Underground Diesel Exhaust Wet Scrubbers: Current Status and Future Prospects

Abstract

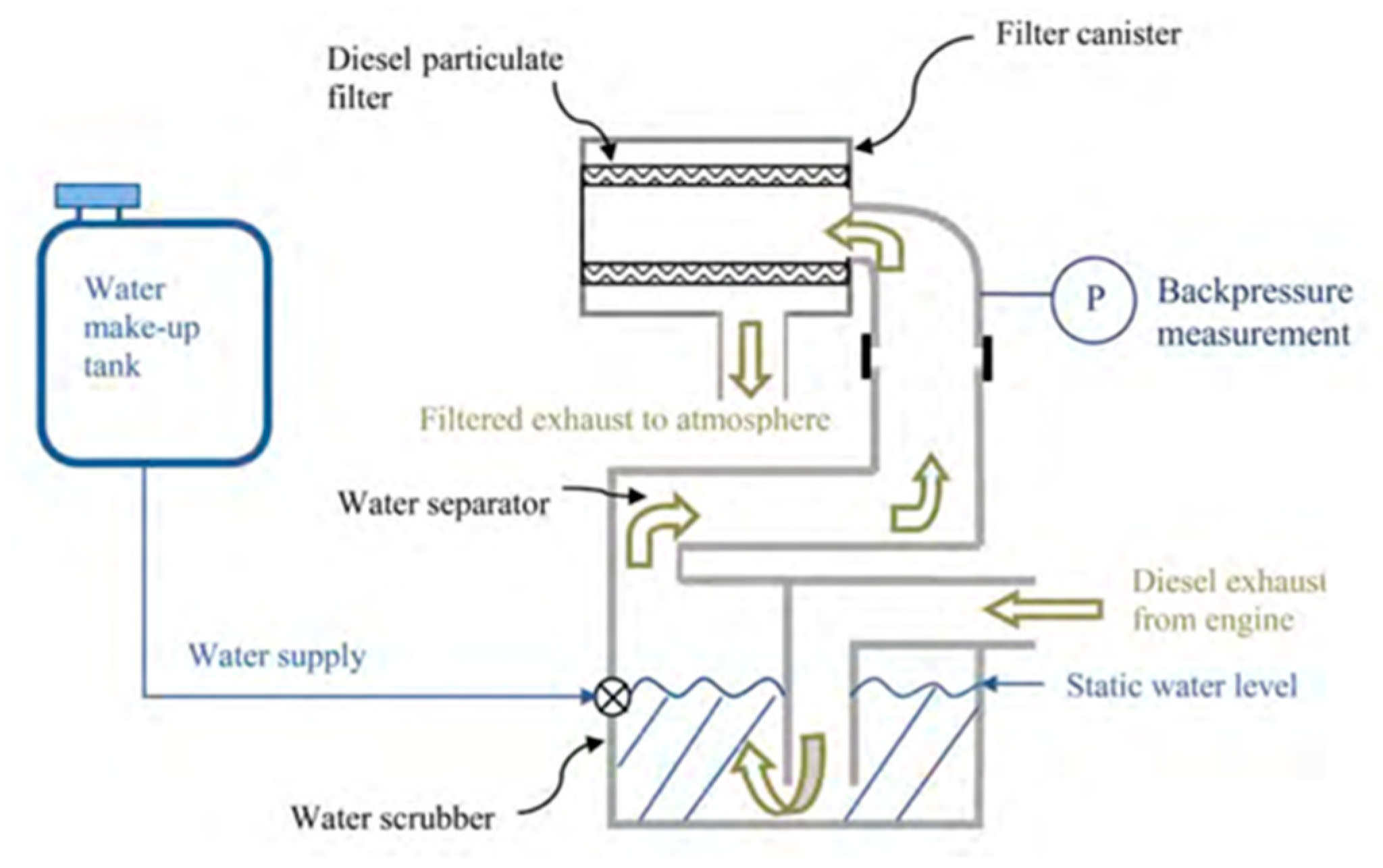

:1. Introduction

2. Background

2.1. Capturing Mechanisms of Pollutants in Wet Scrubbers

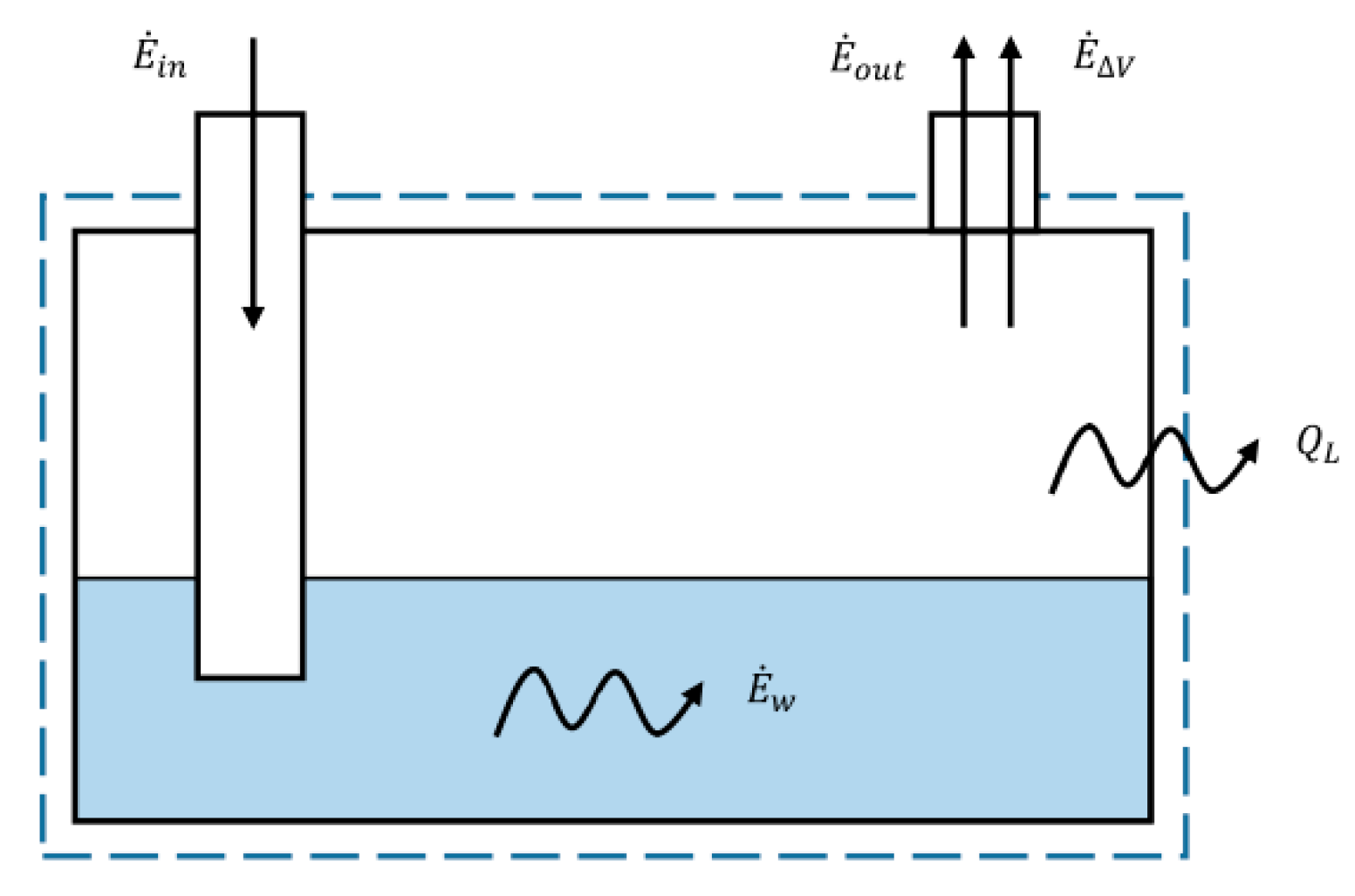

2.2. Heat Transfer Mechanism in Wet Scrubbers

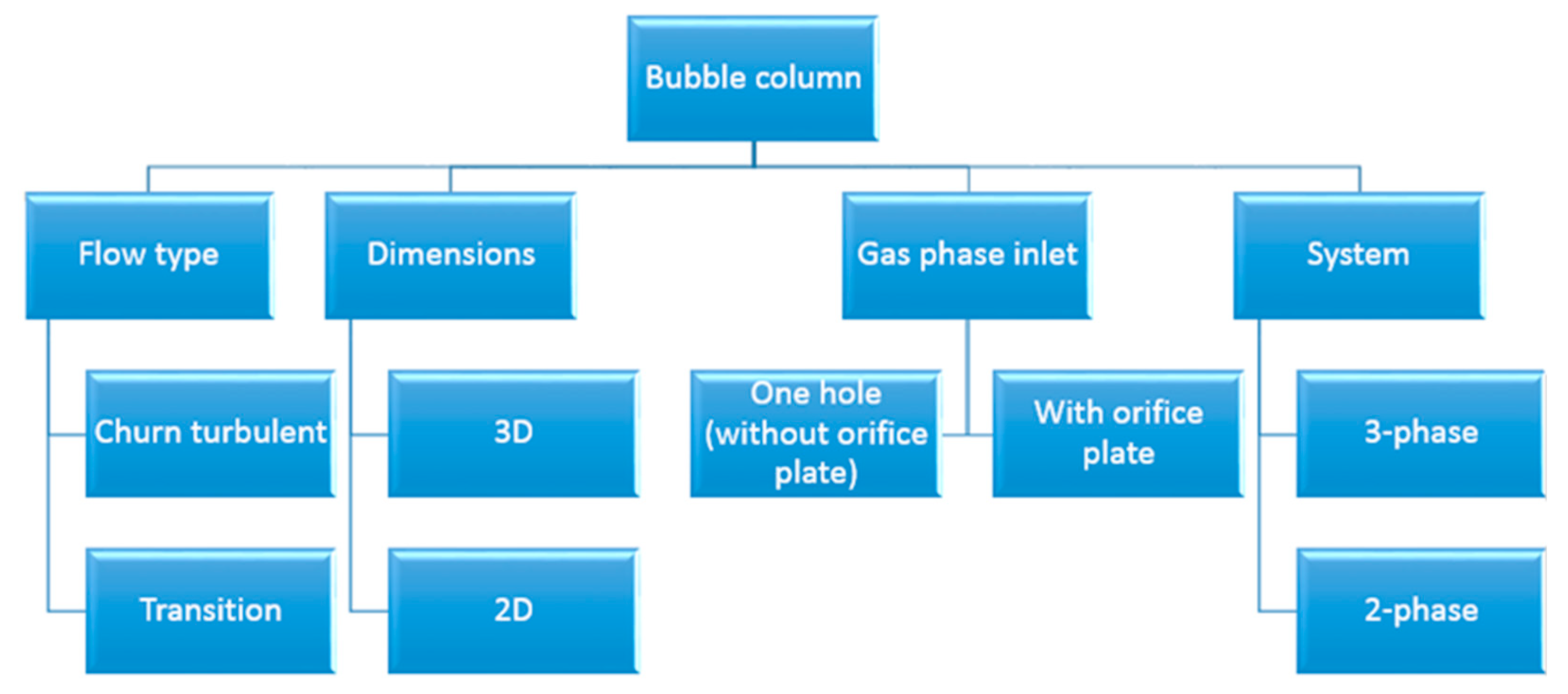

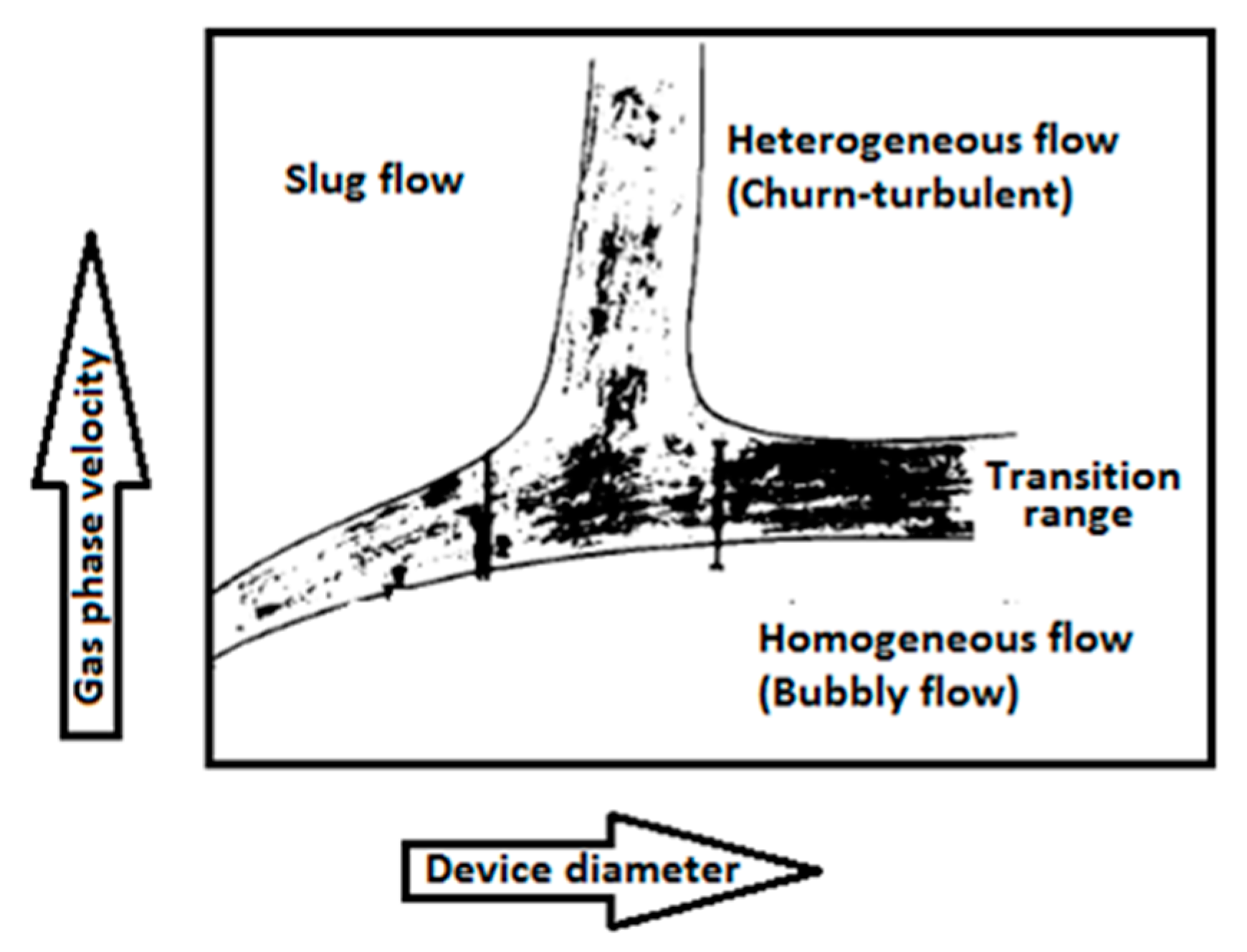

2.3. The Fluid Mechanism in Wet Scrubbers

3. The Governing Parameters of Wet Scrubbers

3.1. The Effect of Inlet Gas Velocity

3.2. The Effect of Bubble Size

3.3. The Effect of Particle Density

3.4. The Effect of the Liquid Thermal Properties on Pollutant Removal

3.5. The Effect of Liquid Volume

4. Performance Parameters

4.1. Scrubber Outlet Conditions (Particularly Temperature and Humidity)

4.2. Removal Efficiency

5. Wet Scrubber Models

5.1. A Thermodynamic Model of the Diesel Exhaust Wet Scrubber

5.2. Bubble Heat Transfer Model

5.2.1. Bubble Size

5.2.2. Bubble Rising Velocity

5.2.3. Bubble Heat Transfer

5.3. Computational Simulations

6. Conclusions

Author Contributions

Conflicts of Interest

Nomenclature

| A | Surface area (m2) | Z | Bubble vertical position |

| AR | Aspect ratio | Greek letters | |

| a | Bubble acceleration (m/s2) | α | Fluid thermal diffusivity (m2/s) |

| Bo | Bond number | β | Dimensionless radius (R/R0) |

| C | Component concentration | 𝛽′ | Dimensionless constant |

| CD | Drag coefficient | 𝛽″ | Contact angle (°) |

| cp | Specific heat (kJ/kg·K) | γ | Thermal expansion coefficient (1/K) |

| DPF | Diesel Particulate Filter | Δ | Changes |

| d | Bubble diameter (m) | ε | Dissipation rate (m2/s3) |

| E | Evaporation rate (kg/s) | ε′ | Hold-up |

| Energy (kW) | η | Removal efficiency (%) | |

| Ec | Eckert number | λ | Latent heat of evaporation (kJ/kg) |

| e | Internal energy (kJ/kg) | µ′ | The fluid drop internal viscosity (mPa.s) |

| F | Force (N) | v | Fluid kinematic viscosity (m2/s) |

| g | Gravity acceleration (m/s2) | ρ | The density of the fluid (kg/m3) |

| h | Fluid enthalpy (kJ/kg) | σ | Surface tension (N/m) |

| hc | Heat transfer coefficient (W/m2·K) | τ | Dimensionless time |

| k | Fluid thermal conductivity (W/m·K) | ∅ | Volume fraction in slurry phase |

| kv | Velocity factor | ∅′ | Surface orientation (°) |

| LLSP | Laser Light Scattering Photometry | Subscript | |

| m. | Mass flow rate (kg/s) | above | Above water surface |

| Nu | Nusselt number | b | Bubble |

| n | Bubble frequency | below | Below water surface |

| nb | The number of bubbles | CO2 | Carbon dioxide |

| P | Pressure (kPa) | D | Drag |

| Pe | Peclet number | e | Equivalent |

| PM | Particulate Matter | f | Liquid |

| Pr | Prandtl number | G | Gravity |

| Q | Heat transfer (kW) | g | Gas |

| Q′ | Average volumetric flow rate (m3/s) | H2O | Water or water vapour |

| q | Heat transfer per kilogram (kW/kg) | i | Sequence |

| q″ | Heat flux (W/m2) | in | Inlet |

| R | Bubble radius (m) | k | Condensation |

| R′ | The curvature radius of a lenticular body (m) | L | Lost |

| R″ | Bubble radial velocity (dR/dt) | l | Liquid |

| Re | Reynolds number | m | Mixture |

| ROS | Reactive Oxygen Species | max | Maximum value |

| RSM | Reynolds Stress Model | N2 | Nitrogen |

| sa | Bubble front face area (m2) | O2 | Oxygen |

| SMPS | Scanning Mobility Particle Sizer | out | Outlet |

| St | Stanton number | r | Relative |

| SVR | Support Vector Regression | sm | Small bubble |

| T | Temperature (K) | T | Terminal |

| TEOM | Tapered Element Oscillating Microbalance | trans | Transition regime |

| t | Time (s) | V | Virtual |

| u | The fluid velocity (m/s) | v | Vapour or gas |

| V | Volume (m3) | W | Wet scrubber storage |

| VOF | Volume of Fluid | Δν | Water volume changing |

| W | Water weight (kg) | 0 | Initial value |

| We | Weber number | ∞ | Bubble surrounding fluid |

| X | Bubble horizontal position |

References

- Ristovski, Z.D.; Miljevic, B.; Surawski, N.C.; Morawska, L.; Fong, K.M.; Goh, F.; Yang, I.A. Respiratory health effects of diesel particulate matter. Respirology 2012, 17, 201–212. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Giechaskiel, B.; Suarez-Bertoa, R.; Lahde, T.; Clairotte, M.; Carrier, M.; Bonnel, P.; Maggiore, M. Evaluation of NOx emissions of a retrofitted euro 5 passenger car for the horizon prize “Engine retrofit”. Environ. Res. 2018, 166, 298–309. [Google Scholar] [CrossRef] [PubMed]

- Giechaskiel, B.; Schwelberger, M.; Delacroix, C.; Marchetti, M.; Feijen, M.; Prieger, K.; Andersson, S.; Karlsson, H. Experimental assessment of solid particle number Portable Emissions Measurement Systems (PEMS) for heavy-duty vehicles applications. J. Aerosol Sci. 2018, 123, 161–170. [Google Scholar] [CrossRef]

- Giechaskiel, B. Solid particle number emission factors of euro VI heavy-duty vehicles on the road and in the laboratory. Int. J. Environ. Res. Public Health 2018, 15, 304. [Google Scholar] [CrossRef] [PubMed]

- Giechaskiel, B.; Clairotte, M.; Valverde-Morales, V.; Bonnel, P.; Kregar, Z.; Franco, V.; Dilara, P. Framework for the assessment of PEMS (Portable Emissions Measurement Systems) uncertainty. Environ. Res. 2018, 166, 251–260. [Google Scholar] [CrossRef] [PubMed]

- Miljevic, B. The Application of a Profluorescent Nitroxide Probe to Detect Reactive Oxygen Spices Derived from Combustion-Generated Particulate Matter. Ph.D. Thesis, Queensland University of Technology, Brisbane City, Australia, 2010. [Google Scholar]

- Rao, V.; Dayawansa, D.; Honnery, D. Reducing Diesel Particulate Matter in Underground Mines by Optimising Design and Operation of Diesel Exhaust Systems. Available online: https://www.acarp.com.au/abstracts.aspx?repId=C23013 (accessed on 19 September 2018).

- Volkwein, J.C.; Mischler, S.E.; Davies, B.; Ellis, C. Field measurement of diesel particulate matter emissions. Ann. Occup. Hyg. 2008, 52, 99–105. [Google Scholar] [CrossRef] [PubMed]

- Gaffney, J.S.; Marley, N.A. The impacts of combustion emissions on air quality and climate—From coal to biofuels and beyond. Atmos. Environ. 2009, 43, 23–36. [Google Scholar] [CrossRef]

- Giakoumis, E.G.; Dimaratos, A.M.; Rakopoulos, C.D.; Rakopoulos, D.C. Combustion instability during starting of turbocharged diesel engine including biofuel effects. J. Energy Eng. 2017, 143, 1–15. [Google Scholar] [CrossRef]

- Pratt, S.; Grainger, A.; Jones, L.; Todd, J.; Brennan, R. Diesel Vehicle Research at BHP Collieries. Available online: https://ro.uow.edu.au/cgi/viewcontent.cgi?referer=https://www.google.com.tw/&httpsredir=1&article=1274&context=coal (accessed on 23 May 2018).

- Papagiannakis, R.G.; Hountalas, D.T.; Krishnan, S.R.; Srinivasan, K.K.; Rakopoulos, C.D.; Rakopoulos, D.C. Numerical evaluation of the effects of compression ratio and diesel fuel Injection timing on the performance and emissions of a fumigated natural gas–diesel dual-fuel engine. J. Energy Eng. 2016, 142, 1–16. [Google Scholar] [CrossRef]

- Suarez-Bertoa, R.; Kousoulidou, M.; Clairotte, M.; Giechaskiel, B.; Nuottimäki, J.; Sarjovaara, T.; Lonza, L. Impact of HVO blends on modern diesel passenger cars emissions during real world operation. Fuel 2019, 235, 1427–1435. [Google Scholar] [CrossRef]

- Rakopoulos, D.C.; Rakopoulos, C.D.; Giakoumis, E.G. Impact of properties of vegetable oil, bio-diesel, ethanol and n-butanol on the combustion and emissions of turbocharged HDDI diesel engine operating under steady and transient conditions. Fuel 2015, 156, 1–19. [Google Scholar] [CrossRef]

- Cardenas, M.D.; Armas, O.; Mata, C.; Soto, F. Performance and pollutant emissions from transient operation of a common rail diesel engine fueled with different biodiesel fuels. Fuel 2016, 185, 743–762. [Google Scholar] [CrossRef]

- Mata, C.; Gómez, A.; Armas, O. The influence of ethanol-diesel blend on pollutant emissions from different bus fleets under acceleration transitions. Fuel 2017, 209, 322–328. [Google Scholar] [CrossRef]

- Rakopoulos, D.C.; Rakopoulos, C.D.; Giakoumis, E.G.; Komninos, N.P.; Kosmadakis, G.M.; Papagiannakis, R.G. Comparative evaluation of ethanol, n-butanol, and diethyl ether effects as biofuel supplements on combustion characteristics, cyclic variations, and emissions balance in light-duty diesel engine. J. Energy Eng. 2017, 143, 1–8. [Google Scholar] [CrossRef]

- Diesel Particulate Matter & Occupational Health Issues. Available online: http://www.gastech.com.au/files/dpm/Diesel-Particulate-Matter-and-Occupational-Health-Issues.pdf (accessed on 26 January 2017).

- Mussatti, D.; Hemmer, P. Wet Scrubbers for Particulate Matter. Available online: https://www3.epa.gov/ttncatc1/dir1/cs6ch2.pdf (accessed on 22 December 2017).

- Situ, R.; Brown, R.J.; Wang, H.; Surawski, N.; Ristovski, Z.D. Exit humidity of wet scrubbers for underground coal mines. In Proceedings of the 18th Australasian Fluid Mechanics Conference, Launceston, Australia, 3–7 December 2012. [Google Scholar]

- Youssef, A.A. Fluid Dynamics and Scale-Up of Bubble Columns with Internals. Ph.D. Thesis, Washington University in St. Louis, Washington, DC, USA, 2010. [Google Scholar]

- Shaikh, A.; Al-Dahhan, M.H. A review on flow regime transition in bubble columns. Int. J. Chem. React. Eng. 2007, 5, 1–68. [Google Scholar] [CrossRef]

- Gabriel, D.; Cox, H.H.J.; Deshusses, M.A. Conversion of full-scale wet scrubbers to biotrickling filters for H2S control at publicly owned treatment works. J. Environ. Eng. 2004, 130, 1110–1117. [Google Scholar] [CrossRef]

- Barbour, W.; Oommen, R.; Shareef, G.S.; Corporation, R.; Vatavuk, W.M. Post-Combustion Controls. Section 5. Available online: https://www3.epa.gov/ttn/ecas/docs/cs5-2ch1.pdf (accessed on 22 December 2017).

- Azzopardi, B.; Zhao, D.; Yan, Y.; Morvan, H.; Mudde, R.F.; Lo, S. Hydrodynamics of Gas-Liquid Reactors; Wiley: Hobbken, NJ, USA, 2011. [Google Scholar]

- Bai, W. Experimental and Numerical Investigation of Bubble Column Reactors. Ph.D. Thesis, Eindhoven University of Technology, Eindhoven, The Netherlands, 2010. [Google Scholar]

- Meikap, B.C.; Kundu, G.; Biswas, M.N. Modeling of a novel multi-stage bubble column scrubber for flue gas desulfurization. Chem. Eng. J. 2002, 86, 331–342. [Google Scholar] [CrossRef]

- Besagni, G.; Inzoli, F.; Ziegenhein, T. Two-phase bubble columns: A comprehensive review. Chem. Eng. 2016, 2, 13. [Google Scholar] [CrossRef]

- Davidson, J.F.; Schüler, B.O.G. Bubble formation at an orifice in a viscous liquid. Ins. Chem. Eng. 1997, 75, 105–115. [Google Scholar] [CrossRef]

- Lienhard, J.H.; Lienhard, J.H. A Heat Transfer Text Book, 4th ed.; Phlogiston Press: Cambridge, MA, USA, 2011. [Google Scholar]

- Yang, G.Q.; Luo, X.; Lau, R.; Fan, L.S. Heat-transfer characteristics in slurry bubble columns at elevated pressures and temperatures. Ind. Eng. Chem. 2000, 39, 2568–2577. [Google Scholar] [CrossRef]

- Harris, P.J.; Al-Awadi, H.; Soh, W.K. An investigation into the effects of heat transfer on the motion of a spherical bubble. ANZIAM J. 2004, 45, 361–371. [Google Scholar] [CrossRef]

- Gandhi, A.B.; Joshi, J.B. Estimation of heat transfer coefficient in bubble column reactors using support vector regression. Chem. Eng. J. 2010, 160, 302–310. [Google Scholar] [CrossRef]

- Jhawar, A.K.; Prakash, A. Analysis of local heat transfer and hydrodynamics in a bubble column using fast response probes. Chem. Eng. J. 2007, 62, 7274–7281. [Google Scholar] [CrossRef]

- Thakre, S.S.; Joshi, J.B. CFD simulation of bubble column reactors: Importance of drag force formulation. Chem. Eng. Sci. 1999, 54, 5055–5060. [Google Scholar] [CrossRef]

- Deckwer, W.D.; Loulsl, Y.; Zaldl, A.; Ralek, M. Hydrodynamic properties of the Fischer-Tropsch slurry process. Ind. Eng. Chem. Process Des. Dev. 1980, 19, 699–708. [Google Scholar] [CrossRef]

- Kurella, S.; Balla, M.; Bhukya, P.K. Scrubbing of HCl gas from synthesis gas in a multistage dual-flow sieve plate wet scrubber by alkaline solution. J. Chem. Eng. Process Technol. 2015, 6, 1–7. [Google Scholar] [CrossRef]

- Walsh, M.A. Overview of Basic Types and Configuration of Wet Scrubber Technologies. Available online: http://wpca.info/pdf/presentations/Eskom2007/2)Overview%20of%20Basic%20Types%20&%20Config%20of%20WFGD%20by%20Mike%20Walsh-Marsulex.pdf (accessed on 17 September 2018).

- Hoque, N.; Situ, R.; Hagan, W.; Almedia, J.; Lin, W.; Brown, R.J. A thermo-fluid study of a diesel engine wet scrubber. In Proceedings of the 19th Australasian Fluid Mechanics Conference, Melbourne, Australia, 8–11 December 2014. [Google Scholar]

- Wang, T.; Wang, J.; Jin, Y. Theoretical prediction of flow regime transition in bubble columns by the population balance model. Chem. Eng. Sci. 2005, 60, 6199–6209. [Google Scholar] [CrossRef]

- Higuera, F.J.; Medina, A. Injection and coalescence of bubbles in a quiescent inviscid liquid. Eur. J. Mech. B/Fluids 2006, 25, 164–171. [Google Scholar] [CrossRef]

- Van Rens, G.L.M.A.; de Wilde, H.P.J. Pre- and After-Treatment Techniques for Diesel Engines in Inland Navigation. Available online: https://www.ecn.nl/publicaties/PdfFetch.aspx?nr=ECN-RX--05-175 (accessed on 26 January 2017).

- Lin, T.; Fan, L. Heat transfer and bubble characteristics from a nozzle in high-pressure bubble columns. Chem. Eng. Sci. 1999, 54, 4853–4859. [Google Scholar] [CrossRef]

- Talaia, M.A.R. Terminal velocity of a bubble rise in a liquid column. World Acad. Sci. Eng. Technol. 2007, 28, 264–268. [Google Scholar]

- Rao, V.; Dayawansa, D.; Honnery, D.; Sharman, S.; Garnier, G.; Curcio, P. Extending the Life of Disposable Exhaust Filters in Vehicles Operating in Underground Coal Mines; ACARP Report C21017; Monash University: Melbourne, Australia, 2013. [Google Scholar]

- Burtscher, H. Physical characterization of particulate emissions from diesel engines: A review. J. Aerosol Sci. 2005, 36, 896–932. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Biswas, M.N. Fly-ash scrubbing in a tapered bubble column scrubber. Process Saf. Environ. Prot. 2006, 84, 54–62. [Google Scholar] [CrossRef]

- Guo, R.; Gao, X. Simultaneous removal of SO2 and NO2 by wet scrubbing using aqueous limestone slurry. In Proceedings of the 11th International Conference on Electrostatic Precipitation, Hangzhou, China, 20–24 October 2008; pp. 602–605. [Google Scholar]

- Bhadra, V.; Singh, H.K.; Kahndelwal, G.; Kumar, A. Effect of flue gases with wet scrubber in 4-stroke C.I engine. Int. J. Sci. Eng. Technol. 2014, 2, 1422–1430. [Google Scholar]

- Van Setten, B.A.A.L.; Makkee, M.; Moulijn, J.A. Science and technology of catalytic diesel particulate filters. Catal. Rev. 2001, 43, 489–564. [Google Scholar] [CrossRef]

- Tokumura, M.; Mizukoshi, A.; Noguchi, M.; Wada, Y.; Usami, Y.; Yamaki, T.; Yanagisawa, Y. Removal of acetaldehyde gas using wet scrubber coupled with photo-Fenton reaction. AIMS Environ. Sci. 2016, 3, 159–167. [Google Scholar] [CrossRef]

- Huang, W. Homogeneous and Heterogeneous Fenton and Photo-Fenton Processes: Impact of Iron Complexing Agent Ethylenediamine-N,N′-disuccinic Acid (EDDS). Available online: https://tel.archives-ouvertes.fr/tel-00788822/document (accessed on 18 September 2018).

- Machulek, A.; Quina, F.H.; Gozzi, F.; Silva, V.O.; Friedrich, L.C.; Moraes, J.E.F. Fundamental Mechanistic Studies of the Photo-Fenton Reaction for the Degradation of Organic Pollutants. Available online: https://www.intechopen.com/books/organic-pollutants-ten-years-after-the-stockholm-convention-environmental-and-analytical-update/fundamental-mechanistic-studies-of-the-photo-fenton-reaction-for-the-degradation-of-organic-pollutan (accessed on 13 September 2018).

- Ebrahiem, E.E.; Al-Maghrabi, M.N.; Mobarki, A.R. Removal of organic pollutants from industrial wastewater by applying photo-Fenton oxidation technology. Arab. J. Chem. 2017, 10, S1674–S1679. [Google Scholar] [CrossRef]

- D’Addio, L.; Natale, F.D.; Carotenuto, C.; Scoppa, G.; Dessy, V.; Lancia, A. Removal of Fine and Ultrafine Combustion Derived Particles in a Wet Electrostatic Scrubber. Available online: http://www.combustion-institute.it/proceedings/XXXVI-ASICI/papers/36proci2013.VI4.pdf (accessed on 12 July 2017).

- DeGuzman, N.M.; Chato, J.C. Evaporative Heat Transfer Characteristics in a Vertical Channel with Obstructions. Available online: https://core.ac.uk/download/pdf/4820839.pdf (accessed on 18 September 2018).

- Ishii, M.; Hibiki, T. Thermo-Fluid Dynamics of Two-Phase Flow; Springer: New York, NY, USA, 2006. [Google Scholar]

- Wang, H.Y.; Dong, F. A method for bubble volume calculating in vertical two-phase flow. J. Phys. Conf. Ser. 2009, 147, 1–12. [Google Scholar] [CrossRef]

- Xu, Y. Direct Contact Condensation with and Without Noncondensable Gas in a Water Pool. Ph.D. Thesis, Purdue University, West Lafayette, IN, USA, 2004. [Google Scholar]

- Levich, V.G. Physiochemical Hydrodynamics; Prentice-Hall: Englewood Cliffs, NJ, USA, 1962. [Google Scholar]

- Martínez-Bazán, C.; Montañéz, J.L.; Lasheras, J.C. On the breakup of an air bubble injected into a fully developed turbulent flow: I: Breakup frequency. J. Fluid Mech. 1999, 401, 157. [Google Scholar] [CrossRef]

- Davidson, J.F.; Schüler, B.O.G. Bubble formation at an orifice in an inviscid liquid. Trans. Inst. Chem. Eng. 1960, 38, 335–342. [Google Scholar]

- Leibson, I.; Holcomb, E.G.; Cacoso, A.G.; Jacmic, J.J. Formation from single orifices. AIChE J. 1956, 2, 296–306. [Google Scholar] [CrossRef]

- Wallis, G.B. One-Dimensional Two-Phase Flow; McGraw-Hill: New York, NY, USA, 1969. [Google Scholar]

- Moalem, D.; Sideman, S. The effect of motion on bubble collapse. Int. J. Heat Mass Trans. 1973, 16, 2321–2329. [Google Scholar] [CrossRef]

- Anagbo, P.E. Formation of ellipsoidal bubbles at free-standing nozzle. Chem. Eng. Sci. 1991, 46, 781–788. [Google Scholar] [CrossRef]

- Lehr, F.; Mewes, D. A transport equation for the interfacial area density applied to bubble columns. Chem. Eng. Sci. 2001, 56, 1159–1166. [Google Scholar] [CrossRef]

- Zhang, L.; Yang, C.; Mao, Z. Unsteady motion of a single bubble in highly viscous liquid and empirical correlation of drag coefficient. Chem. Eng. Sci. 2008, 63, 2099–2106. [Google Scholar] [CrossRef]

- Parkinson, L.; Sedev, R.; Fornasiero, D.; Ralston, J. The terminal rise velocity of 10–100 µm diameter bubbles in water. J. Colloid Interface Sci. 2008, 322, 168–172. [Google Scholar] [CrossRef] [PubMed]

- Raymond, F.; Rosant, J.M. A numerical and experimental study of the terminal velocity and shape of bubbles in viscous liquids. Chem. Eng. Sci. 2000, 55, 943–955. [Google Scholar] [CrossRef]

- Kantarci, N.; Borak, F.; Ulgen, K.O. Bubble column reactors. Process Biochem. 2005, 40, 2263–2283. [Google Scholar] [CrossRef]

- Davies, R.M.; Taylor, G. The mechanics of large bubbles rising through liquids in tubes. Proc. R. Soc. 1950, 375–390. [Google Scholar] [CrossRef]

- Krishna, R.; Swart, J.W.A.D.; Hennephof, D.E.; Ellenberger, J.; Hoefsloot, H.C.J. Influence of increased gas density on hydrodynamics of bubble column reactors. AIChE J. 1994, 40, 112–121. [Google Scholar] [CrossRef]

- Delnoij, E.; Lammers, F.A.; Kuipers, J.A.M.; van Swaaij, W.P.M. Dynamic simulation of dispersed gas-liquid two-phase flow using a discrete bubble model. Chem. Eng. Sci. 1997, 52, 1429–1458. [Google Scholar] [CrossRef] [Green Version]

- Tomiyama, A.; Kataoka, I.; Zun, I.; Sakaguchi, T. Drag coefficients of single bubbles under normal and micro gravity conditions. JSME Int. J. Ser. B 1998, 41, 472–479. [Google Scholar] [CrossRef]

- Tomiyama, A.; Celata, G.P.; Hosokawa, S.; Yoshida, S. Terminal velocity of single bubbles in surface tension force dominant regime. Int. J. Multiph. Flow 2002, 28, 1497–1519. [Google Scholar] [CrossRef]

- Chen, P. Modeling the Fluid Dynamics of Bubble Column Flows. Ph.D. Thesis, Washington University, Washington, DC, USA, 2004. [Google Scholar]

- Abd Ali, M.K. CFD Simulation of bubbly flow through a bubble column. Int. J. Sci. Eng. Res. 2014, 5, 904–910. [Google Scholar]

- Chen, Y.M.; Mayinger, F. Measurement of heat transfer at the phase interface of condensing bubbles. Int. J. Multiph. Flow 1992, 18, 877–890. [Google Scholar] [CrossRef]

- Fair, J.R.; Lambright, A.J.; Andersen, J.W. Heat transfer and gas holdup in a sparged contactor. I EC Process Des. Dev. 1962, 1, 33–36. [Google Scholar] [CrossRef]

- Mikic, B.B.; Rohsenow, M.W. A new correlation of pool-boiling data including the effect of heating surface characteristics. J. Heat Trans. 1969, 9, 245–250. [Google Scholar] [CrossRef]

- Moalem, D.; Sideman, S. Bubble condensation with non-homogeneous distribution of non-condensables. Int. J. Heat Mass Trans. 1971, 14, 2152–2156. [Google Scholar] [CrossRef]

- Theofanous, T.G.; Fauske, H.K. The effect of noncondensables on the rate of sodium vapor condensation from a single-rising HCDA bubble. Nucl. Technol. 1973, 19, 132–139. [Google Scholar] [CrossRef]

- Hart, W.F. Heat transfer in bubble-agitated system. A general correlation. Ind. Eng. Chem. Process Des. 1976, 15, 109–114. [Google Scholar] [CrossRef]

- Ozisik, M.N.; Kress, T.S. Effects of internal circulation velocity and noncondensable gas on vapor condensation from a rising bubble. Nucl. Sci. Eng. 1978, 66, 397–405. [Google Scholar] [CrossRef]

- Hikita, H.; Asal, S.; Klkukawa, H.; Zalke, T.; Ohue, M. Heat transfer coefficient in bubble columns. Am. Chem. Soc. 1981, 20, 540–545. [Google Scholar] [CrossRef]

- Saxena, S.C. Heat transfer from a cylindrical probe immersed in a bubble column. Chem. Eng. J. 1989, 41, 25–39. [Google Scholar] [CrossRef]

- Cho, Y.J.; Woo, K.J.; Kang, Y.; Kim, S.D. Dynamic characteristics of heat transfer coefficient in pressurized bubble columns with viscous liquid medium. Chem. Eng. Process. 2002, 41, 699–706. [Google Scholar] [CrossRef]

- Lee, H.C.; Oh, B.D.; Bae, S.W.; Kim, M.H.; Lee, J.Y.; Song, I.S. Partial nucleate boiling on the microscale heater maintaining constant wall temperature. J. Nucl. Sci. Technol. 2003, 40, 768–774. [Google Scholar] [CrossRef]

- Leong, K.C.; Ho, J.Y.; Wong, K.K. A critical review of pool and flow boiling heat transfer of dielectric fluids on enhanced surfaces. Appl. Therm. Eng. 2017, 112, 999–1019. [Google Scholar] [CrossRef]

- Munkejord, S.T.; Jakobsen, J.P.; Austegard, A.; Molnvik, M.J. Thermo- and fluid-dynamical modelling of two-phase multi-component carbon dioxide mixtures. In Proceedings of the 9th International Conference on Greenhouse Gas Control Technologies, Washington, DC, USA, 16–20 November 2008. [Google Scholar]

- Akhtar, A. CFD Simulations for continuous flow of bubbles through gas-liquid columns: Application of VOF Method. Chem. Prod. Process Model. 2007, 2, 1–19. [Google Scholar] [CrossRef]

- Andras, H.; Christian, J.; Michael, L.; Christia, K.; Aleksander, M.; Michael, H. CFD Simulation of bubble columns using the VOF model: comparison of commercial and open source solvers with an experiment. Chem. Eng. Trans. 2009, 18. [Google Scholar] [CrossRef]

- Khan, K.I. Fluid Dynamic Modelling of Bubble Column Reactor. Ph.D. Thesis, Politecnico di Torino, Turin, Italy, 2014. [Google Scholar]

- Lapin, A.; Lübbert, A. Numerical simulations of the dynamics of two-phase gas-liquid flows in bubble columns. Chem. Eng. Sci. 1994, 49, 3661–3674. [Google Scholar] [CrossRef]

- Ekambara, K.; Dhotre, M.T. CFD Simulation of bubble column. Nucl. Eng. Des. 2010, 240, 963–969. [Google Scholar] [CrossRef]

- Masood, R.M.A.; Rauh, C.; Delgado, A. CFD Simulation of bubble column flows: An explicit algebraic Reynolds stress model approach. Int. J. Multiph. Flow 2014, 66, 11–25. [Google Scholar] [CrossRef]

- Monahan, S.M. Computational Fluid Dynamics Analysis of Air-Water Bubble Columns. Ph.D. Thesis, Iowa State University, Ames, IA, USA, 2007. [Google Scholar]

| No. | Author/Researcher | Correlation | Condition/Technique |

|---|---|---|---|

| 1 | Leibson et al. (1956) [63] | Departure bubble diameter from a single orifice in turbulent flow Re > 10,000. | |

| 2 | Davidson and Schüler (1960) [62] | For a constant flow rate at the orifice without including the inviscid liquid properties and surface. | |

| 3 | Levich (1962) [60] | Churn-turbulent flow regime. | |

| 4 | Wallis (1969) [64] | When the diameter of the orifice is comparable with the radius of the bubble, that is

| |

| 5 | Moalem and Sideman (1973) [65] | Combining the effect of bubble rising velocity and mainstream cross flow to investigate the collapse for pure vapor and at constant bubble velocity. The 1st correlation is for a bubble diameter of 0.4–0.8 cm. The 2nd correlation is for a bubble diameter of less than 0.2 cm. | |

| 6 | Anagbo (1991) [66] | Ellipsoidal bubble formation at free-standing nozzle. | |

| 7 | Martínez-Bazán et al. (1999) [61] | The breaking up of injected bubbles into fully developed turbulent flows based on Kolmogorov’s concept. | |

| 8 | Lehr and Mewes (2001) [67] | Following the idea of Levich [60]. | |

| 9 | Zhang et al. (2008) [68] | The unsteady motion of single bubbles rising freely in a quiescent high viscous liquid. The volumetric gas rate and the number of generated bubbles per unit time were used to calculate the bubble volume based on spherical shape assumption. |

| No. | Author/Researcher | Correlation | Condition/Technique |

|---|---|---|---|

| 1 | Davies and Taylor (1950) [72] | For very large single isolated bubbles under the condition that bubbles have constant pressure over their surfaces. | |

| 2 | Moalem and Sideman (1973) [65] | Collapse for un-pure vapor radius-dependent rising velocity was obtained using a simple energy balance by assuming a quasi-steady state. | |

| 3 | Krishna et al. (1994) [73] | ; , , | For the bubble column reactor for different gas densities. |

| 4 | Delnoij et al. (1997) [74] | For Re < 1000. = 0.44 for Re ≥ 1000. | Small spherical time-dependent two-dimensional gas bubble in a homogeneous regime. |

| 5 | Tomiyama et al. (1998) [75] | For a single bubble under normal and micro gravity effect. | |

| 6 | Tomiyama et al. (2002) [76] | For a single bubble rising through an infinite stagnant liquid in surface tension including surfactant concentration effects. | |

| 7 | Chen (2004) [77]; Ali (2014) [78] | For a single spherical bubble rising at a steady state. | |

| 8 | Talaia (2007) [44] | Re = 3425–7490 & CD = 2.68–2.76 | |

| Re = 695–3425 & de = 0.31–1.34 cm | |||

| Re = 255–695 & de = 0.14–0.31 cm | |||

| Re = 1.3–8.3, de = 1.85–3.9 cm & CD = 9.1–38.1 |

| No. | Author/Researcher | System | Correlation | Conditions |

|---|---|---|---|---|

| 1 | Fair et al. (1962) [80] | Air-water | For vessel sizes equal to or more than 18” and superficial gas velocity = 0–0.5 ft./s. | |

| 2 | Mikic and Rohsenow (1969) [81] | For pool boiling with heating surface. The 2nd correlation is for pool boiling in a laminar range 105 < Ra < 2 × 107. The 3rd correlation is for pool boiling in a turbulent range 2 × 105 < Ra < 3 × 1010. | ||

| 3 | Moalem and Sideman (1971) [82] | Non-homogenous distribution | For bubble condensation. | |

| 4 | Theofanous and Fauske (1973) [83] | Liquid-metal vapor | For single large vapor bubble. condensation in a cool liquid. | |

| 5 | Moalem and Sideman (1973) [65] | For a single bubble in a single and two-component system, either pure or containing non-condensable. | ||

| 6 | Hart (1976) [84] | Air-water, Air-ethylene | For bubble-agitated system with Us > 0.00159 ft/s. | |

| 7 | Ozisik and Kress (1978) [85] | UO2 & Sodium vapors containing non-condensable fission gases | Large rising vapor-gas bubble condensation in a hypothetical core. | |

| 8 | Deckwer et al. (1980) [25] | Nitrogen-xylene, Kogasin, decalin, nitrogen-paraffin-powdered Al2O3 | Based Kolmogoroffs theory of isotropic turbulence and ur = 0.003–0.04 m/s. | |

| 9 | Hikita et al. (1981) [86] | Air-waterAir-butanolAir-sucrosemethanol | 1st condition 2nd condition 3rd condition | |

| 10 | Saxena (1989) [87] | Air-water, air-water-magnetic | For a cylindrical probe immersed in a bubble column and = 0.015–0.333 m/s. | |

| 11 | Chen and Mayinger (1992) [79] | Ethanol, propanol, R113 an water | At the moment of detachment: The 1st correlation is for bubble growing period (formation). The 2nd correlation is for bubble collapsing period (bubble raising). | |

| 12 | Yang et al. (2000) [31] | Nitrogen-Paratherm NF heat transfer fluid-glass beads | For slurry bubble columns with P ≤ 4.2 MPa & T ≤ 81 °C. | |

| 13 | Cho et al. (2002) [88] | Air-viscous fluid | For pressurizedbubble columns with gas velocity = 0–0.12 m/s, pressure = 0.1–0.6 MPa & liquid viscosity = 1–38 mPa.s | |

| 14 | Lee et al. (2003) [89] | R11 | For partial nucleate boiling on the constant wall temperature microscale heater. | |

| 15 | Jhawar and Prakash (2007) [34] | Air-tap water | For bubble column using a fine and a coarse gas distributor: The 1st correlation is for m/s The 2nd correlation is for m/s. | |

| 16 | Leong et al. (2017) [90] | Critical heat flux for pool boiling by adopting the force balance approach including the effects of capillary wicking force and the modified Taylor wavelength. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdulwahid, A.A.; Situ, R.; Brown, R.J. Underground Diesel Exhaust Wet Scrubbers: Current Status and Future Prospects. Energies 2018, 11, 3006. https://doi.org/10.3390/en11113006

Abdulwahid AA, Situ R, Brown RJ. Underground Diesel Exhaust Wet Scrubbers: Current Status and Future Prospects. Energies. 2018; 11(11):3006. https://doi.org/10.3390/en11113006

Chicago/Turabian StyleAbdulwahid, Ahmed Adeeb, Rong Situ, and Richard J. Brown. 2018. "Underground Diesel Exhaust Wet Scrubbers: Current Status and Future Prospects" Energies 11, no. 11: 3006. https://doi.org/10.3390/en11113006

APA StyleAbdulwahid, A. A., Situ, R., & Brown, R. J. (2018). Underground Diesel Exhaust Wet Scrubbers: Current Status and Future Prospects. Energies, 11(11), 3006. https://doi.org/10.3390/en11113006