization for Power Generation and Energy Transportation. Energies, 12(12), 2365. https://doi.org/10.3390/en12122365