Electrical Trees and Their Growth in Silicone Rubber at Various Voltage Frequencies

Abstract

:1. Introduction

2. Experimental Details

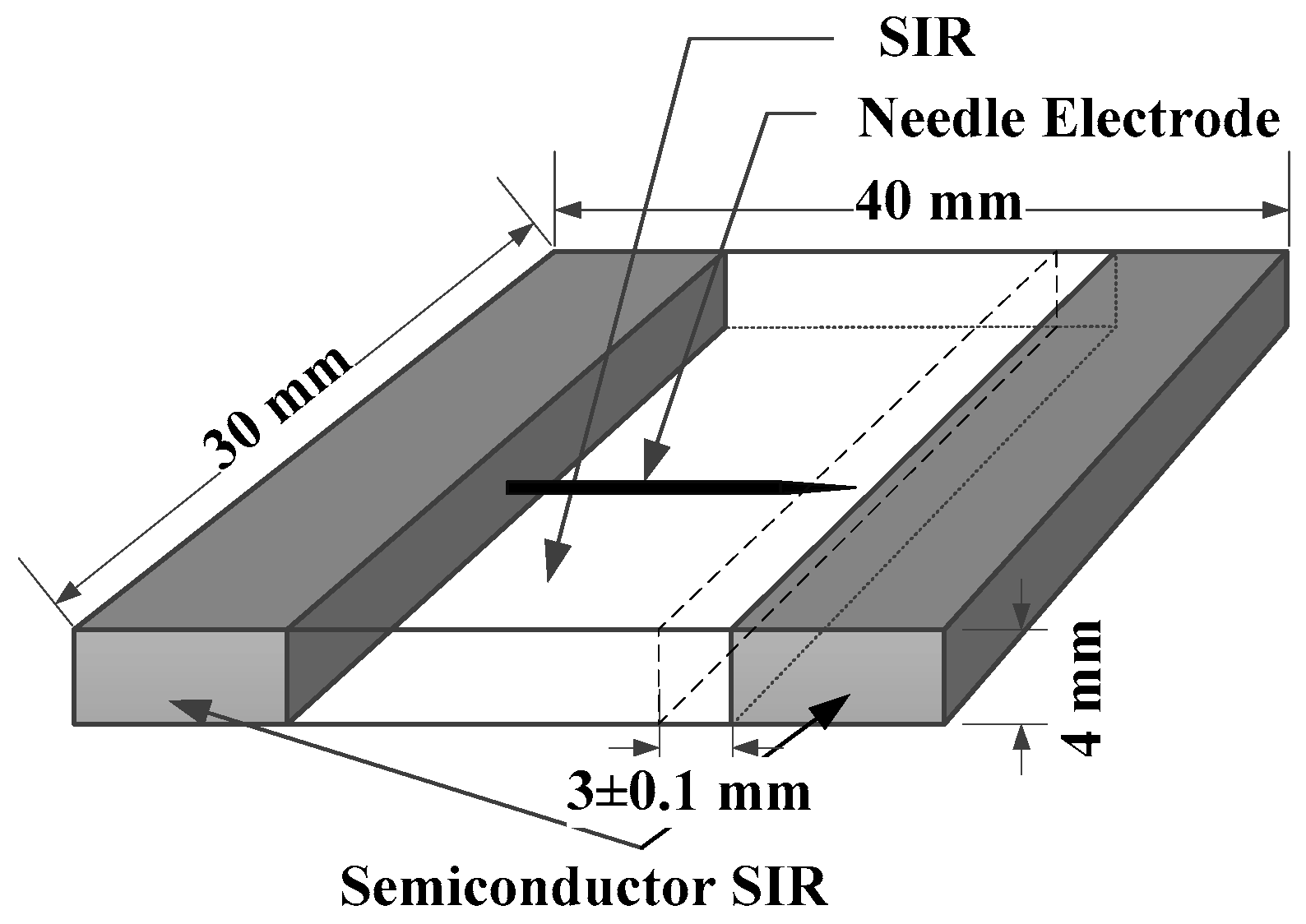

2.1. SIR Samples

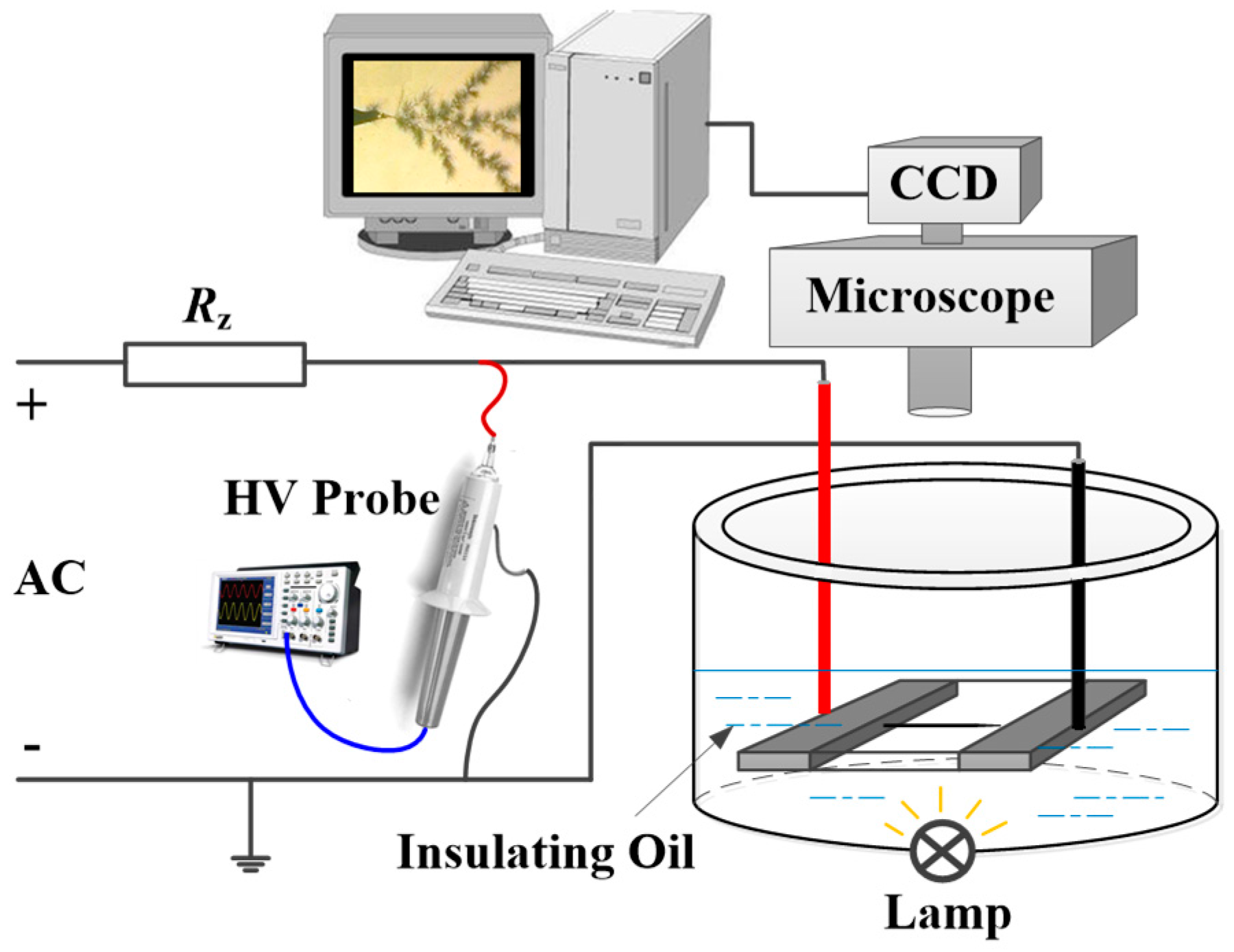

2.2. Electrical Treeing Initiation and Growing Tests

2.3. Tree Initiation Probability

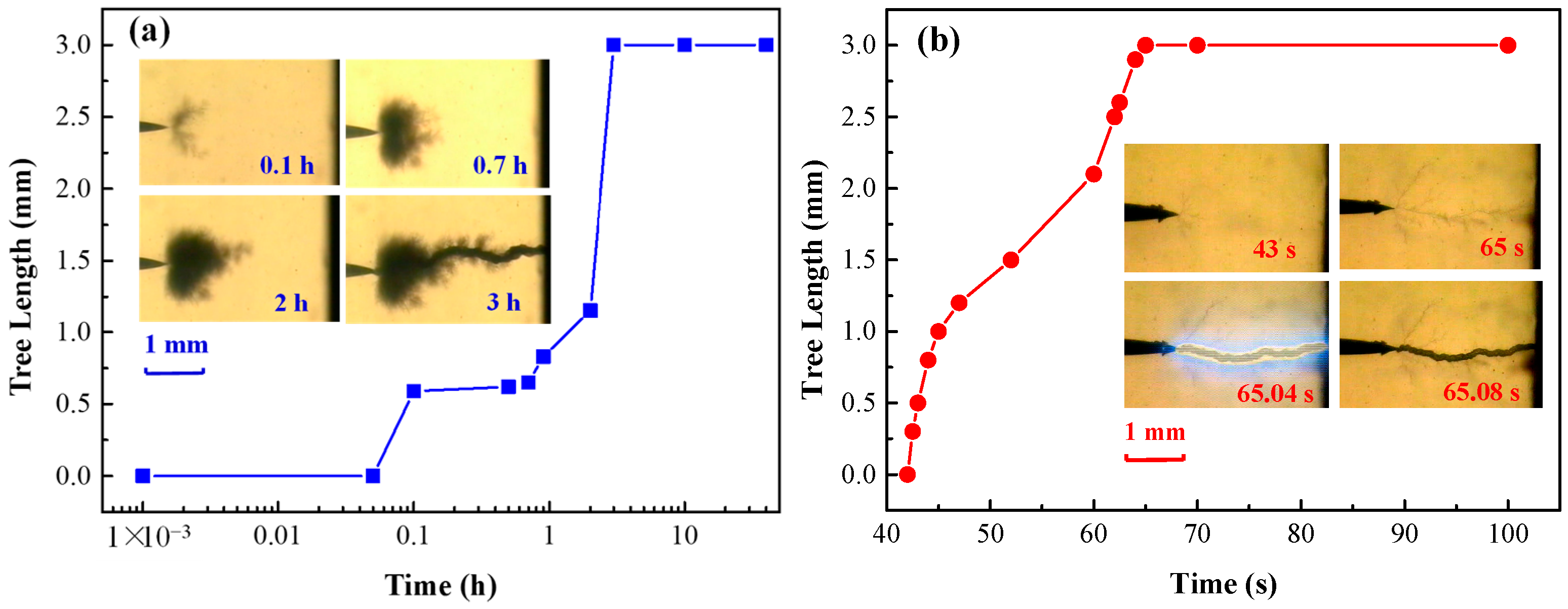

3. Experimental Results

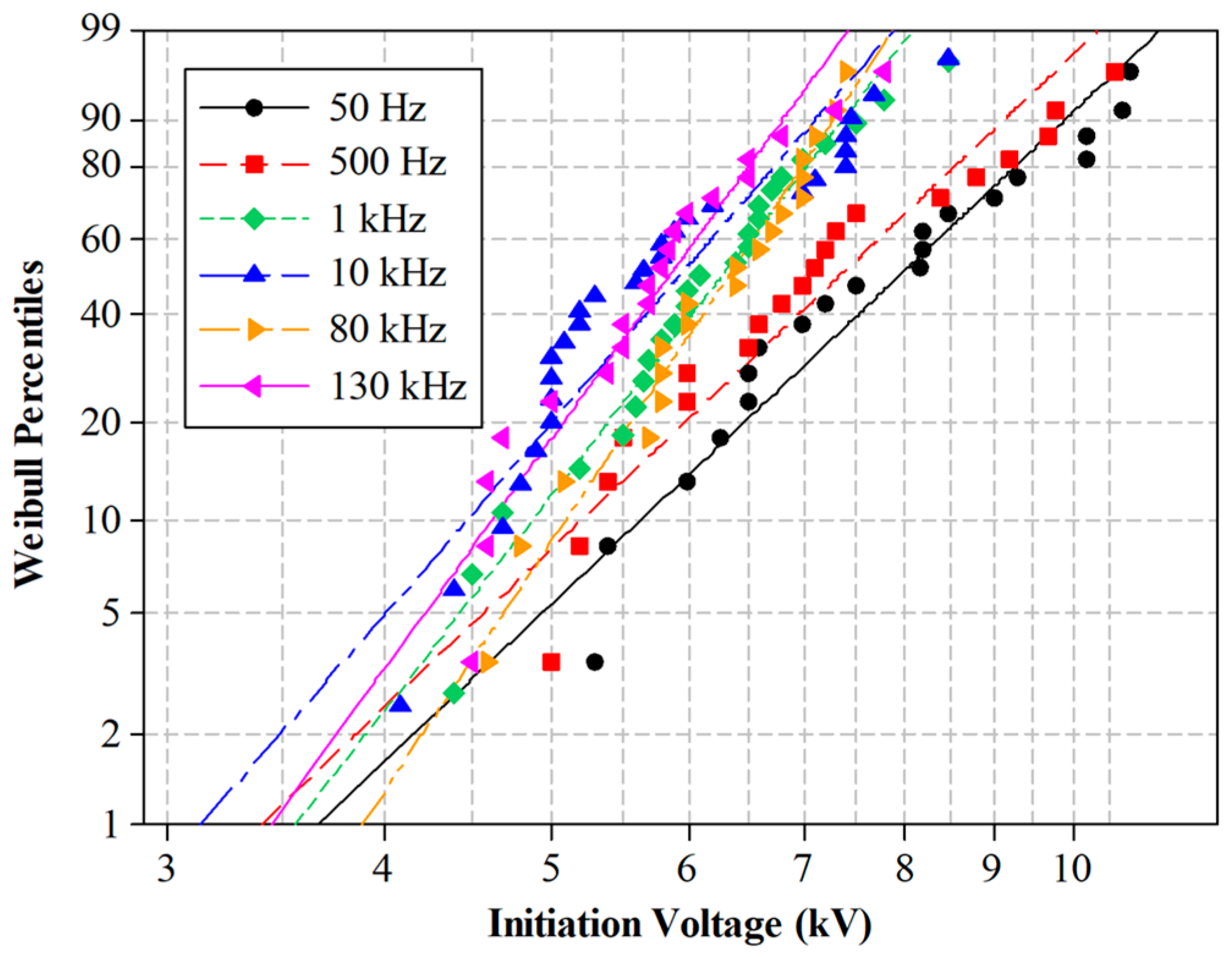

3.1. Electrical Tree Initiation Behaviors

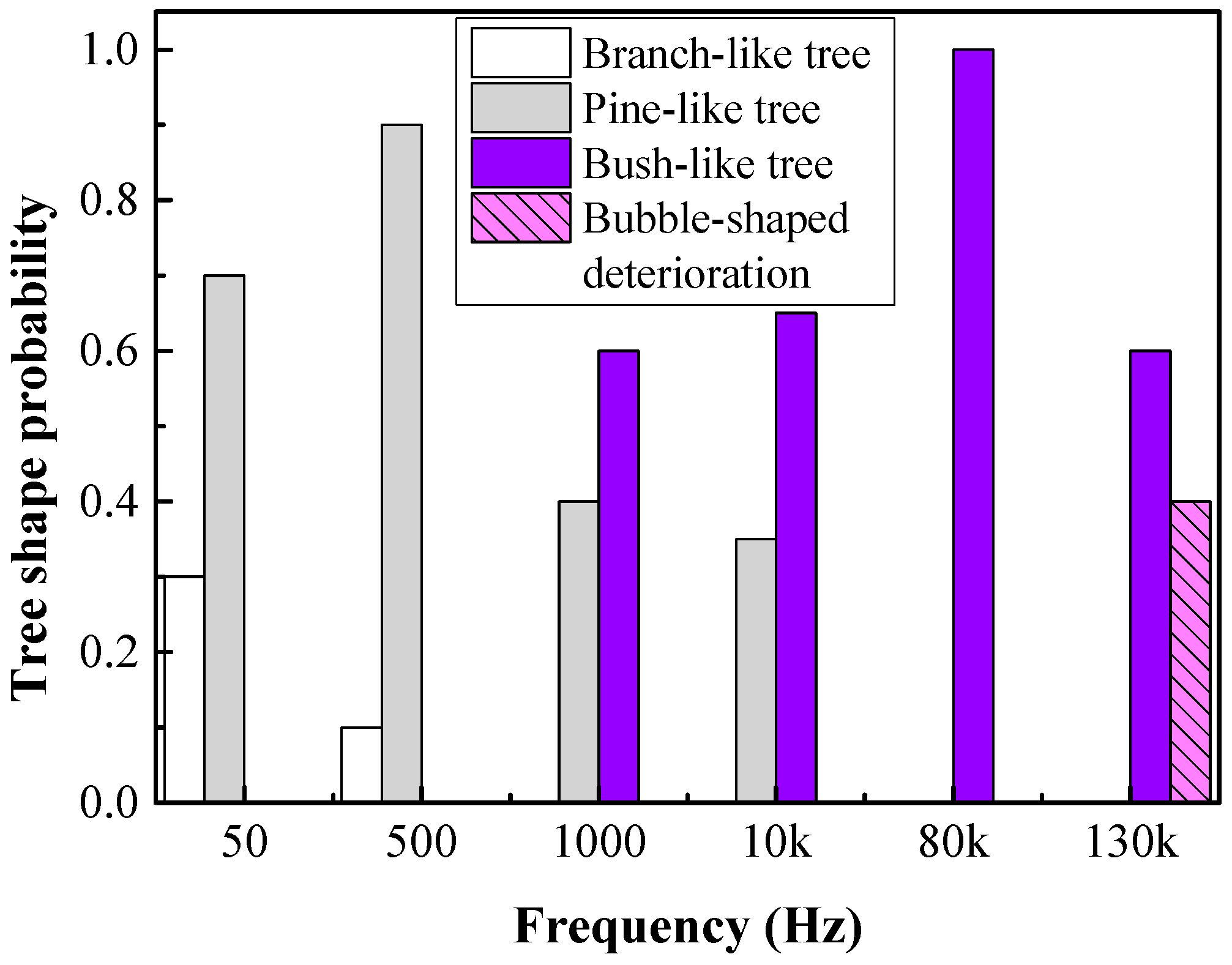

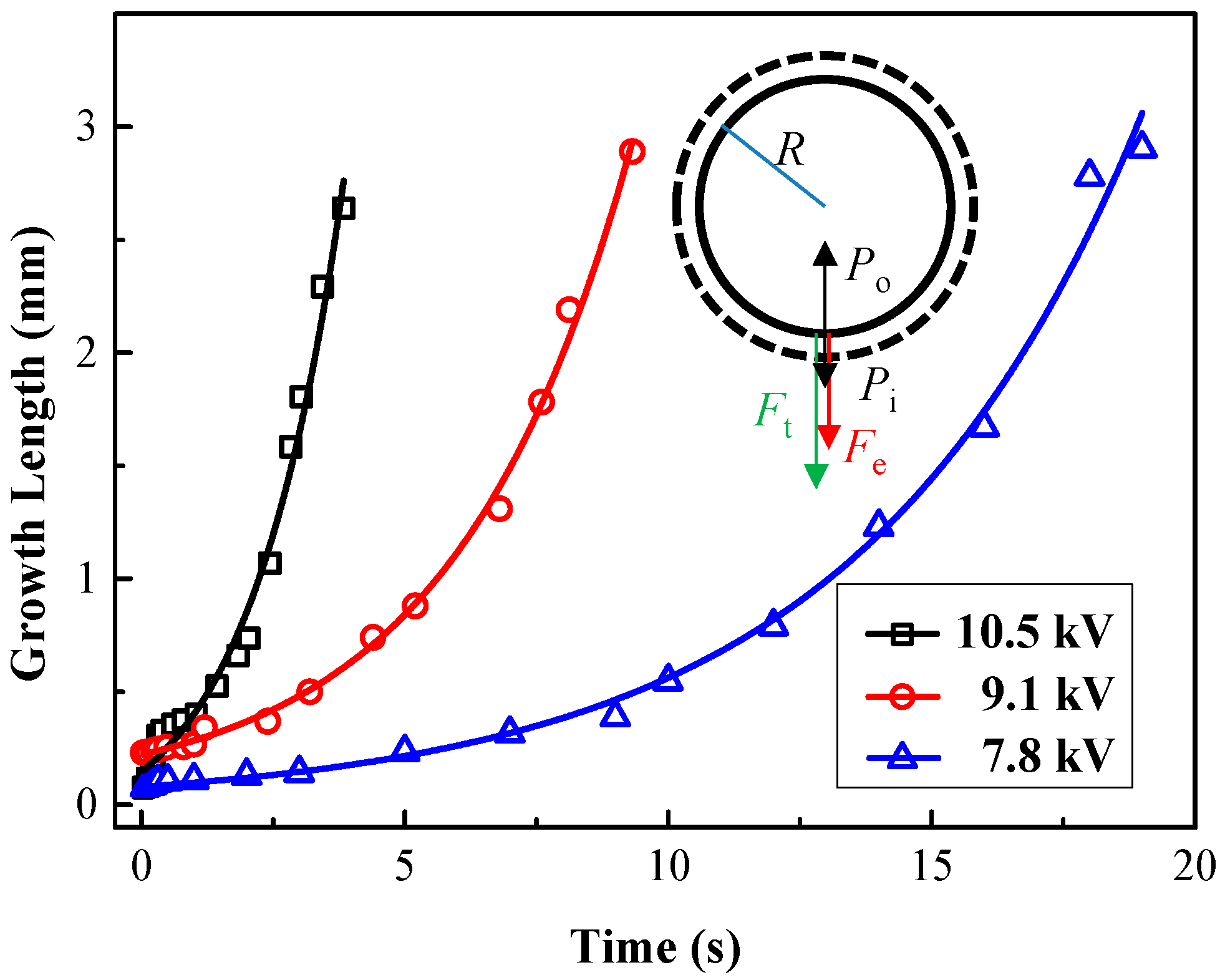

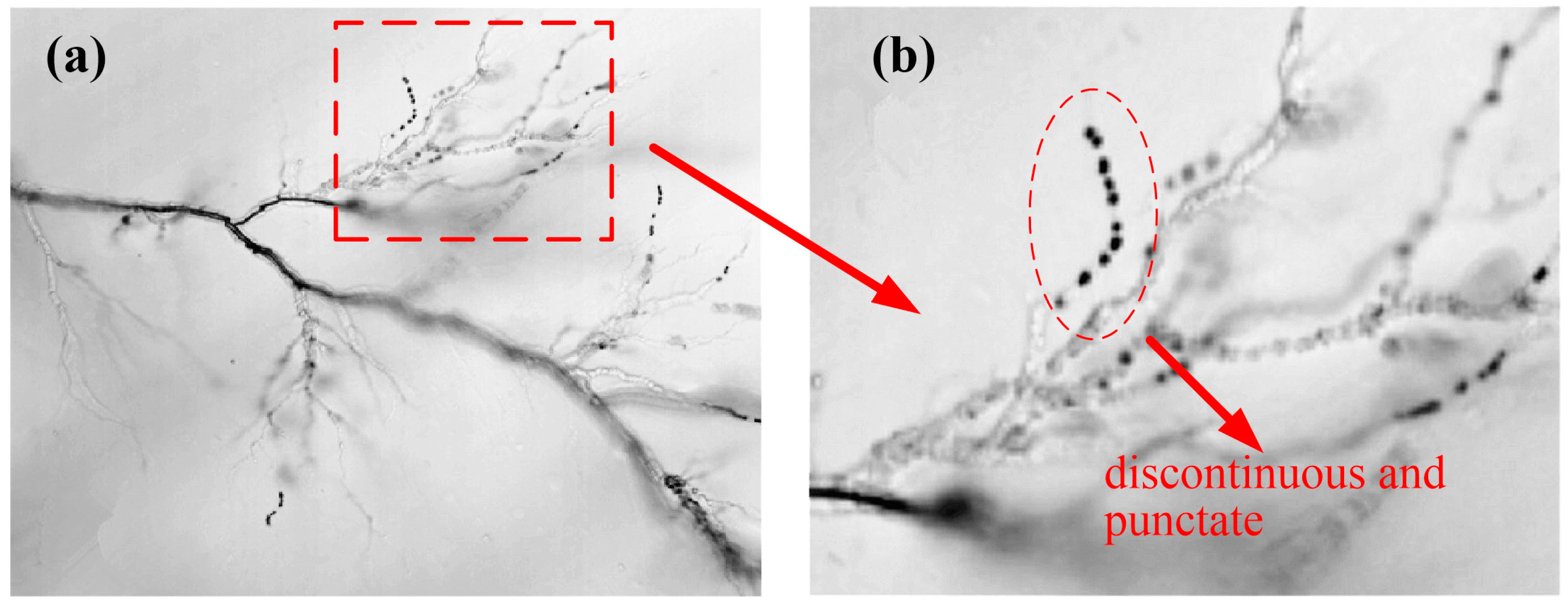

3.2. Electrical Treeing Pattern

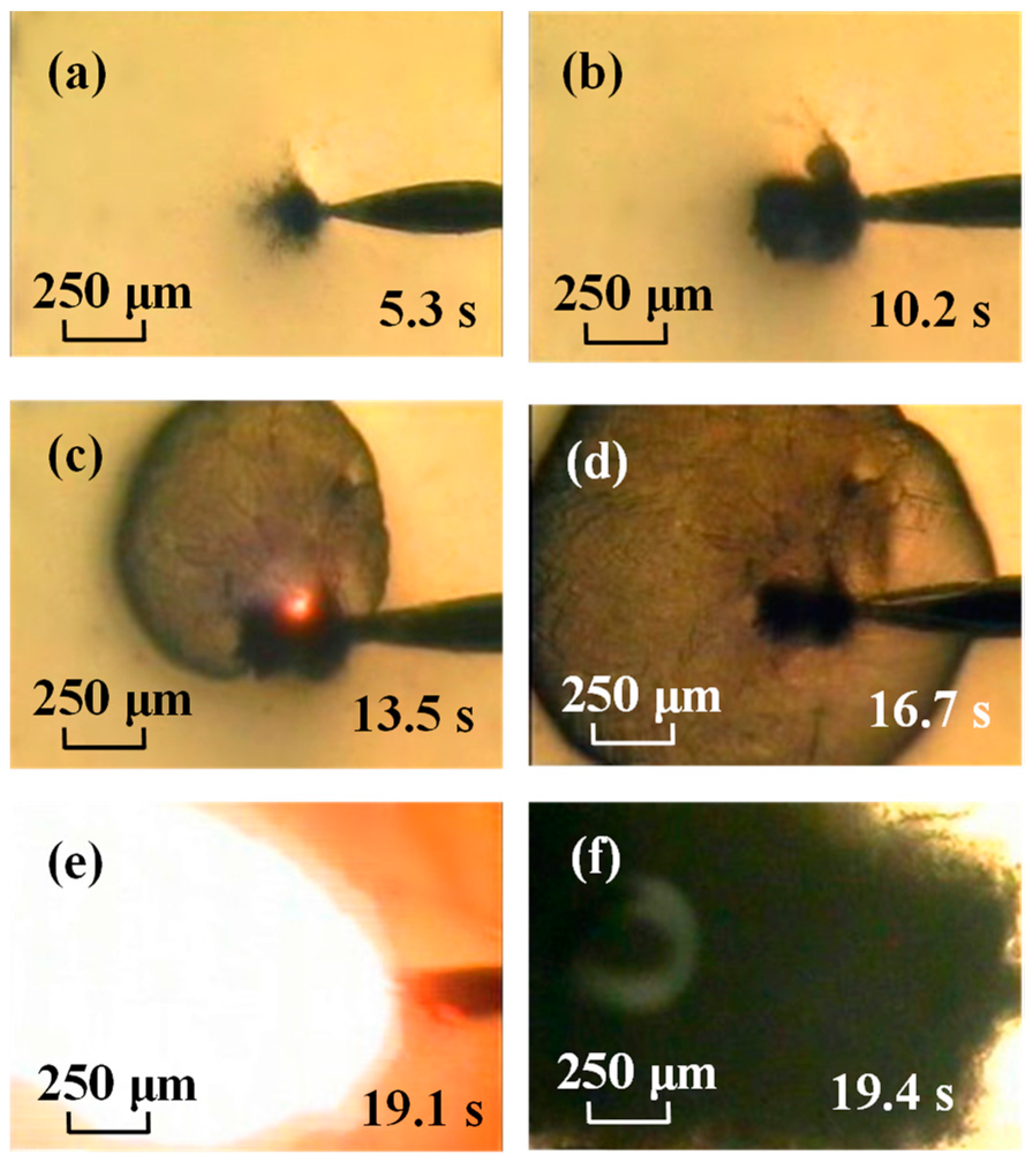

3.3. Bubble Growth at 130 kHz

4. Discussion

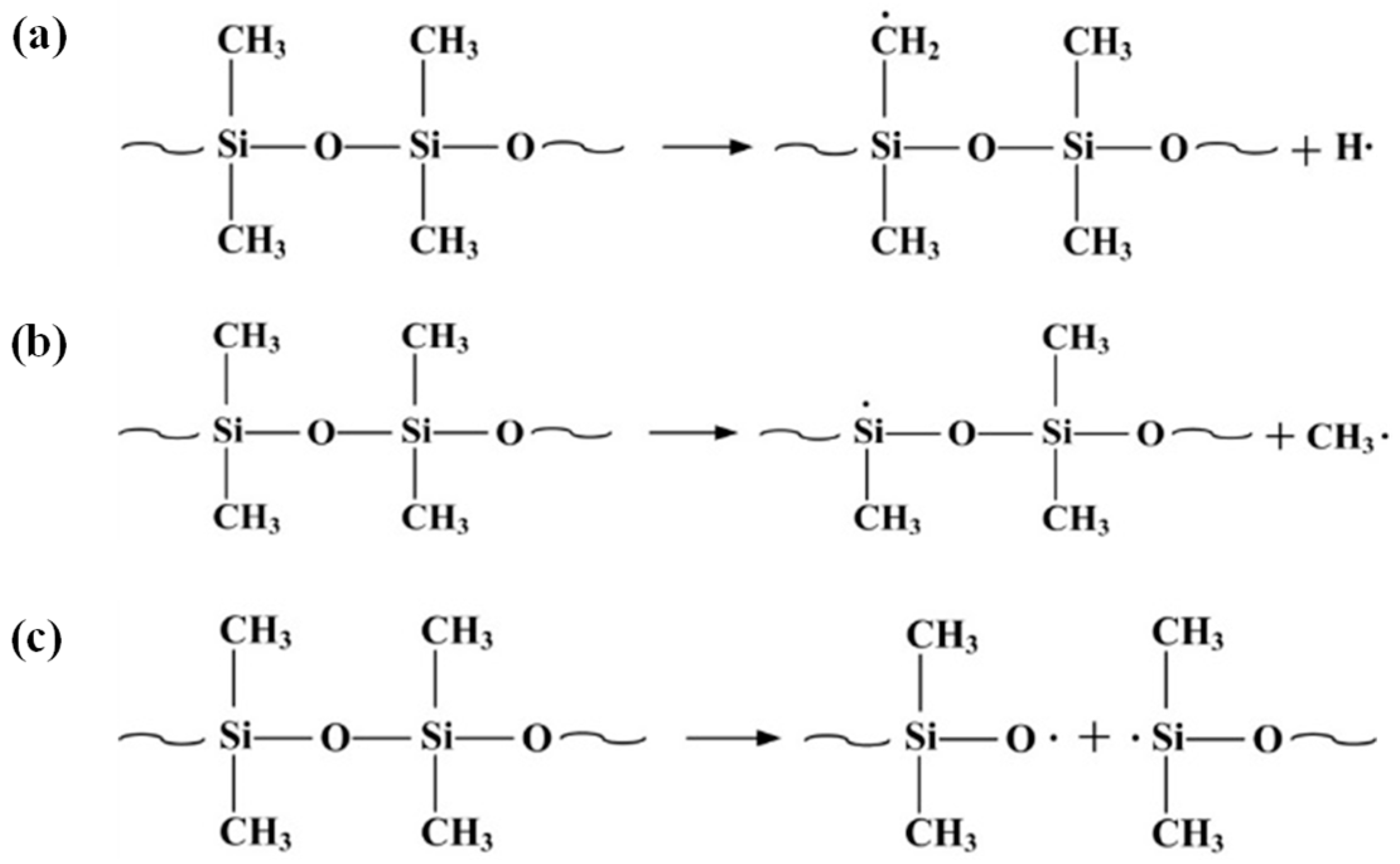

4.1. Effects of Voltage Frequency on Electrical Tree Initiation

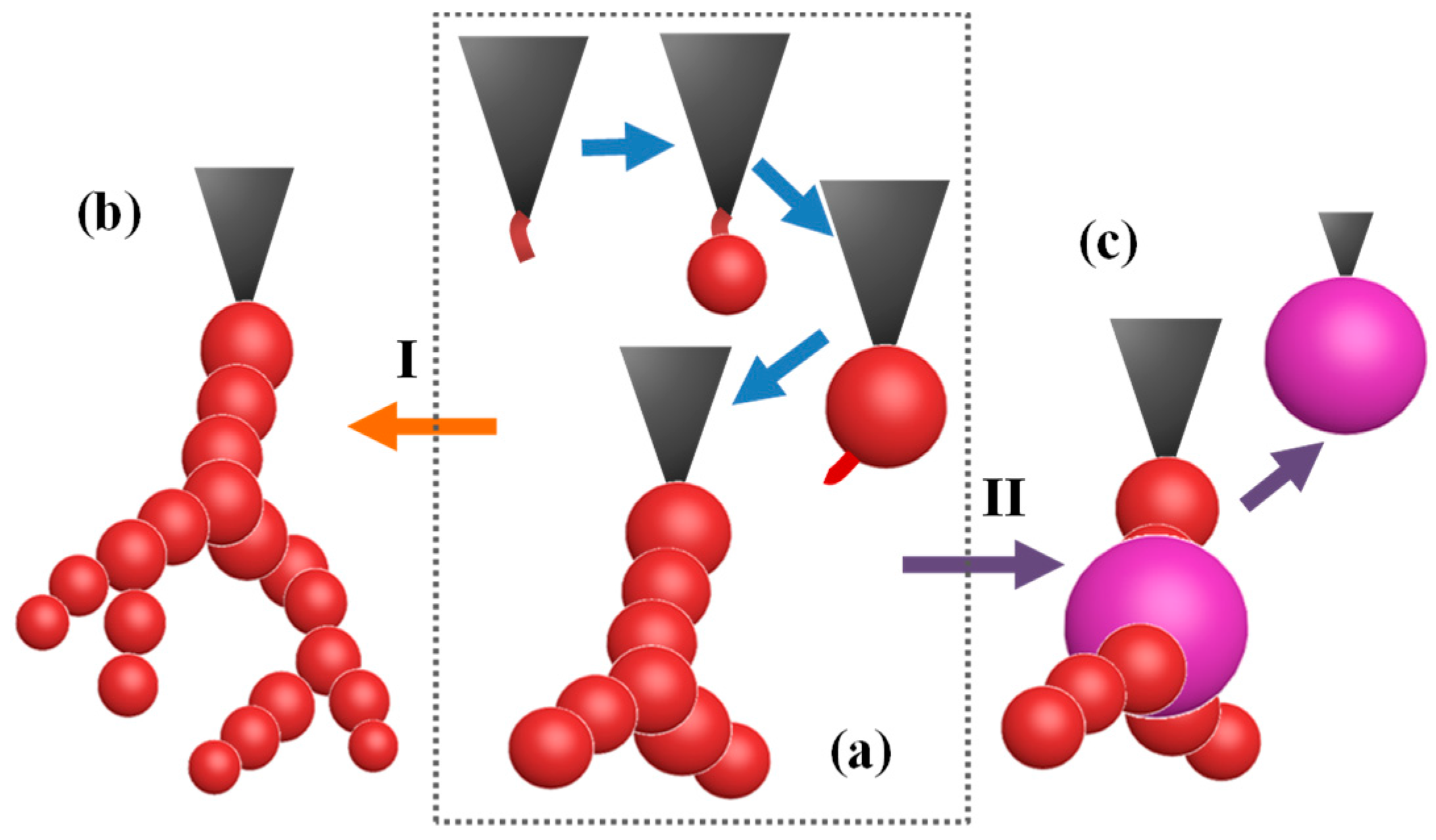

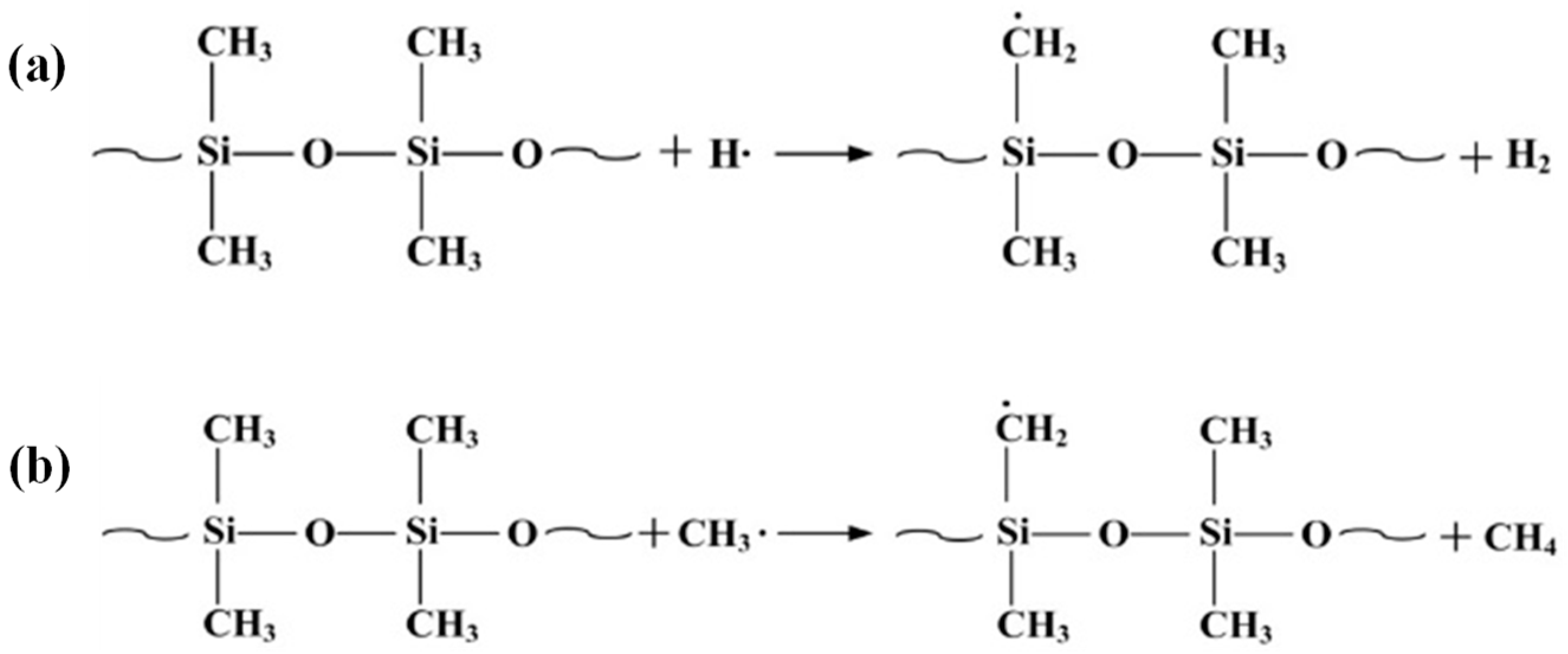

4.2. Potential Growth Model for Electrical Tree in SIR

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Jang, D.; Park, S. Evaluation of electrical tree degradation in cross-linked polyethylene cable using weibull process of propagation time. Energies 2017, 10, 1789. [Google Scholar] [CrossRef]

- Vaughan, A.S.; Hosier, I.L.; Dodd, S.J.; Sutton, S.J. On the structure and chemistry of electrical trees in polyethylene. J. Phys. D Appl. Phys. 2006, 39, 962–978. [Google Scholar] [CrossRef]

- Dissado, L.A. Understanding electrical trees in solids from experiment to theory. IEEE Trans. Dielectr. Electr. Insul. 2002, 9, 483–497. [Google Scholar] [CrossRef]

- Shimizu, N.; Laurent, C. Electrical tree initiation. IEEE Trans. Dielectr. Electr. Insul. 1998, 5, 651–659. [Google Scholar] [CrossRef]

- Du, B.X.; Xue, J.S.; Su, J.G.; Han, T. Effects of ambient temperature on electrical tree in epoxy resin under repetitive pulse voltage. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 1527–1536. [Google Scholar] [CrossRef]

- Dodd, S.J. A deterministic model for the growth of non-conducting electrical tree structures. J. Phys. D Appl. Phys. 2002, 36, 129–141. [Google Scholar] [CrossRef]

- Zhang, Y.X.; Zhou, Y.X.; Liu, R.; Zhang, X.; Wang, M.Y.; Zhang, L. Three-dimensional morphology and spherical growth mechanisms of electrical trees in silicone rubber. J. Electrost. 2015, 76, 83–88. [Google Scholar] [CrossRef]

- Iddrissu, I.; Zheng, H.L.; Rowland, S.M. DC electrical tree growth in epoxy resin and the influence of the size of inceptive AC trees. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 1965–1972. [Google Scholar] [CrossRef]

- Chalashkanov, N.M.; Dodd, S.J.; Dissado, L.A.; Fothergill, J.C. The role of bulk charge transport processes in electrical tree formation and breakdown mechanisms in epoxy resins. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 3256–3266. [Google Scholar] [CrossRef]

- Chen, X.R.; Xu, Y.; Cao, X.L.; Gubanski, S.M. Electrical treeing behavior at high temperature in XLPE cable insulation samples. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 2841–2851. [Google Scholar] [CrossRef]

- Tanaka, T. Space charge injected via interfaces and tree initiation in polymers. In Proceedings of the 2001 Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Kitchener, ON, Canada, 14–17 October 2001; pp. 1–15. [Google Scholar]

- Nie, Q.; Zhou, Y.X.; Chen, Z.Z.; Chen, H.H. Effect of frequency on electrical tree characteristics in silicone rubber. In Proceedings of the IEEE 9th International Conference on the Properties and Applications of Dielectric Materials, Harbin, China, 19–23 July 2009; pp. 513–516. [Google Scholar]

- Du, B.X.; Han, T.; Su, J.G. Electrical tree characteristics in silicone rubber under repetitive pulse voltage. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 720–727. [Google Scholar] [CrossRef]

- Zhou, Y.X.; Zhang, Y.X.; Zhang, L.; Guo, D.W.; Zhang, X.; Wang, M.Y. Electrical tree initiation of silicone rubber after thermal aging. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 748–756. [Google Scholar] [CrossRef]

- Tiemblo, P.; Hoyos, M.; Gómez-Elvira, J.M.; Guzmán, J.; García1, N.; Dardano, A.; Guastavino, F. The development of electrical treeing in LDPE and its nanocomposites with spherical silica and fibrous and laminar silicates. J. Phys. D Appl. Phys. 2008, 41, 1854–1862. [Google Scholar] [CrossRef]

- Chen, X.R.; Xu, Y.; Cao, X.L.; Gubanski, S.M. On the conducting and non-conducting electrical trees in XLPE cable insulation specimens. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 95–103. [Google Scholar] [CrossRef]

- Schurch, R.; Rowland, S.M.; Bradley, R.S.; Withers, P.J. Imaging and analysis techniques for electrical trees using X-ray computed tomography. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 53–63. [Google Scholar] [CrossRef]

- Champion, J.V.; Dodd, S.J.; Alison, J.M. The correlation between the partial discharge behavior and the spatial and temporal development of electrical trees grown in an epoxy resin. J. Phys. D Appl. Phys. 1996, 29, 2689–2695. [Google Scholar] [CrossRef]

- Albertini, M.; Coletti, G.; Gemme, C.; Guastavino, F. Frequency acceleration of surface partial discharge tests on thin polymer films. In Proceedings of the 1994 IEEE International Symposium on Electrical Insulation, Pittsburgh, PA, USA, 5–8 June 1994; pp. 352–355. [Google Scholar]

- Li, G.; Hao, J.; Li, S.; Liao, R.J.; Zhao, X.T.; Yang, L.J. AC breakdown and frequency dielectric response characteristics of the mixed oil-paper insulation with different moisture content. In Proceedings of the 2017 IEEE Conference on Electrical Materials and Power Equipment, Xi’an, China, 14–17 May 2017; pp. 478–481. [Google Scholar]

- Akihiko, S.; Masaki, S.; Hisaaki, K.; Kiyotoshi, T.; Tadao, S. Degradation mechanisms of silicone rubber (SIR) by accelerated ageing for cables of nuclear power plant. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 16–23. [Google Scholar]

- Zhang, Y.X.; Zhou, Y.X.; Chen, M.; Zhang, L.; Zhang, X.; Sha, Y.C. Electrical tree initiation in silicone rubber under DC and polarity reversal voltages. J. Electrostat. 2017, 88, 207–213. [Google Scholar] [CrossRef]

- Zhou, Y.X.; Liu, R.; Hou, F.; Zhang, X.; Xue, W.B. Morphology of electrical trees in silicon rubber. J. Electrostat. 2013, 71, 440–448. [Google Scholar] [CrossRef]

- Aka-Ngnui, T.; Beroual, A. Bubble dynamics and transition into streamers in liquid dielectrics under a high divergent electric field. J. Phys. D Appl. Phys. 2001, 34, 1408–1412. [Google Scholar] [CrossRef]

- Watson, P.K. Electrostatic and hydrodynamic effects in the electrical breakdown of liquid dielectrics. IEEE Trans. Electr. Insul. 1985, 20, 395–399. [Google Scholar] [CrossRef]

- Garton, C.G.; Krasucki, Z. Bubbles in insulating liquids: Stability in an electric field. Proc. R. Soc. 1964, 280, 211–226. [Google Scholar] [CrossRef]

- Bao, M.H.; Tang, S.Y.; He, J.J.; Yin, X.G.; Wang, Q.; Wu, G.L.; Yang, Y. The initiation phenomena of electrical treeing in XLPE cable insulation. In Proceedings of the 2012 IEEE Conference on High Voltage Engineering and Application, Shanghai, China, 17–20 September 2012; pp. 431–434. [Google Scholar]

- Tanaka, T.; Greenwood, A. Effects of charge injection and extraction on tree initiation in polyethylene. IEEE Trans. Power Appar. Syst. 1978, 97, 1749–1759. [Google Scholar] [CrossRef]

- Dissado, L.A.; Fothergill, J.C. Electrical Degradation and Breakdown in Polymers, 1st ed.; Peter Peregrinus Ltd.: London, UK, 1992; pp. 125–131. [Google Scholar]

- Salvatierra, L.M.; Kovalevski, L.I.; Quina, P.L.D.; Irurzun, I.M.; Mola, E.E.; Dodd, S.J.; Dissado, L.A. Self-healing during electrical treeing: A feature of the two-phase liquid-solid nature of silicone gels. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 757–767. [Google Scholar] [CrossRef]

- Kovalevski, L.I.; Salvatierra, L.M.; Quina, P.L.D.; Irurzun, I.M.; Mola, E.E.; Chalashkanov, N.; Dodd, S.J.; Dissado, L.A. Effect of the field frequency during treeing tests in silicone polymers with different degree of crosslinking. In Proceedings of the 2015 IEEE Conference on Electrical Insulation and Dielectric Phenomena, Ann Arbor, MI, USA, 18–21 October 2015; pp. 613–616. [Google Scholar]

- Chalashkanov, N.; Dodd, S.J.; Dissado, L.A.; Salvatierra, L.M.; Kovalevski, L.; Mola, E. Strain produced by electrostatic forces in electrical trees and its relationship with the elastic modulus of the polymer matrix. In Proceedings of the 2015 IEEE Conference on Electrical Insulation and Dielectric Phenomena, Ann Arbor, MI, USA, 18–21 October 2015; pp. 601–604. [Google Scholar]

- Tanaka, T. Internal partial discharge and material degradation. IEEE Trans. Electr. Insul. 1986, 21, 899–905. [Google Scholar] [CrossRef]

- Zhang, L.X.; Xu, Z.; He, S.Y. A model for destruction of the methyl silicone rubber net-structure after the synergistic radiation of proton and electrons. Acta Chim. Sin. Chin. Ed. 2004, 62, 725–728. [Google Scholar]

- Roy, S.L.; Baudoin, F.; Griseri, V.; Laurent, C.; Teyssèdre, G. Space charge modeling in electron-beam irradiated polyethylene: Fitting model and experiments. J. Appl. Phys. 2012, 112, 351–357. [Google Scholar]

| Frequency (Hz) | α (kV) | β |

|---|---|---|

| 50 | 8.50 | 5.47 |

| 500 | 7.84 | 5.50 |

| 1 k | 6.59 | 7.47 |

| 10 k | 6.27 | 6.66 |

| 80 k | 6.61 | 8.68 |

| 130 k | 6.12 | 7.99 |

| Type | Probability | Average Breakdown Duration (min) |

|---|---|---|

| Bush-like treeing | 37.5% | 90.0 |

| Pine-like treeing | 62.5% | 4.98 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Zhou, Y.; Zhang, L.; Zhou, Z.; Nie, Q. Electrical Trees and Their Growth in Silicone Rubber at Various Voltage Frequencies. Energies 2018, 11, 327. https://doi.org/10.3390/en11020327

Zhang Y, Zhou Y, Zhang L, Zhou Z, Nie Q. Electrical Trees and Their Growth in Silicone Rubber at Various Voltage Frequencies. Energies. 2018; 11(2):327. https://doi.org/10.3390/en11020327

Chicago/Turabian StyleZhang, Yunxiao, Yuanxiang Zhou, Ling Zhang, Zhongliu Zhou, and Qiong Nie. 2018. "Electrical Trees and Their Growth in Silicone Rubber at Various Voltage Frequencies" Energies 11, no. 2: 327. https://doi.org/10.3390/en11020327

APA StyleZhang, Y., Zhou, Y., Zhang, L., Zhou, Z., & Nie, Q. (2018). Electrical Trees and Their Growth in Silicone Rubber at Various Voltage Frequencies. Energies, 11(2), 327. https://doi.org/10.3390/en11020327