Thermal Transmittance Measurements of the Historical Masonries: Some Case Studies

Abstract

:1. Introduction

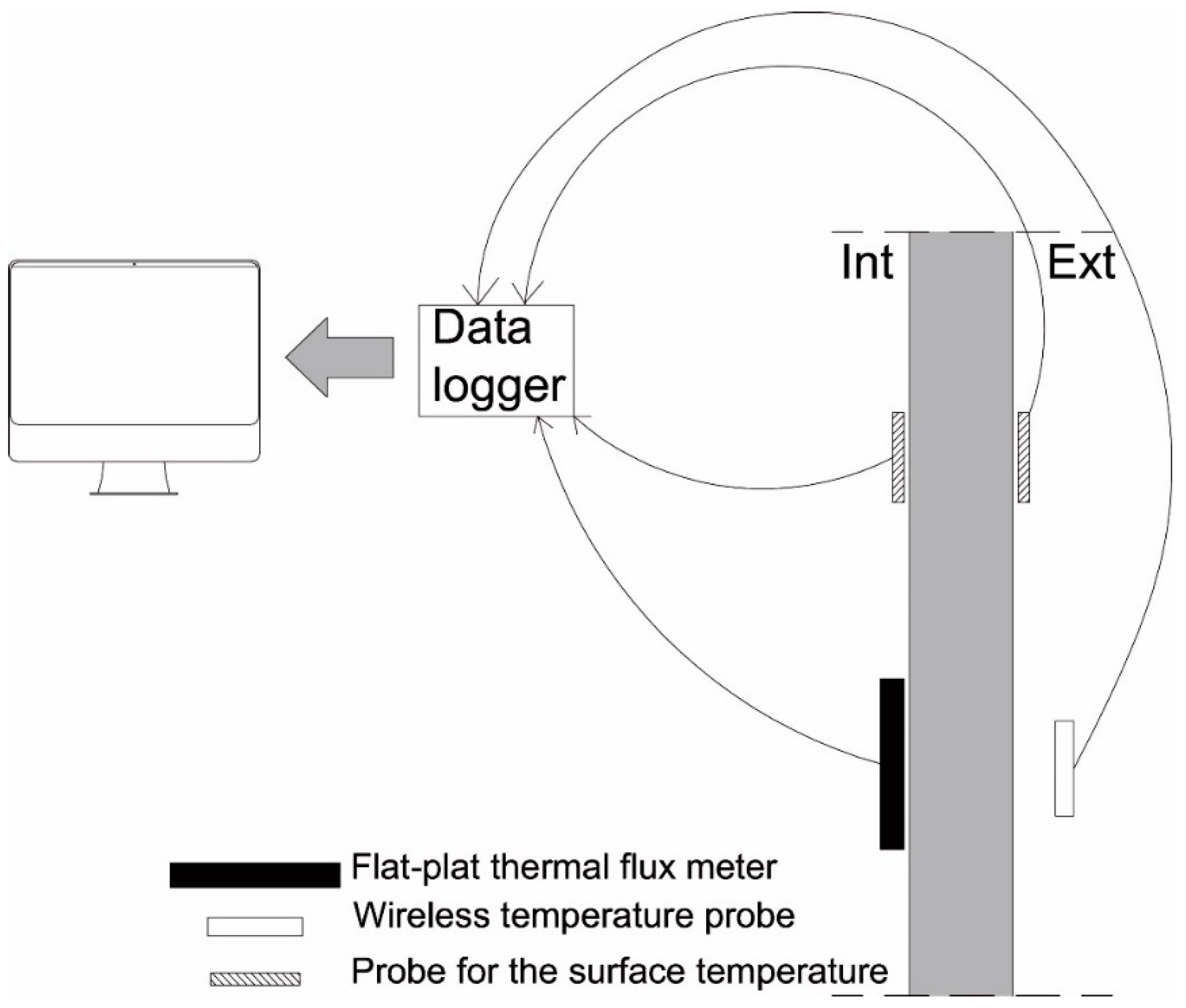

2. Materials and Methods

- they must be performed in accessible areas with confined spaces; on walls not exposed to direct sunlight;

- in environments where the internal temperature is constant, close to 20 degrees and with an internal-external difference of at least 10–15 degrees;

- in the absence of inversion of the thermal flux, that is, with external temperatures higher than 5–10 degrees;

- finally, electricity is necessary to allow the use of the technical equipment.

- the definition of the elements under investigation,

- the implementation of the survey itself,

- data meaning and interpretation,

- calculation of the transmittance value.

3. Results

3.1. Preliminary Analysis for the Selection of Wall Samples

- The wall sample no. 1—M1, that is a masonry of partially squared, medium-sized blocks and stone flakes with plastered inner surface, of 60 cm thickness;

- The wall sample no. 2—M2, that is a masonry of partially squared small and medium-sized stone blocks with plastered surface, of 74 cm thickness;

- The wall sample no. 3—M3, that is a masonry of partially-squared, semi-sized stone blocks and stone flakes with internal and external plastered surfaces, more recent of 55 cm thickness;

- The wall sample no. 4—M4, that is a masonry of stones with roughly squared blocks of medium and large dimensions and flakes with internal plastered surface, of 61 cm thickness.

3.2. Experimental Analyses and the Main Results

- metric and photographic survey of the building aggregate

- analysis of the construction technology of the masonry.

3.2.1. The Wall Sample No. 1—M1

3.2.2. The Wall Sample No. 2—M2

3.2.3. The Wall Sample No. 3—M3

3.2.4. The Wall Sample No. 4—M4

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Oh, J.; Yoo, H.; Kim, S. Evaluation of Strategies to Improve the Thermal Performance of Steel Frames in Curtain Wall Systems. Energies 2016, 9, 1055. [Google Scholar] [CrossRef]

- Allen, A.D. The Role of History in Place Marketing: Can Branding Create a Sense of Place? J. Town City Manag. 2011, 2, 75–83. [Google Scholar]

- Rotilio, P.E.M.; De Berardinis, P.E.P.; Marchionni, C. Principles of sustainability in the Reconstruction Plans of the minor centres struck by the earthquake. A case study: Sant’Eusanio Forconese (Aq). CINECA IRIS Inst. Res. Inf. Syst. 2013. [Google Scholar] [CrossRef]

- Kim, S.-H.; Lee, J.-H.; Kim, J.-H.; Yoo, S.-H.; Jeong, H.-G. The Feasibility of Improving the Accuracy of In Situ Measurements in the Air-Surface Temperature Ratio Method. Energies 2018, 11, 1885. [Google Scholar] [CrossRef]

- Evangelisti, L.; Battista, G.; Guattari, C.; Basilicata, C.; de Lieto Vollaro, R. Influence of the Thermal Inertia in the European Simplified Procedures for the Assessment of Buildings’ Energy Performance. Sustainability 2014, 6, 4514–4524. [Google Scholar] [CrossRef] [Green Version]

- Foucquier, A.; Robert, S.; Suard, F.; Stéphan, L.; Jay, A. State of the art in building modelling and energy performances prediction: A review. Renew. Sustain. Energy Rev. 2013, 23, 272–288. [Google Scholar] [CrossRef]

- Evangelisti, L.; Guattari, C.; Gori, P.; Vollaro, R. In Situ Thermal Transmittance Measurements for Investigating Differences between Wall Models and Actual Building Performance. Sustainability 2015, 7, 10388–10398. [Google Scholar] [CrossRef] [Green Version]

- Laurenti, L.; Marcotullio, F. La Valutazione Della Trasmittanza Termica; Cda (Condizionamento dell’aria, riscaldamento, refrigerazione): Milano, Italy, 2009. [Google Scholar]

- Cucchiella, F.; D’Adamo, I.; Gastaldi, M. Economic Analysis of a Photovoltaic System: A Resource for Residential Households. Energies 2017, 10, 814. [Google Scholar] [CrossRef]

- Corrado, V.; Ballarini, I.; Corgnati, S.P.; Talà, N. Building Typology Brochure—Italy; Politecnico di Torino: Torino, Italy, 2011; pp. 3–20. [Google Scholar]

- UNI 10351:1994. Building Materials. Thermal Conductivities and Vapor Permeabilities; UNI—Italian Organization for Standardization: Milano, Italy, 2018. [Google Scholar]

- UNI 10355. Walls and Floors—Values of Thermal Resistance and Calculation Methods; UNI—Italian Organization for Standardization: Milano, Italy, 2014. [Google Scholar]

- UNI/TS 11300-1. Part 1: Evaluation of Energy Need for Space Heating and Cooling; UNI—Italian Organization for Standardization: Milano, Italy, 2014. [Google Scholar]

- ISO 9869:1994. Thermal Insulation—Building Elements—In-Situ Measurement of Thermal Resistance and Thermal Transmittance; ISO: Geneva, Switzerland, 1994. [Google Scholar]

- Choi, D.S.; Ko, M.J. Comparison of Various Analysis Methods Based on Heat Flowmeters and Infrared Thermography Measurements for the Evaluation of the In Situ Thermal Transmittance of Opaque Exterior Walls. Energies 2017, 10, 1019. [Google Scholar] [CrossRef]

- Adhikari, R.S.; Lucchi, E.; Pracchi, V. Experimental Measurements on Thermal Transmittance of the Opaque Vertical Walls in the Historical Buildings. In Proceedings of the 28th International Plea Conference, Lima, Peru, 7–9 November 2012. [Google Scholar]

- Bellia, L.; d’Ambrosio Alfano, F.R.; Giordano, J.; Ianniello, E.; Riccio, G. Energy requalification of a historical building: A case study. Energy Build. 2015, 95, 184–189. [Google Scholar] [CrossRef]

- Rospi, G.; Cardinale, N.; Negro, E. Energy Performance and Economic Feasibility Study of Historical Building in the City of Matera, Southern Italy. Energies 2017, 10, 2009. [Google Scholar] [CrossRef]

- Pantoli, L.; Muttillo, M.; Ferri, G.; Stornelli, V.; Alaggio, R.; Vettori, D.; Chinzari, L.; Chinzari, F. Remote Sensing System for Condition Monitoring of Modern Wooden Structures. In Proceedings of the 49th Annual Meeting of the Associazione Società Italiana di Elettronica, Palermo, Italy, 21–23 June 2017. [Google Scholar]

- Pantoli, L.; Muttillo, M.; Ferri, G.; Stornelli, V.; Alaggio, R.; Chinzari, F. Distributed sensing and monitoring system for wooden structures. In Proceedings of the SAC Sensors and Actuators Congress, Stockholm, Sweden, 3–6 September 2018. [Google Scholar]

- de Rubeis, T.; Muttillo, M.; Pantoli, L.; Nardi, I.; Leone, I.; Stornelli, V.; Ambrosini, D. A first approach to universal daylight and occupancy control system for any lamps: Simulated case in an academic classroom. Energy Build. 2017, 152, 24–39. [Google Scholar] [CrossRef]

- Tanasiev, V.; Necula, H.; Darie, G.; Badea, A. Web service-based monitoring system for smart management of the buildings. In Proceedings of the International Conference and Exposition on Electrical and Power Engineering (EPE), Iasi, Romania, 16–18 October 2014; pp. 23–25. [Google Scholar]

- De Berardinis, P.; Rotilio, M.; Marchionni, C.; Friedman, A. Improving the energy-efficiency of historic masonry buildings. A case study: A minor centre in the Abruzzo region, Italy. Energy Build. 2014, 80, 415–423. [Google Scholar] [CrossRef]

- Kim, S.-H.; Kim, J.-H.; Jeong, H.-G.; Song, K.-D. Reliability Field Test of the Air–Surface Temperature Ratio Method for In Situ Measurement of U-Values. Energies 2018, 11, 803. [Google Scholar] [CrossRef]

- Lucchi, E. Thermal transmittance of historical brick masonries: A comparison among standard data, analytical calculation procedures, and in situ heat flow meter measurements. Energy Build. 2017, 134, 171–184. [Google Scholar] [CrossRef]

- Lucchi, E. Thermal transmittance of historical stone masonries: A comparison among standard, calculated and measured data. Energy Build. 2017, 151, 393–405. [Google Scholar] [CrossRef]

- Baker, P. U-Values and Traditional Buildings: In Situ Measurements and Their Comparisons to Calculated Values; Hostoric Scotland: Edinburgh, UK, 2011. [Google Scholar]

- Morganti, R.; De Berardinis, P.; Bellicoso, A.; Di Giovanni, G.; Tosone, A.; Marcotullio, F. Energy rehabilitation in the post seismic reconstruction. In Proceedings of the 39th IAHS Changing needs, Adaptive Buildings Smart Cities, Milan, Italy, 17–20 September 2013; pp. 877–885. [Google Scholar]

- Brusaporci, S. Le murature Nell’architettura del Versante Meridionale del Gran Sasso (secc. XI–XIV); Gangemi Editore: Roma, Italy, 2007. [Google Scholar]

- Bonamico, S.; Tamburini, G. Centri Storici Minori; Politecnico di Torino: Turin, Italy, 1995. [Google Scholar]

- Zordan, L.; Bellicoso, A.; De Berardinis, P.; Di Giovanni, G.; Morganti, R. Le Tradizioni del Costruire della Casa in Pietra: Materiali, Tecniche, Modelli e Sperimentazioni; Amazon: Seattle, WA, USA, 2002; Volume 1. [Google Scholar]

- Genova, E.; Fatta, G. The thermophysical characterization of technical elements in the historic architecture: Experiences in Palermo. In Proceedings of the Actas del Congreso Internacional de Eficiencia Energética y Edificación Histórica, Madrid, Spain, 29–30 September 2014; pp. 397–406. [Google Scholar]

- Albatici, R.; Tonelli, A. Verifica Sperimentale In Situ, con Analisi Termografiche e Algoritmi di Calcolo, della Trasmittanza Termica di un Elemento Costruttivo; Museo Civico di Rovereto: Rovereto, Italy, 2008; pp. 103–125. [Google Scholar]

- Crawley, D.B.; Hand, J.W.; Kummert, M.; Griffith, B.T. Contrasting the capabilities of building energy performance simulation programs. Build. Environ. 2008, 43, 661–673. [Google Scholar] [CrossRef] [Green Version]

- Chae, Y.; Lee, Y.; Longinott, D. Assessment of Retrofitting Measures for a Large Historic Research Facility Using a Building Energy Simulation Model. Energies 2016, 9, 466. [Google Scholar] [CrossRef]

- European Commission. EU Construction & Demolition Waste Management Protocol; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- Sivrikaya, O.; Kıyıldı, K.R.; Karaca, Z. Recycling waste from natural stone processing plants to stabilise clayey soil. Environ. Earth Sci. 2013, 71, 4397–4407. [Google Scholar] [CrossRef] [Green Version]

| Heat Flow Meter for Calculating U Value (ref. “Testo 0600 1635”) | |

| Property | Values |

| Temperature application range | −20 to +50 °C |

| Accuracy heat flow meter | ±5% |

| System accuracy U-value | ±12% of measurement value at 15 K temperature difference |

| Radio Probe For External Temperature (ref. “Testo 0613 1001”) | |

| Property | Values |

| Measure range | −50 to +275 °C |

| Accuracy | ±0.5 °C (−20.0 to +80.0 °C) |

| ±0.8 °C (−50.0 to −20.1 °C) | |

| ±0.8 °C (+80.1 to +200.0 °C) | |

| ±1.5 °C (remaining range) | |

| Resolution | ±0.1 °C |

| Probe for Surface Temperature (ref. “Testo 0602 0644”) | |

| Property | Values |

| Measure range | −50 to +400 °C |

| Accuracy | Class 2 (according to standard EN 60584-2, the accuracy of Class 2 refers to −40 to +1200 °C) |

| N. | Day/Month/Year | Hours | W/m2 K | [°C] Ti | [°C] Te | [°C] Tse | [°C] Tsi | Ti-Te | Q [W/m2] | Tsi-Tse | Progressive Sum of Thermal Flux | Progressive Sum Delta Ts | Conductance |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 12/04/14 | 18:49:24 | 1.378 | 20.8 | 10.8 | 12.7 | 19.5 | 10 | 13.78 | 6.8 | 13.78 | 6.8 | 2.026470588 |

| 2 | 12/04/14 | 18:59:24 | 2.272 | 20.7 | 10.9 | 12.8 | 19.7 | 9.8 | 22.2656 | 6.9 | 36.0456 | 13.7 | 2.631065693 |

| 3 | 12/04/14 | 19:09:24 | 3.097 | 20.7 | 10.7 | 12.8 | 19.6 | 10 | 30.97 | 6.8 | 67.0156 | 20.5 | 3.269053659 |

| 4 | 12/04/14 | 19:19:24 | 2.817 | 20.7 | 10.7 | 12.9 | 19.5 | 10 | 28.17 | 6.6 | 95.1856 | 27.1 | 3.512383764 |

| 5 | 12/04/14 | 19:29:24 | 1.671 | 20.8 | 10.7 | 12.9 | 19.5 | 10.1 | 16.8771 | 6.6 | 112.0627 | 33.7 | 3.325302671 |

| 6 | 12/04/14 | 19:39:24 | 2.27 | 21 | 10.7 | 12.9 | 20 | 10.3 | 23.381 | 7.1 | 135.4437 | 40.8 | 3.319698529 |

| 7 | 12/04/14 | 19:49:24 | 2.843 | 20.8 | 10.7 | 12.8 | 19.8 | 10.1 | 28.7143 | 7 | 164.158 | 47.8 | 3.434267782 |

| 8 | 12/04/14 | 19:59:24 | 2.657 | 21 | 10.4 | 12.5 | 20 | 10.6 | 28.1642 | 7.5 | 192.3222 | 55.3 | 3.477797468 |

| 9 | 12/04/14 | 20:09:24 | 2.948 | 21.2 | 10.4 | 12.7 | 20.1 | 10.8 | 31.8384 | 7.4 | 224.1606 | 62.7 | 3.575129187 |

| 10 | 12/04/14 | 20:19:24 | 2.52 | 21.2 | 10.1 | 12.7 | 20 | 11.1 | 27.972 | 7.3 | 252.1326 | 70 | 3.601894286 |

| ⁞ | ⁞ | ⁞ | ⁞ | ⁞ | ⁞ | ⁞ | ⁞ | ⁞ | ⁞ | ⁞ | ⁞ | ⁞ | ⁞ |

| 422 | 15/04/14 | 17:09:24 | 1.996 | 20.1 | 5.8 | 9 | 19.3 | 14.3 | 28.5428 | 10.3 | 5117.0491 | 2037.5 | 2.511435141 |

| 423 | 15/04/14 | 17:19:24 | 0.639 | 20.2 | 5.8 | 9.2 | 19.2 | 14.4 | 9.2016 | 10 | 5126.2507 | 2047.5 | 2.503663346 |

| 424 | 15/04/14 | 17:29:24 | 0.51 | 20.2 | 6 | 9.3 | 19.1 | 14.2 | 7.242 | 9.8 | 5133.4927 | 2057.3 | 2.49525723 |

| 425 | 15/04/14 | 17:39:24 | 0.688 | 20.1 | 5.5 | 8.9 | 19.1 | 14.6 | 10.0448 | 10.2 | 5143.5375 | 2067.5 | 2.48780532 |

| 426 | 15/04/14 | 17:49:24 | 1.326 | 20.1 | 5.7 | 9.2 | 19.2 | 14.4 | 19.0944 | 10 | 5162.6319 | 2077.5 | 2.485021372 |

| 427 | 15/04/14 | 17:59:24 | 1.788 | 20 | 6.1 | 9.1 | 19.3 | 13.9 | 24.8532 | 10.2 | 5187.4851 | 2087.7 | 2.484784739 |

| 428 | 15/04/14 | 18:09:24 | 1.361 | 20.2 | 5.9 | 8.9 | 19.2 | 14.3 | 19.4623 | 10.3 | 5206.9474 | 2098 | 2.48186244 |

| 429 | 15/04/14 | 18:19:24 | 0.605 | 20.4 | 6 | 9.2 | 19.3 | 14.4 | 8.712 | 10.1 | 5215.6594 | 2108.1 | 2.474104359 |

| 430 | 15/04/14 | 18:29:24 | 0.768 | 20.4 | 5.6 | 9 | 19.4 | 14.8 | 11.3664 | 10.4 | 5227.0258 | 2118.5 | 2.467323956 |

| 431 | 15/04/14 | 18:39:24 | 1.086 | 20.4 | 5.4 | 8.9 | 19.6 | 15 | 16.29 | 10.7 | 5243.3158 | 2129.2 | 2.462575521 |

| N. | Day/Month/Year | Hours | W/m2 K | [°C] Ti | [°C] Te | [°C] Tse | [°C] Tsi | Ti-Te | Q [W/m2] | Tsi-Tse | Progressive Sum of Thermal Flux | Progressive Sum Delta Ts | Conductance |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 21/03/15 | 20:05:01 | 1.47 | 20.5 | 8.6 | 8.6 | 19.2 | 11.9 | 17.493 | 10.6 | 17.493 | 10.6 | 1.650283019 |

| 2 | 21/03/15 | 20:15:01 | 1.151 | 19.6 | 8.6 | 8.6 | 18.6 | 11 | 12.661 | 10 | 30.154 | 20.6 | 1.463786408 |

| 3 | 21/03/15 | 20:25:01 | 1.062 | 19.3 | 8.6 | 8.6 | 18.7 | 10.7 | 11.3634 | 10.1 | 41.5174 | 30.7 | 1.352358306 |

| 4 | 21/03/15 | 20:35:01 | 1.244 | 19.1 | 8.7 | 8.7 | 18.5 | 10.4 | 12.9376 | 9.8 | 54.455 | 40.5 | 1.344567901 |

| 5 | 21/03/15 | 20:45:01 | 1.074 | 19.1 | 8.6 | 8.6 | 18.3 | 10.5 | 11.277 | 9.7 | 65.732 | 50.2 | 1.30940239 |

| 6 | 21/03/15 | 20:55:01 | 1.207 | 19 | 8.3 | 8.3 | 18.3 | 10.7 | 12.9149 | 10 | 78.6469 | 60.2 | 1.30642691 |

| 7 | 21/03/15 | 21:05:01 | 1.029 | 18.9 | 8.3 | 8.3 | 18.2 | 10.6 | 10.9074 | 9.9 | 89.5543 | 70.1 | 1.277522111 |

| 8 | 21/03/15 | 21:15:01 | 1.213 | 18.9 | 8.3 | 8.3 | 18.3 | 10.6 | 12.8578 | 10 | 102.4121 | 80.1 | 1.278553059 |

| 9 | 21/03/15 | 21:25:01 | 1.024 | 18.9 | 8.3 | 8.3 | 18.3 | 10.6 | 10.8544 | 10 | 113.2665 | 90.1 | 1.257119867 |

| 10 | 21/03/15 | 21:35:01 | 1.182 | 18.8 | 8.1 | 8.1 | 18.5 | 10.7 | 12.6474 | 10.4 | 125.9139 | 100.5 | 1.252874627 |

| ⁞ | ⁞ | ⁞ | ⁞ | ⁞ | ⁞ | ⁞ | ⁞ | ⁞ | ⁞ | ⁞ | ⁞ | ⁞ | ⁞ |

| 223 | 23/03/15 | 08:35:01 | 0.914 | 18.5 | 5.6 | 5.6 | 18 | 12.9 | 11.7906 | 12.4 | 2510.601 | 2811 | 0.893134472 |

| 224 | 23/03/15 | 08:45:01 | 1.014 | 18.4 | 5.8 | 5.8 | 18 | 12.6 | 12.7764 | 12.2 | 2523.3774 | 2823.2 | 0.893800439 |

| 225 | 23/03/15 | 08:55:01 | 0.921 | 18.5 | 5.8 | 5.8 | 17.9 | 12.7 | 11.6967 | 12.1 | 2535.0741 | 2835.3 | 0.894111417 |

| 226 | 23/03/15 | 09:05:01 | 1.092 | 18.4 | 6.4 | 6.4 | 18 | 12 | 13.104 | 11.6 | 2548.1781 | 2846.9 | 0.895071165 |

| 227 | 23/03/15 | 09:15:01 | 1.027 | 18.5 | 7.1 | 7.1 | 17.9 | 11.4 | 11.7078 | 10.8 | 2559.8859 | 2857.7 | 0.895785387 |

| 228 | 23/03/15 | 09:25:01 | 1.177 | 18.5 | 7.3 | 7.3 | 18 | 11.2 | 13.1824 | 10.7 | 2573.0683 | 2868.4 | 0.897039569 |

| 229 | 23/03/15 | 09:35:01 | 1.079 | 18.5 | 7.6 | 7.6 | 17.9 | 10.9 | 11.7611 | 10.3 | 2584.8294 | 2878.7 | 0.897915517 |

| 230 | 23/03/15 | 09:45:01 | 1.348 | 18.5 | 8.8 | 8.8 | 17.9 | 9.7 | 13.0756 | 9.1 | 2597.905 | 2887.8 | 0.899613893 |

| 231 | 23/03/15 | 09:55:01 | 1.414 | 18.5 | 9.7 | 9.7 | 17.9 | 8.8 | 12.4432 | 8.2 | 2610.3482 | 2896 | 0.901363329 |

| 232 | 23/03/15 | 10:05:01 | 1.374 | 18.5 | 9.6 | 9.6 | 17.9 | 8.9 | 12.2286 | 8.3 | 2622.5768 | 2904.3 | 0.9029979 |

| 233 | 23/03/15 | 10:15:01 | 0.557 | 18.4 | 9.3 | 9.3 | 17.8 | 9.1 | 5.0687 | 8.5 | 2627.6455 | 2912.8 | 0.902102959 |

| N. | Day/Month/Year | Hours | W/m2 K | [°C] Ti | [°C] Te | [°C] Tse | [°C] Tsi | Ti-Te | Q [W/m2] | Tsi-Tse | Progressive Sum of Thermal Flux | Progressive Sum Delta Ts | Conductance |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 29/03/13 | 17:03:00 | −3.593 | 12.6 | 15.4 | 14 | 9 | −2.8 | −10.0604 | −5 | −10.0604 | −5 | 2.01208 |

| 2 | 29/03/13 | 17:13:00 | −0.335 | 10.1 | 15.1 | 14 | 8.9 | −5 | −1.675 | −5.1 | −11.7354 | −10.1 | 1.161920792 |

| 3 | 29/03/13 | 17:23:00 | −0.308 | 9.5 | 15.2 | 13.8 | 8.7 | −5.7 | −1.7556 | −5.1 | −13.491 | −15.2 | 0.887565789 |

| 4 | 29/03/13 | 17:33:00 | −0.474 | 9.3 | 14.5 | 13.5 | 8.9 | −5.2 | −2.4648 | −4.6 | −15.9558 | −19.8 | 0.805848485 |

| 5 | 29/03/13 | 17:43:00 | −0.548 | 9.2 | 14.5 | 13.6 | 9 | −5.3 | −2.9044 | −4.6 | −18.8602 | −24.4 | 0.772959016 |

| 6 | 29/03/13 | 17:53:00 | −0.602 | 9.1 | 14.3 | 13.3 | 9 | −5.2 | −3.1304 | −4.3 | −21.9906 | −28.7 | 0.766222997 |

| 7 | 29/03/13 | 18:03:00 | −0.681 | 9.1 | 14.1 | 13.5 | 9.2 | −5 | −3.405 | −4.3 | −25.3956 | −33 | 0.769563636 |

| 8 | 29/03/13 | 18:13:00 | −0.743 | 9.1 | 13.9 | 13.2 | 9.3 | −4.8 | −3.5664 | −3.9 | −28.962 | −36.9 | 0.784878049 |

| 9 | 29/03/13 | 18:23:00 | −0.937 | 9.1 | 13.4 | 13.2 | 9.3 | −4.3 | −4.0291 | −3.9 | −32.9911 | −40.8 | 0.808605392 |

| 10 | 29/03/13 | 18:33:00 | −1.005 | 9.1 | 13.1 | 13 | 9.4 | −4 | −4.02 | −3.6 | −37.0111 | −44.4 | 0.833583333 |

| ⁞ | ⁞ | ⁞ | ⁞ | ⁞ | ⁞ | ⁞ | ⁞ | ⁞ | ⁞ | ⁞ | ⁞ | ⁞ | ⁞ |

| 959 | 05/04/13 | 08:43:00 | 2.931 | 13.3 | 10.2 | 9.4 | 13.5 | 3.1 | 9.0861 | 4.1 | 7148.6033 | 4560.9 | 1.567366814 |

| 960 | 05/04/13 | 08:53:00 | 3.264 | 13.4 | 10.3 | 9.7 | 13.5 | 3.1 | 10.1184 | 3.8 | 7158.7217 | 4564.7 | 1.568278682 |

| 961 | 05/04/13 | 09:03:00 | 3.837 | 13.5 | 10.7 | 9.8 | 13.4 | 2.8 | 10.7436 | 3.6 | 7169.4653 | 4568.3 | 1.569394589 |

| 962 | 05/04/13 | 09:13:00 | 4.375 | 13.6 | 11 | 10.1 | 13.6 | 2.6 | 11.375 | 3.5 | 7180.8403 | 4571.8 | 1.570681198 |

| 963 | 05/04/13 | 09:23:00 | 4.863 | 13.6 | 11.1 | 10.2 | 13.7 | 2.5 | 12.1575 | 3.5 | 7192.9978 | 4575.3 | 1.572136865 |

| 964 | 05/04/13 | 09:33:00 | 6.052 | 13.7 | 11.6 | 10.5 | 13.8 | 2.1 | 12.7092 | 3.3 | 7205.707 | 4578.6 | 1.57377954 |

| 965 | 05/04/13 | 09:43:00 | 6.099 | 13.7 | 11.7 | 10.6 | 13.8 | 2 | 12.198 | 3.2 | 7217.905 | 4581.8 | 1.57534266 |

| 966 | 05/04/13 | 09:53:00 | 6.621 | 13.8 | 11.9 | 10.7 | 13.9 | 1.9 | 12.5799 | 3.2 | 7230.4849 | 4585 | 1.576986892 |

| 967 | 05/04/13 | 10:03:00 | 6.617 | 13.8 | 11.8 | 10.8 | 13.8 | 2 | 13234 | 3 | 7243.7189 | 4588 | 1.578840214 |

| 968 | 05/04/13 | 10:13:00 | 10.097 | 13.9 | 12.6 | 11.1 | 13.9 | 1.3 | 13.1261 | 2.8 | 7256.845 | 4590.8 | 1.580736473 |

| 969 | 05/04/13 | 10:23:00 | 10.159 | 14.1 | 12.3 | 11.1 | 14 | 1.8 | 18.2862 | 2.9 | 7275.1312 | 4593.7 | 1.583719268 |

| Type of Masonries | Thickness (cm) | U-Values (W/m2K) (UNI-TS 11300) | U-Values (W/m2 K) (UNI ISO 9869) |

|---|---|---|---|

| M1 | 60 | 2.00 | 1.74 |

| M2 | 74 | - | 1.27 |

| M3 | 55 | 2.11 | 1.98 |

| M4 | 61 | - | 1.81 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rotilio, M.; Cucchiella, F.; De Berardinis, P.; Stornelli, V. Thermal Transmittance Measurements of the Historical Masonries: Some Case Studies. Energies 2018, 11, 2987. https://doi.org/10.3390/en11112987

Rotilio M, Cucchiella F, De Berardinis P, Stornelli V. Thermal Transmittance Measurements of the Historical Masonries: Some Case Studies. Energies. 2018; 11(11):2987. https://doi.org/10.3390/en11112987

Chicago/Turabian StyleRotilio, Marianna, Federica Cucchiella, Pierluigi De Berardinis, and Vincenzo Stornelli. 2018. "Thermal Transmittance Measurements of the Historical Masonries: Some Case Studies" Energies 11, no. 11: 2987. https://doi.org/10.3390/en11112987

APA StyleRotilio, M., Cucchiella, F., De Berardinis, P., & Stornelli, V. (2018). Thermal Transmittance Measurements of the Historical Masonries: Some Case Studies. Energies, 11(11), 2987. https://doi.org/10.3390/en11112987