Compared with other enhanced oil recovery (EOR) technologies such as chemical flooding and thermal recovery, low-salinity water flooding is simple, economical and practical. Especially for unconventional reservoirs such as tight reservoirs, the general EOR methods such as polymer flooding cannot be applied because of the difficulty in injecting into such small pores, whose overpressure matrix permeability is less than 0.1 × 10

−3 mD. On the other hand, low-salinity water flooding can enter the small pores at this scale, and the risk is low. Thus, low-salinity water flooding has great application potential in unconventional reservoirs. During the period of low oil prices, low-salinity water flooding has made great progress [

1,

2,

3]. Martin [

4] reported for the first time that decreasing the salinity of injected water improved the recovery of oil. However, this report did not get much attention until 1997 when Tang and Morrow [

5] reported that the oil recovery was effectively improved by injecting low-salinity water and optimizing the composition of injected water. After that, numerous laboratory tests and field tests on low-salinity water flooding were carried out. Robertson, Lager and Seccombe [

6,

7,

8] carried out oil field tests and achieved the desired results, confirming the feasibility of low-salinity water flooding. In 2006, Jerauld [

3] found through numerical simulation that the injection of low-salinity water affected the relative permeability and formation pressure, thus changing the wettability of rock and finally improving the recovery. In 2008, Larger and others [

9] proved through experiments that multicomponent ion exchange (MIE) occurs between low-salinity water injection, clay mineral surface and injected brine, thus enhancing the oil recovery. In 2010, Sorbie [

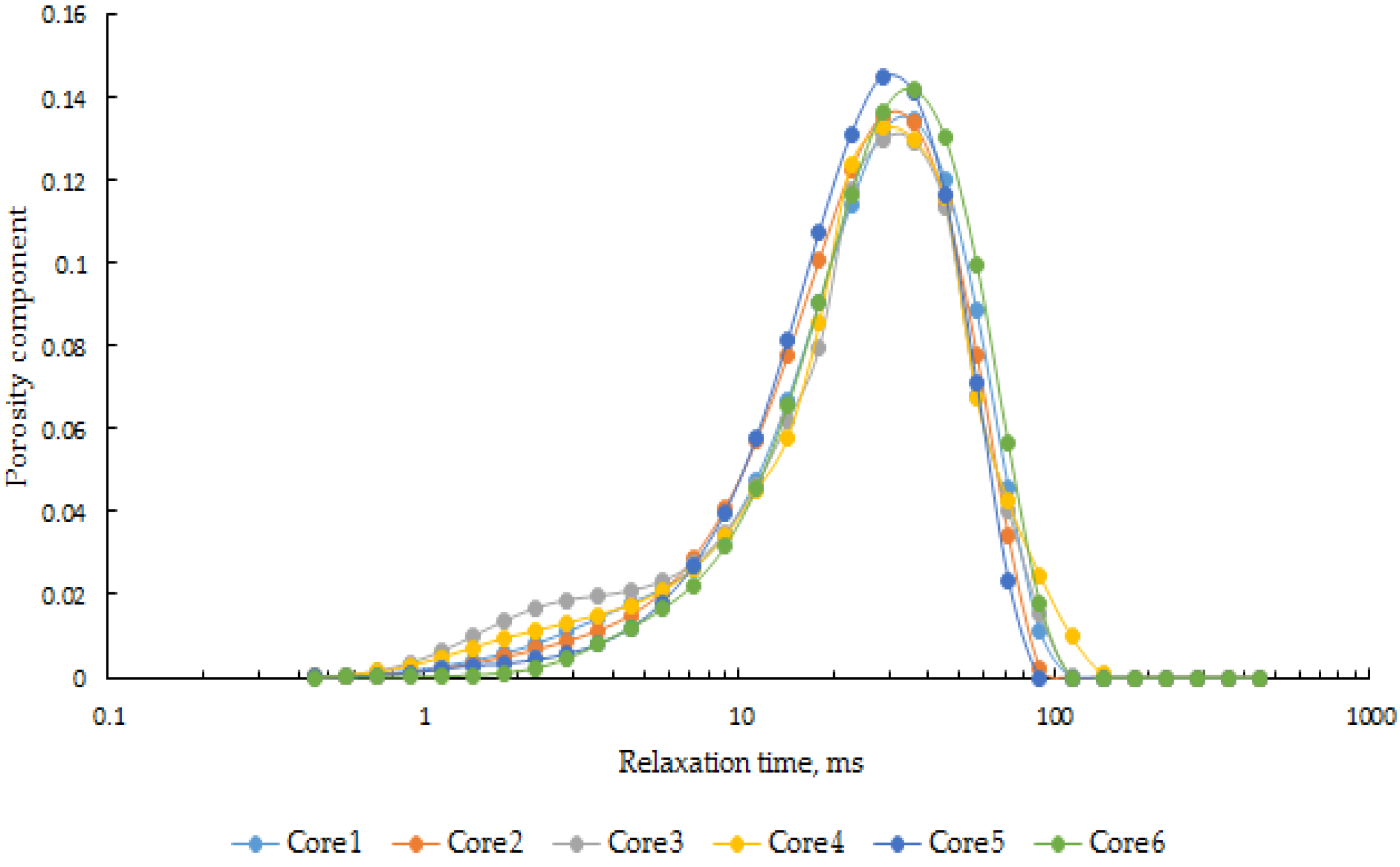

10] proposed a mechanism for low-salinity water flooding, which is believed to be associated with rock porosity by low-salinity water flooding. At the same time, Rezaeidoust [

11] also verified through application of low-salinity water flooding in Beihai sandstone reservoir that when the salinity of the injected water is low enough, the oil recovery can be improved. Many low-salinity water flooding experiments were carried out on limestone cores by Yousef and others [

2,

12,

13] in 2011, and they found that continuous injection of low-salinity water can make rock more hydrophilic and improve recovery by improving pore throat connectivity. In 2015, Wu Jian [

14] analyzed the oilfield experimental data and concluded that the main reason for the enhanced oil recovery effect of low-salinity water flooding is the microscopic transformation of reservoirs caused by migration of clay particles. Recently, Shehata [

15] used zeta-potential measurements in low-salinity water flooding and found that chlorite and illite contributed to a smaller electrical-double-layer expansion compared to kaolinite, feldspars, montmorillonite, and muscovite. It has provoked people’s attention to the effect of clay minerals in low salinity water flooding.

Clay minerals are widely distributed in China and the types and contents of clay minerals in different reservoirs vary greatly [

16,

17,

18], so they have an important impact on oilfield development. According to Li and Zou [

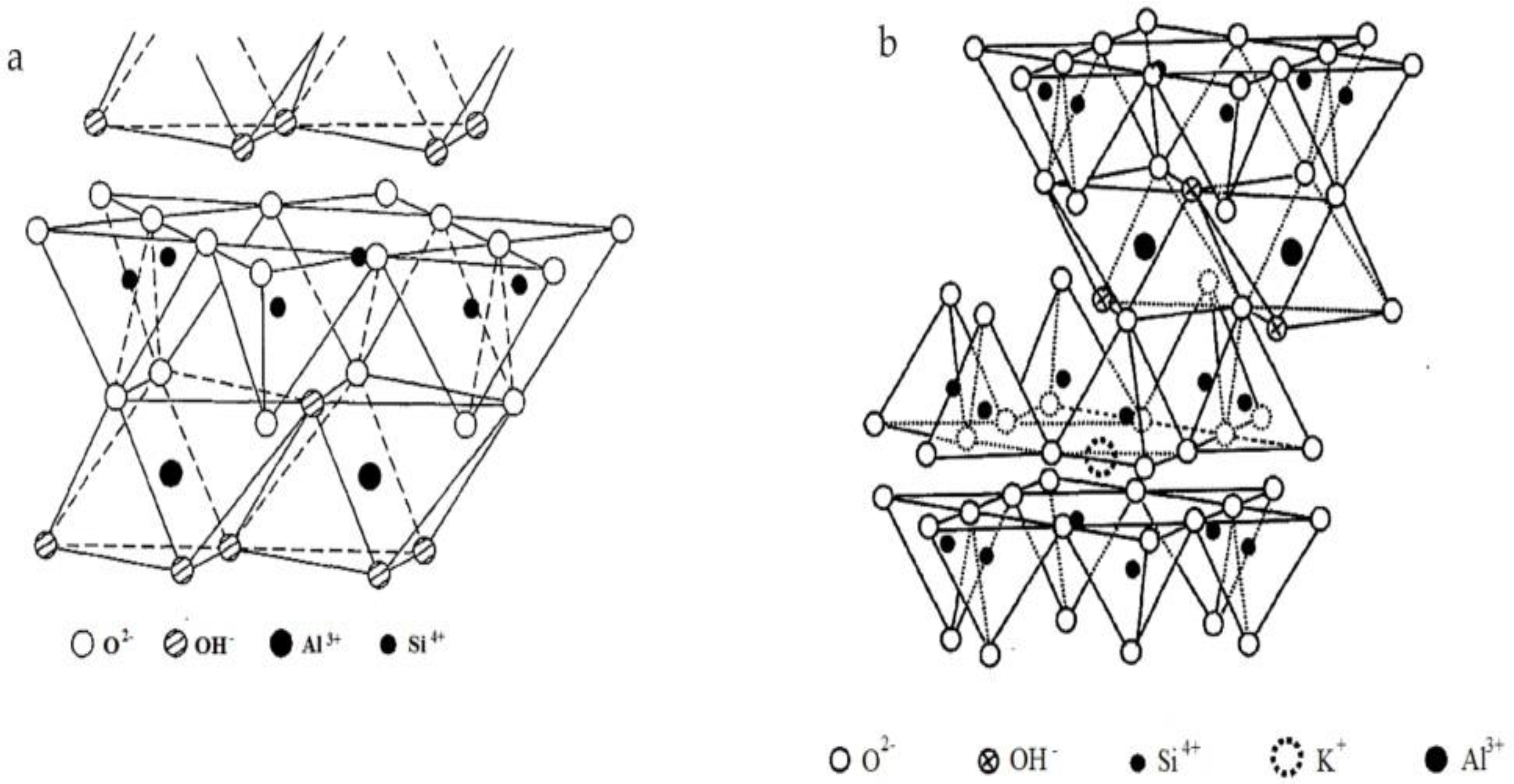

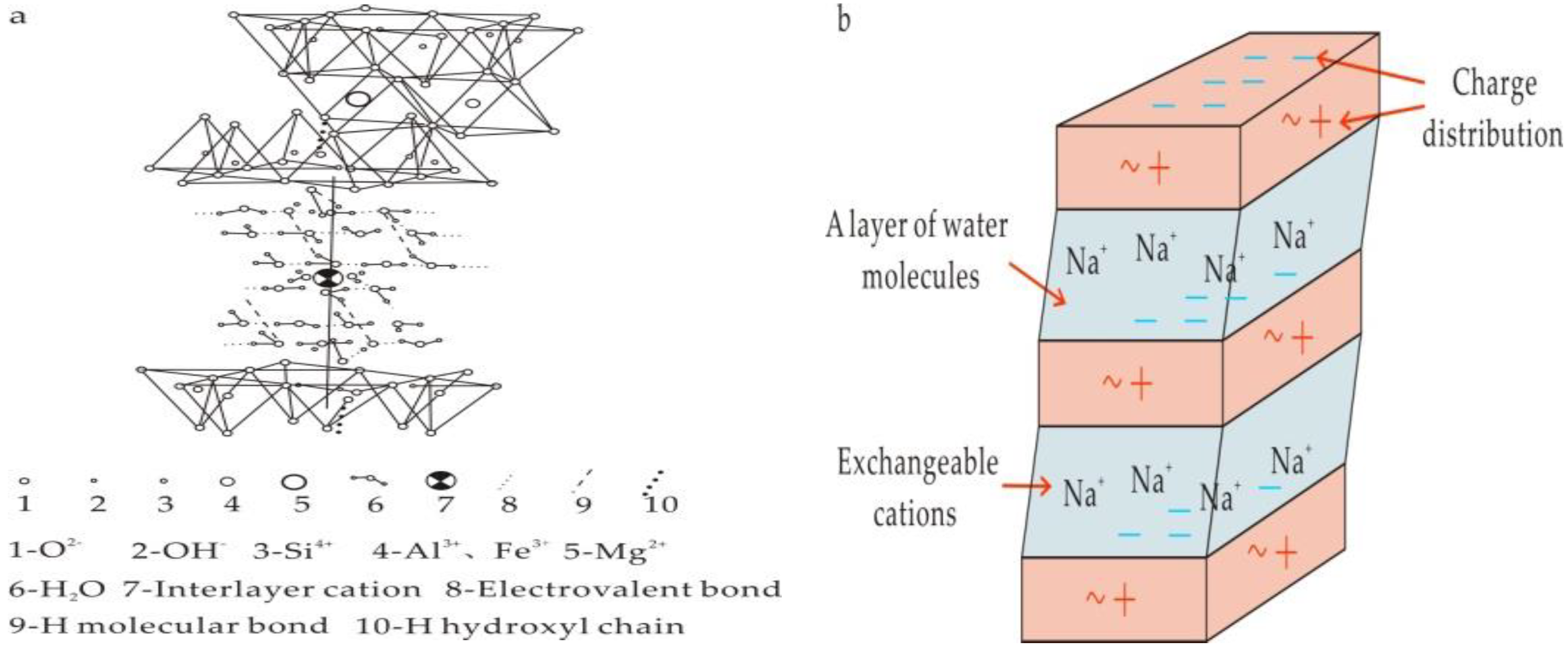

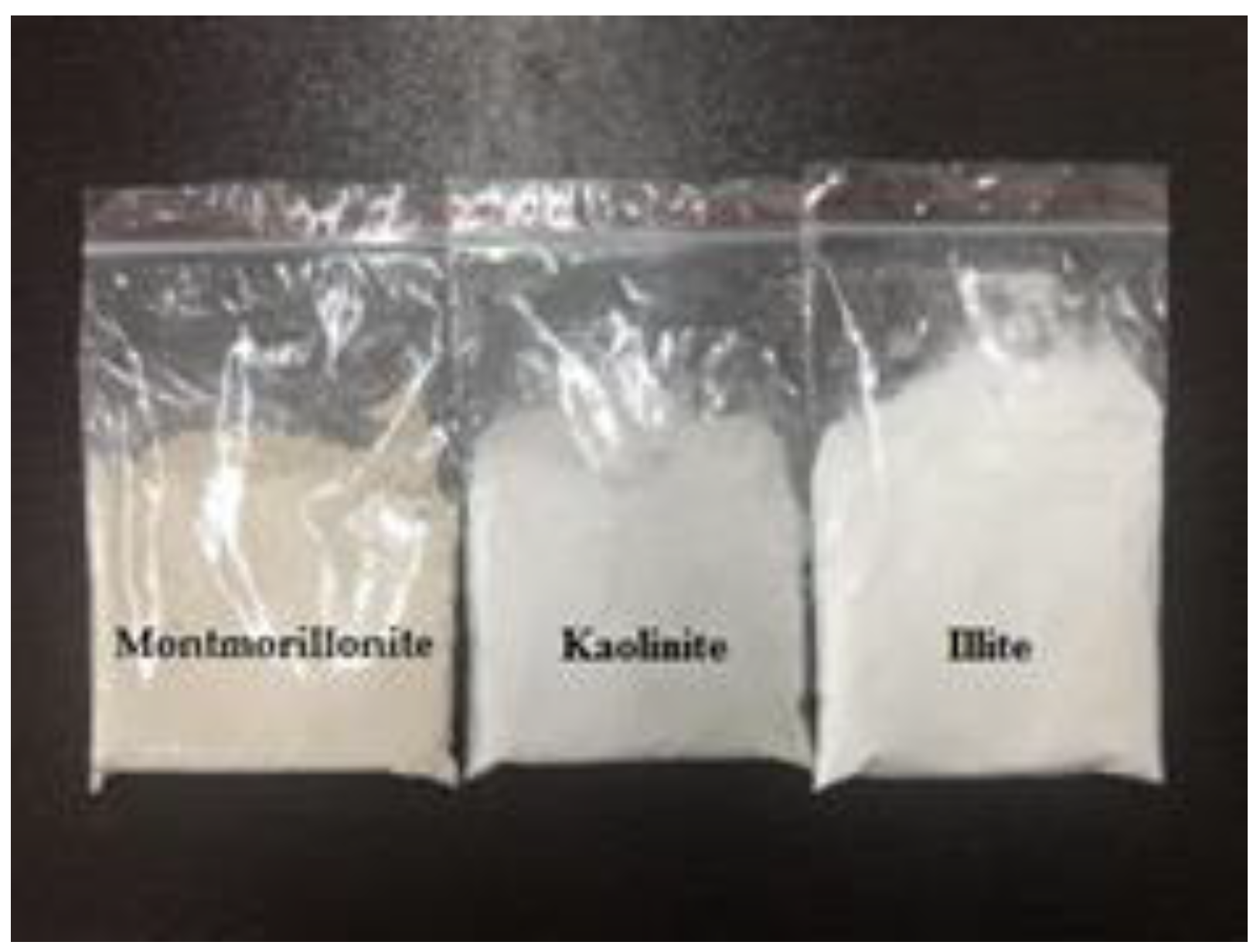

19,

20], three main clay minerals (illite, kaolinite and montmorillonite) have very different crystal structures (

Table 1), which may be the reason for their different effects on low-salinity water flooding.

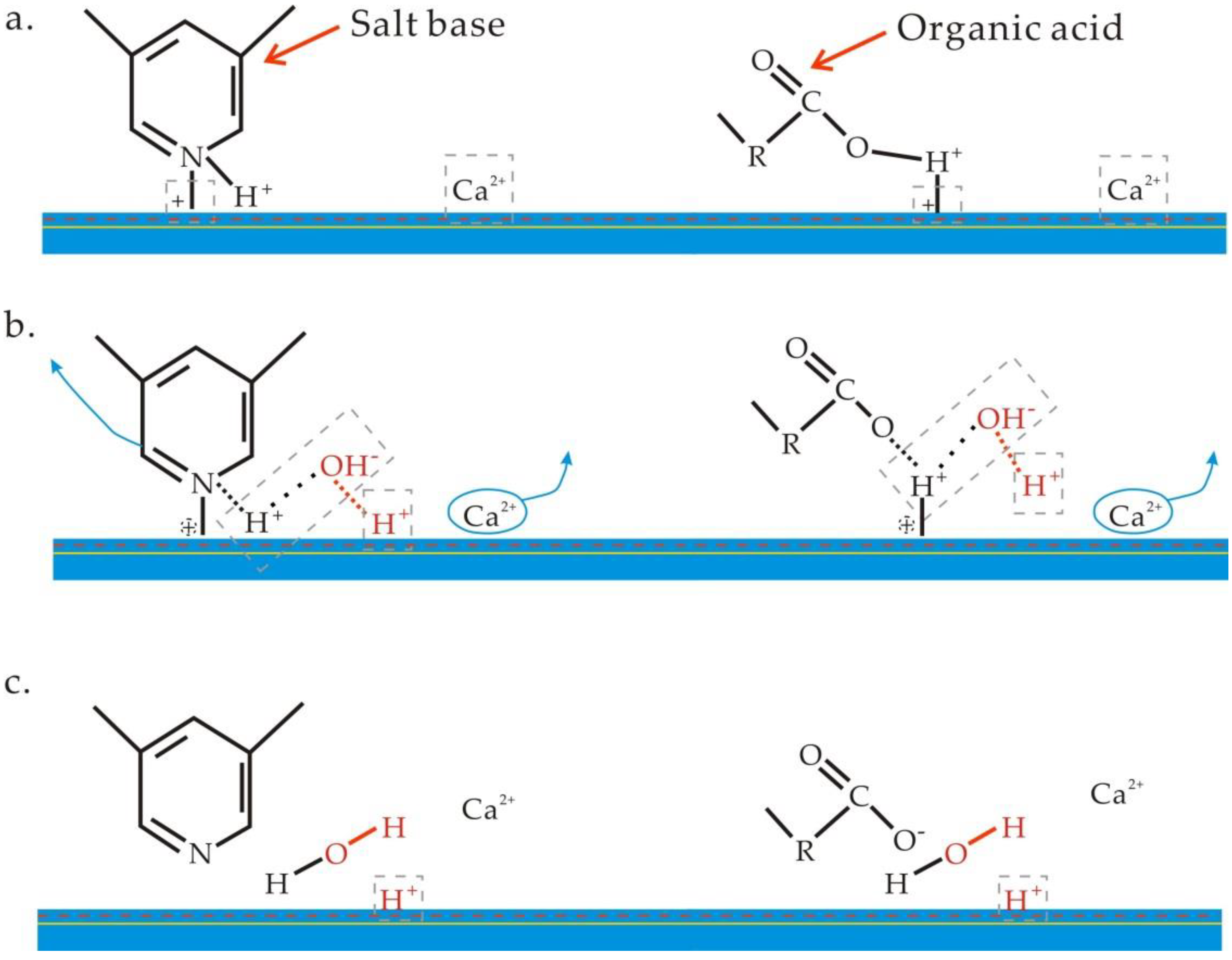

Illite is made up of two Si-O tetrahedral sheets and one A1-O/OH octahedral sheet. The octahedral sheet is between two Si-O tetrahedral sheets. The head of Si-O tetrahedral sheets points to A1-O/OH octahedral sheet, and shares Oxygen atom with A1-O/OH octahedral sheet. Approximately 1/4 of Si

4+ atoms in the Si-O tetrahedron are replaced by A1

3+, causing a lack of positive charge. Consequently, a layer of K

+ is formed between the two structural unit layers to balance the negative charge due to the displacement. During the evolution of mica into illite, K

+ is easily exchanged with other cations. Therefore, Ca

2+ and Mg

2+ are often found in the layers of illite, and the interlayer structure of illite is not stable (

Figure 1b). This property is beneficial for ion exchange on its surface.

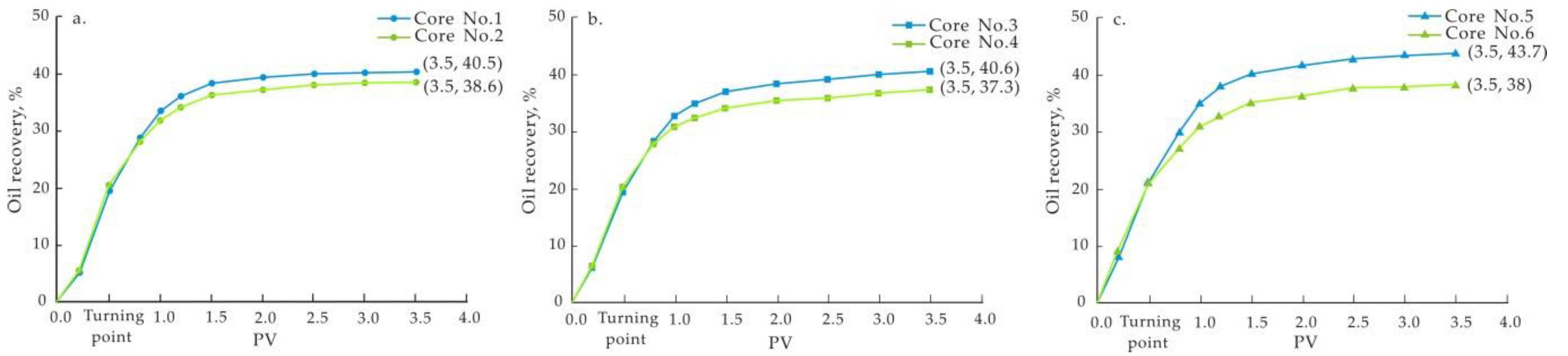

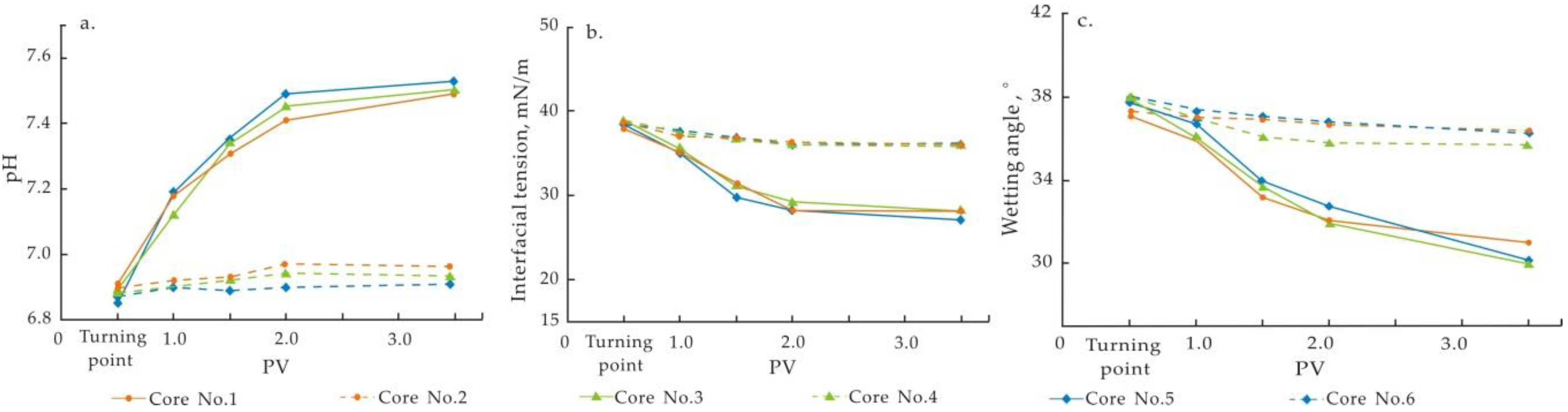

Great progress has been made in the study of the mechanism of low-salinity water flooding, but there is still a lot of controversy. Furthermore, the above studies did not quantitatively analyze the clay mineral composition of the cores used. The effect of low-salinity water flooding is probably related to clay mineral composition, but the influence of clay mineral composition on the EOR mechanism lacks the necessary basic experimental support. Therefore, three groups of experiments were designed in this study, and the influence of clay mineral composition on low-salinity water flooding was quantitatively studied based on the measurements of pH value, interfacial tension and wetting angle. The research results are of great significance for improving the recovery of clay-bearing mineral reservoirs.