Disc Thickness and Spacing Distance Impacts on Flow Characteristics of Multichannel Tesla Turbines

Abstract

:1. Introduction

2. Numerical Approach

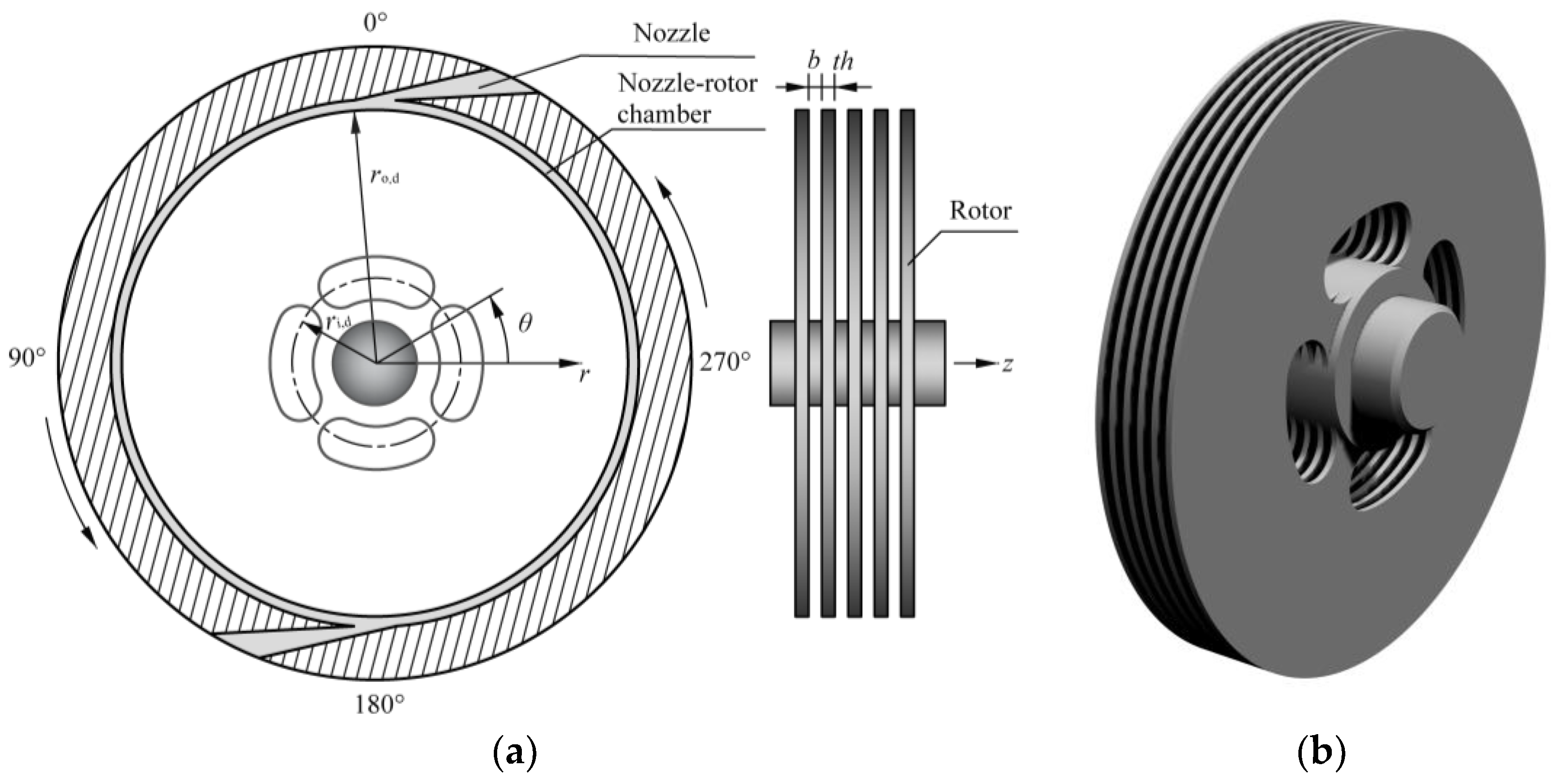

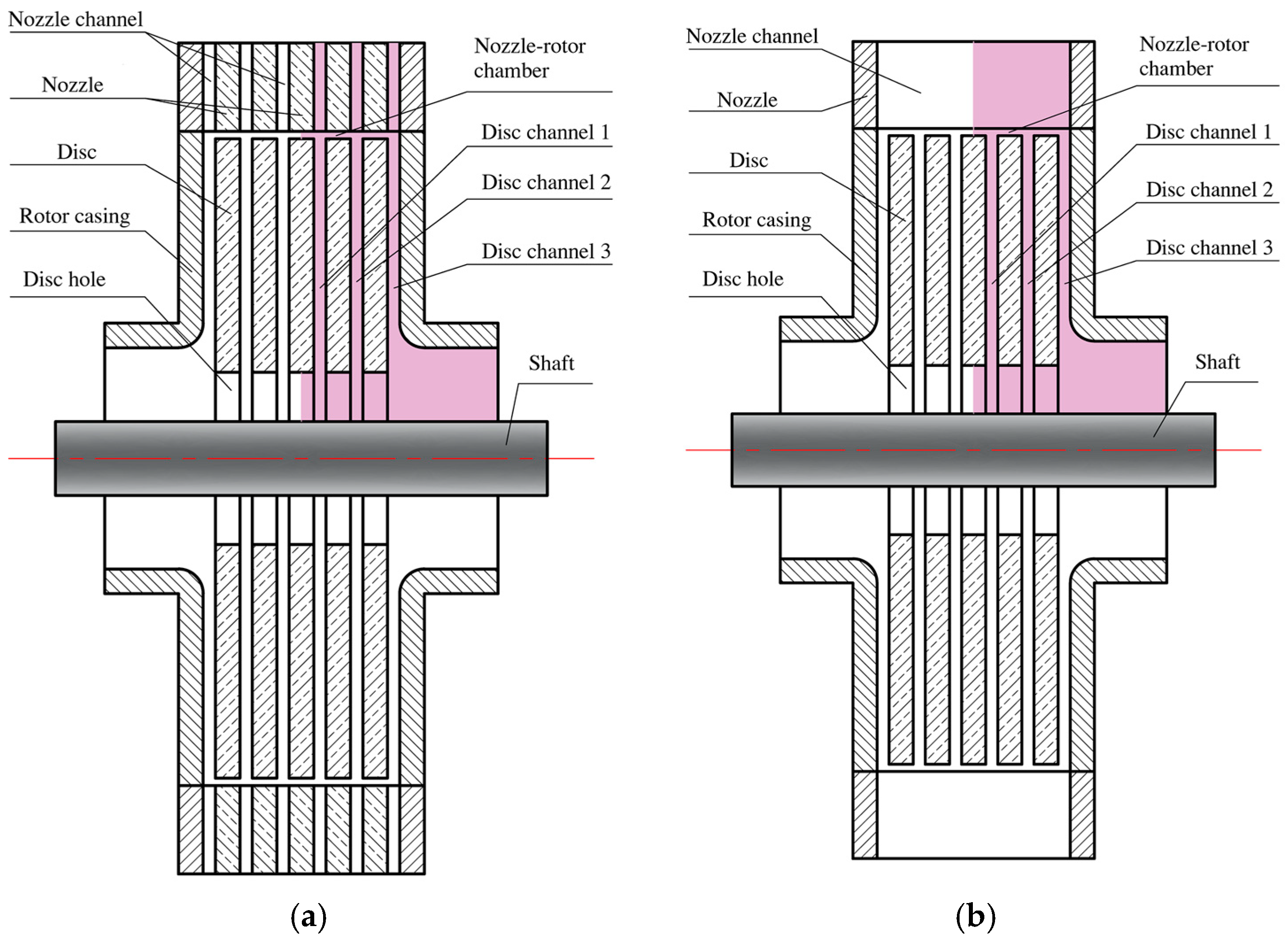

2.1. Geometry Model and Boundary Conditions

2.2. Numerical Solver and Mesh Sensitivity

3. Results and Discussions

3.1. Total Aerodynamic Performance of Two Kinds of Multichannel Tesla Turbines

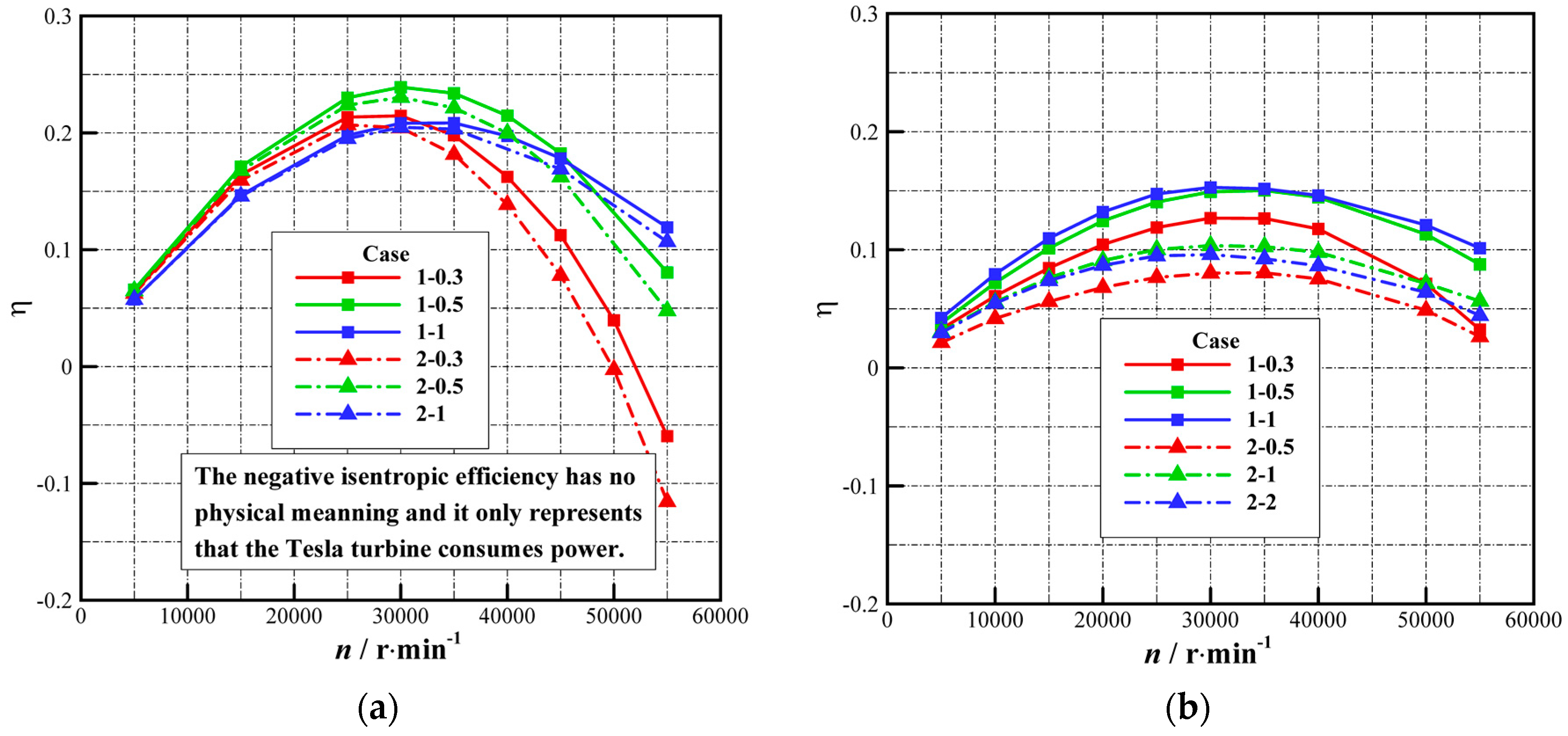

3.1.1. Isentropic Efficiency

3.1.2. Flow Coefficient

3.1.3. Percentages of Mass Flow Rate and Torque in Disc Channels

3.2. Flow Status of One-To-One Multichannel Tesla Turbines

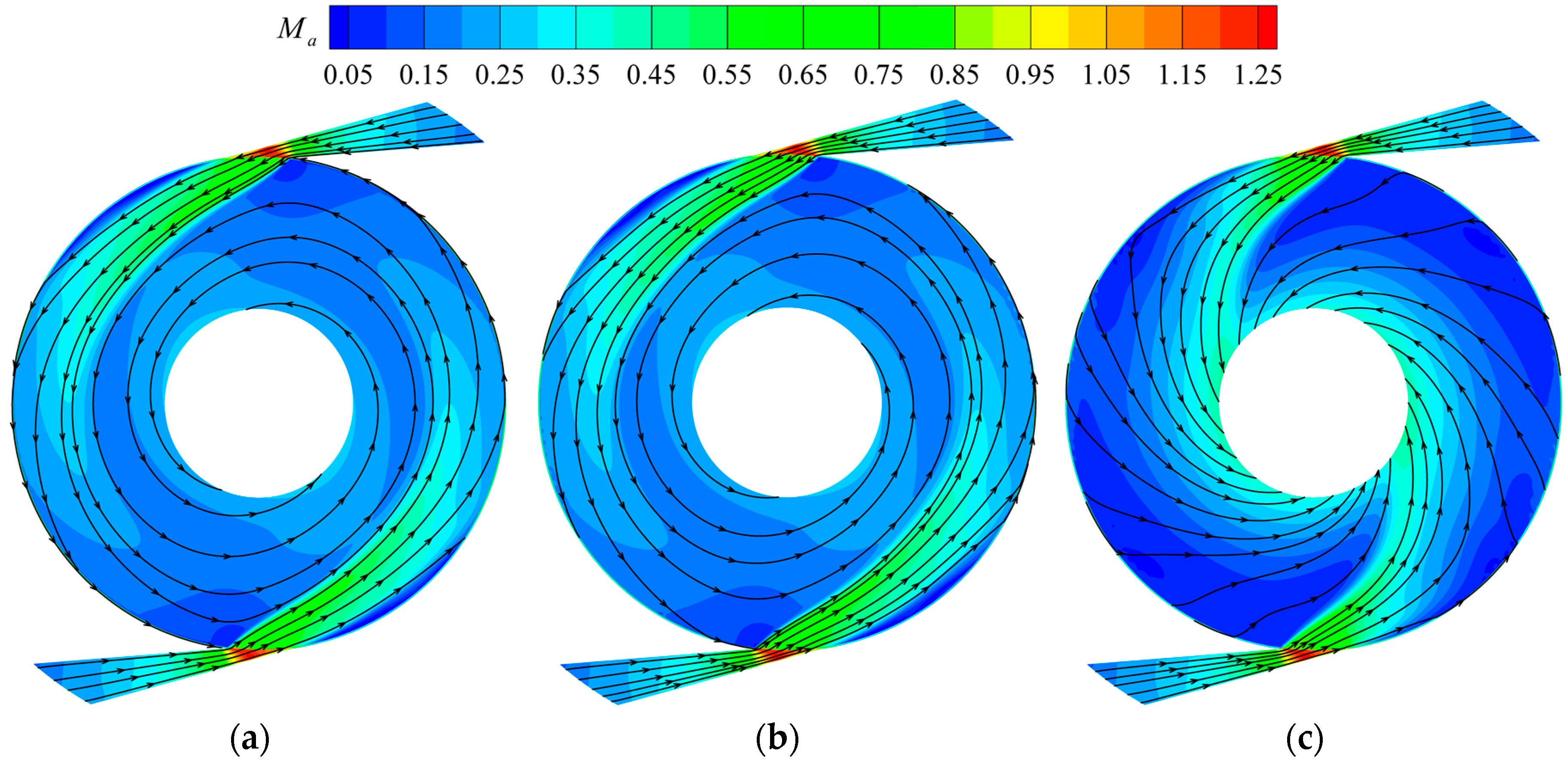

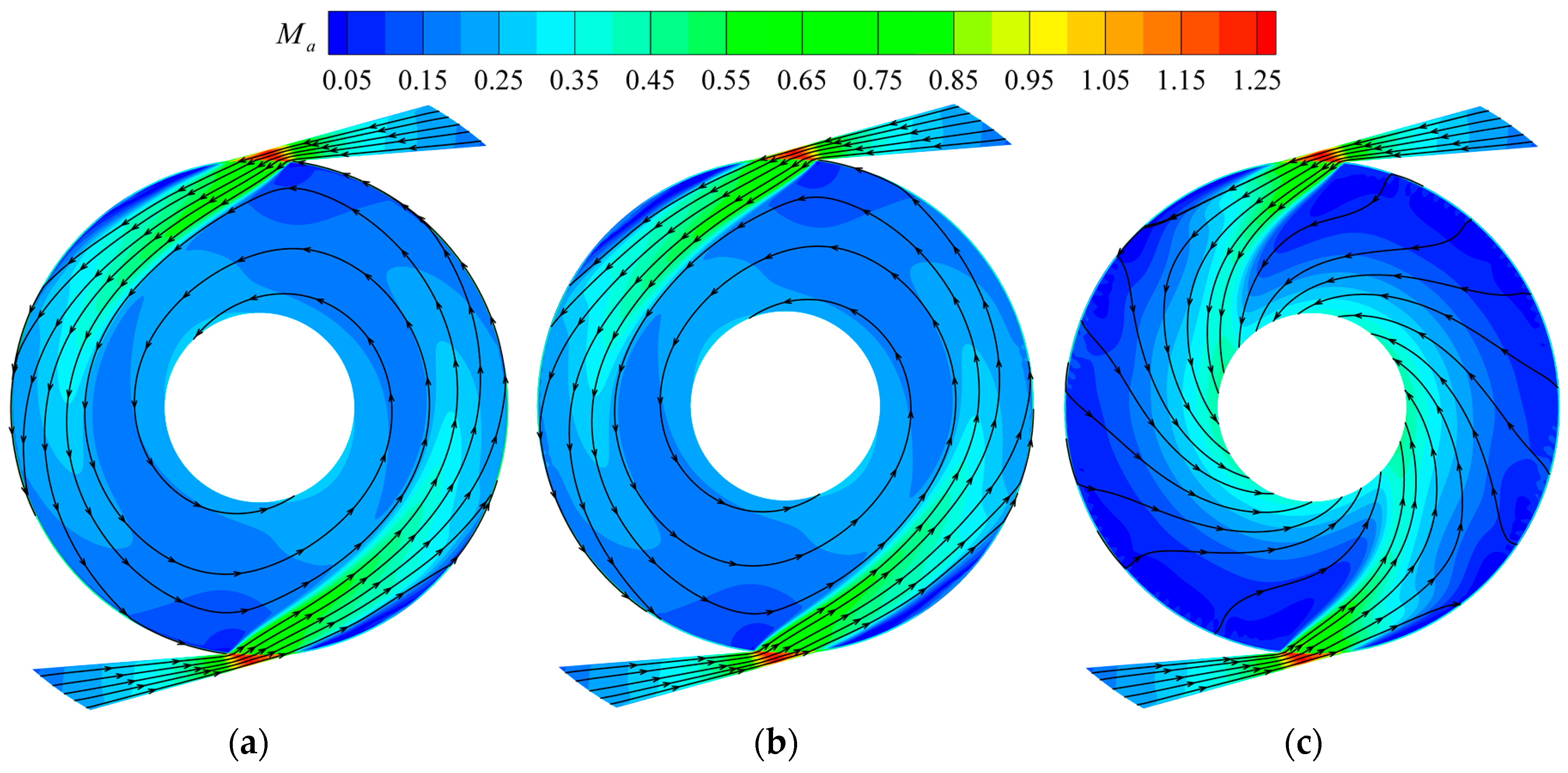

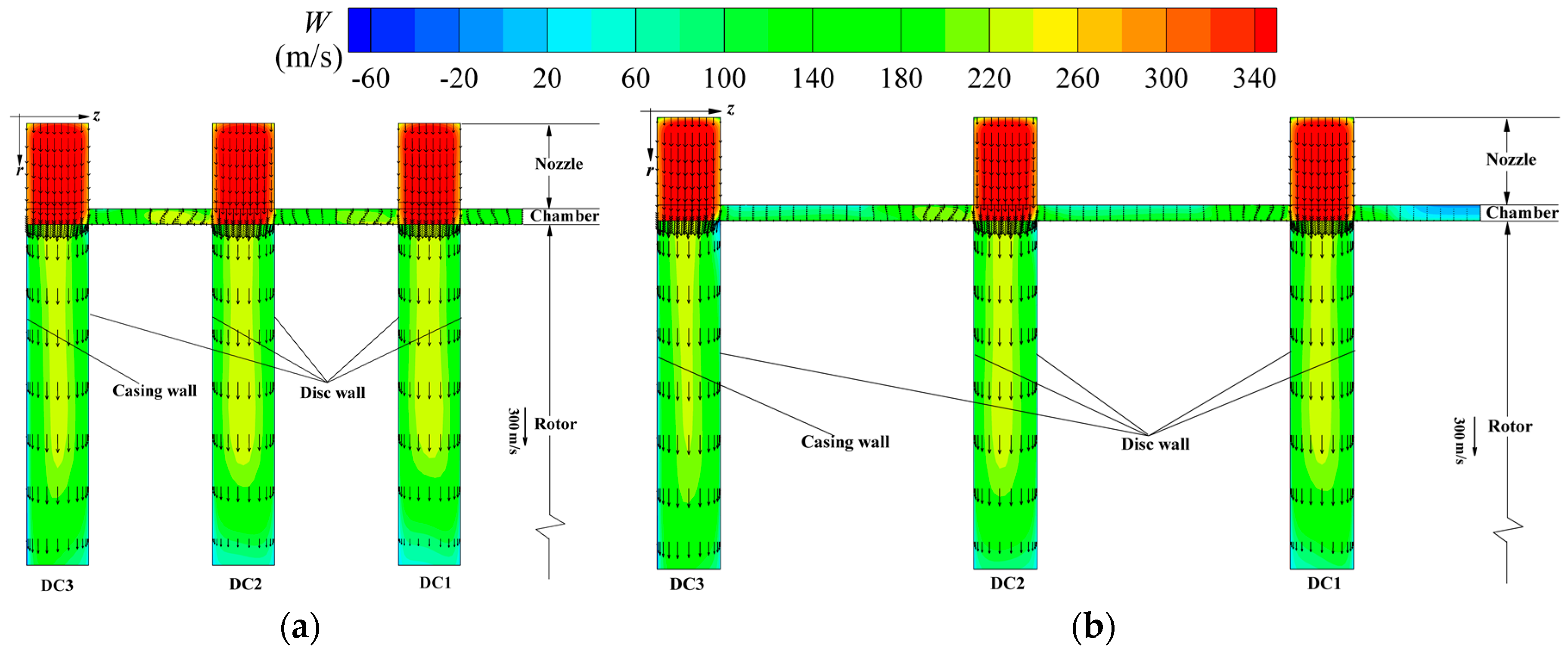

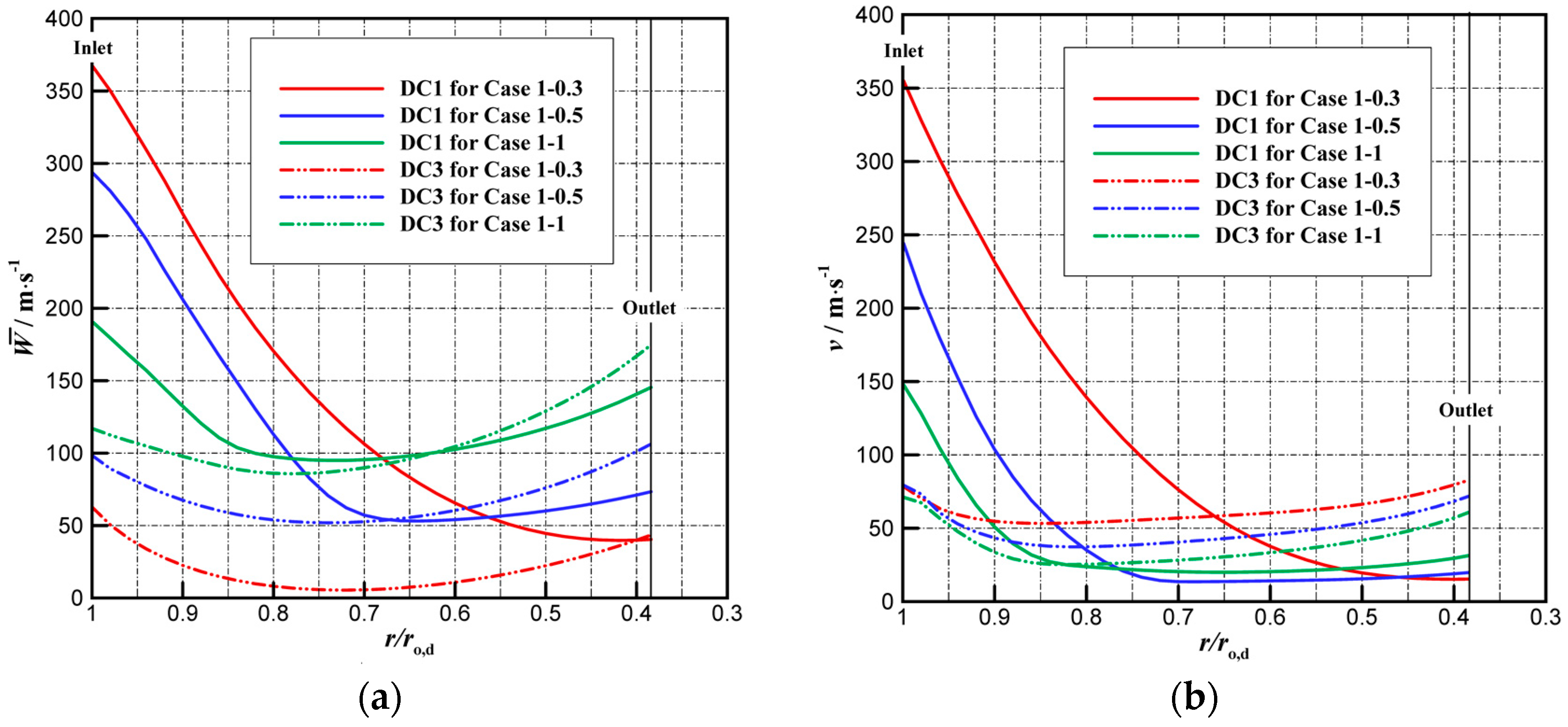

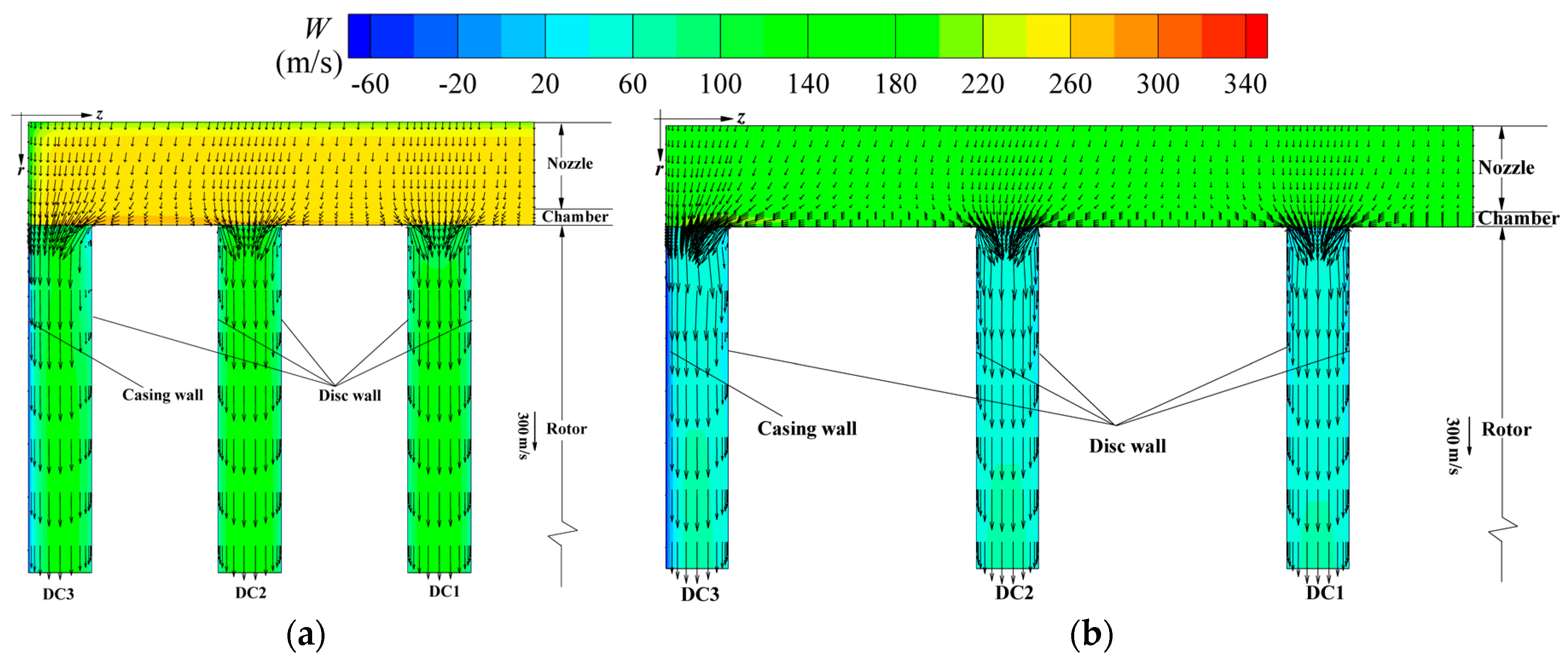

3.2.1. One-To-One Turbine with Different Disc Thickness

3.2.2. One-To-One Turbine with Different Disc Spacing Distance

3.3. Flow Status of One-To-Many Multichannel Tesla Turbines

3.3.1. One-To-Many Turbine with Different Disc Thickness

3.3.2. One-To-Many Turbine with Different Disc Spacing Distance

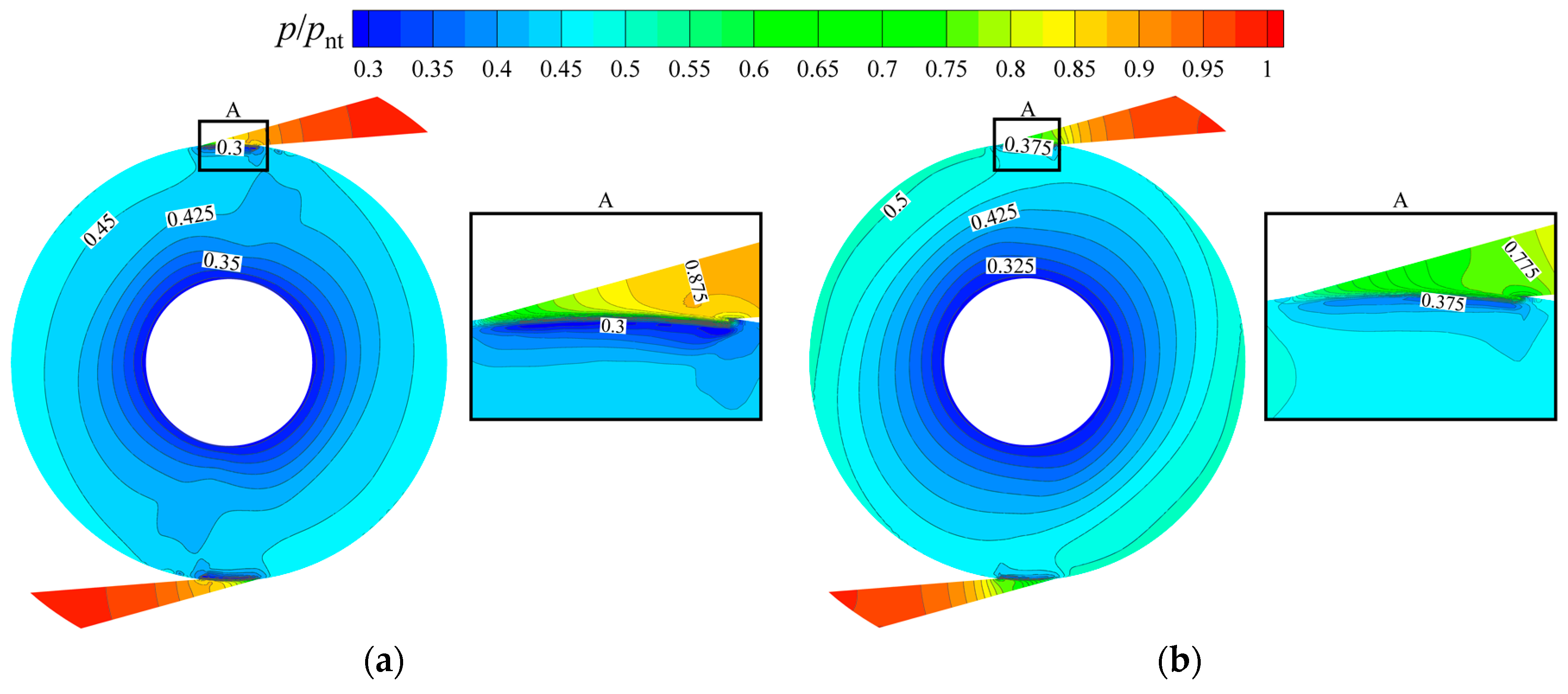

3.4. Influence of Disc Thickness and Spacing Distance on Energy Loss

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| b | disc spacing distance, mm |

| c | radial clearance of nozzle-rotor chamber, mm |

| cp | specific heat at constant pressure, J/kg·K |

| Cm | flow coefficient |

| d | diameter, mm |

| h | static enthalpy, m2/s2 |

| htot | mean total enthalpy, m2/s2 |

| k | turbulent kinetic energy, |

| m | mass flow rate, kg/s |

| M | torque, N·m |

| Ma | Mach number |

| n | rotational speed of the rotor, r/min |

| N | number |

| pabs | absolute pressure |

| pnt/pi | ratio of total pressure at the nozzle inlet to pressure at the turbine outlet |

| P | power, kW |

| turbulent Prandtl number | |

| r | radial coordinate or radius, mm |

| R | specific gas constant of air, |

| SE | energy source, kg/(m·s3) |

| SM | momentum source, kg/(m2·s2) |

| t | time, s |

| th | disc thickness, mm |

| T | temperature, K |

| Tnt | total temperature at the nozzle inlet, K |

| Uj | averaged velocity in three directions, m/s |

| v | average radial velocity, m/s |

| W | relative tangential velocity, m/s |

| average relative tangential velocity, m/s | |

| xj | coordinates in three directions, m |

| z | axial coordinate, m |

| nozzle exit geometrical angle (relative to the tangential direction), ° | |

| specific heat ratio | |

| eddy diffusivity, kg/(m·s) | |

| relative variation of parameters | |

| isentropic enthalpy drop of the whole turbine, J/kg | |

| isentropic efficiency | |

| circumferential coordinate, rad | |

| eddy viscosity or turbulent viscosity, kg/(m·s) | |

| density, kg/m3 | |

| Reynolds stresses | |

| turbulence flux | |

| Reynolds flux | |

| molecular stress tensor, kg/(m·s2) | |

| turbulent frequency, s-1 | |

| rotational angular speed, rad/s | |

| Subscripts | |

| d | disc |

| dc | disc channel |

| i | inner |

| n | nozzle |

| o | outer |

References

- Gerendas, M.; Pfister, R. Development of a very small aero-engine. In Proceedings of the ASME Turbo Expo 2000, Munich, Germany, 8–11 May 2000. [Google Scholar]

- Capata, R.; Sciubba, E. Experimental fitting of the re-scaled Balje maps for low-Reynolds radial turbomachinary. Energies 2015, 8, 7686–8000. [Google Scholar] [CrossRef]

- Capata, R.; Saracchini, M. Experimental campaign tests on ultra micro gas turbines, fuel supply comparison and optimization. Energies 2018, 11, 799. [Google Scholar] [CrossRef]

- Epstein, A.H. Millimeter-scale, MEMS gas turbine engines. J. Eng. Gas Turbines Power 2015, 126, 205–226. [Google Scholar] [CrossRef]

- Fu, L.; Feng, Z.P.; Li, G.J. Experimental investigation on overall performance of a millimeter-scale radial turbine for micro gas turbine. Energy 2017, 134, 1–9. [Google Scholar] [CrossRef]

- Fu, L.; Feng, Z.P.; Li, G.J. Investigation on design flow of a millimeter-scale radial turbine for micro gas turbine. Microsyst. Technol. 2018, 24, 2333–2347. [Google Scholar] [CrossRef]

- Shan, X.C.; Zhang, Q.D.; Sun, Y.F.; Wang, Z.F. Design, fabrication and characterization of an air-driven micro turbine device. J. Phys. 2006, 34, 316–321. [Google Scholar] [CrossRef]

- Isomura, K.; Murayama, M.; Teramoto, S.; Hikichi, K.; Endo, Y.; Togo, S.; Tanaka, S. Experiment verification of the feasibility of a 100 W class micro-scale gas turbine at an impeller diameter of 10 mm. J. Micromech. Microeng. 2006, 16, s254–s261. [Google Scholar] [CrossRef]

- Kim, M.J.; Kim, J.H.; Kim, T.S. The effects of internal leakage on the performance of a micro gas turbine. Appl. Energy 2018, 212, 175–184. [Google Scholar] [CrossRef]

- Deam, R.T.; Lemma, E.; Mace, B.; Collins, R. On scaling down turbines to millimeter size. J. Eng. Gas Turbines Power 2008, 130, 052301. [Google Scholar] [CrossRef]

- Lampart, P.; Kosowski, K.; Piwowarski, M.; Jedrzejewski, L. Design analysis of Tesla micro-turbine operating on a low-boiling medium. Pol. Marit. Res. 2009, 16, 28–33. [Google Scholar] [CrossRef]

- Tesla, N. Turbine. U.S. Patent 1,061,206, 6 May 1913. [Google Scholar]

- Beans, E.W. Investigation into the performance characteristics of a friction turbine. J. Spacecr. 1966, 3, 131–134. [Google Scholar] [CrossRef]

- Breiter, M.C.; Pohlhausen, K. Laminar Flow between Two Parallel Rotating Disks. Available online: https://apps.dtic.mil/dtic/tr/fulltext/u2/275562.pdf (accessed on 8 April 2016).

- Rice, W. An analytical and experimental investigation of multiple-disk turbines. J. Eng. Power 1965, 87, 29–36. [Google Scholar] [CrossRef]

- Adams, R.; Rice, W. Experimental investigation of the flow between corotating disks. J. Appl. Mech. 1970, 37, 844–849. [Google Scholar] [CrossRef]

- Lemma, E.; Deam, R.T.; Toncich, D.; Collins, R. Characterisation of a small viscous flow turbine. Exp. Therm. Fluid Sci. 2008, 33, 96–105. [Google Scholar] [CrossRef]

- Carey, V.P. Assessment of Tesla turbine performance for small scale Rankine combined heat and power systems. J. Eng. Gas Turbines Power 2010, 132, 122301. [Google Scholar] [CrossRef]

- Sengupta, S.; Guha, A. A theory of Tesla disc turbines. Proc. Inst. Mech. Eng. Part A J. Power Energy 2012, 226, 650–663. [Google Scholar] [CrossRef]

- Guha, A.; Sengupta, S. The fluid dynamics of the rotating flow in a Tesla disc turbine. Eur. J. Mech. B/Fluid 2013, 37, 112–123. [Google Scholar] [CrossRef]

- Sengupta, S.; Guha, A. Analytical and computational solutions for three-dimensional flow-field and relative pathlines for the rotating flow in a Tesla disc turbine. Comput. Fluids 2013, 88, 344–353. [Google Scholar] [CrossRef]

- Talluri, L.; Fiaschi, D.; Neri, G.; Ciappi, L. Design and optimization of a Tesla turbine for ORC applications. Appl. Energy 2018, 226, 300–319. [Google Scholar] [CrossRef]

- Hoya, G.P.; Guha, A. The design of a test rig and study of the performance and efficiency of a Tesla disc turbine. Proc. Inst. Mech. Eng. Part A J. Power Energy 2009, 223, 451–465. [Google Scholar] [CrossRef]

- Guha, A.; Smiley, B. Experiment and analysis for an improved design of the inlet and nozzle in Tesla disc turbines. Proc. Inst. Mech. Eng. Part A J. Power Energy 2010, 224, 261–277. [Google Scholar] [CrossRef]

- Schosser, C.; Lecheler, S.; Pfitzner, M. A test rig for the investigation of the performance and flow field of Tesla friction turbines. In Proceedings of the ASME Turbo Expo 2014, Düsseldorf, Germany, 16–20 June 2014. [Google Scholar]

- Lampart, P.; Jedrzejewski, L. Investigations of aerodynamics of Tesla bladeless microturbines. J. Theor. Appl. Mech. 2011, 49, 477–499. [Google Scholar]

- Deng, Q.H.; Qi, W.J.; Feng, Z.P. Improvement of a theoretical analysis method for Tesla turbines. In Proceedings of the ASME Turbo Expo 2013, San Antonio, TX, USA, 3–7 June 2013. [Google Scholar]

- Qi, W.J.; Deng, Q.H.; Feng, Z.P.; Yuan, Q. Influence of disc spacing distance on the aerodynamic performance and flow field of Tesla turbines. In Proceedings of the ASME Turbo Expo 2016, Seoul, Korea, 13–17 June 2016. [Google Scholar]

- Qi, W.J.; Deng, Q.H.; Jiang, Y.; Feng, Z.P.; Yuan, Q. Aerodynamic performance and flow characteristics analysis of Tesla turbines with different nozzle and outlet geometries. Proc. Inst. Mech. Eng. Part A J. Power Energy 2018, accepted. [Google Scholar] [CrossRef]

- Hidema, T.; Okamoto, K.; Teramoto, S.; Nagashima, T. Numerical investigation of inlet effects on Tesla turbine performance. In Proceedings of the AJCPP, Miyazaki, Japan, 4–6 March 2010. [Google Scholar]

- Sengupta, S.; Guha, A. Inflow-rotor interaction in Tesla disc turbines: Effects of discrete inflows, finite disc thickness, and radial clearance on the fluid dynamics and performance of the turbine. Proc. Inst. Mech. Eng. Part A J. Power Energy 2018. accepted. [Google Scholar] [CrossRef]

- Okamoto, K.; Goto, K.; Teramoto, S.; Yamaguchi, K. Experimental investigation of inflow condition effects on Tesla turbine performance. In Proceedings of the ISABE Conference 2017, Manchester, UK, 3–8 September 2017. [Google Scholar]

- Carlson, D.R.; Widnall, S.E.; Peeters, M.F. A flow-visualization study of transition in plane Poiseuille flow. J. Fluid Mech. 1982, 121, 487–505. [Google Scholar] [CrossRef]

- ANSYS. CFX-Solver Theory Guide; Release 12.1; ANSYS Inc.: Canonsburg, PA, USA, 2009. [Google Scholar]

| Group 1 (One-To-One Multichannel Tesla Turbines) | |||

| Case | th(mm) | b(mm) | b/th(-) |

| Case 1-0.3 | 1 | 0.3 | 0.3 |

| Case 1-0.5 | 1 | 0.5 | 0.5 |

| Case 1-1 | 1 | 1 | 1 |

| Case 2-0.3 | 2 | 0.3 | 0.15 |

| Case 2-0.5 | 2 | 0.5 | 0.25 |

| Case 2-1 | 2 | 1 | 0.5 |

| Group 2 (One-To-Many Multichannel Tesla Turbines) | |||

| Case | th(mm) | b(mm) | b/th(-) |

| Case 1-0.3 | 1 | 0.3 | 0.3 |

| Case 1-0.5 | 1 | 0.5 | 0.5 |

| Case 1-1 | 1 | 1 | 1 |

| Case 2-0.5 | 2 | 0.5 | 0.25 |

| Case 2-1 | 2 | 1 | 0.5 |

| Case 2-2 | 2 | 2 | 1 |

| Symbol | Unit | Value |

|---|---|---|

| Nn | (-) | 2 |

| do,d | (mm) | 100 |

| di,d | (mm) | 38.4 |

| c | (mm) | 0.25 |

| Nd | (-) | 5 |

| Ndc | (-) | 6 |

| (°) | 10 | |

| (-) | 3.42 | |

| Tnt | (K) | 373 |

| Case No. | Stator (Nozzle/N-R Chamber) | Rotor (Each Disc Channel) | ||

|---|---|---|---|---|

| Number of Nodes | Total Node Number | Number of Nodes | Total Node Number | |

| Case 1 | (55/13) × (36/269) × 99 | 526,516 | 65 × 288 × 23 | 400,660 |

| Case 2 | (67/17) × (45/335) × 107 | 923,517 | 81 × 333 × 29 | 782,217 |

| Case 3 | (87/21) × (57/417) × 135 | 1,830,306 | 102 × 417 × 37 | 1,581,306 |

| Case No. | Node Number (million) | (kg/s) | (kW) | (-) | |||

|---|---|---|---|---|---|---|---|

| Case 1 | 1.72 | 0.03576 | 0.619 | 0.5960 | 1.568 | 0.1504 | 0.940 |

| Case 2 | 3.27 | 0.03562 | 0.225 | 0.5886 | 0.307 | 0.1491 | 0.067 |

| Case 3 | 6.57 | 0.03554 | 0 | 0.5868 | 0 | 0.1490 | 0 |

| Case Name | Nozzle Loss Coefficient | Disc Loss Coefficient | Leaving-Velocity Loss Coefficient | Isentropic Efficiency |

|---|---|---|---|---|

| Case 1-0.3 | 0.2857 | 0.4196 | 0.0760 | 0.2187 |

| Case 1-0.5 | 0.1849 | 0.4405 | 0.1303 | 0.2443 |

| Case 1-1 | 0.1085 | 0.4358 | 0.2440 | 0.2117 |

| Case Name | Nozzle Loss Coefficient | Disc Loss Coefficient | Leaving-Velocity Loss Coefficient | Isentropic Efficiency |

|---|---|---|---|---|

| Case 1-0.3 | 0.0724 | 0.5539 | 0.2387 | 0.1350 |

| Case 1-0.5 | 0.0578 | 0.4574 | 0.3310 | 0.1538 |

| Case 1-1 | 0.0417 | 0.3936 | 0.4055 | 0.1592 |

| Case 2-0.5 | 0.0699 | 0.4324 | 0.4040 | 0.0937 |

| Case 2-1 | 0.0471 | 0.3504 | 0.4925 | 0.1100 |

| Case 2-2 | 0.0375 | 0.3083 | 0.5561 | 0.0981 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qi, W.; Deng, Q.; Jiang, Y.; Yuan, Q.; Feng, Z. Disc Thickness and Spacing Distance Impacts on Flow Characteristics of Multichannel Tesla Turbines. Energies 2019, 12, 44. https://doi.org/10.3390/en12010044

Qi W, Deng Q, Jiang Y, Yuan Q, Feng Z. Disc Thickness and Spacing Distance Impacts on Flow Characteristics of Multichannel Tesla Turbines. Energies. 2019; 12(1):44. https://doi.org/10.3390/en12010044

Chicago/Turabian StyleQi, Wenjiao, Qinghua Deng, Yu Jiang, Qi Yuan, and Zhenping Feng. 2019. "Disc Thickness and Spacing Distance Impacts on Flow Characteristics of Multichannel Tesla Turbines" Energies 12, no. 1: 44. https://doi.org/10.3390/en12010044

APA StyleQi, W., Deng, Q., Jiang, Y., Yuan, Q., & Feng, Z. (2019). Disc Thickness and Spacing Distance Impacts on Flow Characteristics of Multichannel Tesla Turbines. Energies, 12(1), 44. https://doi.org/10.3390/en12010044