Applicability Analysis of Klinkenberg Slip Theory in the Measurement of Tight Core Permeability

Abstract

1. Introduction

2. Experiments

2.1. Gas Permeability Calculation

2.2. Experimental Apparatus

2.3. Core Samples

2.4. Experimental Procedure

3. Results and Discussion

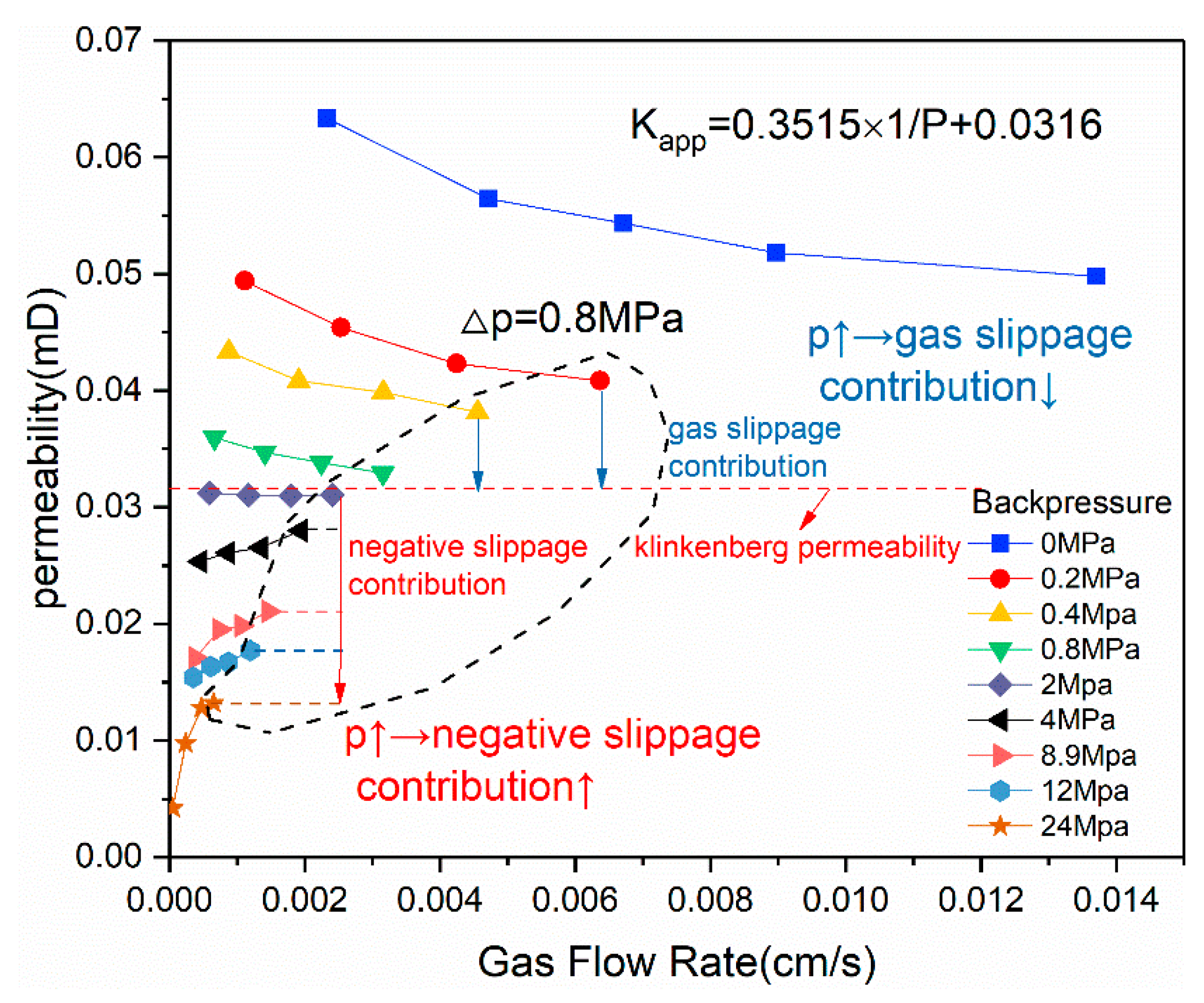

3.1. Relationships between Permeability and Flowrate

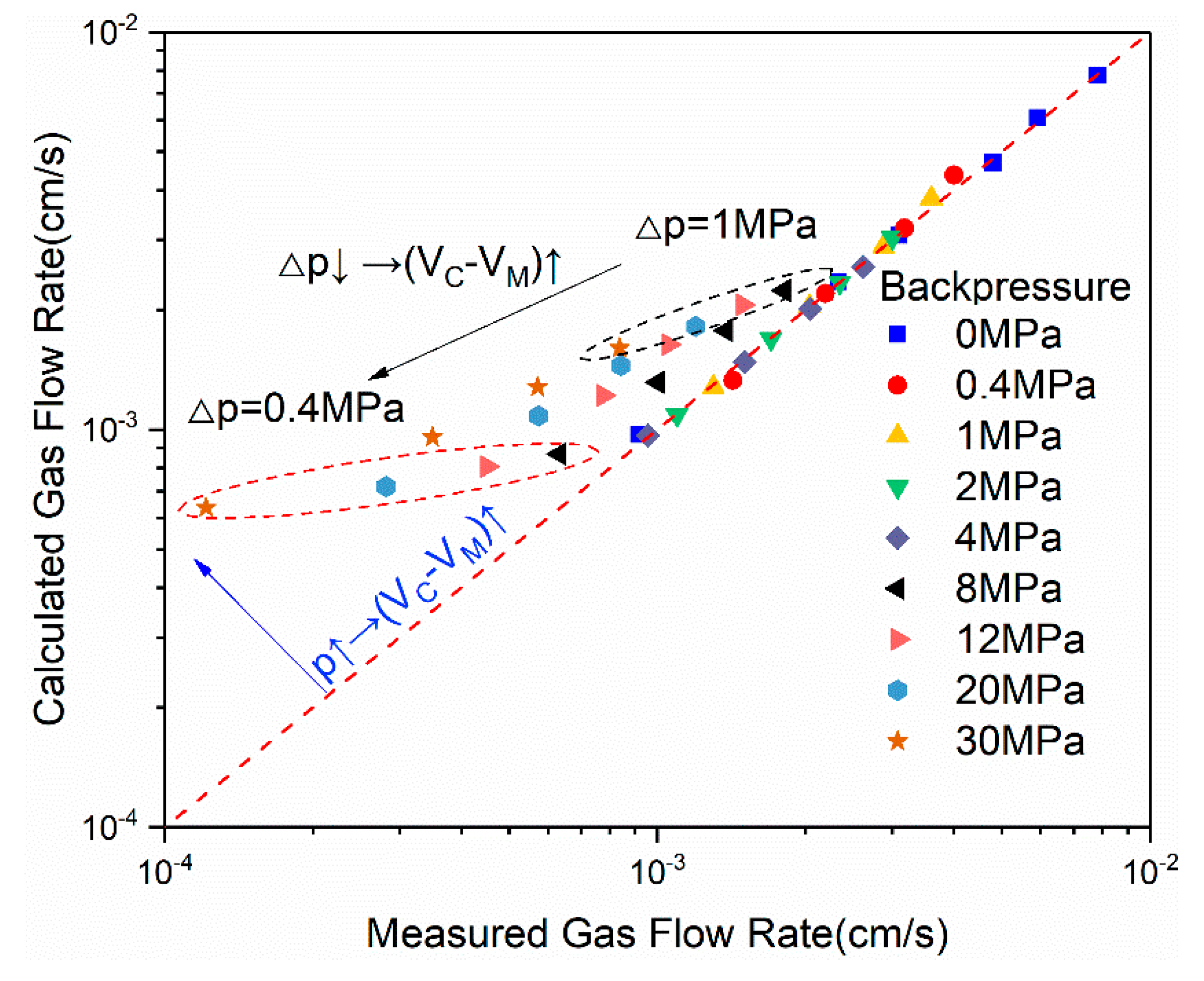

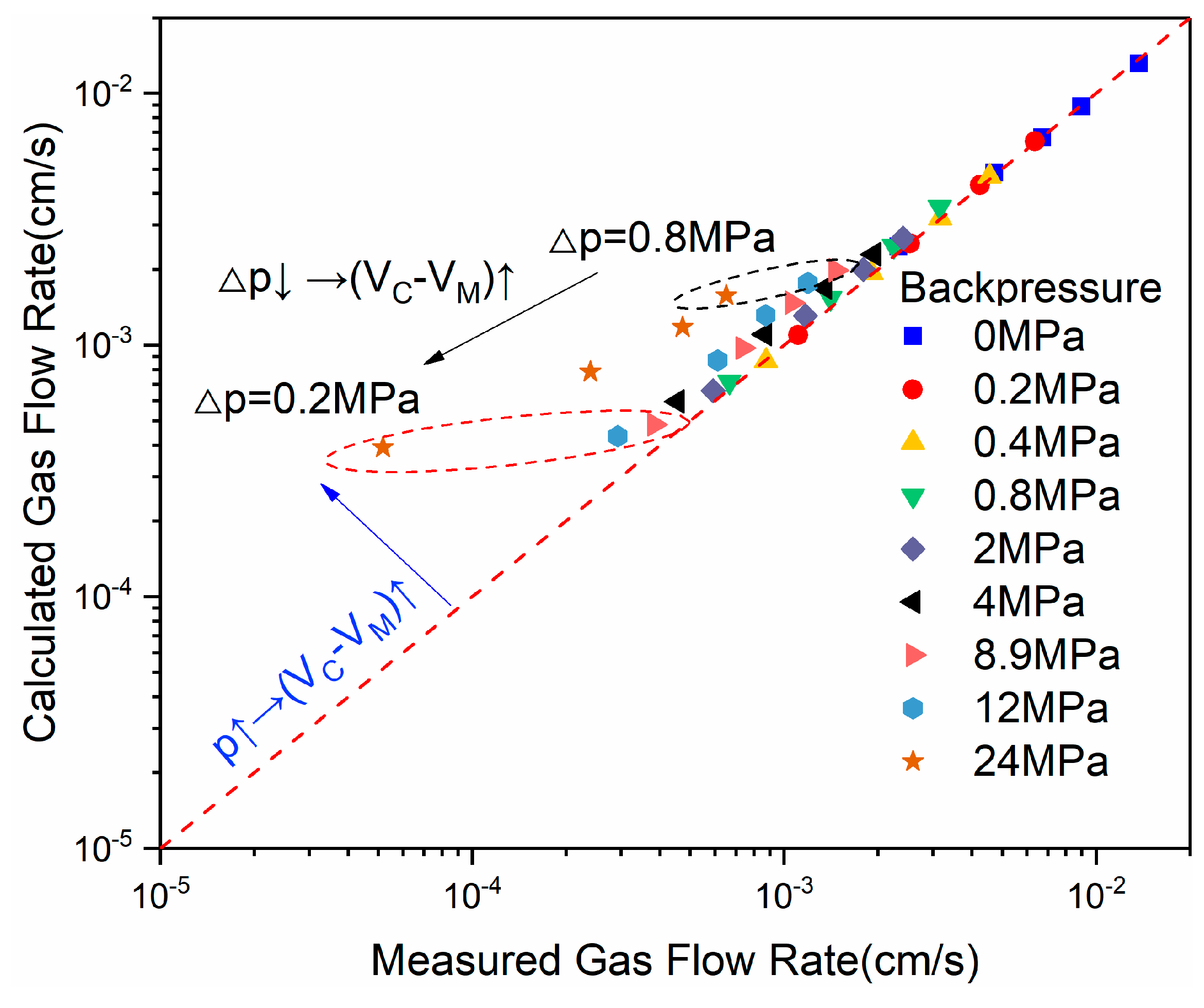

3.2. Measured Flowrate versus Theoretical Flowrate

4. Conclusions and Suggestions

Author Contributions

Funding

Conflicts of Interest

References

- Yuko, K.; Kazuo, F. Some Predictions of Possible Unconventional Hydrocarbons Availability Until 2100. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, Jakarta, Indonesia, 17–19 April 2001; pp. 1–10. [Google Scholar] [CrossRef]

- Jia, C.Z.; Zou, C.N.; Li, J.Z.; Li, D.H.; Zheng, M. China’s tight oil evaluation criteria, main types, basic characteristics and resource prospects. J. Pet. 2012, 33, 343–350. [Google Scholar]

- Wang, L.; Tian, Y.; Yu, X.Y.; Wang, C.; Yao, B.W.; Wang, S.H.; Winterfeld, P.H.; Wang, X.; Yang, Z.Z.; Wang, Y.H.; et al. Advances in improved/enhanced oil recovery technologies for tight and shale reservoirs. Fuel 2017, 210, 425–445. [Google Scholar] [CrossRef]

- Velasco, R.; Panja, P.; Pathak, M.; Deo, M. Analysis of North-American Tight oil production. AICHE J. 2018, 64, 1479–1484. [Google Scholar] [CrossRef]

- Hu, S.Y.; Zhu, R.K.; Wu, S.T.; Bai, B.; Yang, Z.; Cui, J.W. Exploration and development of the benefits of China’s terrestrial tight oil under the background of low oil prices. Exp. Dev. 2018, 45, 1–12. [Google Scholar] [CrossRef]

- Yu, W.; Lashgari, H.R.; Wu, K.; Sepehrnoori, K. CO2 injection for enhanced oil recovery in bakken tight oil reservoirs. Fuel 2015, 159, 354–363. [Google Scholar] [CrossRef]

- Wang, X.Z.; Peng, X.L.; Zhang, S.J.; Du, Z.W.; Zeng, F.H. Characteristics of oil distributions in forced and spontaneous imbibition of tight oil reservoir. Fuel 2018, 224, 280–288. [Google Scholar] [CrossRef]

- Kathel, P.; Mohanty, K.K. Wettability Alteration in a Tight Oil Reservoir. Energy Fuels 2013, 27, 6460–6468. [Google Scholar] [CrossRef]

- Huang, S.; Yao, Y.D.; Zhang, S.; Ji, J.H.; Ma, R.Y. A Fractal Model for Oil Transport in Tight Porous Media. Transp. Porous Med. 2018, 121, 725–739. [Google Scholar] [CrossRef]

- Wan, T.; Yang, S.L.; Wang, L.; Sun, L.T. Experimental investigation of two-phase relative permeability of gas and water for tight gas carbonate under different test conditions. Oil Gas Sci. Technol. 2019, 74, 1–9. [Google Scholar] [CrossRef]

- Ghanbarian, B.; Torres-Verdín, C.W.; Lake, L.; Marder, M. Gas permeability in unconventional tight sandstones: Scaling up from pore to core. J. Pet. Sci. Eng. 2018, 173, 1163–1172. [Google Scholar] [CrossRef]

- Nelson, P. Pore-throat sizes in sandstones, tight sandstones, and shales. AAPG 2009, 93, 329–340. [Google Scholar] [CrossRef]

- Liu, Y.M.; Shen, B.; Yang, Z.Q.; Zhao, P.Q. Pore Structure Characterization and the Controlling Factors of the Bakken Formation. Energies 2018, 11, 2879. [Google Scholar] [CrossRef]

- Yao, J.L.; Deng, X.Q.; Zhao, Y.D.; Han, T.Y.; Chu, M.J.; Pang, J.L. Characteristics of tight oil in the Yanchang Formation of the Ordos Basin. Pet. Explor. Dev. 2013, 40, 150–158. [Google Scholar] [CrossRef]

- Gao, H.; Li, H.A. Pore structure characterization, permeability evaluation and enhanced gas recovery techniques of tight gas sandstones. J. Nat. Gas Sci. Eng. 2016, 28, 536–547. [Google Scholar] [CrossRef]

- Maxwell, J.C. On Stresses in Rarified Gases Arising from Inequalities of Temperature. Philos. Trans. R. Soc. Lond. 1879, 170, 231–256. [Google Scholar] [CrossRef]

- Nazari Moghaddam, R.; Jamiolahmady, M. Slip flow in porous media. Fuel 2016, 173, 298–310. [Google Scholar] [CrossRef]

- Wang, H.L.; Xu, W.Y.; Cai, M.; Zuo, J. An Experimental Study on the Slippage Effect of Gas Flow in a Compact Rock. Transp. Porous Med. 2016, 112, 117–137. [Google Scholar] [CrossRef]

- Rubin, C.; Zamirian, M.; Takbiri-Borujeni, A.; Gu, M. Investigation of gas slippage effect and matrix compaction effect on shale gas production evaluation and hydraulic fracturing design based on experiment and reservoir simulation. Fuel 2019, 241, 12–24. [Google Scholar] [CrossRef]

- Ziarani, A.S.; Aguilera, R. Knudsen’s Permeability Correction for Tight Porous Media. Transp. Porous Med. 2012, 91, 239–260. [Google Scholar] [CrossRef]

- Zhang, W.M.; Meng, G.; Wei, X.Y. A review on slip models for gas microflows. Microfluid Nanofluid 2012, 13, 845–882. [Google Scholar] [CrossRef]

- Sun, F.R.; Yao, Y.D.; Li, G.Z.; Dong, M.D. Transport behaviors of real gas mixture through nanopores of shale reservoir. J. Pet. Sci. Eng. 2019, 177, 1134–1141. [Google Scholar] [CrossRef]

- Darabi, H.; Ettehad, A.; Javadpour, F.; Sepehrnoori, K. Gas flow in ultra-tight shale strata. J. Fluid Mech. 2012, 710, 641–658. [Google Scholar] [CrossRef]

- Klinkenberg, L.J. The permeability of porous media to liquids and gases. Am. Pet. Inst. 1941, 2, 200–213. [Google Scholar] [CrossRef]

- Kundt, A.; Warburg, E. Poggendorfs. Annu. Rev. Plant Physiol. Plant Mol. 1875, 155, 337–525. [Google Scholar]

- Roy, S.; Raju, R.; Chuang, H.F.; Cruden, B.A.; Meyyappan, M. Modeling gas flow through microchannels and nanopores. J. Appl. Phys. 2003, 93, 4870–4879. [Google Scholar] [CrossRef]

- Kazemi, M.; Takbiri-Borujeni, A. An analytical model for shale gas permeability. Int. J. Coal Geol. 2015, 146, 188–197. [Google Scholar] [CrossRef]

- Pizio, O.; Sokołowski, S.; Sokołowska, Z. Electric double layer capacitance of restricted primitive model for an ionic fluid in slit-like nanopores: A density functional approach. J. Chem. Phys. 2012, 137, 175002–175124. [Google Scholar] [CrossRef]

- Manby, F.R.; Stella, M.; Goodpaster, J.D.; Miller, T.F. A Simple, Exact Density-Functional-Theory Embedding Scheme. J. Chem. Theory Comput. 2012, 8, 2564–2568. [Google Scholar] [CrossRef]

- Javadpour, F. Nanopores and Apparent Permeability of Gas Flow in Mudrocks (Shales and Siltstone). J. Can. Pet. Technol. 2009, 48, 16–21. [Google Scholar] [CrossRef]

- Javadpour, F.; Singh, H. Langmuir slip-Langmuir sorption permeability model of shale. Fuel 2016, 164, 28–37. [Google Scholar] [CrossRef]

- Singh, H.; Javadpour, F. Nonempirical Apparent Permeability of Shale. In Proceedings of the Unconventional Resources Technology Conference, Denver, CO, USA, 12–14 August 2013. [Google Scholar]

- Wang, H.Y.; Matteo, M.P. A Unified Model of Matrix Permeability in Shale Gas Formations. In Proceedings of the SPE Reservoir Simulation Symposium, Houston, TX, USA, 23–25 February 2015. [Google Scholar]

- Cai, J.; Lin, D.; Singh, H.; Wei, W.; Zhou, S. Shale gas transport model in 3D fractal porous media with variable pore sizes. Mar. Pet. Geol. 2018, 98, 437–447. [Google Scholar] [CrossRef]

- Singh, H.; Cai, J. A feature-based stochastic permeability of shale: Part 1—Validation and two-phase permeability in a utica shale sample. Transp. Porous Med. 2018, 126, 527–560. [Google Scholar] [CrossRef]

- Singh, H.; Cai, J. A feature-based stochastic permeability of shale: Part 2—Predicting Field-Scale Permeability. Transp. Porous Med. 2019, 126, 561–578. [Google Scholar] [CrossRef]

- Lopez, B.; Aguilera, R. Sorption-Dependent Permeability of Shales. In Proceedings of the SPE/C SUR Unconventional Resources Conference, Calgary, AB, Canada, 20–22 October 2015. [Google Scholar]

- Chen, L.; Zhang, L.; Kang, Q.; Viswanathan, H.S.; Yao, J.; Tao, W. Nanoscale simulation of shale transport properties using the lattice Boltzmann method: Permeability and diffusivity. Sci. Rep. 2015, 5, 8089. [Google Scholar] [CrossRef]

- Civan, F. Effective Correlation of Apparent Gas Permeability in Tight Porous Media. Transp. Porous Med. 2010, 82, 375–384. [Google Scholar] [CrossRef]

- Civan, F.; Rai, C.; Sondergeld, C. Shale-Gas Permeability and Diffusivity Inferred by Improved Formulation of Relevant Retention and Transport Mechanisms. Transp. Porous Med. 2011, 86, 925–944. [Google Scholar] [CrossRef]

- Jones, F.O.; Owens, W.W. A Laboratory Study of Low-Permeability Gas Sands. Soc. Pet. Eng. 1980, 32, 1631–1640. [Google Scholar] [CrossRef]

- Rushing, J.A.; Newsham, K.E.; Lasswell, P.M.; Cox, J.C.; Balsingame, T.A. Klinkenberg-Corrected Permeability Measurements in Tight Gas Sands: Steady-State versus Unsteady-State Techniques. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 26–29 September 2004. [Google Scholar] [CrossRef]

- Zhu, G.Y.; Liu, L.; Yang, Z.M.; Liu, X.G.; Guo, Y.G.; Cui, Y.T. Experiment and Mathematical Model of Gas Flow in Low Permeability Porous Media. In Proceedings of the Fifth International Conference on Fluid Mechanics, Shanghai, China, 15–19 August 2007; pp. 534–537. [Google Scholar]

- Li, S.; Dong, M.; Li, Z. Measurement and revised interpretation of gas flow behavior in tight reservoir cores. J. Pet. Sci. Eng. 2009, 65, 81–88. [Google Scholar] [CrossRef]

- Dong, M.Z.; Li, Z.W.; Li, S.L.; Yao, J. Permeabilities of tight reservoir cores determined for gaseous and liquid CO2 and C2H6 using minimum backpressure method. J. Nat. Gas Sci. Eng. 2012, 5, 1–5. [Google Scholar] [CrossRef]

- Fathi, E.; Tinni, A.; Akkutlu, I.Y. Correction to Klinkenberg slip theory for gas flow in nano-capillaries. Int. J. Coal Geol. 2012, 103, 51–59. [Google Scholar] [CrossRef]

- You, L.J.; Xue, K.L.; Kang, Y.L.; Liao, Y.; Kong, L. Pore Structure and Limit Pressure of Gas Slippage Effect in Tight Sandstone. Sci. World J. 2013, 2013, 1–7. [Google Scholar] [CrossRef]

- Tanikawa, W.; Shimamoto, T. Comparison of Klinkenberg-corrected gas permeability and water permeability in sedimentary rocks. Int. J. Rock Mech. Min. Sci. 2009, 46, 229–238. [Google Scholar] [CrossRef]

- Salam, D.D. Novel Analysis to Determine Gas Permeability. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 28–30 September 2015. [Google Scholar] [CrossRef]

- Yue, X.A.; Wei, H.G.; Zhang, L.J.; Zhao, R.B.; Zhao, Y.P. Low Pressure Gas Percolation Characteristic in Ultra-low Permeability Porous Media. Transp. Porous Med. 2010, 85, 333–345. [Google Scholar] [CrossRef]

- Liu, G.F.; Fan, Z.Q.; Lu, Y.; Li, S.Y.; Feng, B.; Xia, Y.; Zhao, Q.M. Experimental Determination of Gas Relative Permeability Considering Slippage Effect in a Tight Formation. Energies 2018, 11, 467. [Google Scholar] [CrossRef]

- Moghadam, A.A.; Chalaturnyk, R. Expansion of the Klinkenberg’s slippage equation to low permeability porous media. Int. J. Coal Geol. 2014, 123, 2–9. [Google Scholar] [CrossRef]

- Tang, G.H.; Tao, W.Q.; He, Y.L. Gas slippage effect on microscale porous flow using the lattice Boltzmann method. Phys. Rev. E Stat. Nonlin. Soft Matter. Phys. 2005, 72, 56301. [Google Scholar] [CrossRef]

- An, W.Q.; Yue, X.A.; Feng, X.G.; Fang, X. The deviation of gas permeability and classical theory in tight reservoir cores with high pressure. J. Nat. Gas Sci. Eng. 2016, 30, 331–337. [Google Scholar] [CrossRef]

- Sinha, S.; Braun, E.M.; Determan, M.D.; Passey, Q.R.; Leonardi, S.A.; Boros, J.A.; Wood, A.C.; Zirkle, T.; Kudva, R.A. Steady-State Permeability Measurements on Intact Shale Samples at Reservoir Conditions—Effect of Stress, Temperature, Pressure, and Type of Gas. In Proceedings of the SPE Middle East Oil and Gas Show and Conference, Manama, Bahrain, 10–13 March 2013. [Google Scholar] [CrossRef]

- An, W.Q.; Yue, X.A.; Feng, X.G.; Fu, J.; Fang, X.; Zou, J.R.; Fang, W. Non-Klinkenberg slippage phenomenon at high pressure for tight core floods using a novel high pressure gas permeability measurement system. J. Pet. Sci. Eng. 2017, 156, 62–66. [Google Scholar] [CrossRef]

- Sander, R.; Pan, Z.; Connell, L.D. Laboratory measurement of low permeability unconventional gas reservoir rocks: A review of experimental methods. J. Nat. Gas Sci. Eng. 2017, 37, 248–279. [Google Scholar] [CrossRef]

- Moghadam, A.A.; Chalaturnyk, R. Rate dependency of permeability in tight rocks. J. Nat. Gas Sci. Eng. 2017, 40, 208–225. [Google Scholar] [CrossRef]

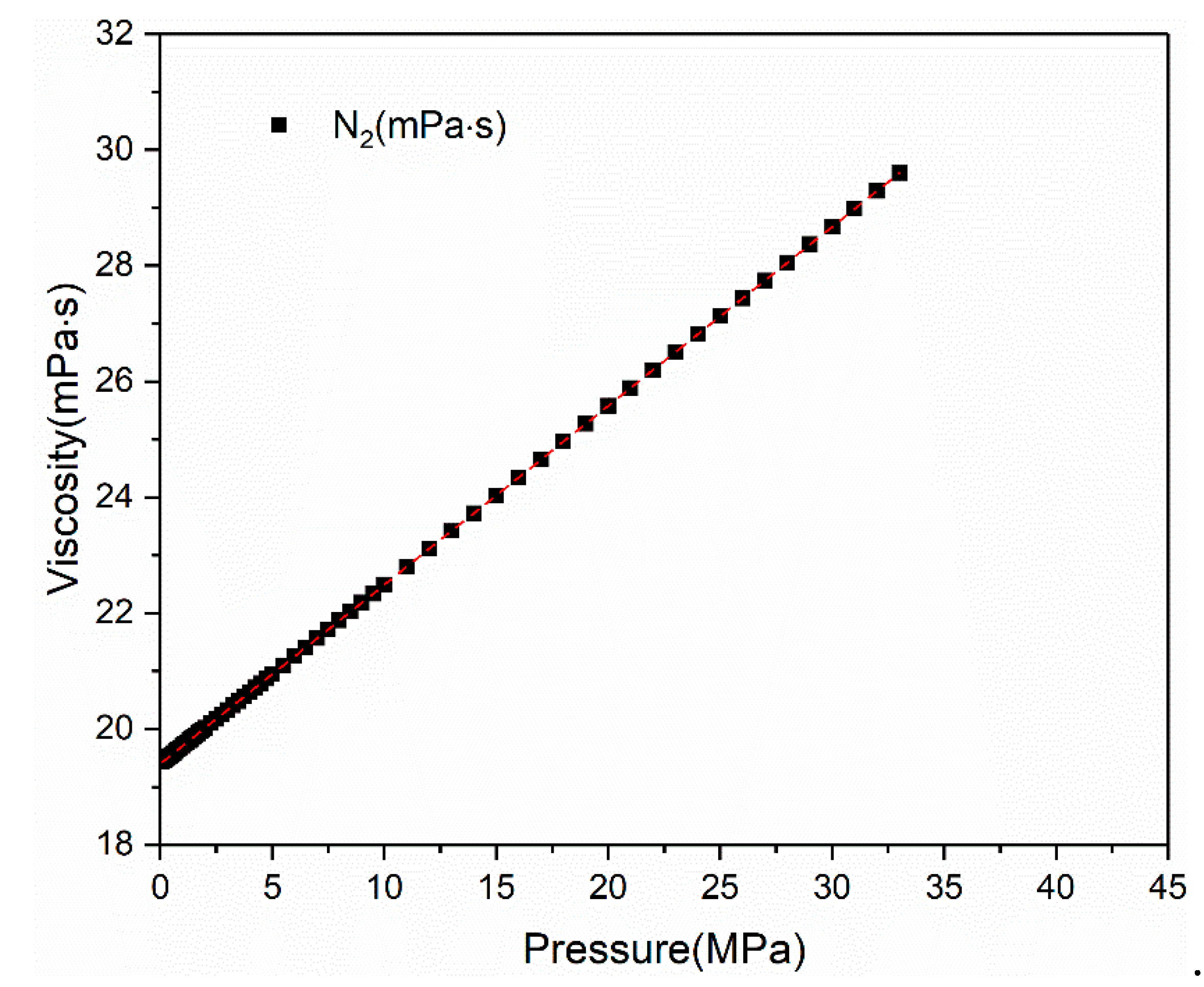

- Cole, W.A.; Wakeham, W.A. The Viscosity of Nitrogen, Oxygen, and Their Binary Mixtures in the Limit of Zero Density. J. Phys. Chem. Ref. Data 1985, 14, 209–226. [Google Scholar] [CrossRef]

- Latto, B.; Saunders, M.W. Viscosity of Nitrogen Gas at Low Temperatures Up to High Pressures: A New Appraisal. Can. Ioicrnal Chem. Eng. 1972, 50, 765–770. [Google Scholar] [CrossRef]

- Fang, X.; Yue, X.A.; An, W.Q.; Feng, X.G. Experimental study of gas flow characteristics in micro-/nano-pores in tight and shale reservoirs using microtubes under high pressure and low pressure gradients. Microfluid Nanofluid 2019, 23, 5. [Google Scholar] [CrossRef]

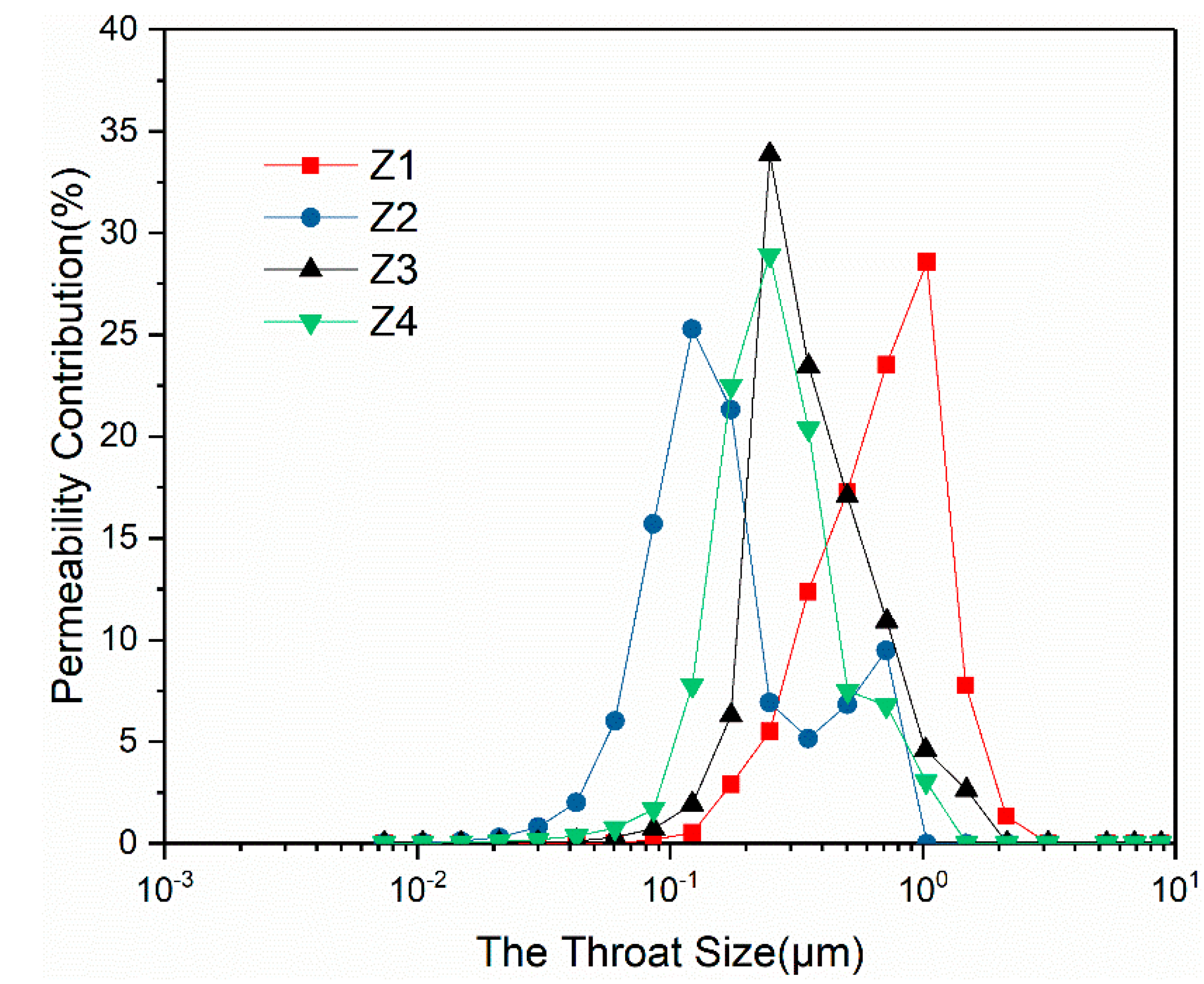

| Core Number | Length (cm) | Diameter (cm) | Porosity (%) | Dominated Throat Radius (μm) | Rock Type |

|---|---|---|---|---|---|

| Z1 | 10.78 | 2.50 | 20.57 | 1.0382 | Sandstone |

| Z2 | 7.46 | 2.50 | 10.50 | 0.1224 | Sandstone |

| Z3 | 4.09 | 2.51 | 11.30 | 0.2480 | Sandstone |

| Z4 | 6.26 | 2.52 | 9.80 | 0.2477 | Sandstone |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zou, J.; Yue, X.; An, W.; Gu, J.; Wang, L. Applicability Analysis of Klinkenberg Slip Theory in the Measurement of Tight Core Permeability. Energies 2019, 12, 2351. https://doi.org/10.3390/en12122351

Zou J, Yue X, An W, Gu J, Wang L. Applicability Analysis of Klinkenberg Slip Theory in the Measurement of Tight Core Permeability. Energies. 2019; 12(12):2351. https://doi.org/10.3390/en12122351

Chicago/Turabian StyleZou, Jirui, Xiangan Yue, Weiqing An, Jun Gu, and Liqi Wang. 2019. "Applicability Analysis of Klinkenberg Slip Theory in the Measurement of Tight Core Permeability" Energies 12, no. 12: 2351. https://doi.org/10.3390/en12122351

APA StyleZou, J., Yue, X., An, W., Gu, J., & Wang, L. (2019). Applicability Analysis of Klinkenberg Slip Theory in the Measurement of Tight Core Permeability. Energies, 12(12), 2351. https://doi.org/10.3390/en12122351