A New Concept of Applying Methanol to Dry Cellulose Insulation at the Stage of Manufacturing a Transformer

Abstract

1. Introduction

2. Drying Methods of Transformer Insulation

- Placing the insulation system in a vacuum dryer—conventional method

- Heat of solvent evaporation—vapor phase drying method

- Direct or low frequency current flow through the windings—LFH method (low-frequency heating)

3. Drying of Cellulose Materials by Means of Methanol

3.1. The Application of Methanol for the Extraction of Water from Fibrous Material—Previous Experience

3.2. The Influence of Water Concentration in Methanol on the Effectiveness of Cellulose Insulation Drying

3.2.1. Measurement Procedure

- Filling the spectrophotometer cuvette with methanol of mass (Mm) and water concentration (Cpi) measured by means of the Karl Fischer Titration (KFT) method

- Measurement of absorbance (Absi) for methanol at water concentration (Cpi)

- Inserting a paper sample of mass (Mp) into a cuvette filled with methanol

- Measurement of absorbance (Abst) after time t

- Mixing methanol in the cuvette for 30 s

- Repeating steps (4) and (5) every four minutes until the absorbance value (Absf) is steady

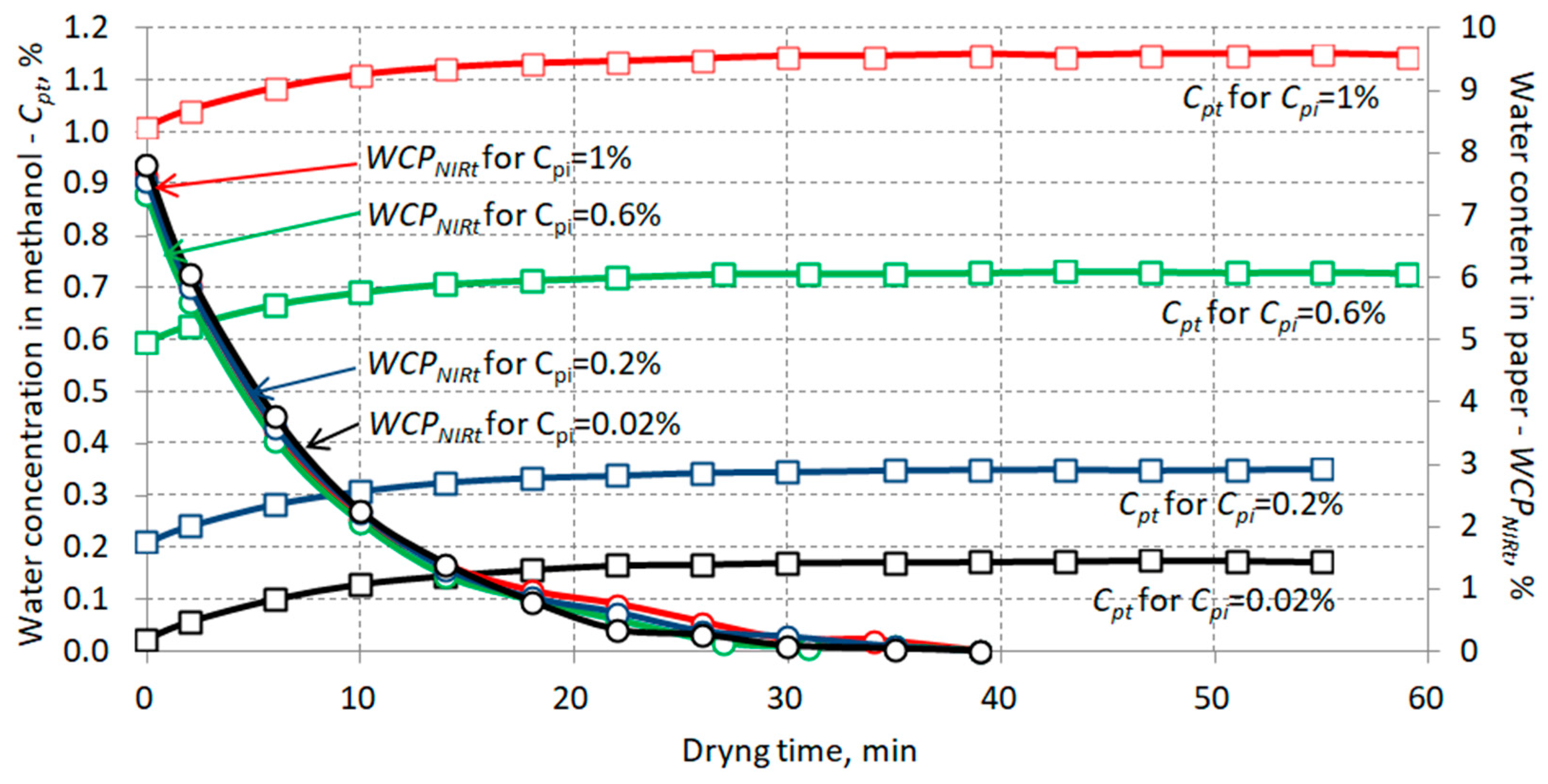

3.2.2. Research Results and Discussion

3.3. The Influence of Water Concentration in Methanol on the Effectiveness of Cellulose Insulation Drying

3.3.1. Measurement Procedure

3.3.2. Research Results and Discussion

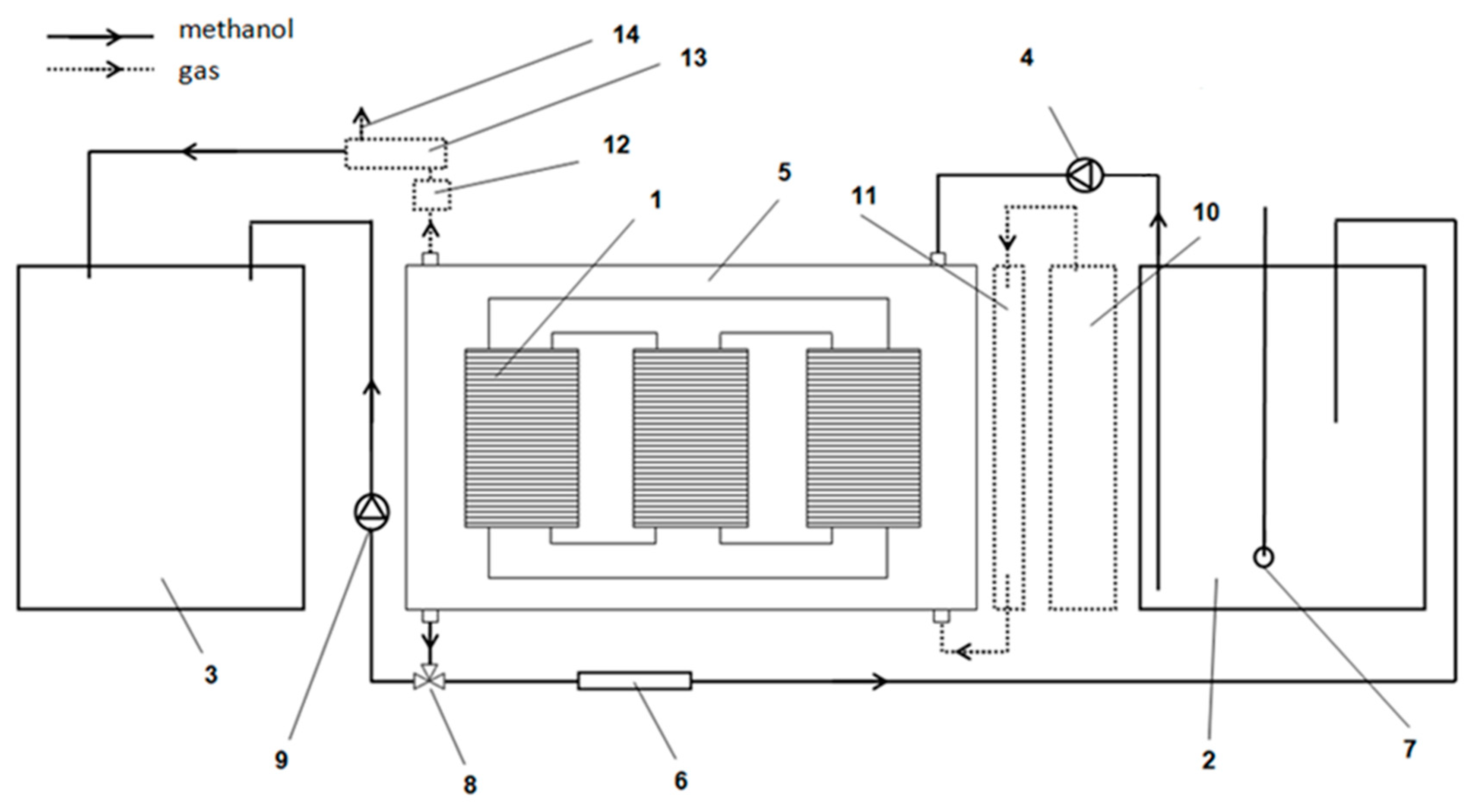

4. The Concept of a System for Drying Transformer Cellulose Insulation by Means of Methanol

5. Conclusions

- Maintaining the initial level of degree of cellulose polymerization after the drying process

- The possibility of complete and uniform drying of the whole of cellulose insulation

- Washing out post-production impurities from the insulation system

- No need to apply a vacuum

- Simplicity of the drying process

- Short drying time

Funding

Conflicts of Interest

References

- Godina, R.; Rodrigues, M.G.; Matias, J.C.O.; Catalao, P.S. Effect of Loads and Other Key Factors on Oil-Transformer Ageing: Sustainability Benefits and Challenges. Energies 2015, 8, 12147–12186. [Google Scholar] [CrossRef]

- Cheng, L.; Yu, T. Dissolved Gas Analysis Principle-Based Intelligent Approaches to Fault Diagnosis and Decision Making for Large Oil-Immersed Power Transformers: A Survey. Energies 2018, 11, 913. [Google Scholar] [CrossRef]

- Peng, L.; Fu, Q.; Zhao, Y.; Qian, Y.; Chen, T.; Fan, S. A Non-Destructive Optical Method for the DP Measurement of Paper Insulation Based on the Free Fibres in Transformer Oil. Energies 2018, 11, 716. [Google Scholar] [CrossRef]

- Wang, X.; Tang, C.; Huang, B.; Hao, J.; Chen, G. Review of Research Progress on the Electrical Properties and Modification of Mineral Insulating Oils Used in Power Transformers. Energies 2018, 11, 487. [Google Scholar] [CrossRef]

- Prevost, T.A.; Oommen, T.V. Cellulose Insulation in Oil-filled Power Transformers: Part I—History and Development. IEEE Electr. Insul. Mag. 2006, 22, 28–35. [Google Scholar] [CrossRef]

- Du, Y.; Zahn, M.; Lesieutre, B.C.; Mamishev, A.V.; Lindgren, S.R. Moisture Equilibrium in Transformer Paper-oil Systems. IEEE Electr. Insul. Mag. 1999, 15, 11–20. [Google Scholar] [CrossRef]

- N’cho, J.S.; Fofana, I.; Hadjadj, Y.; Beroual, A. Review of Physicochemical-based Diagnostic Techniques for Assessing Insulation Condition in Aged Transformers. Energies 2016, 9, 367. [Google Scholar] [CrossRef]

- Moisture Equilibrium and Moisture Migration within Transformer Insulation Systems; Cigré Technical Brochure 349; International Council on Large Electric Systems (CIGRE): Paris, France, 2008.

- Gielniak, J.; Graczkowski, A.; Moranda, H.; Przybylek, P.; Walczak, K.; Nadolny, Z.; Moscicka-Grzesiak, H.; Feser, K.; Gubanski, S.M. Moisture in Cellulose Insulation of Power Transformers-Statistics. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 982–987. [Google Scholar] [CrossRef]

- Shroff, D.H.; Stannett, A.W. A Review of Paper Aging in Power Transformers. IEE Proc. C Gener. Transm. Distr. 1985, 132, 312–319. [Google Scholar] [CrossRef]

- Ageing of Cellulose in Mineral-Oil Insulated Transformers; Cigré Technical Brochure 323; International Council on Large Electric Systems (CIGRE): Paris, France, 2007.

- Przybylek, P.; Moscicka-Grzesiak, H. The Influence of Water Content and Ageing Degree of Paper Insulation on its Mechanical Strength. In Proceedings of the IEEE International Conference on Solid Dielectrics (ICSD), Potsdam, Germany, 4–9 July 2010; pp. 92–94. [Google Scholar] [CrossRef]

- Buerschaper, B.; Kleboth-Lugova, O.; Leibfried, T. The Electrical Strength of Transformer Oil in a Transformerboard-oil System during Moisture Non-equilibrium. In Proceedings of the Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Albuquerque, NM, USA, 19–21 October 2003; pp. 269–272. [Google Scholar] [CrossRef]

- Sokolov, V.; Berler, Z.; Rashkes, V. Effective Methods of Assessment of Insulation System Conditions in Power Transformers: A View Based on Practical Experience. In Proceedings of the Electrical Insulation Conference and Electrical Manufacturing & Coil Winding Conference, Cincinnati, OH, USA, 28 October 1999; pp. 659–667. [Google Scholar] [CrossRef]

- Experiences in Service with New Insulating Liquids; Cigré Technical Brochure 436; International Council on Large Electric Systems (CIGRE): Paris, France, 2010.

- The Effect of Moisture on the Breakdown Voltage of Transformer Oil. White Paper of Vaisala. Available online: https://www.vaisala.com/sites/default/files/documents/CEN-TIA-power-whitepaper-Moisture-and-Breakdown-Voltage-B211282EN-A-LOW.pdf (accessed on 6 June 2018).

- Borsi, H.; Schroder, U. Initiation and Formation of Partial Discharges in Mineral-based Insulating Oil. IEEE Trans. Dielectr. Electr. Insul. 1994, 1, 419–425. [Google Scholar] [CrossRef]

- Dai, J.; Wang, Z.D.; Jarman, P. Moisture and Aging Effect on the Creepage Discharge Characteristics at the Oil/Transformer-board Interface under Divergent Field. In Proceedings of the Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Québec, QC, Canada, 26–29 October 2008; pp. 662–665. [Google Scholar] [CrossRef]

- Sikorski, W.; Walczak, K.; Przybylek, P. Moisture Migration in an Oil-paper Insulation System in Relation to Online Partial Discharge Monitoring of Power Transformers. Energies 2016, 9, 1082. [Google Scholar] [CrossRef]

- Oommen, T.V.; Lindgren, S.R. Bubble Evolution from Transformer Overload. In Proceedings of the Transmission and Distribution Conference Exposition, Atlanta, GA, USA, 2 November 2001; pp. 137–142. [Google Scholar] [CrossRef]

- Przybylek, P. Investigations of the Temperature of Bubble Effect Initiation Oil-paper Insulation. Prz. Elektrotech. 2010, 86, 166–169. [Google Scholar]

- Lopatkiewicz, R.; Nadolny, Z.; Przybylek, P. Influence of Water Content in Paper on its Thermal Conductivity. Prz. Elektrotech. 2010, 86, 55–58. [Google Scholar]

- Lopatkiewicz, R.; Nadolny, Z.; Przybylek, P. The Influence of Water Content on Thermal Conductivity of Paper Used as Transformer Windings Insulation. In Proceedings of the IEEE International Conference on the Properties and Applications of Dielectric Materials (ICPADM), Bangalore, India, 24–28 July 2012. [Google Scholar] [CrossRef]

- Oommen, T.V.; Prevost, T.A. Cellulose Insulation in Oil-filled Power Transformers: Part II—Maintaining Insulation Integrity and Life. IEEE Electr. Insul. Mag. 2006, 22, 5–14. [Google Scholar] [CrossRef]

- Pikus, I.F.; Gimpeleva, L.S.; Koshepavo, L.A. Basic Laws of the Vacuum Drying Process Applied to Cellulose Materials for Electrical Insulation. J. Eng. Phys. Thermophys. 1972, 22, 290–296. [Google Scholar] [CrossRef]

- Gasser, H.P.; Krause, C.; Prevost, T. Water Absorption of Cellulosic Insulating Materials Used in Power Transformer. In Proceedings of the IEEE International Conference on Solid Dielectrics (ICSD), Winchester, UK, 8–13 July 2007. [Google Scholar] [CrossRef]

- Betie, A.; Meghnefi, F.; Fofana, I.; Yeo, Z. Modeling the Insulation Paper Drying Process from Thermogravimetric Analyses. Energies 2018, 11, 517. [Google Scholar] [CrossRef]

- Hasterman, Z.; Mosiński, F.; Maliszewski, A. Electric Strength of Power Transformer; Wydawnictwo Naukowo-Techniczne: Warsaw, Poland, 1983. (In Polish) [Google Scholar]

- Walczak, K. Drying Methods of Power Transformer’s Solid Insulation in the Place of its Installation. In Proceedings of the International Conference Transformator’13, Gdańsk, Poland, 6–8 June 2013. (In Polish). [Google Scholar]

- Steeves, G.R. Vapor Phase Transformer Drying—Part I. Vapor Phase Drying as Part of Transformer Manufacturing Process. Transform. Mag. 2016, 3, 52–56. [Google Scholar]

- Rindlisbacher, G.; von Ah, M. Cut and Dry: Low Frequency Drying Process in Transformer Production Can Cut Energy Costs in Half. ABB Review 2005, 3. Available online: https://library.e.abb.com/public/22f229958625da3ec125707b004c4466/66-69%203M557_ENG72dpi.pdf (accessed on 22 June 2018).

- Koestinger, P.; Aronsen, E.; Boss, P.; Rindlisbacher, G. Practical Experience with the Drying of Power Transformers in the Field, Applying the LFH Technology. In CIGRE Session Papers Proceedings; Reference: A2-205_2004; International Council on Large Electric Systems (CIGRE): Paris, France, 2004. [Google Scholar]

- Przybylek, P. The Influence of Cellulose Insulation Aging Degree on its Water Sorption Properties and Bubble Evolution. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 906–912. [Google Scholar] [CrossRef]

- Lundgaard, L.E.; Hansen, W.; Linhjell, D.; Painter, T.J. Ageing of Oil-impregnated Paper in Power Transformers. IEEE Trans. Power Del. 2004, 19, 230–239. [Google Scholar] [CrossRef]

- Heywood, R.J.; Emsley, A.M.; Ali, M. Degradation of Cellulose Insulation in Power Transformers. Part 1: Factors Affecting the Measurement of the Average Viscometric Degree of Polymerization of New and Aged Electrical Papers. IEE Proc. Sci. Meas. Technol. 2000, 147, 86–90. [Google Scholar] [CrossRef]

- Przybyłek, P. Sposób i Urządzenie do Suszenia Układów Izolacyjnych Urządzeń Elektroenergetycznych. Patent No. PL 226674; Patent Office of the Republic of Poland, Poland, 2017. (In Polish). [Google Scholar]

- Höhlein, I.; Kachler, A.J. Aging of Cellulose at Transformer Service Temperatures. Part 2. Influence of Moisture and Temperature on Degree of Polymerization and Formation of Furanic Compounds in Free-breathing Systems. IEEE Electr. Insul. Mag. 2005, 21, 20–24. [Google Scholar] [CrossRef]

- IEC 60076-7: Loading Guide for Oil-Immersed Power Transformers; International Electrotechnical Commission (IEC): New York, NY, USA, 2005.

- IEC 60450, Measurement of the Average Viscometric Degree of Polymerization of New and Aged Cellulosic Electrically Insulating Materials; International Electrotechnical Commission (IEC): New York, NY, USA, 2004.

- IEC 60814, Insulating Liquids—Oil-Impregnated Paper and Pressboard—Determination of Water by Automatic Coulometric Karl Fischer Titration; International Electrotechnical Commission (IEC): New York, NY, USA, 1997.

- Przybyłek, P. A New Method for Indirect Measurement of Water Content in Fibrous Electro-insulating Materials Using Near-infrared Spectroscopy. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 1798–1804. [Google Scholar] [CrossRef]

- Moisture Measurement in Insulating Fluids and Transformer Insulation—An Evaluation of Solid State Sensors and Chemical Methods; International Council on Large Electric Systems (CIGRE): Paris, France, 2018.

- Przybylek, P. Water Saturation Limit of Insulating Liquids and Hygroscopicity of Cellulose in Aspect of Moisture Determination in Oil-paper Insulation. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 1886–1893. [Google Scholar] [CrossRef]

| Material | Paper No. 1 | Paper No. 2 | Paper No. 3 | Paper No. 4 | Paper No. 5 |

|---|---|---|---|---|---|

| DP before drying process | 1185 | 1180 | 1238 | 1422 | 1325 |

| DP after drying process | 1080 | 1080 | 1059 | 1267 | 984 |

| Decrease of DP during drying | 105 | 100 | 179 | 155 | 341 |

| Percentage decrease of DP, in % | 9 | 8 | 14 | 11 | 26 |

| Sample | Cpi | Mm | Absi | Mp | Absf | Cp | Mw | WCPNIR | Cpf |

|---|---|---|---|---|---|---|---|---|---|

| % | g | - | g | - | % | mg | % | % | |

| 0.02% | 0.0236 | 3.7713 | 0.9773 | 0.0771 | 1.0568 | 0.1487 | 5.61 | 7.81 | 0.1723 |

| 0.2% | 0.2102 | 3.7550 | 1.0801 | 0.0739 | 1.1541 | 0.1384 | 5.19 | 7.54 | 0.3485 |

| 0.6% | 0.5961 | 3.8197 | 1.2881 | 0.0745 | 1.3596 | 0.1335 | 5.10 | 7.33 | 0.7296 |

| 1% | 1.0121 | 3.8156 | 1.5127 | 0.0737 | 1.5864 | 0.1376 | 5.25 | 7.62 | 1.1497 |

| Sample | Thickness mm | Basic Weight g/m2 | Density kg/m3 |

|---|---|---|---|

| Pressboard 0.5 mm | 0.548 | 515 | 939 |

| Pressboard 1 mm | 1.110 | 1167 | 1051 |

| Pressboard 2 mm | 2.104 | 2354 | 1119 |

| Pressboard 3 mm | 3.384 | 3908 | 1155 |

| Sample | Cpi | Mm | Absi | Mp | Absf | Cp | Mw | WCPNIR | Cpf |

|---|---|---|---|---|---|---|---|---|---|

| % | g | - | g | - | % | mg | % | % | |

| Pressboard 0.5 mm | 0.0236 | 3.7397 | 0.9799 | 0.467 | 1.3148 | 0.6363 | 23.95 | 5.41 | 0.6599 |

| Pressboard 1 mm | 0.0236 | 3.6968 | 0.9799 | 0,460 | 1.3242 | 0.6543 | 24.35 | 5.59 | 0.6779 |

| Pressboard 2 mm | 0.0236 | 3.7864 | 0.9776 | 0.469 | 1.3204 | 0.6516 | 24.83 | 5.59 | 0.6752 |

| Pressboard 3 mm | 0.0236 | 3.6926 | 0.9776 | 0.466 | 1.3181 | 0.6470 | 24.05 | 5.44 | 0.6706 |

© 2018 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Przybylek, P. A New Concept of Applying Methanol to Dry Cellulose Insulation at the Stage of Manufacturing a Transformer. Energies 2018, 11, 1658. https://doi.org/10.3390/en11071658

Przybylek P. A New Concept of Applying Methanol to Dry Cellulose Insulation at the Stage of Manufacturing a Transformer. Energies. 2018; 11(7):1658. https://doi.org/10.3390/en11071658

Chicago/Turabian StylePrzybylek, Piotr. 2018. "A New Concept of Applying Methanol to Dry Cellulose Insulation at the Stage of Manufacturing a Transformer" Energies 11, no. 7: 1658. https://doi.org/10.3390/en11071658

APA StylePrzybylek, P. (2018). A New Concept of Applying Methanol to Dry Cellulose Insulation at the Stage of Manufacturing a Transformer. Energies, 11(7), 1658. https://doi.org/10.3390/en11071658