Influence of Temperature on the Microstructure Deterioration of Sandstone

Abstract

1. Introduction

2. Samples and Experiment Methods

2.1. Samples Preparation

- Step 1:

- Step 2:

- 30 min was set to maintain the temperature constant in order for the whole sample to achieve the default state after the target temperature was reached [30].

- Step 3:

2.2. Experiment Schemes

3. Results and Analysis

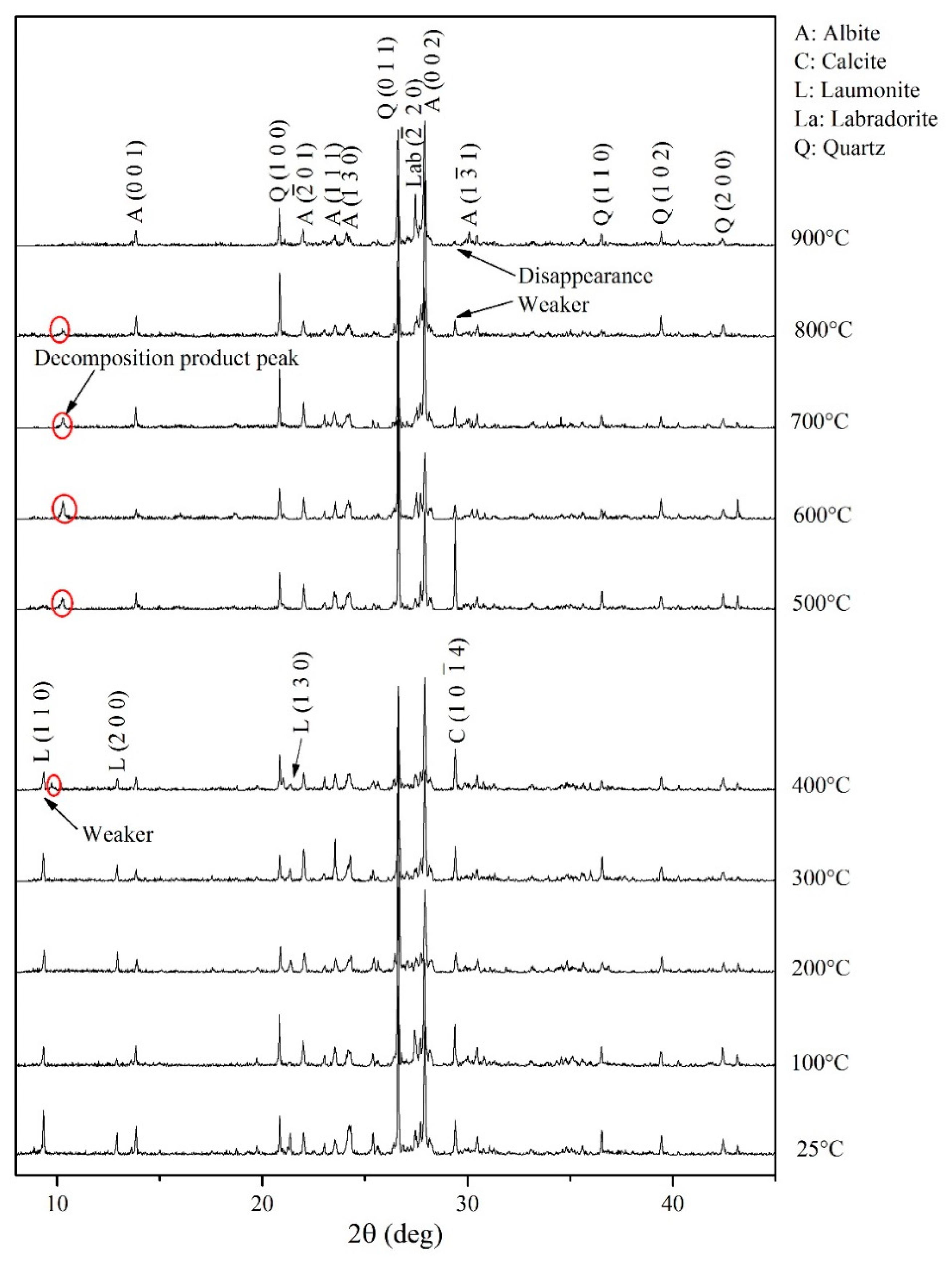

3.1. X-ray Diffraction (XRD) Pattern Results

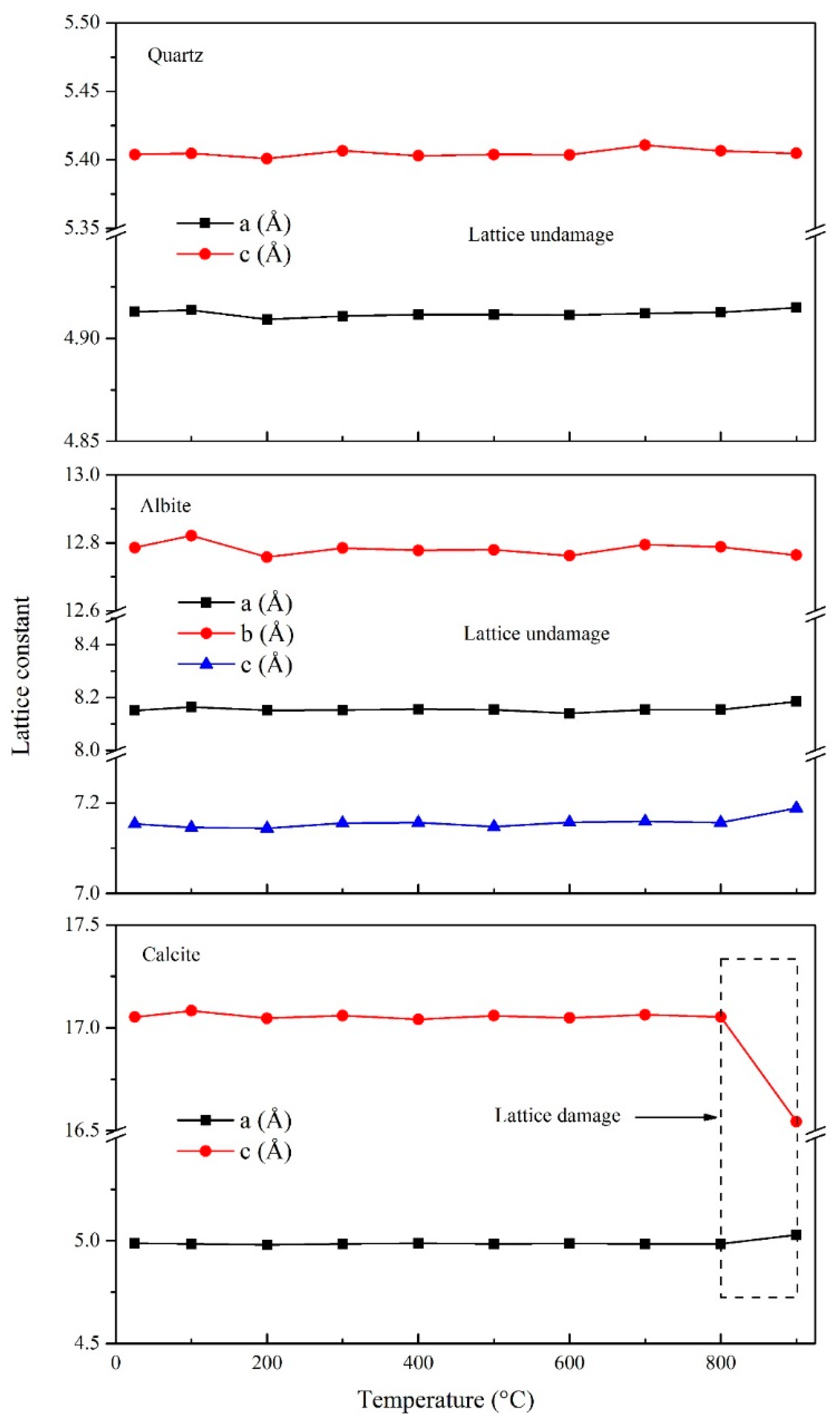

3.2. Lattice Constant Results

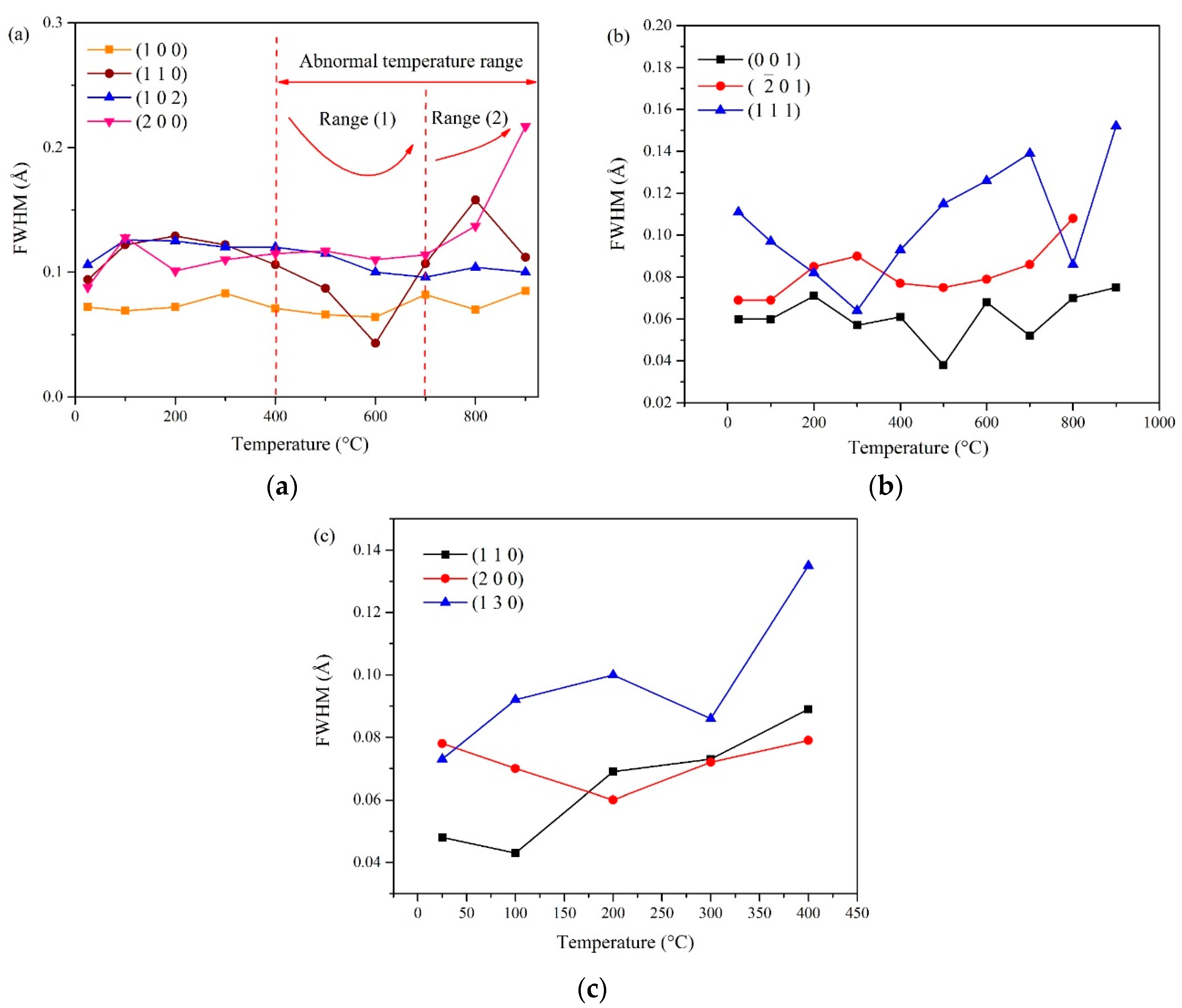

3.3. Diffraction Widening Results

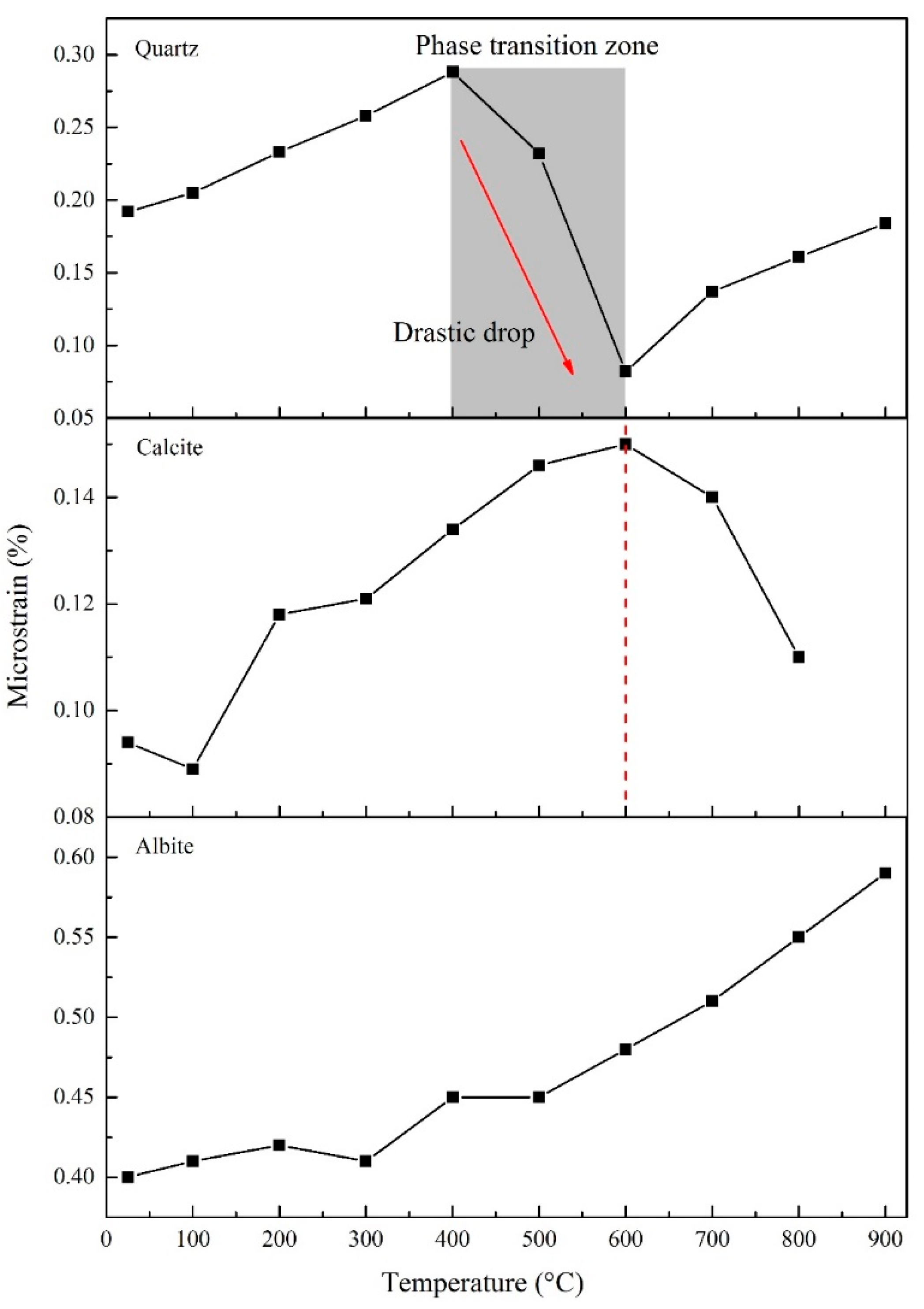

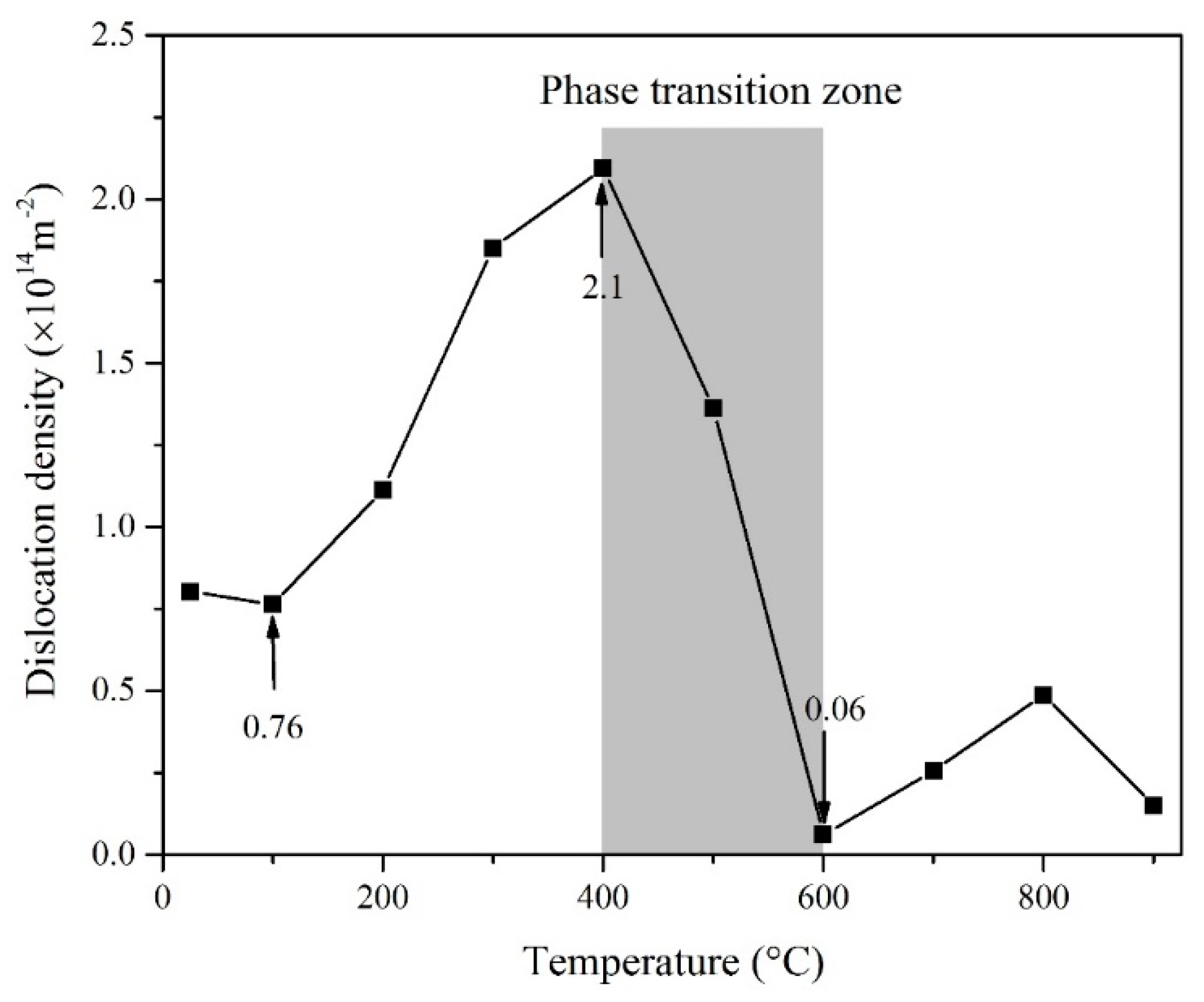

3.4. Dislocation Density Results

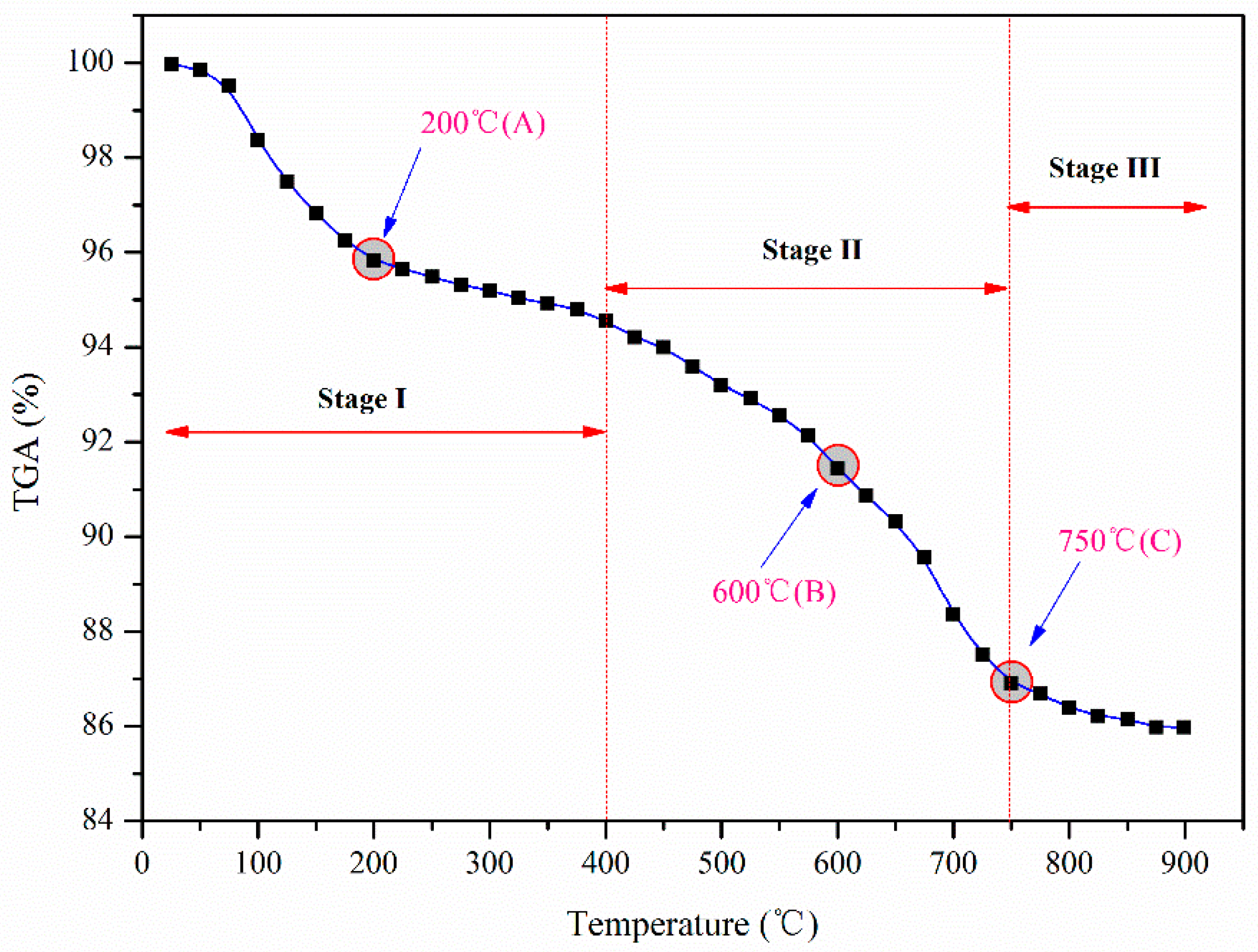

3.5. TGA Curve Analysis

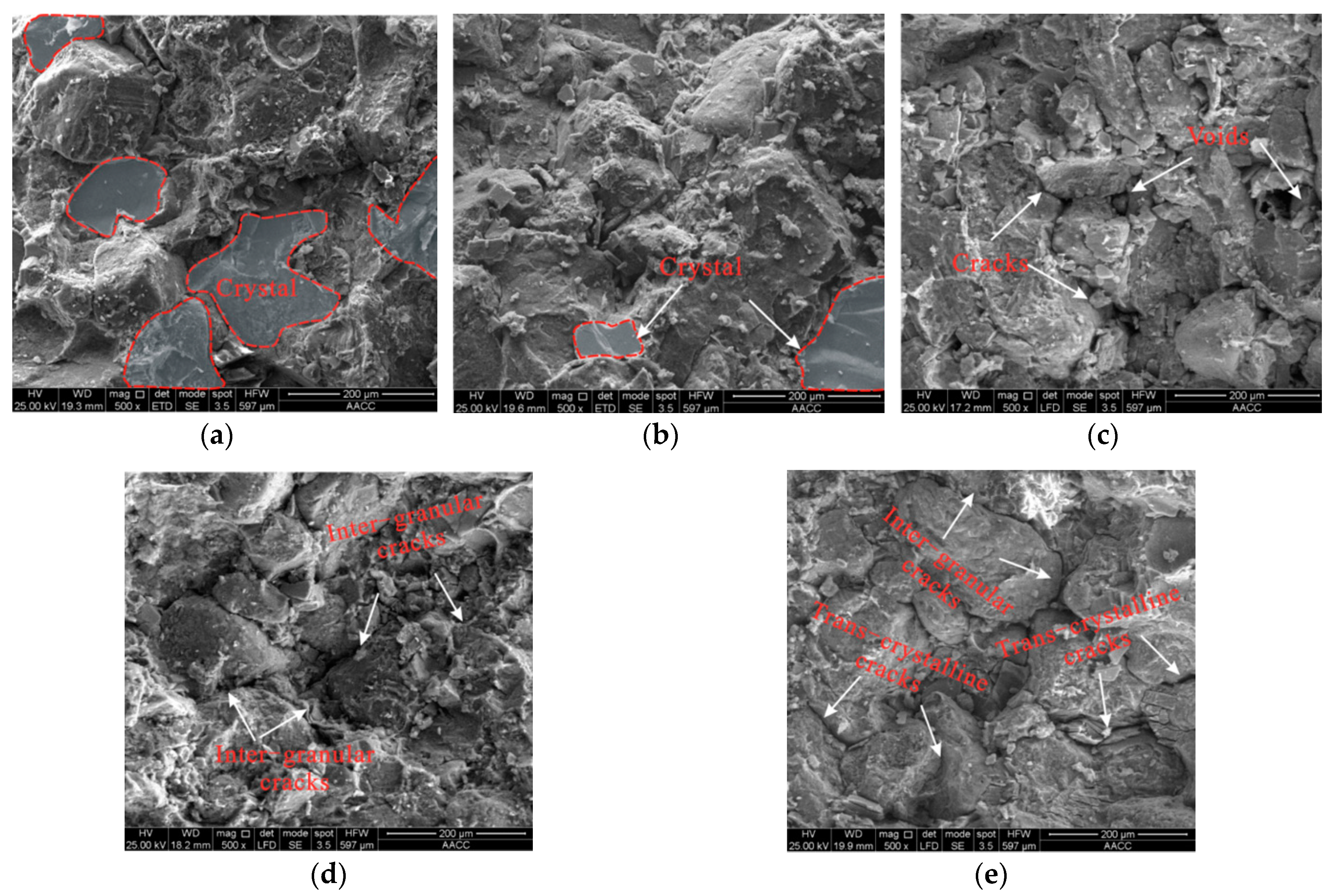

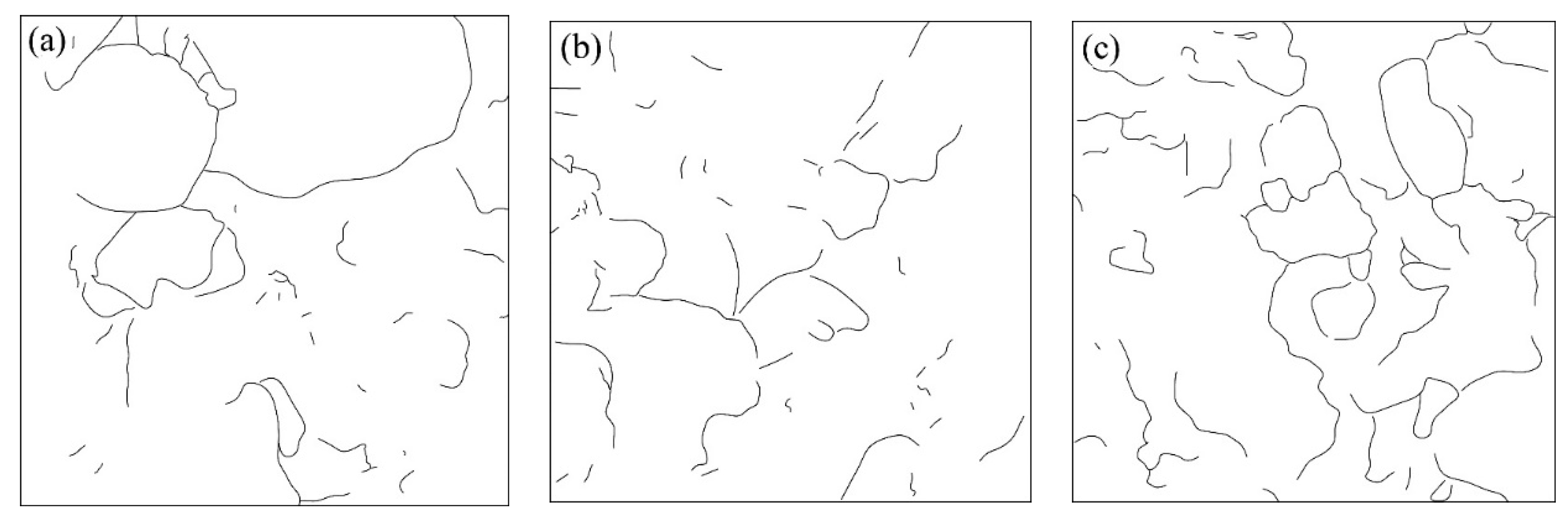

3.6. Temperature-Dependent Failure Characteristics

4. Discussion

- (1)

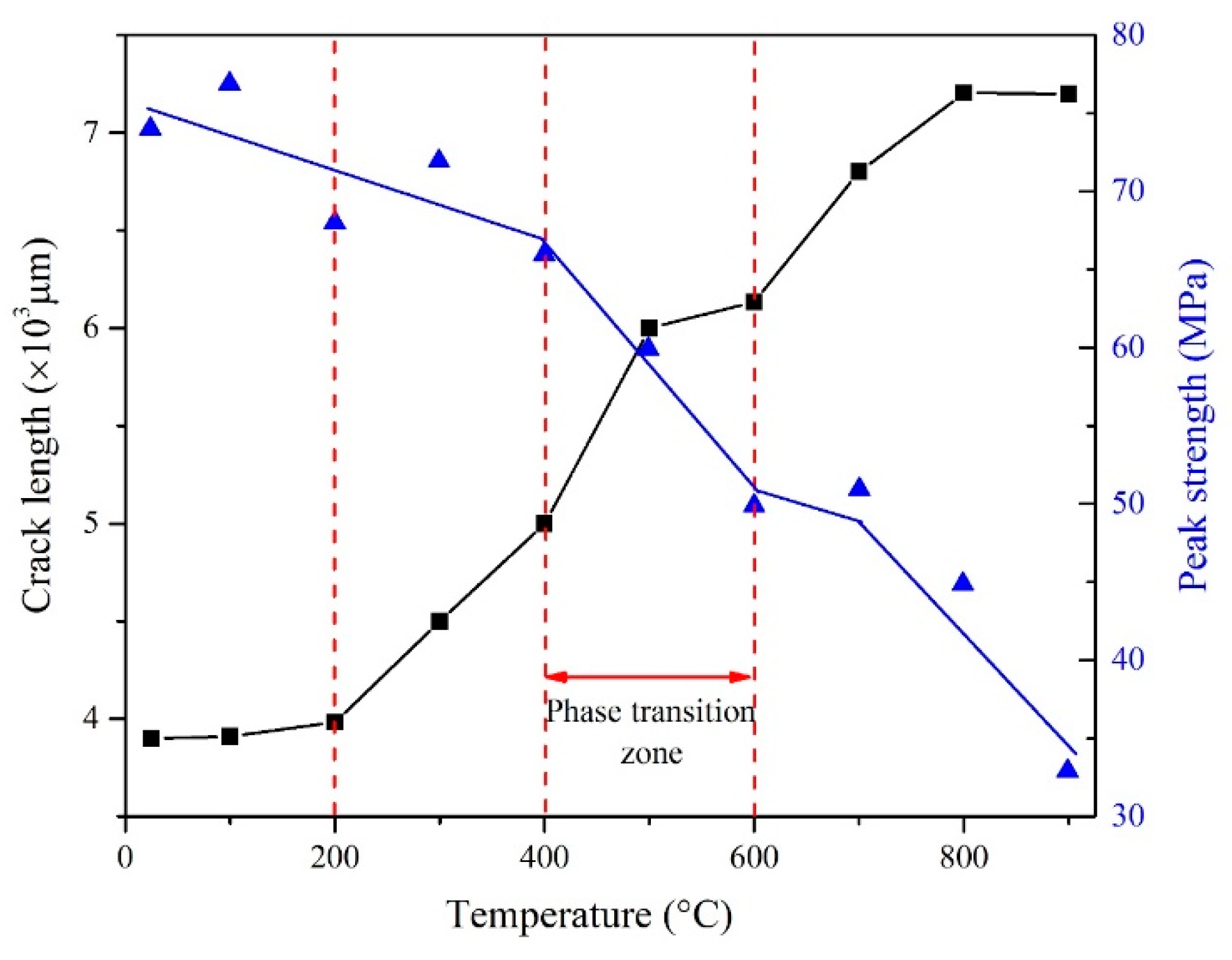

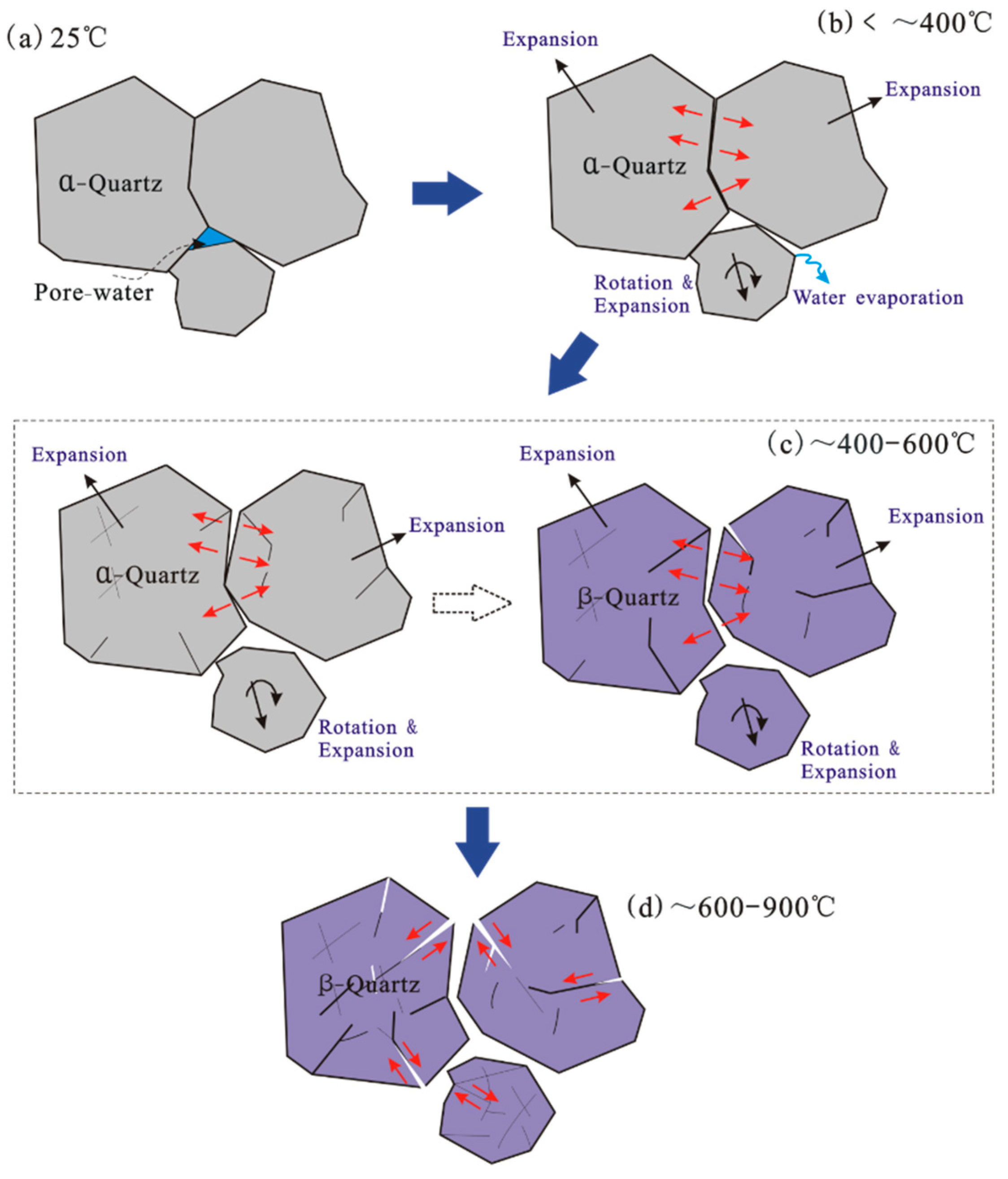

- Thermal stress. The mineral particles would undergo a volumetric expansion as the temperature rises [32,33]. Due to the volumetric change and anisotropic expansion or rotation characteristic of different minerals, the interface of particles would suffer thermal stress, which may cause a debonding failure when the stress exceeds the interface yield stress at certain temperature points. For the sandstone samples tested in this work, the threshold temperature can be regarded as 400 °C. We can observe the microstructure began to degenerate obviously at this temperature point no matter what parameters from XRD patterns, lattice constants, diffraction widening, microstrain, dislocation density, or even TGA curves and failure characteristics of SEM images are considered (Figure 1, Figure 2, Figure 3, Figure 4, Figure 5, Figure 6, Figure 7 and Figure 8). Meanwhile, Figure 9 also verifies the conclusion that the total length increase of cracks tends to be more remarkable when the temperature rises beyond the threshold 400 °C. Of course, during the early stage from 400 °C to 600 °C, the fractures can be classified as inter-granular splitting cracks. The influence of thermal stress in the periphery of crystals is well-explained by means of Griffith’s initial fracturing criterion [59]. Commonly, crack propagation deviates from the boundary of crystals, and then turns to the direction of the maximum of thermal stress rapidly, which causes the fracture surface to be rough for these Griffith’s cracks [60]. In addition, the evaporation process of free water, bounded water and structural water existing in the original defects (pores or voids) mainly occurs below the threshold temperature point 400 °C [61]. The water evaporation (seen in Figure 6), happened in the original defects, and provides enough deformation space and aggravates the thermal expansion of mineral particles to be persistent.

- (2)

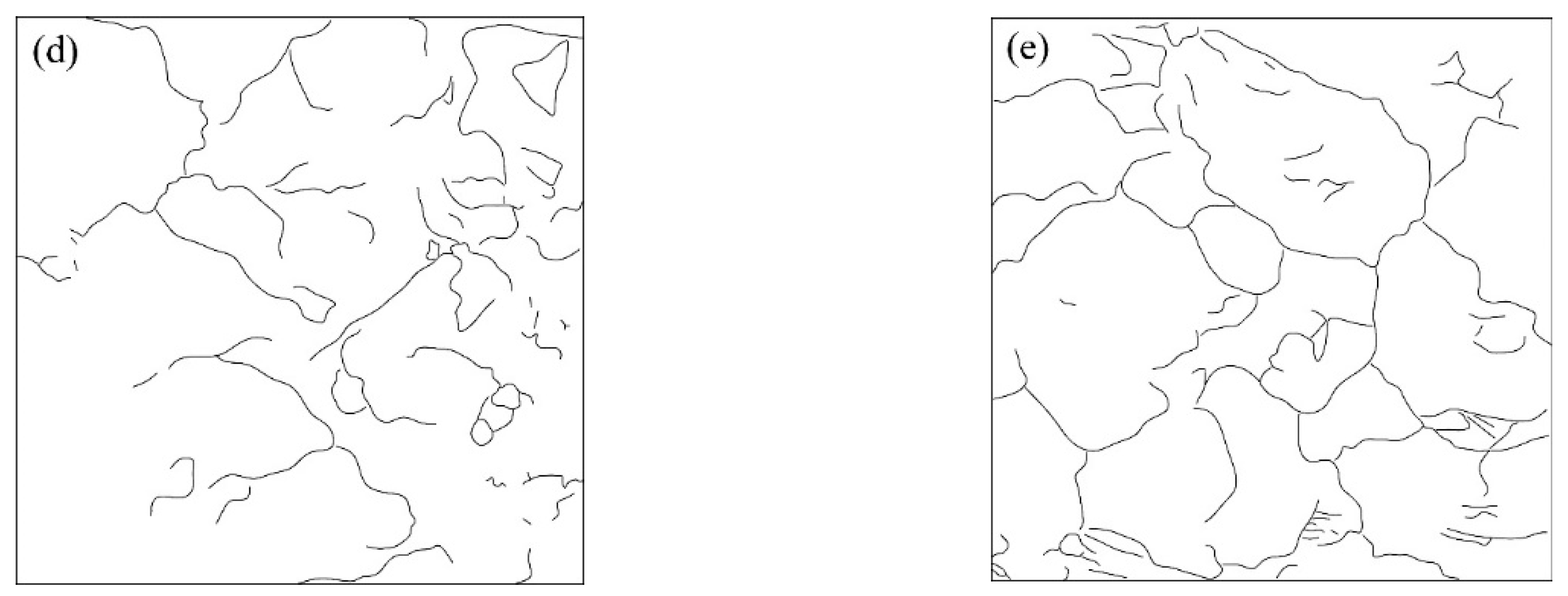

- Thermal fracturing of minerals. When the temperature exceeds the limit state of the internal thermal expansion stress for crystal fracture, mineral particles may suffer thermal fractures and this results in a stress redistribution, thus further causing the microstructure of crystals to be broken. According to Figure 7 and Figure 8, a significant increase is observed in both the number and the persistence of cracks after thermal treatment beyond 600 °C. Specially, more cracks break through the internal crystal structure and cause their sizes to decrease remarkably till the temperature rises up to 800 °C. The TGA curve changes also verify the conclusion that the Moss loss ratio is very large during the interval of 600 °C to 750 °C (Figure 6). These newly-produced cracks would destroy the original microfissure system located in the crystal, and cause the persistence of separate micro-cracks to increase, and then result in a more significant decomposition. Thus, the total number of transcrystalline cracks would be increasing faster as the temperature rises continuously. Besides, the shape of mineral crystals has an obvious influence on the thermal fracturing of minerals. Commonly, the maximum thermal stress is concentrated in the edges or corners of crystals, which leads to tip-cracks happening during the early stage [62]. For the same mineral particle under the same temperature conditions, the trans-crystalline cracks may happen sooner if the boundary of such a crystal seems to be more coarse. It can be observed in Figure 7d,e that the thermal fractures seemed to be more serious for the quartz crystals with more rough boundary surfaces. Similar viewpoints were also reported by some previous studies [62,63] where thermal fractures happened easier along the short axis direction of crystals, the dominant crystal orientation and singular interfaces of crystals.

- (3)

- Thermal reaction. Some physical and chemical reactions of mineral particles also happen during the thermal treatment process. The most significant reaction of sandstone is the shift of quartz, the foundational mineral of sandstone in this study, from α- to β-condition during the phase change period [57,64]. This would cause some microphysical parameters such as lattice constants, diffraction widening, microstrains, and dislocation density to change significantly during this period (Figure 1, Figure 2, Figure 3, Figure 4 and Figure 5), while also causing the microstructure to be more fragile and easier to fracture. The sharp breaking phenomenon of β-quartz is also observed according to the failure characteristics seen in the TGA curves and SEM images (Figure 6, Figure 7 and Figure 8). Meanwhile, in the high-temperatures range (>650 °C), β-quartz also presents a dominant slip and plastic softening appearance [65]. The characteristics of β-quartz makes many trans-crystalline cracks appear and causes the overall strength to fall quickly (Figure 9). The TGA curve change presents a sharpest decline at the range of 600 °C to 750 °C (Figure 6). Furthermore, some hard decomposed minerals such as calcite and albite would begin to compose and even melt under elevated temperature conditions beyond 600 °C. In addition, metallic bonds such as Al–O, Na–O, K–O, and Ca–O generally fracture when the temperature increases to 600 °C because of the influence of solid mineral expansion [61].

5. Conclusions

- (1)

- According to the XRD patterns and lattice constant results, the influence of temperature on mineral crystals mainly affected the change of lattice parameters and the reactions and decomposition of minerals. Commonly, the disappearance and deviation of XRD peaks was related with the decomposition of minerals.

- (2)

- According to our XRD analyses the diffraction widening and microstrain of sandstone present anisotropic characteristics due to the different sensitivity of minerals to temperature. Meanwhile, the phase transition of quartz from α- to β-form at about 573 °C is the core reason why the dislocation density decreases rapidly, which leads to the hardness and strength of sandstone decaying.

- (3)

- Three stages can be classified based on the changes of the TGA curves: (1) Stage I is from room temperature to 400 °C, which is strongly related with the pore-water evaporation and hydration reaction; (2) Stage II is at the range of 400 °C to 750 °C, where a sharp decline ratio of mass loss occurs due to thermal decomposition reactions of the minerals, especially quartz; (3) Stage III is the range of above 750 °C. The curve displays a slow decrease although the decomposition is still continuous.

- (4)

- According to the SEM images of sandstone and statistical results of crack lengths, the surfaces of minerals generally tended to be rough, and the number of surface cracks increased along with increasing temperature, especially above 400 °C. In addition, the cracks appearing in the period below 600 °C can be regarded as inter-granular fractures, which were attributed to thermal stress differences among minerals. Meanwhile, trans-crystalline cracks resulted from thermal deformation of crystal grains when the temperature exceeds 600 °C.

- (5)

- Three reasons can be summarized to explain the microstructure deterioration of sandstone during the heating process from 25 °C to 900 °C, that is, thermal stress, thermal fracturing of minerals, and thermal reactions. All of these reasons lead to these phenomena of mineral crystal thermal expansion and rotation, quartz phase transition and mineral particle decomposition in different temperature intervals.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Dhansay, T.; Navabpour, P.; Wit, M.D.; Ustaszewski, K. Assessing the reactivation potential of pre-existing fractures in the southern Karoo, South Africa: Evaluating the potential for sustainable exploration across its Critical Zone. J. Afr. Earth Sci. 2017, 134, 504–515. [Google Scholar] [CrossRef]

- He, M.C.; Guo, P.Y. Deep rock mass thermodynamic effect and temperature control measures. Chin. J. Rock Mech. Eng. 2013, 32, 2377–2393. [Google Scholar]

- Yang, S.Q.; Tian, W.L.; Ranjith, P.G. Failure Mechanical Behavior of Australian Strathbogie Granite at High Temperatures: Insights from Particle Flow Modeling. Energies 2017, 10, 756. [Google Scholar] [CrossRef]

- Yang, S.Q.; Ranjith, P.G.; Jing, H.W.; Tian, W.L.; Ju, Y. An experimental investigation on thermal damage and failure mechanical behavior of granite after exposure to different high temperature treatments. Geothermics 2017, 65, 180–197. [Google Scholar] [CrossRef]

- Shao, S.; Ranjith, P.G.; Wasantha, P.L.P.; Chen, B.K. Experimental and numerical studies on the mechanical behaviour of Australian Strathbogie granite at high temperatures: An application to geothermal energy. Geothermics 2015, 54, 96–108. [Google Scholar] [CrossRef]

- Lankford, J. Temperature-strain rate dependence of compressive strength and damage mechanisms in aluminium oxide. J. Mater. Sci. 1981, 16, 1567–1578. [Google Scholar] [CrossRef]

- Yavuz, H.; Demirdag, S.; Caran, S. Thermal effect on the physical properties of carbonate rocks. Int. J. Rock Mech. Min. 2010, 47, 94–103. [Google Scholar] [CrossRef]

- Brotóns, V.; Tomás, R.; Ivorra, S.; Alarcón, J.C. Temperature influence on the physical and mechanical properties of a porous rock: San Julian’s calcarenite. Eng. Geol. 2013, 167, 117–127. [Google Scholar] [CrossRef]

- Kong, B.; Wang, E.; Li, Z.; Wang, X.; Liu, X.; Li, N.; Yang, Y. Electromagnetic radiation characteristics and mechanical properties of deformed and fractured sandstone after high temperature treatment. Eng. Geol. 2016, 209, 82–92. [Google Scholar] [CrossRef]

- Lü, C.; Sun, Q.; Zhang, W.; Gen, J.; Qi, Y.; Lu, L. The effect of high temperature on tensile strength of sandstone. Appl. Therm. Eng. 2017, 111, 573–579. [Google Scholar] [CrossRef]

- Wang, Z.; Luan, W.; Huang, J.; Jiang, C. XRD investigation of microstructure strengthening mechanism of shot peening on laser hardened 17-4PH. Mater. Sci. Eng. A 2011, 528, 6417–6425. [Google Scholar] [CrossRef]

- Rosas-Casarez, C.A.; Arredondo-Rea, S.P.; Cruz-Enríquez, A.; Corral-Higuera, R.; Gómez-Soberón, J.M.; Medina-Serna, T.D.J. Influence of size reduction of fly ash particles by grinding on the chemical properties of geopolymers. Appl. Sci. 2018, 8, 365. [Google Scholar] [CrossRef]

- Zhang, W.; Qian, H.; Sun, Q.; Chen, Y. Experimental study of the effect of high temperature on primary wave velocity and microstructure of limestone. Environ. Earth Sci. 2015, 74, 5739–5748. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, Q.; Geng, J. Microstructural characterization of limestone exposed to heat with XRD, SEM and TG-DSC. Mater. Charact. 2017, 134, 285–295. [Google Scholar] [CrossRef]

- Holmboe, M.; Wold, S.; Jonsson, M. Porosity investigation of compacted bentonite using XRD profile modeling. J. Contam. Hydrol. 2012, 128, 19–32. [Google Scholar] [CrossRef] [PubMed]

- Vázquez, M.; Nieto, F.; Morata, D.; Droguett, D.; Carrillo-Rosua, F.J.; Morales, S. Evolution of clay mineral assemblages in the Tinguiririca geothermal field, Andean Cordillera of central Chile: An XRD and HRTEM-AEM study. J. Volcanol. Geotherm. Res. 2014, 282, 43–59. [Google Scholar] [CrossRef]

- Gibeaux, S.; Vázquez, P.; Kock, T.D.; Veerle, C.; Céline, T.-S. Weathering assessment under X-ray tomography of building stones exposed to acid atmospheres at current pollution rate. Constr. Build. Mater. 2018, 168, 187–198. [Google Scholar] [CrossRef]

- De, A.V.; Susini, J.; Salomé, M.; Beraldin, O.; Rigault, C.; Heymes, T. Submicrometer hyperspectral X-ray imaging of heterogeneous rocks and geomaterials: Applications at the Fe K-edge. Anal. Chem. 2012, 83, 4220–4227. [Google Scholar] [CrossRef]

- Li, H.; Li, H.; Gao, B.; Wang, W.; Liu, C. Study on pore characteristics and microstructure of sandstones with different grain sizes. J. Appl. Geophys. 2017, 136, 364–371. [Google Scholar] [CrossRef]

- Sun, H.; Sun, Q.; Deng, W.; Zhang, R.; Wang, Q. Temperature effect on microstructure and P-wave propagation in Linyi sandstone. Appl. Therm. Eng. 2017, 115, 913–922. [Google Scholar] [CrossRef]

- Shao, S.S.; Wasantha, P.L.P.; Ranjith, P.G.; Chen, B.K. Effect of cooling rate on the mechanical behavior of heated Strathbogie granite with different grain sizes. Int. J. Rock Mech. Min. 2014, 70, 381–387. [Google Scholar] [CrossRef]

- Badulla, L.A.I.; Ranjith, P.G.; Tharaka, D.R.; Mandadige, S.A.P.; Dornadula, C.; Wanniarachchige, G.P.K. An influence of thermally-induced micro-cracking under cooling treatments: Mechanical characteristics of Australian granite. Energies 2018, 11, 1338. [Google Scholar] [CrossRef]

- Kihara, K. Molecular dynamics interpretation of structural changes in quartz. Phys. Chem. Miner. 2001, 28, 365–376. [Google Scholar] [CrossRef]

- Arredondo Rea, S.P.; Corral Higuera, R.; Almaral Sánchez, J.L.; Gómez Soberón, J.M.V.; Portillo Pérez, A.D. Physico-Chemical Properties, Porosity and Microstructure of Sustainable Concretes. American Concrete Institute, 2012. Available online: https://upcommons.upc.edu/handle/2117/16924 (accessed on 12 May 2018).

- Aguilar-Penagos, A.; Gómez-Soberón, J.M.; Rojas-Valencia, M.N. Physicochemical, mineralogical and microscopic evaluation of sustainable bricks manufactured with construction wastes. Appl. Sci. 2017, 7, 1012. [Google Scholar] [CrossRef]

- El-Naas, M.H.; Zekri, A.Y. A novel plasma technique to stimulate tight carbonate rocks. Energy Source Part 2002, 24, 181–194. [Google Scholar] [CrossRef]

- Sanjurjo Sánchez, J.; Vidal Romaní, J.R.; Fernández Mosquera, D.; Alves, C.A. Study of origin and composition of coatings in a monument built with granitic rocks, by SEM, XRD, XRF and DTA-TGA. X-Ray Spectrom. 2010, 37, 346–354. [Google Scholar] [CrossRef]

- Sammaljärvi, J.; Rama, M.S.; Ikonen, J.; Muuri, E.; Hellmuth, K.H.; Siitari-Kauppi, M. Free radical polymerisation of methacrylates with thermal initiator in clay rock. Eng. Geol. 2016, 210, 70–83. [Google Scholar] [CrossRef]

- International Society for Rock Mechanics (ISRM). The ISRM Suggested Methods for Rock Characterization, Testing and Monitoring: 2007–2014; Ulusay, R., Ed.; Springer International Publishing: Berlin, Germany, 2015; pp. 35–44. [Google Scholar] [CrossRef]

- Sun, Q.; Geng, J.; Zhang, W.; Chao, L. Variation of wave velocity and thermal conductivity of concrete after high-temperature treatment. Environ. Earth Sci. 2017, 76, 88. [Google Scholar] [CrossRef]

- Sirdesai, N.N.; Mahanta, B.; Ranjith, P.G.; Singh, T.N. Effects of thermal treatment on physico-morphological properties of Indian fine-grained sandstone. Bull. Eng. Geol. Environ. 2017, 1–15. [Google Scholar] [CrossRef]

- Zhu, S.; Zhang, W.; Sun, Q.; Deng, S.; Geng, J.; Li, C. Thermally induced variation of primary wave velocity in granite from Yantai: Experimental and modeling results. Int. J. Therm. Sci. 2017, 114, 320–326. [Google Scholar] [CrossRef]

- Zhang, W.; Sun, Q.; Zhu, S.; Hao, S. The effect of thermal damage on the electrical resistivity of sandstone. J. Geophys. Eng. 2017, 14, 255–261. [Google Scholar] [CrossRef]

- Rahfeld, A.; Kleeberg, R.; Möckel, R.; Gutzmer, J. Quantitative mineralogical analysis of European Kupferschiefer ore. Miner. Eng. 2018, 115, 21–32. [Google Scholar] [CrossRef]

- Jozanikohan, G.; Sahabi, F.; Norouzi, G.H.; Memarian, H.; Moshiri, B. Quantitative analysis of the clay minerals in the Shurijeh reservoir formation using combined X-ray analytical techniques. Russ. Geol. Geophys. 2016, 57, 1048–1063. [Google Scholar] [CrossRef]

- Valverde, J.M.; Perejon, A.; Medina, S.; PerezMaqueda, L.A. Thermal decomposition of dolomite under CO2: Insights from TGA and in situ XRD analysis. Phys. Chem. Phys. 2015, 17, 30162–30176. [Google Scholar] [CrossRef] [PubMed]

- Rodriguez-Navarro, C.; Kudlacz, K.; Ruiz-Agudo, E. The mechanism of thermal decomposition of dolomite: New insights from 2D-XRD and TEM analyses. Am. Mineral. 2012, 97, 38–51. [Google Scholar] [CrossRef]

- Treacy, M.M.J.; Higgins, J.B.; Higgins, J.B. Laumontite. In Collection of Simulated XRD Powder Patterns for Zeolites, 5th ed.; Elsevier: Allentown, PA, USA, 2007; pp. 196–197. ISBN 978-0-444-53067-7. [Google Scholar]

- Fridriksson, T.; Bish, T.; Bird, D.L.; Dennis, K. Hydrogen-bonded water in laumontite: X-ray powder diffraction study of water site occupancy and structural changes in laumontite during room-temperature isothermal hydration/dehydration. Am. Mineral. 2003, 88, 277–287. [Google Scholar] [CrossRef]

- Ståhl, K.; Artioli, G.; Hanson, J.C. The dehydration process in the Zeolite laumontite: A real-time synchrotron X-ray powder diffraction study. Phys. Chem. Miner. 1996, 23, 328–336. [Google Scholar] [CrossRef]

- Valcke, S.L.A.; Casey, M.; Lloyd, G.E.; Kendall, J.M.; Fisher, Q.J. Lattice preferred orientation and seismic anisotropy in sedimentary rocks. Geophys. J. R. Astron. Soc. 2010, 166, 652–666. [Google Scholar] [CrossRef]

- Breivik, M.; Nilsen, T.A.; Fimland, B.O. Temperature dependent lattice constant of InSb above room temperature. J. Cryst. Growth 2013, 381, 165–168. [Google Scholar] [CrossRef]

- Taylor, J.C.; Pecover, S.R. Quantitative analysis of phases in zeolite bearing rocks from full X-ray diffraction profiles. Aust. J. Phys. 1988, 41, 323–336. [Google Scholar] [CrossRef]

- Branlund, J.M.; Hofmeister, A.M. Effects of hydrogen impurities on the lattice thermal diffusivity of quartz and quartzites up to 1000 °C. In AGU Fall Meeting Abstracts; American Geophysical Union: Washington, DC, USA, 2004; Volume 12. [Google Scholar]

- Gualtieri, A.F.; Zanni, M. Quantitative determination of crystalline and amorphous phase in traditional ceramics by combined Rietveld–RIR method. Mater. Sci. Forum 1998, 278–281, 834–839. [Google Scholar] [CrossRef]

- Gualtieri, A.F. Accuracy of XRPD QPA using the combined Rietveld–RIR method. J. Appl. Crystallogr. 2000, 33, 267–278. [Google Scholar] [CrossRef]

- Shim, S.H.; Kim, S.J.; Ahn, J.H. Quantitative analysis of alkali feldspar minerals using rietveld refinement of X-ray diffraction data. Am. Mineral. 1996, 81, 1133–1140. [Google Scholar] [CrossRef]

- Langford, J.I. A rapid method for analysing the breadths of diffraction and spectral lines using the Voigt function. J. Appl. Crystallogr. 1978, 11, 10–14. [Google Scholar] [CrossRef]

- Guo, L.; Huang, M.; Zhang, X. Effects of sintering temperature on structure of hydroxyapatite studied with rietveld method. J. Mater. Sci. Mater. Med. 2003, 14, 817–822. [Google Scholar] [CrossRef] [PubMed]

- Barbish, A.B.; Gardner, G.H.F. The effect of heat on some mechanical properties of igneous rocks. Soc. Pet. Eng. J. 1969, 9, 395–402. [Google Scholar] [CrossRef]

- Kern, H. The effect of high temperature and high confining pressure on compressional wave velocities in quartz bearing and quartz free igneous and metamorphic rocks. Tectonophysics 1978, 44, 185–203. [Google Scholar] [CrossRef]

- Homand-Etienne, F.; Houpert, R. Thermally induced microcracking in granite: Characterization and analysis. Int. J. Mech. Min. Sci. Geomech. Abstr. 1989, 26, 125–134. [Google Scholar] [CrossRef]

- David, C.; Menendez, B.; Darot, M. Influence of stress-induced and thermal cracking on physical properties and microstructures of La Peyratte granite. Int. J. Rock Mech. Min. 1999, 36, 433–488. [Google Scholar] [CrossRef]

- Williamson, G.K.; Smallman, R.E. III. Dislocation densities in some annealed and cold-worked metals from measurements on the X-ray debye-scherrer spectrum. Philos. Mag. 1956, 1, 34–46. [Google Scholar] [CrossRef]

- Dong, J.; Wang, L.; Zhang, T. Study on the strength development, hydration process and carbonation process of NaOH-activated Pisha Sandstone. Constr. Build. Mater. 2014, 66, 154–162. [Google Scholar] [CrossRef]

- Sun, Q.; Lü, C.; Cao, L.; Li, W.; Geng, J.; Zhang, W. Thermal properties of sandstone after treatment at high temperature. Int. J. Rock Mech. Min. 2016, 85, 60–66. [Google Scholar] [CrossRef]

- Mackenzie, R.C.; Berg, L.G.; Berggren, G. Differential Thermal Analysis Vol. 2: Application; Academic Press: London, UK, 1972; pp. 135–142. ISBN 0124644023. [Google Scholar]

- Jiao, K.; Yao, S.; Liu, C.; Gao, Y.Q.; Wu, H.; Li, M.C.; Tang, Z.Y. The characterization and quantitative analysis of nanopores in unconventional gas reservoirs utilizing FESEM–FIB and image processing: An example from the lower Silurian Longmaxi shale, Upper Yangtze region, China. Int. J. Coal Geol. 2014, 128–129, 1–11. [Google Scholar] [CrossRef]

- Griffith, A.A. The Phenomena of Rupture and Flow in Solids. Philos. Trans. R. Soc. Lond. 1921, 221, 163–198. [Google Scholar] [CrossRef]

- Han, L.; He, Y.; Zhang, H. Study of rock splitting failure based on Griffith strength theory. Int. J. Rock Mech. Min. 2016, 83, 116–121. [Google Scholar] [CrossRef]

- Shen, Y.; Yang, Y.; Yang, G.; Hou, X.; Ye, W.; You, Z.; Xi, J. Damage characteristics and thermo-physical properties changes of limestone and sandstone during thermal treatment from −30 °C to 1000 °C. Heat Mass Transf. 2018, 5, 1–19. [Google Scholar] [CrossRef]

- Xu, X. Research on the Mechanical Characteristics and Micro-Mechanism of Granite under Temperature Loads. Ph.D. Thesis, China University of Mining and Technology, Xuzhou, China, 2008. [Google Scholar]

- Chen, Y.L.; Wang, S.R.; Ni, J.; Rafig, A.; Tomás, M.F. An experimental study of the mechanical properties of granite after high temperature exposure based on mineral characteristics. Eng. Geol. 2017, 220, 234–242. [Google Scholar] [CrossRef]

- Seipold, U. Temperature dependence of thermal transport properties of crystalline rocks—A general law. Tectonophysics 1998, 291, 161–171. [Google Scholar] [CrossRef]

- Mainprice, D.; Bouchez, J.L.; Blumenfeld, P.; Tubià, J.M. Dominant c slip in naturally deformed quartz: Implications for dramatic plastic softening at high temperature. Geology 1986, 14, 819–822. [Google Scholar] [CrossRef]

| Version | Voltage and Current | Anode | Radius of Measuring Instrument | DS | SS |

| D8 Advance | 40 kV, 30 mA | Cu | 250 mm | 0.6 mm | 8 mm |

| Filter | Detector Opening | Primary and Secondary Soller Slit | Scanning Speed | Sampling Interval | |

| Ni | 2.82° | 2.5° | 0.2 s/step | 0.01945° |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, Y.-J.; Zhang, Y.-L.; Gao, F.; Yang, G.-S.; Lai, X.-P. Influence of Temperature on the Microstructure Deterioration of Sandstone. Energies 2018, 11, 1753. https://doi.org/10.3390/en11071753

Shen Y-J, Zhang Y-L, Gao F, Yang G-S, Lai X-P. Influence of Temperature on the Microstructure Deterioration of Sandstone. Energies. 2018; 11(7):1753. https://doi.org/10.3390/en11071753

Chicago/Turabian StyleShen, Yan-Jun, Yu-Liang Zhang, Feng Gao, Geng-She Yang, and Xing-Ping Lai. 2018. "Influence of Temperature on the Microstructure Deterioration of Sandstone" Energies 11, no. 7: 1753. https://doi.org/10.3390/en11071753

APA StyleShen, Y.-J., Zhang, Y.-L., Gao, F., Yang, G.-S., & Lai, X.-P. (2018). Influence of Temperature on the Microstructure Deterioration of Sandstone. Energies, 11(7), 1753. https://doi.org/10.3390/en11071753