A New Physics-Based Modeling Approach for a 0D Turbulence Model to Reflect the Intake Port and Chamber Geometries and the Corresponding Flow Structures in High-Tumble Spark-Ignition Engines

Abstract

1. Introduction

2. Tumble Model Development

2.1. Generation of Tumble Motion

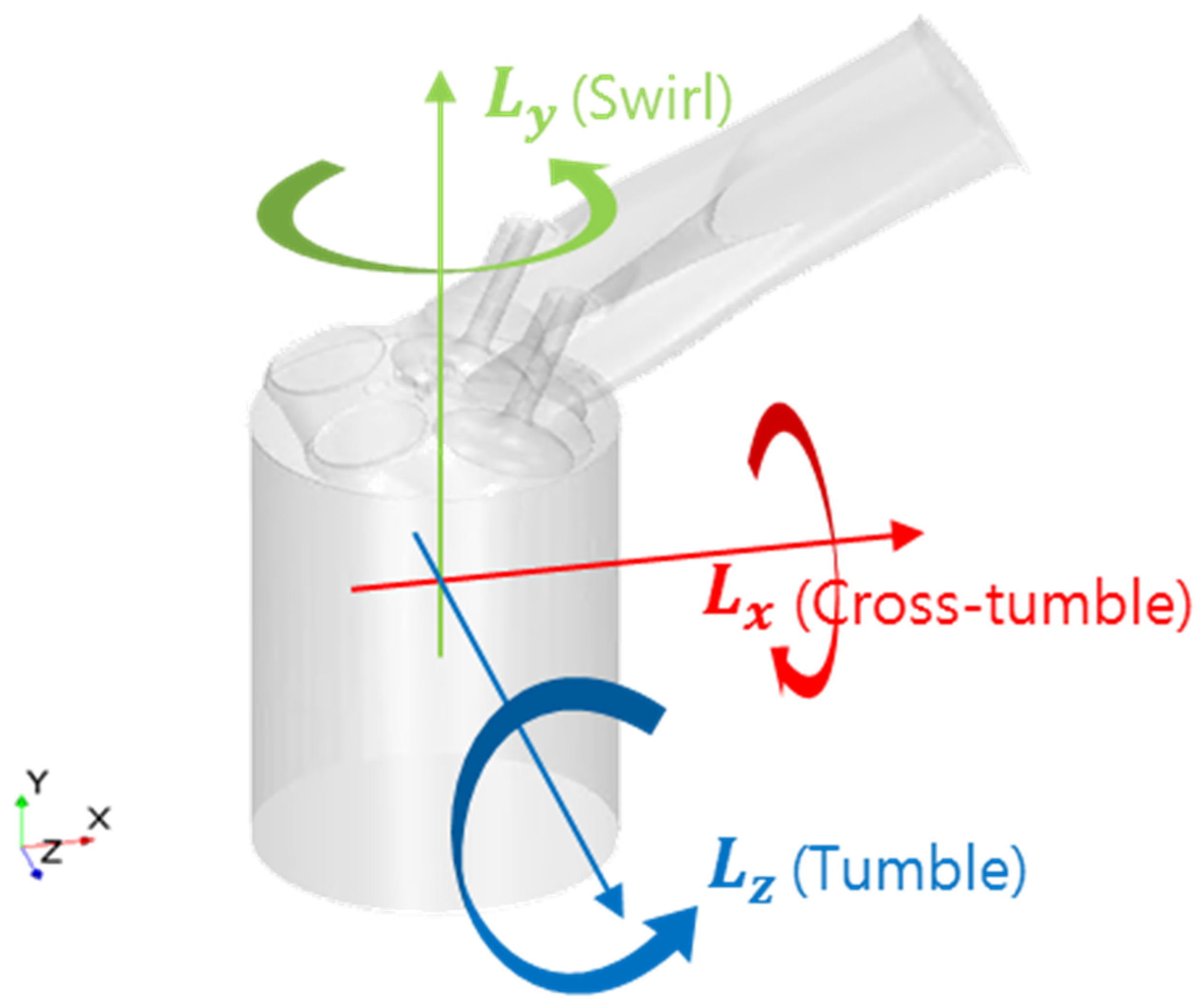

2.1.1. Mechanism of Tumble Generation

2.1.2. Modeling Concept

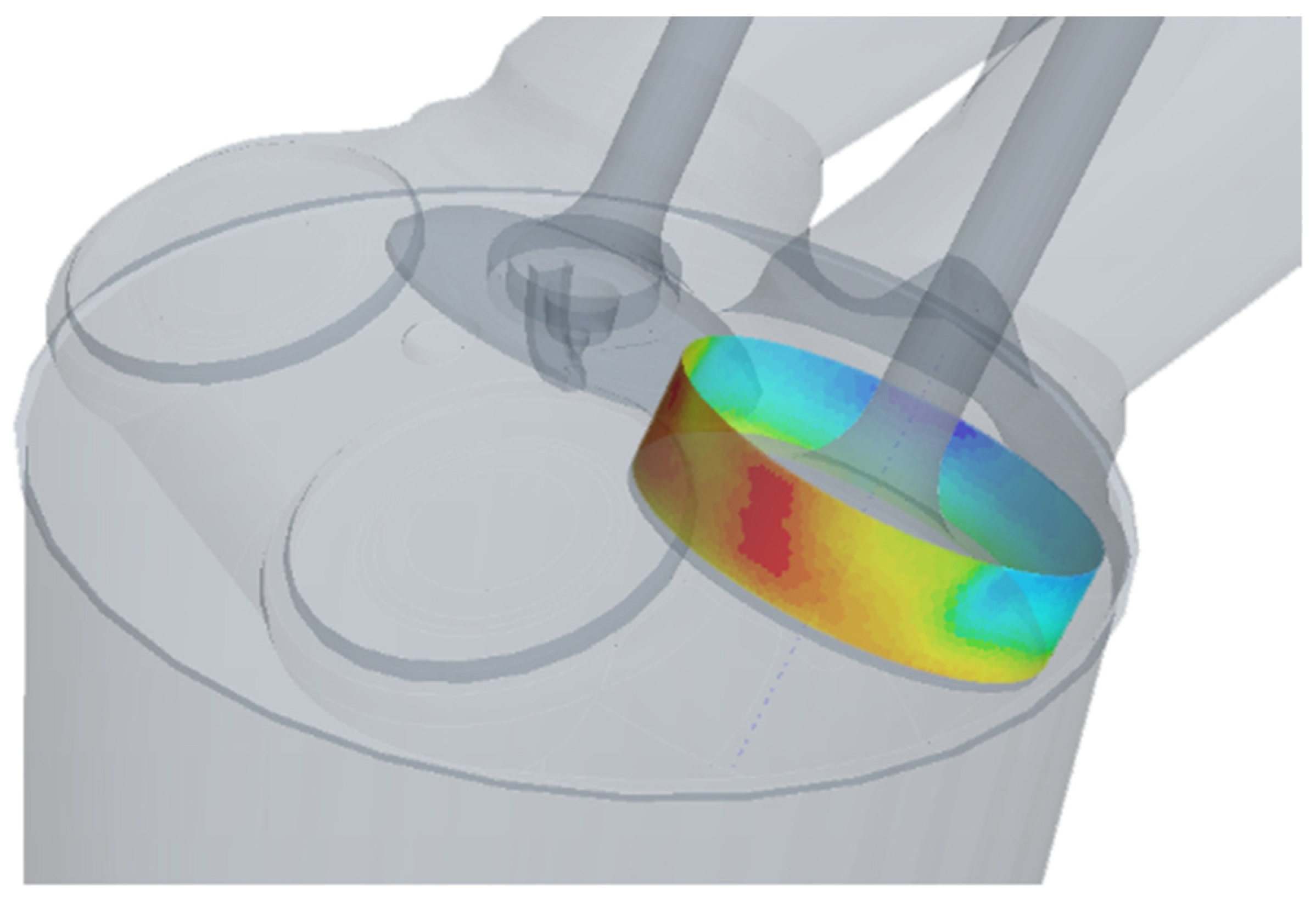

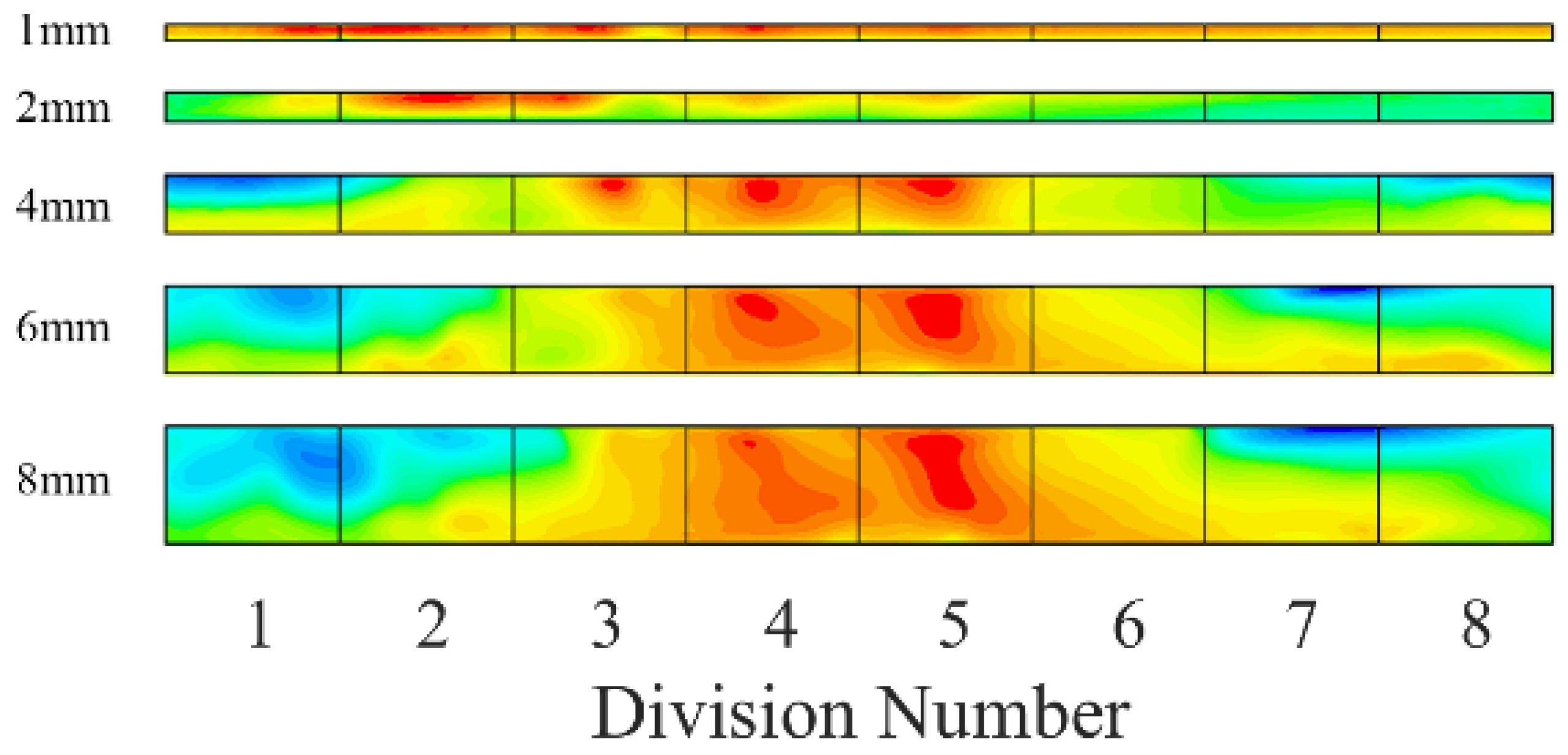

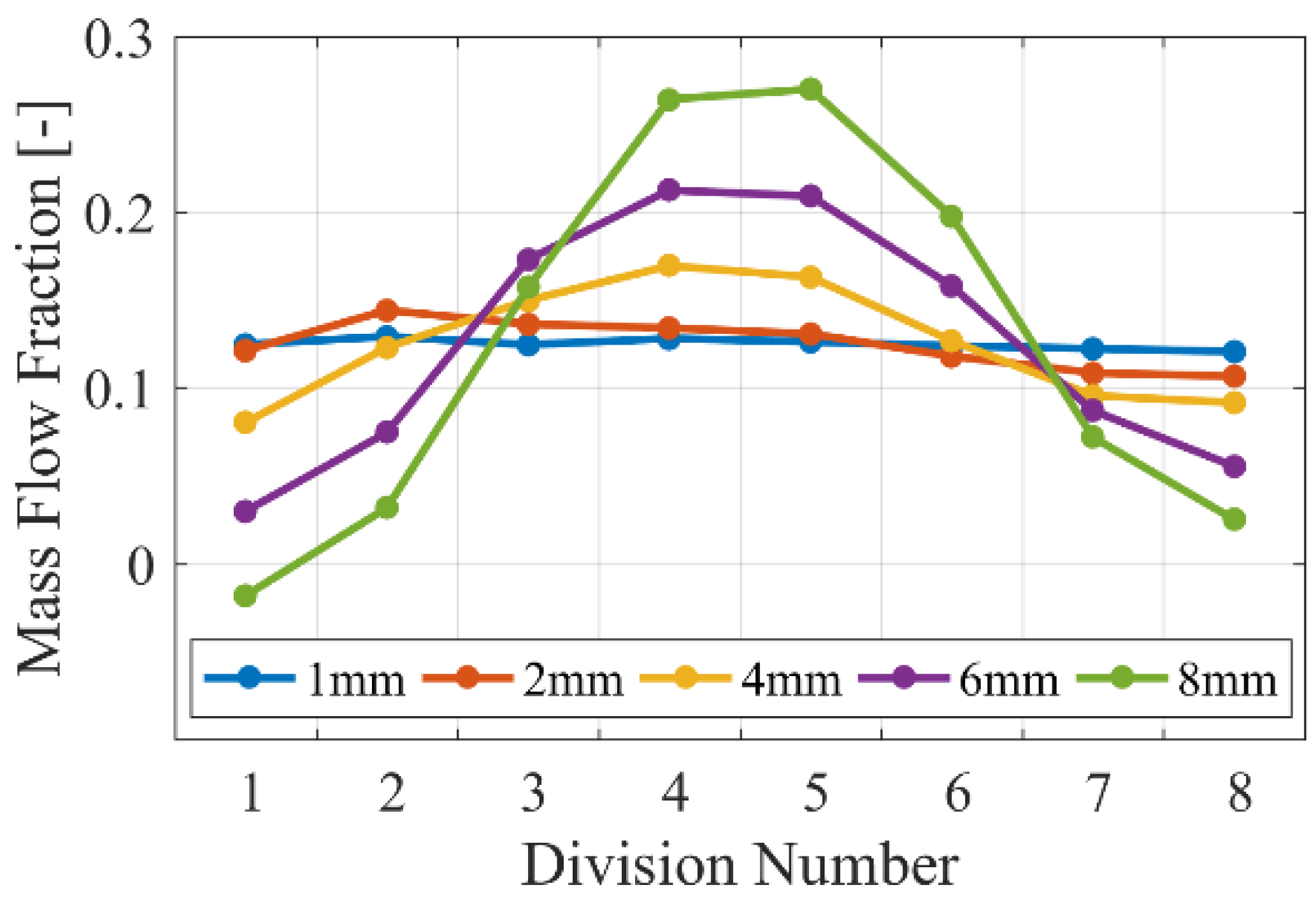

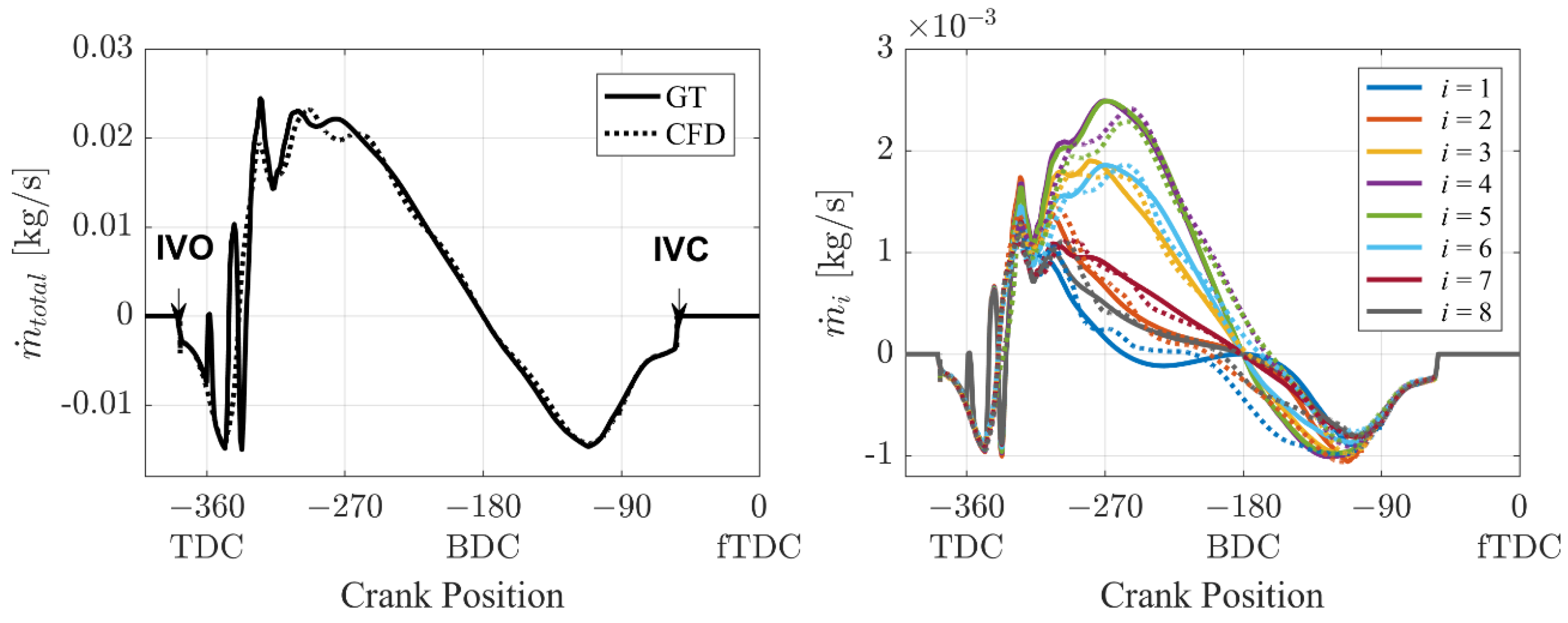

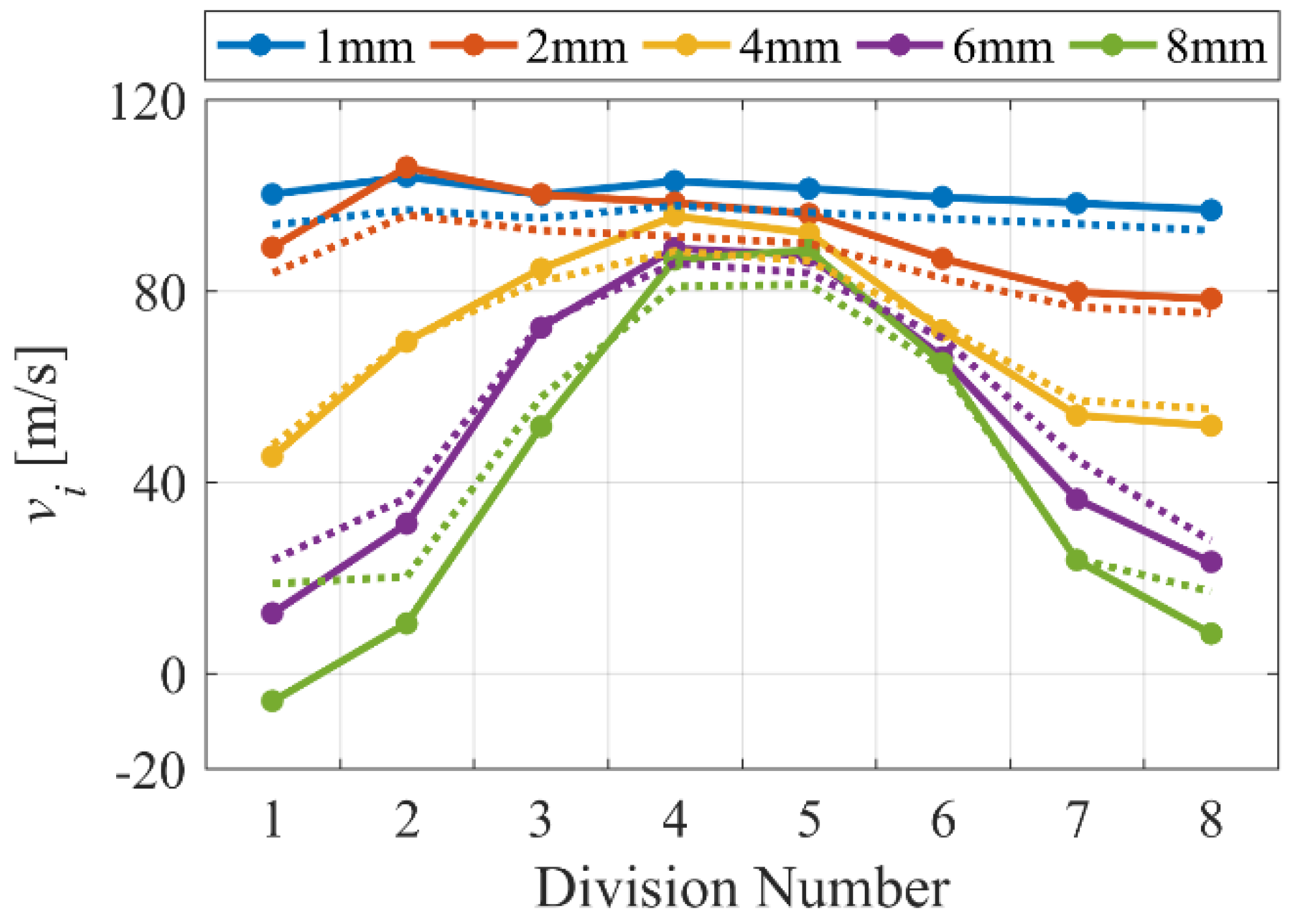

2.1.3. Head Characterization

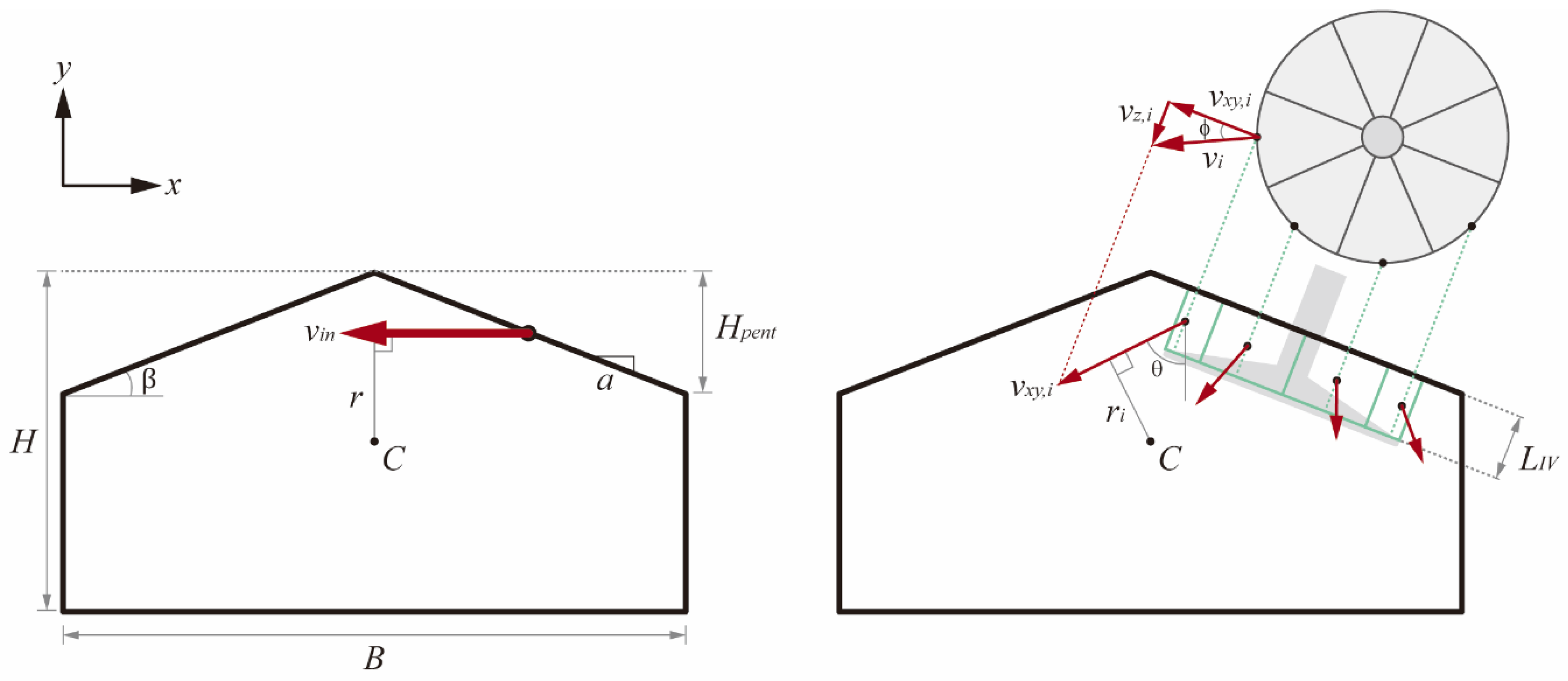

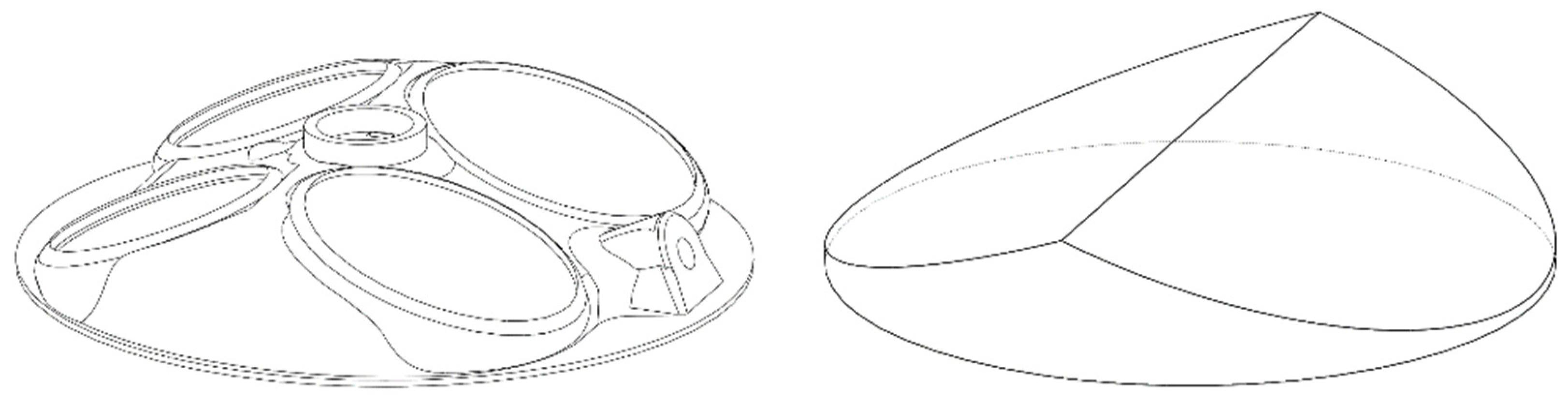

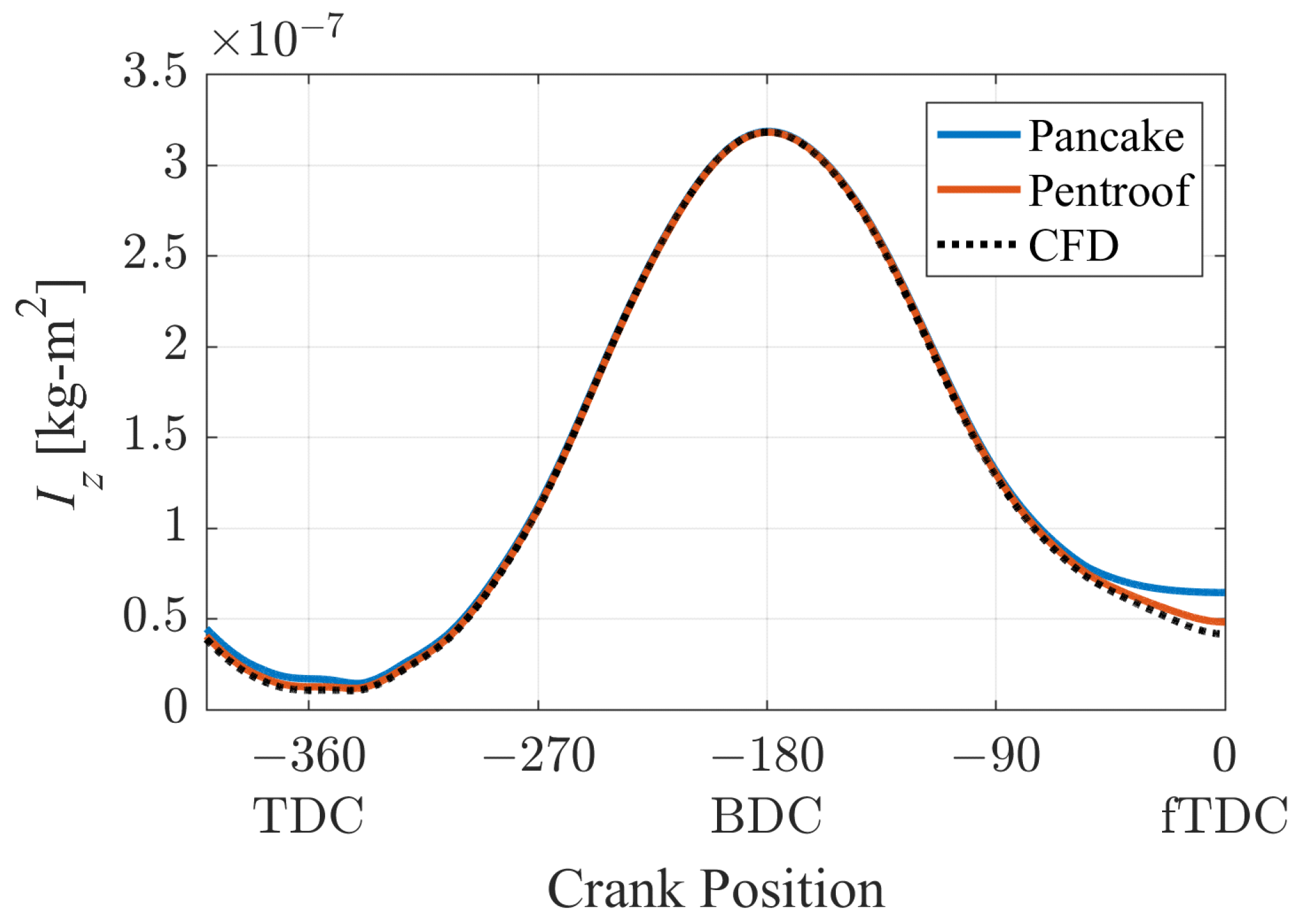

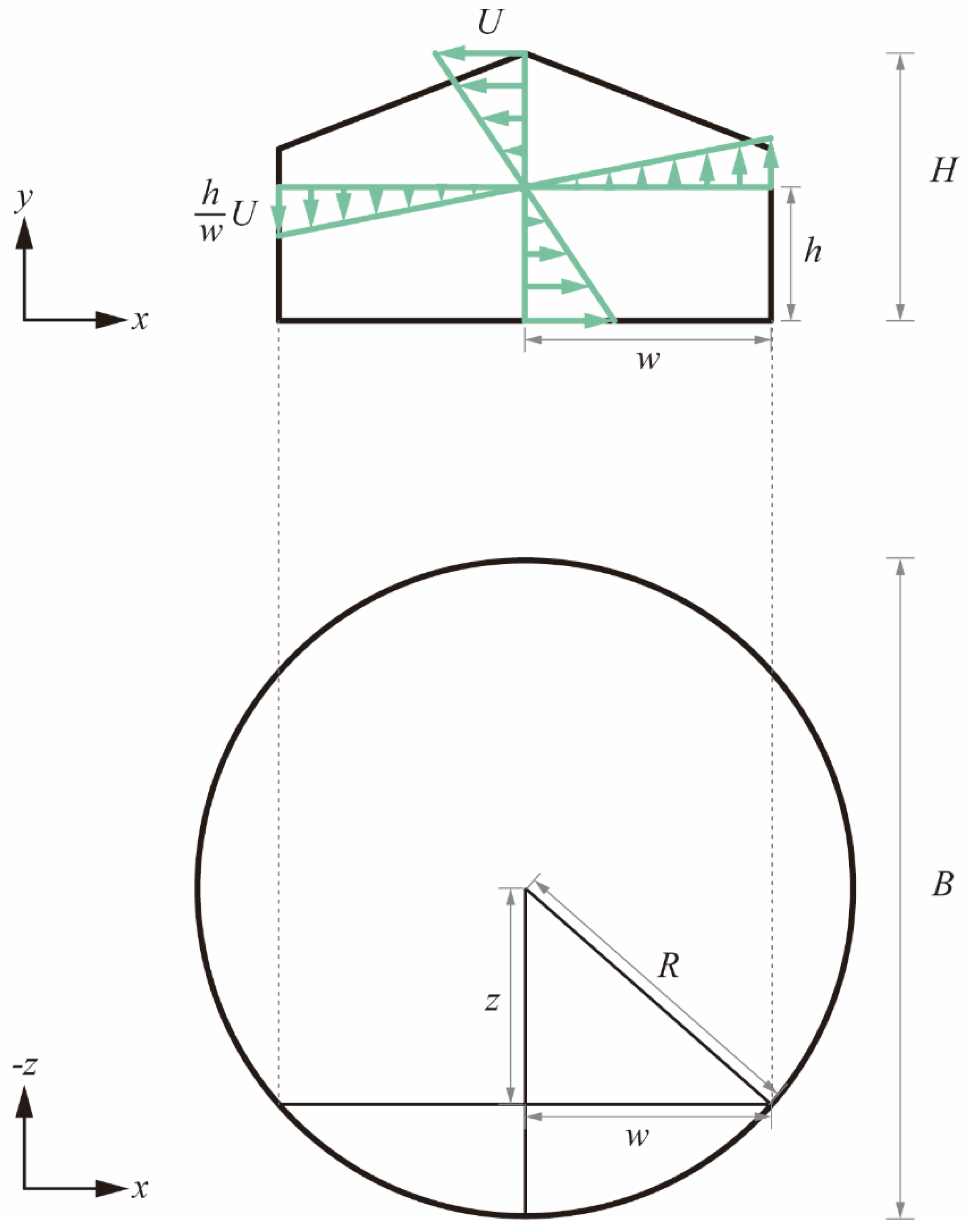

2.1.4. Application of Pentroof Geometry

2.2. Decay of Tumble Motion

2.2.1. Modeling Concept

2.2.2. Flow Field Definition

2.2.3. Governing Equations

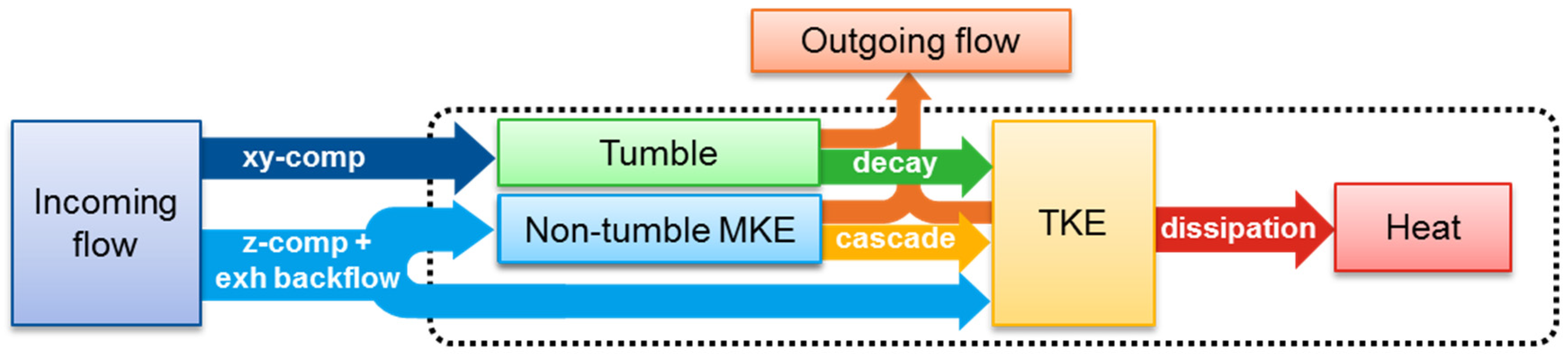

3. New Turbulence Model

3.1. Integration into Turbulence Model

3.2. Modeling Constants

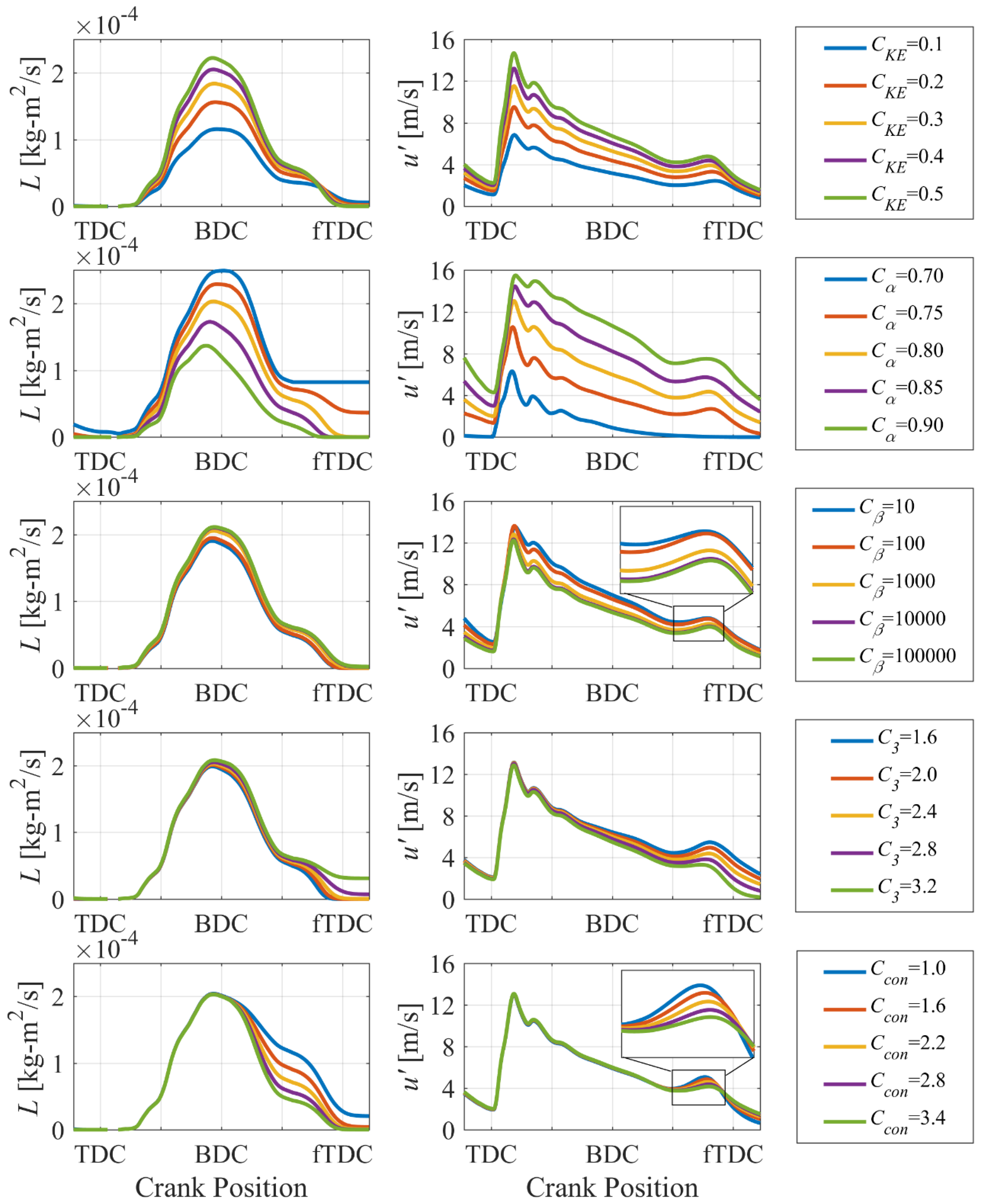

3.2.1. Definition

- is the coefficient to take into account the flow velocity decrease as it passes the valve opening. Since the cause is interpreted to be the change of flow area, it may be correlated to the ratio of the valve curtain area to the cylinder bore area, as in [23]. This coefficient must be less than 1 because the velocity cannot be increased after expansion.

- is the split factor of non-tumble intake kinetic energy between non-tumble MKE and the instantaneous TKE. The instantaneous TKE is interpreted as a consequence of significant shearing of inflow at valve opening [14,15], so it seems plausible to express it as a function of valve diameter and/or lift. As a split factor, it should lie between 0 and 1, as well.

- is the coefficient for the cascade rate of non-tumble MKE into TKE. It basically controls the residence time of the minor mean motion and the corresponding TKE production period. As it only comprises of minor mean motions, the cascade is presumed to be rather quick. Plus, since the extent of non-tumble MKE is dependent on , the influence of diminishes with the increase of . Therefore, can be considered as a subsidiary coefficient.

- is the coefficient of the dissipation rate corresponding to tumble-generated TKE, which is newly added in the epsilon equation in our proposed model. This is adopted for structural consistency with the other terms in the standard k-ε model, so it is expected to also be universal, once specified. The coefficient for the non-tumble MKE term is 2.88 (Equation (20)), and the reasonable range for is supposed to be a similar order of magnitude.

- is the multiplier of loss term caused by outgoing flow (e.g., back-flow into the intake port). This is applied particularly to the angular momentum because of the flow structure inside the cylinder. In case of a high tumble engine, it is unquestionable that flow in the outer side has greater velocity, and the role of is to compensate for the fact that outgoing mass has relatively higher velocity compared to the mass-averaged value. It would be possibly related to the boundary velocity and/or chamber dimension, which may affect the velocity gradient. A rough range of 1 to 5 seemed to be reasonable for this coefficient.

3.2.2. Influence on Tumble and Turbulence

3.2.3. Calibration of Modeling Constants

4. Model Validation

4.1. Experimental Data

4.2. Validation Method

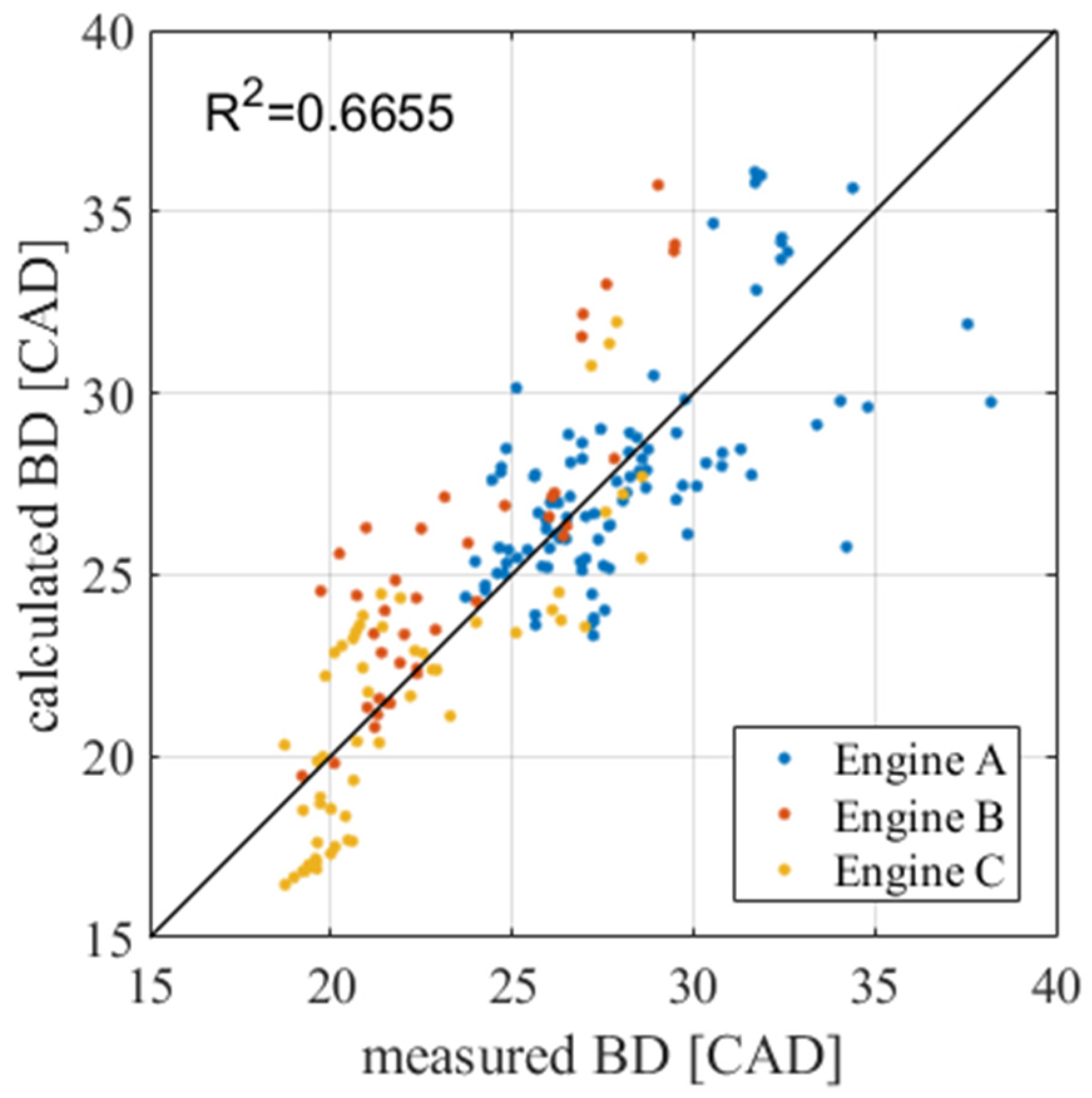

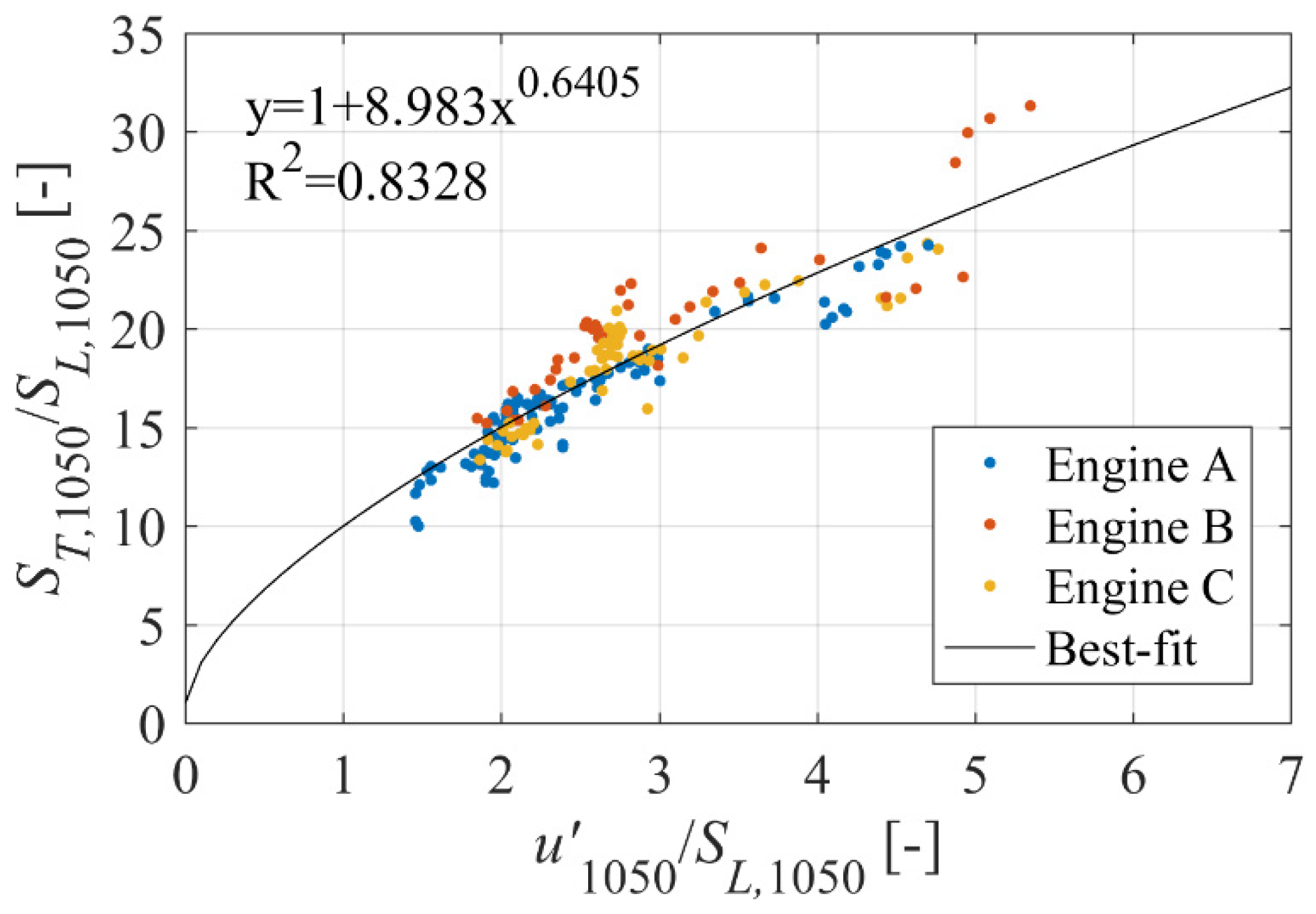

4.3. Correlation between Model Prediction and Experimental Data

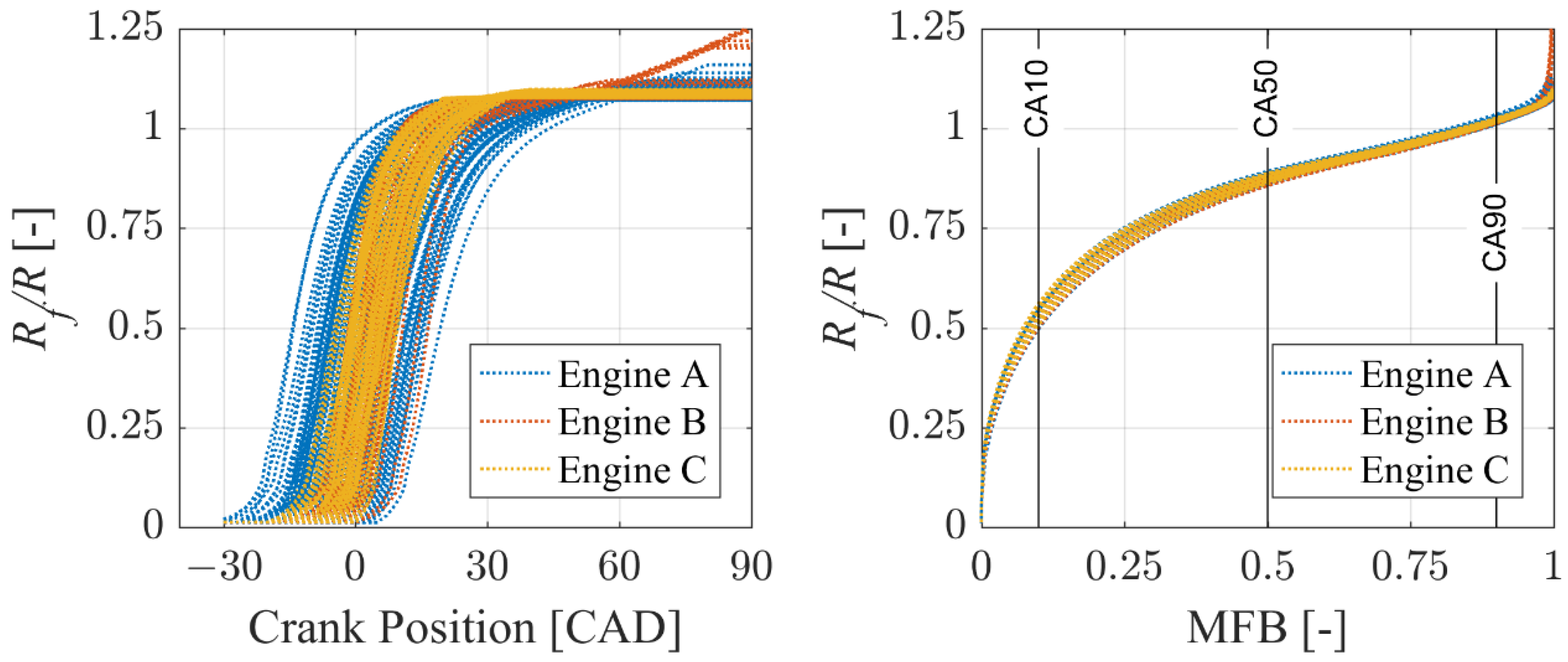

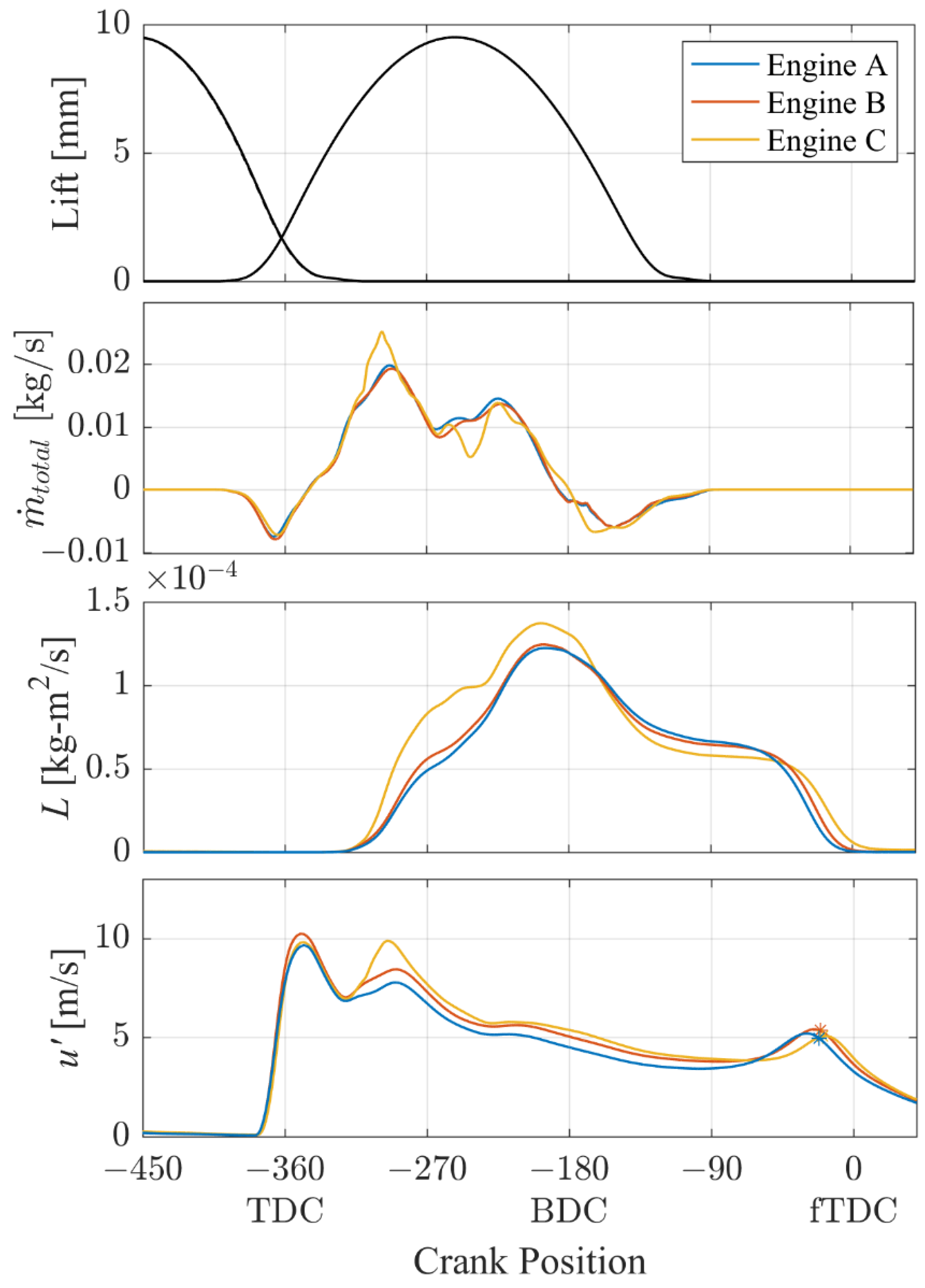

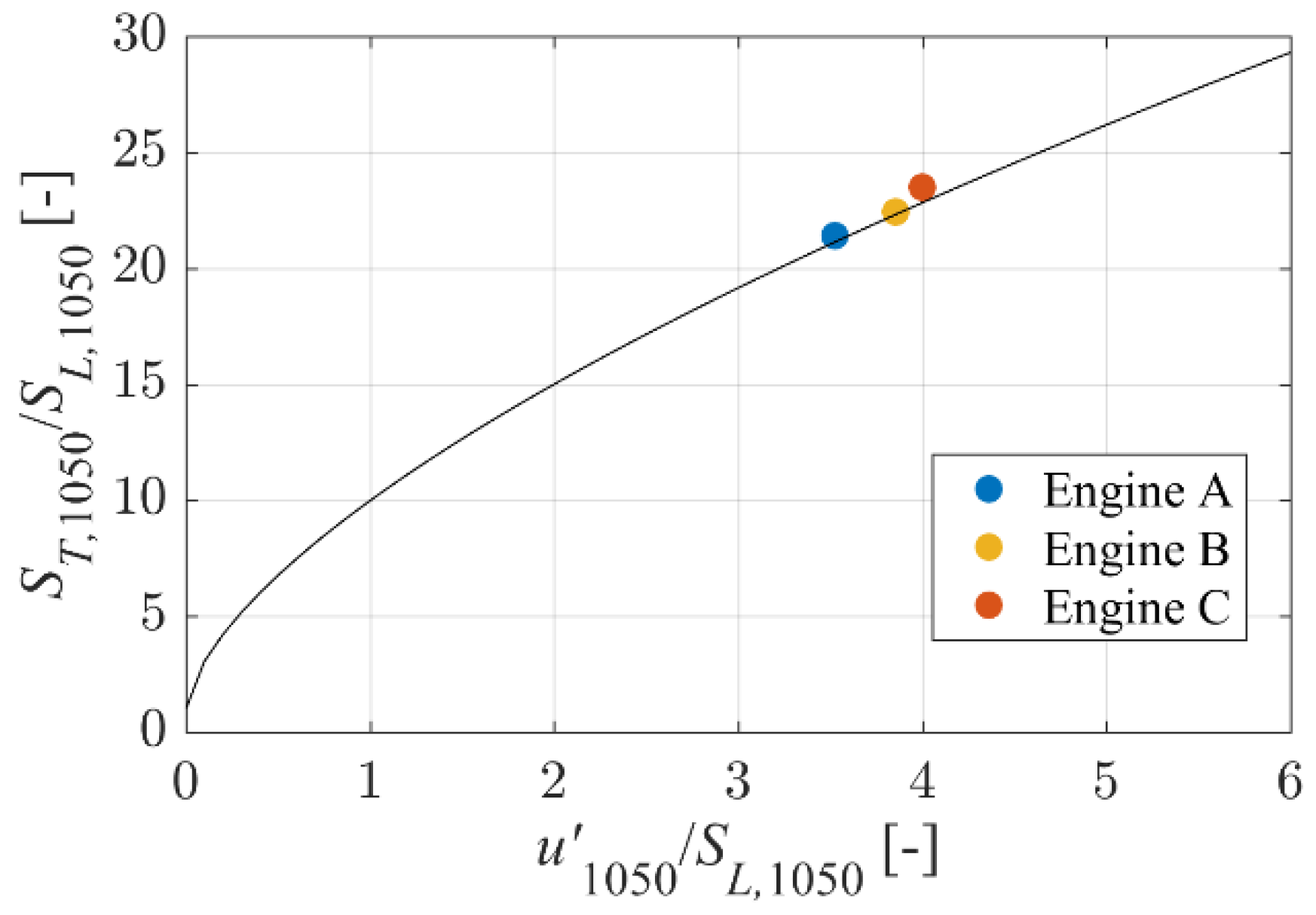

4.4. Detailed Analysis on Model Prediction

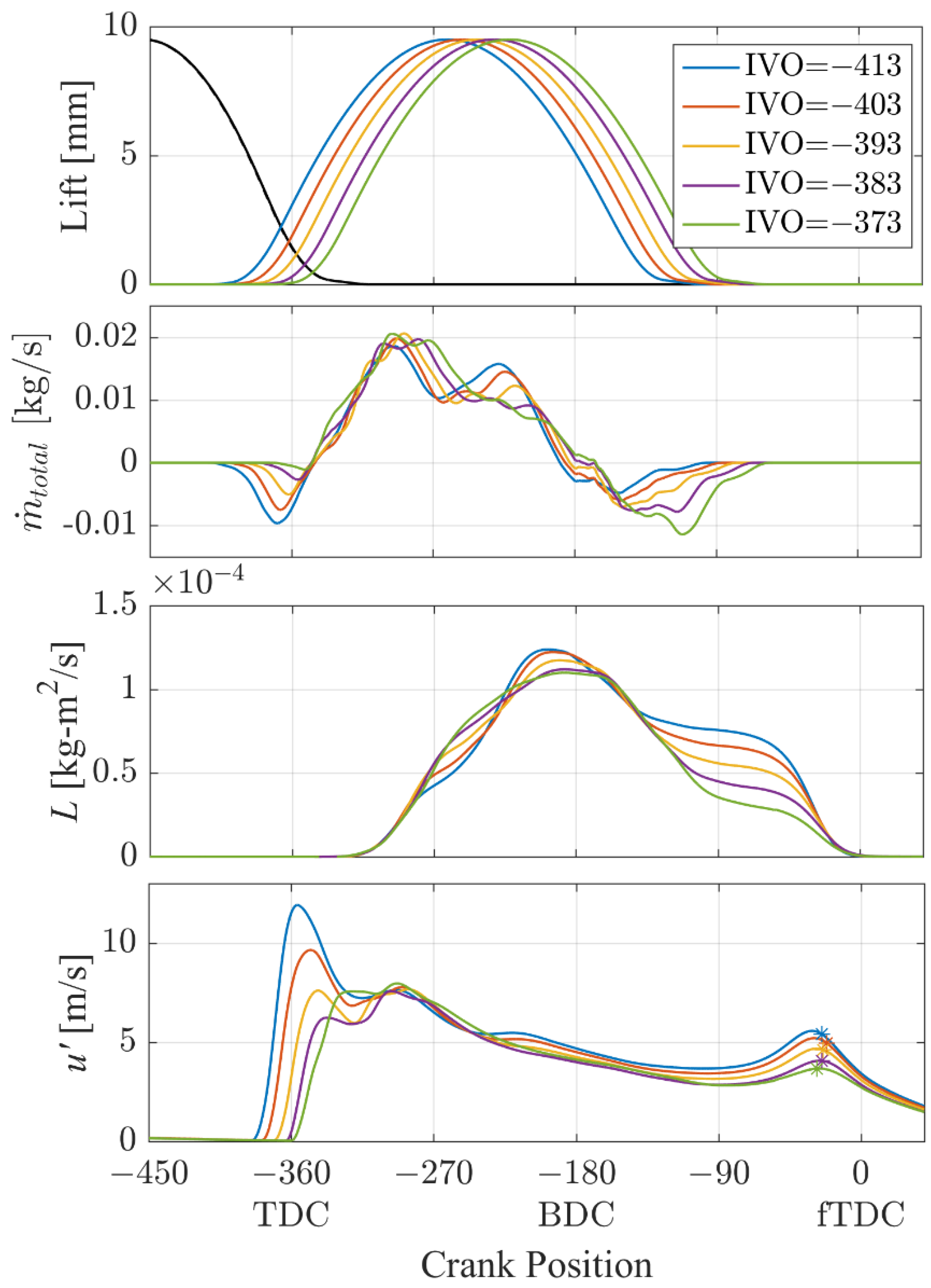

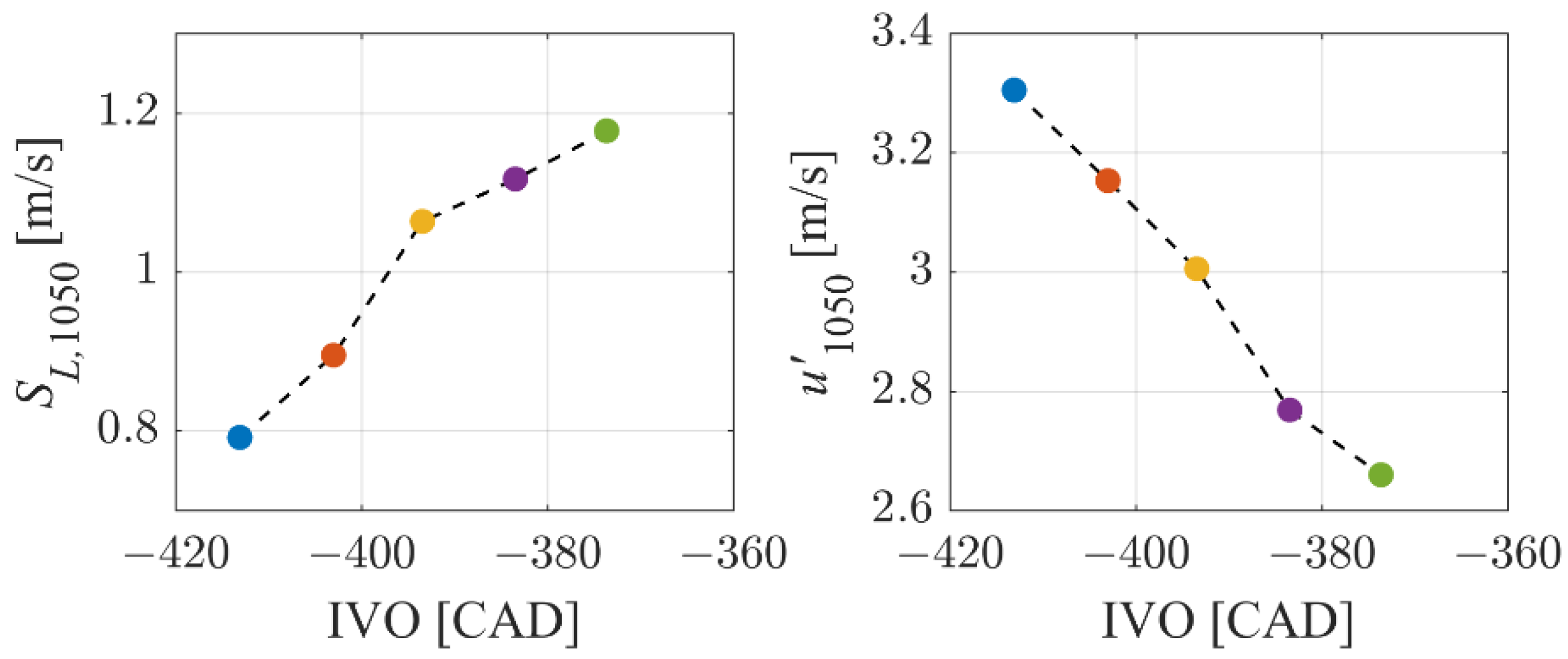

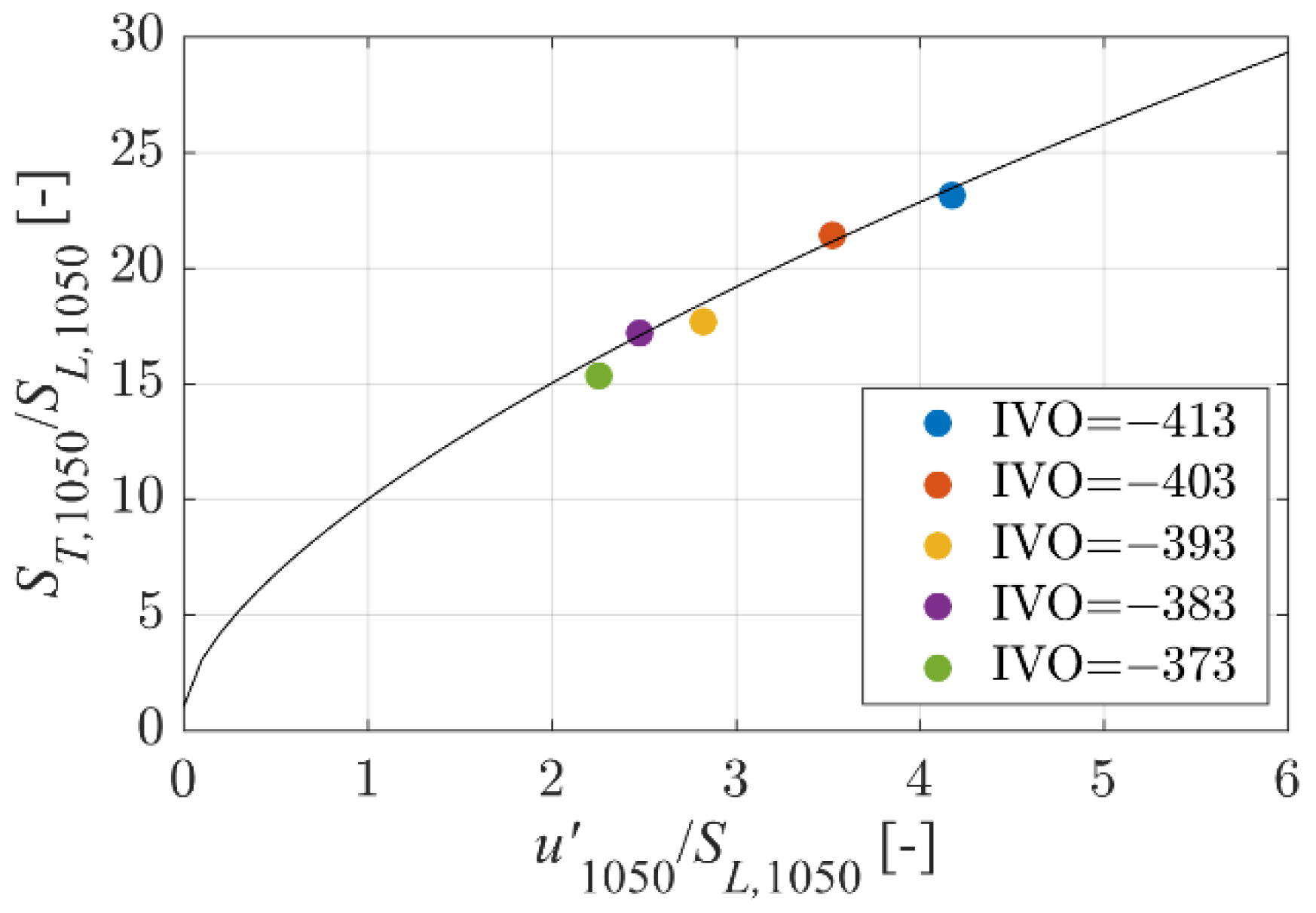

4.4.1. Effect of Intake Valve Timing Sweep

4.4.2. Effect of Engine Geometry

5. Conclusions

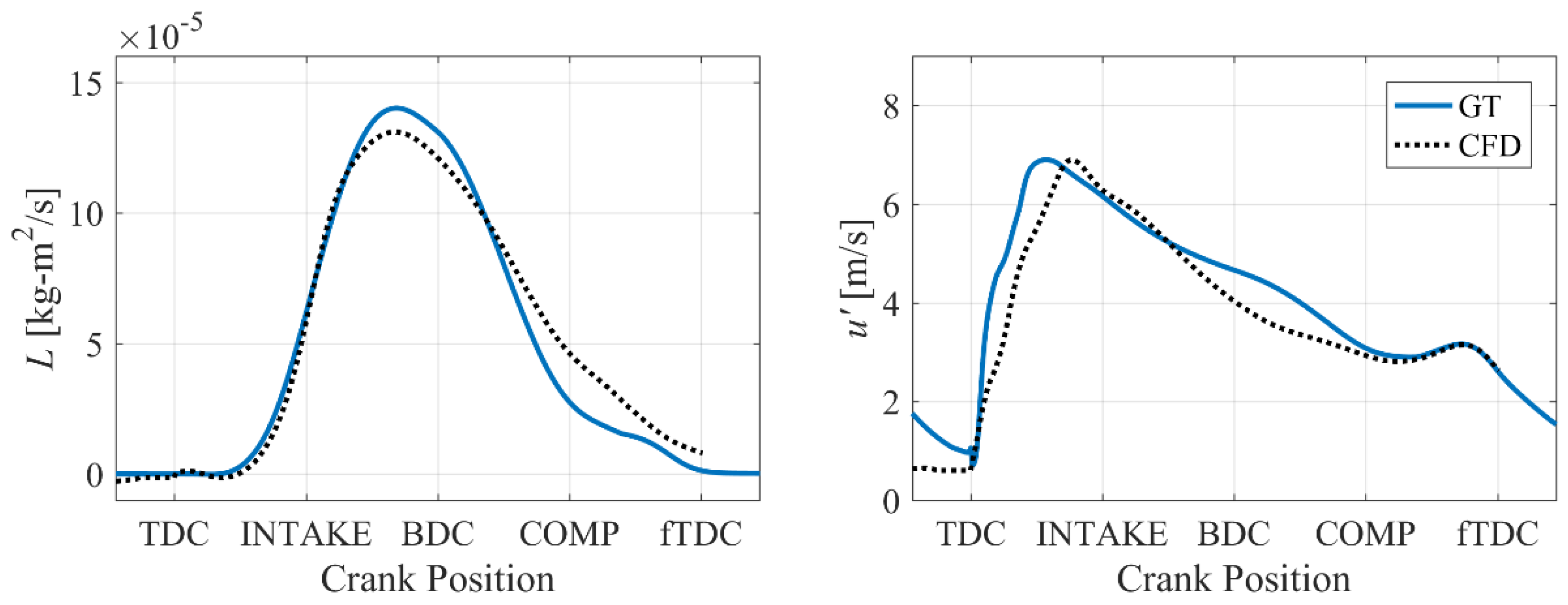

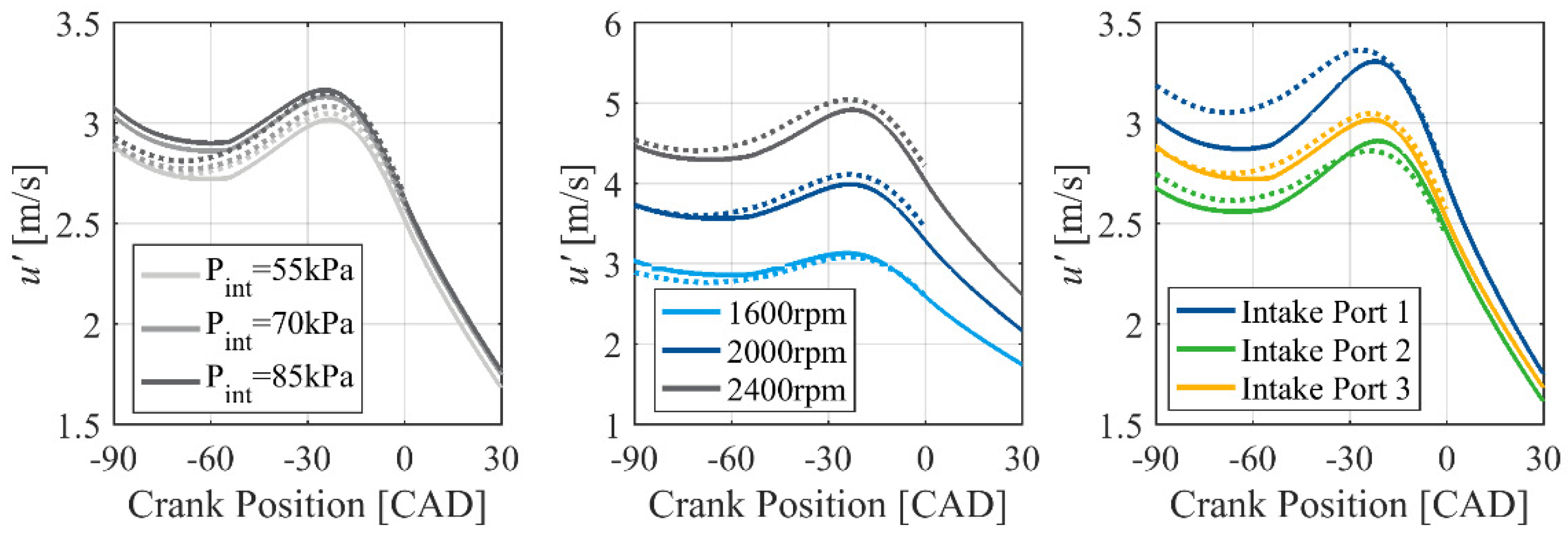

- describes the port characterization methodology in detail, which is verified via comparing the model prediction with the transient CFD results. This port characterization facilitates 0D model to predict the detailed flow characteristics with accuracy comparable to 3D CFD regardless of operating condition, which is quite noteworthy for a 0D model.

- suggests a physics-based approach to calculate tumble generation and decay rates for given engine geometry, utilizing the pre-obtained detailed flow characteristics. This QD tumble model is integrated into the k-ε model to complete the new predictive turbulence model.

- demonstrates the validation of the developed model with engine experiment results to verify whether the model correctly considers for port and cylinder geometry and whether it is applicable for various operating conditions. An adequate correlation between the model and experiment results has been observed with fixed modeling constants, implying that the developed model could sufficiently capture the core physics related to engine geometry and operating condition.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| area | |

| pentroof slope | |

| cylinder bore | |

| tumble center | |

| CA10, CA50, CA90 | 10, 50, 90% burn angle |

| tumble coefficient | |

| model constants | |

| non-tumble intake kinetic energy flux | |

| cylinder height | |

| , w | vertical/horizontal distance from tumble center |

| moment of inertia | |

| non-tumble mean kinetic energy | |

| turbulent kinetic energy | |

| angular momentum | |

| geometric length scale | |

| intake valve lift | |

| mass flow rate | |

| number of divisions | |

| TKE and dissipation production from non-tumble MKE | |

| cylinder radius | |

| flame radius | |

| moment arm length | |

| turbulent and laminar flame speed | |

| axial velocities | |

| characteristic velocity | |

| turbulent intensity | |

| volume | |

| velocity | |

| Greek Letters | |

| pentroof angle | |

| dissipation rate | |

| flow angles | |

| turbulent viscosity | |

| gas density | |

| term related to tumble decay | |

| Subscripts | |

| averaged value over CA10-50 | |

| effective | |

| division number | |

| pentroof | |

| tum | tumble-effective |

| Abbreviations | |

| 0D | zero-dimensional |

| 1D | one-dimensional |

| 3D | three-dimensional |

| BD | burn duration |

| BDC | bottom dead center |

| CAD | crank angle degree |

| CFD | computational fluid dynamics |

| EGR | exhaust gas recirculation |

| fTDC | firing top dead center |

| IMEP | gross indicated mean effective pressure |

| IVC | intake valve closing |

| IVO | intake valve opening |

| MFB | mass fraction burned |

| MKE | mean kinetic energy |

| RMF | residual mass fraction |

| TDC | top dead center |

| TKE | turbulent kinetic energy |

| QD | quasi-dimensional |

References

- Ikeya, K.; Takazawa, M.; Yamada, T.; Park, S.; Tagishi, R. Thermal Efficiency Enhancement of a Gasoline Engine. SAE Int. J. Engines 2015, 8, 1579–1586. [Google Scholar] [CrossRef]

- Hirooka, H.; Mori, S.; Shimizu, R. Effects of High Turbulence Flow on Knock Characteristics. SAE Trans. 2004, 113, 651–659. [Google Scholar]

- Berntsson, A.W.; Josefsson, G.; Ekdahl, R.; Ogink, R.; Grandin, B. The Effect of Tumble Flow on Efficiency for a Direct Injected Turbocharged Downsized Gasoline Engine. SAE Int. J. Engines 2011, 4, 2298–2311. [Google Scholar] [CrossRef]

- Ogink, R.; Babajimopoulos, A. Investigating the Limits of Charge Motion and Combustion Duration in a High-Tumble Spark-Ignited Direct-Injection Engine. SAE Int. J. Engines 2016, 9, 2129–2141. [Google Scholar] [CrossRef]

- Achuth, M.; Mehta, P.S. Predictions of Tumble and Turbulence in Four-Valve Pentroof Spark Ignition Engines. Int. J. Engine Res. 2001, 2, 209–227. [Google Scholar] [CrossRef]

- Bozza, F.; Teodosio, L.; De Bellis, V.; Fontanesi, S.; Iorio, A. Refinement of a 0D Turbulence Model to Predict Tumble and Turbulent Intensity in SI Engines. Part II: Model Concept, Validation and Discussion. SAE Technical Paper Series. 2018. [Google Scholar] [CrossRef]

- Yoshihara, Y.; Nakata, K.; Takahashi, D.; Omura, T.; Ota, A. Development of High Tumble Intake-Port for High Thermal Efficiency Engines. SAE Technical Paper. 2016. [Google Scholar] [CrossRef]

- Heywood, J.B. Internal Combustion Engine Fundamentals; McGraw-Hill Education: Columbus, OH, USA, 1988. [Google Scholar]

- Li, Y.-f.; Liu, S.-l.; Shi, S.; Feng, M.; Sui, X. An investigation of in-cylinder tumbling motion in a four-valve spark ignition engine. J. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2001, 215, 273–284. [Google Scholar] [CrossRef]

- Falfari, S.; Forte, C.; Brusiani, F.; Bianchi, G.M.; Cazzoli, G.; Catellani, C. Development of a 0D Model Starting from Different RANS CFD Tumble Flow Fields in Order to Predict the Turbulence Evolution at Ignition Timing. SAE Technical Paper Series. 2014. [Google Scholar] [CrossRef]

- Kent, J.; Mikulec, A.; Rimal, L.; Adamczyk, A.; Mueller, S.; Stein, R.; Warren, C. Observations on the effects of intake-generated swirl and tumble on combustion duration. SAE Trans. 1989, 98, 2042–2053. [Google Scholar]

- Gosman, A.; Tsui, Y.; Vafidis, C. Flow in a Model Engine with a Shrouded Valve-A Combined Experimental and Computational Study. SAE Technical Paper. 1985. [Google Scholar] [CrossRef]

- Dai, W.; Newman, C.E.; Davis, G.C. Predictions of in-cylinder tumble flow and combustion in SI engines with a quasi-dimensional model. SAE Trans. 1996, 105, 2014–2025. [Google Scholar]

- Grasreiner, S.; Neumann, J.; Luttermann, C.; Wensing, M.; Hasse, C. A quasi-dimensional model of turbulence and global charge motion for spark ignition engines with fully variable valvetrains. Int. J. Engine Res. 2014, 15, 805–816. [Google Scholar] [CrossRef]

- Fogla, N.; Bybee, M.; Mirzaeian, M.; Millo, F.; Wahiduzzaman, S. Development of a K-k-ε Phenomenological Model to Predict In-Cylinder Turbulence. SAE Int. J. Engines 2017, 10, 562–575. [Google Scholar] [CrossRef]

- Kim, Y.; Kim, M.; Kim, J.; Song, H.H.; Park, Y.; Han, D. Predicting the Influences of Intake Port Geometry on the Tumble Generation and Turbulence Characteristics by Zero-Dimensional Spark Ignition Engine Model. SAE Technical Paper. 2018. [Google Scholar] [CrossRef]

- Kent, J.; Haghgooie, M.; Mikulec, A.; Davis, G.; Tabaczynski, R. Effects of Intake Port Design and Valve Lift on In-Cylinder Flow and Burnrate. SAE Technical Paper. 1987. [Google Scholar] [CrossRef]

- Baratta, M.; Misul, D.; Spessa, E.; Viglione, L.; Carpegna, G.; Perna, F. Experimental and numerical approaches for the quantification of tumble intensity in high-performance SI engines. Energy Convers. Manag. 2017, 138, 435–451. [Google Scholar] [CrossRef]

- Kuwahara, K.; Watanabe, T.; Takemura, J.; Omori, S.; Kume, T.; Ando, H. Optimization of in-cylinder flow and mixing for a center-spark four-valve engine employing the concept of barrel-stratification. SAE Trans. 1994, 103, 1502–1513. [Google Scholar]

- Benjamin, S. Prediction of barrel swirl and turbulence in reciprocating engines using a phenomenological model. In Proceedings of the Institute of Mechanical Engineers Conference on Experimental and Predictive Methods in Engine Research and Development, Birmingham, UK, 17 November 1993. [Google Scholar]

- Ramajo, D.; Zanotti, A.; Nigro, N. Assessment of a zero-dimensional model of tumble in four-valve high performance engine. Int. J. Numer. Methods Heat Fluid Flow 2007, 17, 770–787. [Google Scholar] [CrossRef]

- Kim, M.; Kim, Y.; Song, H.H. Development of Zero-Dimensional Spark Ignition Engine Model Considering Turbulence Formation in Various Intake Pressure Conditions and Intake Manifold Designs. In Proceedings of the 56th KOSCO Symposium, Jeonju, Korea, 10–12 May 2018. [Google Scholar]

- Kim, N.; Ko, I.; Min, K. Development of a zero-dimensional turbulence model for a spark ignition engine. Int. J. Engine Res. 2018, 20, 441–451. [Google Scholar] [CrossRef]

- Morel, T.; Mansour, N. Modeling of Turbulence in Internal Combustion Engines. SAE Technical Paper. 1982. [Google Scholar] [CrossRef]

- Oh, S.; Cho, S.; Seol, E.; Song, C.; Shin, W.; Min, K.; Song, H.H.; Lee, B.; Jinwook, S.; Woo, S.H. An Experimental Study on the Effect of Stroke-to-Bore Ratio of Atkinson DISI Engines with Variable Valve Timing. J. SAE Int. J. Engines 2018, 11, 1183–1193. [Google Scholar] [CrossRef]

| 0.5 | |

| 0.8273 | |

| 500 | |

| 1.8125 | |

| 3.5 |

| Parameter | Engine A | Engine B | Engine C |

|---|---|---|---|

| Displacement (cc) | - | 500 | |

| Bore (mm) | 86 | 81 | 75.6 |

| Stroke (mm) | 86 | 97 | 111 |

| Conrod Length (mm) | 211.65 | 207.65 | 199.15 |

| Stroke-to-Bore Ratio (-) | 1.0 | 1.2 | 1.47 |

| Compression Ratio (-) | 12 ± 0.1 | ||

| Intake Valve Diameter (mm) | 33 | 29 | 29 |

| Exhaust Valve Diameter (mm) | 27 | 27 | 27 |

| Pentroof Angle (degree) | 15 | ||

| Number of data points | 98 | 40 | 56 |

| Engine speed (rpm) | 1500, 2000 |

| IMEP (bar) | 4.5–10.5 |

| Valve open duration (In/Ex) (CAD) | 280/240 |

| InCam shift range (CAD) | −40–0(default1) |

| ExCam shift range (CAD) | 0(default1)–30 |

| Valve Overlap (CAD) | 35–105 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, Y.; Kim, M.; Oh, S.; Shin, W.; Cho, S.; Song, H.H. A New Physics-Based Modeling Approach for a 0D Turbulence Model to Reflect the Intake Port and Chamber Geometries and the Corresponding Flow Structures in High-Tumble Spark-Ignition Engines. Energies 2019, 12, 1898. https://doi.org/10.3390/en12101898

Kim Y, Kim M, Oh S, Shin W, Cho S, Song HH. A New Physics-Based Modeling Approach for a 0D Turbulence Model to Reflect the Intake Port and Chamber Geometries and the Corresponding Flow Structures in High-Tumble Spark-Ignition Engines. Energies. 2019; 12(10):1898. https://doi.org/10.3390/en12101898

Chicago/Turabian StyleKim, Yirop, Myoungsoo Kim, Sechul Oh, Woojae Shin, Seokwon Cho, and Han Ho Song. 2019. "A New Physics-Based Modeling Approach for a 0D Turbulence Model to Reflect the Intake Port and Chamber Geometries and the Corresponding Flow Structures in High-Tumble Spark-Ignition Engines" Energies 12, no. 10: 1898. https://doi.org/10.3390/en12101898

APA StyleKim, Y., Kim, M., Oh, S., Shin, W., Cho, S., & Song, H. H. (2019). A New Physics-Based Modeling Approach for a 0D Turbulence Model to Reflect the Intake Port and Chamber Geometries and the Corresponding Flow Structures in High-Tumble Spark-Ignition Engines. Energies, 12(10), 1898. https://doi.org/10.3390/en12101898