An Optimal Burn-In Policy for Cellular Phone Lithium-Ion Batteries Using a Feature Selection Strategy and Relevance Vector Machine

Abstract

:1. Introduction

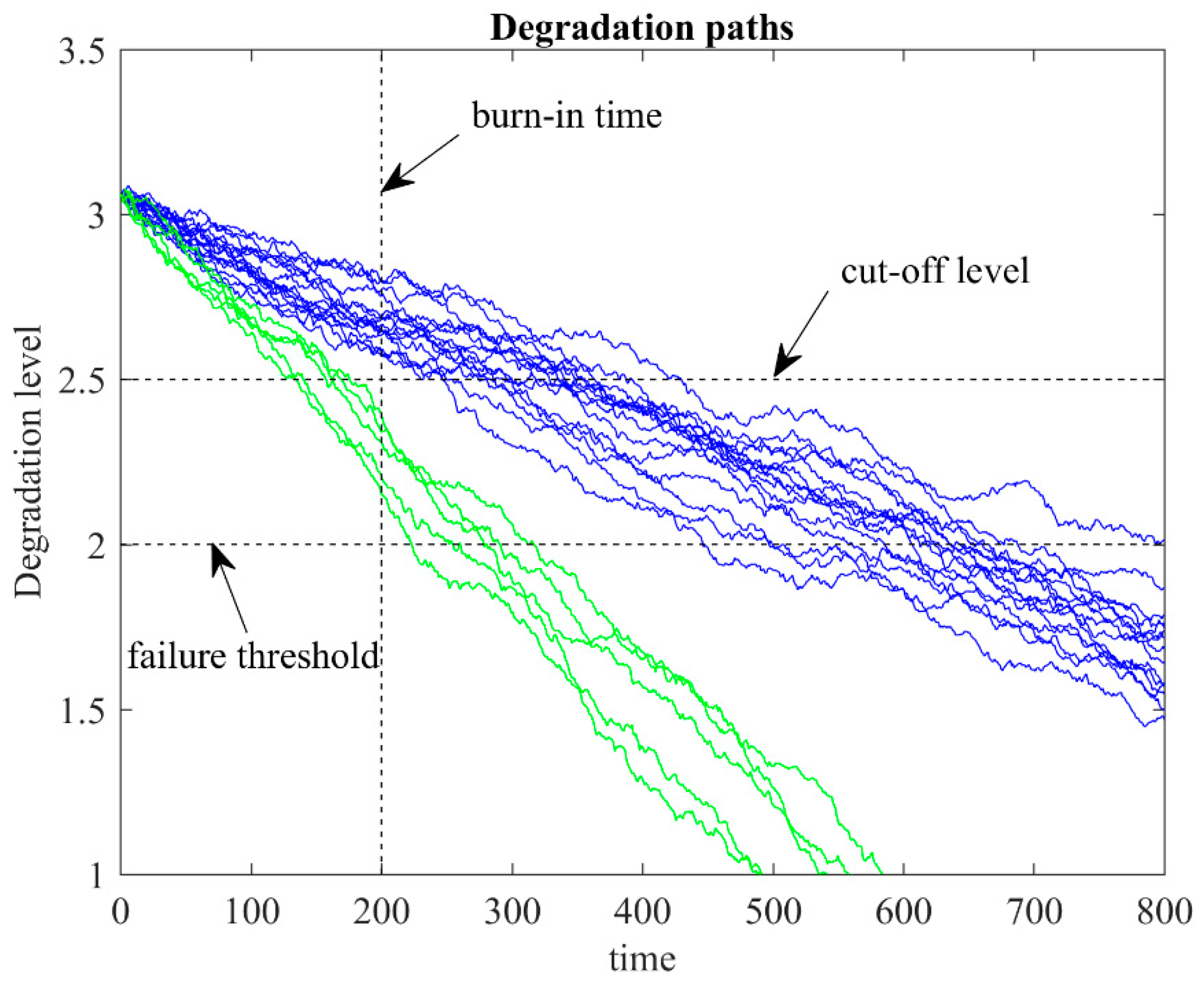

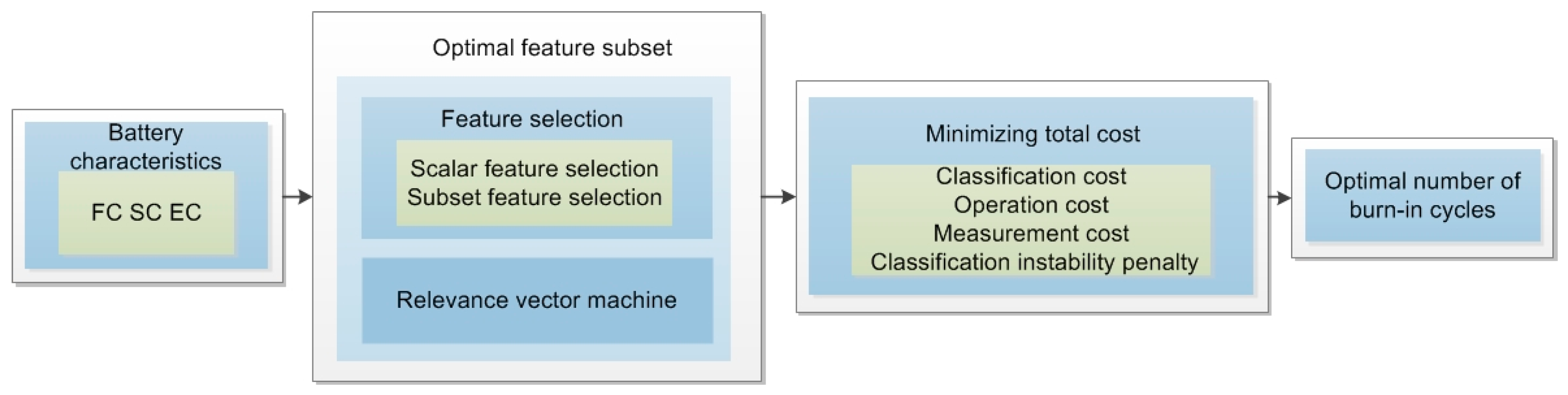

2. Framework of Optimal Burn-In Policy Design

3. Battery Characteristics Selection

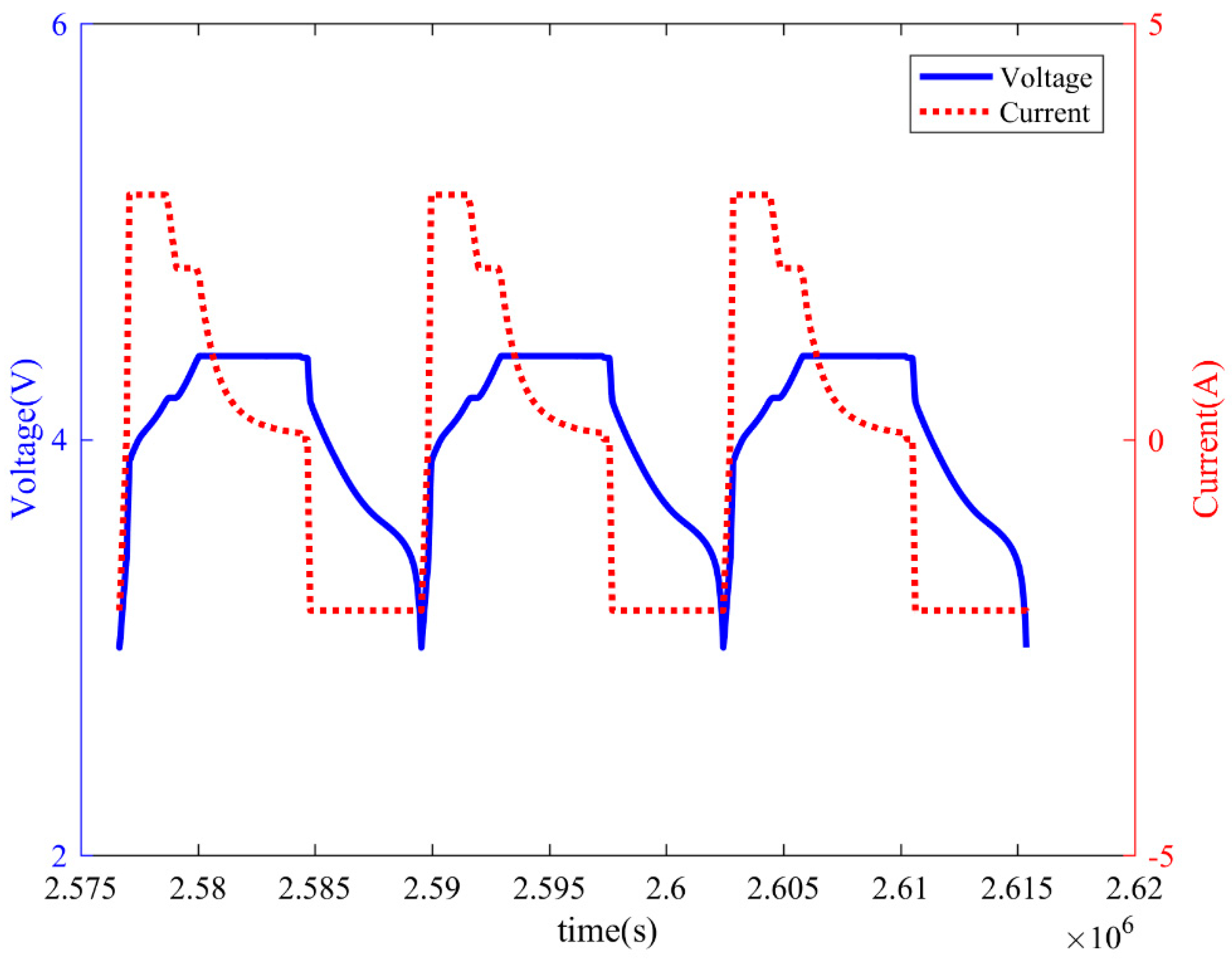

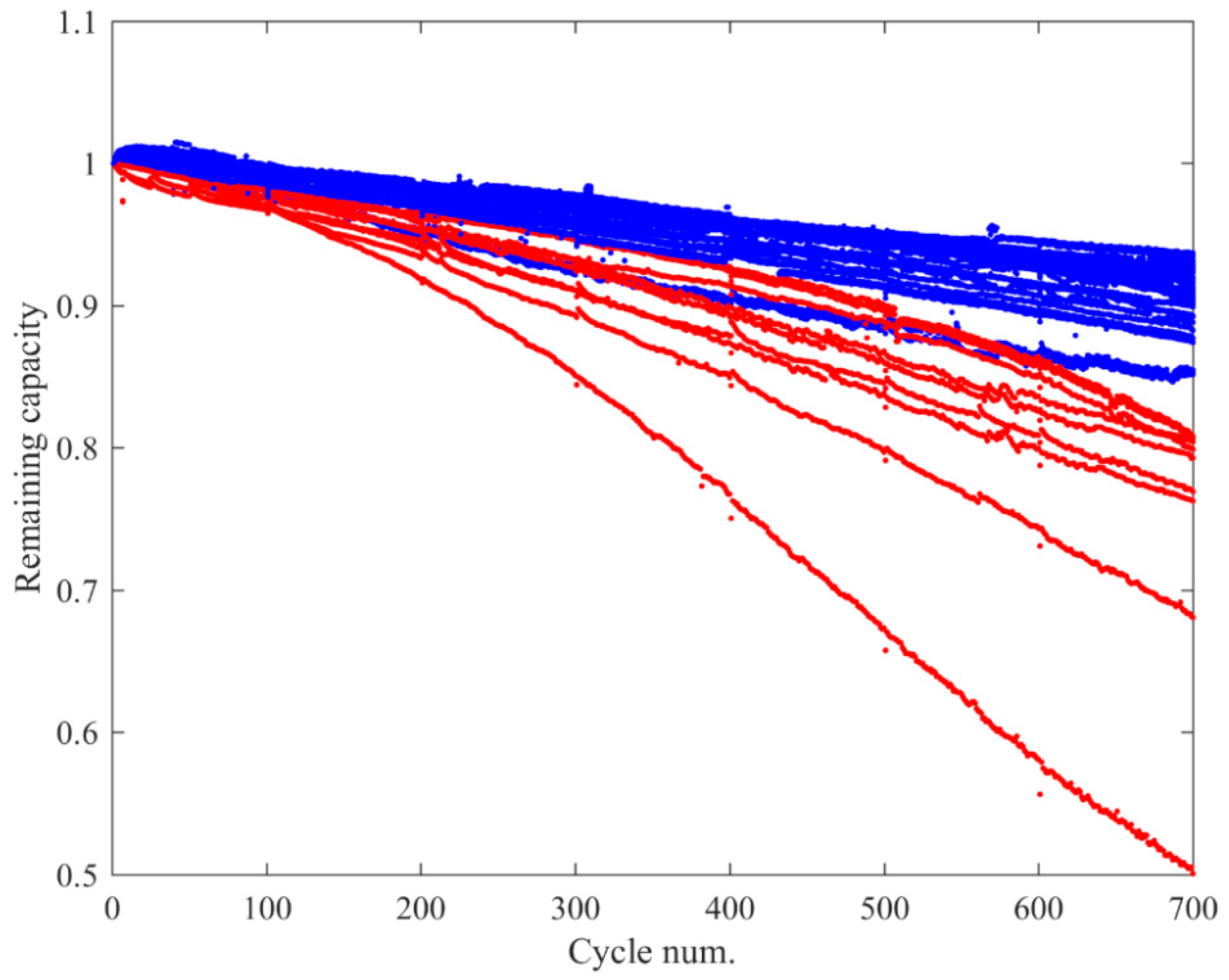

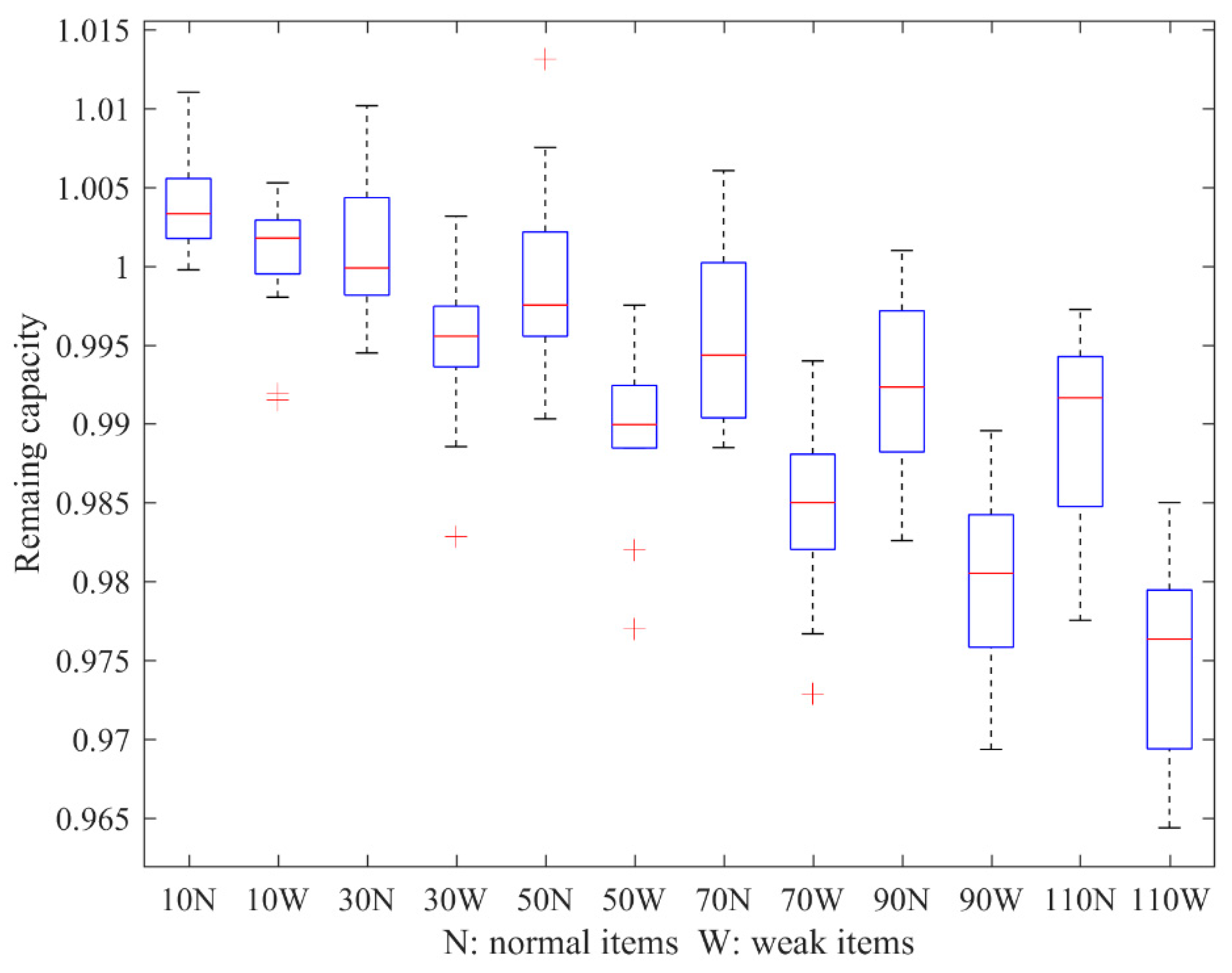

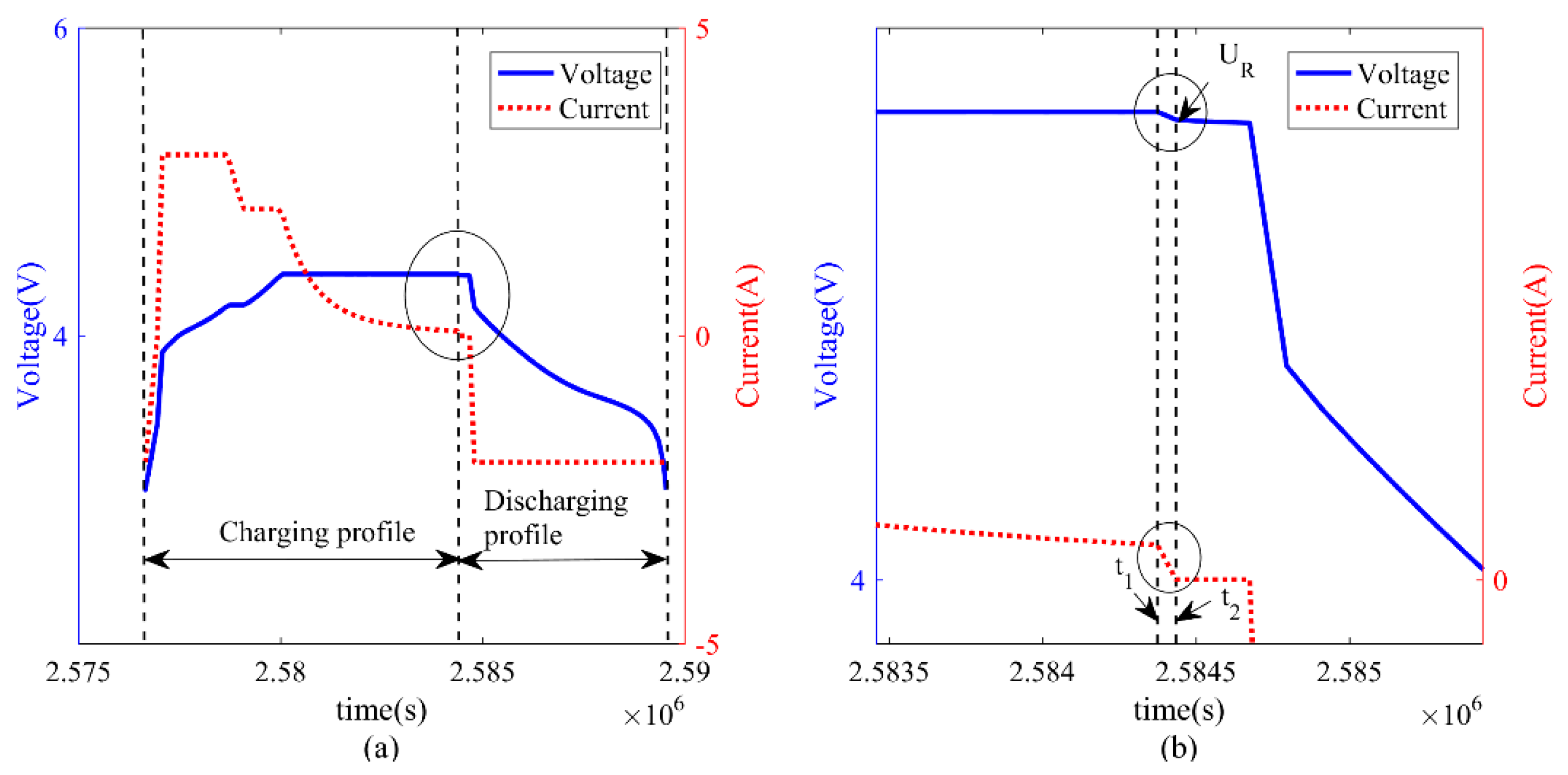

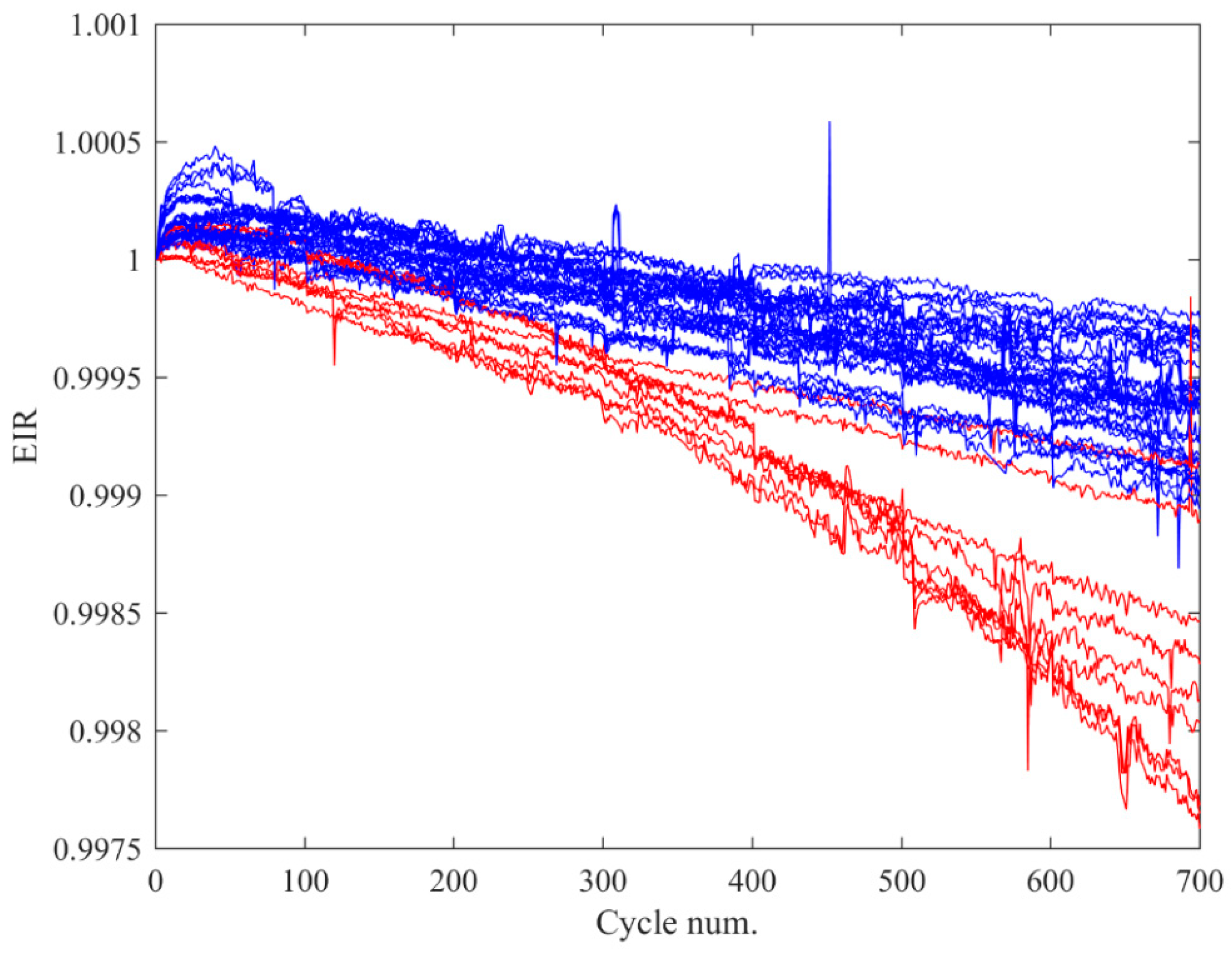

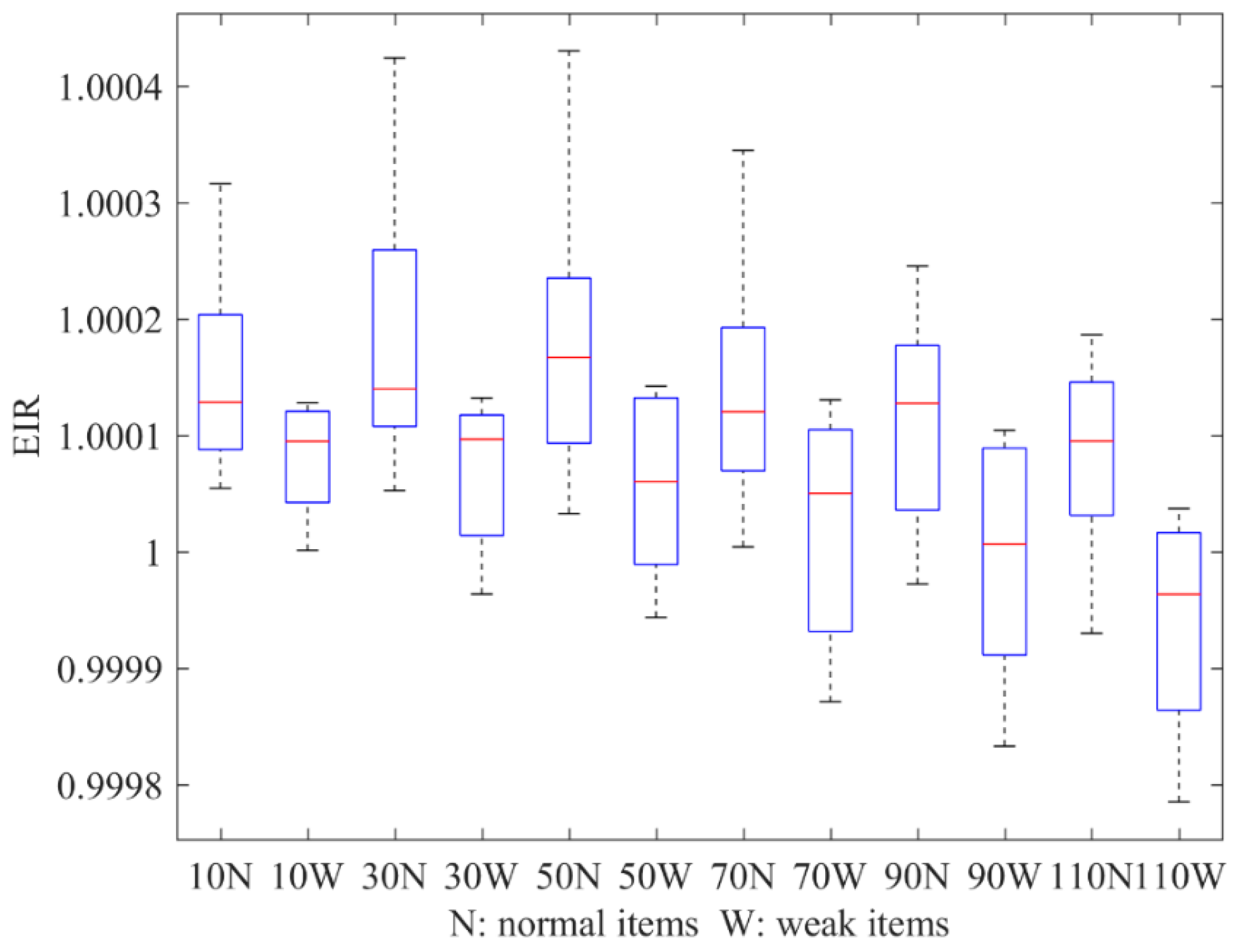

3.1. Data Description

3.2. Battery Characteristics

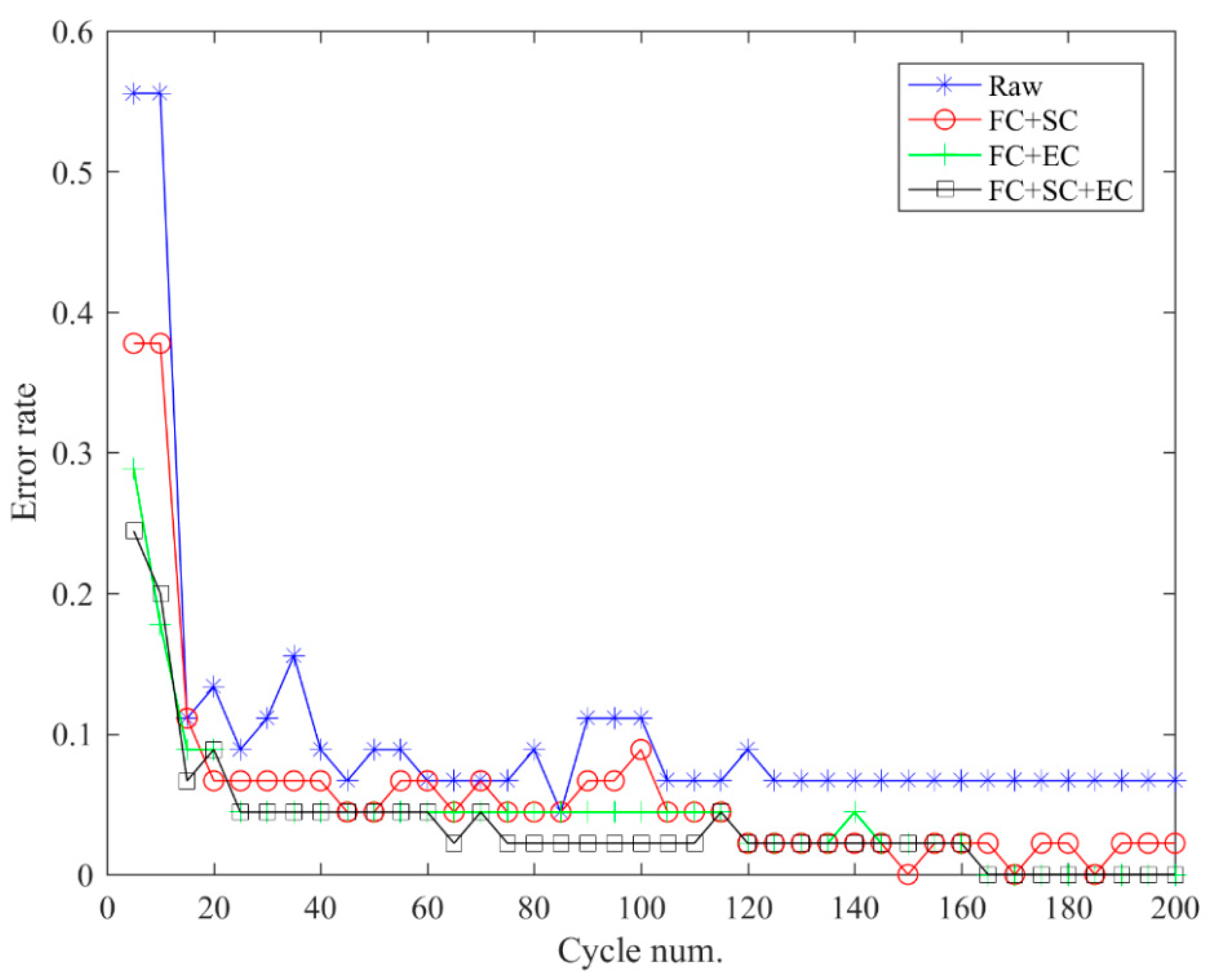

4. Classifier Design with Feature Selection Strategy

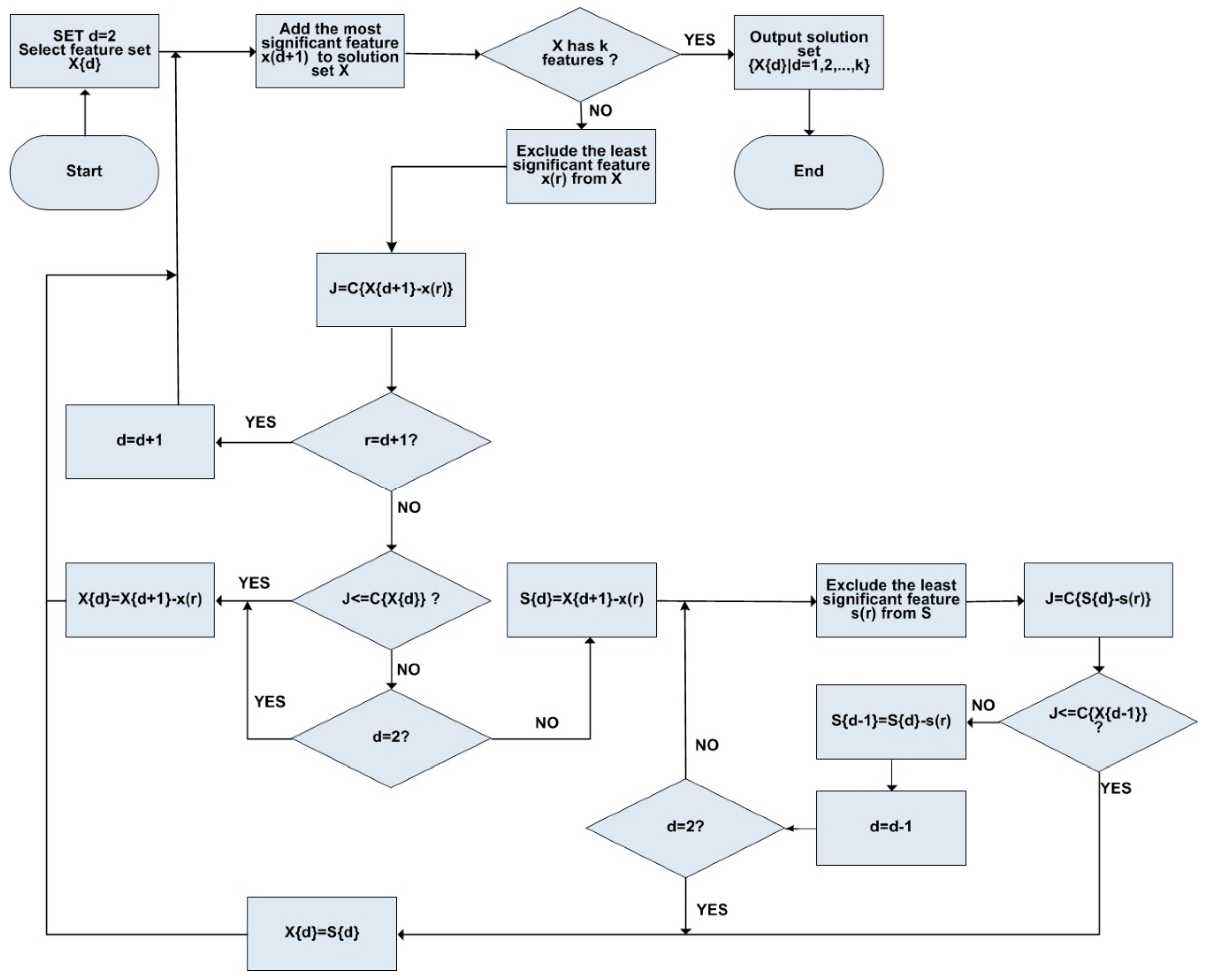

4.1. Feature Selection

- Input: A set of , d is the desired number of features, is the criterion function with the feature subset ;

- Output: the optimal feature subsetsInitialization: d = 2, using sequential forward selection, select the feature subset .

4.2. Classifier Design

- Given a fixed value of , the posterior distribution over is obtained by maximizingwhere A = diag() and is a target value vector. The iterative reweighted least squares (IRLS) method [41] is applied to solve this problem. Then the mean and covariance of the Gaussian approximation is expressed as:where is the design matrix with elements ; B is an N × N diagonal matrix with .

- Suppose , then the approximate log marginal likelihood in the form is obtained by:where . Then can be updated by:where .

- The previous two steps are repeated until convergence or a maximum number of iterations is reached.

- Then the output is calculated by ; assuming that the threshold of the posterior probabilities is , then

5. Optimal Number of Burn-In Cycles

6. Results and Discussion

6.1. Results

- The cost of a Type I error

- The cost of a Type II error

- Operational cost

- Measurement cost

- Classification instability penalty cost

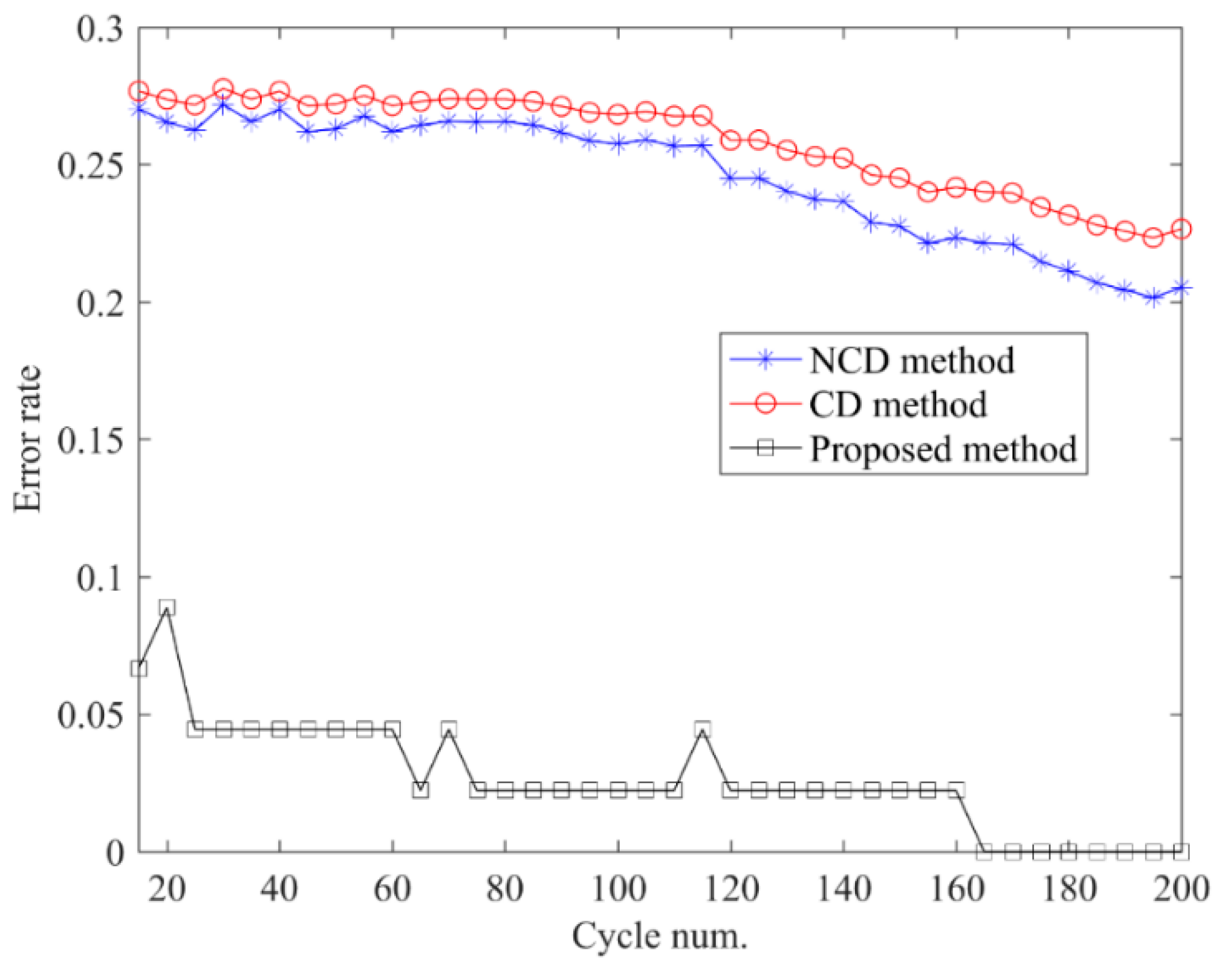

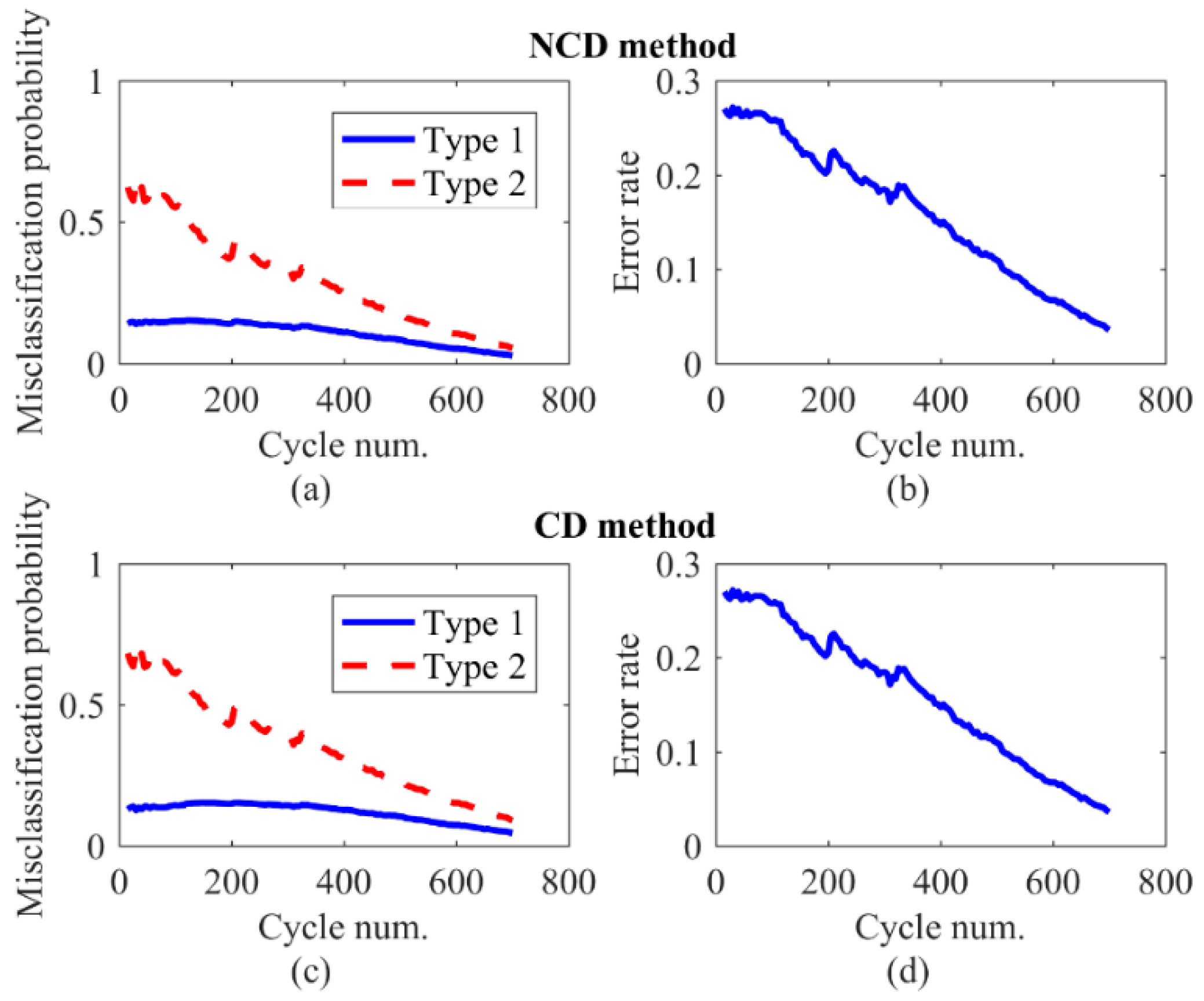

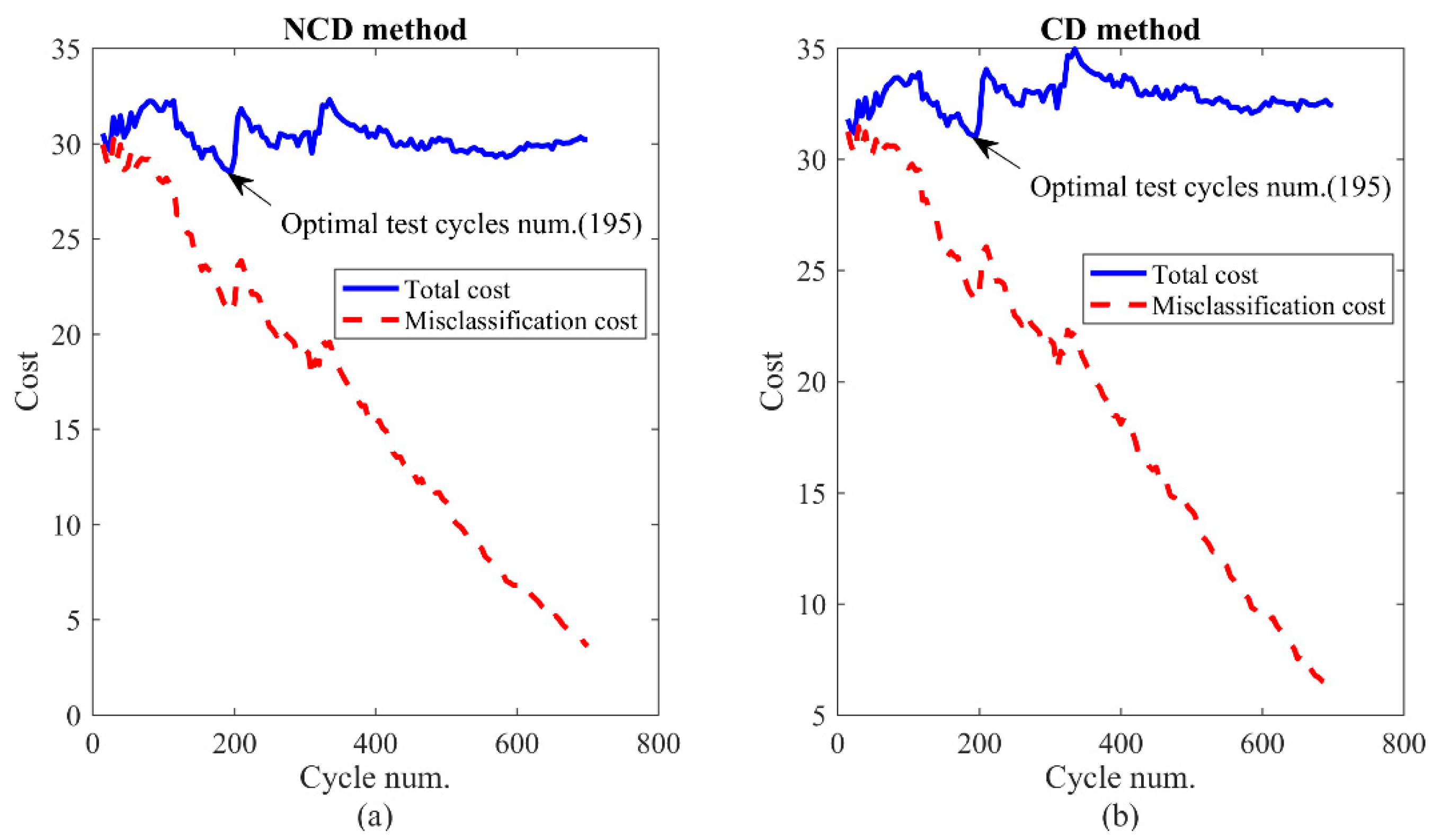

6.2. Comparison with Other Methods

- (a)

- The error rate of the classification

- (b)

- The optimal number of burn-in cycles

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| RVM | Relevance vector machine |

| SFFS | Sequential floating forward search |

| QC | Quality characteristic |

| CD | Cumulative Degradation model |

| NCD | Non-Cumulative Degradation method |

| ADTs | Accelerated degradation tests |

| SVM | Support vector machine |

| EIR | Equivalent internal resistance |

| FC | First derivatives characteristic |

| SC | Second derivatives characteristic |

| EC | Equivalent internal resistance characteristic |

| FDR | Fisher Discrimination Ratio |

References

- Mankowski, P.J.; Kanevsky, J.; Bakirtzian, P.; Cugno, S. Cellular phone collateral damage: A review of burns associated with lithium battery powered mobile devices. Burns 2016, 42, 61–64. [Google Scholar] [CrossRef] [PubMed]

- Yu, J.; Liang, S.; Tang, D.; Liu, H. Remaining Discharge Time Prognostics of Lithium-Ion Batteries Using Dirichlet Process Mixture Model and Particle Filtering Method. IEEE Trans. Instrum. Meas. 2017, 66, 2317–2328. [Google Scholar] [CrossRef]

- Yu, J.; Mo, B.; Tang, D.; Yang, J.; Wan, J.; Liu, J. Indirect State-of-Health Estimation for Lithium-Ion Batteries under Randomized Use. Energies 2017, 10, 2012. [Google Scholar] [CrossRef]

- Patil, M.; Panchal, S.; Kim, N.; Lee, M.-Y. Cooling Performance Characteristics of 20 Ah Lithium-Ion Pouch Cell with Cold Plates along Both Surfaces. Energies 2018, 11, 2550. [Google Scholar] [CrossRef]

- Panchal, S.; McGrory, J.; Kong, J.; Fraser, R.; Fowler, M.; Dincer, I.; Agelin-Chaab, M. Cycling degradation testing and analysis of a LiFePO4 battery at actual conditions. Int. J. Energy Res. 2017, 41, 2565–2575. [Google Scholar] [CrossRef]

- Shafiee, M.; Chukova, S.; Yun, W.Y. Optimal burn-in and warranty for a product with post-warranty failure penalty. Int. J. Adv. Manuf. Technol. 2013, 70, 297–307. [Google Scholar] [CrossRef]

- Shiau, J.J.H.; Lin, H.H. Analyzing accelerated degradation data by nonparametric regression. IEEE Trans. Reliab. 1999, 48, 149–158. [Google Scholar] [CrossRef]

- Rohner, M.; Kerber, A.; Kerber, M. Voltage Acceleration of TBD and Its Correlation to Post Breakdown Conductivity of N- and P-Channel MOSFETs. In Proceedings of the 2006 IEEE International Reliability Physics Symposium Proceedings, San Jose, CA, USA, 26–30 March 2006; pp. 76–81. [Google Scholar]

- Ye, Z.S.; Xie, M. Stochastic modelling and analysis of degradation for highly reliable products. Appl. Stoch. Models Bus. Ind. 2015, 31, 16–32. [Google Scholar] [CrossRef]

- Tseng, S.T.; Tang, J. Optimal burn-in time for highly reliable products. Int. J. Ind. Eng. 2001, 8, 329–338. [Google Scholar]

- Tseng, S.T.; Tang, J.; Ku, I.H. Determination of burn-in parameters and residual life for highly reliable products. Nav. Res. Logist. 2003, 50, 1–14. [Google Scholar] [CrossRef]

- Tseng, S.T.; Peng, C.Y. Optimal burn-in policy by using an integrated Wiener process. IIE Trans. 2004, 36, 1161–1170. [Google Scholar] [CrossRef]

- Wang, W.; Carr, M.; Xu, W.; Kobbacy, K. A model for residual life prediction based on Brownian motion with an adaptive drift. Microelectron. Reliab. 2011, 51, 285–293. [Google Scholar] [CrossRef]

- Huang, Z.; Xu, Z.; Wang, W.; Sun, Y. Remaining Useful Life Prediction for a Nonlinear Heterogeneous Wiener Process Model with an Adaptive Drift. IEEE Trans. Reliab. 2015, 64, 687–700. [Google Scholar] [CrossRef]

- Wang, D.; Tsui, K.L. Brownian motion with adaptive drift for remaining useful life prediction: Revisited. Mech. Syst. Signal Process. 2018, 99, 691–701. [Google Scholar] [CrossRef]

- Tsai, C.; Tseng, S.; Balakrishnan, N. Optimal Burn-In Policy for Highly Reliable Products Using Gamma Degradation Process. IEEE Trans. Reliab. 2011, 60, 234–245. [Google Scholar] [CrossRef]

- Zhang, M.; Ye, Z.; Xie, M. Optimal Burn-in Policy for Highly Reliable Products Using Inverse Gaussian Degradation Process. In Proceedings of the Engineering Asset Management–Systems, Professional Practices and Certification, Hong Kong, China, 30 October–1 November 2013; pp. 1003–1011. [Google Scholar]

- Peng, C.Y. Optimal Classification Policy and Comparisons for Highly Reliable Products. Indian J. Stat. 2015, 77, 321–358. [Google Scholar] [CrossRef]

- Chen, Z.; Xia, T.; Pan, E. Optimal multi-level classification and preventive maintenance policy for highly reliable products. Int. J. Prod. Res. 2016, 55, 2232–2250. [Google Scholar] [CrossRef]

- Park, J.I.; Baek, S.H.; Jeong, M.K.; Bae, S.J. Dual Features Functional Support Vector Machines for Fault Detection of Rechargeable Batteries. IEEE Trans. Syst. Man Cybern. Part C Appl. Rev. 2009, 39, 480–485. [Google Scholar] [CrossRef]

- Fisher, W.D.; Camp, T.K.; Krzhizhanovskaya, V.V. Anomaly detection in earth dam and levee passive seismic data using support vector machines and automatic feature selection. J. Comput. Sci. 2017, 20, 143–153. [Google Scholar] [CrossRef]

- Ma, S.; Li, X.; Wang, Y. Classification of Gene Expression Data Using Multiobjective Differential Evolution. Energies 2016, 9, 1061. [Google Scholar] [CrossRef]

- Ebrahimi, M.A.; Khoshtaghaza, M.H.; Minaei, S.; Jamshidi, B. Vision-based pest detection based on SVM classification method. Comput. Electron. Agric. 2017, 137, 52–58. [Google Scholar] [CrossRef]

- Jaramillo, F.; Orchard, M.; Muñoz, C.; Antileo, C.; Sáez, D.; Espinoza, P. On-line estimation of the aerobic phase length for partial nitrification processes in SBR based on features extraction and SVM classification. Chem. Eng. J. 2018, 331, 114–123. [Google Scholar] [CrossRef]

- Li, J.; Weng, Z.; Xu, H.; Zhang, Z.; Miao, H.; Chen, W.; Liu, Z.; Zhang, X.; Wang, M.; Xu, X.; et al. Support Vector Machines (SVM) classificationof prostate cancer Gleason score in central gland using multiparametric magnetic resonance images: A cross-validated study. Eur. J. Radiol. 2018, 98, 61–67. [Google Scholar] [CrossRef] [PubMed]

- Xiang, Q.; Yuan, Y.; Yu, Y.; Chen, K. Rotor Position Self-Sensing of SRM Using PSO-RVM. Energies 2018, 11, 66. [Google Scholar] [CrossRef]

- Tsai, T.R.; Lin, C.W.; Sung, Y.L.; Chou, P.T.; Chen, C.L.; Lio, Y. Inference from Lumen Degradation Data Under Wiener Diffusion Process. IEEE Trans. Reliab. 2012, 61, 710–718. [Google Scholar] [CrossRef]

- Ye, Z.S.; Shen, Y.; Xie, M. Degradation-based burn-in with preventive maintenance. Eur. J. Oper. Res. 2012, 221, 360–367. [Google Scholar] [CrossRef]

- Ye, Z.S.; Xie, M.; Tang, L.C.; Shen, Y. Degradation-Based Burn-In Planning Under Competing Risks. Technometrics 2012, 54, 159–168. [Google Scholar] [CrossRef]

- Liu, B.; Zhao, X.; Yeh, R.H.; Kuo, W. Imperfect Inspection Policy for Systems with Multiple Correlated Degradation Processes. IFAC-Pap. OnLine 2016, 49, 1377–1382. [Google Scholar] [CrossRef]

- Zhai, Q.; Ye, Z.S.; Yang, J.; Zhao, Y. Measurement errors in degradation-based burn-in. Reliab. Eng. Syst. Saf. 2016, 150, 126–135. [Google Scholar] [CrossRef]

- Bebbington, M.; Lai, C.D.; Zitikis, R. Optimum Burn-in Time for a Bathtub Shaped Failure Distribution. Methodol. Comput. Appl. Probab. 2007, 9, 1–20. [Google Scholar] [CrossRef]

- Cha, J.H.; Finkelstein, M. Stochastically Ordered Subpopulations and Optimal Burn-In Procedure. IEEE Trans. Reliab. 2010, 59, 635–643. [Google Scholar] [CrossRef]

- Ye, Z.S.; Tang, L.C.; Xie, M. A Burn-In Scheme Based on Percentiles of the Residual Life. J. Qual. Technol. 2017, 43, 334–345. [Google Scholar] [CrossRef]

- Yu, H.F.; Peng, C.Y. Designing a Degradation Test with a Two-Parameter Exponential Lifetime Distribution. Commun. Stat. Simul. Comput. 2014, 43, 1938–1958. [Google Scholar] [CrossRef]

- Pudil, P.; Novovičová, J.; Kittler, J. Floating search methods in feature selection. Pattern Recognit. Lett. 1994, 15, 1119–1125. [Google Scholar] [CrossRef]

- Ashok, B.; Aruna, P. Comparison of Feature selection methods for diagnosis of cervical cancer using SVM classifier. Int. J. Eng. Res. Appl. 2016, 6, 94–99. [Google Scholar]

- Kohavi, R.; John, G.H. Wrappers for feature subset selection. Artif. Intell. 1997, 97, 273–324. [Google Scholar] [CrossRef]

- Theodoridis, S.; Pikrakis, A.; Koutroumbas, K.; Cavouras, D. Feature Selection. In Introduction to Pattern Recognition, 1st ed.; Theodoridis, S., Pikrakis, A., Koutroumbas, K., Cavouras, D., Eds.; Academic Press: Boston, MA, USA, 2010; Chapter 4; pp. 107–135. ISBN 978-0-12-374486-9. [Google Scholar]

- Tipping, M.E. Sparse bayesian learning and the relevance vector machine. J. Mach. Learn. Res. 2001, 1, 211–244. [Google Scholar] [CrossRef]

- Nabney, I.T. Efficient training of RBF networks for classification. In Proceeding of the 9th International Conference on Artificial Neural Networks (ICANN), Edinburgh, UK, 7–10 September 1999; pp. 210–215. [Google Scholar]

- Platt, J. Probabilistic Outputs for Support Vector Machines and Comparisons to Regularized Likelihood Methods. Adv. Large Margin Classif. 1999, 10, 64–74. [Google Scholar]

| Cycle Num. | Selected Feature Subsets (d = 10) | ||

|---|---|---|---|

| FC | SC | EC | |

| 10 | [2, 3, 6, 9] | [11, 12, 13] | [21, 23, 25] |

| 20 | [4, 7, 10] | [32, 35] | [42, 43, 46, 54, 57] |

| 30 | [10, 13, 21, 23] | [43, 48, 50, 53] | [60, 61] |

| 40 | [4, 10, 13, 21] | [53, 58, 63, 73] | [83, 86] |

| 50 | [10, 13] | [54, 73, 92] | [101, 122, 125, 132, 147] |

| 60 | [10, 13] | [64, 83, 102] | [121, 142, 145, 152, 167] |

| NCD Method | CD Method | Proposed Method | |

|---|---|---|---|

| Model | |||

| Error rate | |||

| Misclassification cost | |||

| Optimal cut-off level | is determined as requested | ||

| Total cost | |||

| Optimal test cycle num. | |||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, J.; Yang, J.; Tang, D.; Dai, J. An Optimal Burn-In Policy for Cellular Phone Lithium-Ion Batteries Using a Feature Selection Strategy and Relevance Vector Machine. Energies 2018, 11, 3021. https://doi.org/10.3390/en11113021

Yu J, Yang J, Tang D, Dai J. An Optimal Burn-In Policy for Cellular Phone Lithium-Ion Batteries Using a Feature Selection Strategy and Relevance Vector Machine. Energies. 2018; 11(11):3021. https://doi.org/10.3390/en11113021

Chicago/Turabian StyleYu, Jinsong, Jie Yang, Diyin Tang, and Jing Dai. 2018. "An Optimal Burn-In Policy for Cellular Phone Lithium-Ion Batteries Using a Feature Selection Strategy and Relevance Vector Machine" Energies 11, no. 11: 3021. https://doi.org/10.3390/en11113021

APA StyleYu, J., Yang, J., Tang, D., & Dai, J. (2018). An Optimal Burn-In Policy for Cellular Phone Lithium-Ion Batteries Using a Feature Selection Strategy and Relevance Vector Machine. Energies, 11(11), 3021. https://doi.org/10.3390/en11113021