NOx and SO2 Emissions during Co-Combustion of RDF and Anthracite in the Environment of Precalciner

Abstract

1. Introduction

2. Experimental Section

2.1. Preparation of Fuels

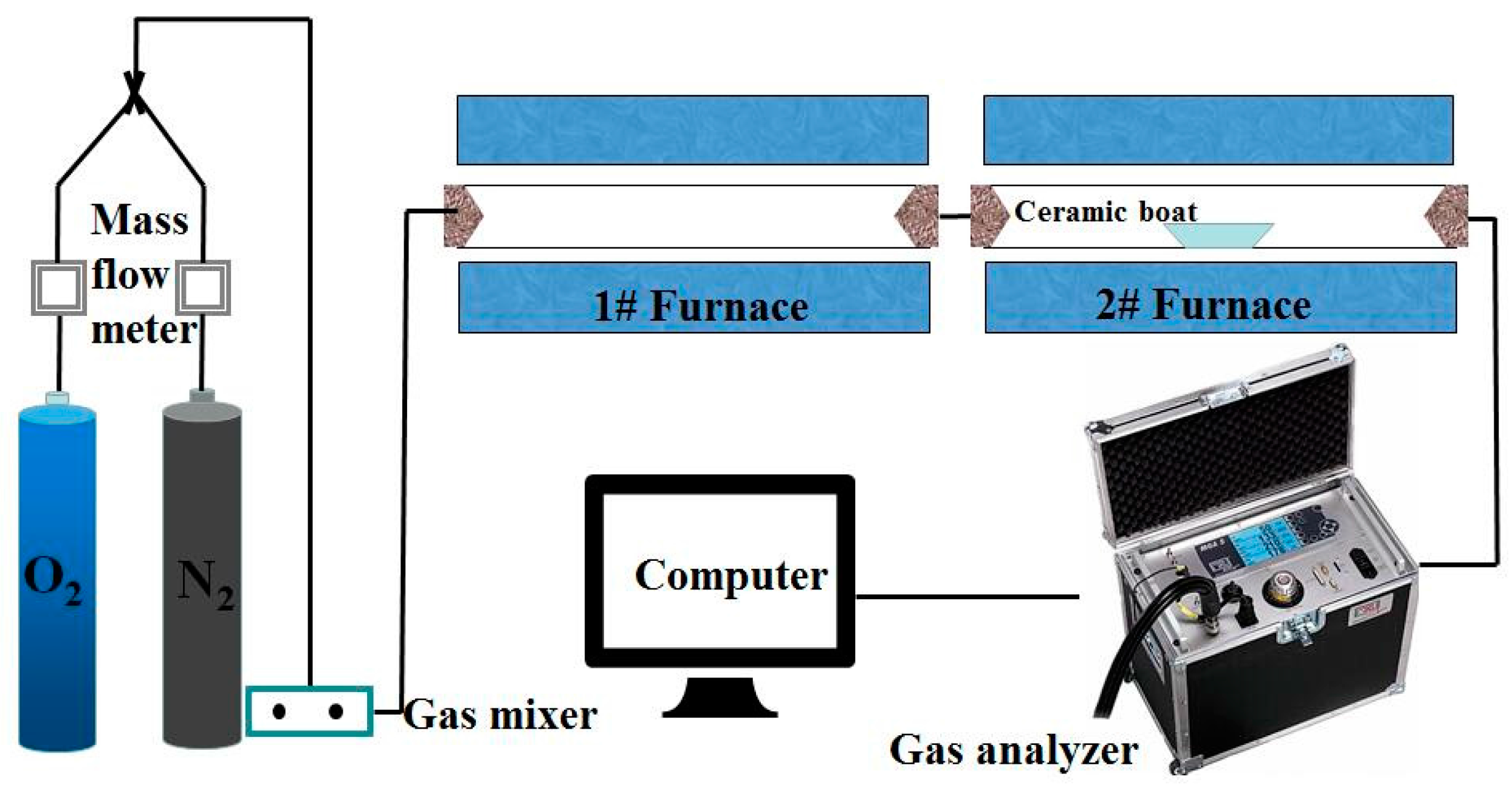

2.2. Apparatus and Methods

3. Results and Discussion

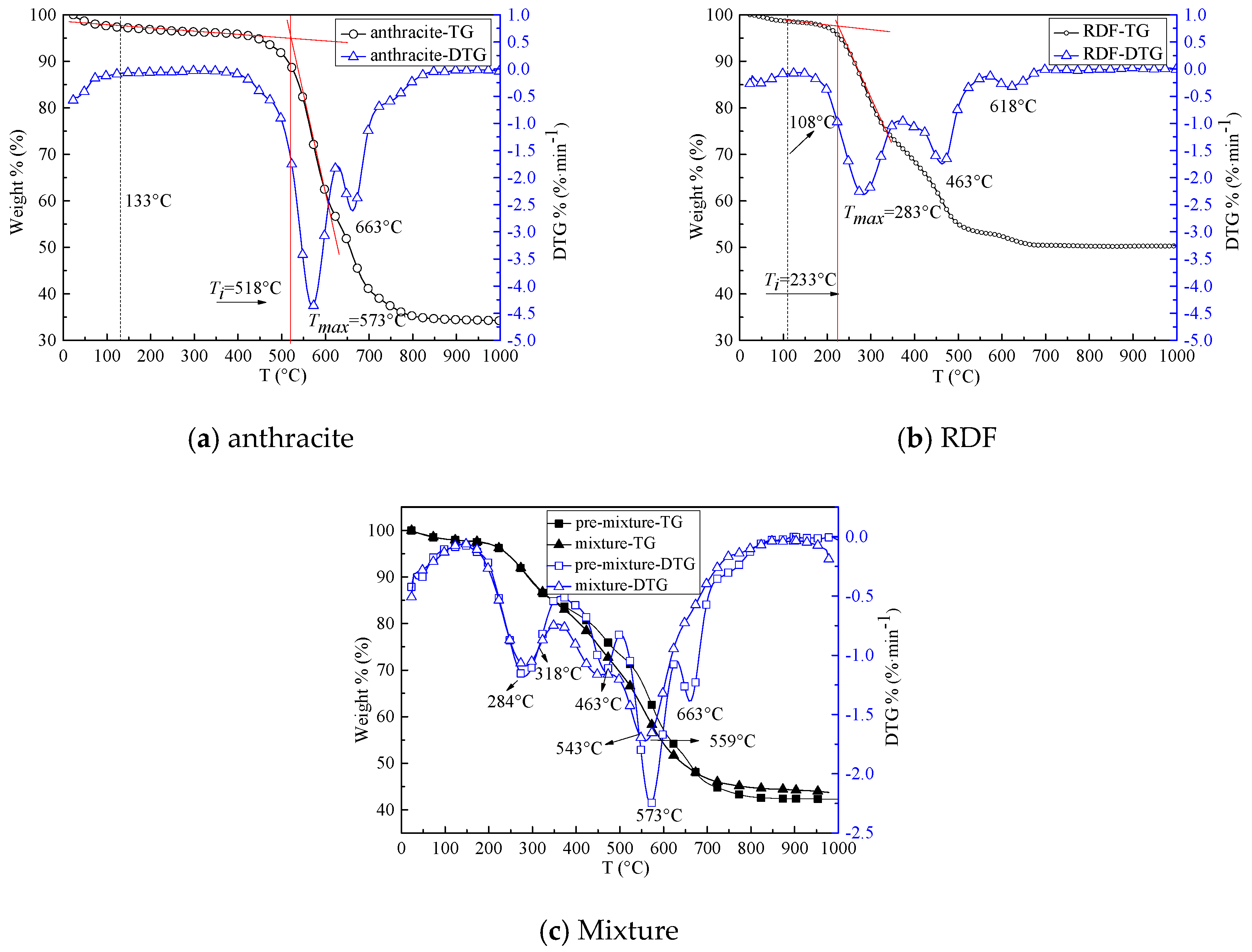

3.1. Combustion Experiments with Thermogravimetric Analyzer (TGA)

- (1)

- Rmax = (dW/dT)max is the maximum weight loss rate, Tmax is the corresponding temperature.

- (2)

- Ti is the ignition temperature.

- (3)

- C = Rmax*106/Ti2 is the flammability index, which shows the reaction capacity in the early stage of combustion.

- (4)

- Rw = 560/Ti + 650/Tmax + 0.27*(dW/dT)max is the ignition stability index.

- (5)

- t0 is the burning-out time.

3.2. Combustion Experiments with a Double Furnaces Reactor

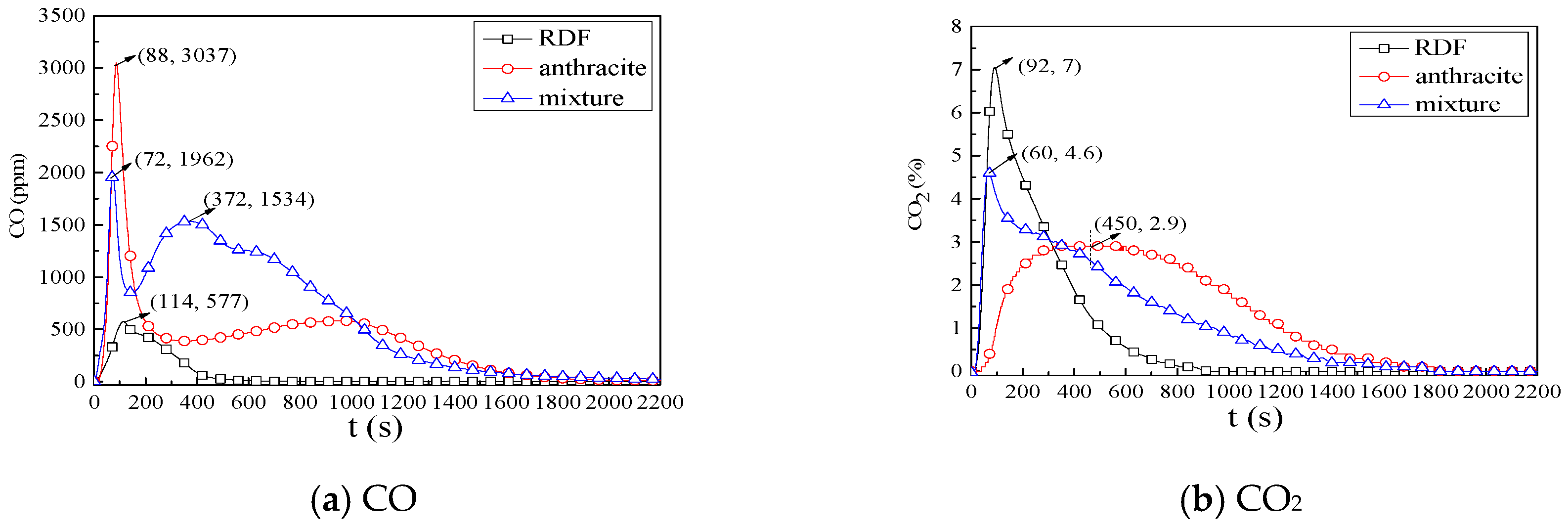

3.2.1. Combustion Process

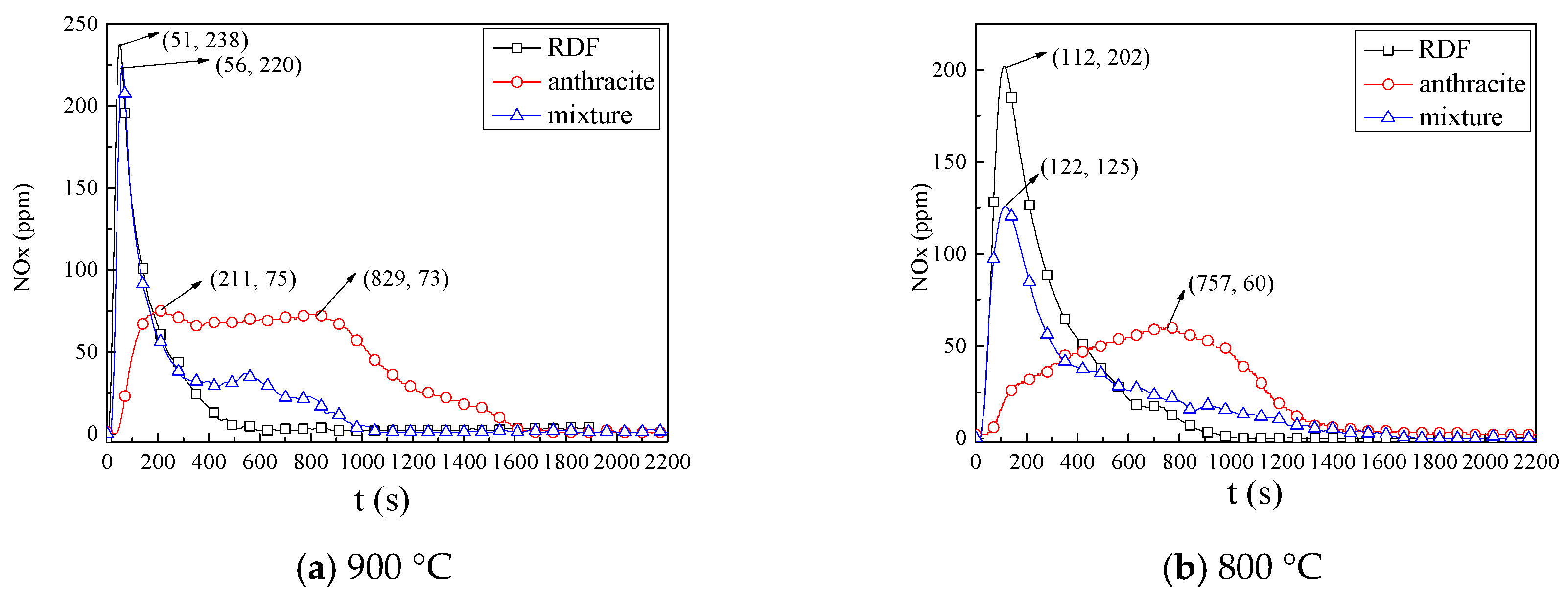

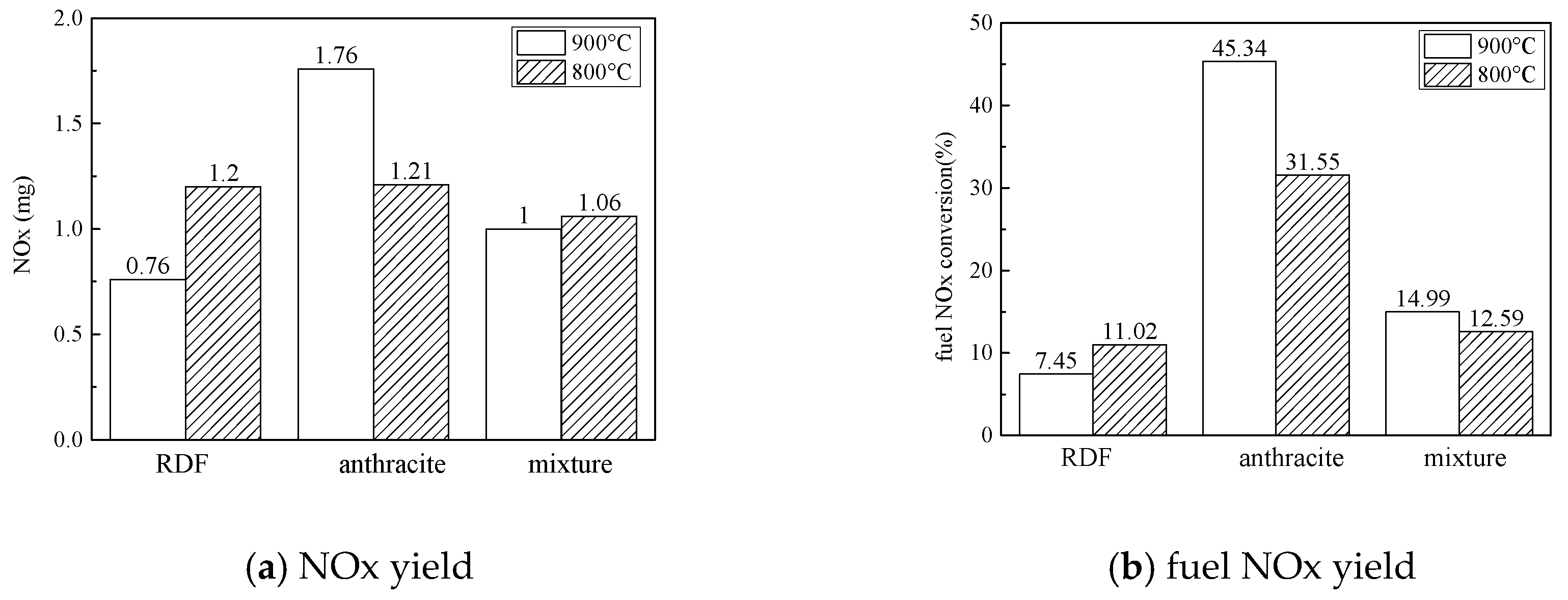

3.2.2. NOx Emission Characteristics

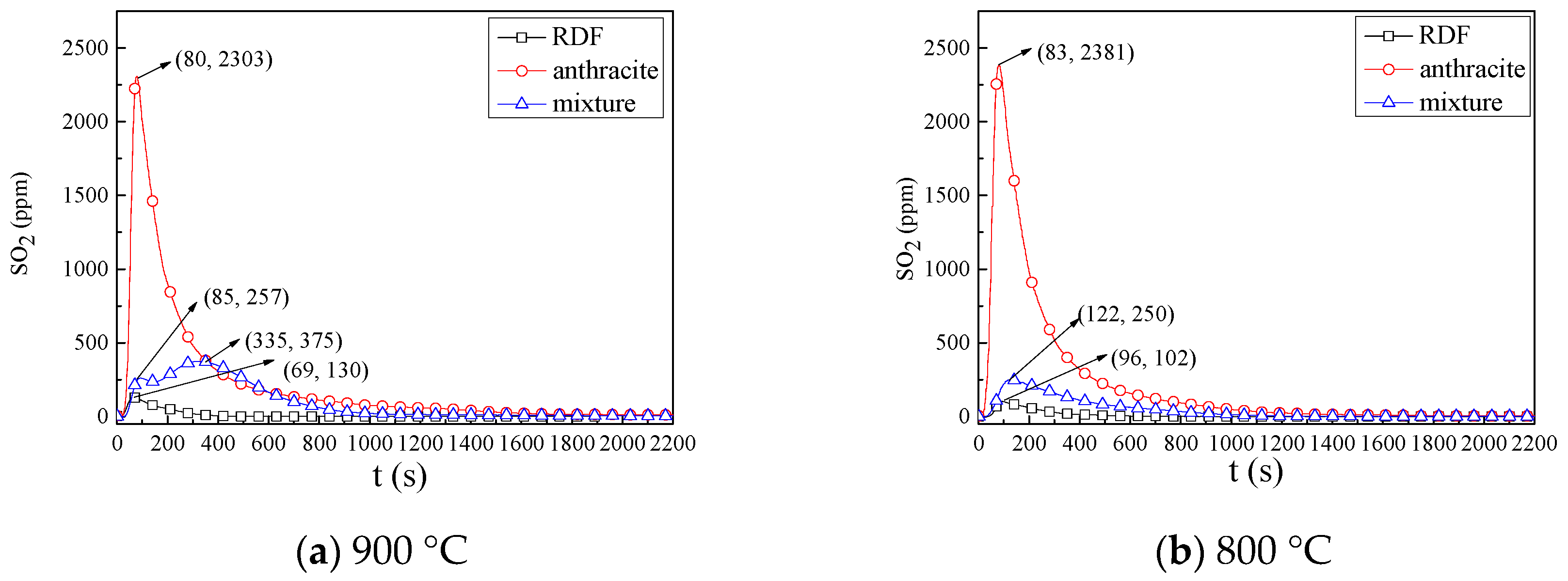

3.2.3. SO2 Emission Characteristics

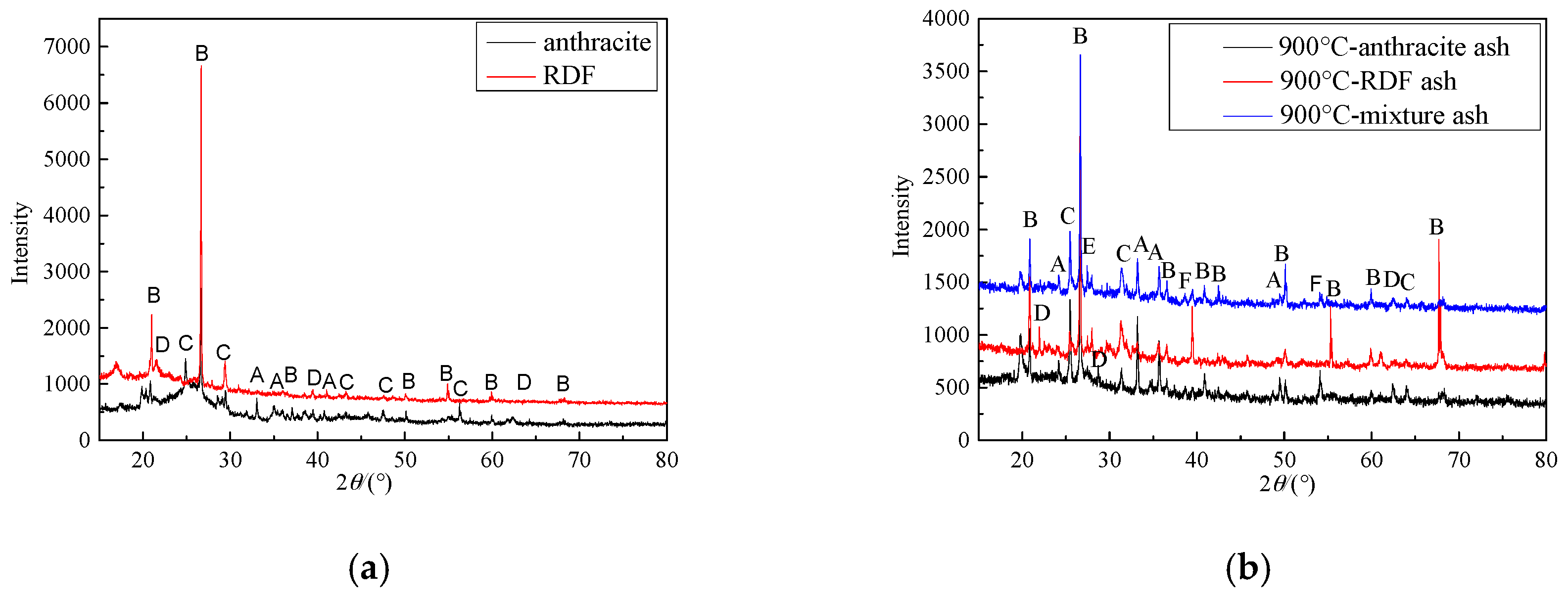

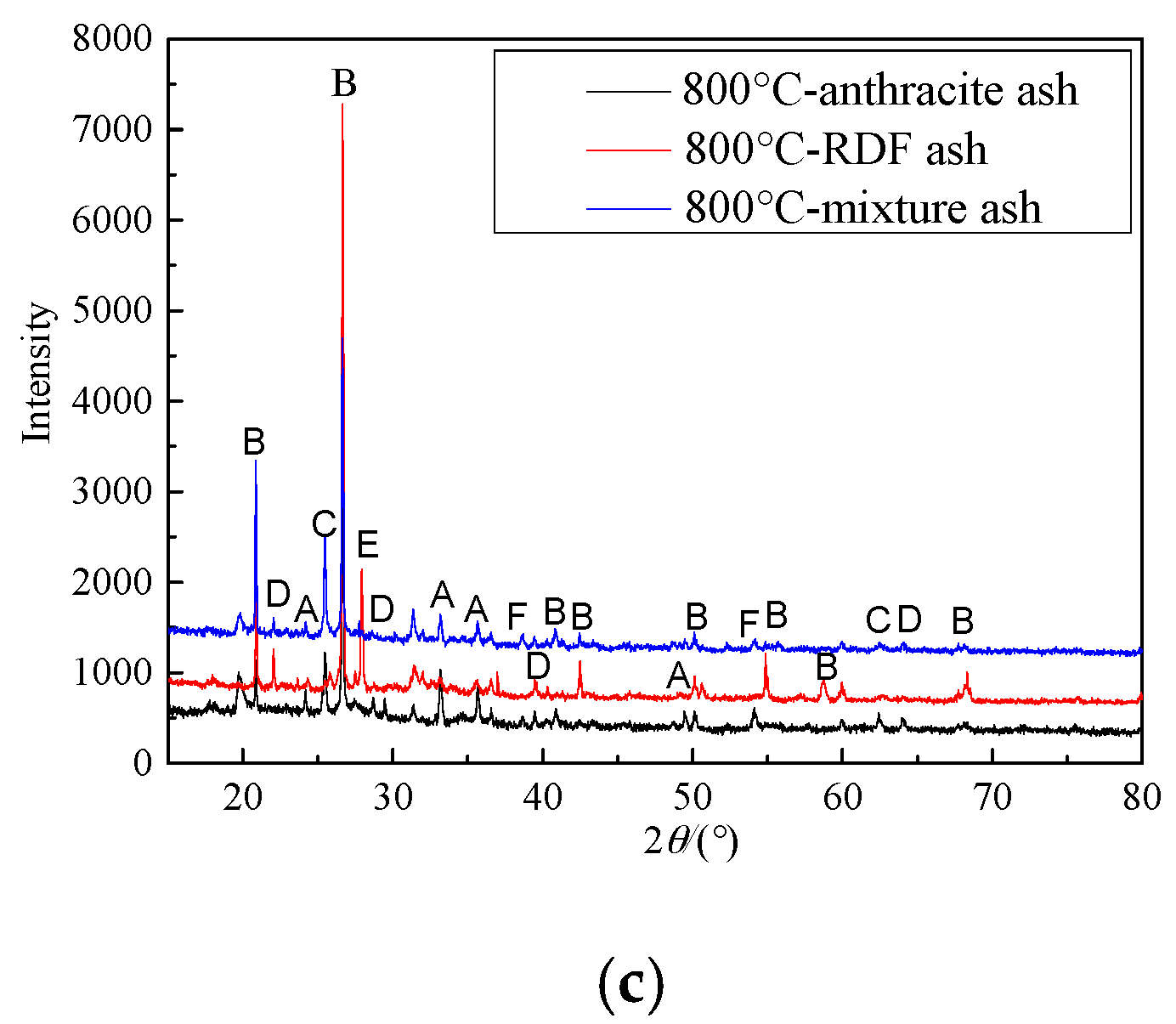

3.3. Ash Characteristics

4. Conclusions

- (1)

- The combustion characteristics: The combustion process of RDF is dominated by devolatilization and volatile matter combustion, whose ignition temperature is low and whose burn-out time is short; the combustion process of anthracite is dominated by char combustion, whose ignition temperature is high and whose burn-out time is long; in the early stage of co-combustion, constituting the linear additive effect of the separate combustion of RDF and anthracite, the later co-combustion stage constitutes the synergistic effect. It is feasible to use the mixture of RDF and anthracite as an alternative fuel in the cement plant.

- (2)

- The temperature effect on the co-combustion process: At 900 °C, the synergistic effect is obvious in the char combustion stage, which could promote the combustion of anthracite and shorten the burn-out time; at 800 °C, the combustion rate is low in the whole combustion process, and the burn-out time of the co-combustion is nearly the same as the time of the separate combustion of anthracite.

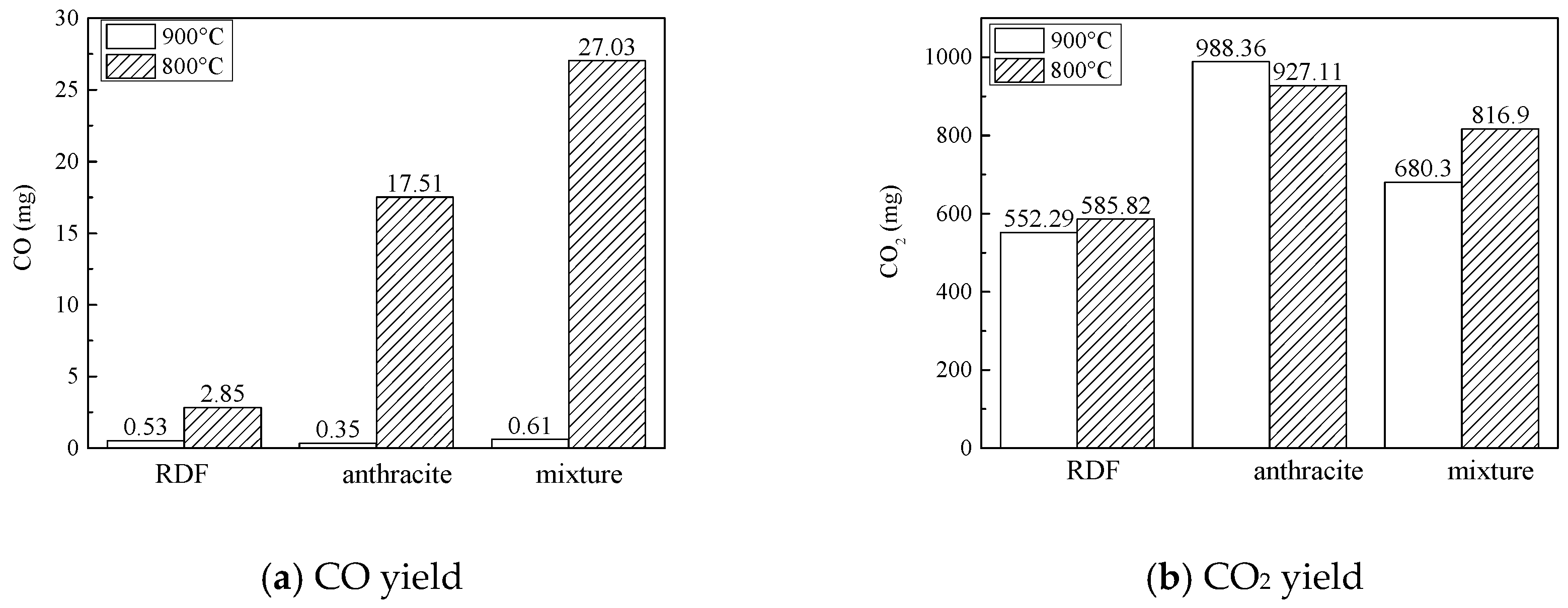

- (3)

- NOx emission characteristics: During co-combution, at 900 °C, NOx released rapidly during the devolatilization stage, but in the char combustion stage the NOx formation were inhibited; at 800 °C, a large amount of CO formed, which could reduce the NOx. In general, at 900 °C and at 800 °C, the application of co-combustion could lower the NOx emission yield and lower the NOx conversion.

- (4)

- SO2 emission characteristics: Combined the combustion characteristics and the XRD results, it was indicated that during co-combustion, at 800 °C, the SO2 formation reaction was inhibited by metal oxides, and the SO2 yield and conversion were quite low.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Vesterinen, R.; Flyktman, M. Organic emissions from co-combustion of RDF with wood chips and milled peat in a bubbling fluidized bed boiler. Chemosphere 1996, 32, 681–689. [Google Scholar] [CrossRef]

- Zhu, T.Y.; Ye, M.; Jing, P.F.; Xu, W.Q.; Xiao, Y.H. Properties of flue gas from mixed incineration of municipal solid waste and coal in a 1.5 MW circulating fluidized bed boiler. CIESC J. 2010, 61, 2468–2473. [Google Scholar]

- Bai, J.S.; Yu, C.J.; Li, L.M.; LI, X.L.; Wang, Q.H.; Luo, Z.Y. Experimental Investigation on Co-firing of Coal and Refuse-derived Fuel in a Pilot-scale Circulating Fluidized Bed Combustor. Proc. CSEE 2012, 32, 36–41. [Google Scholar] [CrossRef]

- Lee, J.M.; Kim, D.W.; Kim, J.S.; Na, J.G.; Lee, S.H. Co-combustion of refuse derived fuel with Korean anthracite in a commercial circulating fluidized bed boiler. Energy 2010, 35, 2814–2818. [Google Scholar] [CrossRef]

- Li, X.G.; Lv, Y.; Ma, B.G.; Jian, S.W.; Tan, H.B. Thermogravimetric investigation on co-combustion characteristics of tobacco residue and high-ash anthracite coal. Bioresour. Technol. 2011, 102, 9783–9787. [Google Scholar] [CrossRef] [PubMed]

- Fan, W.Y.; Zhu, T.L.; Sun, Y.F.; Dong, L. Effects of gas compositions on NOx reduction by selective non-catalytic reduction with ammonia in a simulated cement precalciner atmosphere. Chemosphere 2014, 113, 182–187. [Google Scholar] [CrossRef] [PubMed]

- Mikulčić, H.; Berg, E.V.; Vujanović, M.; Priesching, P.; Tatschl, R.; Duic, N. Numerical analysis of cement calciner fuel efficiency and pollutant emissions. Clean Technol. Environ. 2013, 15, 489–499. [Google Scholar] [CrossRef]

- Liu, H.F.; Liu, Y.H.; Liu, Y.H.; Che, D.F. N2 formation from coal nitrogen during pyrolysis and combustion. J. Xian Jiaotong Univ. 2008, 42, 350–353. [Google Scholar]

- Gong, Z.Q.; Liu, Z.C.; Zhu, Z.P.; Yu, K.S.; Meng, G.J.; Liu, J.P.; Ouyang, Z.Q.; Sun, Y.K.; Lv, Q.G. Experimental study on semi-coke combustion and coal pyrolysis and combustion coupling. J. China Coal Soc. 2014, 39, 519–525. [Google Scholar]

- Zhou, H.; Huang, Y.; Mo, G.Y.; Liao, Z.Y.; Cen, K.F. Conversion of Fuel-N to N2O and NOx during Coal Combustion in Combustors of Different Scale. Chin. J. Chem. Eng. 2013, 21, 999–1006. [Google Scholar] [CrossRef]

- Collings, M.E.; Mann, M.D.; Young, B.C. Effect of coal rank and circulating fluidized-bed operating parameters on nitrous oxide emissions. Energy Fuels 1993, 7, 554–558. [Google Scholar] [CrossRef]

- Bo, L. Fluidized bed combustion: Mixing and pollutant limitation. Prog. Energy Combust. 1998, 24, 31–61. [Google Scholar] [CrossRef]

- De, D.L.F.; Londono, C.A.; Wang, X.S.; Gibbs, B.M. Influence of operating parameters on NOx and N2O axial profiles in a circulating fluidized bed combustor. Fuel 1996, 75, 971–978. [Google Scholar] [CrossRef]

- Lin, Z.M.; Wang, Z.H.; Liu, J.; Ge, L.C.; Zhang, Y.W.; Zhang, Q.; Zhou, J.H.; Cen, K.F. Experimental study on combustion and NOx emission characteristics of Zhehun blended coal. Therm. Power Gen. 2014, 43, 44–48. [Google Scholar]

- Chui, E.H.; Majeski, A.J.; Douglas, M.A.; Tan, Y.; Thambimuthu, K.V. Numerical investigation of oxy-coal combustion to evaluate burner and combustor design concepts. Energy 2004, 29, 1285–1296. [Google Scholar] [CrossRef]

- Muto, M.; Watanabe, H.; Kurose, R.; Komori, S.; Balusamy, S.; Hochgreb, S. Large-eddy simulation of pulverized coal jet flame—Effect of oxygen concentration on NOx formation. Fuel 2015, 142, 152–163. [Google Scholar] [CrossRef]

- Christopher, R.S.; Alejandro, M. Fundamental investigation of NOx formation during oxy-fuel combustion of pulverized coal. P. Combust. Inst. 2011, 33, 1723–1730. [Google Scholar] [CrossRef]

- Zhou, Z.J.; Zhou, N.; Chen, Y.J.; Zhou, J.H.; Liu, J.Z.; Cen, K.F. Experimental Research on the Combustion and NOx Generation Characteristics of Low Volatile Coal. Proc. CSEE 2010, 30, 55–61. [Google Scholar]

- Liu, Z.G.; Quek, A.; Hoekman, S.K.; Srinivasan, M.P.; Balasubramanian, R. Thermogravimetric investigation of hydrochar-lignite co-combustion. Bioresour. Technol. 2012, 123, 646–652. [Google Scholar] [CrossRef] [PubMed]

| Samples | Proximate Analysis/wt % | Ultimate Analysis/wt % | Qnet,daf/MJ·kg−1 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mad | Aad | Vad | Fcad | Cad | Had | Oad | Nad | Sad | ||

| RDF | 3.60 | 48.75 | 46.9 | 0.75 | 36.78 | 4.36 | 4.57 | 1.16 | 0.78 | 12.42 |

| anthracite | 2.70 | 36.16 | 8.39 | 52.75 | 55.26 | 1.32 | 3.81 | 0.38 | 3.07 | 19.59 |

| Samples | Anthracite | RDF | Mixture | Pre-Mixture |

|---|---|---|---|---|

| Ti (°C) | 518 | 233 | 318 | 398 |

| Rmax (mg·min−1) | 4.36 | 2.31 | 1.72 | 2.24 |

| C (mg·min−1·°C−1) | 16.25 | 42.55 | 17.01 | 14.14 |

| Tmax (°C) | 573 | 283 | 559 | 573 |

| Rw (°C−1) | 3.39 | 5.32 | 3.39 | 3.15 |

| Loss weight (%) | 65.74 | 49.48 | 55.61 | 57.27 |

| t0 (min) | 81.63 | 67.47 | 78.03 | 80.05 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Xie, J.; Mei, S.; He, F. NOx and SO2 Emissions during Co-Combustion of RDF and Anthracite in the Environment of Precalciner. Energies 2018, 11, 337. https://doi.org/10.3390/en11020337

Chen X, Xie J, Mei S, He F. NOx and SO2 Emissions during Co-Combustion of RDF and Anthracite in the Environment of Precalciner. Energies. 2018; 11(2):337. https://doi.org/10.3390/en11020337

Chicago/Turabian StyleChen, Xiaolin, Junlin Xie, Shuxia Mei, and Feng He. 2018. "NOx and SO2 Emissions during Co-Combustion of RDF and Anthracite in the Environment of Precalciner" Energies 11, no. 2: 337. https://doi.org/10.3390/en11020337

APA StyleChen, X., Xie, J., Mei, S., & He, F. (2018). NOx and SO2 Emissions during Co-Combustion of RDF and Anthracite in the Environment of Precalciner. Energies, 11(2), 337. https://doi.org/10.3390/en11020337