Co-Optimized Analysis and Design of Electric and Natural Gas Infrastructures

Abstract

1. Introduction

2. Co-Optimized Expansion Planning Problem

3. Co-Optimized Expansion Planning Problem Using Piecewise Linear Functions

4. Alternative Formulation Using Piecewise Linear Functions

5. Results

5.1. Model Results

5.2. Comparative Results

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Sets (Indices) | ||

| D | compression/reduction stations | |

| compression stations | ||

| reduction stations | ||

| F | fuels | |

| G | generation units | |

| candidate generation units | ||

| existing generation units | ||

| partitions for the squared pressure variables | ||

| J | nodes | |

| area nodes | ||

| pipeline nodes | ||

| K | generation technologies | |

| gas-fired generation technologies | ||

| L | transmission lines | |

| candidate transmission lines | ||

| existing transmission lines | ||

| M | months | |

| P | pipelines | |

| candidate pipelines | ||

| existing pipelines | ||

| S | load blocks | |

| T | years |

| Symbols | |

| final year | |

| compression/reduction station start node | |

| transmission line start node | |

| pipeline start node | |

| compression/reduction station end node | |

| transmission line end node | |

| pipeline end node |

| Tuples (Set of Indices) | ||

| compression/reduction station tuple | ||

| generation units tuple | ||

| transmission lines tuple | ||

| pipelines tuple |

| Parameters | |

| heat rate value for generator (MMBTU/MWh) | |

| natural gas heat value (MMBTU/MMcf) | |

| generator type k lifetime (years) | |

| transmission line lifetime (years) | |

| pipeline lifetime (years) | |

| discount rate in year t (%) | |

| maximum squared pressure in node j, year t, month m and block s (psig) | |

| minimum squared pressure in node j, year t, month m and block s (psig) | |

| load shedding cost (USD/MWh) | |

| carbon emissions for generator type k and fuel f (lb-CO/MMBTU) | |

| theoretical squared pressure for partition i and node j (psig) | |

| non-electric gas cost in area j, year t and month m (USD/MMcf) | |

| transmission line investment cost in year t (USD) | |

| pipeline investment cost in year t (USD) | |

| carbon emissions cost in year t (USD/lb-CO) | |

| fixed operational cost for generator , node j and year t (USD/MW) | |

| investment cost for generator , node j and year t (USD/MW) | |

| operational cost for compressor/reductor in year t (USD/psigh) | |

| operational cost for transmission line in year t (USD/MWh) | |

| operational cost for transmission line (opposite direction) in year t (USD/MWh) | |

| operational cost for pipeline in year t (USD/MMcf) | |

| operational cost for pipeline (opposite direction) in year t (USD/MMcf) | |

| fuel cost for generator , fuel f, year t and month m (USD/MMBTU) | |

| variable operational cost for generator , area j and year t (USD/MWh) | |

| gas production cost in area j, year t and month m (USD/MMBTU) | |

| maximum investment value for generator in year t (units) | |

| existing units of generator in area j (units) | |

| maximum capacity for generator (MW/unit) | |

| capacity credit for generator in year t, month m and block s (%) | |

| capacity factor for generator in year t (%) | |

| firm capacity for generator in year t (MW/unit) | |

| theoretical gas flow for pipeline in year t, month m, block s, and partition i (MMcf/h) | |

| theoretical gas flow for pipeline in year t, month m, block s, and partition (i, i’) (MMcf/h) | |

| non-electric gas demand in area j, year t, month m, and block s (MMcf/h) | |

| maximum gas production rate in area j, year t, month m and block s (MMcf/h) | |

| maximum capacity for pipeline , year t, month m and block s (MMcf/h) | |

| minimum capacity for pipeline , year t, month m and block s (MMcf/h) | |

| block duration (h) | |

| pipelines large constant | |

| transmission lines large constant | |

| power demand in area j, year t, month m and block s (MW) | |

| power peak demand in area j and year t (MW) | |

| maximum capacity for transmission line in year t, month m and block s (MW) | |

| minimum capacity for transmission line in year t, month m and block s (MW) | |

| generation reserves in area j | |

| per unit power base (MVA) | |

| technical coefficient for compressor/reductor | |

| reactance for transmission line (p.u.) | |

| technical coefficient for pipeline (psig/(MMcf/h)) |

| Continuous Decision Variables | |

| squared gas flow across pipeline in year t, month m and block s ((MMcf/h)) | |

| linear combination coefficients for gas flow across pipeline in year t, month m, block s and | |

| partition point () | |

| linear combination coefficients for squared pressure in node j, year t, month m, block s and | |

| partition point i | |

| squared pressure in node j, year t, month m and block s (psig) | |

| squared pressure in node , year t, month m and block s (psig) | |

| voltage angle in area j, year t, month m and block s (rad) | |

| net present cost (USD) | |

| number of units for generator in year t (units) | |

| gas flow across compressor/reductor in year t, month m and block s (MMcf/h) | |

| gas flow across compressor/reductor (opposite direction) in year t, month m, and block s (MMcf/h) | |

| gas production rate for area j, technology type k, year t, month m and block s (MMcf/h) | |

| total gas production rate for area j, year t, month m and block s (MMcf/h) | |

| gas flow across pipeline in year t, month m and block s (MMcf/h) | |

| gas flow across pipeline (opposite direction) in year t, month m and block s (MMcf/h) | |

| power level for generator , in year t, month m and block s (MW) | |

| load shedding in area j, year t, month m and block s (MW) | |

| power across transmission line in year t, month m and block s (MW) | |

| power across transmission line (opposite direction) in year t, month m, and block s (MW) |

| Integer Decision Variables | |

| investments for generator in year t (units) | |

| retirements for generator in year t (units) |

| Binary Decision Variables | |

| set to 1 if transmission line has been installed until period t, 0 otherwise, for l | |

| set to 1 if pipeline has been installed until period t, 0 otherwise, for p | |

| set to 1 if transmission line is installed in period t, 0 otherwise, for l | |

| set to 1 if pipeline is installed in period t, 0 otherwise, for p |

| Special Ordered Sets of Type 2 (SOS2) Decision Variables | |

| linear combination coefficients for squared pressure in area j, year t, month m, block s and partition i | |

| linear combination coefficients for gas flow across pipe in year t, month m, block s and partition i |

References

- Li, T.; Eremia, M.; Shahidehpour, M. Interdependency of Natural Gas Network and Power System Security. IEEE Trans. Power Syst. 2008, 23, 1817–1824. [Google Scholar] [CrossRef]

- North American Electric Reliability Corporation. 2011 Special Reliability Assessment: A Primer of the Natural Gas and Electric Power Interdependency in the United States; Technical Report; NERC: Atlanta, GA, USA, 2011. [Google Scholar]

- North American Electric Reliability Corporation. 2013 Special Reliability Assessment: Accommodating an Increased Dependence on Natural Gas for Electric Power. Phase II: A Vulnerability and Scenario Assessment for the North American Bulk Power System; Technical Report; NERC: Atlanta, GA, USA, 2013. [Google Scholar]

- Unsihuay, C.; Marangon-Lima, J.W.; de Souza, A. Integrated Power Generation and Natural Gas Expansion Planning. In Proceedings of the IEEE Lausanne Power Tech, Lausanne, Switzerland, 1–5 July 2007; pp. 1404–1409. [Google Scholar] [CrossRef]

- Erdener, B.C.; Pambour, K.A.; Lavin, R.B.; Dengiz, B. An integrated simulation model for analysing electricity and gas systems. Int. J. Electr. Power Energy Syst. 2014, 61, 410–420. [Google Scholar] [CrossRef]

- Clegg, S.; Mancarella, P. Integrated Electrical and Gas Network Flexibility Assessment in Low-Carbon Multi-Energy Systems. IEEE Trans. Sustain. Energy 2016, 7, 718–731. [Google Scholar] [CrossRef]

- Clegg, S.; Mancarella, P. Integrated Modeling and Assessment of the Operational Impact of Power-to-Gas (P2G) on Electrical and Gas Transmission Networks. IEEE Trans. Sustain. Energy 2015, 6, 1234–1244. [Google Scholar] [CrossRef]

- Qiao, Z.; Guo, Q.; Sun, H.; Pan, Z.; Liu, Y.; Xiong, W. An interval gas flow analysis in natural gas and electricity coupled networks considering the uncertainty of wind power. Appl. Energy 2017, 201, 343–353. [Google Scholar] [CrossRef]

- Correa-Posada, C.M.; Sánchez-Martín, P. Integrated Power and Natural Gas Model for Energy Adequacy in Short-Term Operation. IEEE Trans. Power Syst. 2015, 30, 3347–3355. [Google Scholar] [CrossRef]

- Zlotnik, A.; Roald, L.; Backhaus, S.; Chertkov, M.; Andersson, G. Coordinated Scheduling for Interdependent Electric Power and Natural Gas Infrastructures. IEEE Trans. Power Syst. 2017, 32, 600–610. [Google Scholar] [CrossRef]

- Zheng, J.; Wu, Q.; Jing, Z. Coordinated scheduling strategy to optimize conflicting benefits for daily operation of integrated electricity and gas networks. Appl. Energy 2017, 192, 370–381. [Google Scholar] [CrossRef]

- Quelhas, A.; Gil, E.; McCalley, J.; Ryan, S. A Multiperiod Generalized Network Flow Model of the U.S. Integrated Energy System: Part I—Model Description. IEEE Trans. Power Syst. 2007, 22, 829–836. [Google Scholar] [CrossRef]

- Quelhas, A.; McCalley, J. A Multiperiod Generalized Network Flow Model of the U.S. Integrated Energy System: Part II—Simulation Results. IEEE Trans. Power Syst. 2007, 22, 837–844. [Google Scholar] [CrossRef]

- Unsihuay-Vila, C.; Marangon-Lima, J.W.; de Souza, A.; Perez-Arriaga, I.; Balestrassi, P. A Model to Long-Term, Multiarea, Multistage, and Integrated Expansion Planning of Electricity and Natural Gas Systems. IEEE Trans. Power Syst. 2010, 25, 1154–1168. [Google Scholar] [CrossRef]

- Bahiense, L.; Oliveira, G.C.; Pereira, M.; Granville, S. A Mixed Integer Disjunctive Model for Transmission Network Expansion. IEEE Trans. Power Syst. 2001, 16, 560–565. [Google Scholar] [CrossRef]

- Barati, F.; Nateghi, A.; Seifi, H.; Sepasian, M. Generation and transmission expansion planning with considering natural gas network. In Proceedings of the 21st Iranian Conference on Electrical Engineering (ICEE), Mashhad, Iran, 14–16 May 2013; pp. 1–7. [Google Scholar] [CrossRef]

- Behrouzpanah, M.; Sepasian, M.; Bayat, S. Subtransmission system expansion planning with dgs considering natural gas transmission constraints. In Proceedings of the 4th Conference on Thermal Power Plants, Tehran, Iran, 18–19 December 2012; pp. 1–6. [Google Scholar]

- Chaudry, M.; Jenkins, N.; Qadrdan, M.; Wu, J. Combined gas and electricity network expansion planning. Appl. Energy 2014, 113, 1171–1187. [Google Scholar] [CrossRef]

- Hu, Y.; Bie, Z.; Ding, T.; Lin, Y. An NSGA-II based multi-objective optimization for combined gas and electricity network expansion planning. Appl. Energy 2016, 167, 280–293. [Google Scholar] [CrossRef]

- Khaligh, V.; Oloomi Buygi, M.; Anvari-Moghaddam, A.M.; Guerrero, J. A Multi-Attribute Expansion Planning Model for Integrated Gas-Electricity System. Energies 2018, 11, 2573. [Google Scholar] [CrossRef]

- Liu, A.; Hobbs, B.; Ho, J.; McCalley, J.; Krishnan, V.; Shahidehpour, M.; Zheng, Q. Co-Optimization of Transmission and Other Supply Resources; White Paper; NARUC: Washington, DC, USA, 2013. [Google Scholar]

- Romero, R.; Monticelli, A.; Garcia, A.; Haffner, S. Test systems and mathematical models for transmission network expansion planning. IEE Proc. Gener. Transm. Distrib. 2002, 149, 27–36. [Google Scholar] [CrossRef]

- Binato, S. Optimal Expansion of Transmission Networks by Benders Decomposition and Cutting Planes. Ph.D. Thesis, University of Rio de Janeiro, Rio de Janeiro, Brazil, 2000. [Google Scholar]

- Li, Y. Transmission Design and Optimization at the National Level. Ph.D. Thesis, Iowa State University, Ames, IA, USA, 2014. [Google Scholar]

- Martin, A.; Möller, M.; Moritz, S. Mixed Integer Models for the Stationary Case of Gas Network Optimization. Math. Programm. 2006, 105, 563–582. [Google Scholar] [CrossRef]

- Urbina, M.; Li, Z. A Combined Model for Analyzing the Interdependency of Electrical and Gas Systems. In Proceedings of the 39th North American Power Symposium, as Cruces, NM, USA, 30 September–2 October 2007; pp. 468–472. [Google Scholar] [CrossRef]

- The Eastern Interconnection Planning Collaborative Website. Phase II Documents. DOE Award Project DE-OE0000343, 2015. Available online: https://www.eipconline.com/phase-ii-documents (accessed on 20 March 2019).

- Lemos-Cano, S. Co-Optimized Analysis of Electric and Natural Gas Infrastructures. Ph.D. Thesis, Iowa State University, Ames, IA, USA, 2017. [Google Scholar]

| Region | Generation Technologies | |||||

|---|---|---|---|---|---|---|

| Coal | Gas | Hydro | Nuclear | Others | Wind | |

| ENT | 0.7 | 24.6 | 1.9 | 5.3 | 0.3 | 0.1 |

| FRCC | 0.5 | 28.3 | 0.1 | 24.4 | 0.9 | 0.0 |

| HQ | 0.0 | 0.0 | 4.8 | 0.0 | 0.0 | 0.0 |

| IESO | 0.0 | 3.6 | 9.1 | 11.5 | 1.5 | 5.0 |

| MAPP_CA | 0.0 | 2.7 | 7.2 | 0.0 | 0.0 | 0.6 |

| MAPP_US | 0.0 | 2.1 | 2.2 | 0.5 | 0.2 | 9.9 |

| MISO_IN | 0.6 | 6.4 | 0.1 | 0.0 | 0.1 | 11.5 |

| MISO_MI | 0.0 | 24.9 | 2.0 | 1.9 | 0.5 | 16.0 |

| MISO_MO-IL | 1.8 | 6.9 | 1.1 | 2.2 | 0.5 | 28.3 |

| MISO_W | 0.0 | 16.6 | 0.5 | 2.3 | 0.5 | 136.2 |

| MISO_WUMS | 0.5 | 9.8 | 0.3 | 1.6 | 0.2 | 3.3 |

| NB | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| NE | 0.2 | 7.1 | 0.2 | 1.3 | 0.1 | 17.9 |

| NEISO | 0.0 | 10.5 | 6.3 | 4.6 | 1.6 | 4.9 |

| NonRTO_Midwest | 0.0 | 11.5 | 0.9 | 0.0 | 0.1 | 0.1 |

| NYISO_A-F | 0.0 | 1.8 | 5.8 | 3.2 | 0.6 | 6.7 |

| NYISO_G-I | 0.0 | 2.7 | 0.0 | 2.0 | 0.3 | 0.2 |

| NYISO_J-K | 0.0 | 14.7 | 0.0 | 0.0 | 0.6 | 0.0 |

| PJM_E | 0.0 | 19.7 | 0.7 | 8.5 | 0.7 | 8.6 |

| PJM_ROM | 0.5 | 7.9 | 3.6 | 5.0 | 0.7 | 18.1 |

| PJM_ROR | 2.2 | 72.1 | 5.4 | 20.0 | 1.5 | 19.1 |

| SOCO | 0.5 | 35.0 | 6.7 | 14.5 | 0.5 | 0.0 |

| SPP_N | 0.5 | 11.3 | 0.0 | 1.2 | 0.1 | 41.6 |

| SPP_S | 1.0 | 20.2 | 2.6 | 0.0 | 0.1 | 43.5 |

| TVA | 1.0 | 19.6 | 6.9 | 7.9 | 0.3 | 0.0 |

| VACAR | 1.3 | 23.9 | 4.8 | 13.8 | 0.4 | 30.0 |

| Link | Lines (GW) | Pipes (MMcf/h) | ||

|---|---|---|---|---|

| Initial | Invest. | Initial | Invest. | |

| ENT to MISO_MO-IL | 2.5 | 0.0 | 265.6 | 63.0 |

| ENT to SOCO | 2.4 | 0.0 | 312.5 | 0.0 |

| ENT to SPP_N | 7.3 | 0.0 | NA | NA |

| ENT to SPP_S | 4.3 | 2.0 | 208.3 | 0.0 |

| ENT to TVA | 3.0 | 0.0 | 265.6 | 0.0 |

| FRCC to SOCO | 3.7 | 0.0 | 215.0 | 0.0 |

| HQ to NEISO | NA | NA | 8.3 | 0.0 |

| IESO to MAPP_CA | 0.3 | 0.0 | 187.5 | 0.0 |

| IESO to MISO_MI | 3.1 | 4.0 | 125.0 | 63.0 |

| IESO to MISO_W | 0.2 | 0.0 | NA | NA |

| IESO to NEISO | NA | NA | 31.3 | 21.0 |

| IESO to NYISO_A-F | 2.2 | 0.0 | NA | NA |

| MAPP_CA to MAPP_US | 0.4 | 0.0 | 156.3 | 0.0 |

| Link | Lines (GW) | Pipes (MMcf/h) | ||

|---|---|---|---|---|

| Initial | Invest. | Initial | Invest. | |

| MAPP_CA to MISO_W | 2.0 | 0.0 | 93.8 | 0.0 |

| MAPP_US to MISO_W | 2.6 | 0.0 | 156.3 | 0.0 |

| MAPP_US to NE | 2.0 | 0.0 | NA | NA |

| MISO_IN to MISO_MI | 5.5 | 0.0 | 41.7 | 0.0 |

| MISO_IN to MISO_MO-IL | 5.0 | 24.0 | 156.3 | 0.0 |

| MISO_IN to NonRTO_Midwest | 4.8 | 0.0 | NA | NA |

| MISO_IN to PJM_ROR | 1.0 | 12.0 | 187.5 | 0.0 |

| MISO_MI to MISO_MO-IL | NA | NA | 104.2 | 0.0 |

| MISO_MI to MISO_WUMS | 0.3 | 0.0 | NA | NA |

| MISO_MI to PJM_ROR | 1.4 | 2.0 | 41.7 | 0.0 |

| MISO_MO-IL to MISO_W | 4.0 | 34.0 | NA | NA |

| MISO_MO-IL to MISO_WUMS | NA | NA | 62.5 | 0.0 |

| MISO_MO-IL to NE | NA | NA | 62.5 | 0.0 |

| MISO_MO-IL to PJM_ROR | 1.2 | 0.0 | NA | NA |

| MISO_MO-IL to SPP_N | 4.0 | 2.0 | 114.6 | 0.0 |

| MISO_MO-IL to TVA | 4.0 | 10.0 | NA | NA |

| MISO_W to MISO_WUMS | 1.7 | 6.0 | 93.8 | 0.0 |

| MISO_W to NE | 3.6 | 0.0 | 133.3 | 0.0 |

| MISO_W to PJM_ROR | 19.8 | 0.0 | NA | NA |

| MISO_W to SPP_N | 3.2 | 0.0 | NA | NA |

| MISO_WUMS to PJM_ROR | 1.6 | 0.0 | NA | NA |

| NE to SPP_N | 1.9 | 2.0 | NA | NA |

| NEISO to NYISO_A-F | 0.6 | 0.0 | 93.8 | 0.0 |

| NEISO to NYISO_G-I | 0.6 | 0.0 | NA | NA |

| NEISO to NYISO_J-K | 1.0 | 0.0 | NA | NA |

| NonRTO_Midwest to PJM_ROR | NA | NA | 156.3 | 42.0 |

| NonRTO_Midwest to TVA | 2.4 | 0.0 | 166.7 | 0.0 |

| NYISO_A-F to NYISO_G-I | 5.3 | 2.0 | 20.8 | 0.0 |

| NYISO_A-F to NYISO_J-K | NA | NA | 20.8 | 42.0 |

| NYISO_A-F to PJM_ROM | 2.0 | 0.0 | 187.5 | 0.0 |

| NYISO_G-I to NYISO_J-K | 6.1 | 2.0 | NA | NA |

| NYISO_G-I to PJM_E | 1.5 | 0.0 | NA | NA |

| NYISO_J-K to PJM_E | 0.3 | 0.0 | NA | NA |

| PJM_E to PJM_ROM | 8.0 | 0.0 | 125.0 | 0.0 |

| PJM_ROM to PJM_ROR | 8.0 | 0.0 | 250.0 | 0.0 |

| PJM_ROR to TVA | 2.5 | 0.0 | NA | NA |

| PJM_ROR to VACAR | 3.0 | 0.0 | 125.0 | 189.0 |

| SOCO to TVA | 3.2 | 10.0 | NA | NA |

| SOCO to VACAR | 3.0 | 0.0 | 156.0 | 126.0 |

| SPP_N to SPP_S | 4.0 | 2.0 | NA | NA |

| TVA to VACAR | 0.9 | 0.0 | NA | NA |

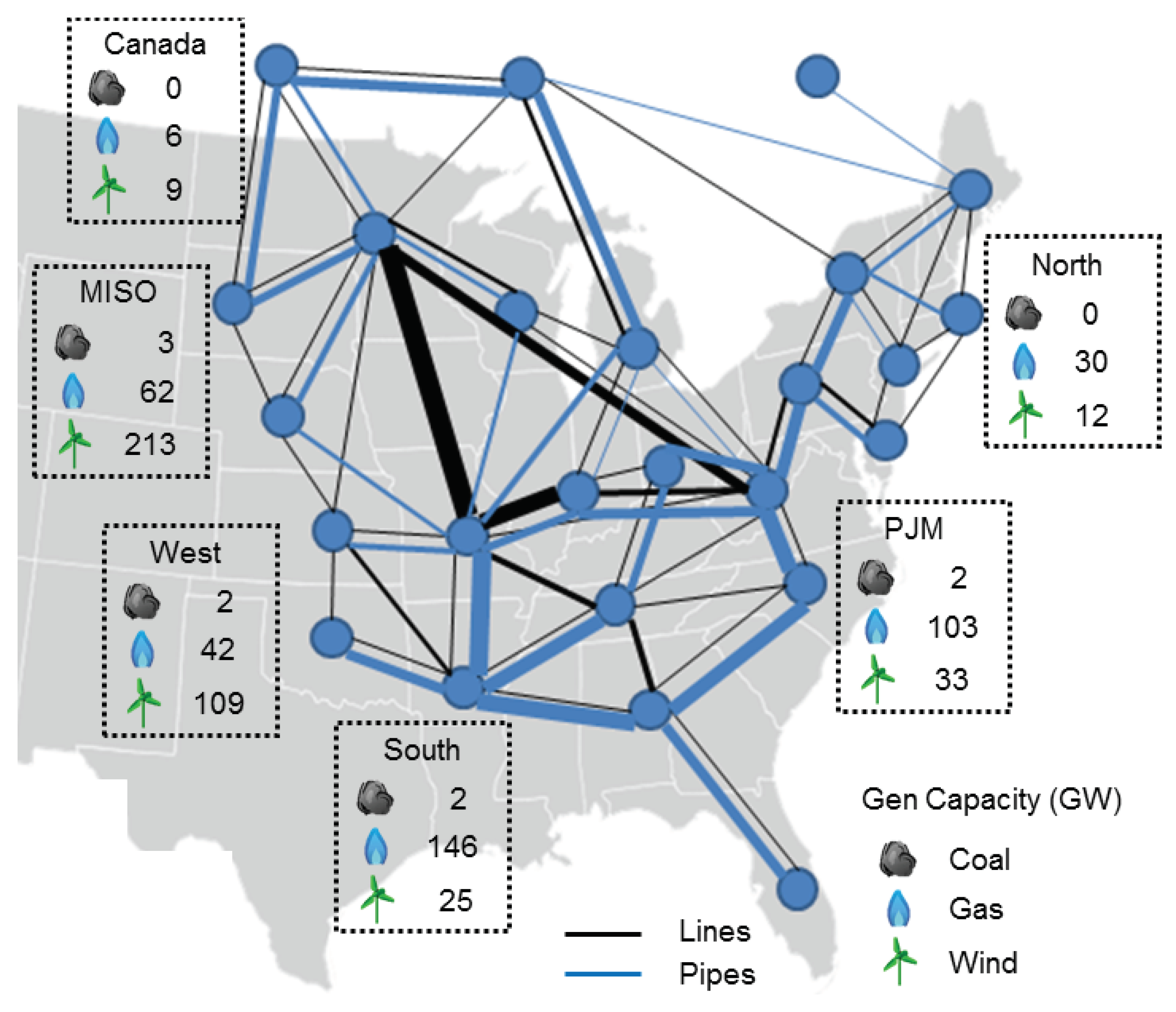

| Super Regions | Areas |

|---|---|

| Canada | HQ, IESO, MAPP_CA |

| MISO | MISO (IN, MI, MO-IL, W, WUMS) |

| North | NEISO, NYISO (A-F, G-I, J-K) |

| PJM | PJM (E, ROM, ROR) |

| West | MAPP_US, NE, SPP (N, S) |

| South | ENT, FRCC, NonRTO Midwest, SOCO, TVA, VACAR |

| Costs | Model 1 | Model 2 | Model 3 | |

|---|---|---|---|---|

| O&M | Generation | |||

| Lines | ||||

| Pipes | – | |||

| Investment | Generation | |||

| Lines | ||||

| Pipes | – | |||

| Other | Emissions | |||

| End Horizon | ||||

| Total Cost | ||||

| Capacity | Unit | Model 1 | Model 2 | Model 3 |

|---|---|---|---|---|

| Lines | GW | 272 | 272 | 266 |

| Pipes | MMcf/h | – | 4456 | 4871 |

| Generation | GW | 1055 | 1049 | 1014 |

| Coal | GW | 9 | 9 | 11 |

| Gas | GW | 397 | 395 | 384 |

| Hydro | GW | 75 | 75 | 73 |

| Nuclear | GW | 122 | 124 | 132 |

| Offshore Wind | GW | – | – | 55 |

| Onshore Wind | GW | 442 | 436 | 347 |

| Others | GW | 11 | 11 | 12 |

| Parameter | Model 1 | Model 2 | Model 3 |

|---|---|---|---|

| Simulation time (hh:mm:ss) | 1:35:06 | 1:57:57 | 197:54:10 |

| Relative gap | 0.001757 | 0.001871 | 0.014033 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lemos-Cano, S.; McCalley, J. Co-Optimized Analysis and Design of Electric and Natural Gas Infrastructures. Energies 2019, 12, 2012. https://doi.org/10.3390/en12102012

Lemos-Cano S, McCalley J. Co-Optimized Analysis and Design of Electric and Natural Gas Infrastructures. Energies. 2019; 12(10):2012. https://doi.org/10.3390/en12102012

Chicago/Turabian StyleLemos-Cano, Santiago, and James McCalley. 2019. "Co-Optimized Analysis and Design of Electric and Natural Gas Infrastructures" Energies 12, no. 10: 2012. https://doi.org/10.3390/en12102012

APA StyleLemos-Cano, S., & McCalley, J. (2019). Co-Optimized Analysis and Design of Electric and Natural Gas Infrastructures. Energies, 12(10), 2012. https://doi.org/10.3390/en12102012