Investigation on the Suction Reed Valve Motion with Sticky Force in a Refrigerator Compressor

Abstract

1. Introduction

2. Experimental Method

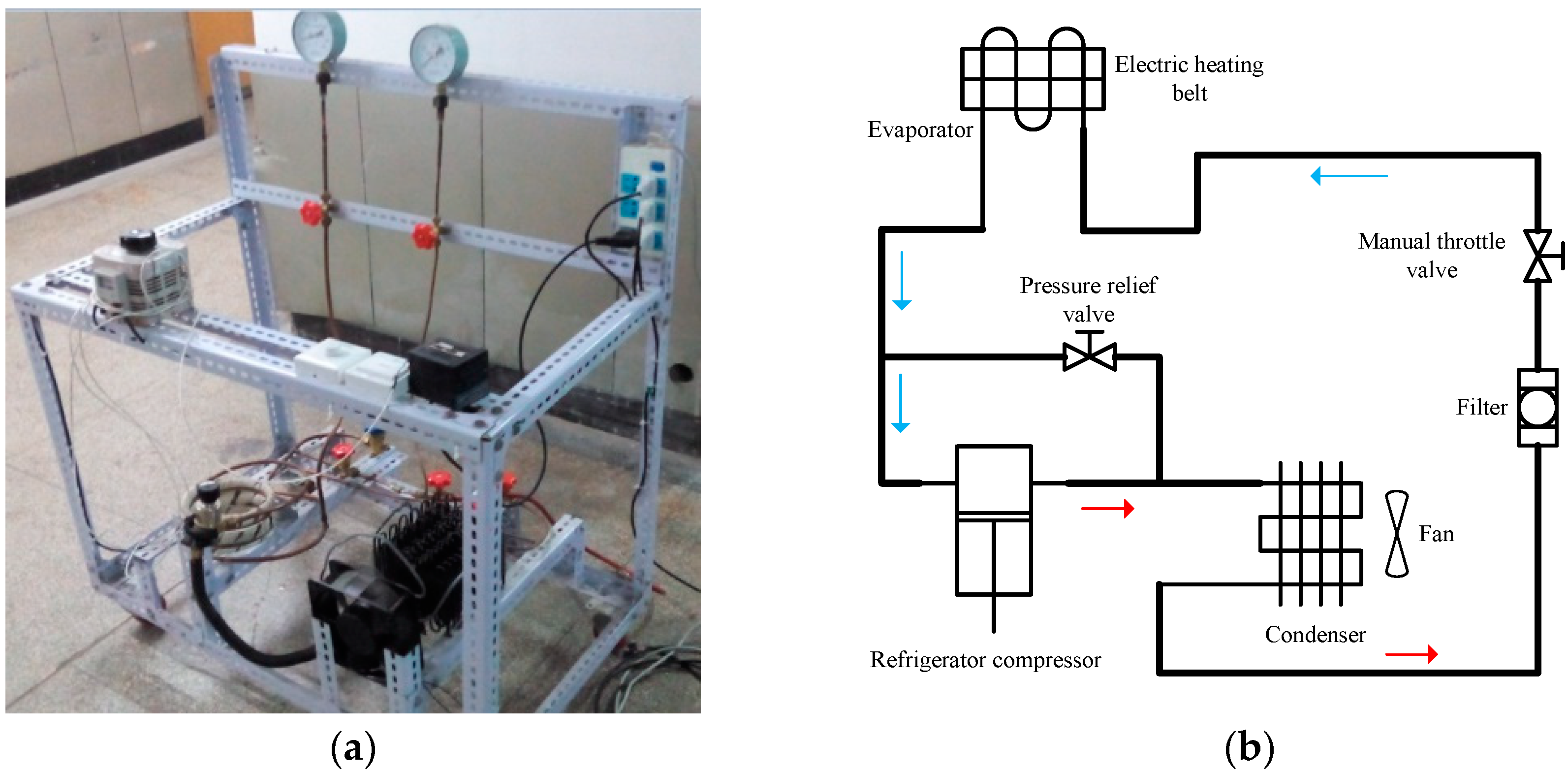

2.1. Refrigeration System

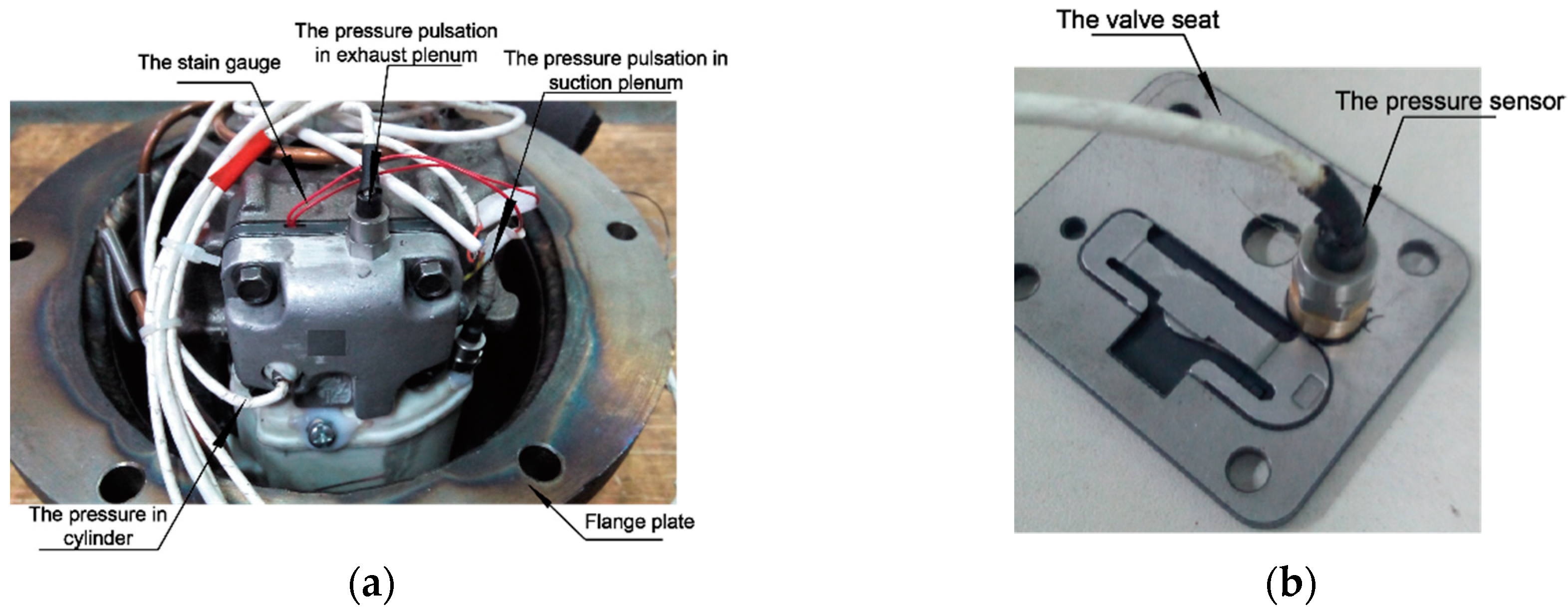

2.2. Pressure Measurement

2.3. Measurement to Motion of Suction Reed Valve

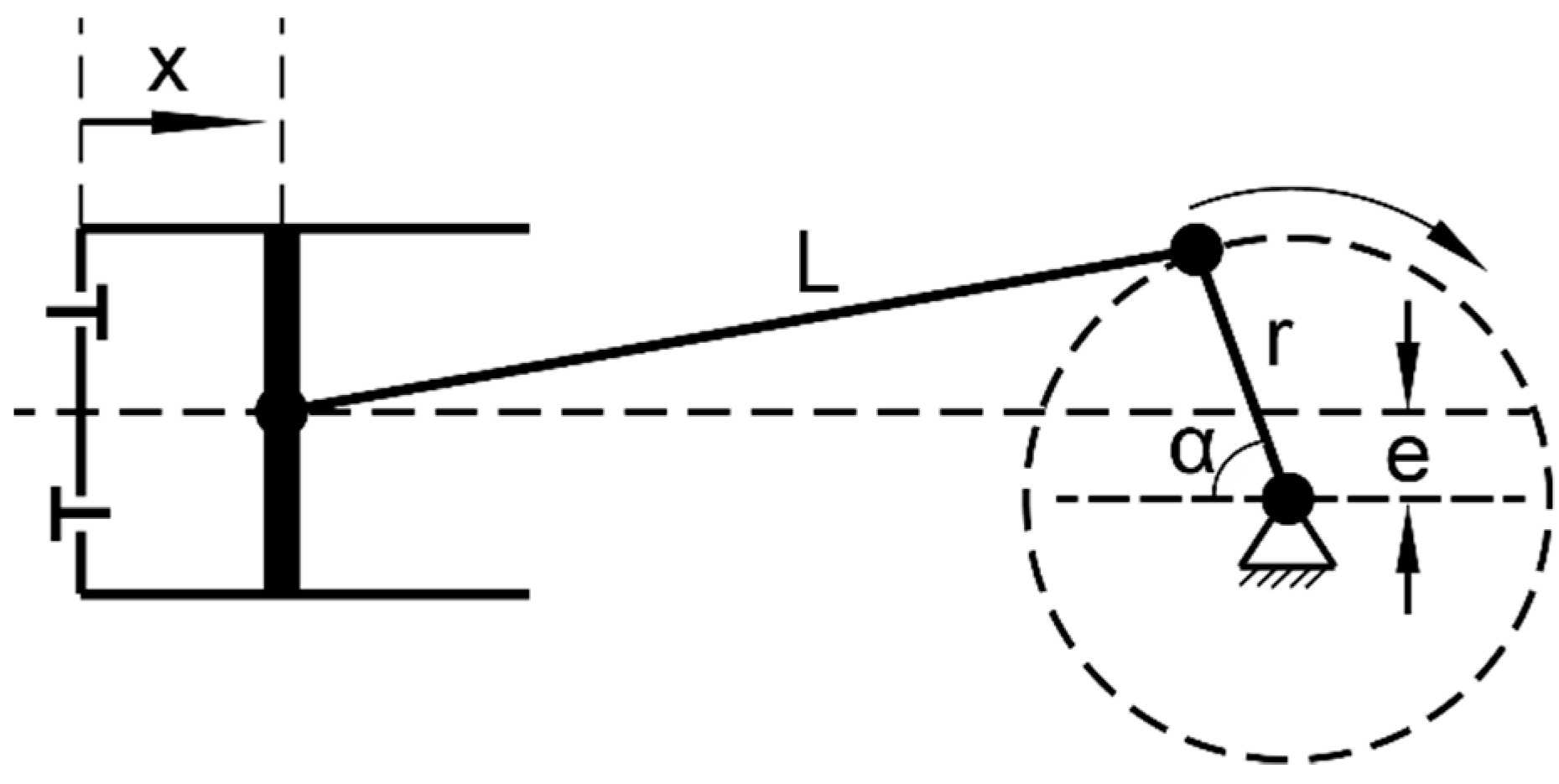

2.4. The Refrigerator Compressor Kinematics

2.5. Uncertainty Analysis

3. Results and Discussion

3.1. Pressure in the Cylinder

3.2. Motion of the Suction Valve with Sticky Force

4. Conclusions

- The experimental method which integrates pressure variety and valve movement presented in this study offers a promising tool for the development of high-performance refrigerator compressors. The strong coupling of the suction valve motion with the pressure in the cylinder and the suction plenum were clearly observed. The pressure pulsations in the cylinder were caused by the motion of the valve while the pressure pulsation in the suction chamber was generated as the reed valve stayed contacted with the valve seat during the suction process.

- The flow loss through the suction valve was investigated in the experiment. There was a considerable power loss of up to 14.5% in the suction process was found under experimental conditions, while the differential pressure was up to 0.37 bar.

- The sticky force of oil has a significant effect on both the motion of the suction valve and the suction phase of the compressor. Due to the sticky force, the valve stayed contacted with the valve seat in the suction process, which decreased the flow area of the valve and increased the suction loss. Furthermore, the speed and deformation of the valve were increased due to the sticky force.

- During the suction process, there was an excessive reduction of the pressure in the suction chamber due to the flow loss in the muffler and the delayed opening of the reed valve while a pressure pulsation was generated as the reed valve stayed contacted on the valve seat, which increased the power consumption of the compressor.

- The proposed experimental method which integrates the pressure variety and valve movement could contribute to an efficient testing and the optimization of refrigerator compressor. The combination of experiments and numerical simulations is an effective solution to study the dynamics of compressors and reed valves.

Author Contributions

Conflicts of Interest

Nomenclature

| The piston displacement from the TDC | |

| The crank radius | |

| The ratio of the crank radius to the length of the connecting rod | |

| The crank angle | |

| The eccentric distance | |

| The differential pressure | |

| The pressure in the cylinder |

References

- Stouffs, P.; Mohand, T.; Pierre, W. Thermodynamic analysis of reciprocating compressors. Int. J. Therm. Sci. 2001, 40, 52–66. [Google Scholar] [CrossRef]

- Ma, Y.; He, Z.L.; Peng, X.Y.; Xing, Z.W. Experimental investigation of the discharge valve dynamics in a reciprocating compressor for trans-critical CO2 refrigeration cycle. Appl. Therm. Eng. 2012, 32, 13–21. [Google Scholar] [CrossRef]

- Pichler, K.; Lughofer, E.; Pichler, M.; Buchegger, T.; Klement, E.P.; Huschenbett, M. Detecting cracks in reciprocating compressor valves using pattern recognition in the pV diagram. Pattern Anal. Appl. 2015, 18, 461–472. [Google Scholar] [CrossRef]

- Wang, Y.; Feng, J.M.; Zhang, B.; Peng, X.Y. Modeling the valve dynamics in a reciprocating compressor based on two-dimensional computational fluid dynamic numerical simulation. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2013, 227, 295–308. [Google Scholar] [CrossRef]

- Sun, S.Y.; Ren, T.R. New method of thermodynamic computation for a reciprocating compressor: Computer simulation of working process. Int. J. Mech. Sci. 1995, 37, 343–353. [Google Scholar] [CrossRef]

- Farzaneh-Gord, M.; Niazmand, A.; Deymi-Dashtebayaz, M.; RezaRahbari, H. Thermodynamic analysis of natural gas reciprocating compressors based on real and ideal gas models. Int. J. Refrig. 2015, 56, 186–197. [Google Scholar] [CrossRef]

- Dutra, T.; Deschamps, C.J. A simulation approach for hermetic reciprocating compressors including electrical motor modeling. Int. J. Refrig. 2015, 59, 168–181. [Google Scholar] [CrossRef]

- Stiaccini, I.; Galoppi, G.; Ferrari, L.; Ferrara, G. A reciprocating compressor hybrid model with acoustic FEM characterization. Int. J. Refrig. 2016, 63, 171–183. [Google Scholar] [CrossRef]

- Liu, G.B.; Zhao, Y.Y.; Tang, B.; Li, L.S. Dynamic performance of suction valve in stepless capacity regulation system for large-scale reciprocating compressor. Appl. Therm. Eng. 2016, 96, 167–177. [Google Scholar] [CrossRef]

- Bhakta, A.; Dhar, S.; Bahadur, V.; Angadi, S.; Dey, S. A valve design methodology for improved reciprocating compressor performance. In Proceedings of the 21th International Compressor Engineering Conference, West Lafayette, IN, USA, 14–19 July 2012. [Google Scholar]

- Gasche, J.L.; Arantes, D.M.; Andreotti, T. Experimental analysis of the fluid structure interaction in a suction valve model. In Proceedings of the 22nd International Compressor Engineering Conference, West Lafayette, IN, USA, 14–19 July 2014. [Google Scholar]

- Nagata, S.; Nozaki, T.; Akizawa, T. Analysis of dynamic behavior of suction valve using strain gauge in reciprocating compressor. In Proceedings of the 2010 International Compressor Engineering Conference, West Lafayette, IN, USA, 12–15 July 2010. [Google Scholar]

- Real, M.A.; Pereira, E.A.G. Using PV diagram synchronized with the valve functioning to increase the efficiency on the reciprocating hermetic compressors. In Proceedings of the 2010 International Compressor Engineering Conference, West Lafayette, IN, USA, 12–15 July 2010. [Google Scholar]

- Khalifa, H.E.; Xin, L. Analysis of stiction effect on the dynamics of compressor suction valve. In Proceedings of the 1998 International Compressor Engineering Conference, West Lafayette, IN, USA, 14–17 July 1998. [Google Scholar]

- Pizarro-Recabarren, R.A.; Barbosa, J.R., Jr.; Deschamps, C.J. Modeling the stiction effect in automatic compressor valves. Int. J. Refrig. 2013, 36, 1916–1924. [Google Scholar] [CrossRef]

- Yoshizumi, F.; Kondoh, Y.; Moroi, T.; Tamano, S.; Morinishi, Y. Numerical simulation on the opening delay of a discharge reed valve in compressors. In Proceedings of the 22nd International Compressor Engineering Conference, West Lafayette, IN, USA, 14–19 July 2014. [Google Scholar]

- Bauer, F. The influence of liquids on compressor valves. In Proceedings of the 1990 International Compressor Engineering Conference, West Lafayette, IN, USA, 17–20 July 1990. [Google Scholar]

- Pringle, S. Oil Stiction in Automatic Compressor Valves. Ph.D. Thesis, University of Strathclyde, Glasgow, UK, 1976. [Google Scholar]

- Giacomelli, E.; Giorgetti, M. Evaluation of oil stiction in ring valves. In Proceedings of the 1974 International Compressor Engineering Conference, West Lafayette, IN, USA, 10–12 July 2014. [Google Scholar]

- Resch, M.; Scheidl, R. A model for fluid stiction of quickly separating circular plates. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2014, 228, 1540–1556. [Google Scholar] [CrossRef]

- Liu, Z.J.; Li, H.; Liu, K.J.; Yu, H.C.; Cheng, K.W. Design of high-performance water-in-glass evacuated tube solar water heaters by a high-throughput screening based on machine learning: A combined modeling and experimental study. Sol. Energy 2017, 142, 61–67. [Google Scholar] [CrossRef]

- Liu, Z.J.; Wu, D.; Yu, H.C.; Ma, W.S.; Gin, G.Y. Field measurement and numerical simulation of combined solar heating operation modes for domestic buildings based on the Qinghai-Tibetan plateau case. Energy Build. 2018, 167, 312–321. [Google Scholar] [CrossRef]

- Pichler, K.; Lughofer, E.; Pichler, M.; Buchegger, T.; Klement, E.P.; Huschenbett, M. Fault detection in reciprocating compressor valves under varying load conditions. Mech. Syst. Signal Process. 2016, 70, 104–119. [Google Scholar] [CrossRef]

- Aprea, C.; Mastrullo, R.; Renno, C. Determination of the compressor optimal working conditions. Appl. Therm. Eng. 2009, 29, 1991–1997. [Google Scholar] [CrossRef]

- Wang, T.; Guo, Y.; He, Z.L.; Peng, X.Y. Investigation on the delayed closure of the suction valve in the refrigerator compressor by FSI modeling. Int. J. Refrig. 2018, 91, 111–121. [Google Scholar]

- Jomde, A.; Bhojwani, V.; Kedia, S.; Jangale, N.; Kolas, K.; Khedkar, P.; Deshmukh, S. Modeling and simulation performance of reed valve in linear compressor. Mater. Today Proc. 2017, 4, 7228–7233. [Google Scholar] [CrossRef]

- Belman-Flores, J.M.; Ledesma, S.; Barroso-Maldonado, J.M.; Navarro-Esbrí, J. A comparison between the modeling of a reciprocating compressor using artificial neural network and physical model. Int. J. Refrig. 2015, 59, 144–156. [Google Scholar] [CrossRef]

| Compressor Parameters | Value |

|---|---|

| Cylinder diameter | 31 mm |

| Connecting rod length | 39.5 mm |

| Crank radius | 12 mm |

| Rated speed | 2950 r·min−1 |

| Variable | Uncertainty Value |

|---|---|

| Pressure | 0.1% (full scale) |

| Differential pressure | 0.14% (maximum) |

| Reed displacement | 1% (full scale) |

| Reed velocity | 2% (maximum) |

| Working Condition Parameters | Pressure | Temperature |

|---|---|---|

| Suction | 0.574 bar | 0.8 °C |

| discharge | 5.80 bar |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Ji, L.; Xing, Z.; Peng, X. Investigation on the Suction Reed Valve Motion with Sticky Force in a Refrigerator Compressor. Energies 2018, 11, 2897. https://doi.org/10.3390/en11112897

Zhang W, Ji L, Xing Z, Peng X. Investigation on the Suction Reed Valve Motion with Sticky Force in a Refrigerator Compressor. Energies. 2018; 11(11):2897. https://doi.org/10.3390/en11112897

Chicago/Turabian StyleZhang, Wei, Lantian Ji, Ziwen Xing, and Xueyuan Peng. 2018. "Investigation on the Suction Reed Valve Motion with Sticky Force in a Refrigerator Compressor" Energies 11, no. 11: 2897. https://doi.org/10.3390/en11112897

APA StyleZhang, W., Ji, L., Xing, Z., & Peng, X. (2018). Investigation on the Suction Reed Valve Motion with Sticky Force in a Refrigerator Compressor. Energies, 11(11), 2897. https://doi.org/10.3390/en11112897