Prediction of Remaining Useful Life of Wind Turbine Bearings under Non-Stationary Operating Conditions

Abstract

:1. Introduction

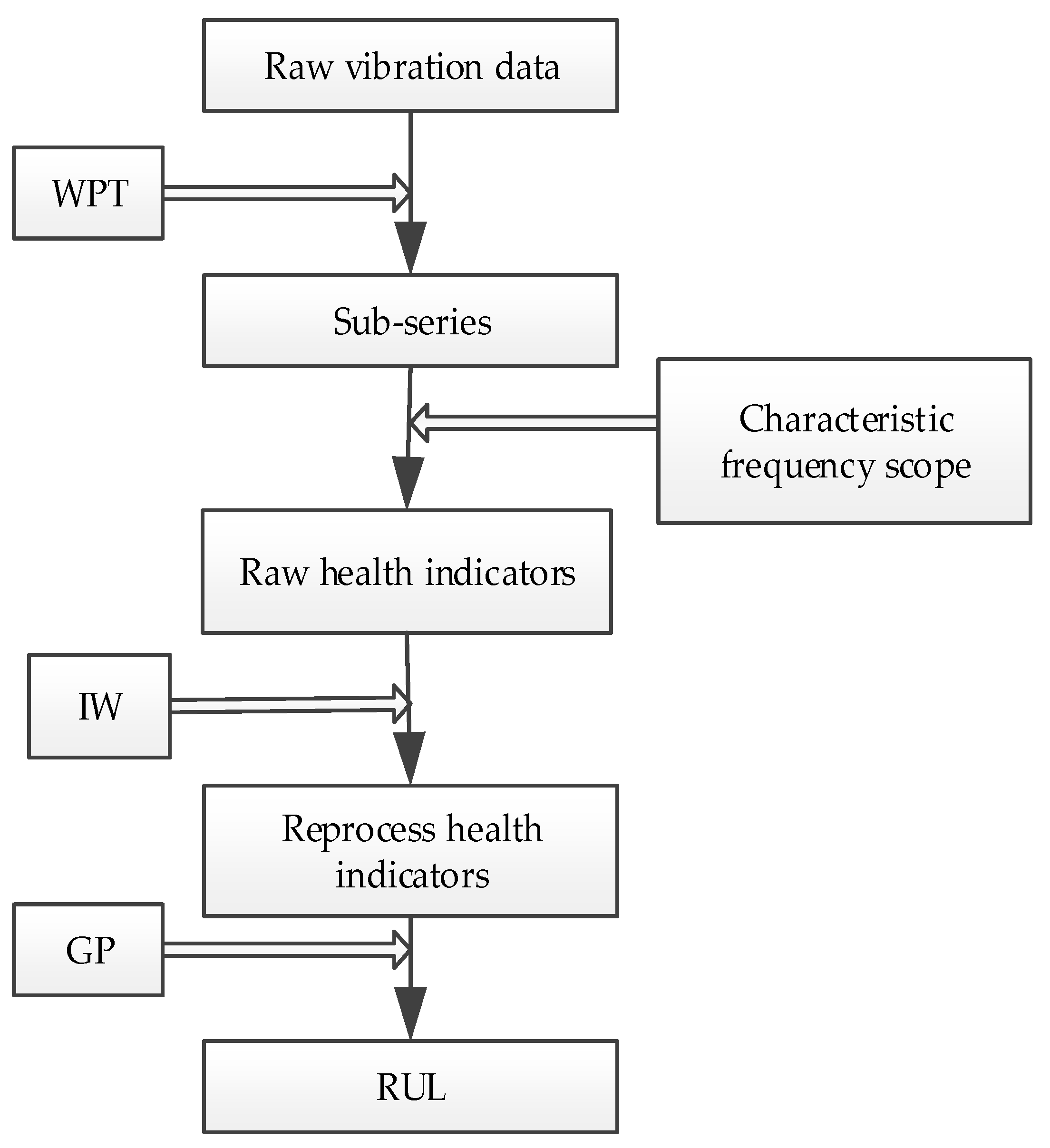

2. The Basic Theory of Gaussian Process

3. The Proposed RUL Prediction Method

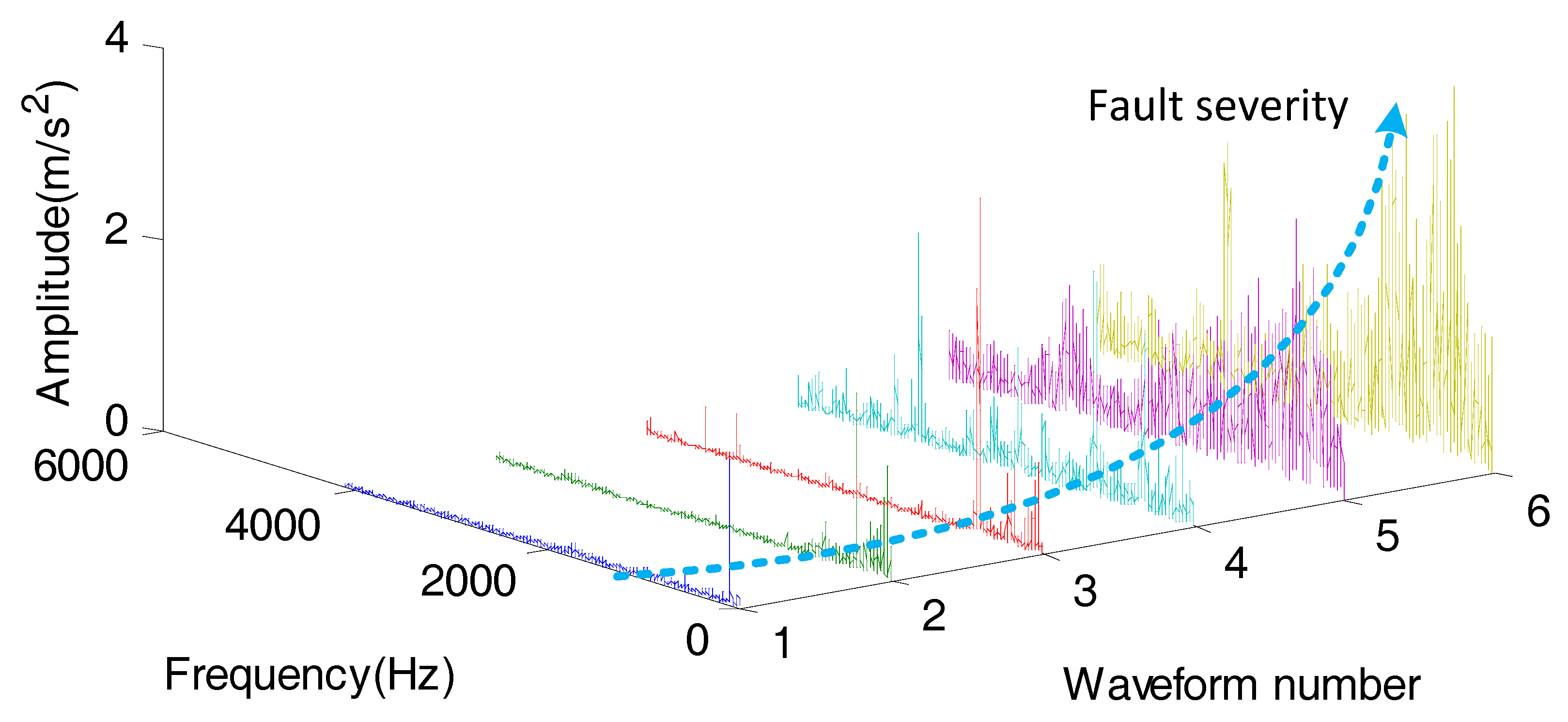

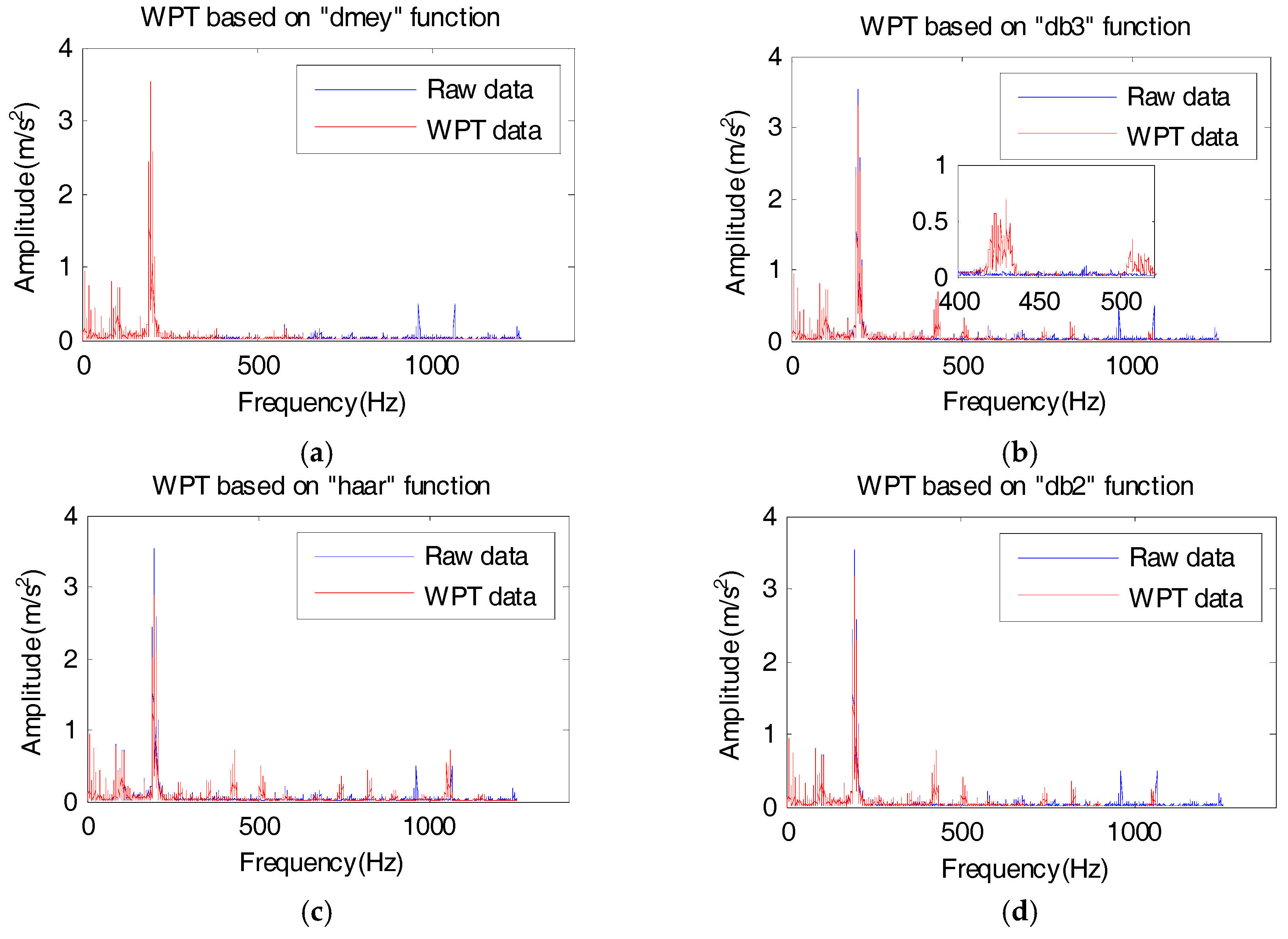

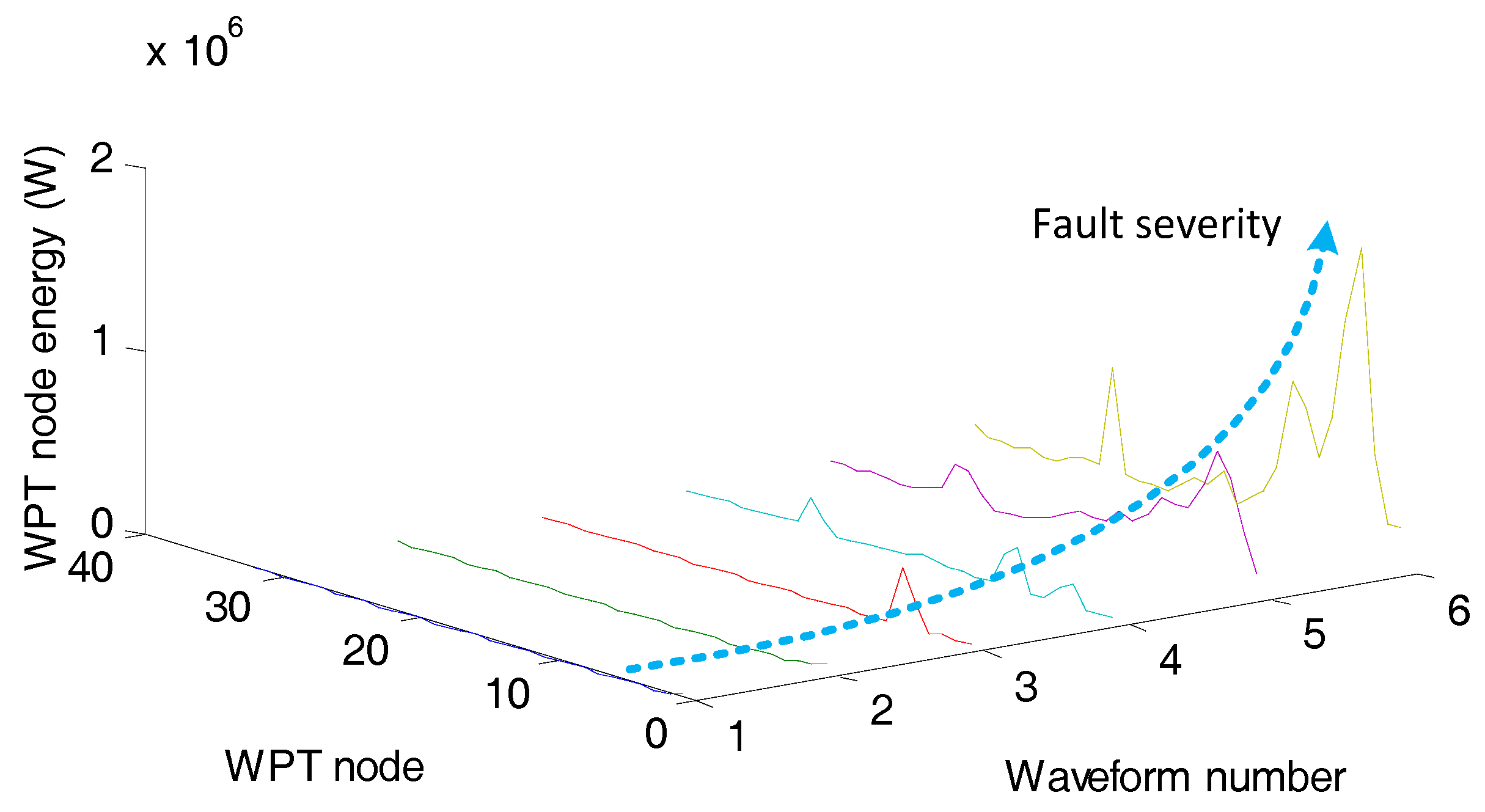

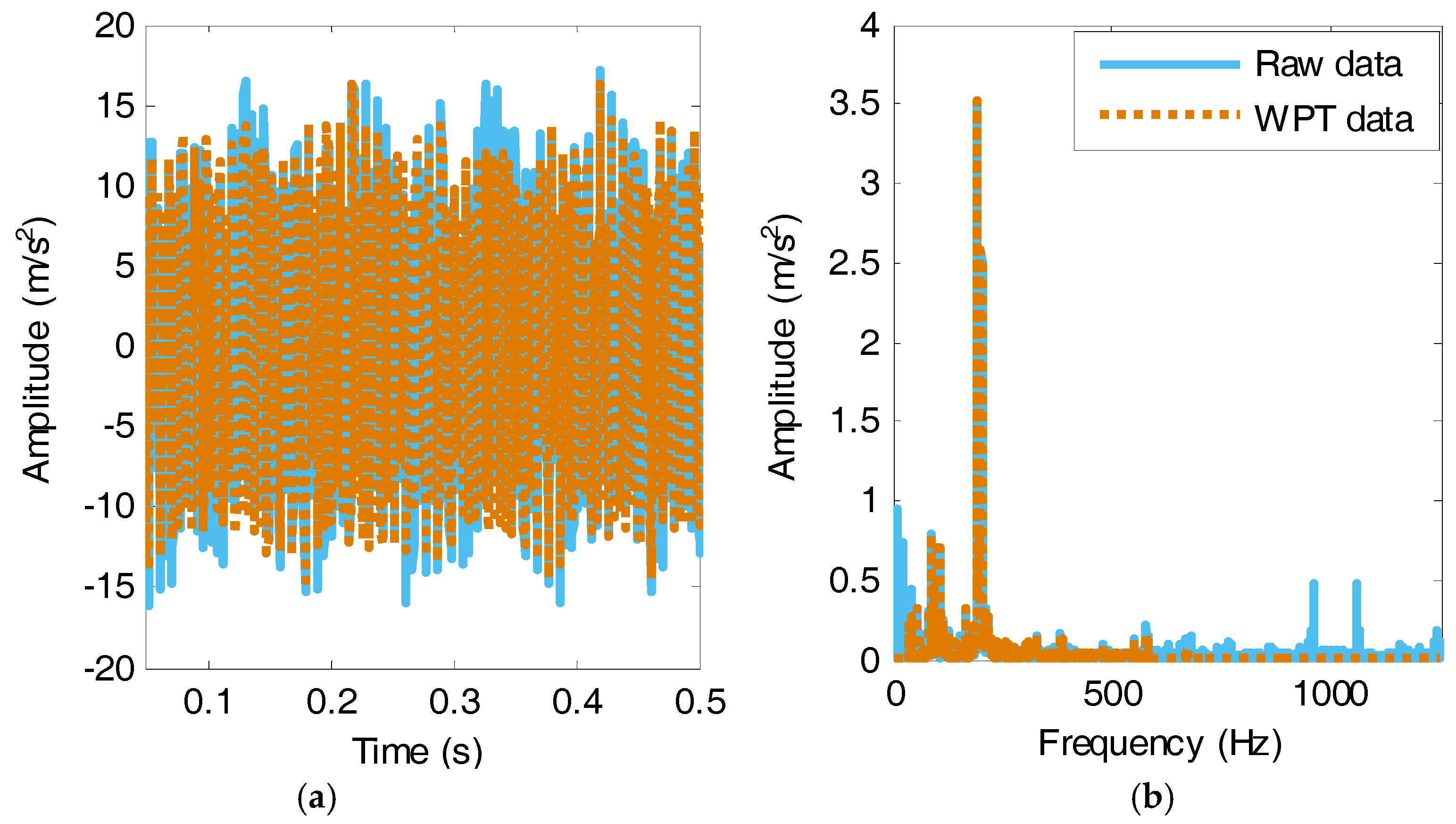

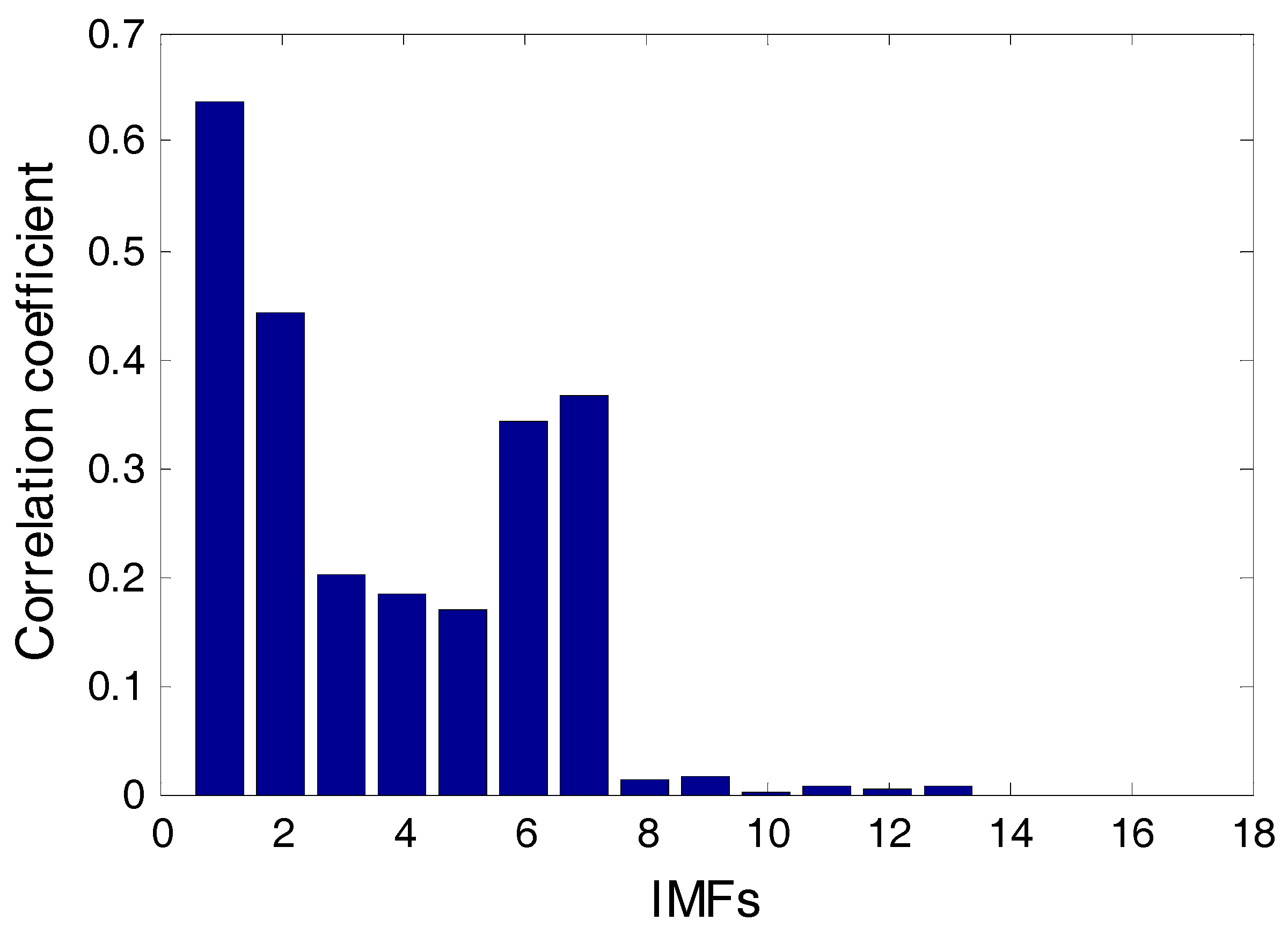

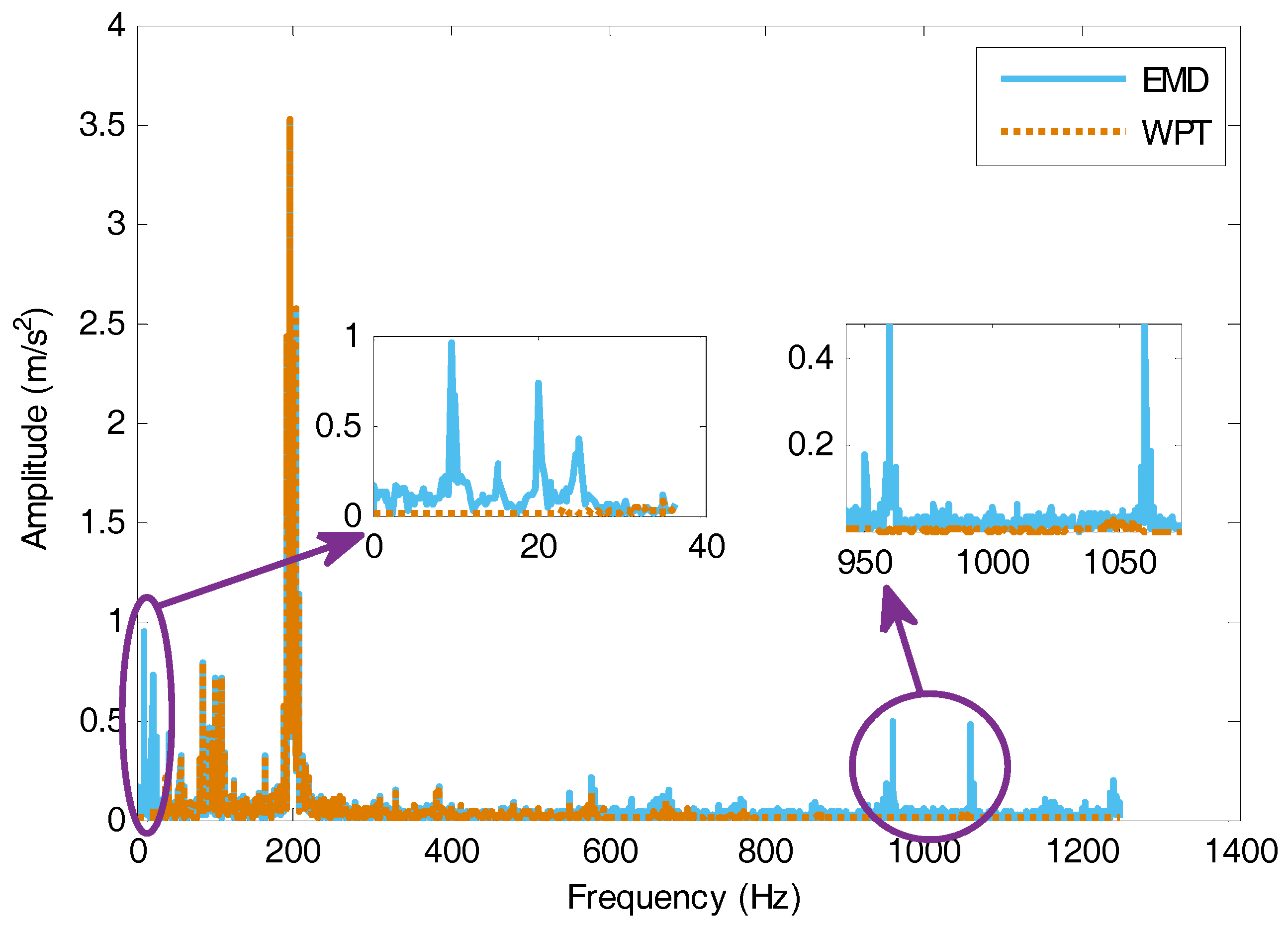

3.1. Health Indicators Extraction

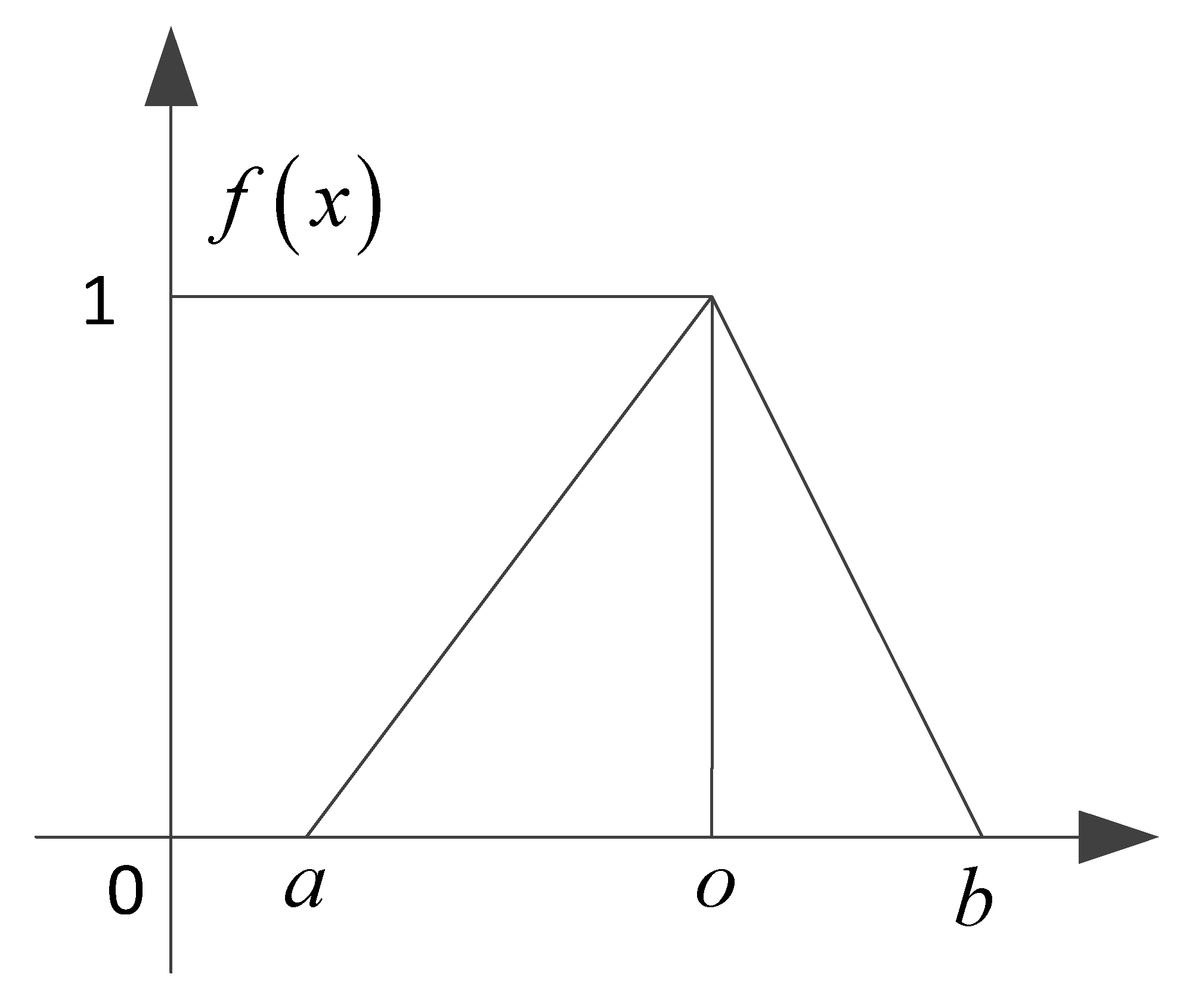

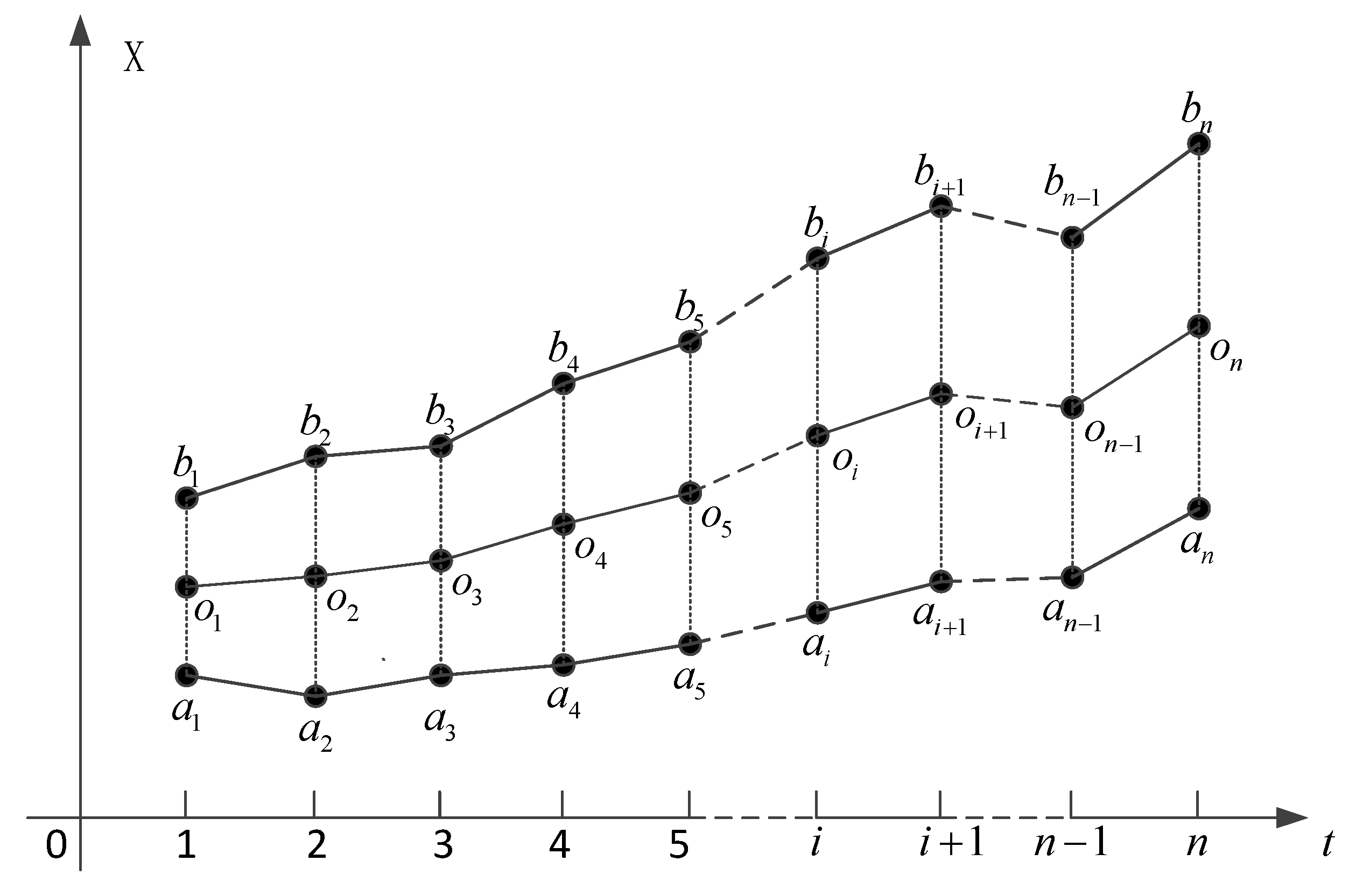

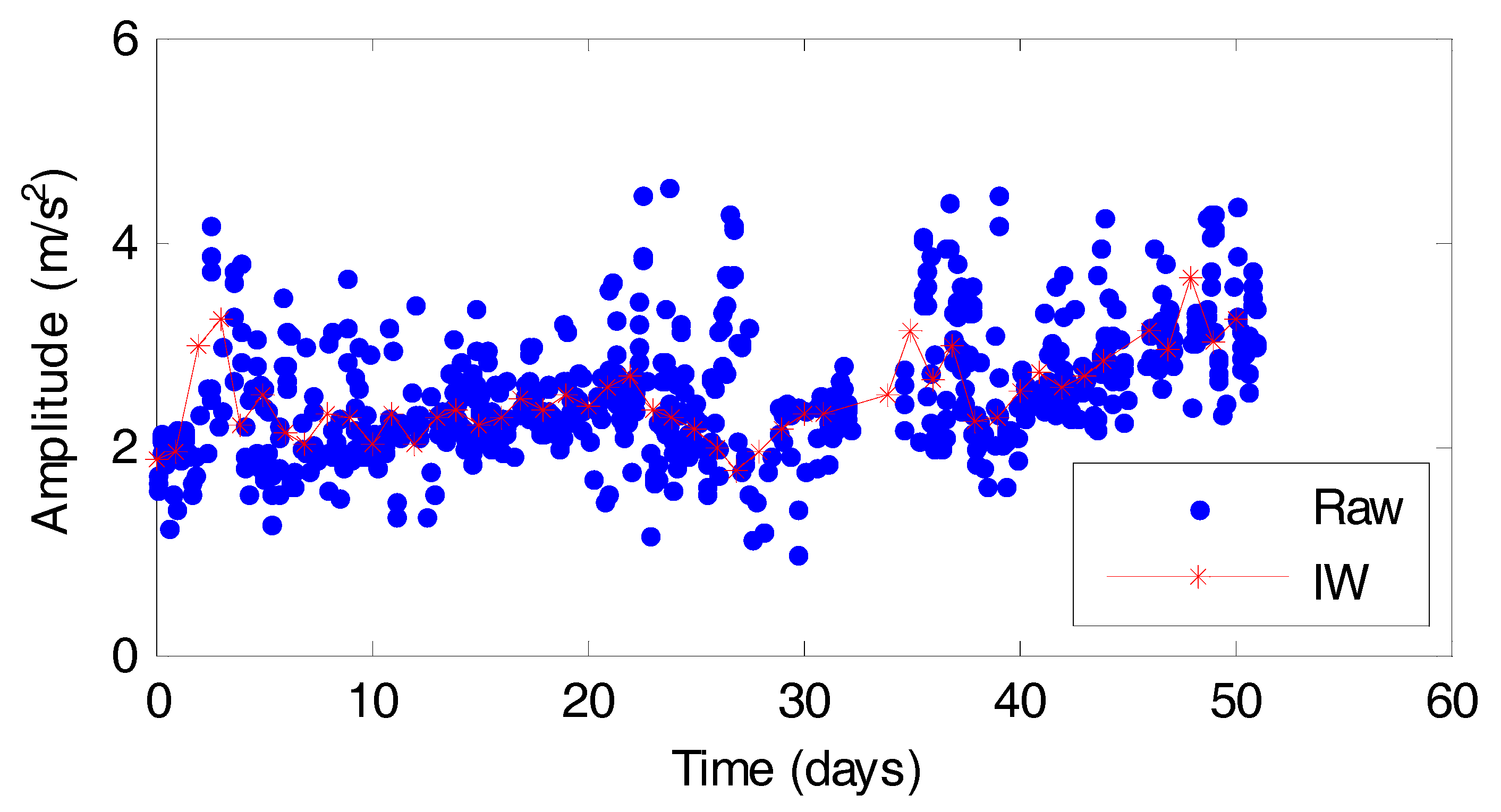

3.2. Interval Whitenization (IW) Method

3.3. RUL Prediction

4. Experimental Validation

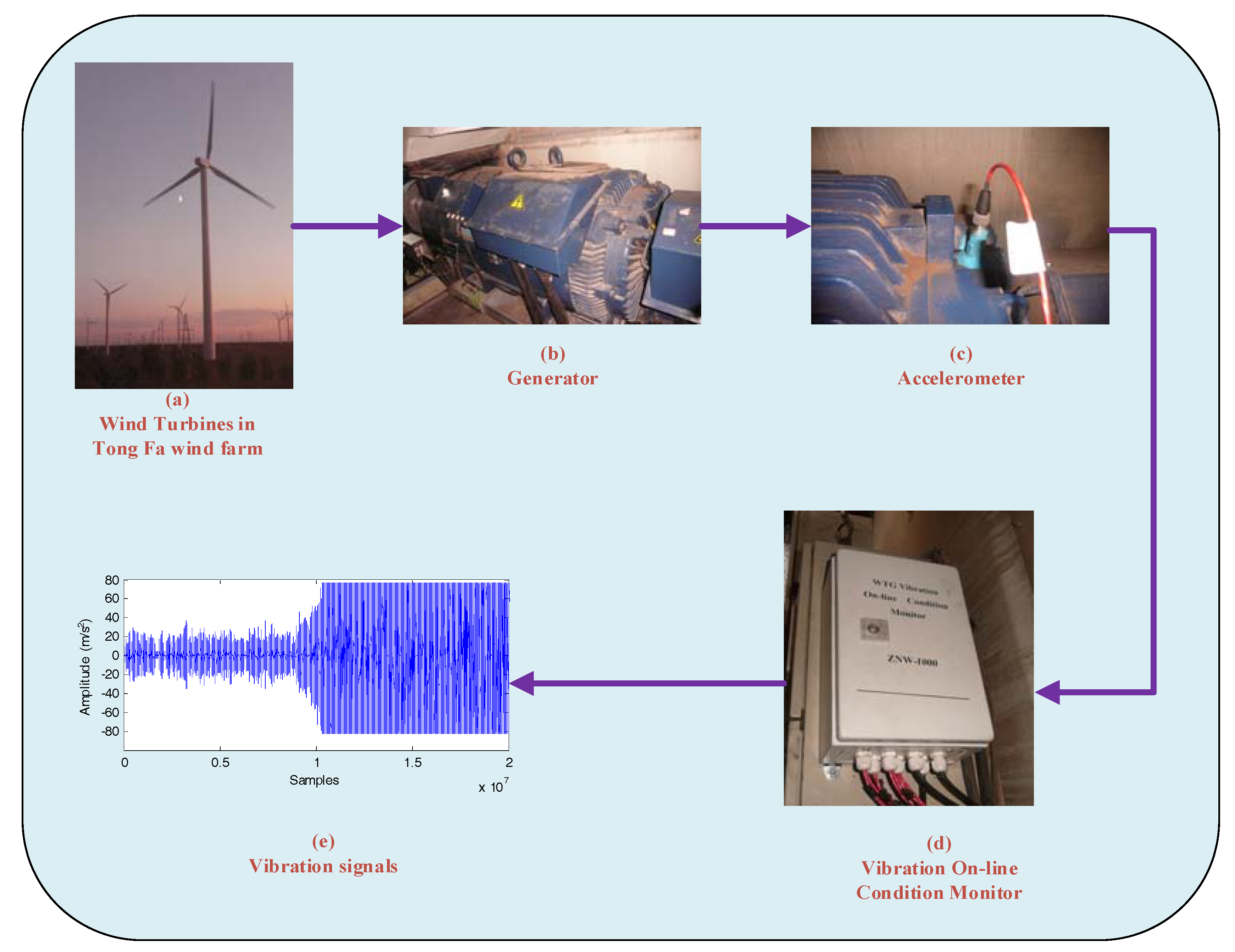

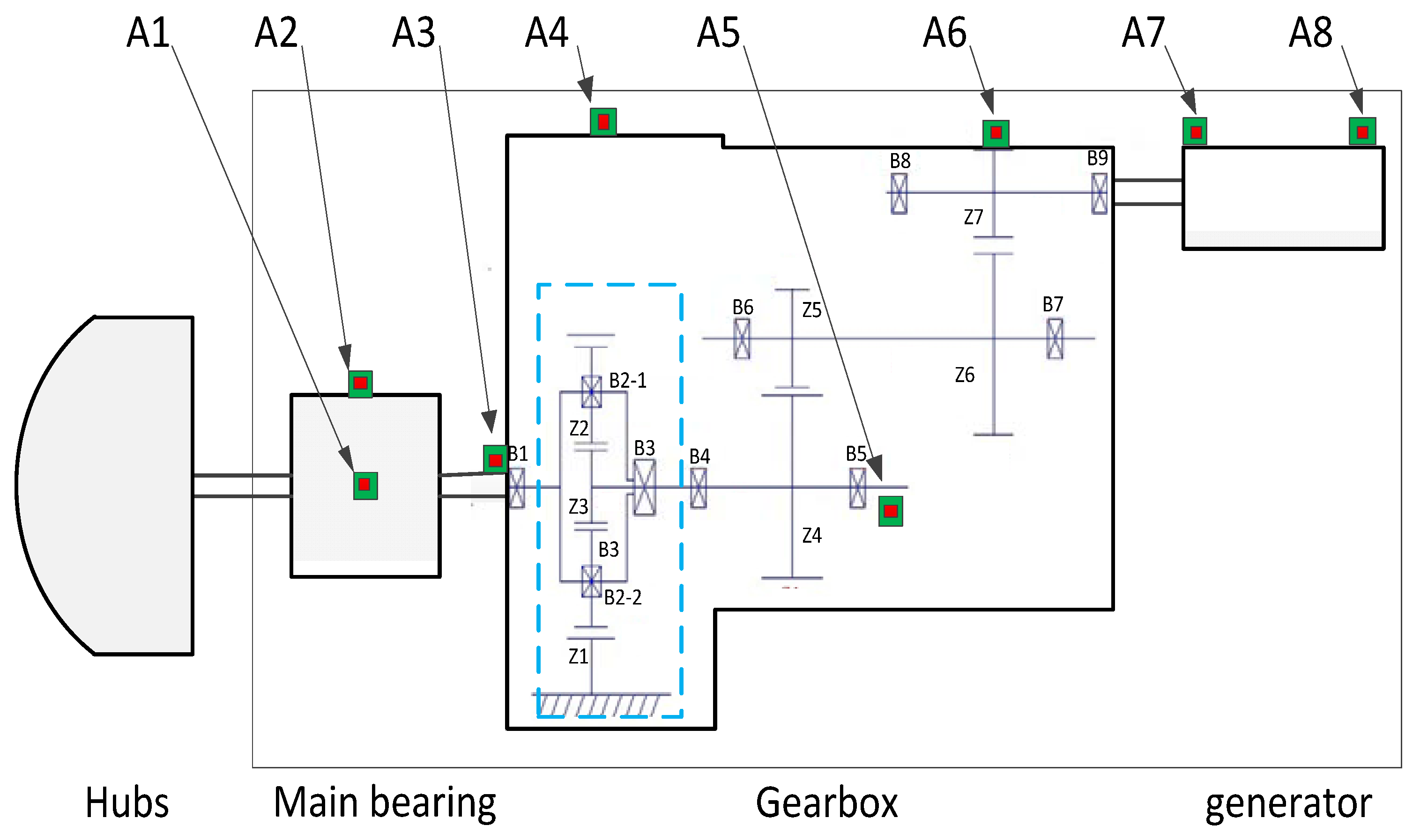

4.1. Data Introduction

4.2. The Effectiveness of the Proposed Model

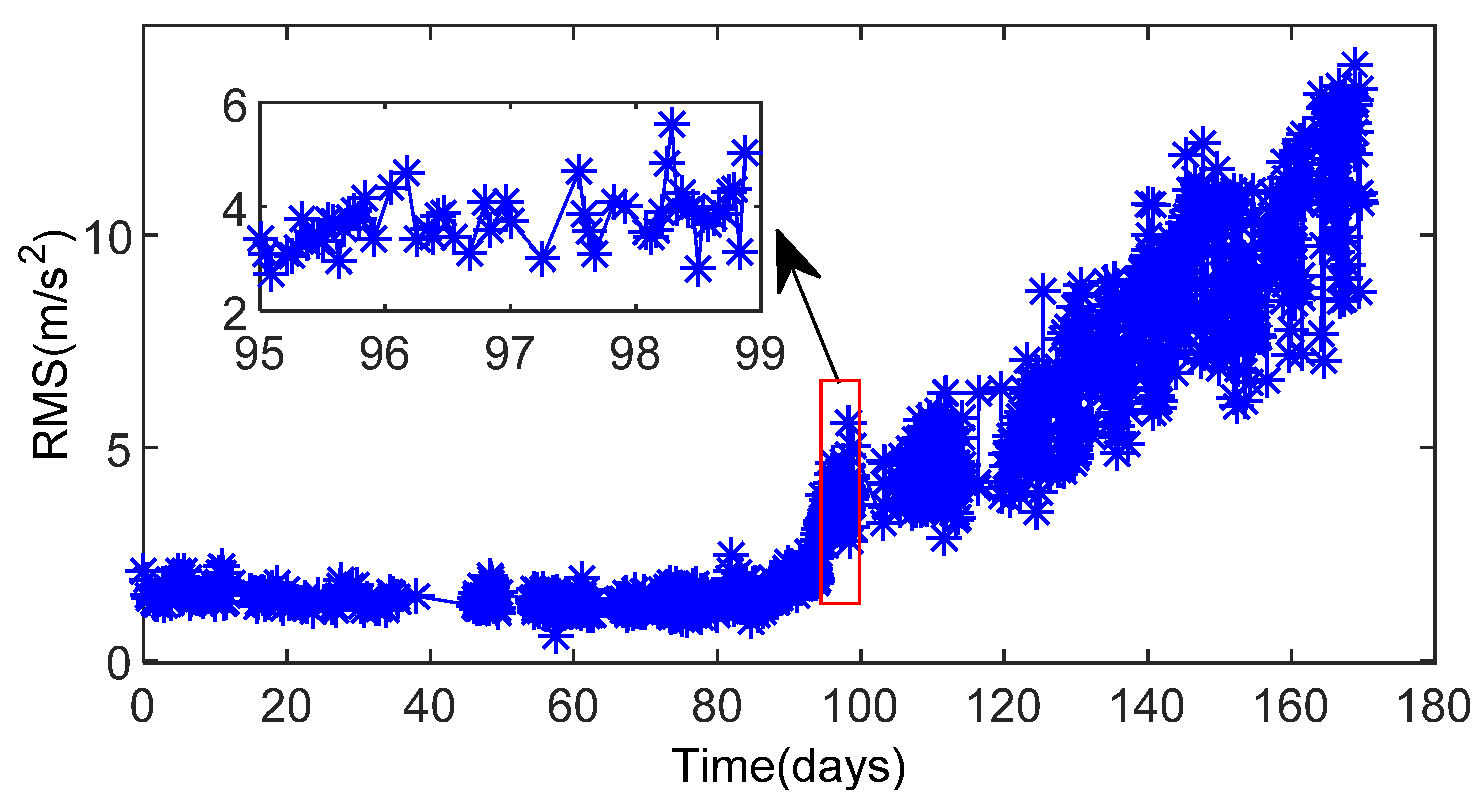

4.2.1. The Effectiveness of the Health Indicators

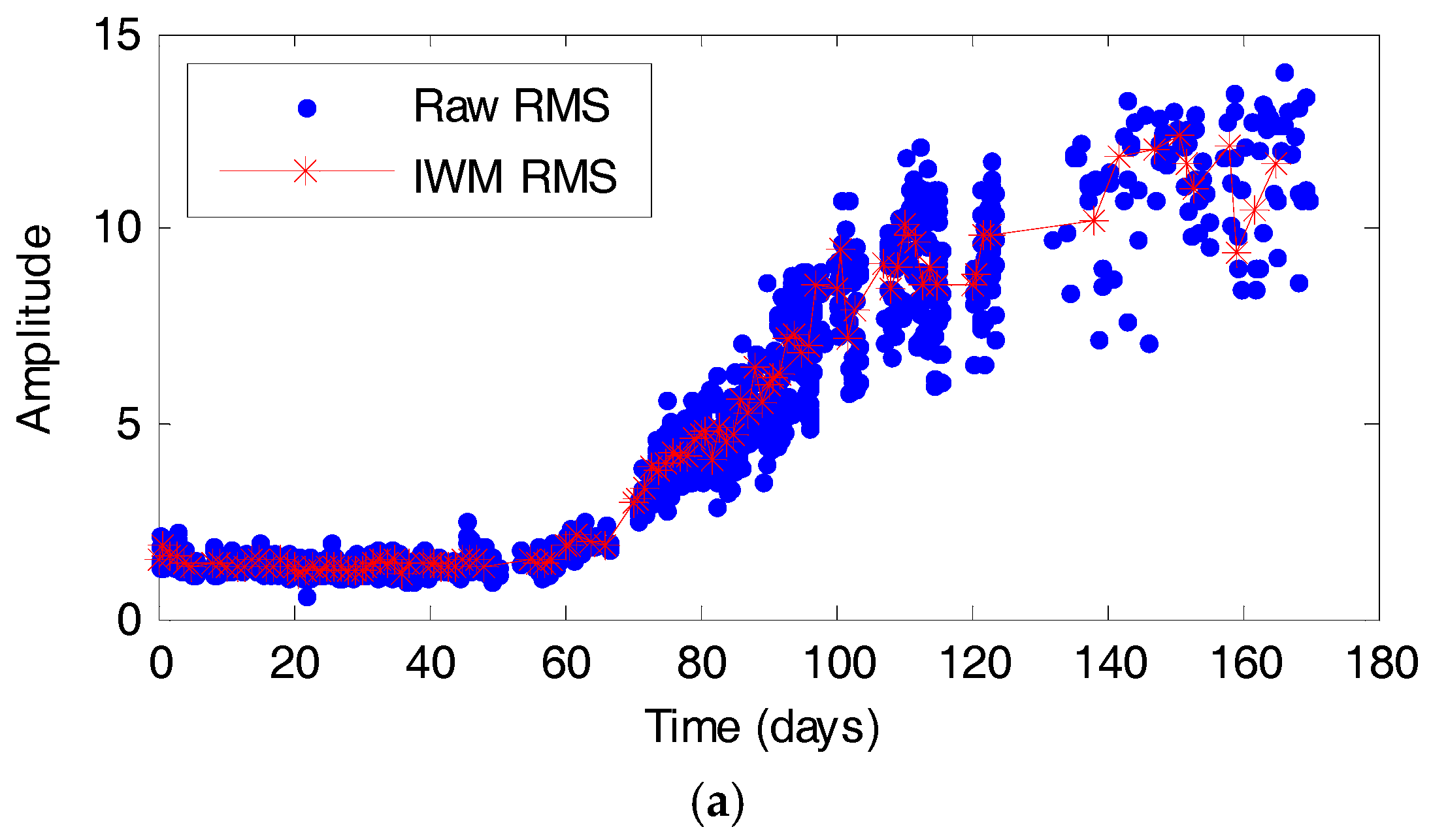

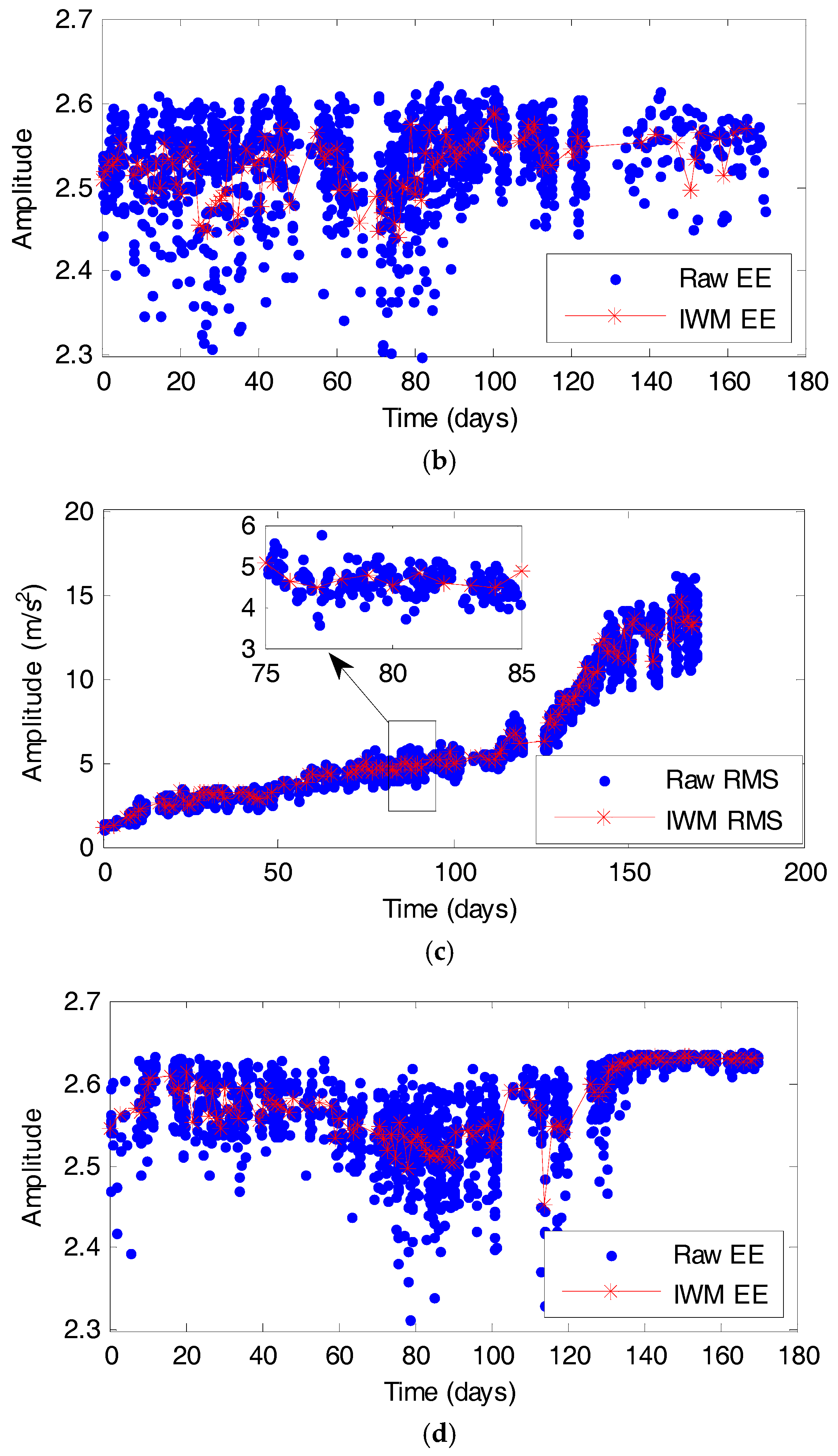

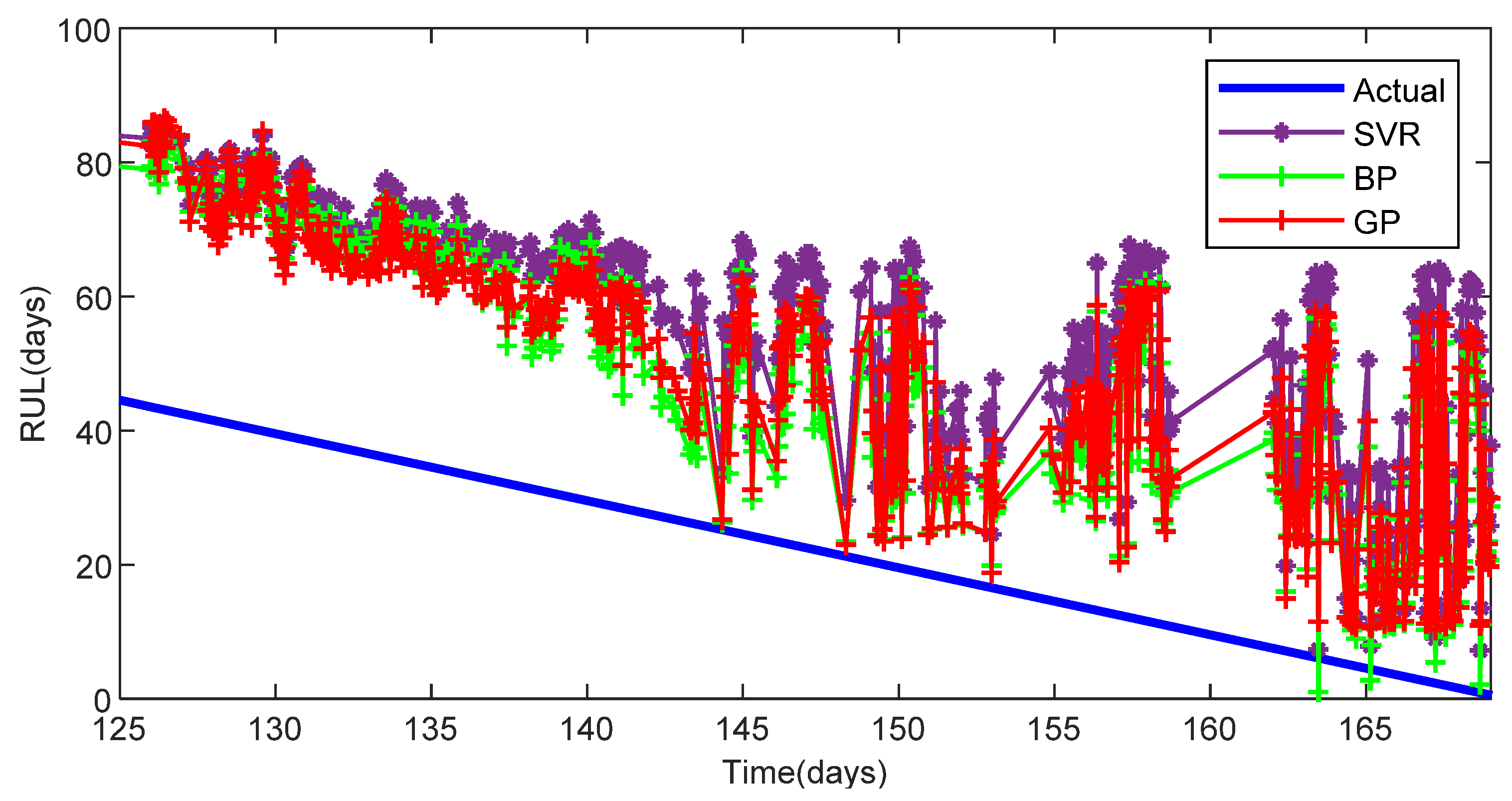

4.2.2. The Effectiveness of the IW Method

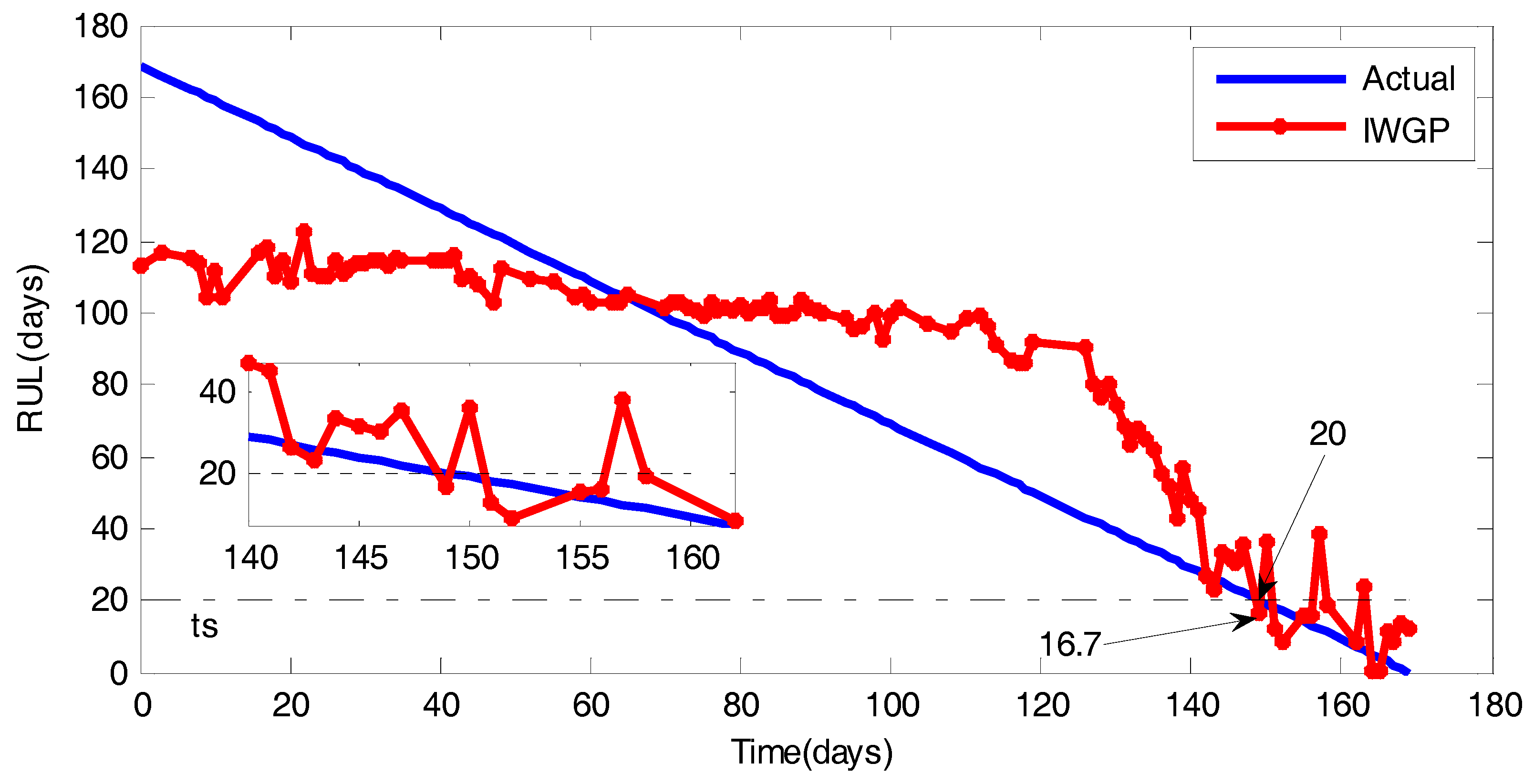

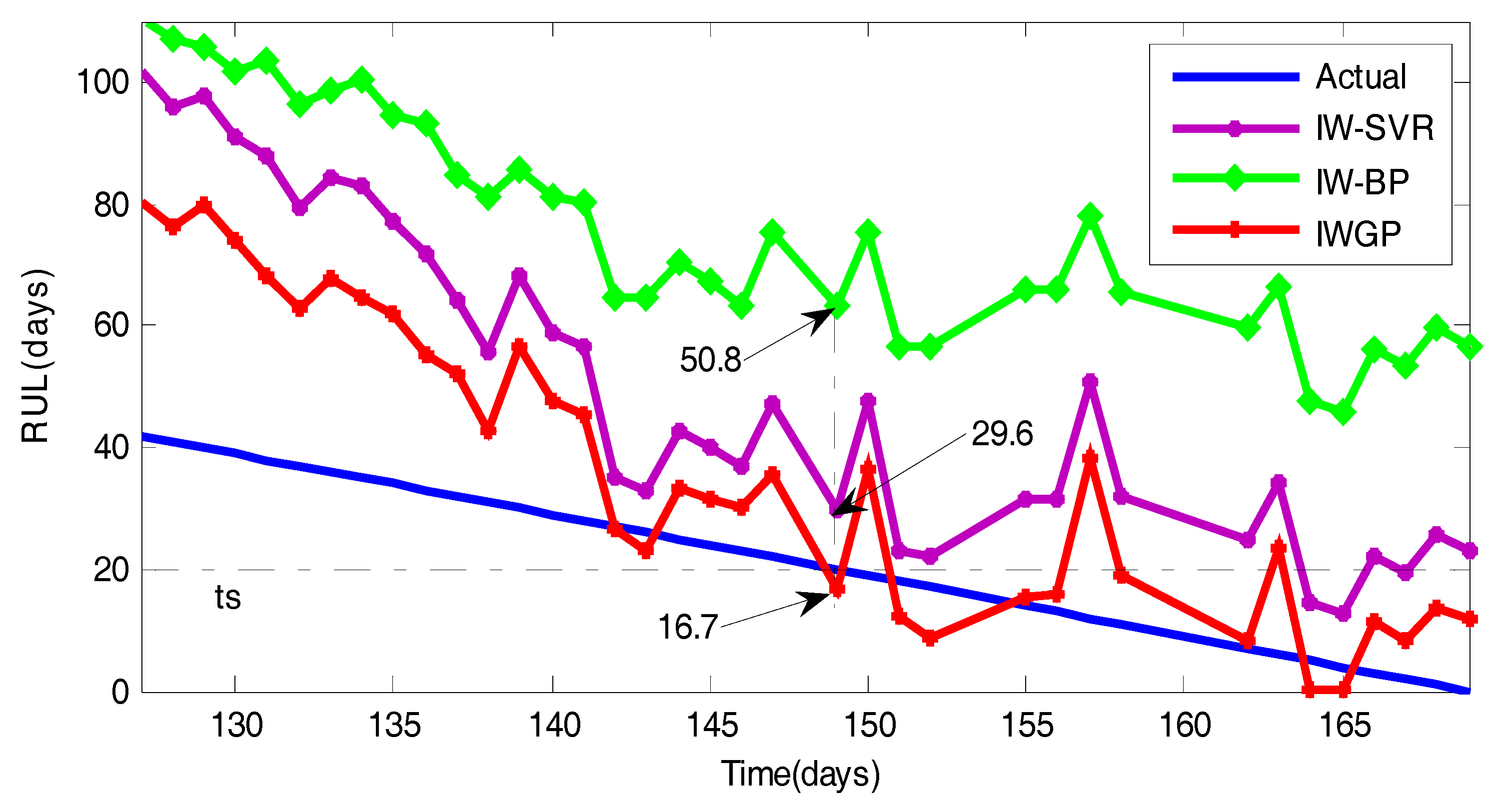

4.2.3. The Effectiveness of the Prediction Model

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| RUL | remaining useful life |

| O&M | operation and maintenance |

| PF | particle filtering |

| ANN | artificial neural network |

| IF | instantaneous frequency |

| TFD | time frequency distribution |

| SCADA | supervisory control and data acquisition |

| IWGP | interval whitenization and gaussian process |

| IW | interval whitenization |

| GP | gaussian process |

| SVR | support vector regression |

| SVM | support vector machine |

| WPT | wavelet packet transform |

| BPFI | ball pass inner race |

| FTF | fundamental train frequency |

| BSF | ball spin frequency |

| BPFO | ball pass outer race |

| WTGB | wind turbine generator bearing |

| RMS | root mean square |

| EE | energy entropy |

| SPMT | short period of measurement time |

| probability density function | |

| MM | match matrix |

| EKF | extend kalman filtering |

| EMD | empirical mode decomposition |

| IMF | intrinsic mode function |

References

- Hu, Y.; Li, H.; Shi, P.; Chai, Z.; Wang, K.; Xie, X.; Chen, Z. A prediction method for the real-time remaining useful life of wind turbine bearings based on the wiener process. Renew. Energy 2018, 127, 452–460. [Google Scholar] [CrossRef]

- Peeters, C.; Guillaume, P.; Helsen, J. Vibration-based bearing fault detection for operations and maintenance cost reduction in wind energy. Renew. Energy 2018, 116, 74–87. [Google Scholar] [CrossRef]

- de Azevedo, H.D.M.; Araújo, A.M.; Bouchonneau, N. A review of wind turbine bearing condition monitoring: State of the art and challenges. Renew. Sustain. Energy Rev. 2016, 56, 368–379. [Google Scholar] [CrossRef]

- Sheng, S. Wind Turbine Gearbox Reliability Database, Condition Monitoring, and O&M Research Update; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2016.

- Lin, Y.; Tu, L.; Liu, H.; Li, W. Fault analysis of wind turbines in china. Renew. Sustain. Energy Rev. 2016, 55, 482–490. [Google Scholar] [CrossRef]

- Gao, Q.W.; Liu, W.Y.; Tang, B.P.; Li, G.J. A novel wind turbine fault diagnosis method based on intergral extension load mean decomposition multiscale entropy and least squares support vector machine. Renew. Energy 2018, 116, 169–175. [Google Scholar] [CrossRef]

- Chen, J.; Pan, J.; Li, Z.; Zi, Y.; Chen, X. Generator bearing fault diagnosis for wind turbine via empirical wavelet transform using measured vibration signals. Renew. Energy 2016, 89, 80–92. [Google Scholar] [CrossRef]

- Yang, D.; Li, H.; Hu, Y.; Zhao, J.; Xiao, H.; Lan, Y. Vibration condition monitoring system for wind turbine bearings based on noise suppression with multi-point data fusion. Renew. Energy 2016, 92, 104–116. [Google Scholar] [CrossRef]

- Zhang, P.; Neti, P. Detection of gearbox bearing defects using electrical signature analysis for doubly fed wind generators. IEEE Trans. Ind. Appl. 2015, 51, 2195–2200. [Google Scholar] [CrossRef]

- Teng, W.; Zhang, X.; Liu, Y.; Kusiak, A.; Ma, Z. Prognosis of the remaining useful life of bearings in a wind turbine gearbox. Energies 2017, 10, 32. [Google Scholar] [CrossRef]

- Cheng, F.; Qu, L.; Qiao, W. Fault prognosis and remaining useful life prediction of wind turbine gearboxes using current signal analysis. IEEE Trans. Sustain. Energy 2018, 9, 157–167. [Google Scholar] [CrossRef]

- LaCava, W.; Xing, Y.; Marks, C.; Guo, Y.; Moan, T. Three-dimensional bearing load share behaviour in the planetary stage of a wind turbine gearbox. IET Renew. Power Gener. 2013, 7, 359–369. [Google Scholar] [CrossRef]

- Saidi, L.; Ben Ali, J.; Bechhoefer, E.; Benbouzid, M. Wind turbine high-speed shaft bearings health prognosis through a spectral kurtosis-derived indices and SVR. Appl. Acoust. 2017, 120, 1–8. [Google Scholar] [CrossRef]

- Kim, H.; Tan, A.C.C.; Mathew, J.; Choi, B. Bearing fault prognosis based on health state probability estimation. Expert Syst. Appl. 2012, 39, 5200–5213. [Google Scholar] [CrossRef]

- Fu, L.; Wei, Y.; Fang, S.; Zhou, X.; Lou, J. Condition monitoring for roller bearings of wind turbines based on health evaluation under variable operating states. Energies 2017, 10, 1564. [Google Scholar] [CrossRef]

- Djeziri, M.A.; Benmoussa, S.; Sanchez, R. Hybrid method for remaining useful life prediction in wind turbine systems. Renew. Energy 2018, 116, 173–187. [Google Scholar] [CrossRef]

- Qiao, W.; Lu, D. A survey on wind turbine condition monitoring and fault diagnosis 2014; part II: Signals and signal processing methods. IEEE Trans. Ind. Electron. 2015, 62, 6546–6557. [Google Scholar] [CrossRef]

- Lei, Y.; Li, N.; Gontarz, S.; Lin, J.; Radkowski, S.; Dybala, J. A model-based method for remaining useful life prediction of machinery. IEEE Trans. Reliab. 2016, 65, 1314–1326. [Google Scholar] [CrossRef]

- Saidi, L.; Ben Ali, J.; Benbouzid, M.; Bechhofer, E. An integrated wind turbine failures prognostic approach implementing Kalman smoother with confidence bounds. Appl. Acoust. 2018, 138, 199–208. [Google Scholar] [CrossRef]

- Lei, Y.; Li, N.; Lin, J. A new method based on stochastic process models for machine remaining useful life prediction. IEEE Trans. Instrum. Meas. 2016, 65, 2671–2684. [Google Scholar] [CrossRef]

- Gong, X.; Qiao, W. Current-based mechanical fault detection for direct-drive wind turbines via synchronous sampling and impulse detection. IEEE Trans. Ind. Electron. 2015, 62, 1693–1702. [Google Scholar] [CrossRef]

- Singleton, R.K.; Strangas, E.G.; Aviyente, S. The use of bearing currents and vibrations in lifetime estimation of bearings. IEEE Trans. Ind. Inform. 2017, 13, 1301–1309. [Google Scholar] [CrossRef]

- Boukra, T. Identifying new prognostic features for remaining useful life prediction using particle filtering and neuro-fuzzy system predictor. In Proceedings of the 2015 IEEE 15th International Conference on Environment and Electrical Engineering (EEEIC), Rome, Italy, 10–13 June 2015; pp. 1533–1538. [Google Scholar]

- Qian, Y.; Yan, R. Remaining useful life prediction of rolling bearings using an enhanced particle filter. IEEE Trans. Instrum. Meas. 2015, 64, 2696–2707. [Google Scholar] [CrossRef]

- Chehade, A.; Bonk, S.; Liu, K. Sensory-based failure threshold estimation for remaining useful life prediction. IEEE Trans. Reliab. 2017, 66, 939–949. [Google Scholar] [CrossRef]

- Sun, F.; Wang, N.; Li, X.; Zhang, W. Remaining useful life prediction for a machine with multiple dependent features based on bayesian dynamic linear model and copulas. IEEE Access 2017, 5, 16277–16287. [Google Scholar] [CrossRef]

- Zimroz, R.; Bartelmus, W.; Barszcz, T.; Urbanek, J. Diagnostics of bearings in presence of strong operating conditions non-stationarity—A procedure of load-dependent features processing with application to wind turbine bearings. Mech. Syst. Signal Process. 2014, 46, 16–27. [Google Scholar] [CrossRef]

- He, G.; Ding, K.; Li, W.; Jiao, X. A novel order tracking method for wind turbine planetary gearbox vibration analysis based on discrete spectrum correction technique. Renew. Energy 2016, 87, 364–375. [Google Scholar] [CrossRef]

- Li, Y.; Ding, K.; He, G.; Jiao, X. Non-stationary vibration feature extraction method based on sparse decomposition and order tracking for gearbox fault diagnosis. Measurement 2018, 124, 453–469. [Google Scholar] [CrossRef]

- Feng, Z.; Chen, X.; Wang, T. Time-varying demodulation analysis for rolling bearing fault diagnosis under variable speed conditions. J. Sound Vib. 2017, 400, 71–85. [Google Scholar] [CrossRef]

- Kan, M.S.; Tan, A.C.C.; Mathew, J. A review on prognostic techniques for non-stationary and non-linear rotating systems. Mech. Syst. Signal Process. 2015, 62–63, 1–20. [Google Scholar] [CrossRef]

- Hong, S.; Zhou, Z. Application of gaussian process regression for bearing degradation assessment. In Proceedings of the 2012 6th International Conference on New Trends in Information Science, Service Science and Data Mining (ISSDM2012), Taipei, Taiwan, 23–25 October 2012; Shen, C.W., Kuo, S.Y., DalKwack, K., Chen, Y.W., Hsu, P.Y., Ko, F., Eds.; pp. 644–648. [Google Scholar]

- Boškoski, P.; Gašperin, M.; Petelin, D.; Juričić, Đ. Bearing fault prognostics using rényi entropy based features and gaussian process models. Mech. Syst. Signal Process. 2015, 52–53, 327–337. [Google Scholar] [CrossRef]

- Kocijan, J.; Tanko, V. Prognosis of gear health using gaussian process model. In Proceedings of the 2011 IEEE EUROCON—International Conference on Computer as a Tool, Lisbon, Portugal, 27–29 April 2011. [Google Scholar]

- Liu, D.; Pang, J.; Zhou, J.; Peng, Y.; Pecht, M. Prognostics for state of health estimation of lithium-ion batteries based on combination gaussian process functional regression. Microelectron. Reliab. 2013, 53, 832–839. [Google Scholar] [CrossRef]

- Chen, N.; Qian, Z.; Nabney, I.T.; Meng, X. Wind power forecasts using gaussian processes and numerical weather prediction. IEEE Trans. Power Syst. 2014, 29, 656–665. [Google Scholar] [CrossRef]

- Kanwal, S.; Khan, B.; Ali, S.M.; Mehmood, C.A. Gaussian process regression based inertia emulation and reserve estimation for grid interfaced photovoltaic system. Renew. Energy 2018, 126, 865–875. [Google Scholar] [CrossRef]

- Hoolohan, V.; Tomlin, A.S.; Cockerill, T. Improved near surface wind speed predictions using gaussian process regression combined with numerical weather predictions and observed meteorological data. Renew. Energy 2018, 126, 1043–1054. [Google Scholar] [CrossRef]

- Kong, D.; Chen, Y.; Li, N. Gaussian process regression for tool wear prediction. Mech. Syst. Signal Process. 2018, 104, 556–574. [Google Scholar] [CrossRef]

- Rasmussen, C.E.; Williams, C.K.I. Gaussian Processes for Machine Learning; The MIT Press: Cambridge, UK, 2006; pp. 24–50. [Google Scholar]

- Williams, C.K.I. Regression with Gaussian Processes; Springer: New York, NY, USA, 1997. [Google Scholar]

- Mollasalehi, E.; Wood, D.; Sun, Q. Indicative fault diagnosis of wind turbine generator bearings using tower sound and vibration. Energies 2017, 10, 1853. [Google Scholar] [CrossRef]

- García Plaza, E.; Núñez López, P.J. Analysis of cutting force signals by wavelet packet transform for surface roughness monitoring in CNC turning. Mech. Syst. Signal Process. 2018, 98, 634–651. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, G.; Liang, L.; Jiang, K. Detection of weak transient signals based on wavelet packet transform and manifold learning for rolling element bearing fault diagnosis. Mech. Syst. Signal Process. 2015, 54–55, 259–276. [Google Scholar] [CrossRef]

- Gómez Muñoz, C.Q.; Arcos Jiménez, A.; García Márquez, F.P. Wavelet transforms and pattern recognition on ultrasonic guides waves for frozen surface state diagnosis. Renew. Energy 2018, 116, 42–54. [Google Scholar] [CrossRef]

- Barszcz, T.; Sawalhi, N. Fault detection enhancement in rolling element bearings using the minimum entropy deconvolution. Arch. Acoust. 2012, 37, 131–141. [Google Scholar] [CrossRef]

- Liu, S.; Tao, L.; Xie, N.; Yang, Y. On the new model system and framework of grey system theory. J. Grey Syst. 2016, 28, 1–15. [Google Scholar]

- Liu, J.; Djurdjanovic, D.; Ni, J.; Casoetto, N.; Lee, J. Similarity based method for manufacturing process performance prediction and diagnosis. Comput. Ind. 2007, 58, 558–566. [Google Scholar] [CrossRef]

- Wang, W.P.; Liao, S.; Xing, T.W. Particle filter for state and parameter estimation in passive ranging. In Proceedings of the 2009 IEEE International Conference on Intelligent Computing and Intelligent Systems, Shanghai, China, 20–22 November 2009; pp. 257–261. [Google Scholar]

- Arulampalam, S.; Ristic, B. Comparison of the particle filter with range-parameterized and modified polar ekfs for angle-only tracking. Proc. SPIE 2000, 4048, 288–299. [Google Scholar]

- Jiang, Y.; Tang, B.; Qin, Y.; Liu, W. Feature extraction method of wind turbine based on adaptive morlet wavelet and SVD. Renew. Energy 2011, 36, 2146–2153. [Google Scholar] [CrossRef]

- Lei, Y.; Lin, J.; He, Z.; Zuo, M.J. A review on empirical mode decomposition in fault diagnosis of rotating machinery. Mech. Syst. Signal Process. 2013, 35, 108–126. [Google Scholar] [CrossRef]

- Le, B.; Andrews, J. Modelling wind turbine degradation and maintenance. Wind Energy 2016, 19, 571–591. [Google Scholar] [CrossRef]

| Wind Turbine Number | Data Length | Sampling Frequency | Sensor Location |

|---|---|---|---|

| #1 (training) | 165 days | 2500 Hz | A8 |

| #2 (test) | 169 days | 2500 Hz | A8 |

| Fault Type | |||

|---|---|---|---|

| Characteristic frequency (Hz) | 3.133 | 4.867 | 2.198 |

| Variation range (Hz) | 57.6–87.7 | 89.6–136.3 | 40.4–61.5 |

| Four-octave coverage (Hz) | 57.6–350.8 | 89.6–545.2 | 40.4–246 |

| Waveform Number | 1 | 2 | 3 | 4 | 5 | 6 | Mean | ||

|---|---|---|---|---|---|---|---|---|---|

| Nodes Energy Radio | |||||||||

| Nodes | |||||||||

| 0–10 nodes | 0.6935 | 0.9189 | 0.9770 | 0.5789 | 0.6745 | 0.7507 | 0.7656 | ||

| 0–11 nodes | 0.7091 | 0.9213 | 0.9778 | 0.5896 | 0.7163 | 0.7722 | 0.7810 | ||

| 0–12 nodes | 0.7300 | 0.9251 | 0.9787 | 0.6076 | 0.7436 | 0.7870 | 0.7953 | ||

| 0–13 nodes | 0.7150 | 0.9296 | 0.9787 | 0.6173 | 0.7611 | 0.7965 | 0.7997 | ||

| 0–14 nodes | 0.7945 | 0.9338 | 0.9792 | 0.6490 | 0.7984 | 0.8219 | 0.8295 | ||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, L.; Qian, Z.; Zareipour, H.; Wood, D.; Mollasalehi, E.; Tian, S.; Pei, Y. Prediction of Remaining Useful Life of Wind Turbine Bearings under Non-Stationary Operating Conditions. Energies 2018, 11, 3318. https://doi.org/10.3390/en11123318

Cao L, Qian Z, Zareipour H, Wood D, Mollasalehi E, Tian S, Pei Y. Prediction of Remaining Useful Life of Wind Turbine Bearings under Non-Stationary Operating Conditions. Energies. 2018; 11(12):3318. https://doi.org/10.3390/en11123318

Chicago/Turabian StyleCao, Lixiao, Zheng Qian, Hamid Zareipour, David Wood, Ehsan Mollasalehi, Shuangshu Tian, and Yan Pei. 2018. "Prediction of Remaining Useful Life of Wind Turbine Bearings under Non-Stationary Operating Conditions" Energies 11, no. 12: 3318. https://doi.org/10.3390/en11123318

APA StyleCao, L., Qian, Z., Zareipour, H., Wood, D., Mollasalehi, E., Tian, S., & Pei, Y. (2018). Prediction of Remaining Useful Life of Wind Turbine Bearings under Non-Stationary Operating Conditions. Energies, 11(12), 3318. https://doi.org/10.3390/en11123318