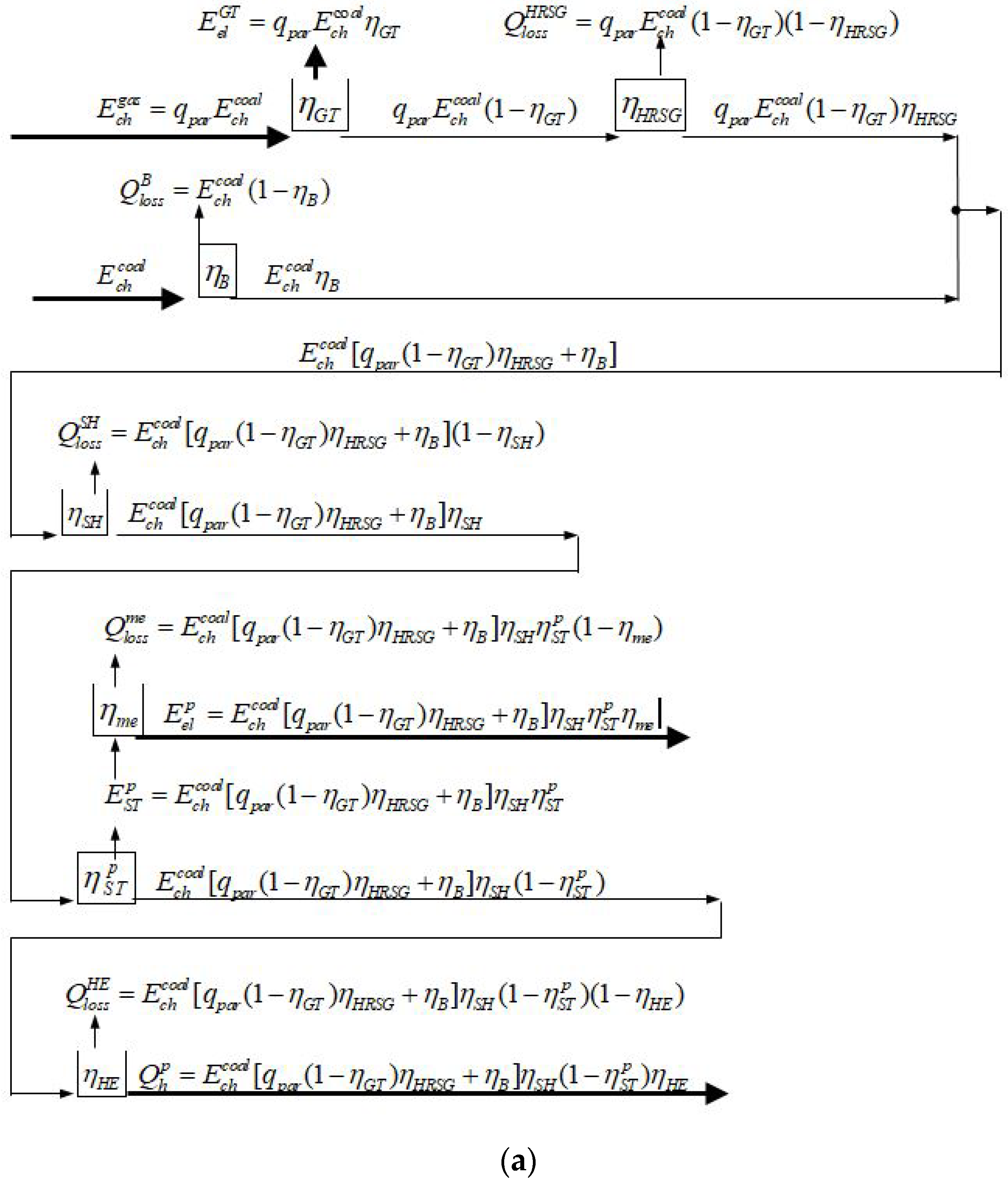

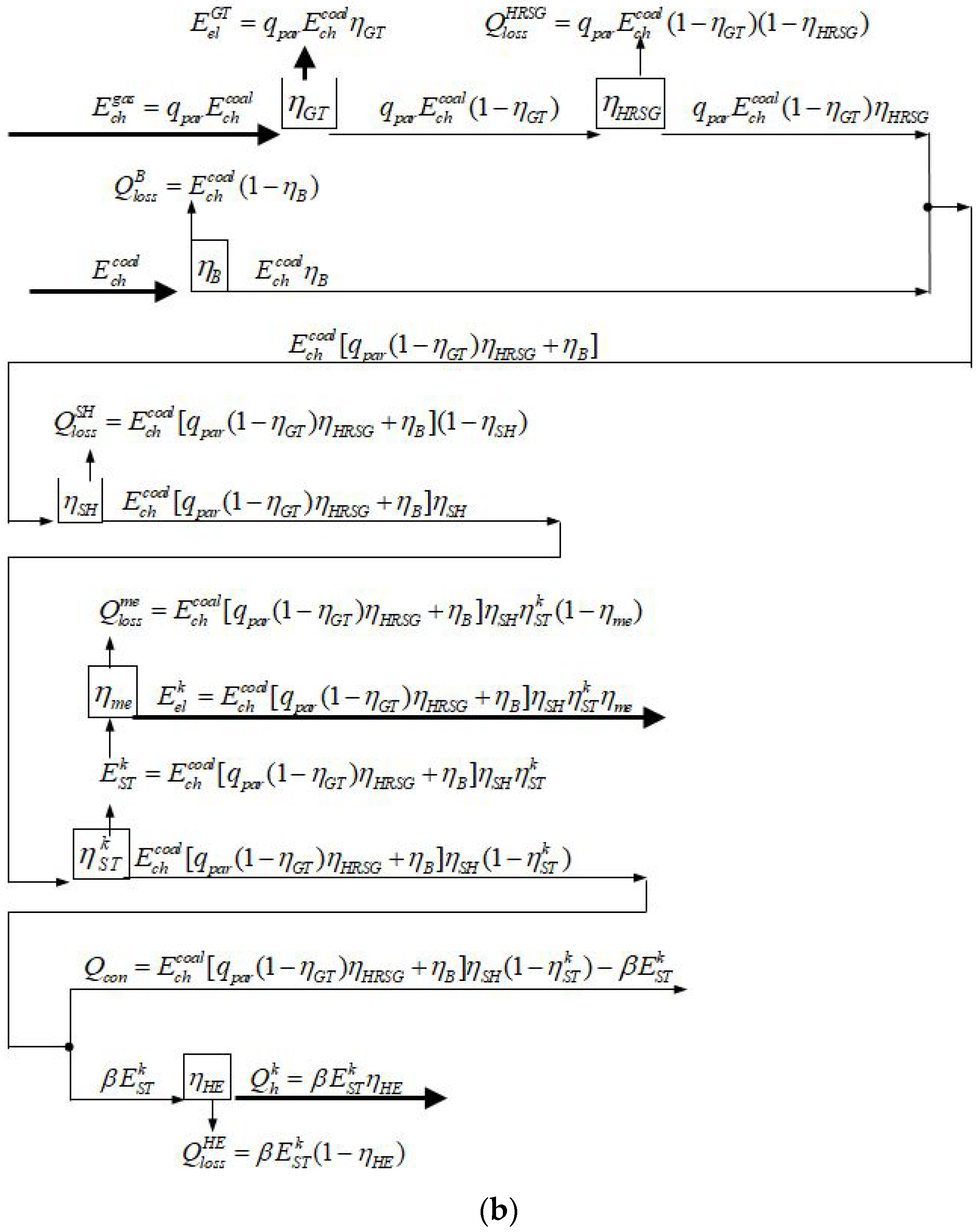

Rectangles in these balances with gross energy efficiencies corresponding to them represent individual devices in the combined heat and power plant to which energy is delivered and extracted. For example, for gas turbine with efficiency , the chemical energy of the gas is supplied, and the electricity and enthalpy of the exhaust gas are extracted out of it. This enthalpy is then routed to the recovery boiler with the efficiency of , etc.

3.1.1. Mathematical Models for the System of Extraction-Backpressure Turbine

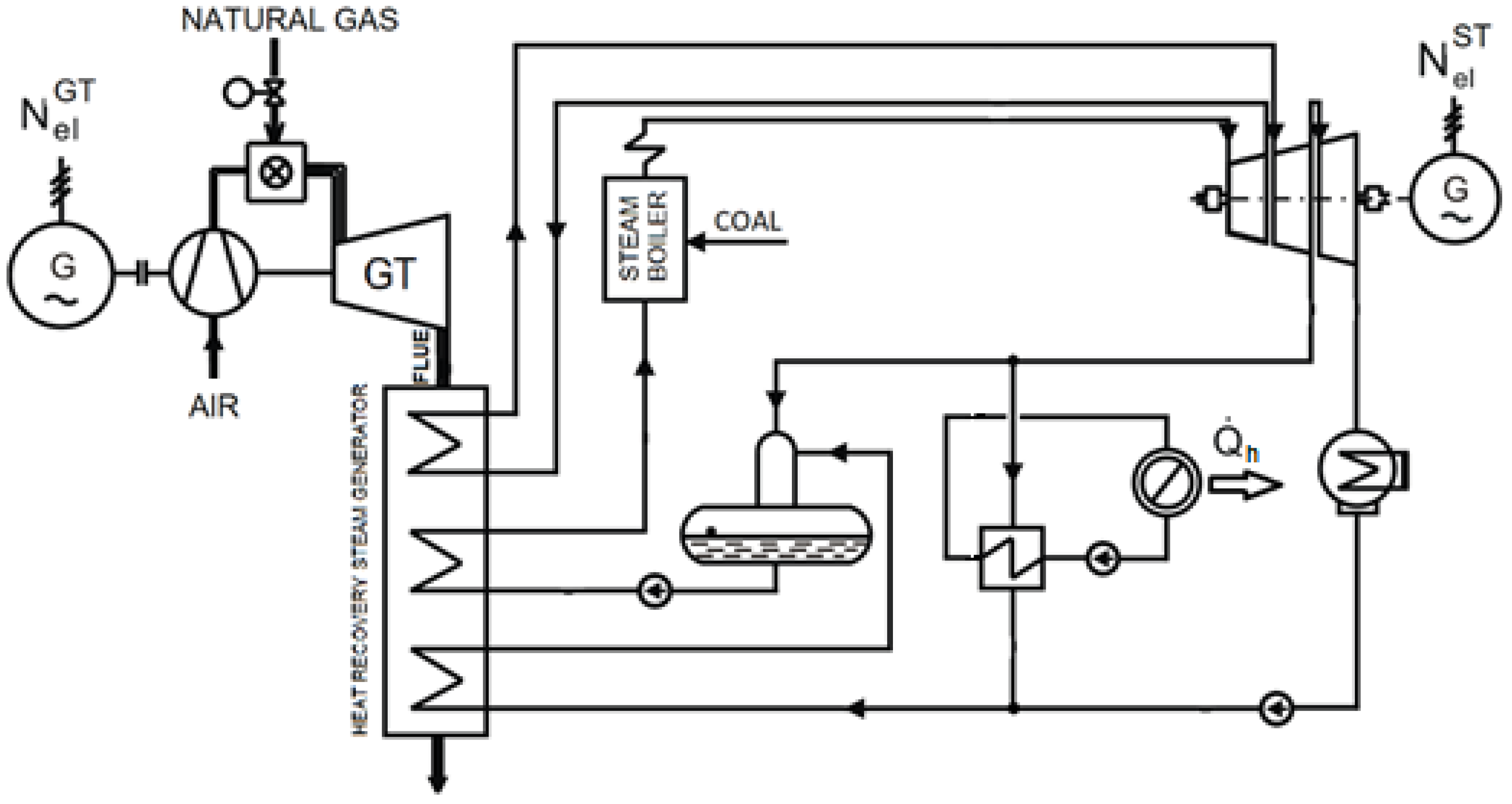

In a dual-fuel gas-steam combined heat and power plant in a parallel system with extraction backpressure steam turbine (

Figure 2a), the desired form of the specific average heat production cost, i.e., as a function of the searching value

, is given by:

where:

i—specific (per unit of power) investment outlay per CHP plant, , (its value depends on the associated technology used for generation of heat and electricity);

—annual time of using thermal maximum power (peak) heat and power plant ; .

This formula was obtained from Formula (19) after substituting the dependencies resulting from the energy balance presented in

Figure 2a:

When calculating from Formula (22) the derivative

is obtained:

and then from the necessary condition for the existence of an extreme

, the value of the extremist

cost

is determined:

As we can see from Formula (27), the value which forms the extreme of the cost does not exist. This is because this value in the Formula (27) does not occur (this situation can be changed by development of a relation which relates the specific investment “i” to the value of ) From Formula (27), however, it is possible to determine the boundary prices of gas and coal for a given electricity price, i.e., for the prices where the cost assumes a constant value, and therefore is independent of , since then the derivative fulfills the condition .

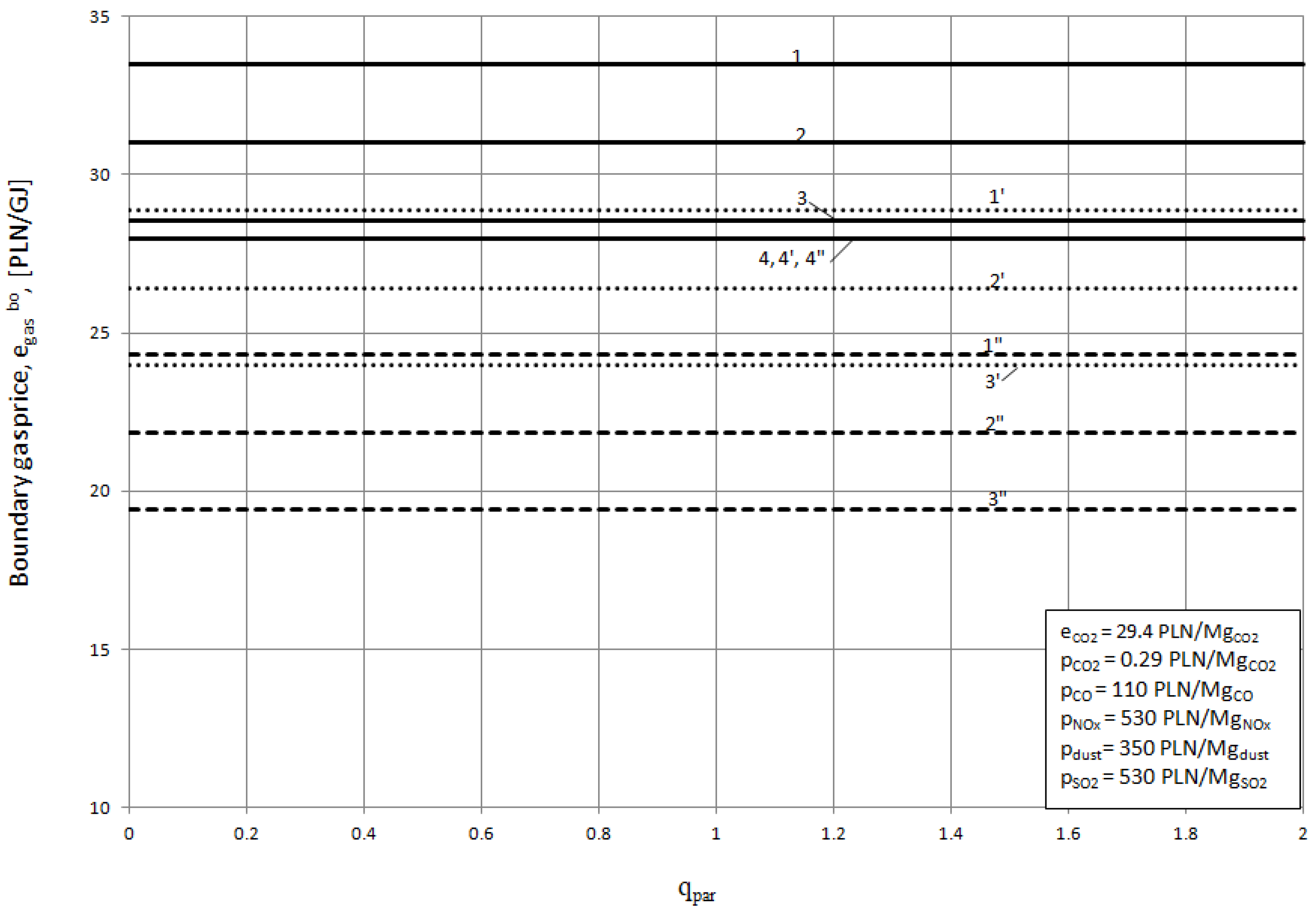

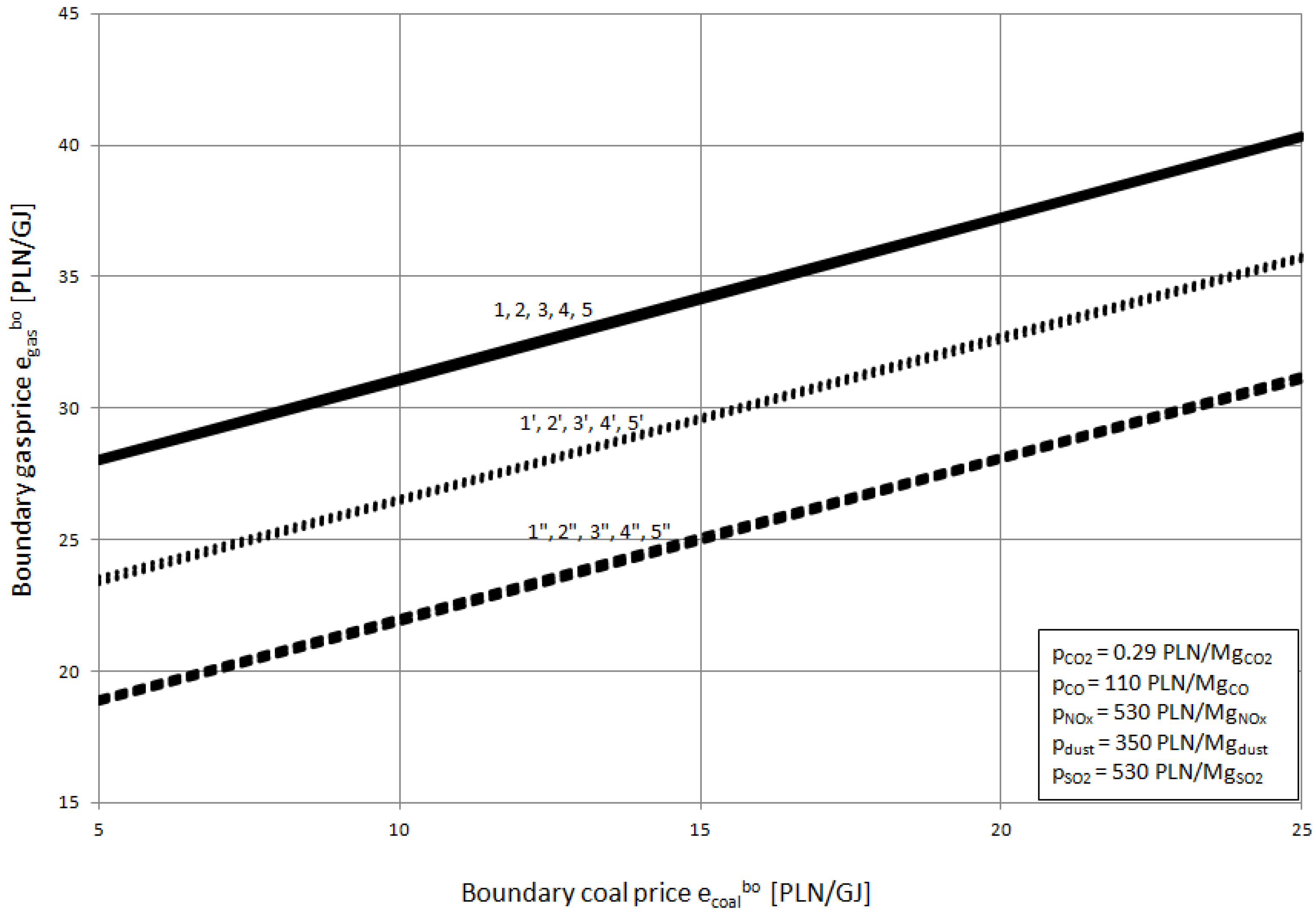

Thus, for a given price of coal and electricity derived from Formula (27), a boundary price of the gas can be set, and vice versa, the boundary price of coal is determined for a given prices of gas and electricity . Thus, the boundary prices of gas and coal are closely related (Figures 6 and 7) and substituted into the formula in (26), which leads to the value of zero obtained in this formula. On the other hand, if other values are inserted into Formula (26), for example current coal and gas prices (current coal and gas prices in Poland are equal to , ), which is different from boundary values, and the formula takes a positive or negative value.

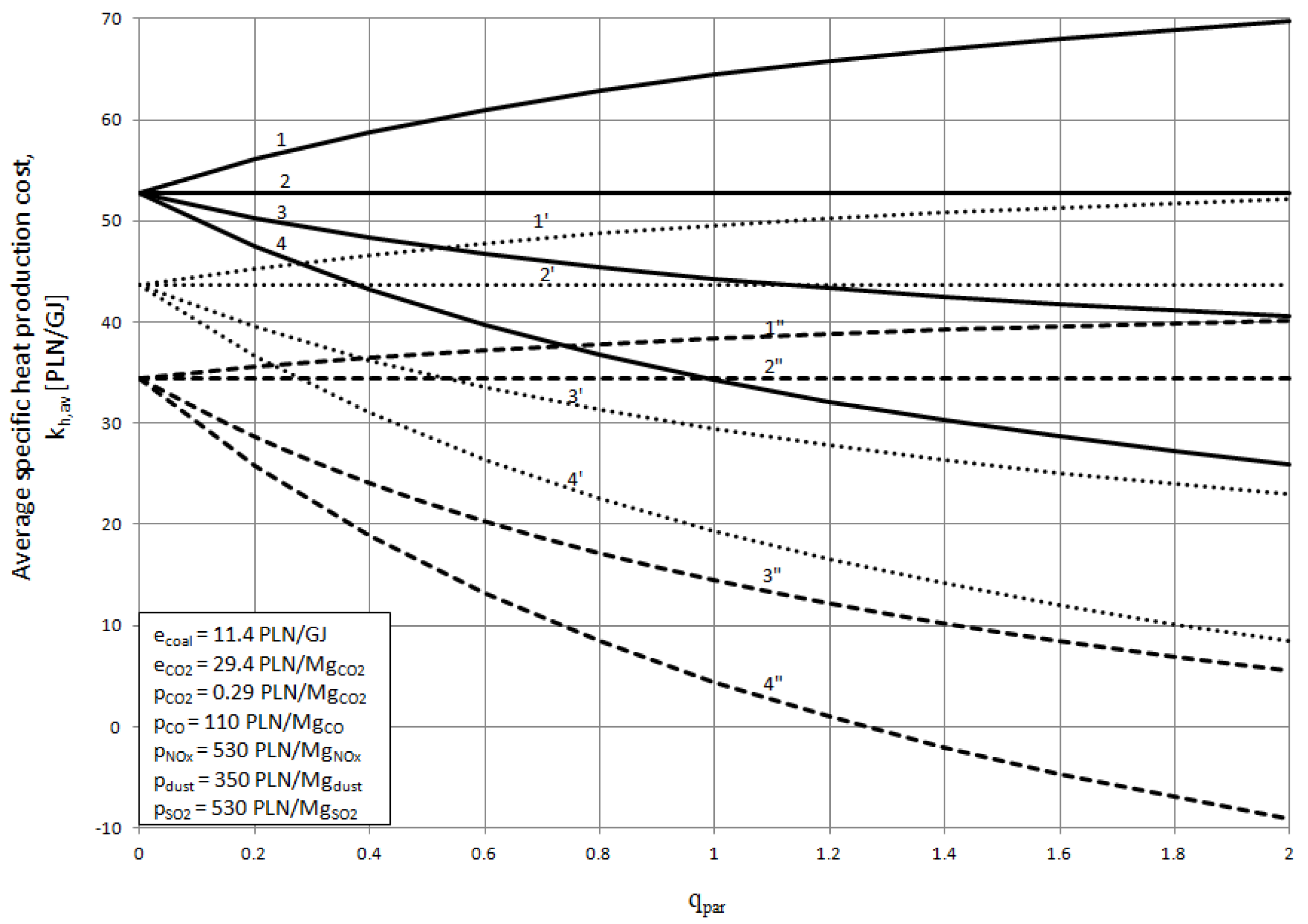

If the cost of gas in Formula (27) exceeds the costs associated with coal combustion, then and the cost increases along with a higher value of , and vice versa, when the cost associated with gas is lower than the cost associated with coal, and then the relation is met and the cost decreases along with the increase in the capacity of the gas turbine set. However, it should be noted that the relation is possible in two cases. Firstly, when the price of coal is higher than its boundary price (then the cost of heat production is the highest, Figures 4 and 9) and secondly, when the price of gas is lower than its boundary price (then the cost is the lowest, Figures 3 and 8).

Therefore, the necessary condition for the economic feasibility of an investment in a dual-fuel gas-steam CHP plant compared to a coal-fired CHP plant (i.e., , Figures 3 and 8), needs to involve not only an assumption that the relation is met, but also the gas price has to be lower than its boundary price determined from Formula (27) for the current coal and electricity prices.

The necessary condition for the profitability of the construction of dual-fuel CHP plants should, therefore, be finally expressed by means of the following relation:

The higher the prices of electricity and coal , the higher the boundary value , and thus the price of gas, for which the construction of dual-fuel gas-steam CHP plant will be feasible can be higher (Figures 6 and 7).

If the relationship is fulfilled, the gas turbine set with the maximum capacity forms the most profitable alternative, and the greatest value is then obtained (Formula (21)). Therefore, knowledge of the boundary price of coal and gas offers very important inputs for the analysis.

With the input of these values, we are able to answer the question whether a dual-fuel gas-steam combined heat and power plant is more economically feasible for the current gas and electricity and coal prices, as well as emission charges on harmful products emitted into the environment in connection with the power unit’s operation and the investment made in its construction, or whether it is more profitable to build a single coal-fired CHP plant.

We should also note that the higher the ratio of the price of electricity to the prices of fuels , (especially expensive gas ), the lower the specific cost of heat production (Formula (19)).

The revenue from the sale of electricity produced in the combined heat and power plant increases with the increase of , which takes on a minus sign as the avoided cost of heat production: (Formula (19)).

This revenue also increases along with higher electricity output, so the higher capacity of the gas turbine leads to higher value of . If this income is higher from the cost of heat production, then the specific cost takes on a negative value—Figure 8. Curve 4”—and therefore NPV profit (Formula (13)) that is obtained from the operation of combined heat and power plant is greater.

3.1.2. Mathematical Models of a System with Extraction-Condensing Turbine

In a dual-fuel gas-steam combined heat and power plant with an extraction-condensing steam turbine operating in a parallel system (

Figure 2b), the form of the average specific cost of heat production, i.e., as a function of the value

, is given by:

This formula was obtained from Formula (19) after substituting the dependencies resulting from the energy balance presented in

Figure 2b:

When we calculate the derivative of

from the formula in (29), the following relation is obtained:

and from this dependence for the necessary condition regarding the existence of the extreme

of the cost, i.e., resulting in zeroing the derivative

, and an identical formula is obtained as that in Formula (27). This comes as a consequence of adoption of a lack of a dependence between the specific investment “

i” and the variable

in the mathematical model. The boundary gas price in the case of its combustion in a combined heat and power plant—Figures 6 and 7—for given coal and electricity prices does not depend on the type of steam turbine installed in it, despite the fact that the specific cost

apparently is relative to it. This is because the specific investment is greater for a combined heat and power plant with an extraction-condensing steam turbine than for an extraction-backpressure steam turbine. This results from the necessity of incurring a cost associated with the steam condenser and the cooling tower in the system comprising an extraction-condensing turbine, whereas this cost does not occur in a system with an extraction-backpressure turbine.

In the calculations, it was assumed that specific investment in a combined heat and power plant with an extraction-condensing steam turbine is equal to

i = 4.6 million PLN/MW, whereas for a combined heat and power plant with extraction-backpressure turbine, this cost is equal to

i = 4 million PLN/MW. At the same time, in the present study it was assumed that the efficiency of the Clausius–Rankine cycle of the extraction-condensing steam turbine is

= 0.45, and the extraction-backpressure turbine it is equal to

= 0.4. The following input values were also adopted in the calculations:

b = 4 years,

β = 2,

= 0.35,

= 0.85,

= 0.9,

= 0.98,

= 0.98,

= 0.95,

= 0.04, δ

serv = 0.03,

r = 7%,

= 3000 h/a,

T = 20 years. All calculation results presented in the paper correspond to zero values of all exponents

,

,

,

,

,

,

,

,

. Thus, the prices of energy carriers and environmental fees are constant over the whole operation period

T of a combined heat and power plant, and they form integral mean values over the

T period. For example, the integral mean value of the electricity price varying in time according to the formula

is calculated according to the formula:

The value of the chemical energy share of fuel in its total annual consumption was also used for calculations, for which

CO2 emission allowances are not required,

u = 0, because from 2020 there will no longer be free emission allocations. This means that all installations will have to pay for each tonne of the carbon dioxide that is emitted. Formulas (22) and (29) can also be used to analyze the impact of technical and economic parameters on the specific cost of heat production. This analysis is most conveniently carried out using differential calculus [

26]. As demonstrated in [

26], this cost is most sensitive to fuel prices and relations between them. However, technical parameters as well as the efficiency of equipment, have a relatively small impact.