PV Module Monitoring System Based on Low-Cost Solutions: Wireless Raspberry Application and Assessment

Abstract

:1. Introduction

- PV installations are monitored at the PV-module level according to the current IEC-61724 standard, estimating PV-module performances and providing predictive maintenance.

- Low-cost and open-source wireless solutions are used to facilitate the integration of the proposed system in PV power plants.

- The wireless solution is flexible and can be adapted according to the layout and configuration of the PV modules.

2. Proposed Low-Cost Solution

2.1. Preliminaries

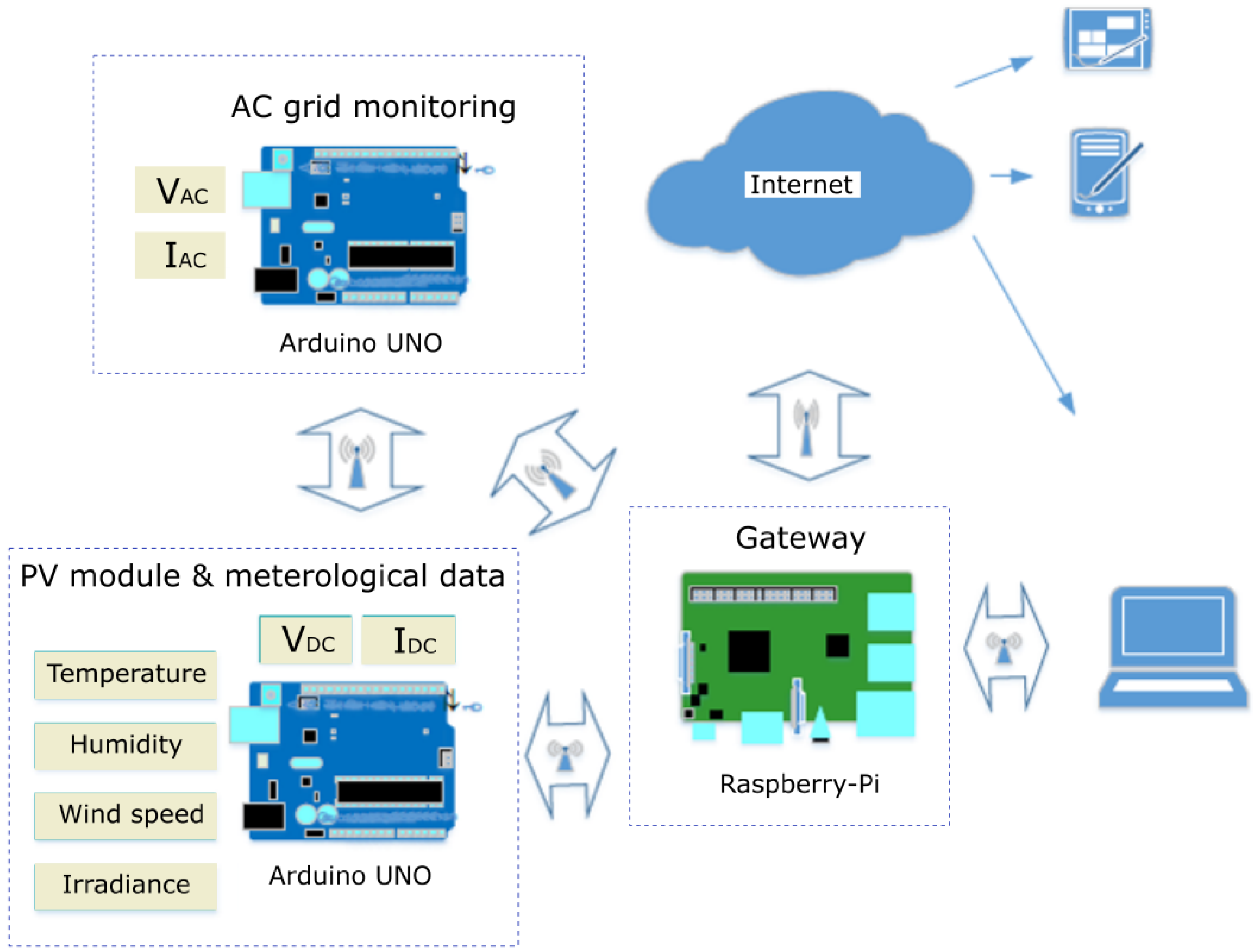

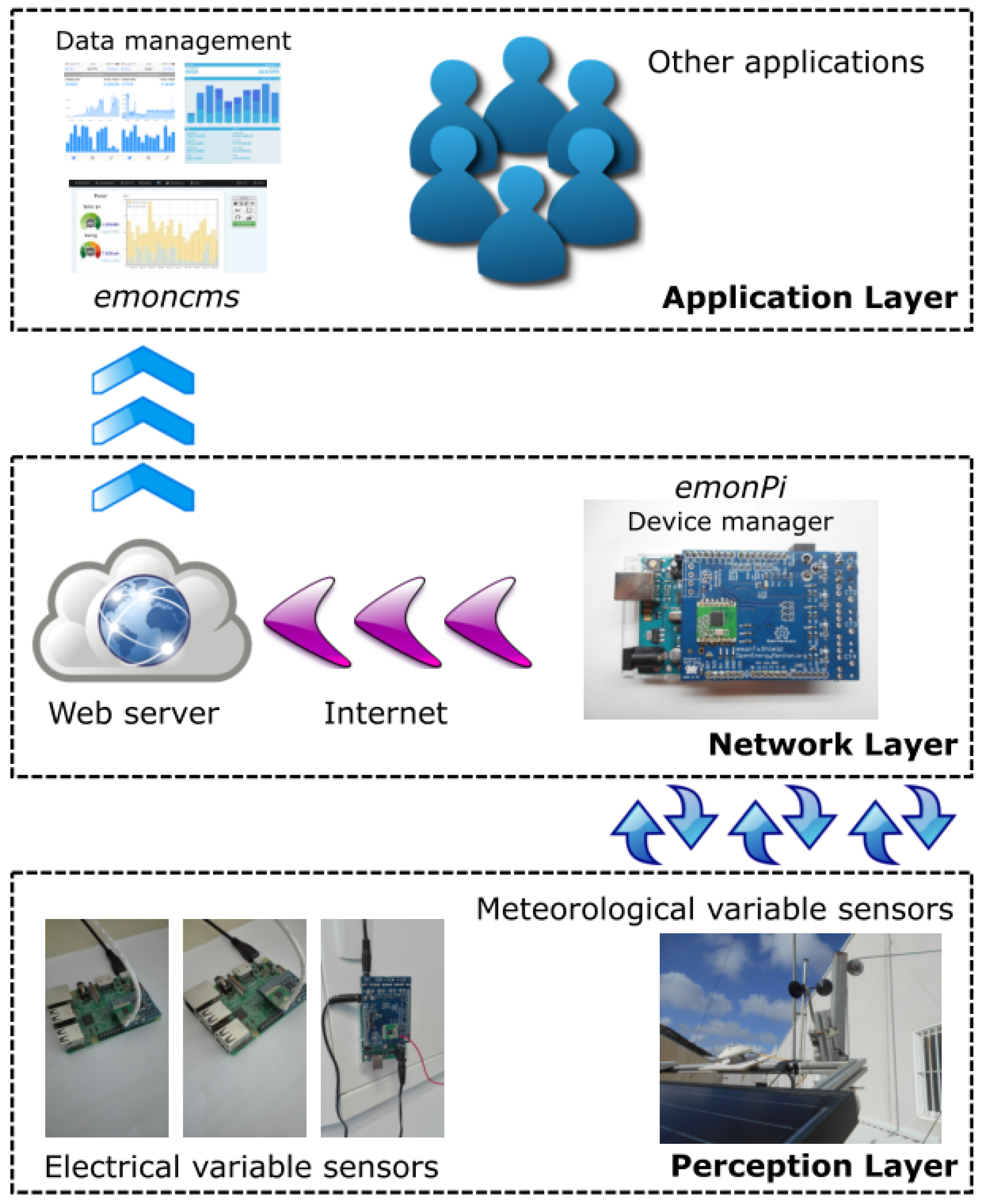

2.2. General Architecture

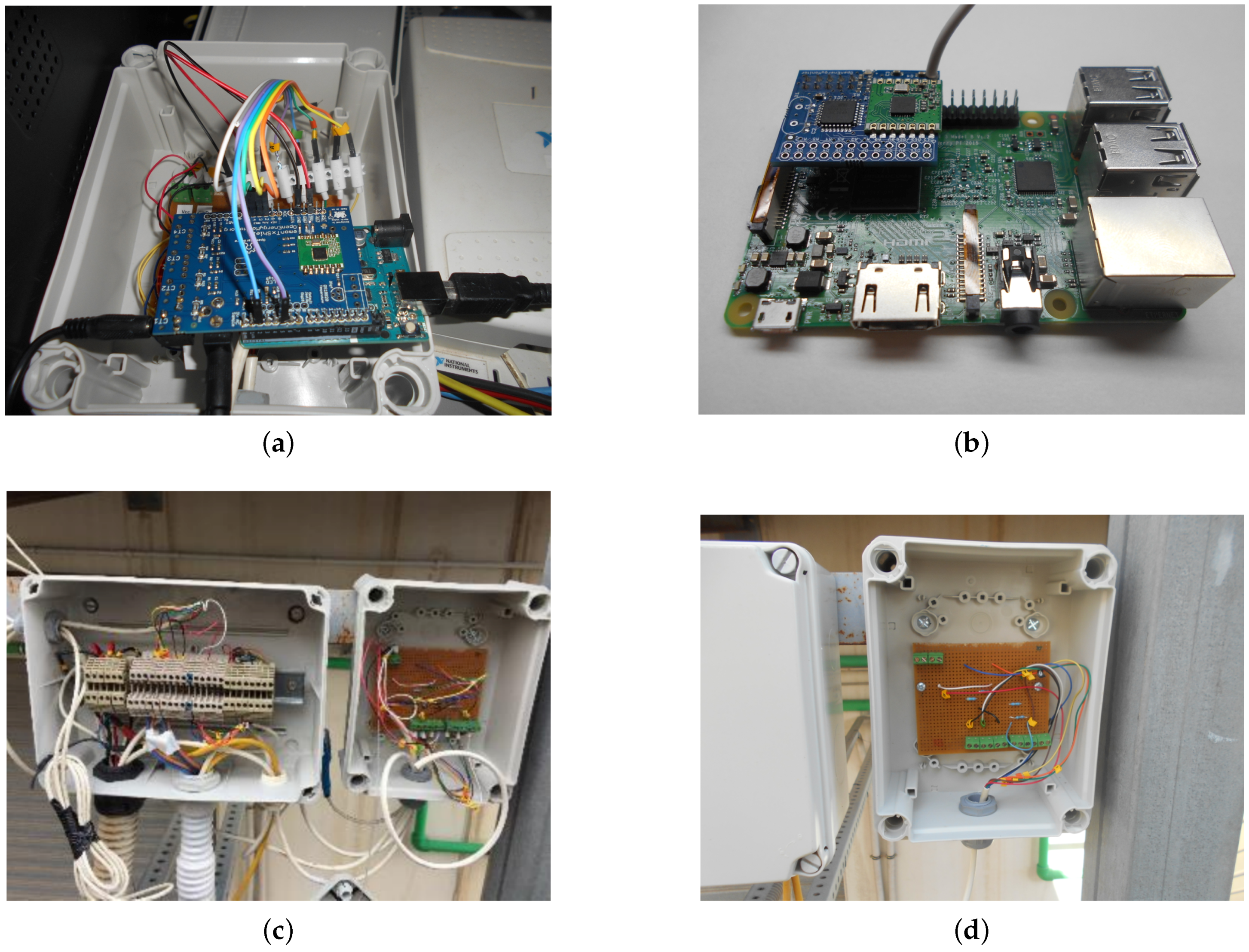

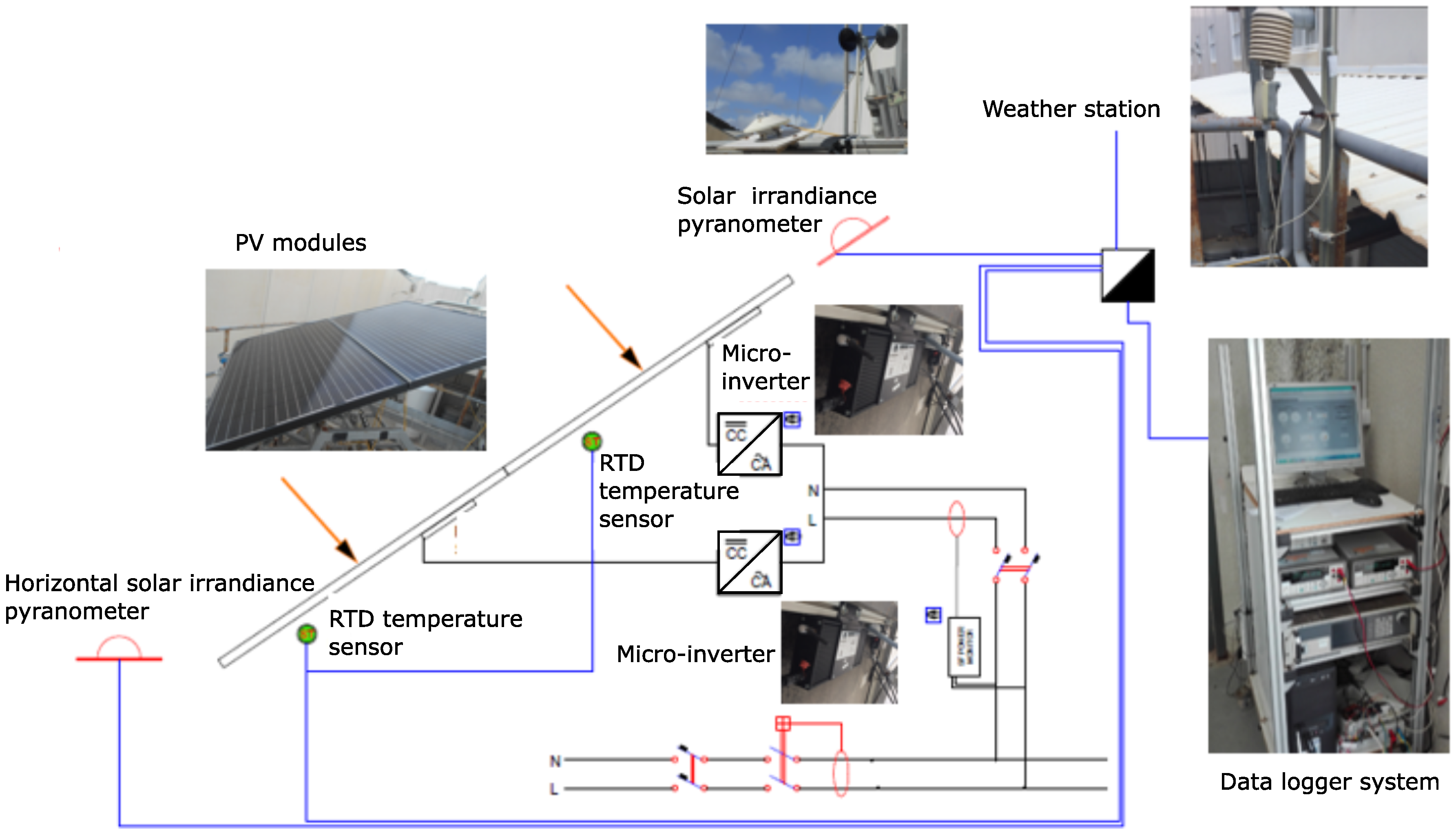

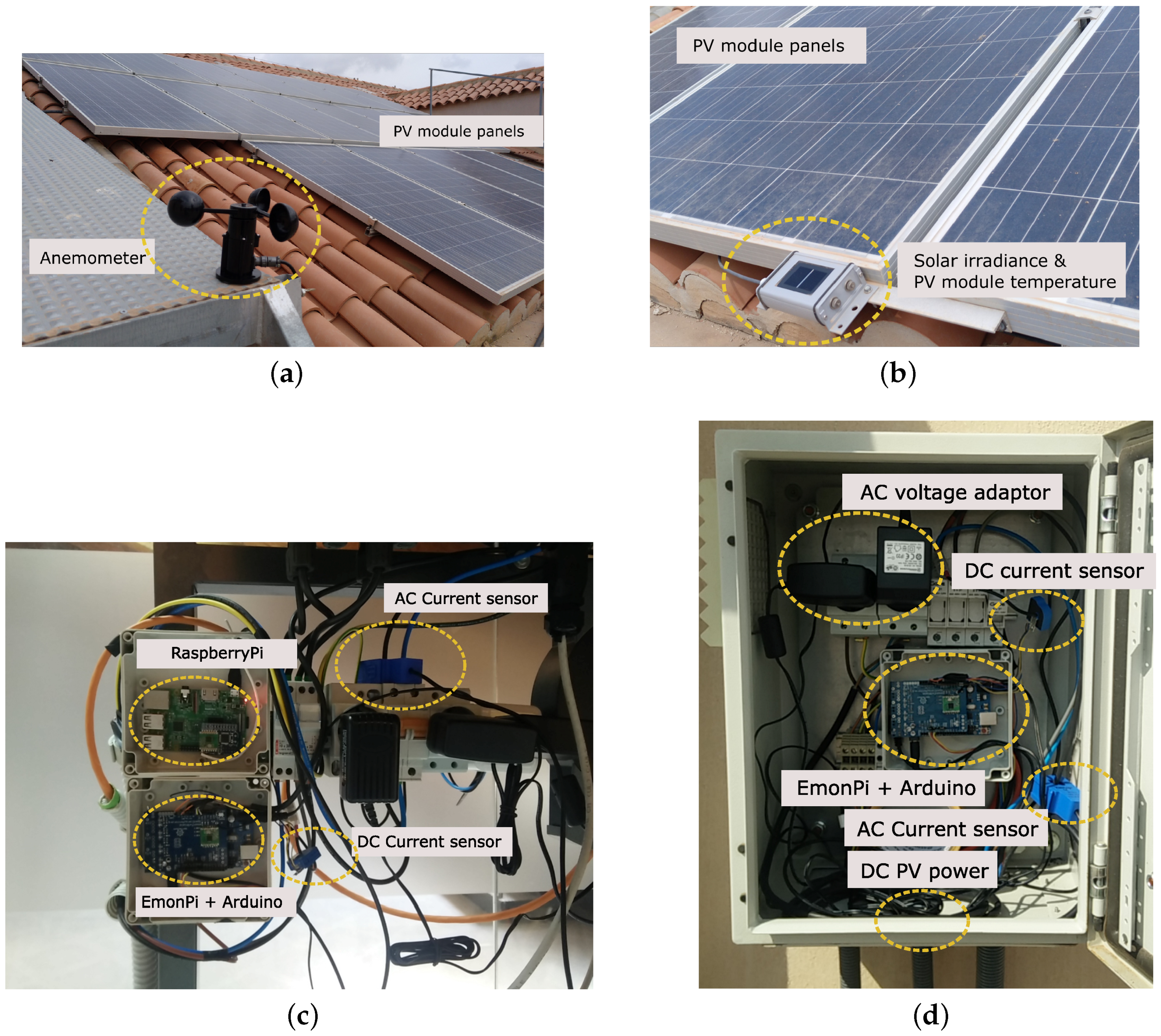

2.3. Hardware Solution: Sensors

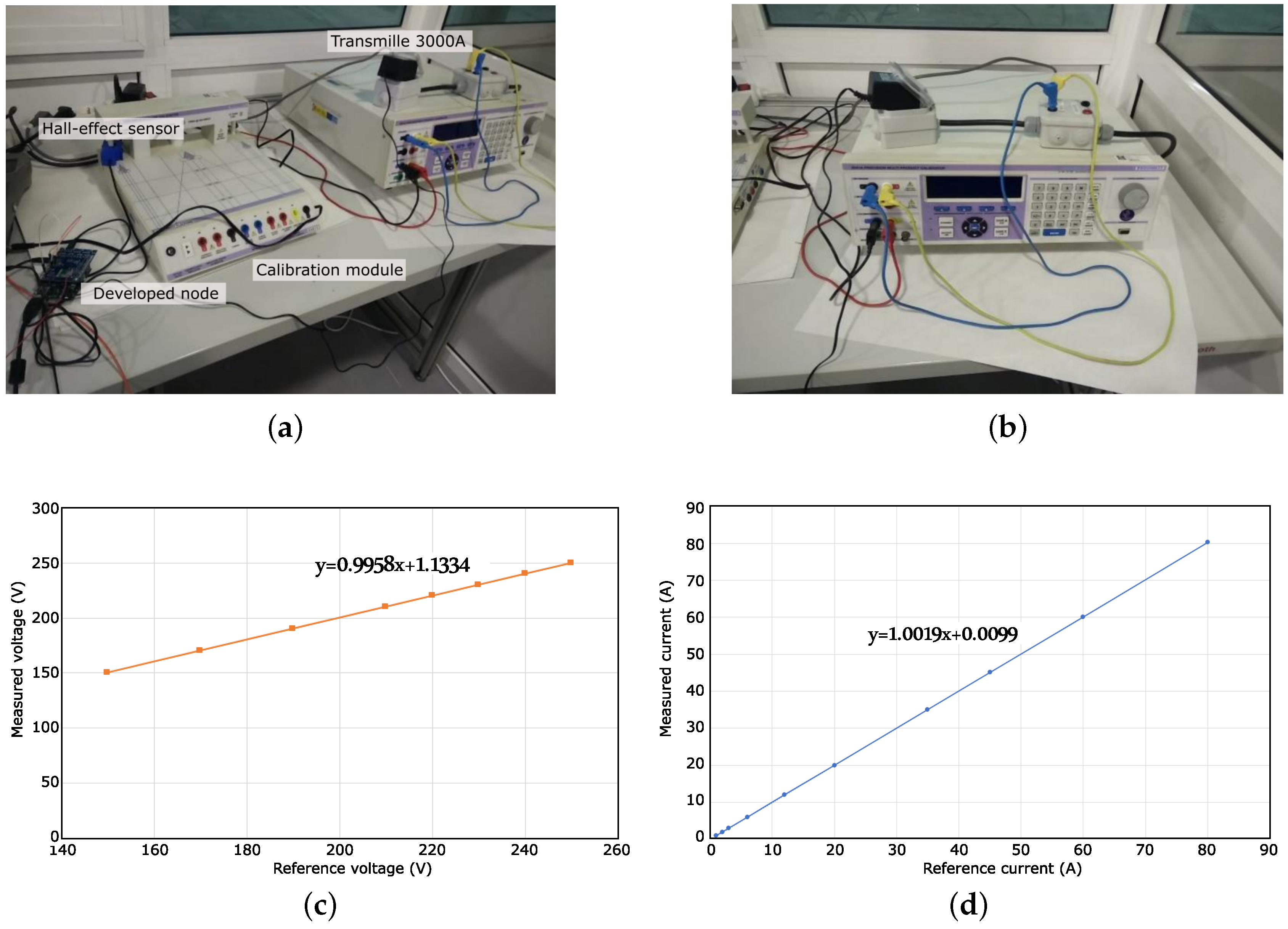

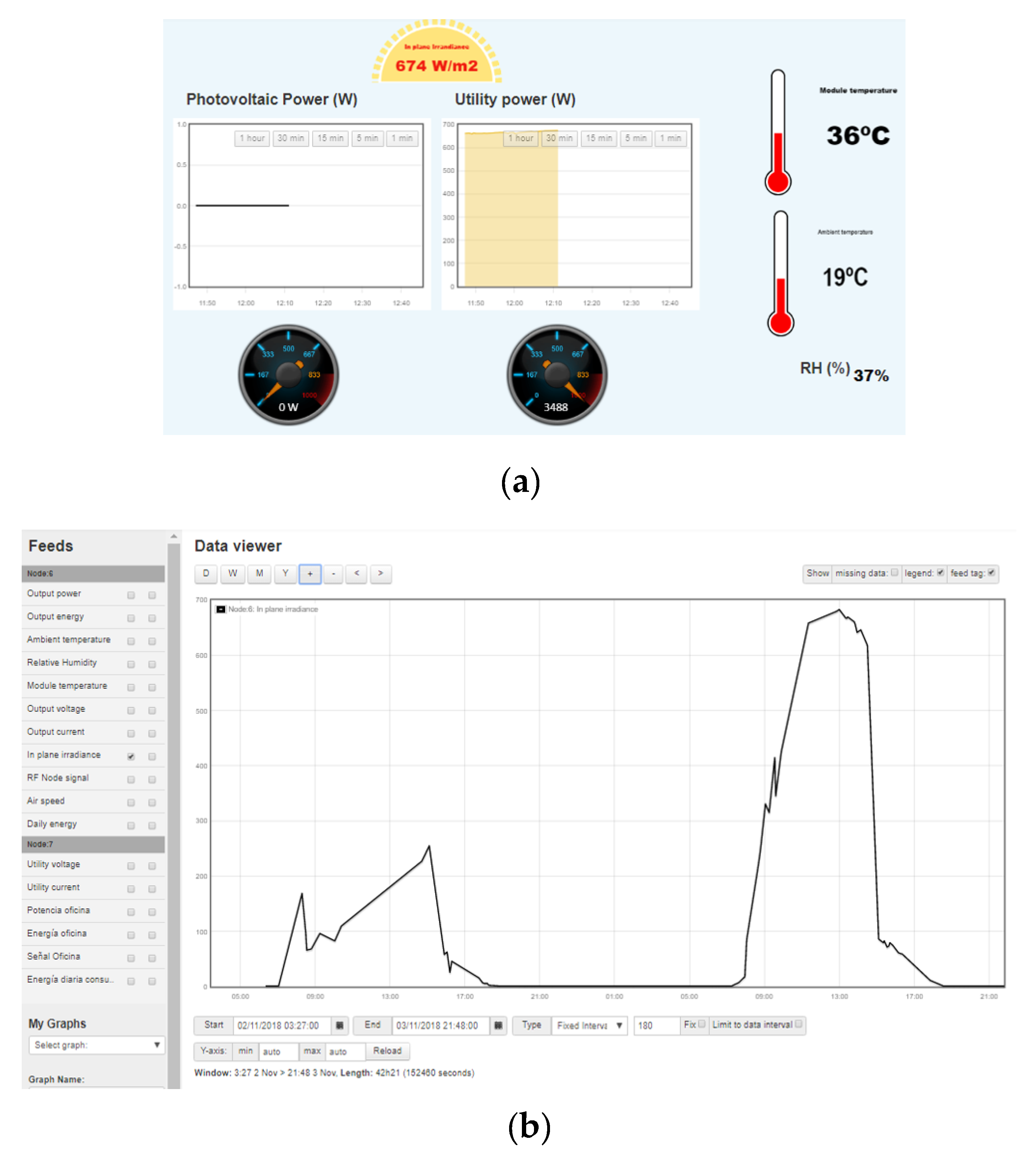

2.4. Software Design

2.5. Economic Evaluation: Cost-Effectiveness

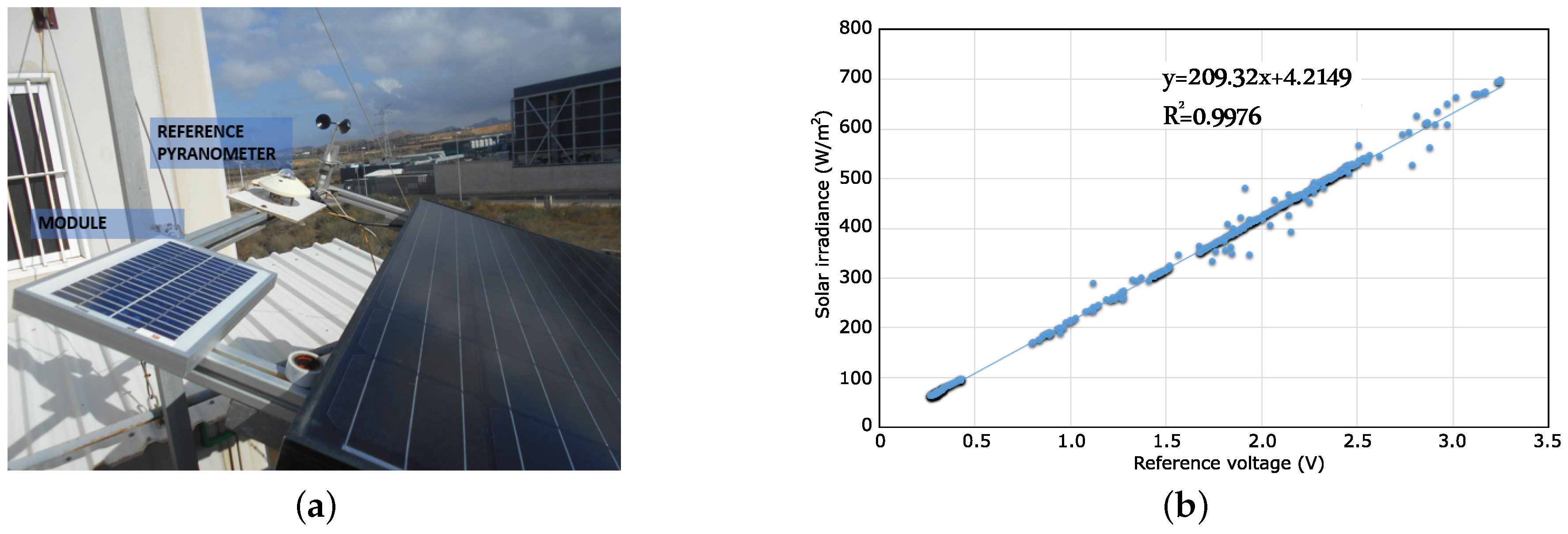

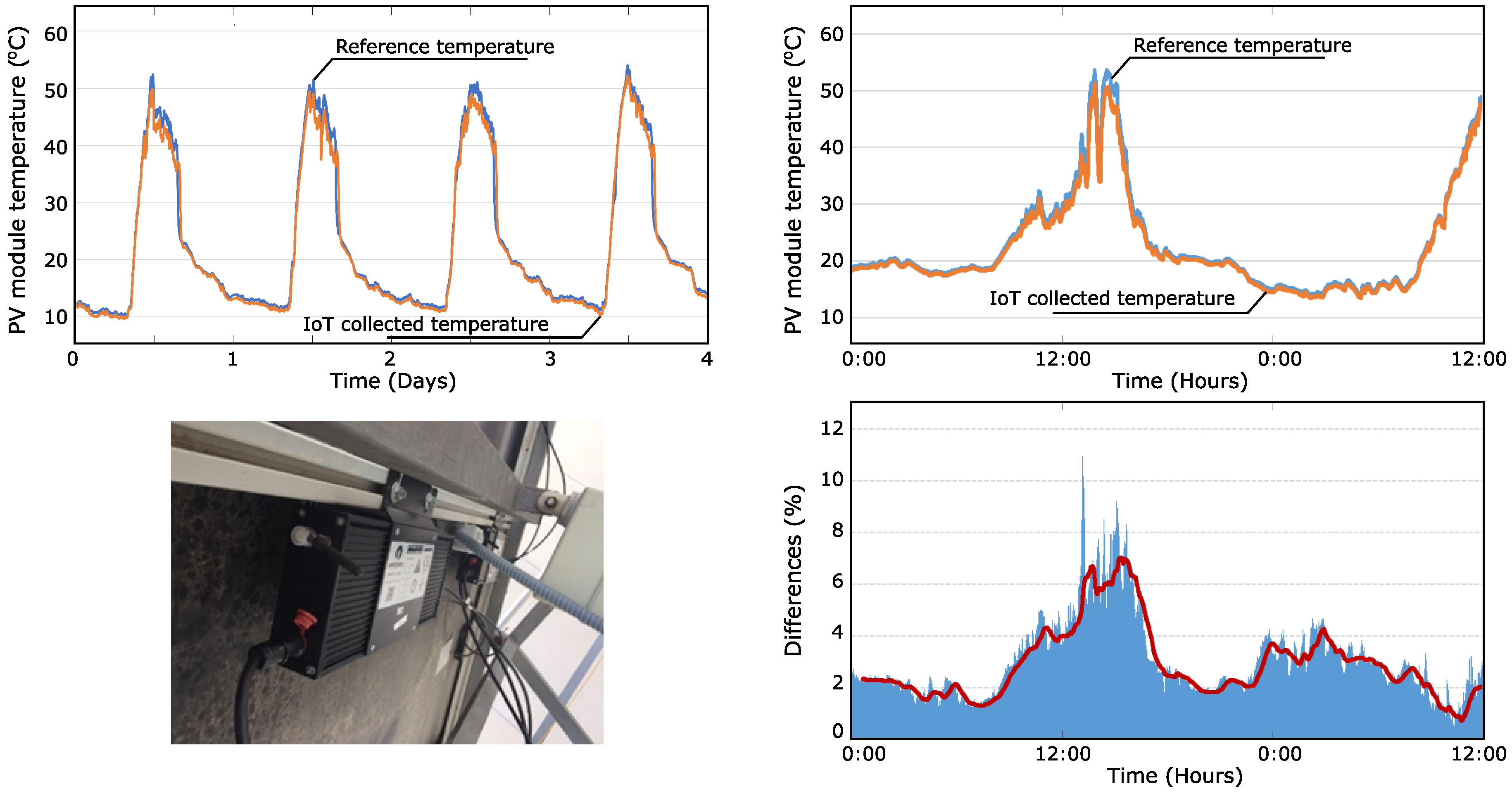

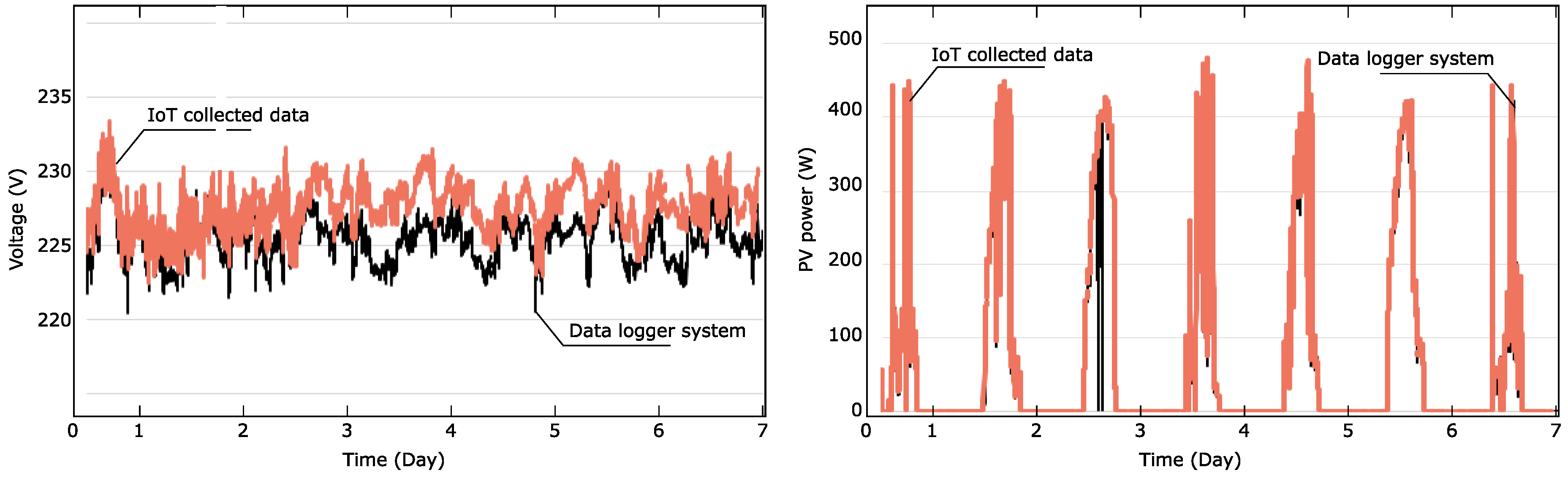

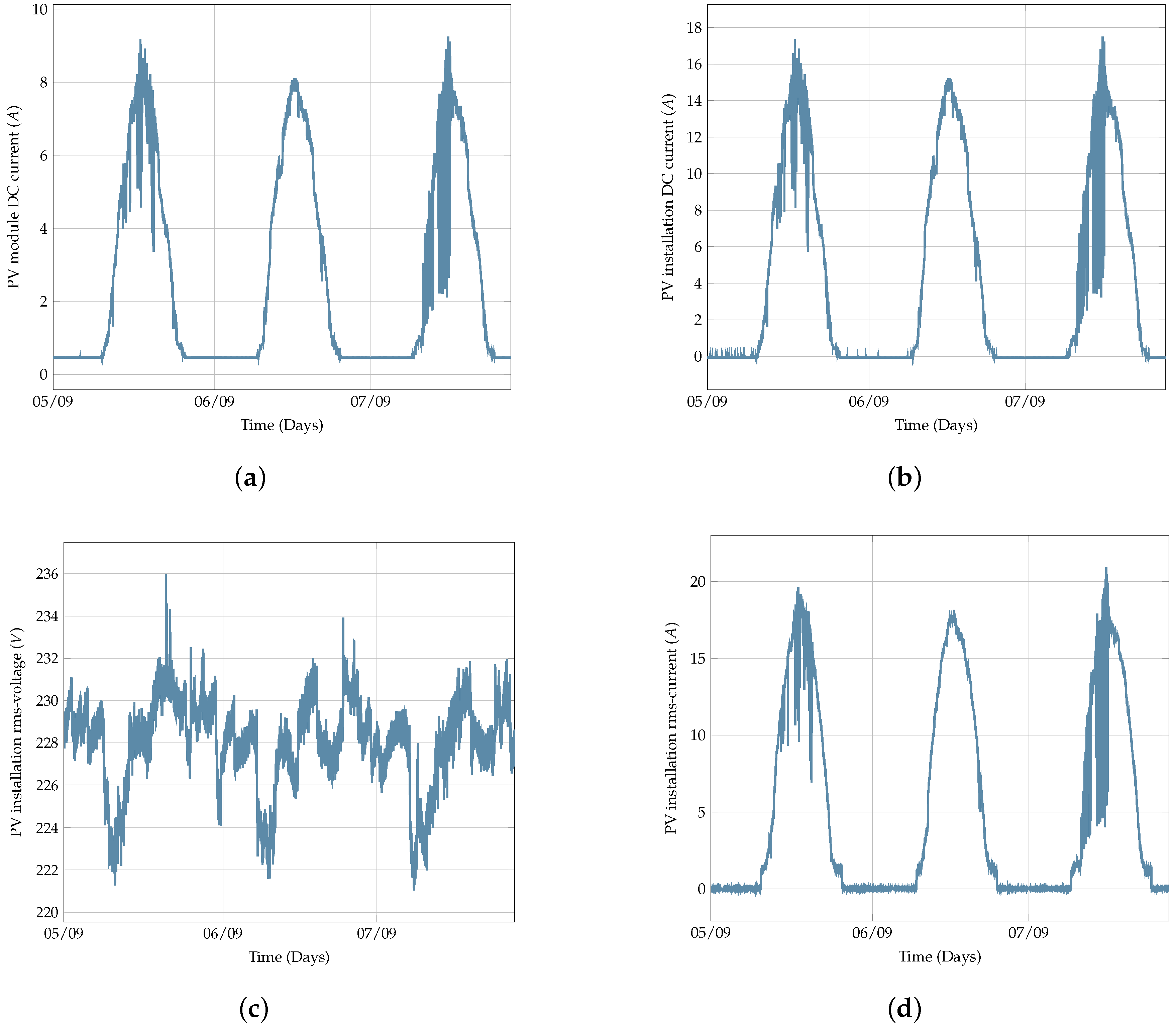

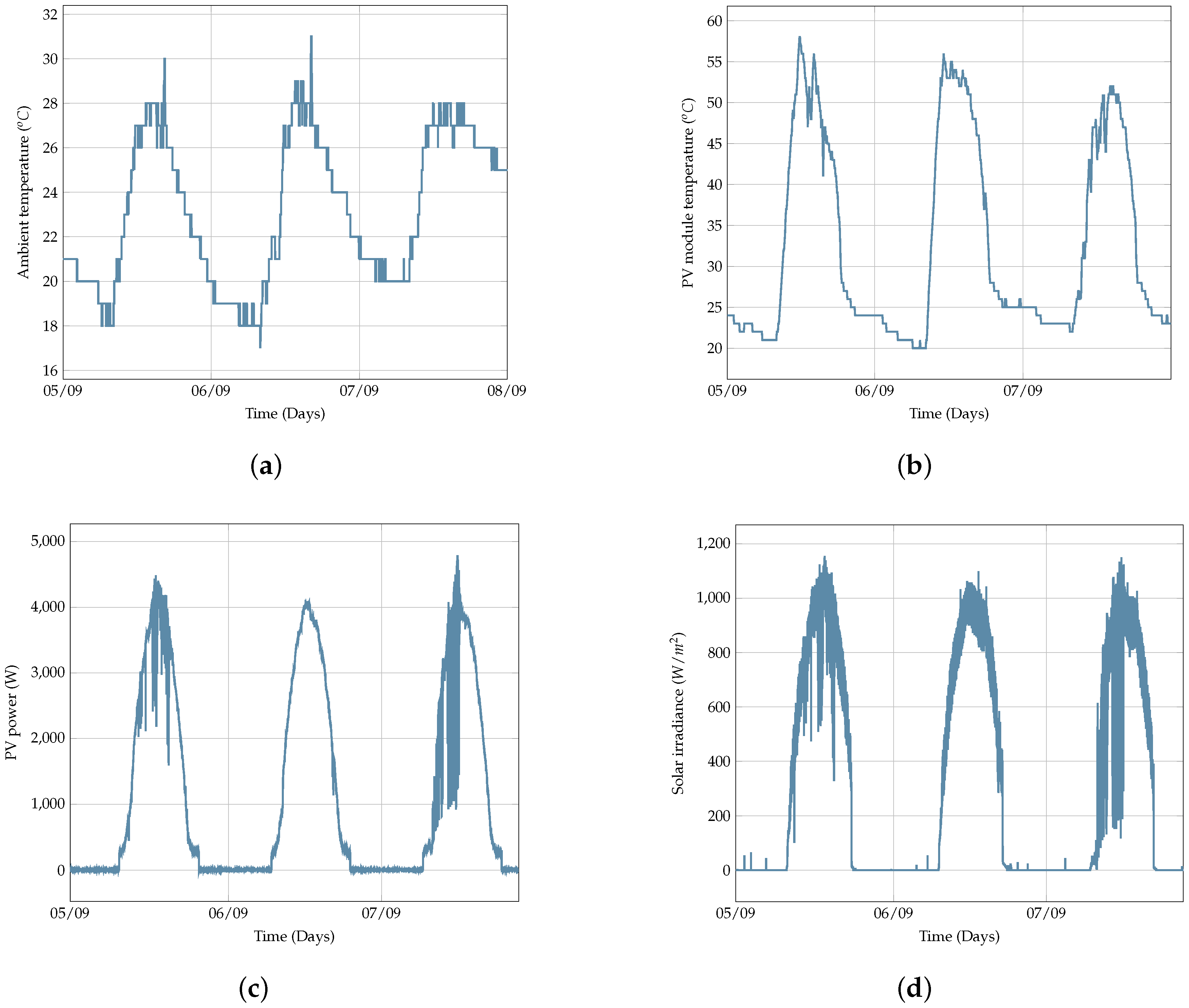

3. Results and Solution Assessment

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- International Energy Agency. Perspectives for the Energy Transition: Investment Needs for a Low-Carbon Energy System; Technical Report, OECD/IEA and IRENA 2017; IEA Publications, Printed by German Federal Ministry for Economic Affairs and Energy; March 2017; Available online: http://www.irena. org/DocumentDownloads/Publications/Perspectives_for_the_Energy_Transition_2017.pdf (accessed on 27 October 2018).

- Nieto, J.; Carpintero, O.; Miguel, L. Less than 2C? An Economic-Environmental Evaluation of the Paris Agreement. Ecol. Econ. 2018, 146, 69–84. [Google Scholar] [CrossRef]

- IRENA. Solar PV Costs 2010–2015. Available online: http://www.irena.org/costs/ (accessed on 27 October 2018).

- IRENA. Renewable Capacity Statistics 2018; International Renewable Energy Agency (IRENA): Abu Dhabi, UAE, 2018; Available online: http://irena.org/-/media/Files/IRENA/Agency/Publication/2018/Mar/IRENA_RE_Capacity_Statistics_2018.pdf (accessed on 27 October 2018)ISBN 978-92-9260-057-0.

- Best, R.; Burke, P.J. Adoption of solar and wind energy: The roles of carbon pricing and aggregate policy support. Energy Policy 2018, 118, 404–417. [Google Scholar] [CrossRef]

- Kraan, O.; Kramer, G.; Nikolic, I. Investment in the future electricity system—An agent-based modelling approach. Energy 2018, 151, 569–580. [Google Scholar] [CrossRef]

- Trujillo-Baute, E.; del Rio, P.; Mir-Artigues, P. Analysing the impact of renewable energy regulation on retail electricity prices. Energy Policy 2018, 114, 153–164. [Google Scholar] [CrossRef] [Green Version]

- Ellabban, O.; Abu-Rub, H.; Blaabjerg, F. Renewable energy resources: Current status, future prospects and their enabling technology. Renew. Sustain. Energy Rev. 2014, 39, 748–764. [Google Scholar] [CrossRef]

- Pietzcker, R.C.; Ueckerdt, F.; Carrara, S.; de Boer, H.S.; Després, J.; Fujimori, S.; Johnson, N.; Kitous, A.; Scholz, Y.; Sullivan, P.; et al. System integration of wind and solar power in integrated assessment models: A cross-model evaluation of new approaches. Energy Econ. 2017, 64, 583–599. [Google Scholar] [CrossRef] [Green Version]

- Kamaruzzaman, Z. Effect of grid–connected photovoltaic systems on static and dynamic voltage stability with analysis techniques—A review. Przegląd Elektrotech. 2015, 1, 136–140. [Google Scholar] [CrossRef]

- Hung, D.Q.; Shah, M.R.; Mithulananthan, N. Technical Challenges, Security and Risk in Grid Integration of Renewable Energy. In Smart Power Systems and Renewable Energy System Integration; Jayaweera, D., Ed.; Springer International Publishing: Cham, Switzerland, 2016; pp. 99–118. [Google Scholar] [CrossRef]

- Chiandone, M.; Sulligoi, G.; Massucco, S.; Silvestro, F. Hierarchical Voltage Regulation of Transmission Systems with Renewable Power Plants: An overview of the Italian case. In Proceedings of the 3rd IET Renewable Power Generation Conference, Naples, Italy, 24–25 September 2014; pp. 261–265. [Google Scholar]

- Bonfiglio, A.; Brignone, M.; Delfino, F.; Procopio, R. Optimal Control and Operation of Grid-Connected Photovoltaic Production Units for Voltage Support in Medium-Voltage Networks. IEEE Trans. Sustain. Energy 2014, 5, 254–263. [Google Scholar] [CrossRef]

- Weckx, S.; D’hulst, R.; Driesen, J. Locational Pricing to Mitigate Voltage Problems Caused by High PV Penetration. Energies 2015, 8, 4607–4628. [Google Scholar] [CrossRef] [Green Version]

- Smith, J.C.; Milligan, M.R.; DeMeo, E.A.; Parsons, B. Utility Wind Integration and Operating Impact State of the Art. IEEE Trans. Power Syst. 2007, 22, 900–908. [Google Scholar] [CrossRef]

- Shi, J.; Lee, W.; Liu, Y.; Yang, Y.; Wang, P. Forecasting Power Output of Photovoltaic Systems Based on Weather Classification and Support Vector Machines. IEEE Trans. Ind. Appl. 2012, 48, 1064–1069. [Google Scholar] [CrossRef]

- Bracale, A.; Caramia, P.; Carpinelli, G.; Di Fazio, A.R.; Ferruzzi, G. A Bayesian Method for Short-Term Probabilistic Forecasting of Photovoltaic Generation in Smart Grid Operation and Control. Energies 2013, 6, 733–747. [Google Scholar] [CrossRef] [Green Version]

- Zamo, M.; Mestre, O.; Arbogast, P.; Pannekoucke, O. A benchmark of statistical regression methods for short-term forecasting of photovoltaic electricity production, part I: Deterministic forecast of hourly production. Sol. Energy 2014, 105, 792–803. [Google Scholar] [CrossRef]

- Petrone, G.; Spagnuolo, G.; Teodorescu, R.; Veerachary, M.; Vitelli, M. Reliability Issues in Photovoltaic Power Processing Systems. IEEE Trans. Ind. Electron. 2008, 55, 2569–2580. [Google Scholar] [CrossRef]

- Colak, I.; Sagiroglu, S.; Fulli, G.; Yesilbudak, M.; Covrig, C.F. A survey on the critical issues in smart grid technologies. Renew. Sustain. Energy Rev. 2016, 54, 396–405. [Google Scholar] [CrossRef]

- Mahjoubi, A.; Mechlouch, R.; Brahim, A. A Low Cost Wireless Data Acquisition System for a Remote Photovoltaic (PV) Water Pumping System. Energies 2011, 4, 68–89. [Google Scholar] [CrossRef] [Green Version]

- Han, J.; Choi, C.; Park, W.; Lee, I.; Kim, S. PLC-based photovoltaic system management for smart home energy management system. IEEE Trans. Consum. Electron. 2014, 60, 184–189. [Google Scholar] [CrossRef]

- Han, J.; Jeong, J.D.; Lee, I.; Kim, S.H. Low-cost monitoring of photovoltaic systems at panel level in residential homes based on power line communication. IEEE Trans. Consum. Electron. 2017, 63, 435–441. [Google Scholar] [CrossRef]

- Wang, Y.; Wen, H.; Hou, X.; Tang, H.; Sun, H.; Zheng, K.; Li, S. Comparison of Differential-Mode and Mixed-Mode Conducted Emission for Household Appliances in Power-Line Communication System. IEEE Trans. Electromagn. Compat. 2017, 59, 2023–2028. [Google Scholar] [CrossRef]

- Pop-Calimanu, I.M.; Anna, T.; Popescu, V.; Muntean, G. A Low Cost System for Testing and Monitoring the Performance of Photovoltaic Module. Adv. Electr. Comput. Eng. 2013, 13, 93–98. [Google Scholar] [CrossRef]

- Dhimish, M.; Holmes, V.; Mehrdadi, B. Grid-connected PV monitoring system (GCPV-MS). In Proceedings of the 2016 4th International Symposium on Environmental Friendly Energies and Applications (EFEA), Belgrade, Serbia, 14–16 September 2016; pp. 1–6. [Google Scholar] [CrossRef]

- Papageorgas, P.; Piromalis, D.; Antonakoglou, K.; Vokas, G.; Tseles, D.; Arvanitis, K. Smart Solar Panels: In-situ Monitoring of Photovoltaic Panels based on Wired and Wireless Sensor Networks. Energy Procedia 2013, 36, 535–545. [Google Scholar] [CrossRef]

- Shariff, F.; Rahim, N.A.; Hew, W.P. ZigBee-based data acquisition system for online monitoring of grid-connected photovoltaic system. Expert Syst. Appl. 2015, 42, 1730–1742. [Google Scholar] [CrossRef]

- Batista, N.; Melicio, R.; Matias, J.; Catalao, J. Photovoltaic and wind energy systems monitoring and building/home energy management using ZigBee devices within a smart grid. Energy 2013, 49, 306–315. [Google Scholar] [CrossRef]

- Fuentes, M.; Vivar, M.; Burgos, J.; Aguilera, J.; Vacas, J. Design of an accurate, low-cost autonomous data logger for PV system monitoring using Arduino™ that complies with IEC standards. Sol. Energy Mater. Sol. Cells 2014, 130, 529–543. [Google Scholar] [CrossRef]

- Madeti, S.R.; Singh, S. Monitoring system for photovoltaic plants: A review. Renew. Sustain. Energy Rev. 2017, 67, 1180–1207. [Google Scholar] [CrossRef]

- Molina-García, A.; Campelo, J.; Blanc, S.; Serrano, J.; García-Sánchez, T.; Bueso, M. A Decentralized Wireless Solution to Monitor and Diagnose PV Solar Module Performance Based on Symmetrized-Shifted Gompertz Functions. Sensors 2015, 15, 18459–18479. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Friansa, K.; Haq, I.N.; Santi, B.M.; Kurniadi, D.; Leksono, E.; Yuliarto, B. Development of Battery Monitoring System in Smart Microgrid Based on Internet of Things (IoT). Procedia Eng. 2017, 170, 482–487. [Google Scholar] [CrossRef]

- Wang, Y. Design and Implementation of a Wireless Sensor Network Node Based on Arduino. Int. J. Online Eng. 2017, 13, 128. [Google Scholar] [CrossRef]

- Sipani, J.P.; Patel, R.H.; Upadhyahya, T.; Desai, A. Wireless Sensor Network for Monitoring & Control of Environmental Factors using Arduino. Int. J. Interact. Mob. Technol. 2018, 12, 15. [Google Scholar] [CrossRef]

- Raspberry Pi Foundation. Available online: https://www.raspberrypi.org/ (accessed on 27 October 2018).

- Cleevely, D. Annual Review; Technical Report; Raspberry-Pi Foundation: Cambridge, UK, 2017. [Google Scholar]

- Anire, R.B.; Cruz, F.R.G.; Agulto, I.C. Environmental wireless sensor network using raspberry Pi 3 for greenhouse monitoring system. In Proceedings of the 9th IEEE International Conference on Humanoid, Nanotechnology, Information Technology, Communication and Control, Environment and Management, Manila, Philippines, 1–3 December 2017. [Google Scholar] [CrossRef]

- Othman, N.A.; Zainodin, M.R.; Anuar, N.; Damanhuri, N.S. Remote monitoring system development via Raspberry-Pi for small scale standalone PV plant. In Proceedings of the 2017 7th IEEE International Conference on Control System, Computing and Engineering, Penang, Malaysia, 24–26 November 2017. [Google Scholar] [CrossRef]

- Pereira, R.I.; Dupont, I.M.; Carvalho, P.C.; Jucá, S.C. IoT embedded linux system based on Raspberry Pi applied to real-time cloud monitoring of a decentralized photovoltaic plant. Measurement 2018, 114, 286–297. [Google Scholar] [CrossRef]

- Lobaccaro, G.; Carlucci, S.; Lofstrom, E. A Review of Systems and Technologies for Smart Homes and Smart Grids. Energies 2016, 9, 348. [Google Scholar] [CrossRef]

- Lu, X.; Wang, S.; Li, W.; Jiang, P.; Zhang, C. Development of a WSN based real time energy monitoring platform for industrial applications. In Proceedings of the 19th International Conference on Computer Supported Cooperative Work in Design, Calabria, Italy, 6–8 May 2015; pp. 337–342. [Google Scholar] [CrossRef]

- Openenergymonitor. Available online: https://openenergymonitor.org/ (accessed on 27 October 2018).

- HOPE MicroElectronics Co., Ltd. RFM69CW Datasheet; Technical Report; Available online: http://www. hoperf.com/upload/rf/RFM69CW-V1.1.pdf (accessed on 27 October 2018).

- Kumar, A.; Hancke, G.P. Energy Efficient Environment Monitoring System Based on the IEEE 802.15.4 Standard for Low Cost Requirements. IEEE Sens. J. 2014, 14, 2557–2566. [Google Scholar] [CrossRef] [Green Version]

- Fuertes, W.; Carrera, D.; Villacís, C.; Toulkeridis, T.; Galárraga, F.; Torres, E.; Aules, H. Distributed System as Internet of Things for a New Low-Cost, Air Pollution Wireless Monitoring on Real Time. In Proceedings of the 2015 IEEE/ACM 19th International Symposium on Distributed Simulation and Real Time Applications (DS-RT), Chengdu, China, 14–16 October 2015; pp. 58–67. [Google Scholar] [CrossRef]

- Ram, S.A.; Siddarth, N.; Manjula, N.; Rogan, K.; Srinivasan, K. Real-time automation system using Arduino. In Proceedings of the 2017 International Conference on Innovations in Information, Embedded and Communication Systems (ICIIECS), Coimbatore, India, 17–18 March 2017; pp. 1–5. [Google Scholar] [CrossRef]

- Nisio, A.D.; Noia, T.D.; Carducci, C.G.C.; Spadavecchia, M. Design of a low cost multipurpose wireless sensor network. In Proceedings of the 2015 IEEE International Workshop on Measurements Networking (M&N), Coimbra, Portugal, 12–13 October 2015; pp. 1–6. [Google Scholar] [CrossRef]

- Rahim, A.; Ali, Z.; Bharti, R.; Sabeel, S.; Ramya, B.K. Design and Implementation of a Low Cost Wireless Sensor Network using Arduino and nRF24L01(+). Int. J. Sci. Res. Eng. Technol. 2016, 5, 307–309. [Google Scholar]

- IEC 61724-1. Photovoltaic System Performance Monitoring—Guidelines for Measurement, Data Exchange, and Analysis (Part 1); Technical Report 1; International Electrotechnical Commission (IEC)’: Switzerland, Geneva, 2017. [Google Scholar]

- del Ama Gonzalo, F.; Hernandez, J.A.; Moreno, B. Wireless low cost temperature and humidity sensors with PV microcells. Determination of design parameters by means of experimental measurements. In Proceedings of the 2016 5th International Conference on Electronic Devices, Systems and Applications (ICEDSA), Ras Al Khaimah, UAE, 6–8 December 2016; pp. 1–4. [Google Scholar] [CrossRef]

- Priya, C.G.; AbishekPandu, M.; Chandra, B. Automatic plant monitoring and controlling system over GSM using sensors. In Proceedings of the 2017 IEEE Technological Innovations in ICT for Agriculture and Rural Development (TIAR), Chennai, India, 7–8 April 2017; pp. 173–176. [Google Scholar] [CrossRef]

- Hulea, M.; Mois, G.; Folea, S.; Miclea, L.; Biscu, V. Wi-sensors: A low power Wi-Fi solution for temperature and humidity measurement. In Proceedings of the IECON 2013 39th Annual Conference of the IEEE Industrial Electronics Society, Vienna, Austria, 10–13 November 2013; pp. 4011–4015. [Google Scholar] [CrossRef]

- Saha, S.; Majumdar, A. Data centre temperature monitoring with ESP8266 based Wireless Sensor Network and cloud based dashboard with real time alert system. In Proceedings of the 2017 Devices for Integrated Circuit (DevIC), Kalyani, India, 23–24 March 2017; pp. 307–310. [Google Scholar] [CrossRef]

- Vicente, E.M.; Moreno, R.L.; Ribeiro, E.R. MPPT Technique Based on Current and Temperature Measurements. Int. J. Photoenergy 2015, 1–9. [Google Scholar] [CrossRef]

- Muellejans, H.; Zaaiman, W.; Dunlop, E.; Ossenbrink, H.A. Calibration of photovoltaic reference cells by global sunlight method. Metrologia 2005, 42, 360–367. [Google Scholar] [CrossRef]

- Stokler, S.; Schillings, C.; Kraas, B. Solar resource assessment study for Pakistan. Renew. Sustain. Energy Rev. 2016, 58, 1184–1188. [Google Scholar] [CrossRef]

- Hussain, F.; Othman, M.; Yatim, B.; Ruslan, H.; Sopian, K.; Anuar, Z.; Khairuddin, S. An improved design of photovoltaic/thermal solar collector. Sol. Energy 2015, 122, 885–891. [Google Scholar] [CrossRef]

- Skoplaki, E.; Palyvos, J. Operating temperature of photovoltaic modules: A survey of pertinent correlations. Renew. Energy 2009, 34, 23–29. [Google Scholar] [CrossRef]

- Kaldellis, J.; Kapsali, M.; Kavadias, K. Temperature and wind speed impact on the efficiency of PV installations. Experience obtained from outdoor measurements in Greece. Renew. Energy 2014, 66, 612–624. [Google Scholar] [CrossRef]

- Copper, J.; Bruce, A.; Spooner, T.; Calais, M.; Pryor, T.; Watt, M. Australian Technical Guidelines for Monitoring and Analysing Photovoltaic Systems; Technical Report; Australian PV Institute (APVI): Sydney, Australia, 2013. [Google Scholar] [CrossRef]

- Schwingshackl, C.; Petitta, M.; Wagner, J.E.; Belluardo, G.; Moser, D.; Castelli, M.; Zebisch, M.; Tetzlaff, A. Wind effect on PV module temperature: Analysis of different techniques for an accurate estimation. Energy Procedia 2013, 40, 77–86. [Google Scholar] [CrossRef]

- Skoplaki, E.; Palyvos, J. On the temperature dependence of photovoltaic module electrical performance: A review of efficiency/power correlations. Sol. Energy 2009, 83, 614–624. [Google Scholar] [CrossRef]

- Dubey, S.; Sarvaiya, J.N.; Seshadri, B. Temperature Dependent Photovoltaic (PV) Efficiency and Its Effect on PV Production in the World—A Review. Energy Procedia 2013, 33, 311–321. [Google Scholar] [CrossRef]

- Skoplaki, E.; Boudouvis, A.; Palyvos, J. A simple correlation for the operating temperature of photovoltaic modules of arbitrary mounting. Sol. Energy Mater. Sol. Cells 2008, 92, 1393–1402. [Google Scholar] [CrossRef]

- Emery, K.; Smith, R. Monitoring System Performance; Technical Report; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2011.

- Yaácob, M.E.; Hizam, H.; Radzi, M.A.M.; Kadir, M. Field Measurement of PV Array Temperature for Tracking and Concentrating 1 kWp Generators Installed in Malaysia. Int. J. Photoenergy 2013, 1–8. [Google Scholar] [CrossRef]

- Arunachalam, B.; Devi, R.; Patvardhan, A.; Aiswarya, R.; Prasen, V. Embedded Temperature Monitoring and Control Unit. In Proceedings of the International Conference on Recent Trends in Information, Telecommunication and Computing, Kerala, India, 12–13 March 2010; pp. 293–297. [Google Scholar] [CrossRef]

- Ozemoya, A.; Swart, A.; Pienaar, H.; Schoeman, R. Factors impacting on the surface temperature of a PV panel. In Proceedings of the Southern Africa Telecommunication Networks and Applications Conference (SATNAC), Hermanus, South Africa, 6–9 Setptember 2013; pp. 1–5. [Google Scholar]

- Dechang Electric Co. SCT013-000 Current Transformer Datasheet; Technical Report; Dechang Electric Co., Ltd. (CN): Shenzhen, China, 2015. [Google Scholar]

- Pocero, L.; Amaxilatis, D.; Mylonas, G.; Chatzigiannakis, I. Open source IoT meter devices for smart and energy-efficient school buildings. HardwareX 2017, 1, 54–67. [Google Scholar] [CrossRef]

- Openenergymonitor. Measuring AC Voltage with an AC to AC Power Adapter. Available online: https://learn.openenergymonitor.org/electricity-monitoring/voltage-sensing/measuring-voltage-with-an-acac-power-adapter (accessed on 27 October 2018).

- Gabriele, T.; Pantoli, L.; Stornelli, V.; Chiulli, D.; Muttillo, M. Smart power management system for home appliances and wellness based on wireless sensors network and mobile technology. In Proceedings of the XVIII AISEM Annual Conference, Trento, Italy, 3–5 February 2015; pp. 1–4. [Google Scholar] [CrossRef]

- Gyrard, A.; Datta, S.K.; Bonnet, C.; Boudaoud, K. A Semantic Engine for Internet of Things: Cloud, Mobile Devices and Gateways. In Proceedings of the 9th International Conference on Innovative Mobile and Internet Services in Ubiquitous Computing, Santa Cantarina, Brazil, 8–10 July 2015; pp. 336–341. [Google Scholar] [CrossRef]

- Sethi, P.; Sarangi, S. Internet of Things: Architectures, Protocols, and Applications. J. Electr. Comput. Eng. 2017, 1–25. [Google Scholar] [CrossRef]

- Lee, Y.; Nair, S. A Smart Gateway Framework for IOT Services. In Proceedings of the 2016 IEEE International Conference on Internet of Things (iThings) and IEEE Green Computing and Communications (GreenCom) and IEEE Cyber, Physical and Social Computing (CPSCom) and IEEE Smart Data (SmartData), Chengdu, China, 15–18 December 2016; pp. 107–114. [Google Scholar] [CrossRef]

- Vaupel, S.; Segura, L.L.O.; Vaupel, H. SmartCalculator: The individual and general cost-saving potential of dynamic electricity rates. In Proceedings of the 2016 IEEE International Conference on Industrial Technology (ICIT), Taipei, Taiwan, 14–17 March 2016; pp. 558–563. [Google Scholar] [CrossRef]

- Sacoto-Cabrera, E.; Rodriguez-Bustamante, J.; Gallegos-Segovia, P.; Arevalo-Quishpi, G.; León-Paredes, G. Internet of Things: Informatic system for metering with communications MQTT over GPRS for smart meters. In Proceedings of the CHILEAN Conference on Electrical, Electronics Engineering, Information and Communication Technologies, Pucon, Chile, 18–20 October 2017; pp. 1–6. [Google Scholar] [CrossRef]

- Openenergymonitor. Emoncms. Available online: http://emoncms.org (accessed on 27 October 2018).

- Efergy. Efergy Pro. Available online: https://efergy.com/efergypro/ (accessed on 27 October 2018).

- Victron Energy. Available online: https://www.victronenergy.com/ (accessed on 27 October 2018).

- Solar Monitor. Available online: https://shop.solarmonitor.cz/en/7-solar-monitor-2 (accessed on 27 October 2018).

- Soltec. Solar-Traker Soltec. 2017. Available online: http://www.soltec.com (accessed on 27 October 2018).

- Martinez, M.; Andujar, J.; Enrique, J. A New and Inexpensive Pyranometer for the Visible Spectral Range. Sensors 2009, 9, 4615–4634. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bayrak, G.; Cebeci, M. Monitoring a grid connected PV power generation system with labview. In Proceedings of the 2013 International Conference on Renewable Energy Research and Applications (ICRERA), Madrid, Spain, 20–23 October 2013; pp. 562–567. [Google Scholar] [CrossRef]

- Ocoleanu, C. Solution for humidity measurement using NI PCI 6221 and LabVIEW. In Proceedings of the IEEE 2nd International Forum on Research and Technologies for Society and Industry Leveraging a better tomorrow (RTSI), Bologna, Italy, 7–9 September 2016; pp. 1–5. [Google Scholar] [CrossRef]

- Daliento, S.; Chouder, A.; Guerriero, P.; Pavan, A.M.; Mellit, A.; Moeini, R.; Tricoli, P. Monitoring, Diagnosis, and Power Forecasting for Photovoltaic Fields: A Review. Int. J. Photoenergy 2017, 1–13. [Google Scholar] [CrossRef]

| Symbol | Units | ||

|---|---|---|---|

| Meteorological | Total irradiance (on the array) | W/m | |

| Ambient temperature | °C | ||

| Wind speed (optional) | m/s | ||

| Wind direction (optional) | degrees | ||

| Photovoltaic array | Output voltage | V | |

| Output Current | A | ||

| Output power | W | ||

| Module temperature | °C | ||

| Utility grid | Utility voltage | V | |

| Current to/from utility grid | A | ||

| Power to/from utility grid | W |

| Parameter | IEC-61724 Minimum Accuracy | Results |

|---|---|---|

| Current | ||

| Voltage | ||

| Power |

| Description | Number | Unit Price (Euro) | Total Price (Euro) |

|---|---|---|---|

| emonTx Arduino Shield SMT | 1 | 3.14 | 3.14 |

| RFM69HW 433 Mhz Wireless Transceiver | 1 | 1.85 | 1.85 |

| PV module (5 Wp, 22 V, 30 W) | 1 | 8.75 | 8.75 |

| Cement resistance 5 W 10 10R 5% | 1 | 0.13 | 0.13 |

| AC-AC Power Supply Adapter | 1 | 4.95 | 4.95 |

| Non-invasive AC Sensor | 1 | 4.31 | 4.31 |

| 30 A DC Hall Current Sensor | 1 | 1.58 | 1.58 |

| 5 V DC USB Power Adapter | 1 | 2.40 | 2.40 |

| Digital Temperature and Humidity Sensor | 1 | 0.71 | 0.71 |

| LM35 TO-220 temperature | 1 | 1.13 | 1.13 |

| 2.54 mm PCB Screw Connector | 6 | 0.17 | 1.02 |

| Aluminum Electrolytic Capacitor 400 V | 2 | 0.02 | 0.04 |

| Metal film resistance 1 M 1.2 M 1.5 M 2 M 2.2 M | 6 | 0.05 | 0.30 |

| Prototype PCB Universal Board | 1 | 0.35 | 0.35 |

| Outdoor enclosure and wiring | 1 | 3.50 | 3.50 |

| Total | 34.16 |

| Description | Number | Unit Price (Euro) | Total Price (Euro) |

|---|---|---|---|

| emonTx Arduino Shield SMT | 1 | 3.14 | 3.14 |

| RFM69HW 433Mhz Wireless Transceiver | 1 | 1.94 | 1.94 |

| AC-AC Power Supply Adapter | 1 | 4.95 | 4.95 |

| Non-invasive AC Sensor | 1 | 4.31 | 4.31 |

| 5 V DC USB Power Adapter | 1 | 2.06 | 2.06 |

| 2.54 mm PCB Screw Connector | 6 | 0.17 | 1.02 |

| Aluminum Electrolytic Capacitor 400 V | 2 | 0.02 | 0.04 |

| Metal Film Resistors 1% | 8 | 0.03 | 0.24 |

| Prototype PCB Universal Board | 1 | 0.35 | 0.35 |

| Outdoor enclosure and wiring | 1 | 3.50 | 3.50 |

| Total | 21.55 |

| Description | Number | Unit Price (Euro) | Total Price (Euro) |

|---|---|---|---|

| Raspberry Pi 3 Model B Board | 1 | 32.33 | 32.33 |

| Sd card 32 Gb | 1 | 3.27 | 3.27 |

| 5 V DC USB Power Adapter | 1 | 2.06 | 2.06 |

| Raspberry ABS Case Black Transparent | 1 | 2.05 | 2.05 |

| RFM69HW 433 Mhz Wireless Transceiver | 1 | 1.85 | 1.85 |

| RFM69 Breakout Board | 1 | 1.00 | 1.00 |

| Total | 42.56 |

| Parameter | IEC61724 Required Accuracy | Results |

|---|---|---|

| Current | ||

| Voltage | ||

| Power |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paredes-Parra, J.M.; Mateo-Aroca, A.; Silvente-Niñirola, G.; Bueso, M.C.; Molina-García, Á. PV Module Monitoring System Based on Low-Cost Solutions: Wireless Raspberry Application and Assessment. Energies 2018, 11, 3051. https://doi.org/10.3390/en11113051

Paredes-Parra JM, Mateo-Aroca A, Silvente-Niñirola G, Bueso MC, Molina-García Á. PV Module Monitoring System Based on Low-Cost Solutions: Wireless Raspberry Application and Assessment. Energies. 2018; 11(11):3051. https://doi.org/10.3390/en11113051

Chicago/Turabian StyleParedes-Parra, José Miguel, Antonio Mateo-Aroca, Guillermo Silvente-Niñirola, María C. Bueso, and Ángel Molina-García. 2018. "PV Module Monitoring System Based on Low-Cost Solutions: Wireless Raspberry Application and Assessment" Energies 11, no. 11: 3051. https://doi.org/10.3390/en11113051

APA StyleParedes-Parra, J. M., Mateo-Aroca, A., Silvente-Niñirola, G., Bueso, M. C., & Molina-García, Á. (2018). PV Module Monitoring System Based on Low-Cost Solutions: Wireless Raspberry Application and Assessment. Energies, 11(11), 3051. https://doi.org/10.3390/en11113051