Abstract

The accurate estimation of pressure drop during multiphase fluid flow in vertical pipes has been widely recognized as a critical problem in oil wells completion design. The flow of fluids through the vertical tubing strings causes great losses of energy through friction, where the value of this loss depends on fluid flow viscosity and the size of the conduit. A number of friction factor correlations, which have acceptably accurate results in large diameter pipes, are significantly in error when applied to smaller diameter pipes. Normally, the pressure loss occurs due to friction between the fluid flow and the pipe walls. The estimation of the pressure gradients during the multiphase flow of fluids is very complex due to the variation of many fluid parameters along the vertical pipe. Other complications relate to the numerous flow regimes and the variabilities of the fluid interfaces involved. Accordingly, knowledge about pressure drops and friction factors is required to determine the fluid flow rate of the oil wells. This paper describes the influences of the pressure drop on the measurement of the fluid flow by estimating the friction factor using different empirical friction correlations. Field experimental work was performed at the well site to predict the fluid flow rate of 48 electrical submersible pump (ESP) oil wells, using the newly developed mathematical model. Using Darcy and Colebrook friction factor correlations, the results show high average relative errors, exceeding ±18.0%, in predicted liquid flow rate (oil and water). In gas rate, more than 77% of the data exceeded ±10.0% relative error to the predicted gas rate. For the Blasius correlation, the results showed the predicted liquid flow rate was in agreement with measured values, where the average relative error was less than ±18.0%, and for the gas rate, 68% of the data showed more than ±10% relative error.

1. Introduction

In the oil and gas industry, multiphase flow in vertical pipes often occurs. The flow of fluids through the vertical pipe string causes a loss of energy through friction losses, where the value of this loss depends on the fluid flow viscosity and the size of the conduit. Often, the friction loss is an important part of the oil well completion design [1]. The pressure drop occurs as a result of the changes in potential and kinetic energy of the fluid due to the friction on the pipe walls [2]. Generally, the total pressure drop in the vertical conduit is basically related to four main components: frictional, hydrostatic, acceleration, and pressure drop. Among these four components, calculation of the pressure drop is the most complex component and has received extensive attention by researchers [3,4]. Many researchers have attempted to determine the two-phase frictional pressure drop over the whole range of flow patterns through a vertical pipe. A substantial number of experiments have been carried out to determine fluid flow friction losses in both Newtonian [1,2,5,6,7,8,9,10,11] and non-Newtonian systems [5,12]. A large number of experimental works was made in short tubes. Consequently, a lot of engineering problems come up when efforts are made to extend these experimental results to real oil field conditions where a longer pipe is used. In those experiments, the data shows only a limited number of variables, and as a result, imprecisions are introduced when the friction correlations are applied outside the limitations of the experimental data. As a consequence of the limited amount of data available for these experiments, the effects of some significant variables were ignored in the early studies [13,14,15,16,17]. The accuracy of the pressure drop prediction in flowing wells has a significant influence on the fluid flow measurement. There are many particular solutions, but they are valid only for some specific conditions. This is due to the complexity of two-phase flow analysis. In some conditions, the gas travels at a much higher velocity than the liquid. Accordingly, the flowing density of the gas–liquid mixture is higher than the corresponding density. Moreover, the liquid’s velocity inside the pipe wall can be different over a short distance and can cause a variable friction loss. The difference in velocity and flow regime of the two phases strongly affect pressure drop computations [13], meaning that slippage is a consequence of the difference between the combined velocities of the two phases, which is caused by the physical properties of the fluids involved. For single-phase flow, the frictional pressure losses do not normally increase with a decrease in the tubing size or an increase in well production flow rate. This refers to the existence of a gas phase, which tends to slip by the liquid phase without essentially contributing to its lift. Many researchers have tried to show a relationship between the slippage losses and the friction losses [15,16,17,18]. A method for the estimation of gas–liquid flow rates in the vertical pipe has been proposed [19]. The method was used to calibrate a differential pressure sensor to predict the flow rates of both phases in air–water flow. The estimations were in good agreement with real flow rate measurements. A study by Daev and Kairakbaev [20] proposed a new model of the liquid flow through pipes that incorporated flow straighteners. The prediction of the flow rate of liquid was studied and the parameters affecting the process of measuring the flow rate of liquid were considered. An experimental study of the two-phase flow regime and frictional pressure drop inside the pipe was done by Cai et al. [21]. The flow patterns were defined and recorded by a high-speed camera. A new empirical correlation was proposed based on the experimental results to predict the liquid multiplier factor of the test channel. A two-phase flow measurement applying a resistive void fraction meter combined to a venturi, or orifice plate, was suggested by Oliveira et al. [22]. This method was applied to determine the fluid mass flow rates using an air–water experimental apparatus. The results showed that the flow path has no important effect on the meters in relation to the frictional pressure drop in the experimental process range. The outcomes of the experimental work displayed a mean slip ratio of less than 1.1, when slug and bubbly flow patterns were lower than 70%.

This research work aims to evaluate the influence of a pressure drop on the measurement of the fluid flow rate in ESP oil wells. A new mathematical model was developed to determine the fluid flow rate of the oil wells through the prediction of multiphase flow parameter variations inside a vertical pipe based on local temperature and pressure changes with depth and applying multiphase flow physics equations and empirical correlations. The objective of this study was to obtain data from well tests conducted in a long vertical pipe and utilize this data to evaluate the effects of slippage and friction factor, in different flow regimes, on the calculation accuracies of the fluid flow rate of the oil wells. The approach measured the liquid hold-up along the conduit and used different friction correlations such as Blasius, Darcy, and Colebrook friction factor correlations to compare the predicted fluid flow rate with the measured fluid flow rate for each oil well. Generally, the results show that any errors in pressure drop calculation will generate inaccuracies in the prediction of fluid flow rate.

2. Experimental Arrangements and Measurement Procedure

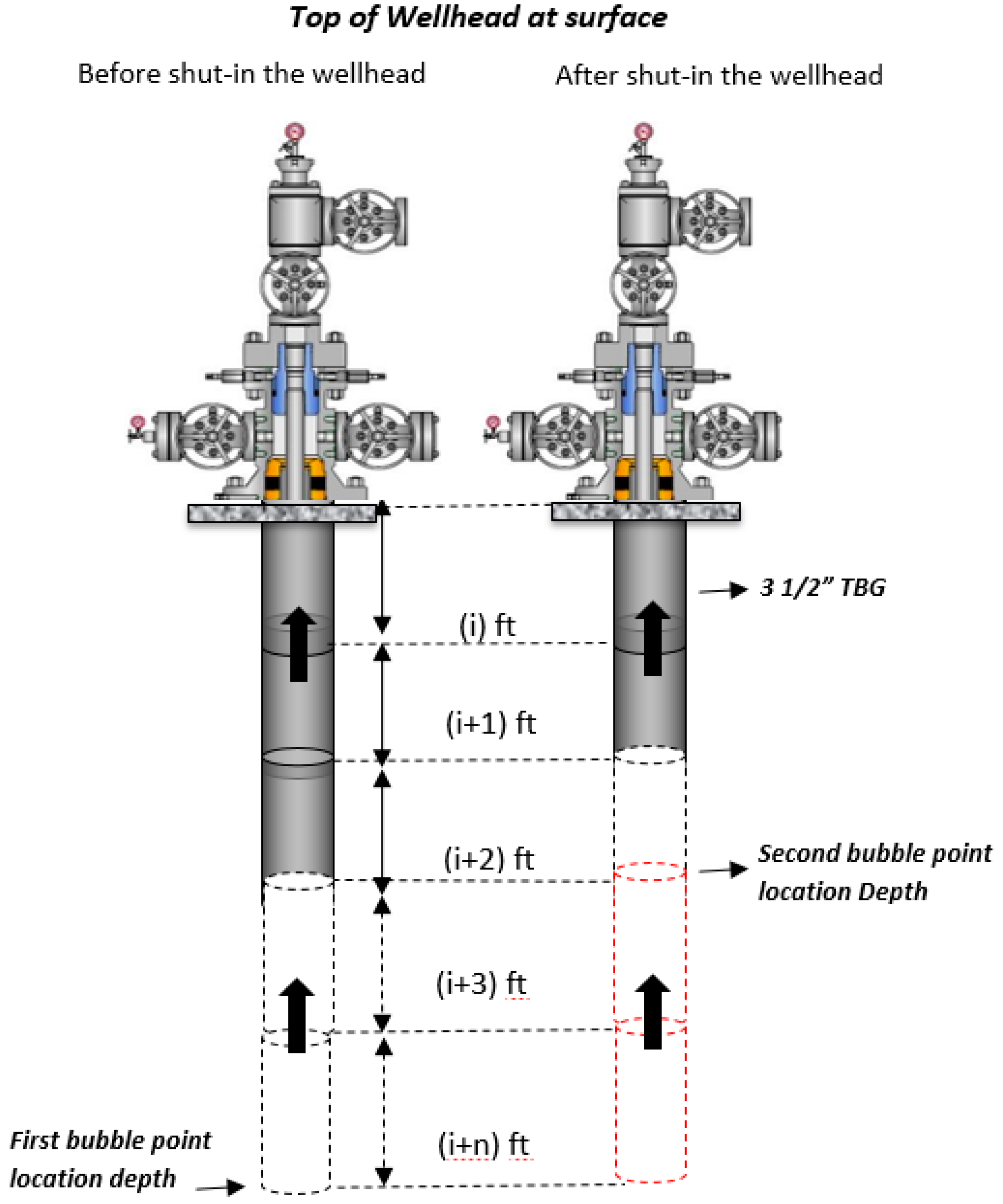

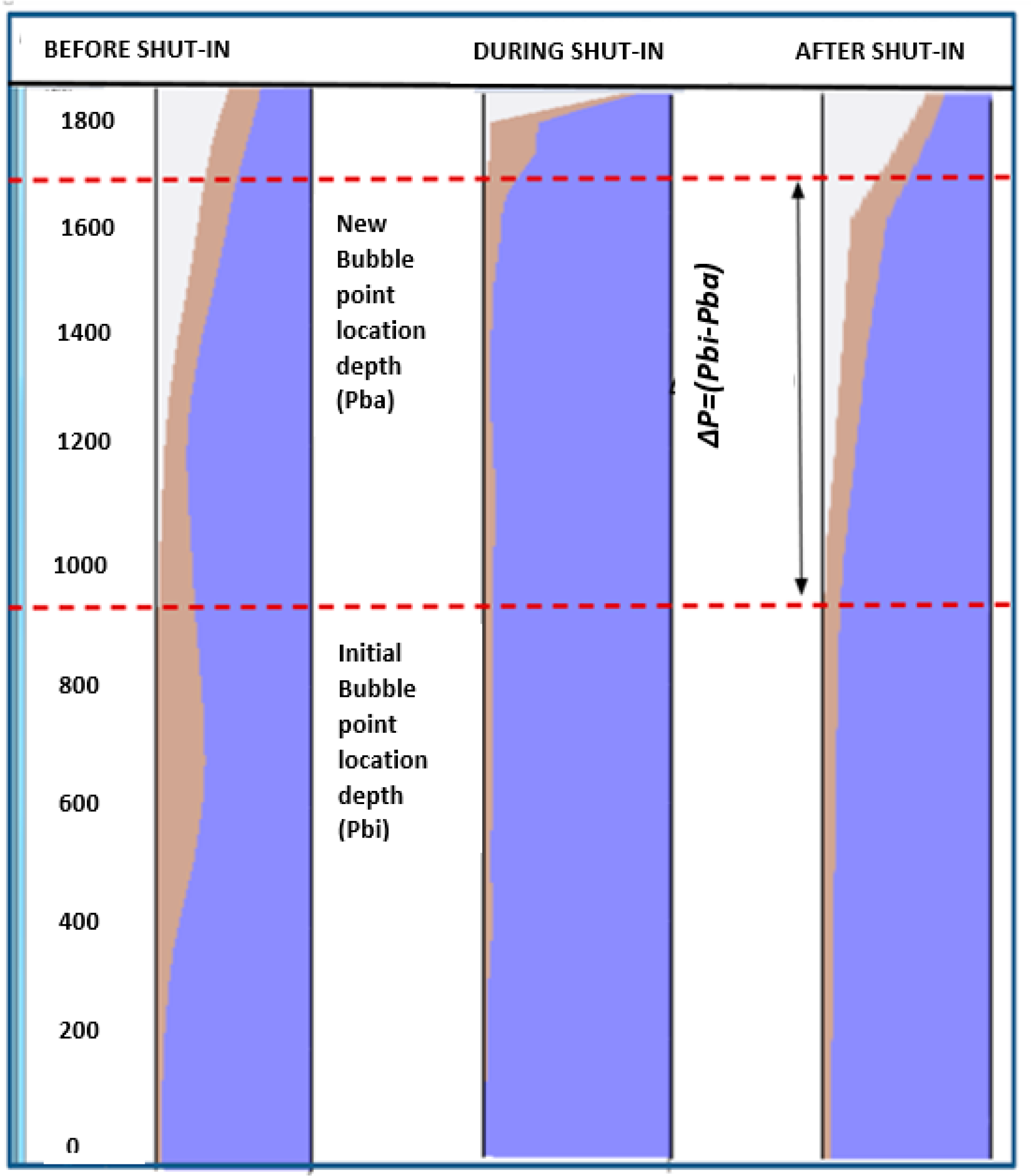

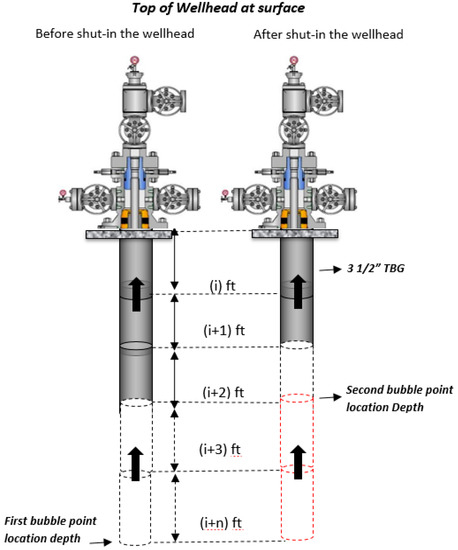

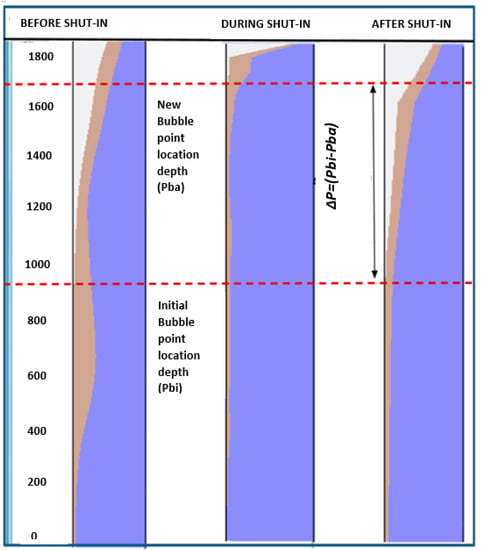

The experiments conducted in the present study were carried out for two-phase flow through a vertical pipe of 48 oil wells using ESP pumps. A schematic of the experimental system is shown in Figure 1. The flow measurement starts at the surface wellhead, and then down to the bubble point pressure location depth in the well. Wellhead flowing pressure was measured at normal production conditions before and after the wing valve shut-in, leaving the ESP pump running, to measure the build-up of pressure at the wellhead. The total shut-in time period of the wellhead valve was then recorded. The first free gas bubbles started liberating from the bubble point location depth inside the tubing string. This occurred in the production flowing well before and after the wellhead wing valve shut-in, and the changes of flow patterns inside the pipe were reallocated once again, due to variations of temperature and pressure along the conduit. As a consequence, the liberated gas was dissolved in the oil phase, and the location depth of the bubble point pressure relocated to another position after the wellhead wing valve shut-in. The column of liquid that replaced the liberated gas column space, during the shut-in time period, was the difference between the first and second bubble point location depths. Figure 2 shows the bubble point location depths before and after the wellhead wing valve shut-in. A conceptual basis of physics for prediction of fluid flow rate in the conduit was employed along with multiphase empirical correlations to compute the variations of fluid flow parameters inside the tubing.

Figure 1.

Schematic of the flow measurement stages in a vertical pipe before and after the well head wing valve shut-in.

Figure 2.

Bubble point location depths before and after closing the well head wing valve.

Several assumptions were made to conduct the calculations such as: assumed one-dimensional flow in the conduit, assumed uniform cross-sectional area of the pipe, the phase’s properties varied with depth, the frictional factor varied along the conduit, and the effect of the liquid compressibility was neglected.

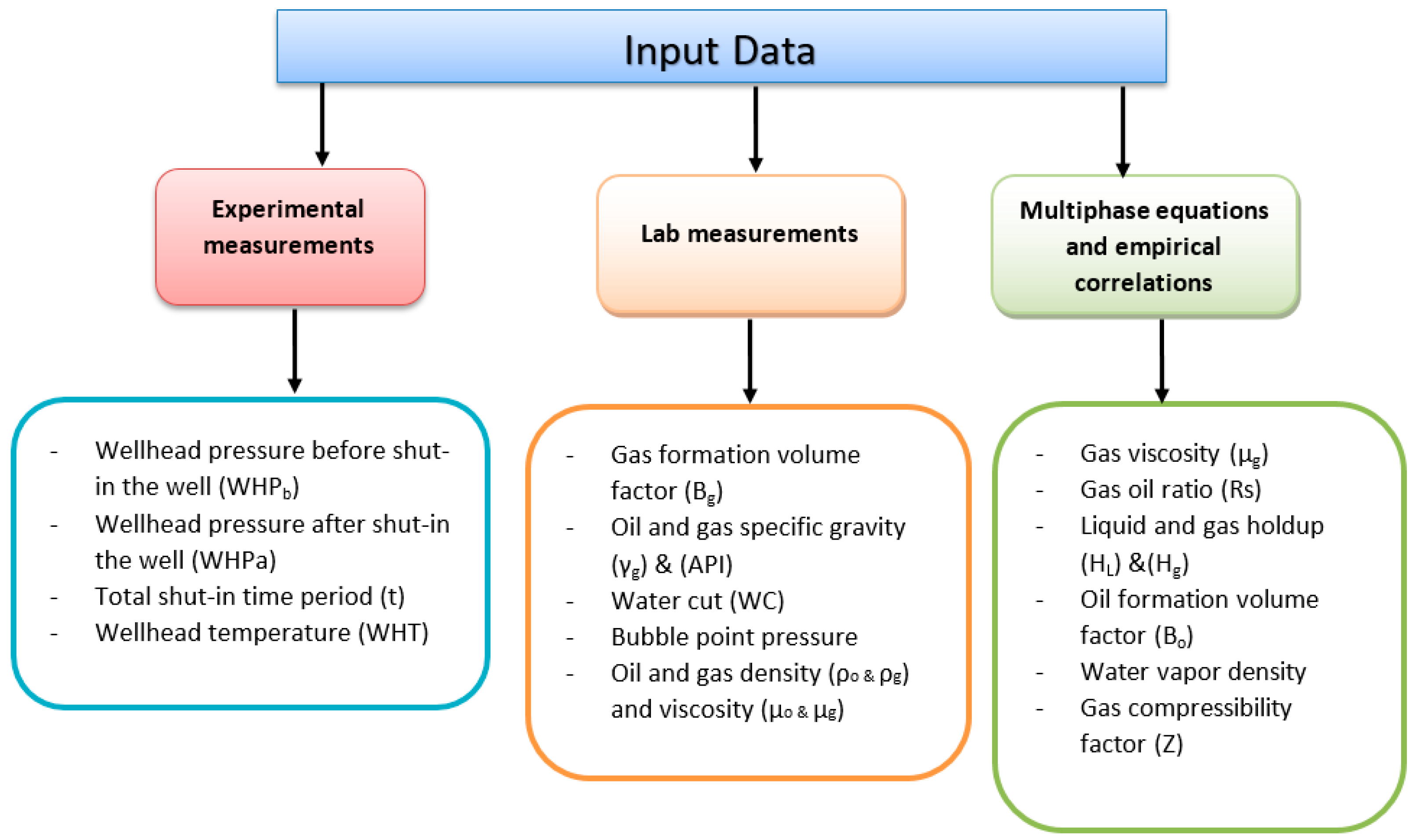

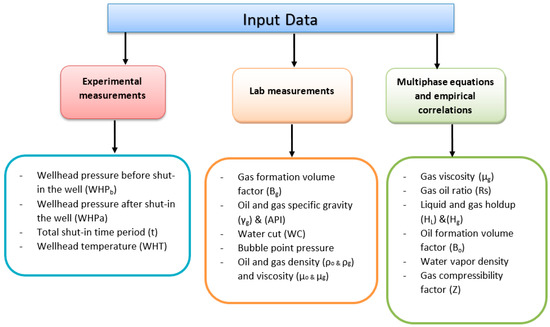

2.1. Required Input Data

The input data required were the well parameters data and physical properties data of the fluid, as seen in Table 1. To carry out this study, 48 ESP oil wells were selected where the wells were producing from four different reservoirs using same production pipe diameter. Also, these reservoirs had almost the same reservoir fluid properties: the bubble point pressure ranged from 924 psi to 1124 psi, the American Petroleum Institute (API) oil gravity ranged from 36 to 37 @ 60 °F, the oil viscosity ranged from 0.784 cP to 1.0119 cP, and the reservoir temperature ranged from 157 °F to 186 °F. Furthermore, Figure 3 classifies the input data required.

Table 1.

Well and physical properties of the fluid.

Figure 3.

Input data required.

2.2. Computational Algorithm

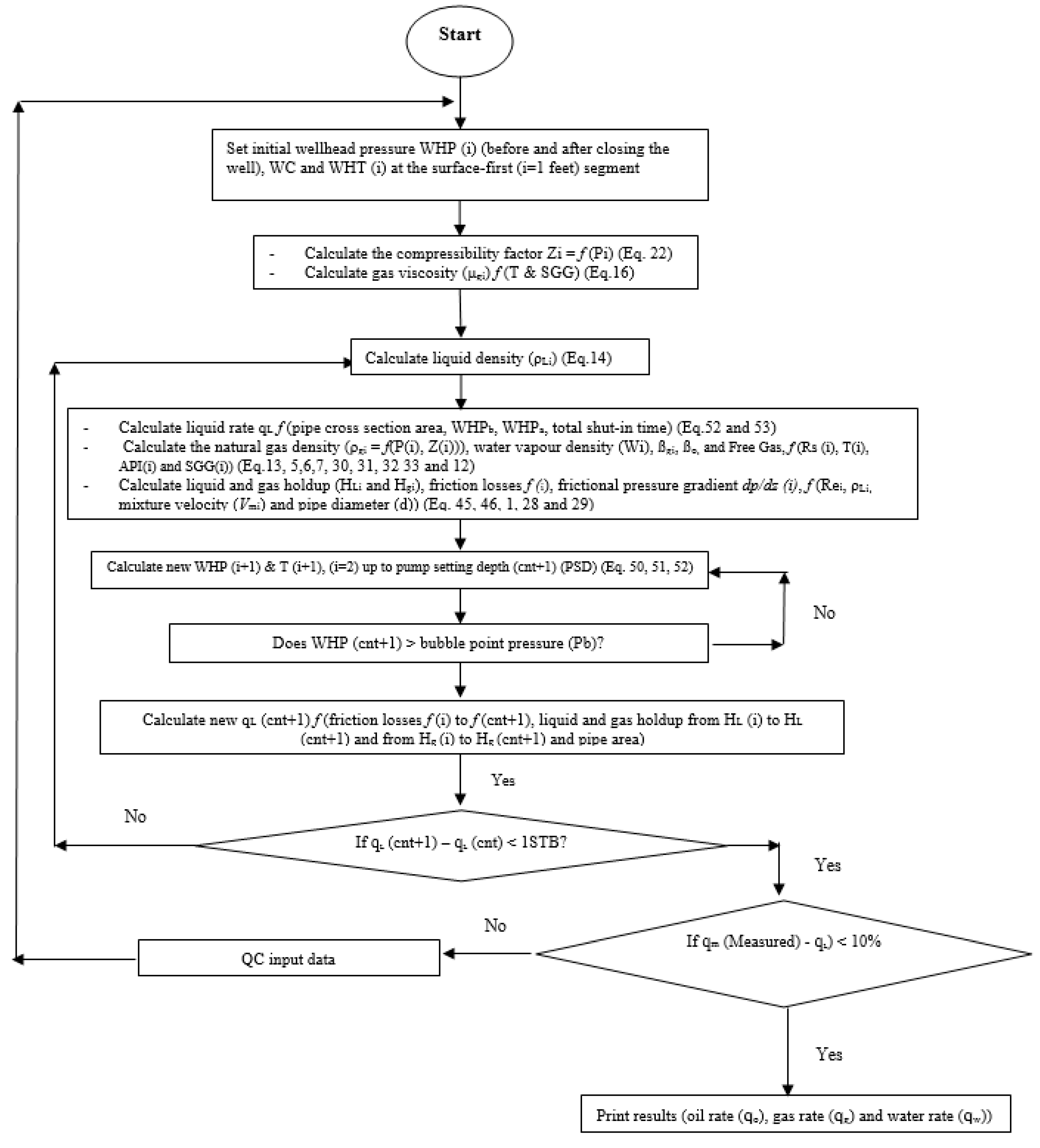

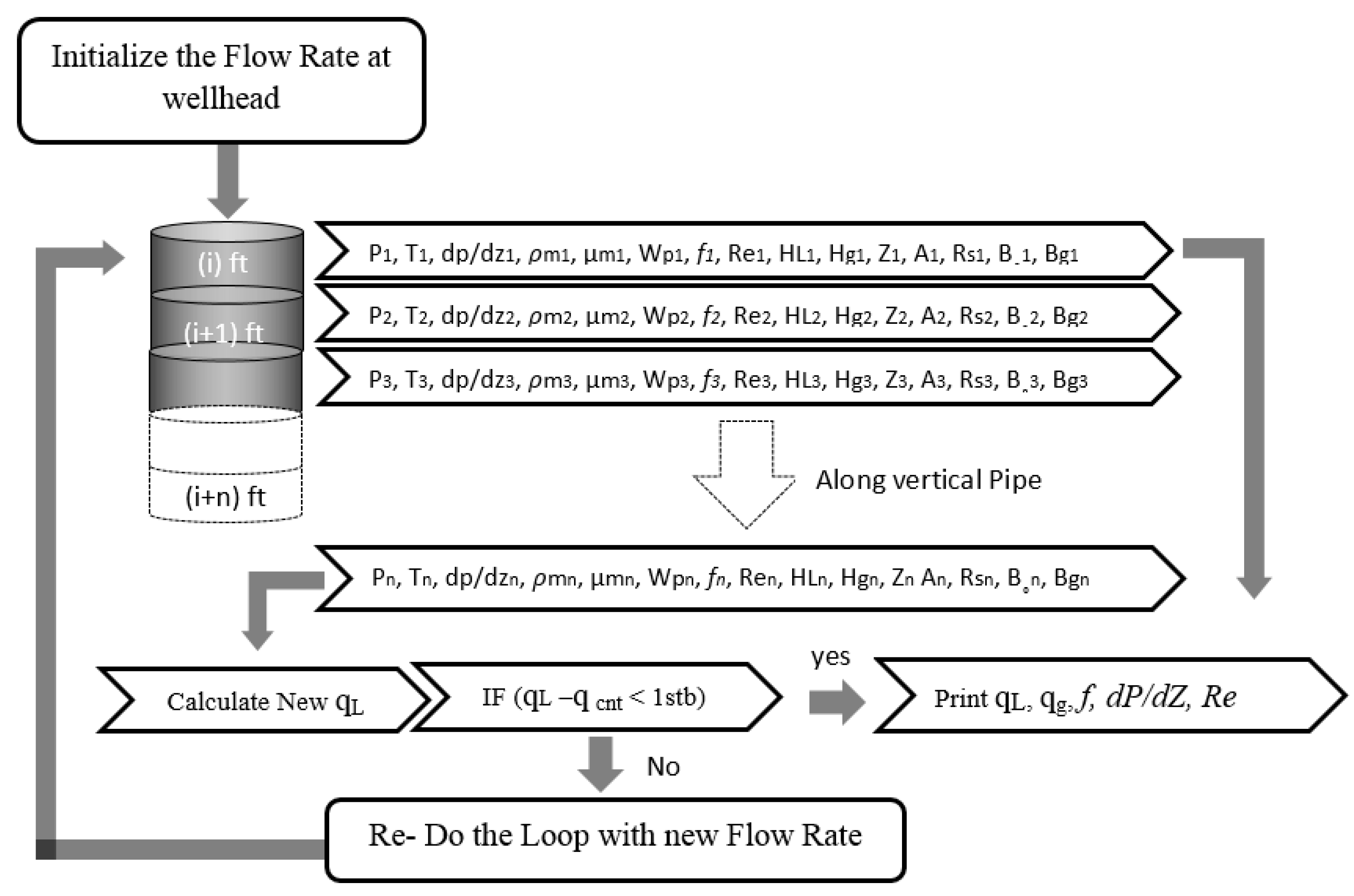

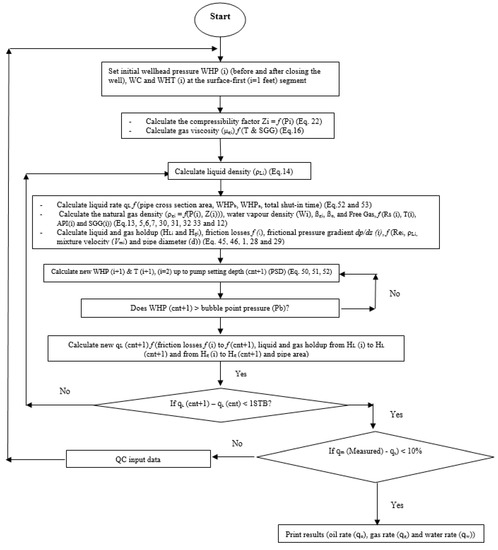

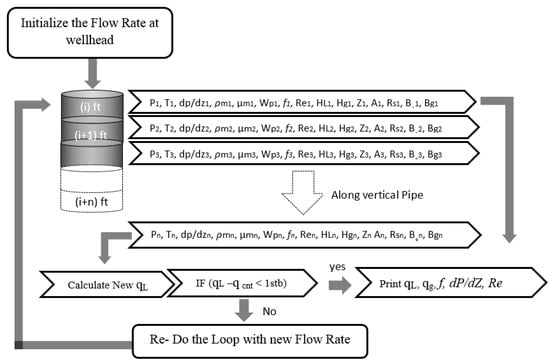

Figure 4 shows the algorithm steps to evaluate the mathematical model. The algorithm classified all the main stages and sub-steps in the model. In this process, the calculations were performed to obtain the bubble point pressure location depth before and after the wellhead wing valve shut-in. The fluid flowing pressure gradient could be calculated anywhere inside the pipe. All the variables needed to be identified to correctly evaluate the physics interactions between all the fluid parameters using the suitable multi-physics equations and empirical correlations.

Figure 4.

Flowchart of the new mathematical model algorithm.

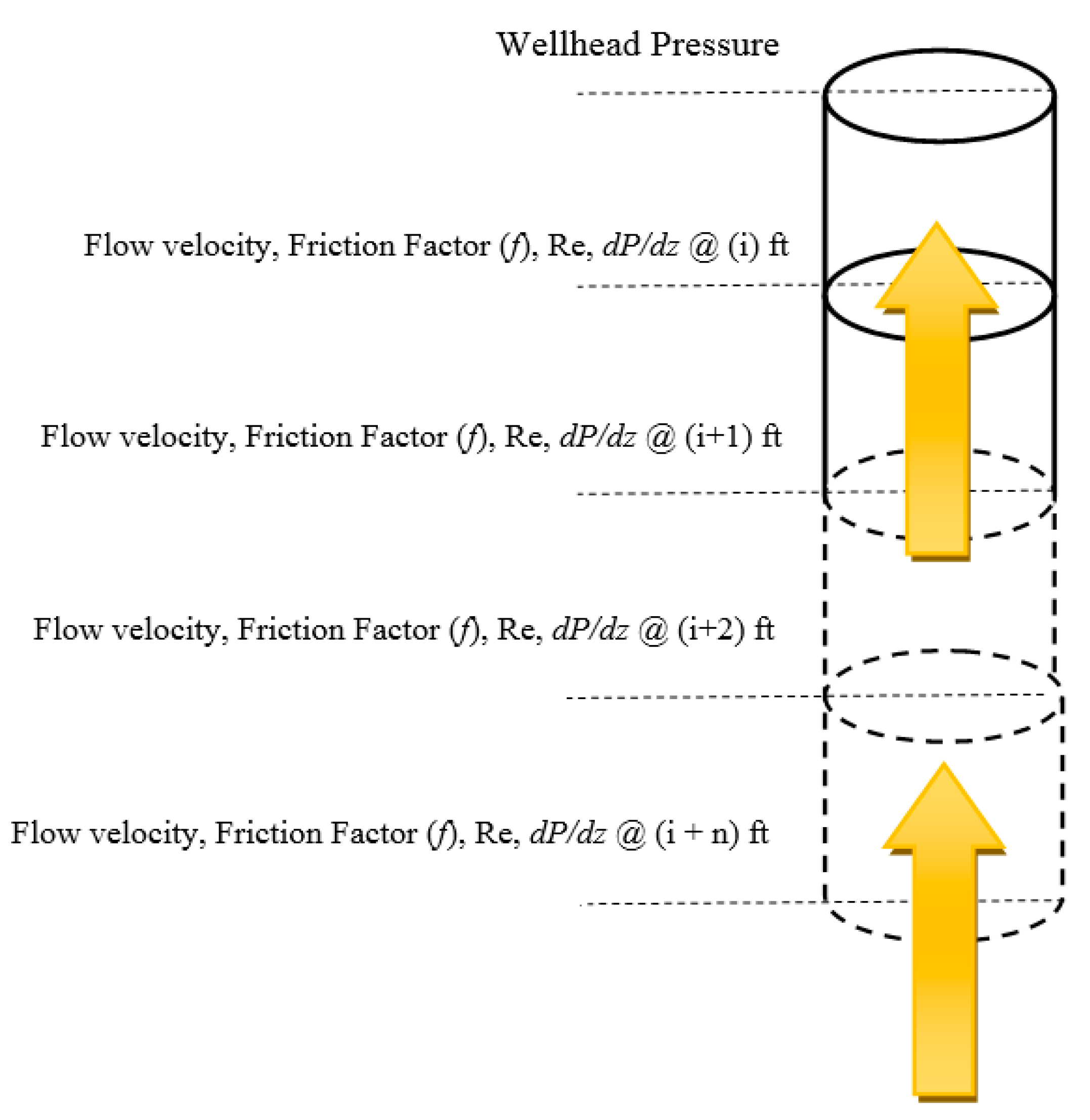

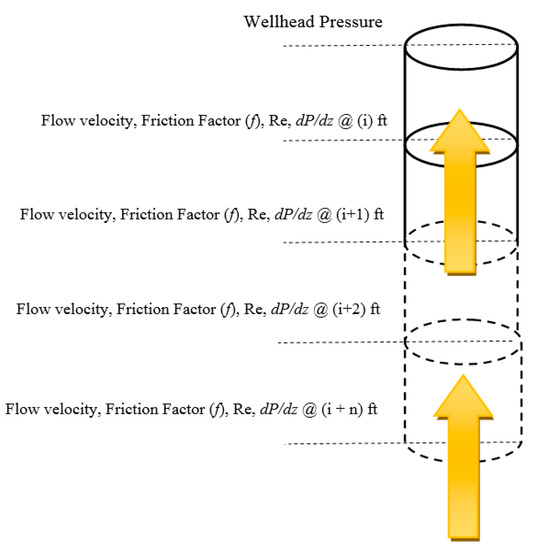

The calculation starts at the surface wellhead and then down to the location depth of the bubble point pressure as a function of temperature and pressure variations with depth. To consider the fact that flow regimes vary depending on the in situ flow rates of gas/liquid, the model calculates, at each foot along the vertical pipe, the variations of supercritical velocities, viscosities, and densities for both phases (liquid and gas). The in situ flow rate can also be calculated by the mathematical model at any flow regime at any depth. As shown in Figure 5 and Figure 6, the calculation iteration can stop at any depth (i, ..., i + n) using all the equations (from Equation (1) to Equation (56)), where there is a different flow regime along the vertical pipe.

Figure 5.

Stages of computational methodology.

Figure 6.

Flow diagram of new computational method procedure.

The following are the physics equations and the correlations applied to determine each independent variable at every single foot.

Total pressure losses expressed as

Hydrostatic head is expressed as

Darcy–Weisbach equation [23] was used to calculate the frictional pressure loss

Reynolds number is given by

Three different friction factor correlations were applied to evaluate the impact of the friction on the computation of the fluid flow rate. The first correlation is the Blasius empirical correlation for turbulent flow [24].

The second friction correlation applied is Darcy correlation [23]

The third friction factor correlation applied is from Colebrook [25]

for Re <≈ 2300 and Re >≈ 4000.

The gas density is expressed as

The density at wellbore condition, is given by

The oil density is expressed as

where

Liquid density is given by

Mixture density is expressed as

The gas viscosity is determined by the following equation [26]:

where

Mixture viscosity is given by

Beggs and Brill equation [27] was applied to estimate the gas compressibility factor (Z)

Using Standing and Katz equations [28] to obtain the pseudo critical temperature and pressure of the gas mixture

and

Superficial gas velocity is expressed as

Superficial liquid velocity is expressed as

The water vapor density using the Sloan correlation [29] is expressed as

where the values of constants c1 to c6 are shown in Table 2.

Table 2.

Constants c1 to c6.

The gas formation volume factor is expressed as

Using the Vasquez and Beggs equation [30] to obtain the oil formation volume factor

and oil gas ratio

where the coefficients C1, C2 and C3 are given by

| Coefficient | °API ≤ 30 | °API ≥ 30 |

| C1 | 27.64 | 56.060 |

| C2 | 1.0937 | 1.187 |

| C3 | 11.172 | 10.393 |

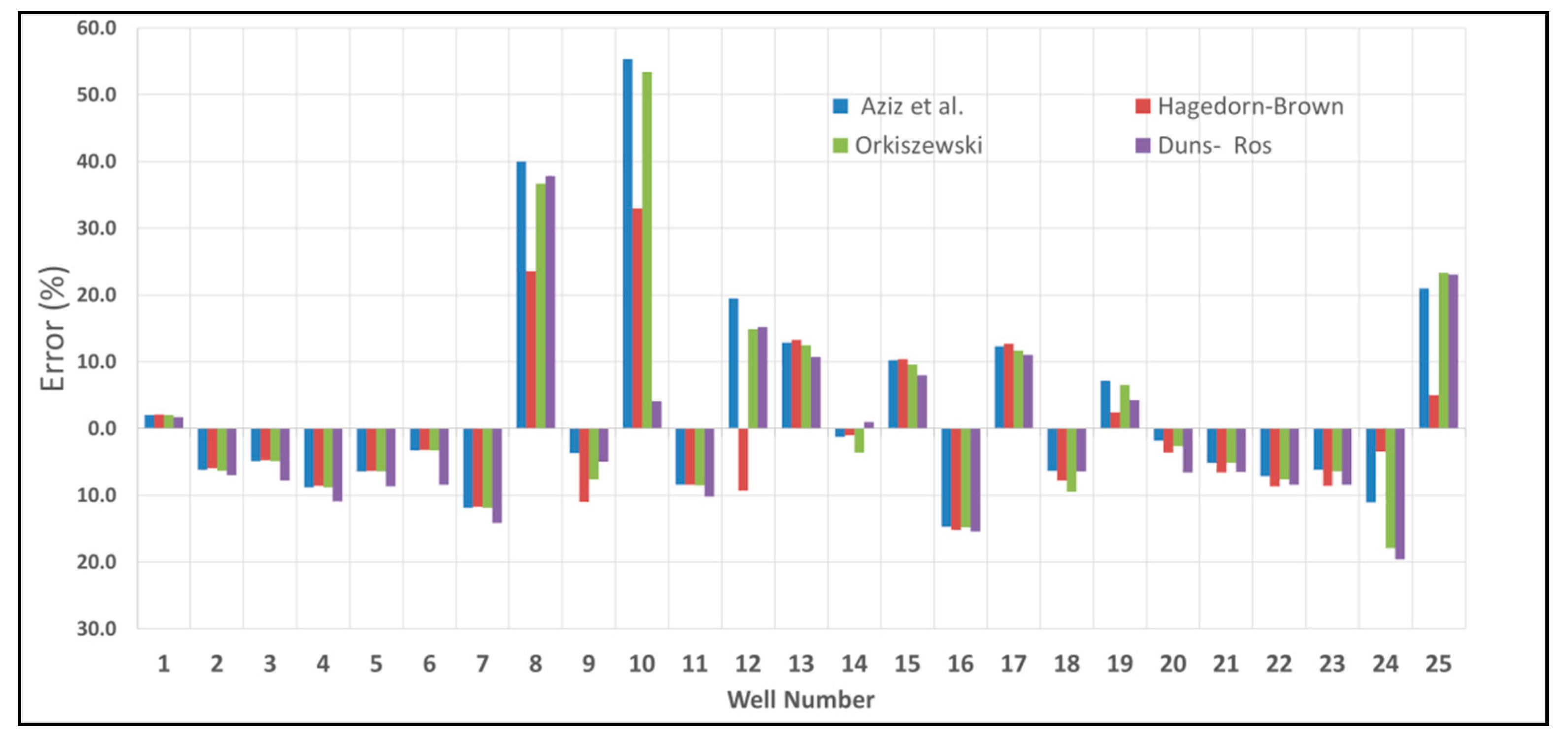

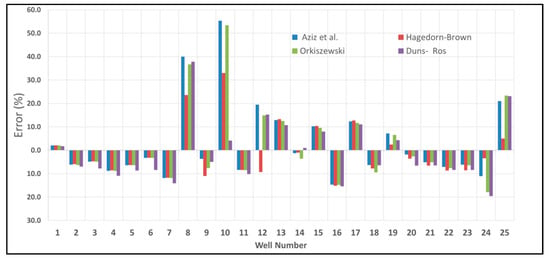

To make sure that the obtained liquid and gas hold-up is accurate, some popular correlations, used by the industry and are included in almost every commercial software package, were considered to predict the liquid and gas hold-up inside each well. The correlations considered in this study are the ones developed by Hagedorn and Brown [31], Duns and Ros [32], Orkiszewski [33], and Aziz et al. [34]. The statistical results for the various prediction methods when applied to all 25 well tests are shown in Figure 7 and Table 3. These results indicate that the Hagedorn and Brown correlation seems to predict liquid and gas hold-up better than the other correlations selected in this study. However, the overall results show minor differences between the different correlations. This is because each correlation was developed based on certain assumption and for a particular range of data.

Figure 7.

Hold-up prediction accuracy using some popular correlations.

Table 3.

Statistical results for the various prediction correlations.

Using the Hagedorn-Brown empirical correlation [31] to obtain liquid and gas hold-up (HL and Hg)

where

where

where

The liquid hold-up is

and

The liquid flow rate is expressed as

the cross section of the conduit is given by

as

then

and

then

The flow rates for gas, oil, and water are expressed as

3. Results and Discussion

The experiments were run on 48 ESP oil wells from four different reservoirs. For each friction factor correlation, the measured oil flow rate values for each oil well were compared against the predicted flow rate values. It should be noted that as the points near the dotted straight line drawn at 45° (i.e., ) in the graph, the more accurate the prediction was. The results show that the pressure drop value was the significant parameter that had the main influence on the fluid flow rate computation. Indeed, any errors in pressure drop values would lead to high uncertainty errors of fluid flow rate prediction. For this reason, the properties of independent variables needed to be considered. Likewise, the interactions between each phase needed to be taken into account along with mixture properties and in situ volume fractions of oil and gas inside the conduit. Each multiphase flow correlation found the friction factor differently. Typically, each friction correlation made its own assumptions and modifications to make them useable to multiphase conditions. The prediction of frictional pressure drop in two-phase flow was usually complicated due to pressure and temperature variations along the flow path. When estimating the friction factor, there were a number of methods for calculating the Reynolds number depending on how much of the two-phase flow mixture was defined. Therefore, the oil and water were considered as a single liquid phase while the gas was considered as a separate phase.

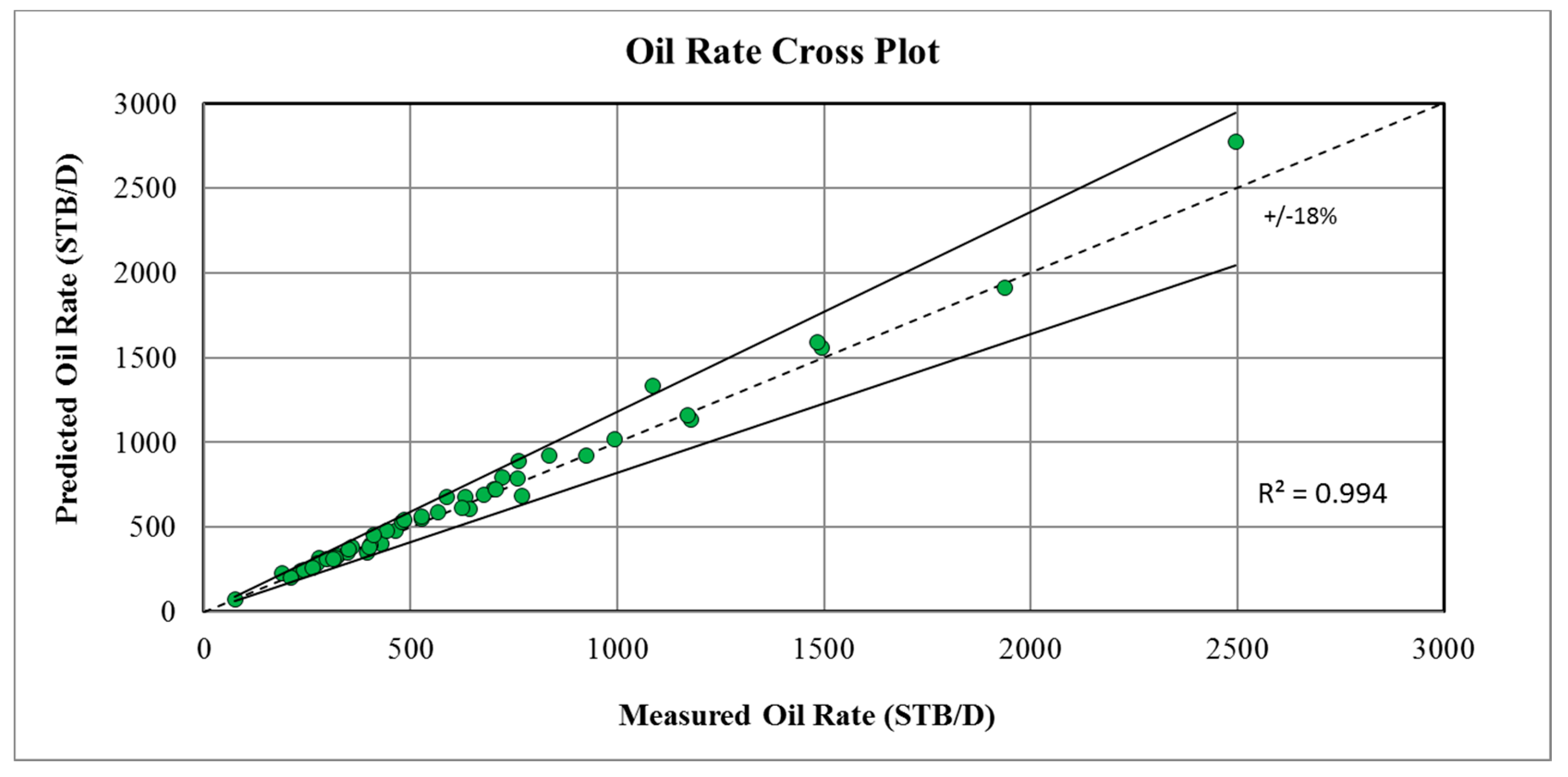

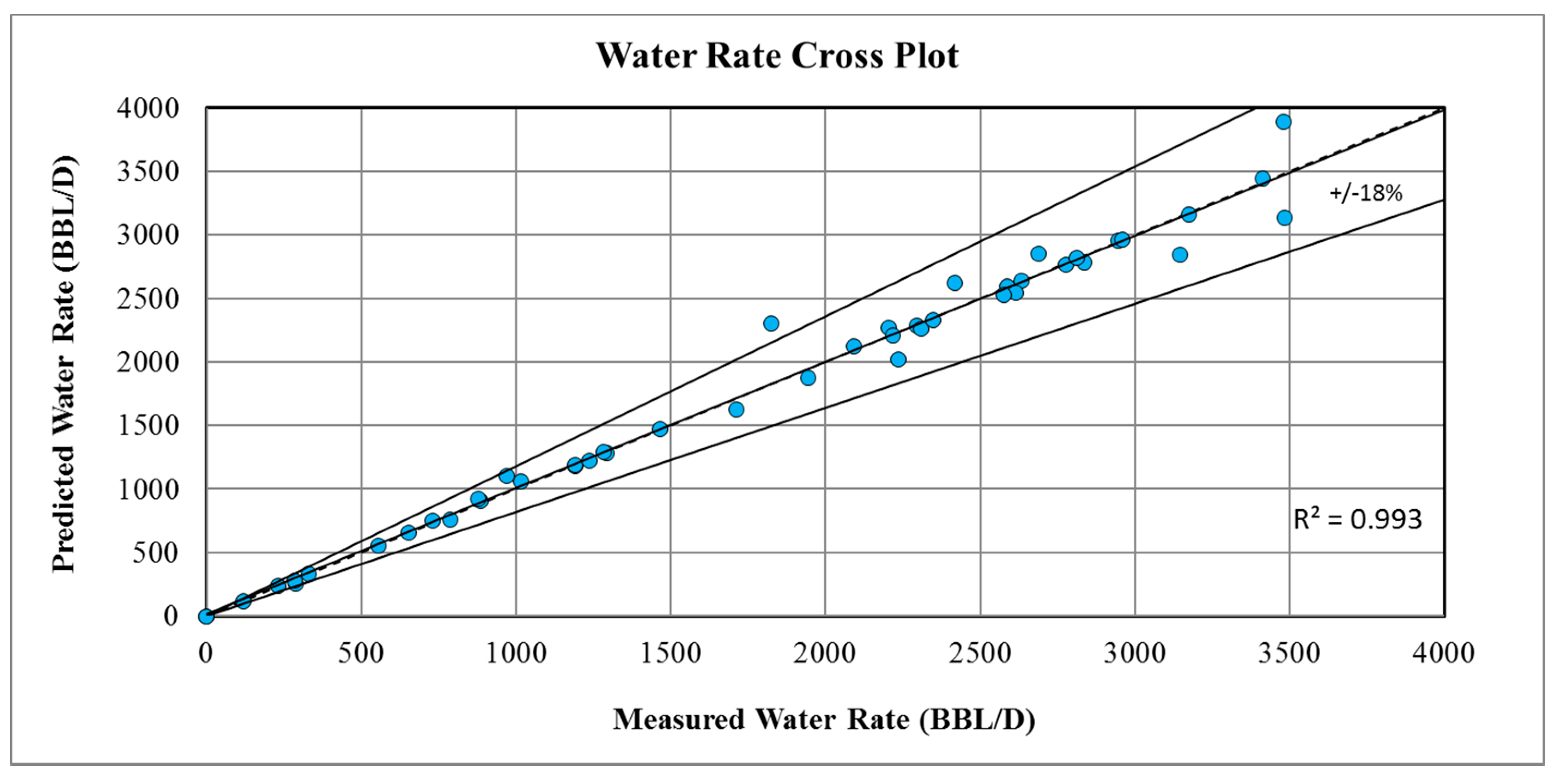

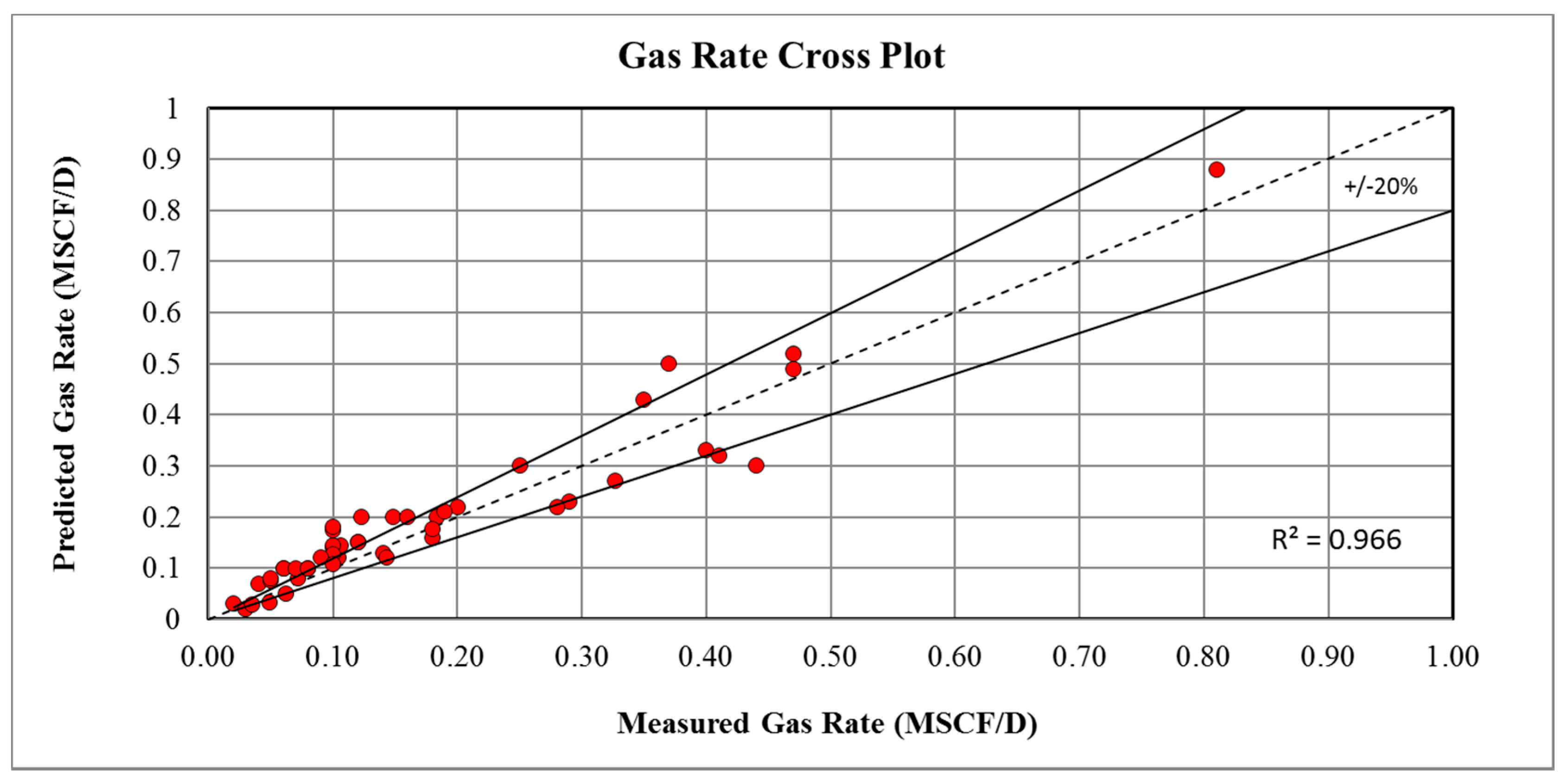

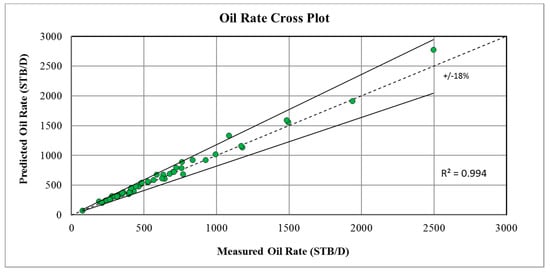

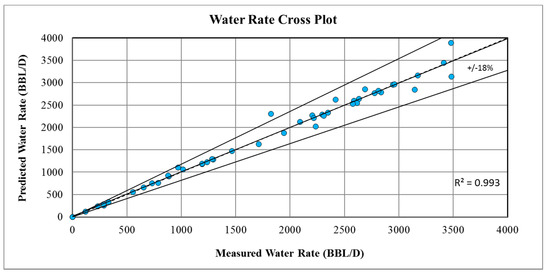

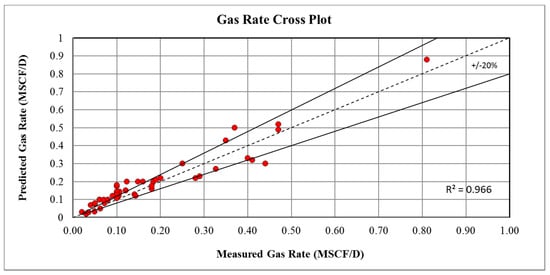

By using the Blasius friction factor correlation, the differences between the predicted flow rate and the measured flow rate were very small. R-squared (R2) explained exactly how the data points were fitted close to the regression line (). Figure 8, Figure 9 and Figure 10 displayed the regression model for oil, water, and gas flow rate measurements. It can be seen that the plots show that most data points lie on or close to the unit slope line (e.g., best fit line), indicating that the predicted and actual values were in excellent agreement and illustrated an accurate flow rate prediction for oil, water, and gas with good correlating coefficients of 0.994, 0.993, and 0.966, respectively. This means that 99.4%, 99.3%, and 96.6% of the variance in the oil, water, and gas data, respectively, was explained by the line and 0.6%, 0.7%, and 3.4% of the variance was due to unexplained effects. The figures show that the predicted wells flow rates fell within the accepted uncertainty when compared with the measured flow rates.

Figure 8.

Predicted vs measured oil rate using the Blasius correlation.

Figure 9.

Predicted vs measured water rate using the Blasius correlation.

Figure 10.

Predicted vs measured gas rate using the Blasius correlation.

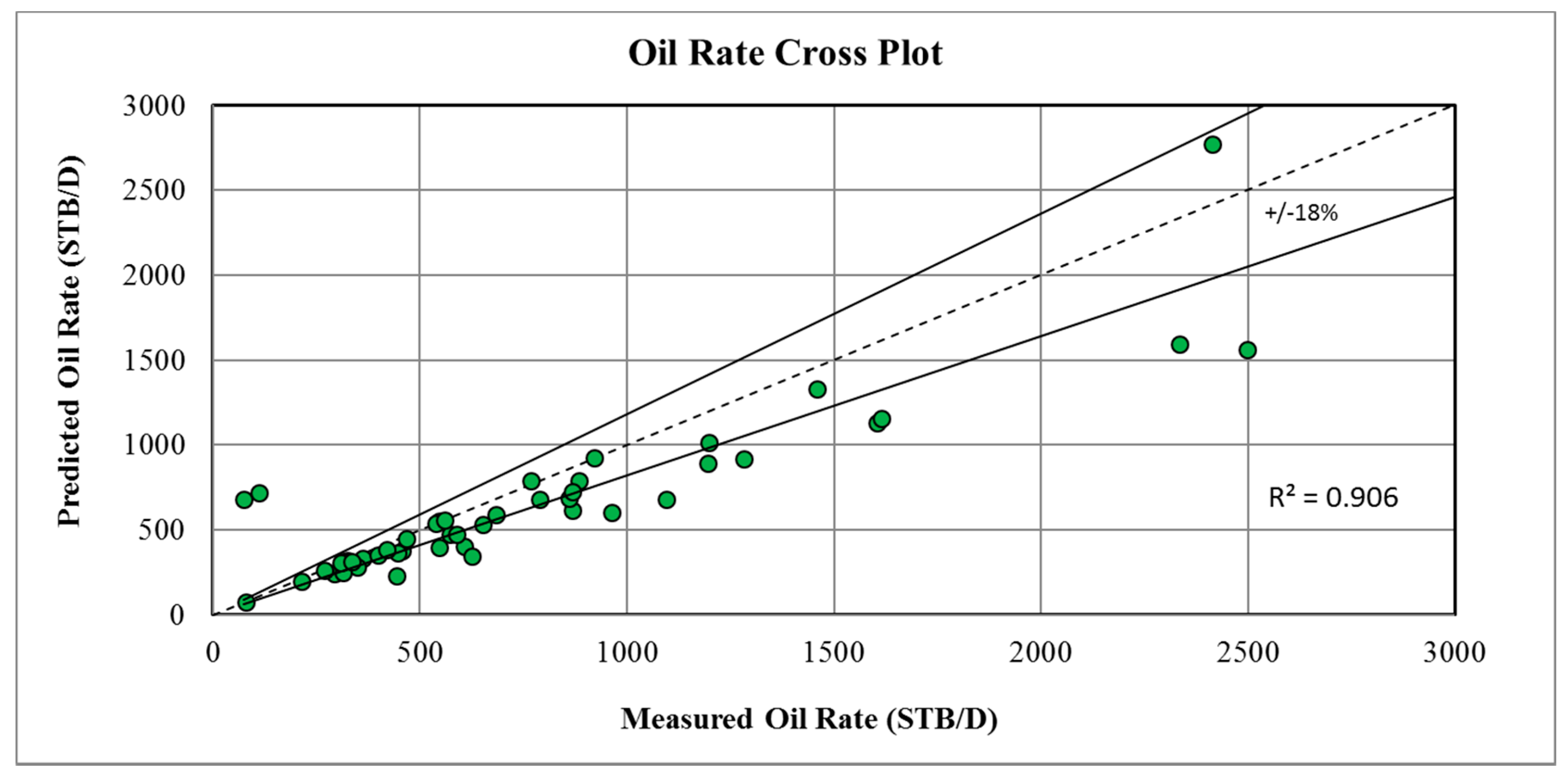

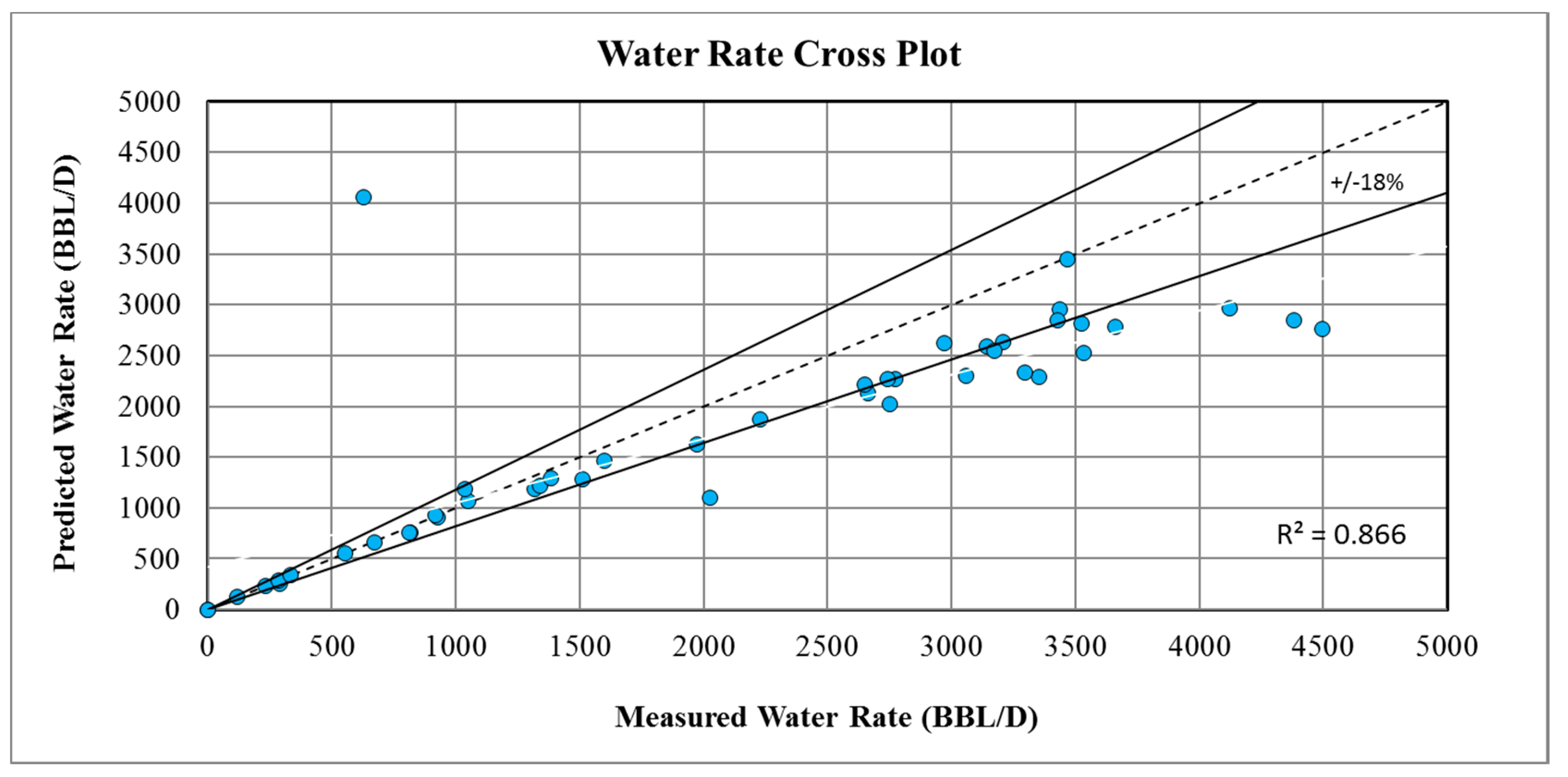

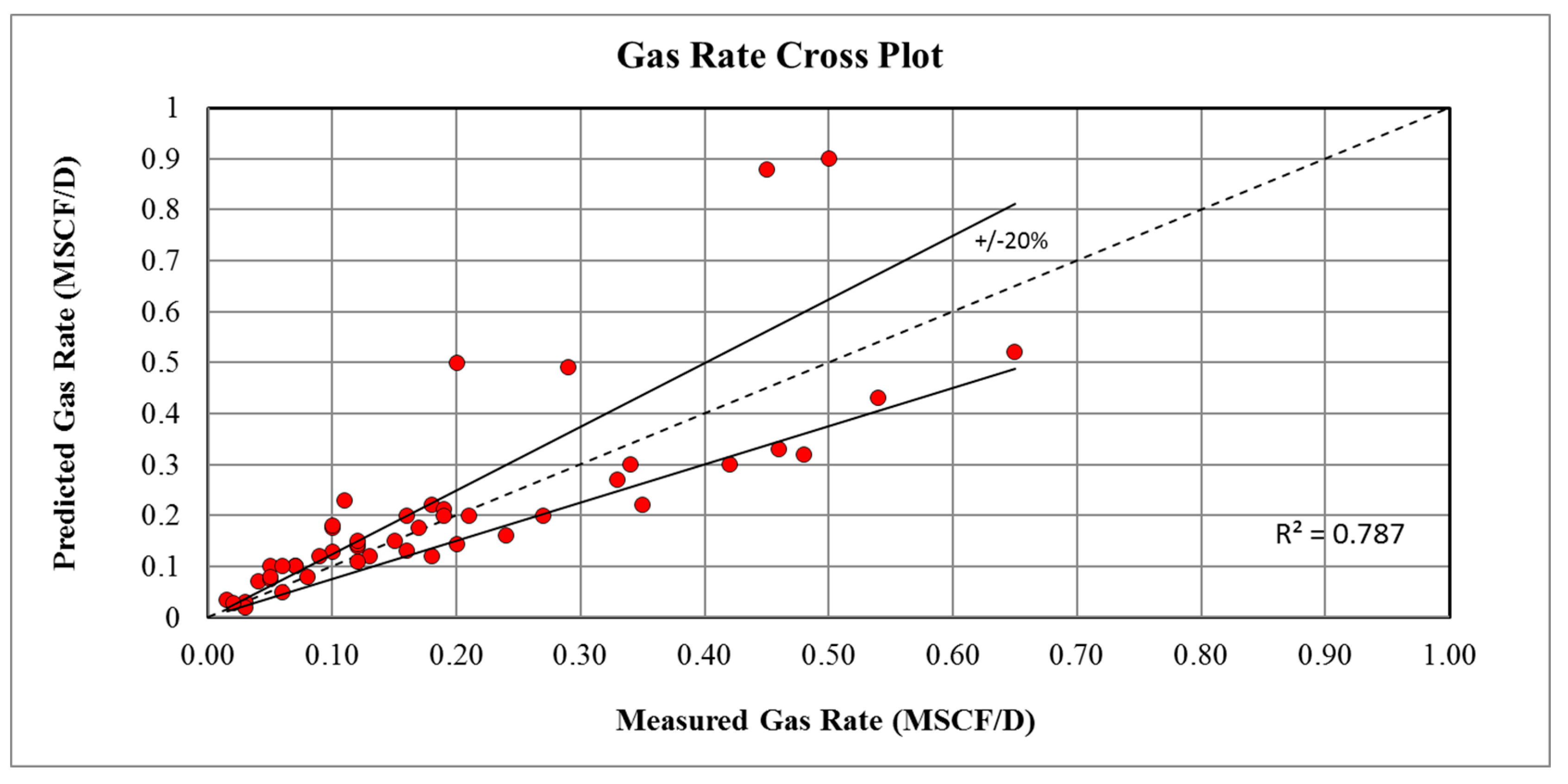

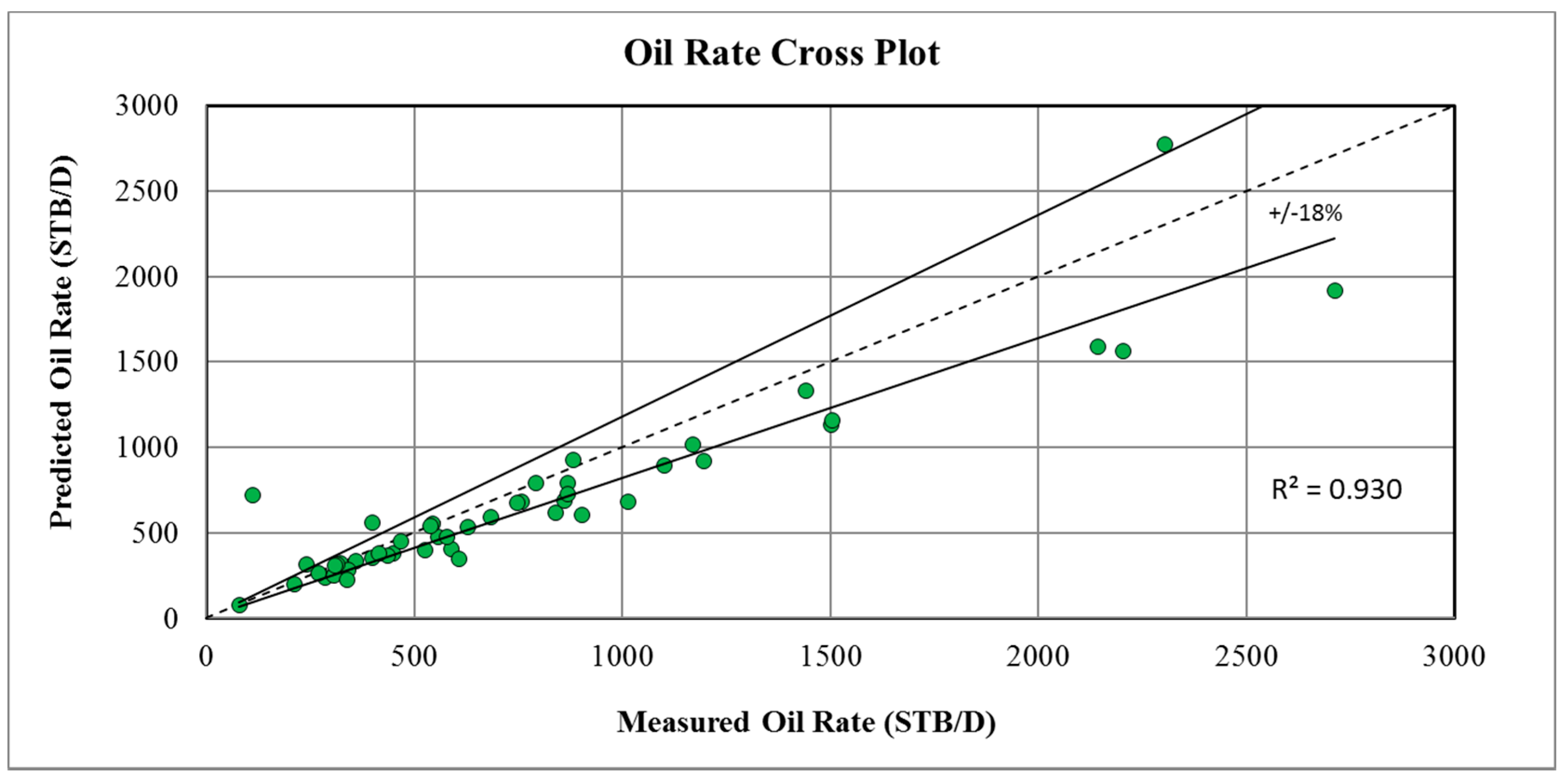

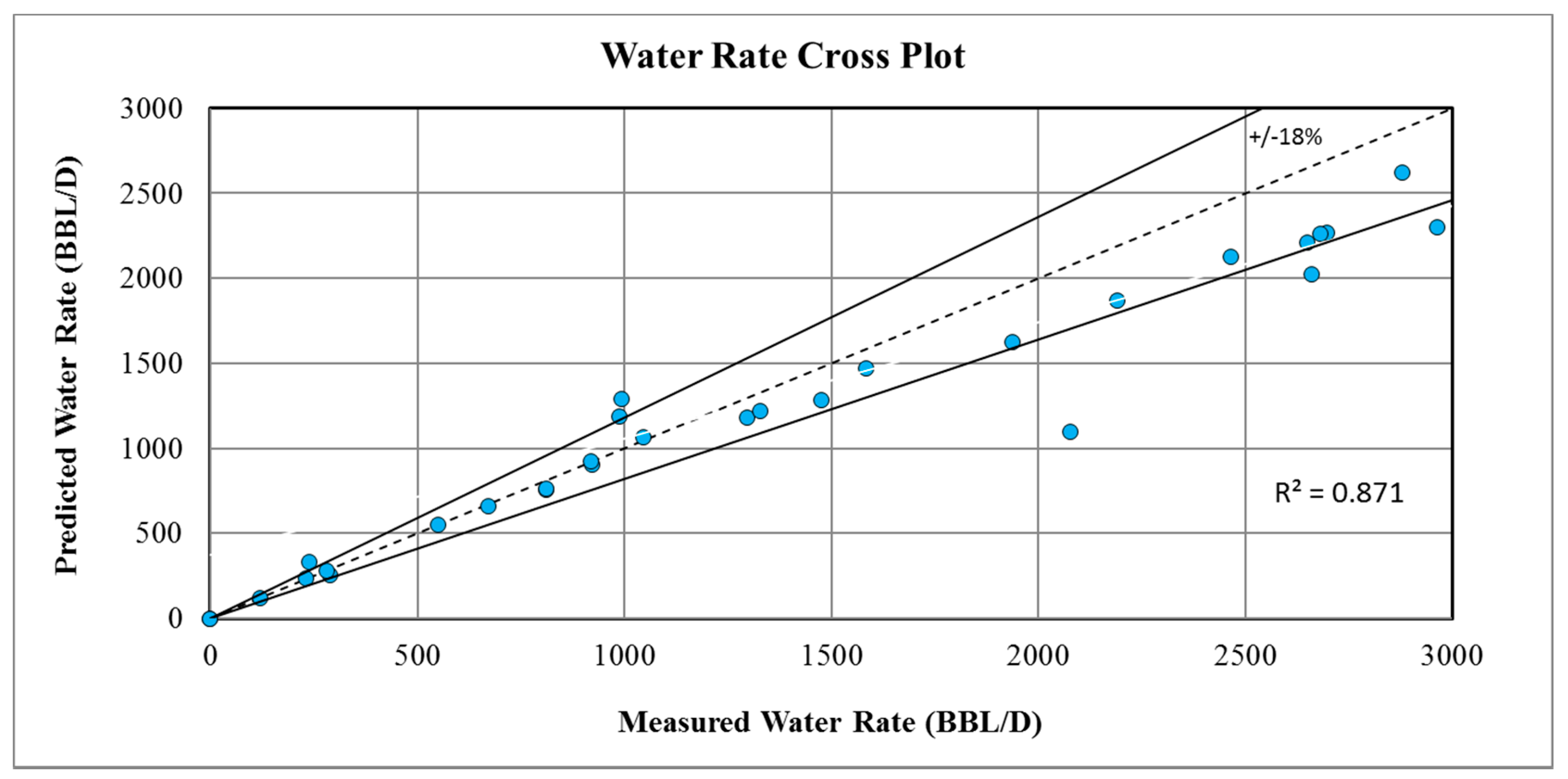

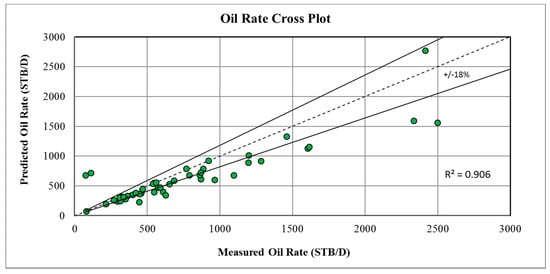

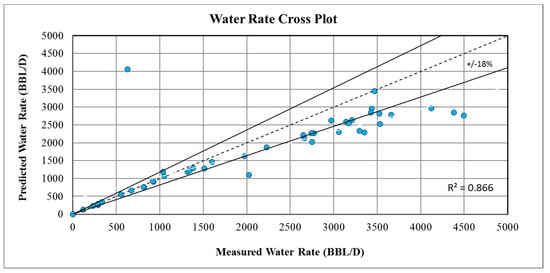

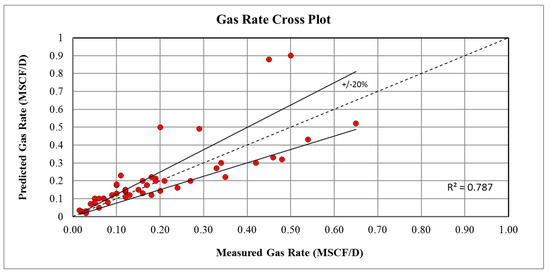

By using the Darcy friction factor correlation, the differences between the predicted fluid flow rates with the measured flow rates were larger than those of the Blasius correlation. Figure 11, Figure 12 and Figure 13 displayed the regression model for oil, water, and gas flow rate measurements. From these figures, one can easily recognize that the data plotted is under-estimated for oil and water flow rates and scattered around the best fit line for gas flow rates. This discrepancy was more evident for high flow rates where the correlation coefficients for oil, water, and gas flow rates accounted for 90.6%, 86.6%, and 78.7% of the variance, respectively. The figures show that the predicted well flow rates did not fall within the accepted uncertainty when compared with the measured flow rates.

Figure 11.

Predicted vs measured oil rate using the Darcy correlation.

Figure 12.

Predicted vs measured water rate using the Darcy correlation.

Figure 13.

Predicted vs measured gas rate using the Darcy correlation.

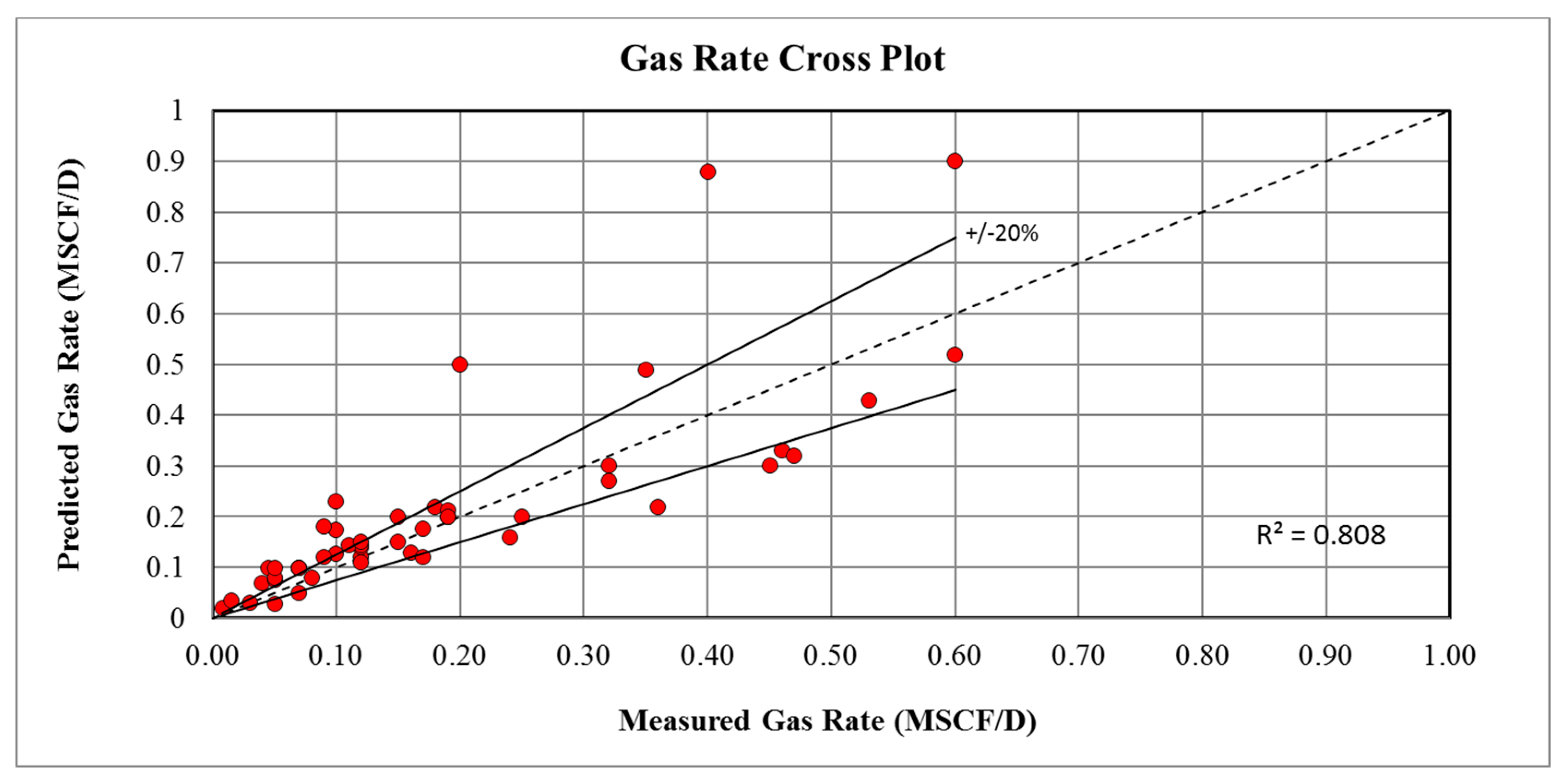

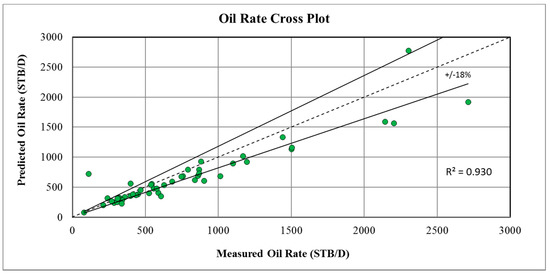

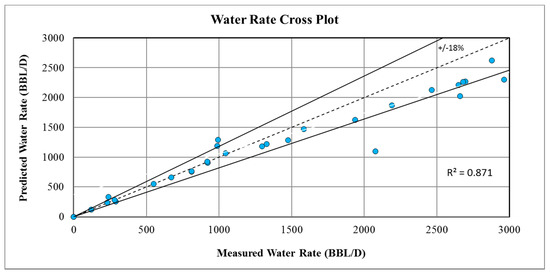

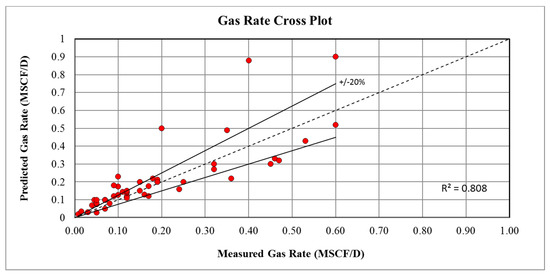

By using the Colebrook friction factor correlation, the differences between the predicted fluid flow rates with the measured flow rates were slightly better than the Darcy correlation performance, but still less than the Blasius correlation performance. Figure 14, Figure 15 and Figure 16 displays the data fitting for oil, water, and gas flow rate measurements. Similar to the performance of the Darcy correlation, one can easily recognize that the data plotted is under-estimated for oil and water flow rates and scattered around the best fit line for gas flow rates. This discrepancy was more evident for high flow rates where the correlation coefficients for oil, water, and gas flow rates accounted for 93.0%, 87.1%, and 80.8% of the variance, respectively. The figures showed that the predicted wells flow rates did not fall within the accepted uncertainty when compared with the measured flow rates.

Figure 14.

Predicted vs measured oil rate using the Colebrook correlation.

Figure 15.

Predicted vs measured water rate using the Colebrook correlation.

Figure 16.

Predicted vs measured gas rate using the Colebrook correlation.

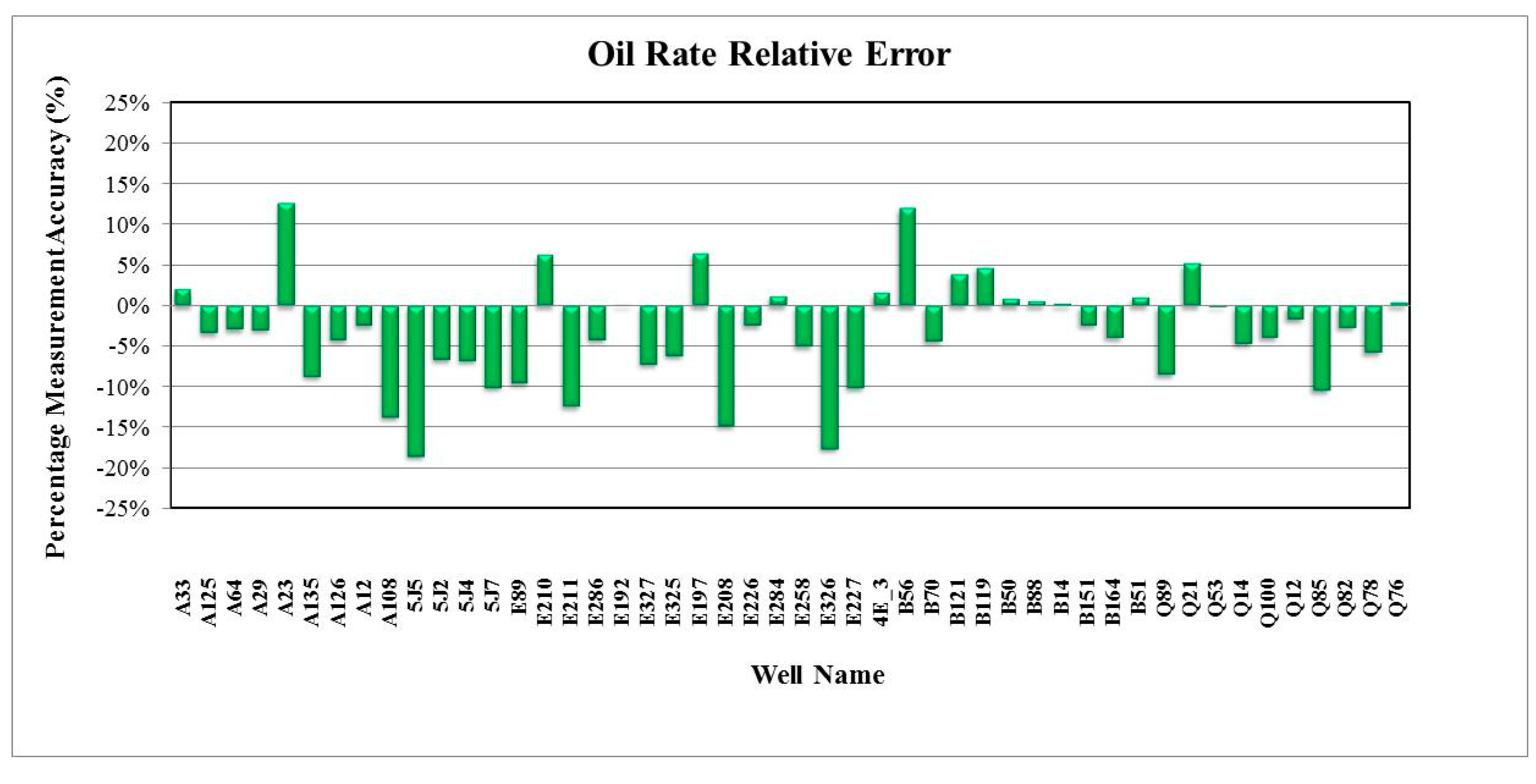

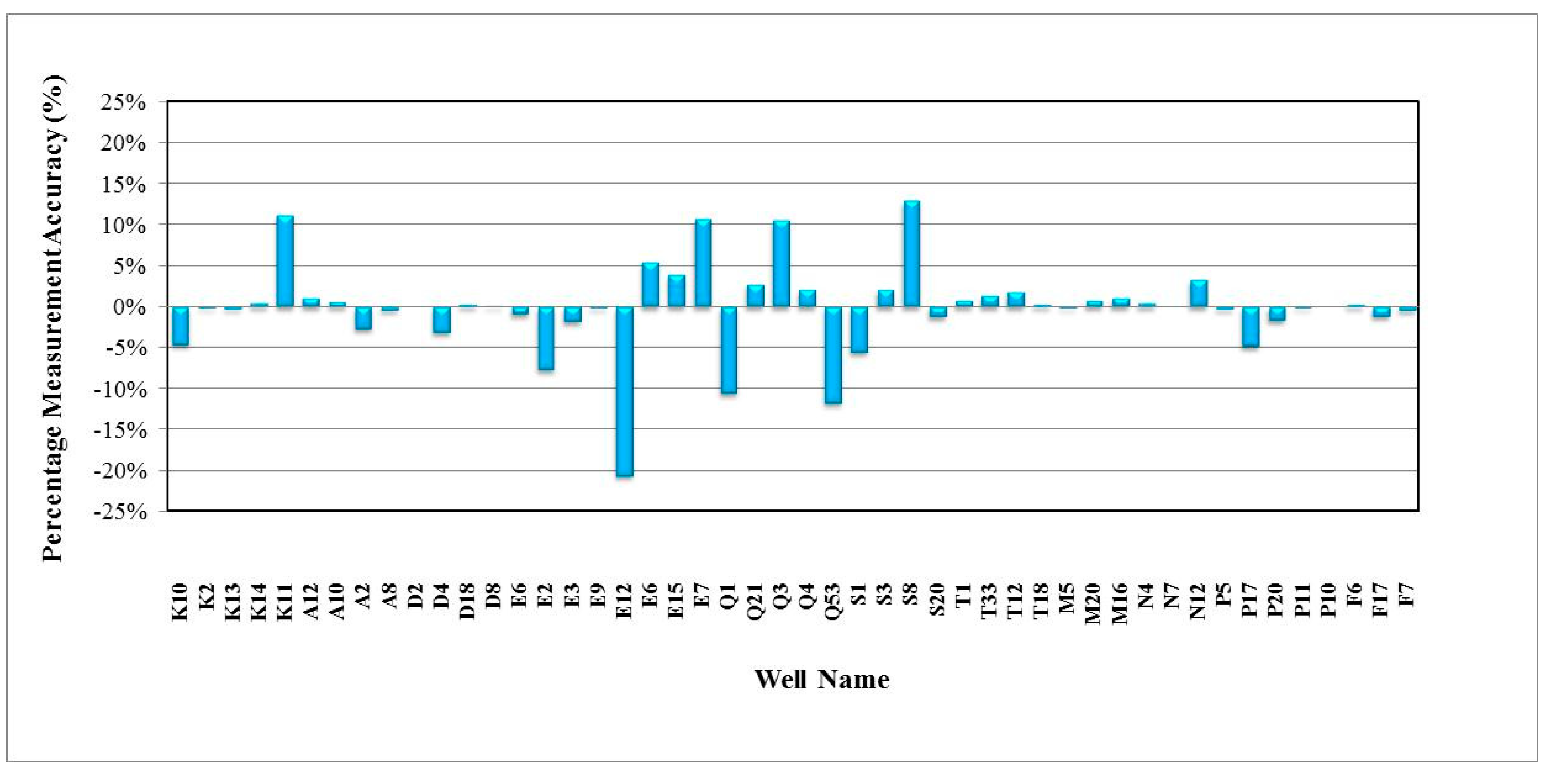

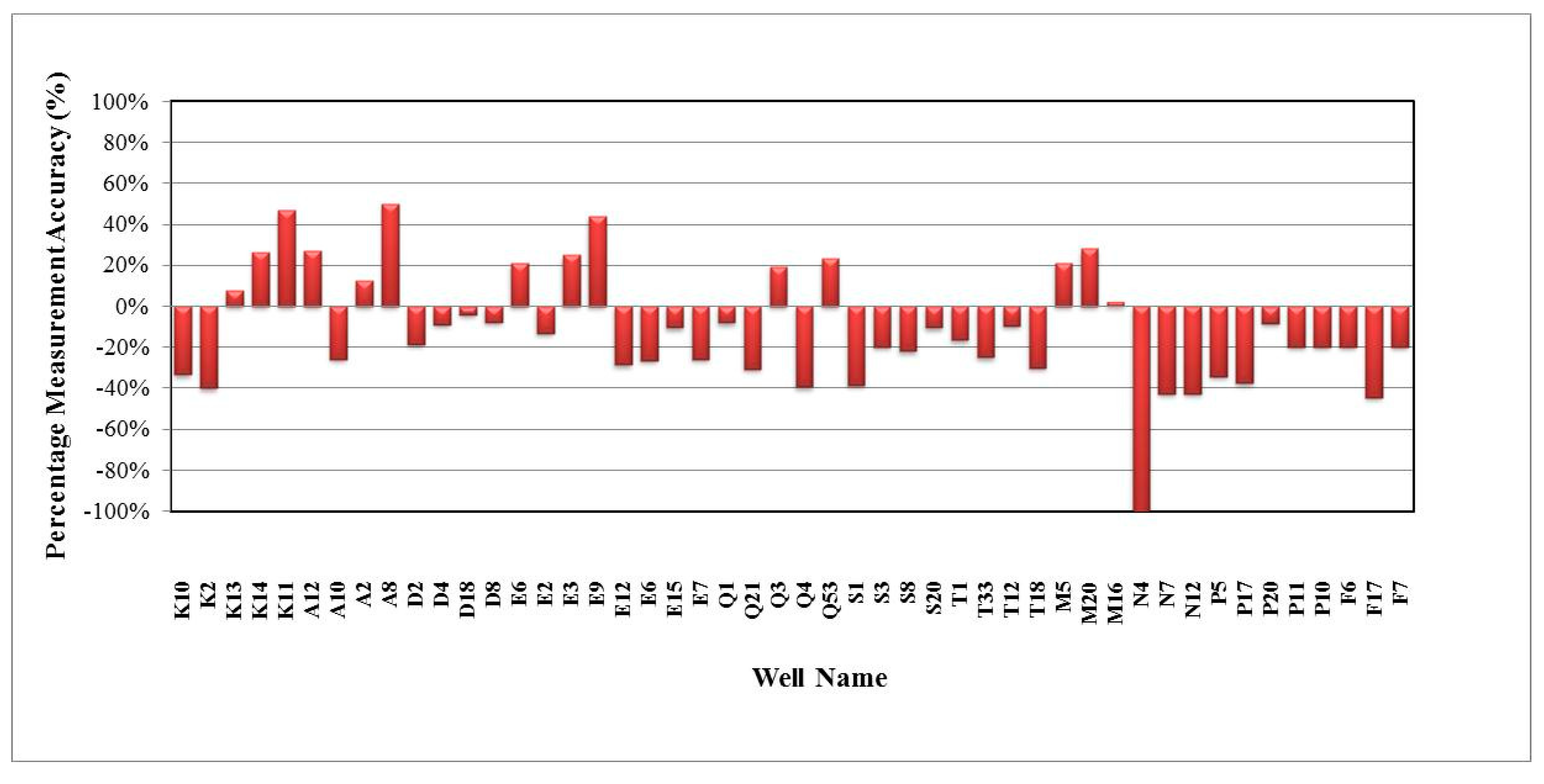

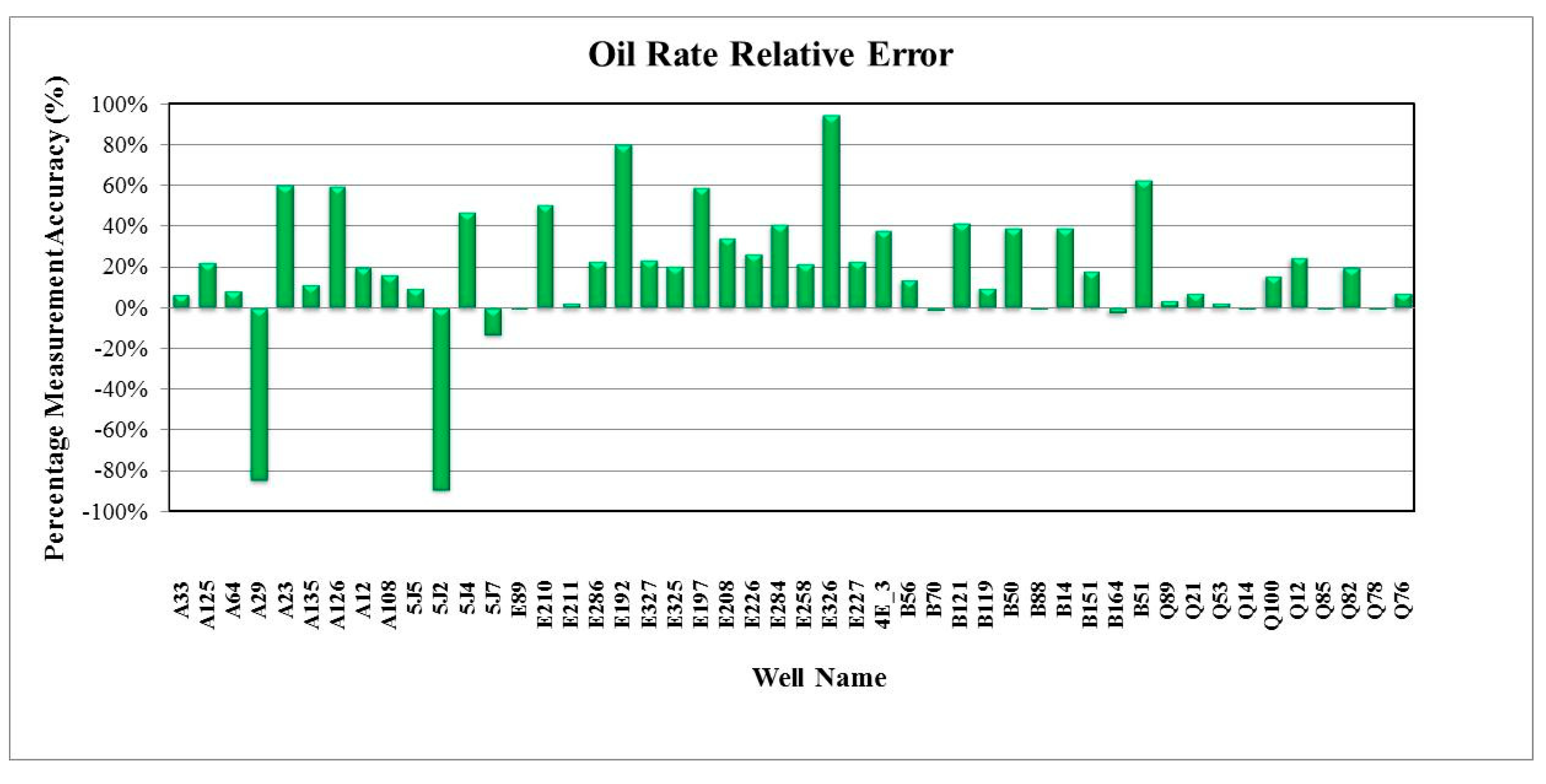

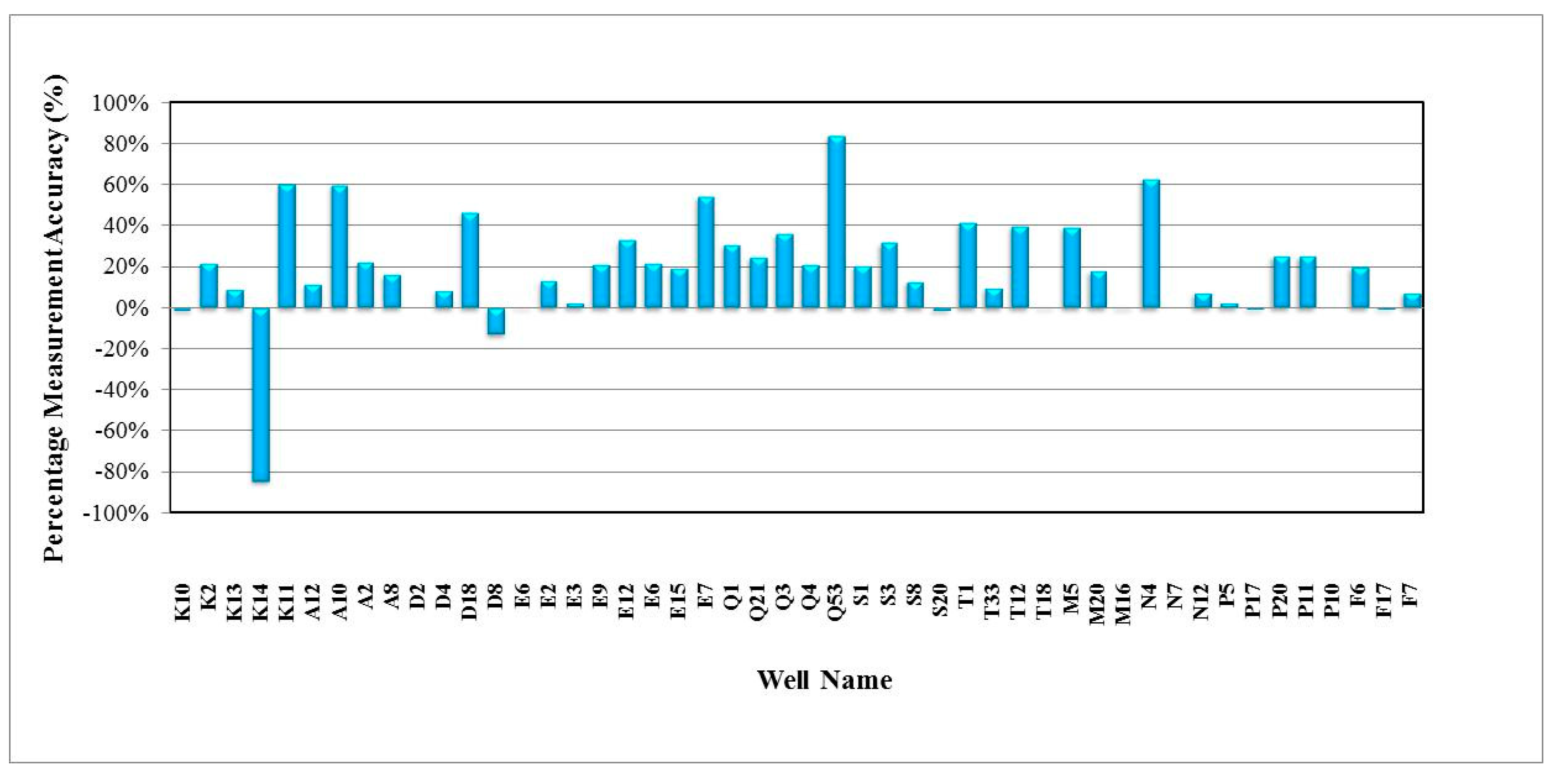

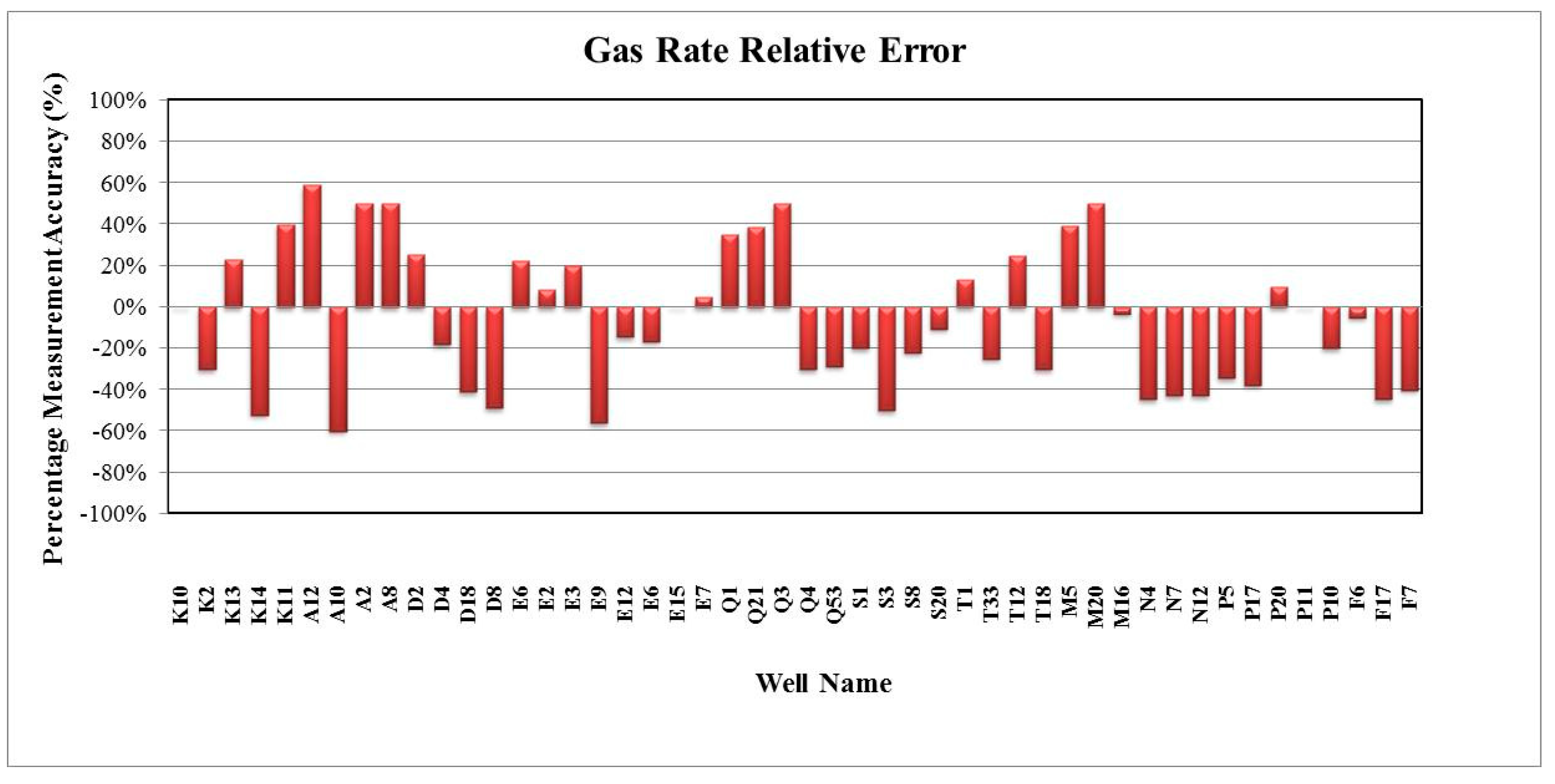

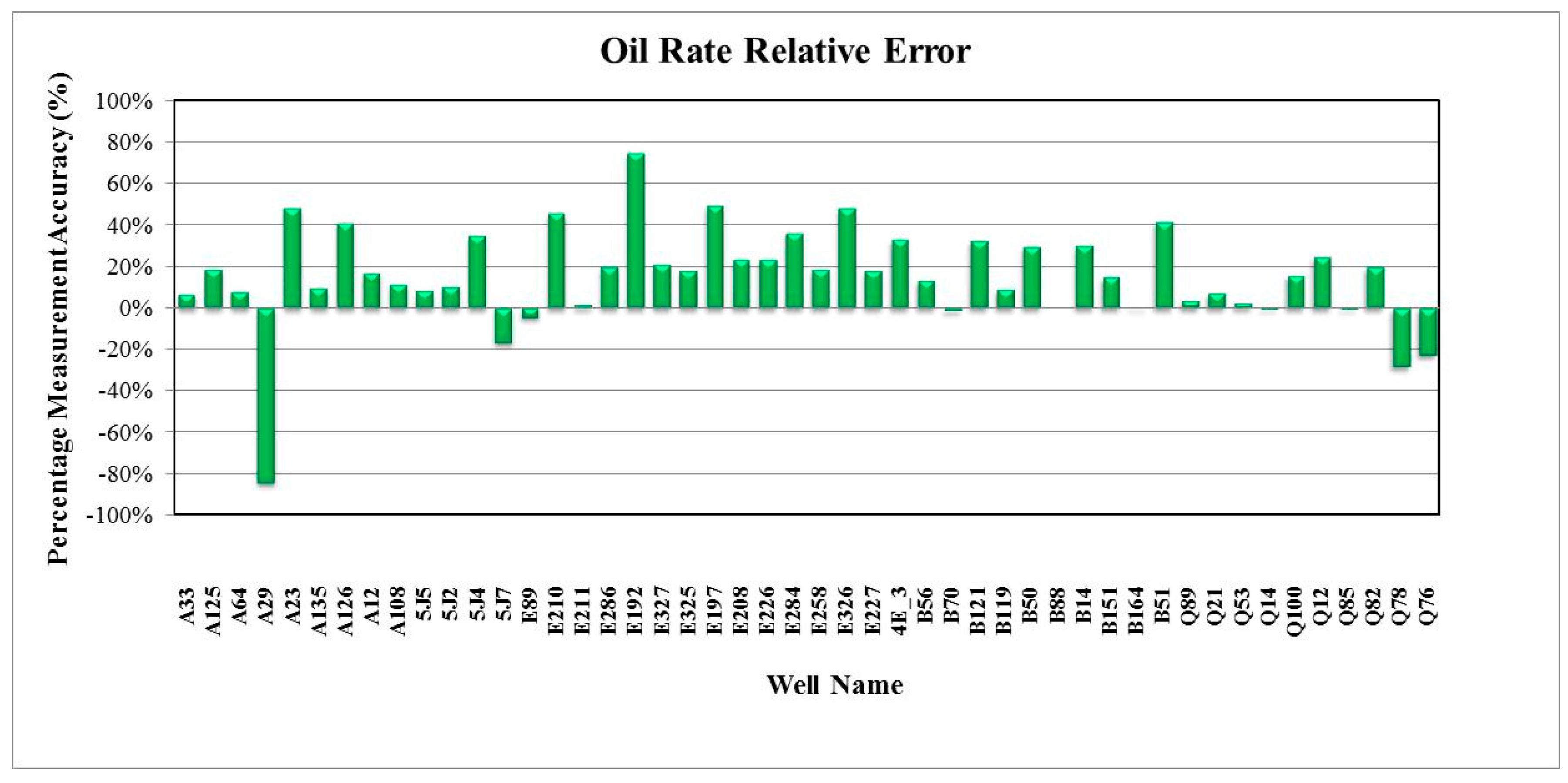

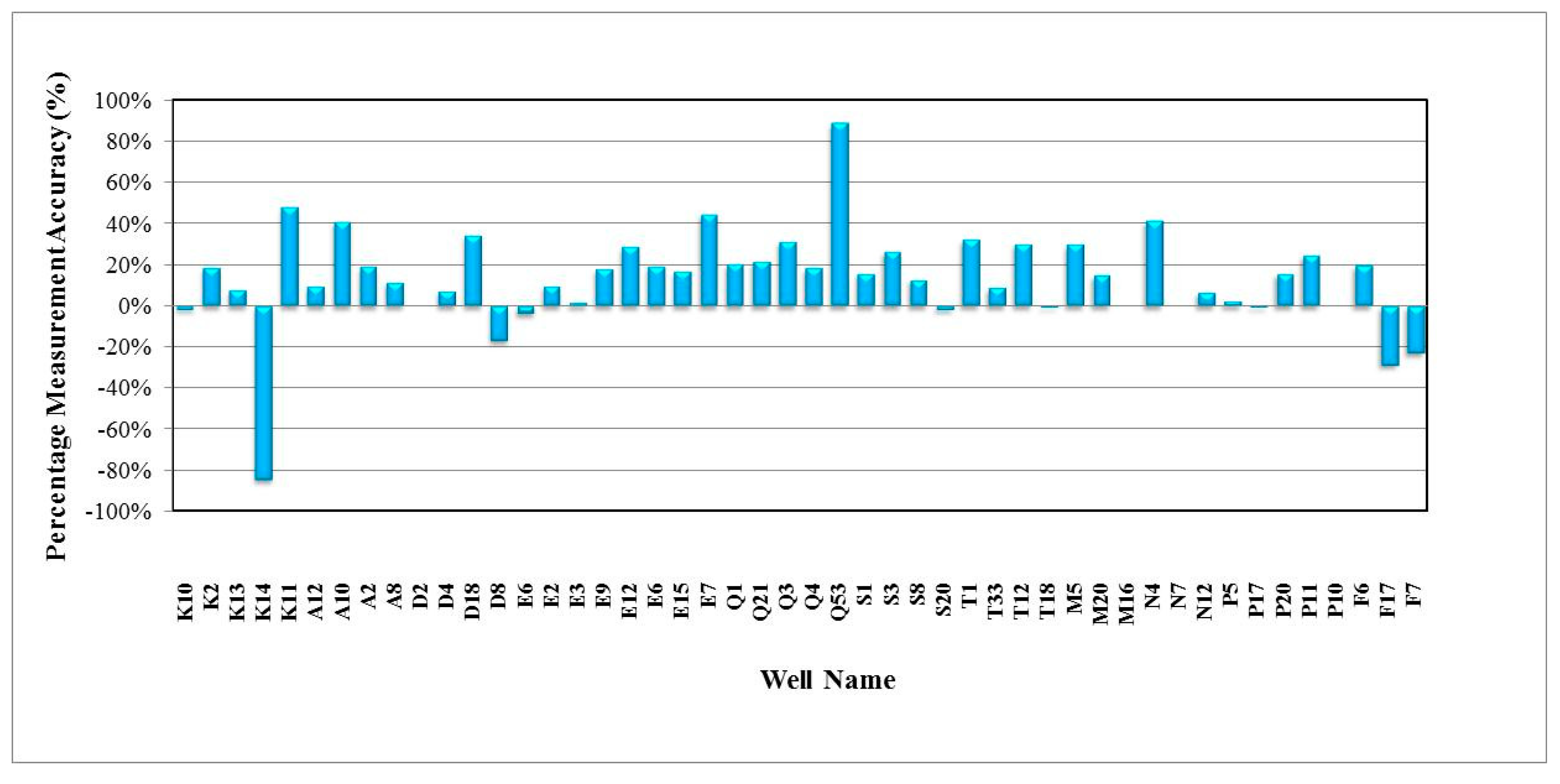

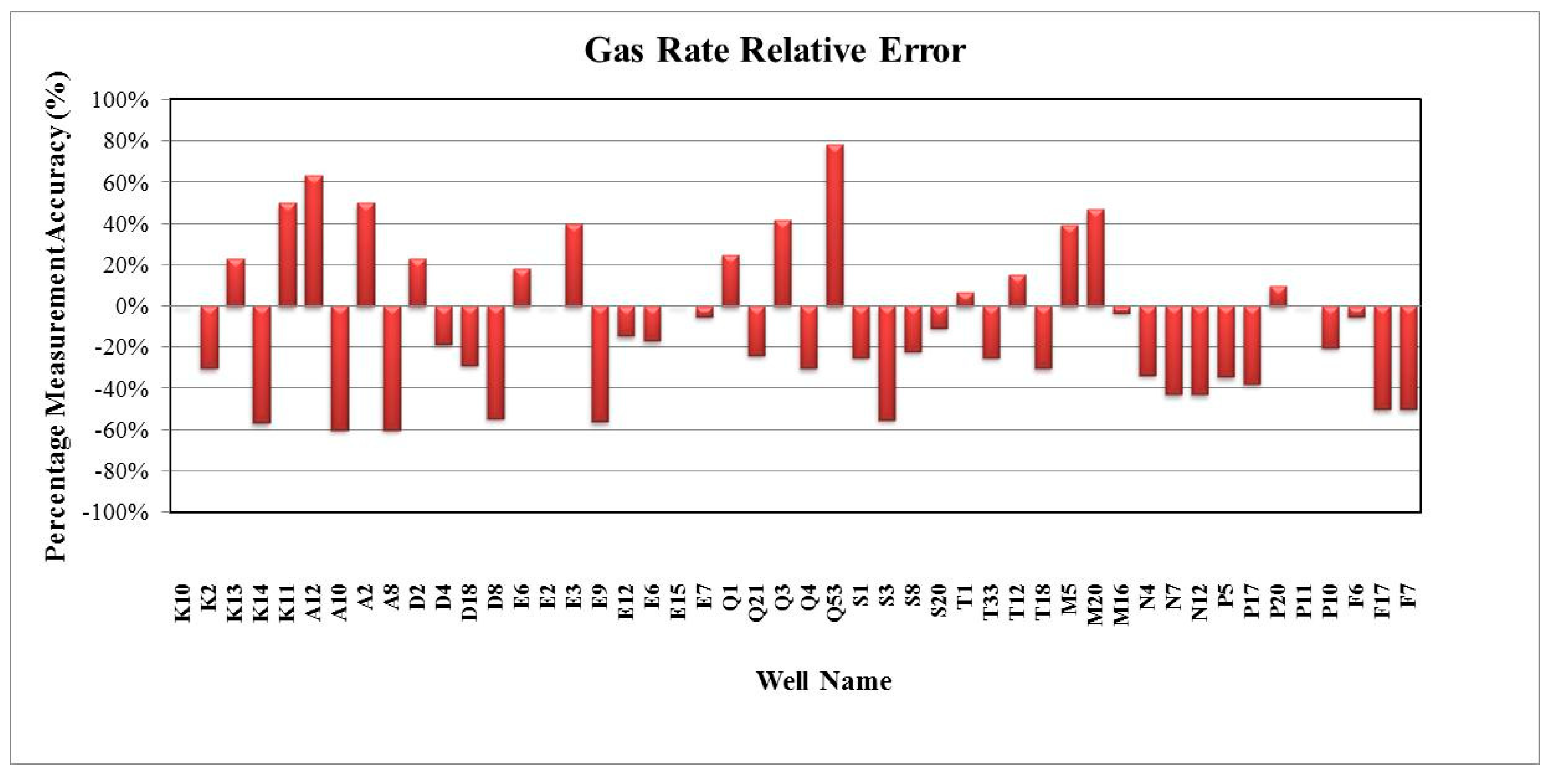

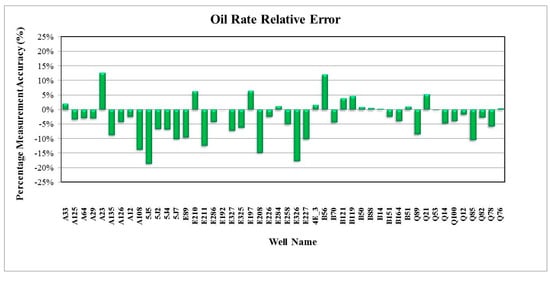

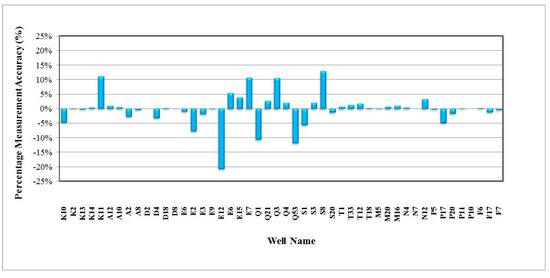

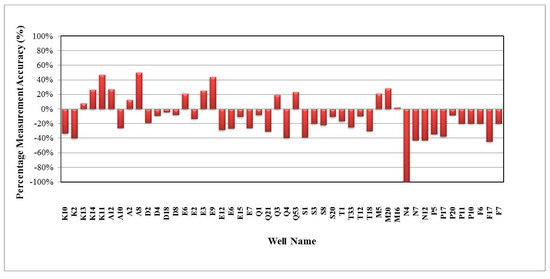

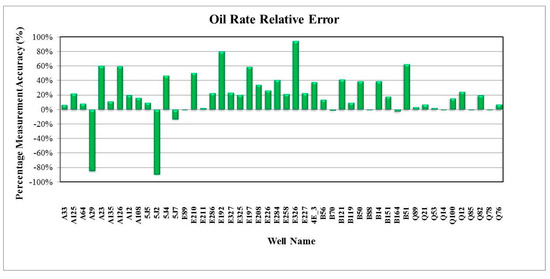

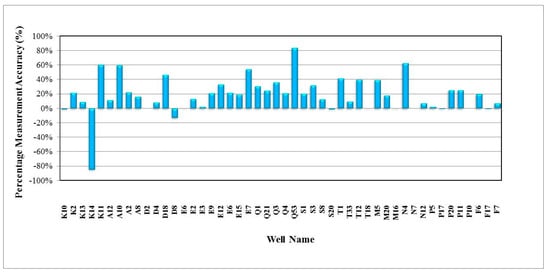

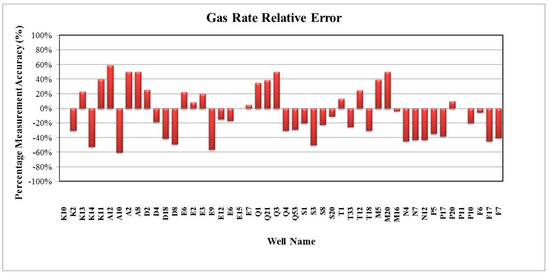

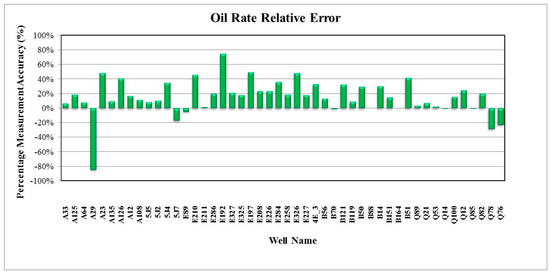

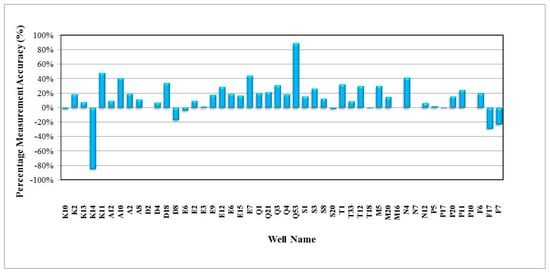

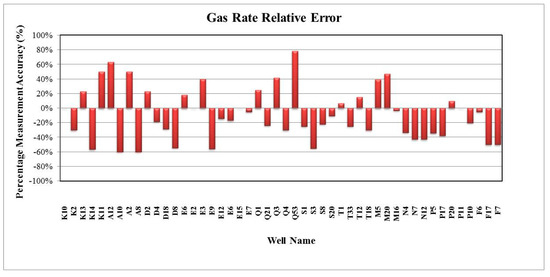

In general, the validation results of the predicted fluid flow rates were satisfactory when using the Blasius correlation rather than the Darcy or Colebrook correlations, where 96% and 98% of the predicted fluid flow rates were in good agreement with the real measured oil and water flow rate, respectively. Furthermore, the relative errors were less than ±18%, which were still within the reasonable uncertainty, as shown in Figure 17 and Figure 18. For the predicted and measured gas rates, 68% of the wells showed about ±10% relative errors, as shown in Figure 19. By using the Darcy correlation, 63% and 70% of the wells were not in good agreement with the predicted and measured oil and water rate, respectively, with more than ±18% for relative errors, as shown in Figure 20 and Figure 21. For predicted and measured gas rates, 79% of the wells showed more than ±10% relative errors, as shown in Figure 22. By using the Colebrook correlation, 67% and 75% of the wells were not in good agreement with the predicted and measured oil and water rate, respectively, with more than ±18% relative errors, as shown in Figure 23 and Figure 24. For predicted and measured gas rates, 77% of the wells showed more than ±10% relative errors, as shown in Figure 25.

Figure 17.

Oil rate measurement accuracy using the Blasius correlation.

Figure 18.

Water rate measurement accuracy using the Blasius correlation.

Figure 19.

Gas rate measurement accuracy using the Blasius correlation.

Figure 20.

Oil rate measurement accuracy using the Darcy correlation.

Figure 21.

Water rate measurement accuracy using the Darcy correlation.

Figure 22.

Gas rate measurement accuracy using the Darcy correlation.

Figure 23.

Oil rate measurement accuracy using the Colebrook correlation.

Figure 24.

Water rate measurement accuracy using the Colebrook correlation.

Figure 25.

Gas rate measurement accuracy using the Colebrook correlation.

The results showed high relative errors in gas rate prediction which can happen due to the oil separator meters being insufficiently accurate. Also, these errors may occur due to fixed orifice plate meters used to measure the gas flow rate despite the fact that orifice plates are not appropriate to measure low gas rates. Besides, wear and corrosion can increase the orifice size and cause excessive loss.

4. Summary and Conclusions

The prediction of the fluid flow rate of oil wells using the new mathematical model has been made and validated with experimentally measured fluid flow rate data. To evaluate the influence of the frictional pressure drop value on the measurement of fluid flow rate of oil wells, Blasius, Darcy, and Colebrook friction correlations were applied. Using the Blasius correlation, the analysis showed that the predicted fluid flow rate values were in accord with the measured values, while by using the Darcy and Colebrook friction correlations, the results were not in good agreement with the measured values. This discrepancy was due to the fact that each friction correlation found the friction factor differently. To determine the friction factor, many expressions were used to compute the Reynolds number. Essentially, each empirical correlation states its own assumptions and modifications to defend the variable components in order to be applicable to multiphase conditions. The two-phase flow significantly complicated the pressure drop calculations, where any errors in determining the frictional pressure drop values would generate some inaccuracies in predicting the fluid flow rate of the oil wells. Consequently, mixture properties and the interactions between the existing phase’s properties must be considered. Therefore, the gas and liquid volume fractions throughout the conduit needed to be determined. Overall, the performance of the new mathematical model indicated that the selection of the appropriate friction factor correlation would lead to predicting the gas and liquid flow rate within the acceptable accuracy. However, the friction loss dominated only with very high flow rates. For relatively small flow rates, the hydrostatic pressure played the key role in the overall pressure drop in the vertical tubing. Thus, different multiphase flow models, either empirical or mechanistic model, used in the computation would output different predictions. That being said, the Blasius equation may be superior to other models coupled with the Hagedorn-Brown empirical correlation, as it has been shown in this work. Indeed, a very reasonable average relative error of 4.6% was observed between the predicted and measured flow rates. However, it may not be as good as it is when coupled with other mechanistic models that may further reduce this error. Further research is needed to further validate the developed model by accounting for other sophisticated multiphase models.

Author Contributions

T.A.G. derived the mathematical model, carried out the experimental validation and drafted the manuscript. M.H. contributed to data presentation, analysis of results and revision preparation.

Funding

The authors would like to acknowledge the Petroleum Engineering Department and Centre of Research in Enhanced Oil Recovery (COEOR) at Universiti Teknologi PETRONAS for the funding (YUTP-0153AA-E70) and the technical assistance.

Acknowledgments

Special thanks are due to production engineering staff of Waha Oil Company for their support. The authors also gratefully acknowledge assistance received from Lynn Mason for editing this manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| A | cross-sectional area, (sq ft) |

| API | American Petroleum Institute |

| Bo | oil formation volume factor, (bbl/stb) |

| Bob | oil formation volume (at bubble point pressure), (bbl/STB) |

| Bg | gas formation volume factor, (cf/scf) |

| Cnt | count |

| dp/dz | pressure gradient, (psi/ft) |

| d | inside diameter, (ft) |

| ESP | electrical submersible pump |

| f | friction factor, (unitless) |

| g | Gravity, (ft/s2) |

| HL | liquid hold-up |

| HG | gas hold-up |

| H1 | bubble point pressure (at location depth before shut-in the well head valve), (ft) |

| H2 | bubble point pressure (at location depth after shut-in the well head valve), (ft) |

| mt | mass flow rate, (lb/day) |

| Ngv | gas velocity number, (unitless) |

| NLv | liquid velocity number, (unitless) |

| Nd | pipe diameter number, (unitless) |

| NCL | coefficient number of viscosity correction, (unitless) |

| NL | liquid viscosity number, (unitless) |

| qo | oil rate, (stb/day) |

| qg | gas rate, (stb/day) |

| qw | water rate, (stb/day) |

| qL | liquid rate, (stb/day) |

| qm | measured flow rate, (stb/day) |

| QC | quality check |

| P | pressure, (psia) |

| Pr | pseudo-critical pressure (for gas mixture), (psia) |

| Pb | bubble point pressure, (psia) |

| Psc | pressure at standard conditions (P = 14.7 atm, T = 60 °F), (psia) |

| PSD | pump setting depth |

| SGG | gas specific gravity |

| STB | stock tank barrel (for liquid) |

| rw | wellbore radius, (ft) |

| Rs | gas-oil ratio, (scf/stb ) |

| Rsb | gas oil ratio at bubble point pressure, (cf/scf) |

| Re | Reynolds number, (unitless) |

| T | temperature, (°F) |

| t | total shut-in time, (min) |

| Tr | pseudo-critical temperature (for gas mixture), (psia) |

| Tsc | temperature at standard condition, (°R) |

| Tr | reservoir fluid temperature, (°F) |

| VR | gas volume at reservoir conditions, (ft3) |

| Vsc | gas volume at standard condition, (ft3) |

| VSL | superficial velocity for liquid, (ft/sec) |

| VSg | superficial velocity for gas, (ft/sec) |

| Vm | total mixture velocity, (ft/sec) |

| WHPa | well head pressure (after shut-in the well), (psia) |

| WHPb | well head pressure (before shut-in the well), (psia) |

| WC | water cut (unitless) |

| WHT | well head temperature, (°F) |

| W | water vapor density, (unitless) |

| Z | gas compressibility factor (unitless) |

| Greek Symbols | |

| ΔP | pressure drop, (psia) |

| HL/ψ | hold-up correlation factor |

| γo | oil gravity |

| γw | water gravity |

| γg | gas gravity |

| σ | surface tension, (dyne/m) |

| ΔH | differences between bubble point pressure location depths (before and after shut-in the well head valve), (ft) |

| ρo | oil density, (lbm/ft3) |

| ρg | gas density, (lbm/ft3) |

| ρw | water density, (lbm/ft3) |

| ρL | liquid density, (lb/ft3) |

| ρm | mixture density, (lbm/ft3) |

| µo | oil viscosity, cP |

| µg | gas viscosity, cP |

| µL | liquid viscosity, cP |

| Subscripts | |

| gsc | gas (at standard condition) |

| h | hydrostatic |

| L | liquid |

| m | mixture (liquid and gas) |

| o | oil |

| sc | standard condition |

| w | water |

References

- Saeb, M.B.; Philip, D.M.; David, C.C.; Ali, J. Modeling friction factor in pipeline flow using a GMDH-type neural network. Cogent Eng. 2015, 2. [Google Scholar] [CrossRef]

- Shannak, B.A. Frictional pressure drop of gas liquid two-phase flow in pipes. Nuclear Eng. Des. 2008, 238, 3277–3284. [Google Scholar] [CrossRef]

- Jiang, J.Z.; Zhang, W.M.; Wang, Z.M. Research progress in pressure-drop theories of gas-liquid two-phase pipe flow. In Proceedings of the China International Oil & Gas Pi (CIPC 2011), Langfang, China, 5 September 2011. [Google Scholar]

- Xu, Y.; Fang, X.D.; Su, X.H.; Zhou, Z.R.; Chen, W.W. Evaluation of frictional pressure drop correlations for two-phase flow in pipes. Nuclear Eng. Des. 2012, 253, 86–97. [Google Scholar] [CrossRef]

- Mittal, G.S.; Zhang, J. Friction factor prediction for Newtonian and non-Newtonian fluids in pipe flows using neural networks. Int. J. Food Eng. 2007, 3, 1–18. [Google Scholar] [CrossRef]

- Fadare, D.A.; Ofidhe, U.I. Artificial neural network model for prediction of friction factor in pipe flow. J. Appl. Sci. 2009, 5, 662–670. [Google Scholar]

- Bilgil, A.; Altun, H. Investigation of flow resistance in smooth open channels using artificial neural networks. Flow Meas. Instrum. 2008, 19, 404–408. [Google Scholar] [CrossRef]

- Özger, M.; Yildirim, G. Determining turbulent flow friction coefficient using adaptive neuro-fuzzy computing techniques. Adv. Eng. Softw. 2009, 40, 281–287. [Google Scholar] [CrossRef]

- Shayya, W.H.; Sablani, S.S.; Campo, A. Explicit calculation of the friction factor for non-Newtonian fluids using artificial neural networks. Dev. Chem. Eng. Miner. Process. 2005, 13, 5–20. [Google Scholar] [CrossRef]

- Yuhong, Z.; Wenxin, H. Application of artificial neural network to predict the friction factor of open channel flow. Commun. Nonlinear Sci. Numer. Simul. 2009, 14, 2373–2378. [Google Scholar] [CrossRef]

- Yazdi, M.; Bardi, A. Estimation of friction factor in pipe flow using artificial neural networks. Can. J. Autom. Control Intell. Syst. 2011, 2, 52–56. [Google Scholar]

- Sablani, S.S.; Shayya, W.H. Neural network based non-iterative calculation of the friction factor for power law fluids. J. Food Eng. 2003, 57, 327–335. [Google Scholar] [CrossRef]

- Griffith, P. Two-Phase Flow in Pipes. In Special Summer Program; Massachusetts Institute of Technology: Cambridge, MA, USA, 1962. [Google Scholar]

- Raxendell, P.B. The Calculation of Pressure Gradients in High-Rate Flowing Wells. J. Pet. Technol. 1961, 13, 1023. [Google Scholar] [CrossRef]

- Fancher, G.H.; Brown, K.E. Prediction of Pressure Gradients for Multiphase Flow in Tubing. Soc. Pet. Eng. J. 1963, 3, 59. [Google Scholar] [CrossRef]

- Hagedorn, A.R.; Brown, K.E. The Effect of Liquid Viscosity in Vertical Two-Phase Flow. J. Pet. Technol. 1964, 16, 203. [Google Scholar] [CrossRef]

- Poettmann, F.H.; Carpenter, P.G. The Multiphase Flow of Gas, Oil and Water through Vertical Flow Strings with Application to the Design of Gas-Lift Installations. In Proceedings of the Drilling and Production Practice, New York, NY, USA, 1 January 1952; Volume 52, p. 257. [Google Scholar]

- Tek, M.R. Multiphase Flow of Water, Oil and Natural Gas Through Vertical Flow Strings. J. Pet. Technol. 1961, 13, 1029. [Google Scholar] [CrossRef]

- Shaban, H.; Tavoularis, S. Identification of flow regime in vertical upward air–water pipe flow using differential pressure signals and elastic maps. Int. J. Multiph. Flow 2014, 61, 62–72. [Google Scholar] [CrossRef]

- Daev, Z.A.; Kairakbaev, A.K. Measurement of the Flow Rate of Liquids and Gases by Means of Variable Pressure Drop Flow Meters with Flow Straighteners. Meas. Tech. 2017, 59, 1170–1174. [Google Scholar] [CrossRef]

- Cai, B.; Guo, D.X.; Jing, F.W. Study on gas-liquid two-phase flow patterns and pressure drop in a helical channel with complex section. In Proceedings of the 23rd International Compressor Engineering Conference, West Lafayette, IN, USA, 11–14 July 2016. [Google Scholar]

- Oliveira, J.L.G.; Passos, J.C.; Verschaeren, R.; Van der Geld, C. Mass flow rate measurements in gas-liquid flows by means of a venturi or orifice plate coupled to a void fraction sensor. Exp. Therm. Fluid Sci. 2009, 33, 253–260. [Google Scholar] [CrossRef]

- Brown, G.O. The history of the Darcy-Weisbach equation for pipe flow resistance. Environment. Available online: https://ascelibrary.org/doi/abs/10.1061/40650 (accessed on 17 September 2018).

- Blasius, H. Das Ähnlichkeitsgesetz bei Reibungsvorgängen in Flüssigkeiten, Mitteilung 131 über Forschungsarbeiten auf dem Gebiete des Ingenieurwesens; Springer: Berlin, Germany, 1913. [Google Scholar]

- Colebrook, C.F. Turbulent flow in pipes, with particular reference to the transition region between the smooth and rough pipe laws. J. Inst. Civ. Eng. 1939, 11, 133–156. [Google Scholar] [CrossRef]

- Lee, A.L.; Gonzalez, M.H.; Eakin, B.E. The Viscosity of Natural Gases. J. Pet. Technol. 1966, 18, 997–1000. [Google Scholar] [CrossRef]

- Beggs, D.H.; Brill, J.P. A study of two-phase flow in inclined pipes. J. Pet. Technol. 1973, 25, 607–617. [Google Scholar] [CrossRef]

- Standing, M.B.; Katz, D.L. Density of natural gases. Trans. AIME 1942, 146, 140–149. [Google Scholar] [CrossRef]

- Sloan, E.; Khoury, F.; Kobayashi, R. Measurement and interpretation of the water content of a methane-propane mixture in the gaseous state in equilibrium with hydrate. Ind. Eng. Chem. Fundam. 1982, 21, 391–395. [Google Scholar]

- Vazquez, M.; Beggs, H.D. Correlations for Fluid Physical Property Prediction. J. Pet. Technol. 1980, 32, 968–970. [Google Scholar] [CrossRef]

- Hagedorn, A.R.; Brown, K.E. Experimental Study of Pressure Gradients Occurring during Continuous Two-Phase Flow in Small Diameter Vertical Conduit. J. Pet. Technol. 1965, 17, 475–484. [Google Scholar] [CrossRef]

- Duns, H., Jr.; Ros, N. Vertical Flow of Gas and Liquid Mixtures in Wells. In Proceedings of the 6th World Petroleum Congress, Frankfurt am Main, Germany, 19–26 June 1963; p. 451. [Google Scholar]

- Orkiszewski, J. Predicting Two-Phase Pressure Drops in Vertical Pipe. J. Pet. Technol. 1967, 19, 829–838. [Google Scholar] [CrossRef]

- Aziz, K.; Govier, G.; Fogarasi, M. Pressure Drop in Wells Producing Oil and Gas. J. Can. Pet. Technol. 1972, 11, 38. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).