Installation of XLPE-Insulated 400 kV Submarine AC Power Cables under the Dardanelles Strait: A 4 GW Turkish Grid Reinforcement

Abstract

:1. Introduction

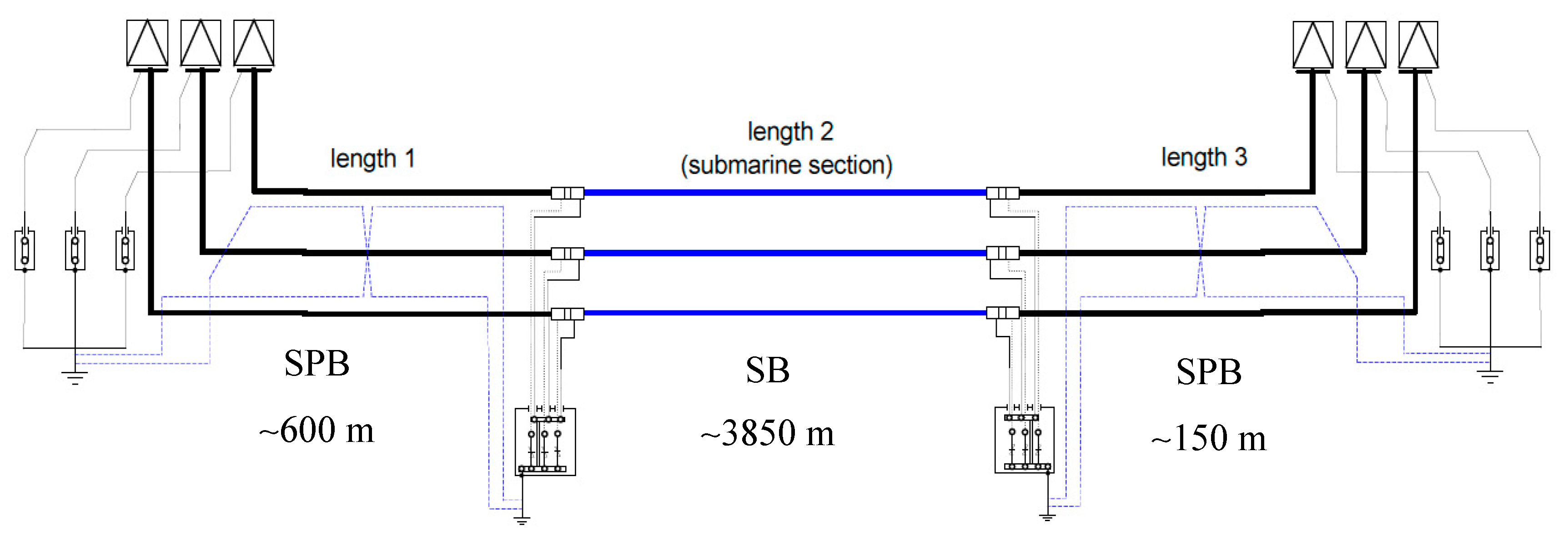

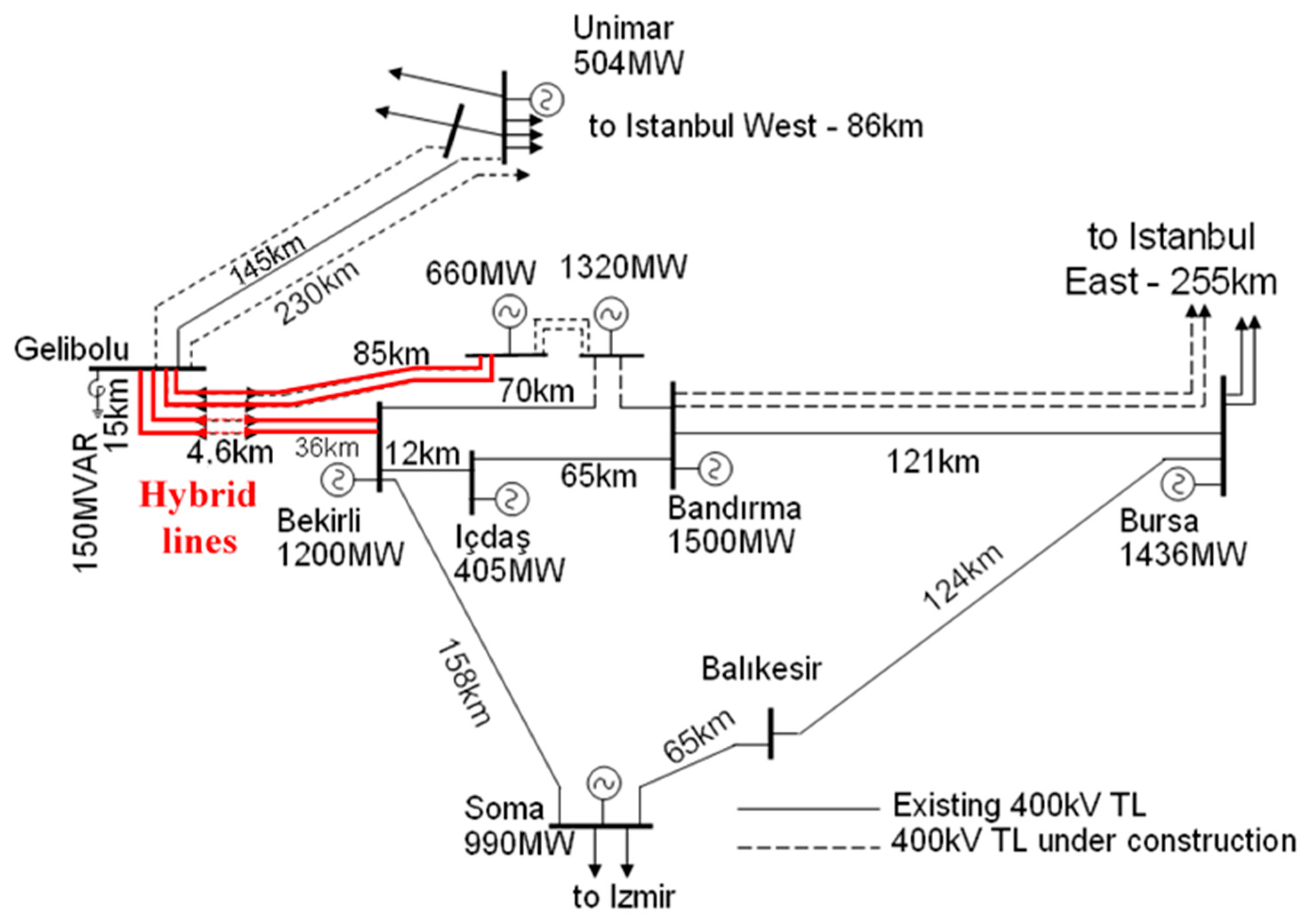

2. Description of the Link

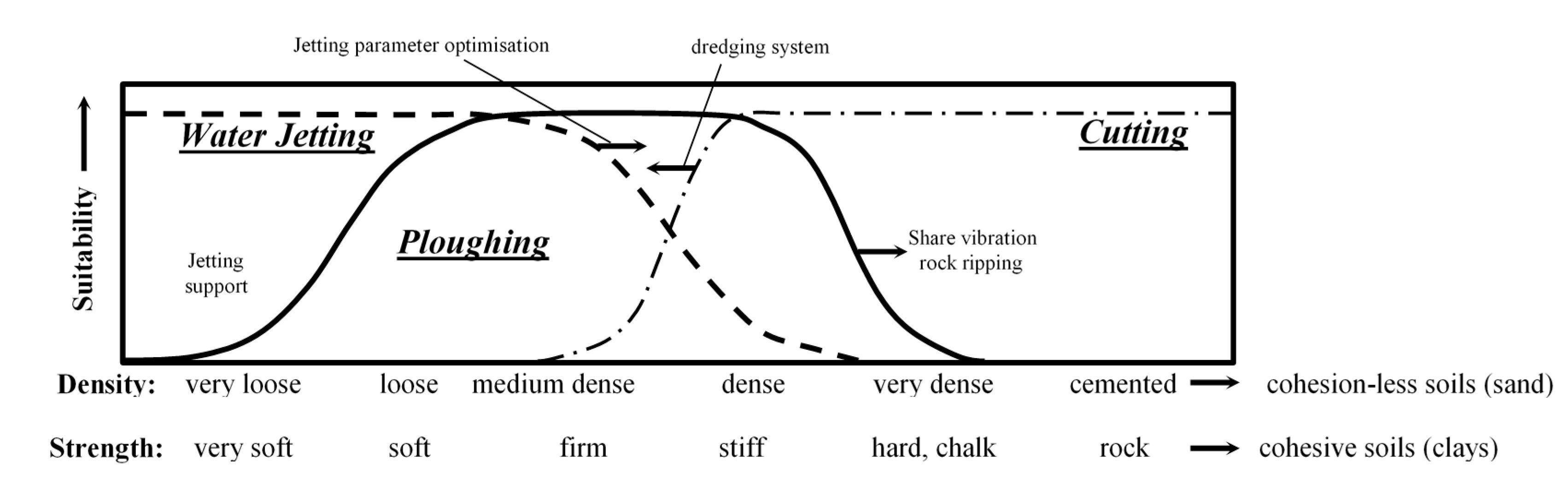

3. A Brief Overview of the Submarine Cable Protection Techniques

“a plow has been devised by engineers of the Western Union Telegraph Company which when pulled along the ocean bottom is expected to cut a furrow, drop the cable into it, and back fill over the cable”.

- ➢

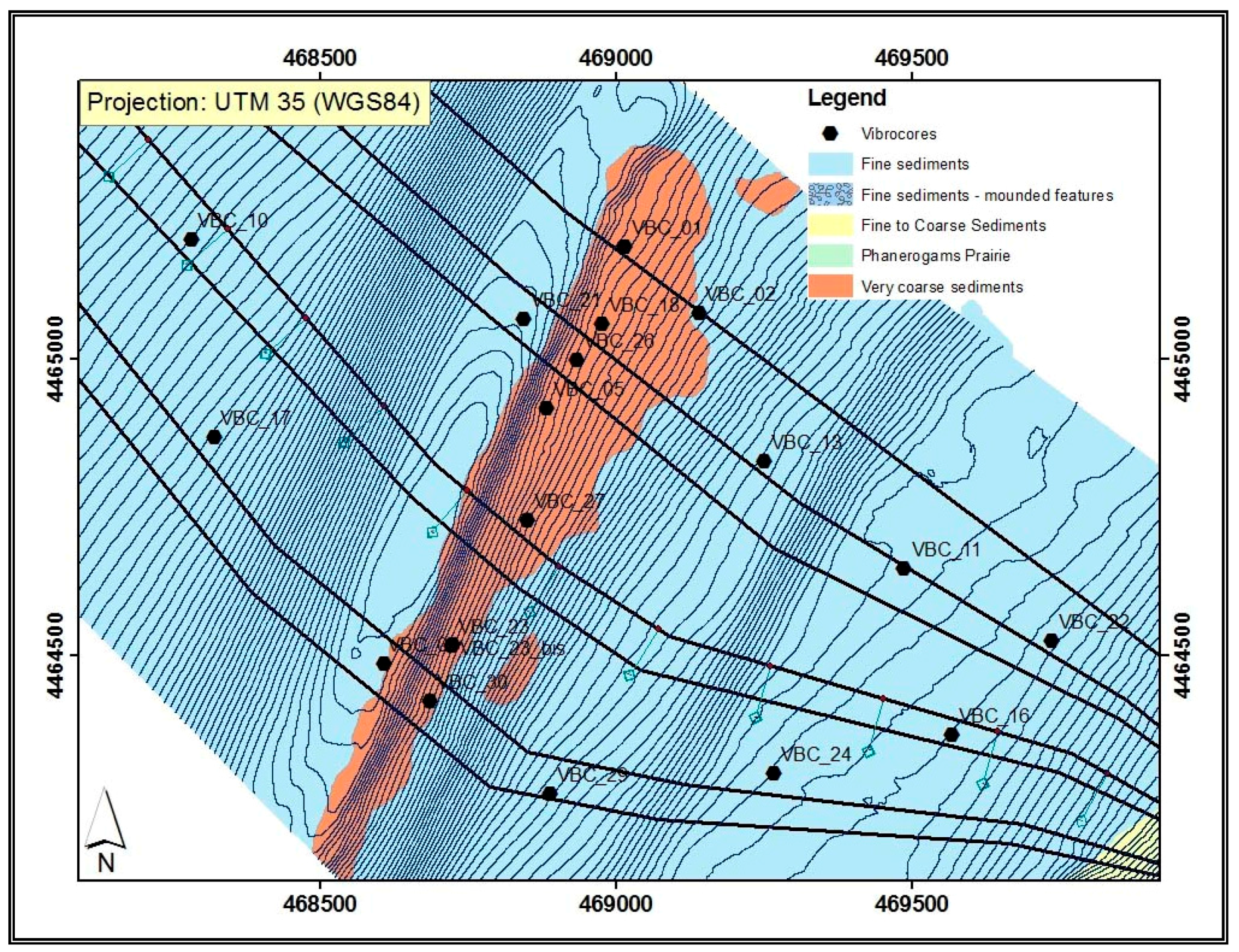

- A route cable survey comprising of geophysical and geotechnical portions;

- ➢

- A marine survey, which could include an extraction of samples from the seabed.

- ➢

- Fishing activity;

- ➢

- Ship anchoring (chiefly in shallow water).

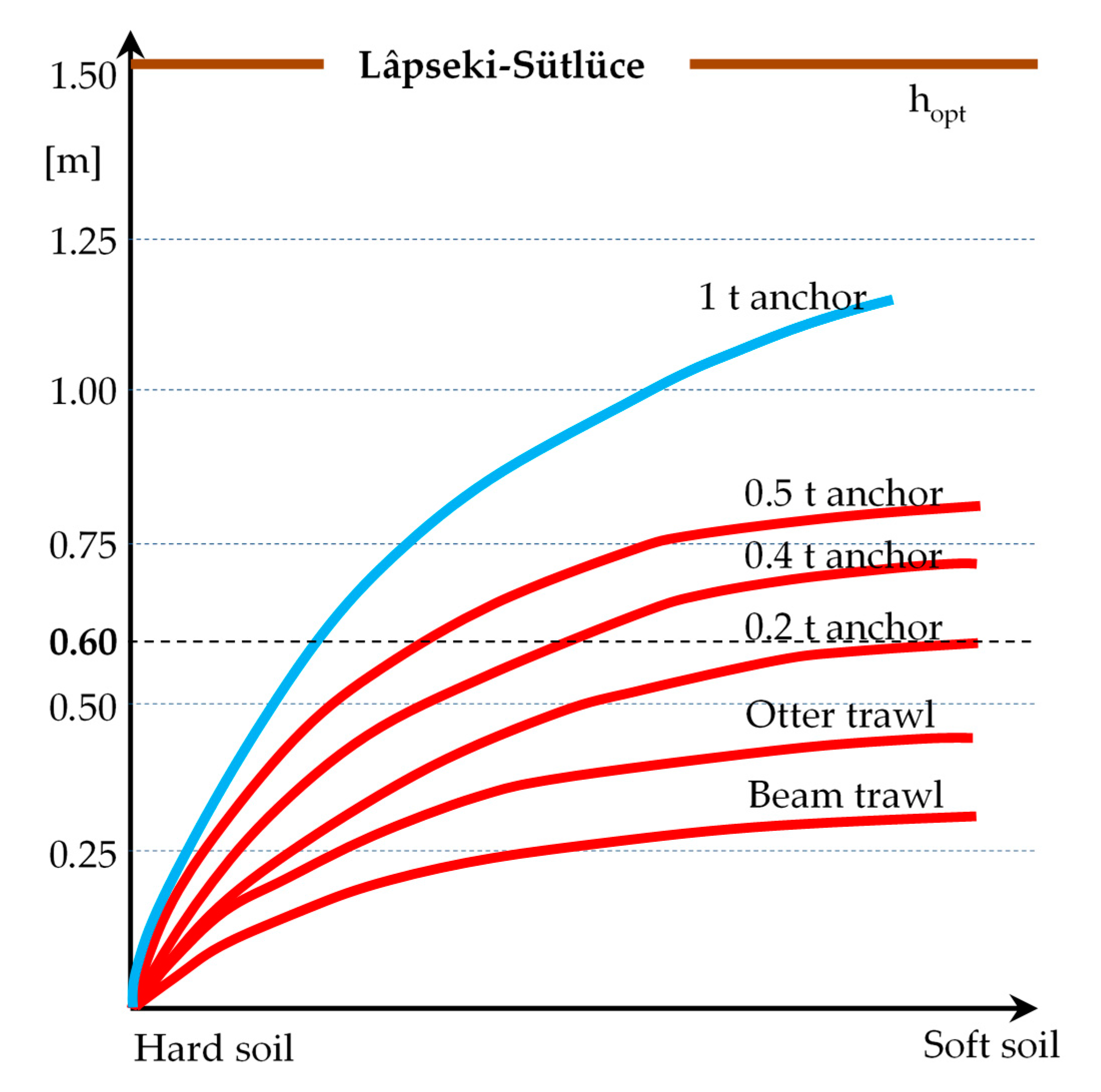

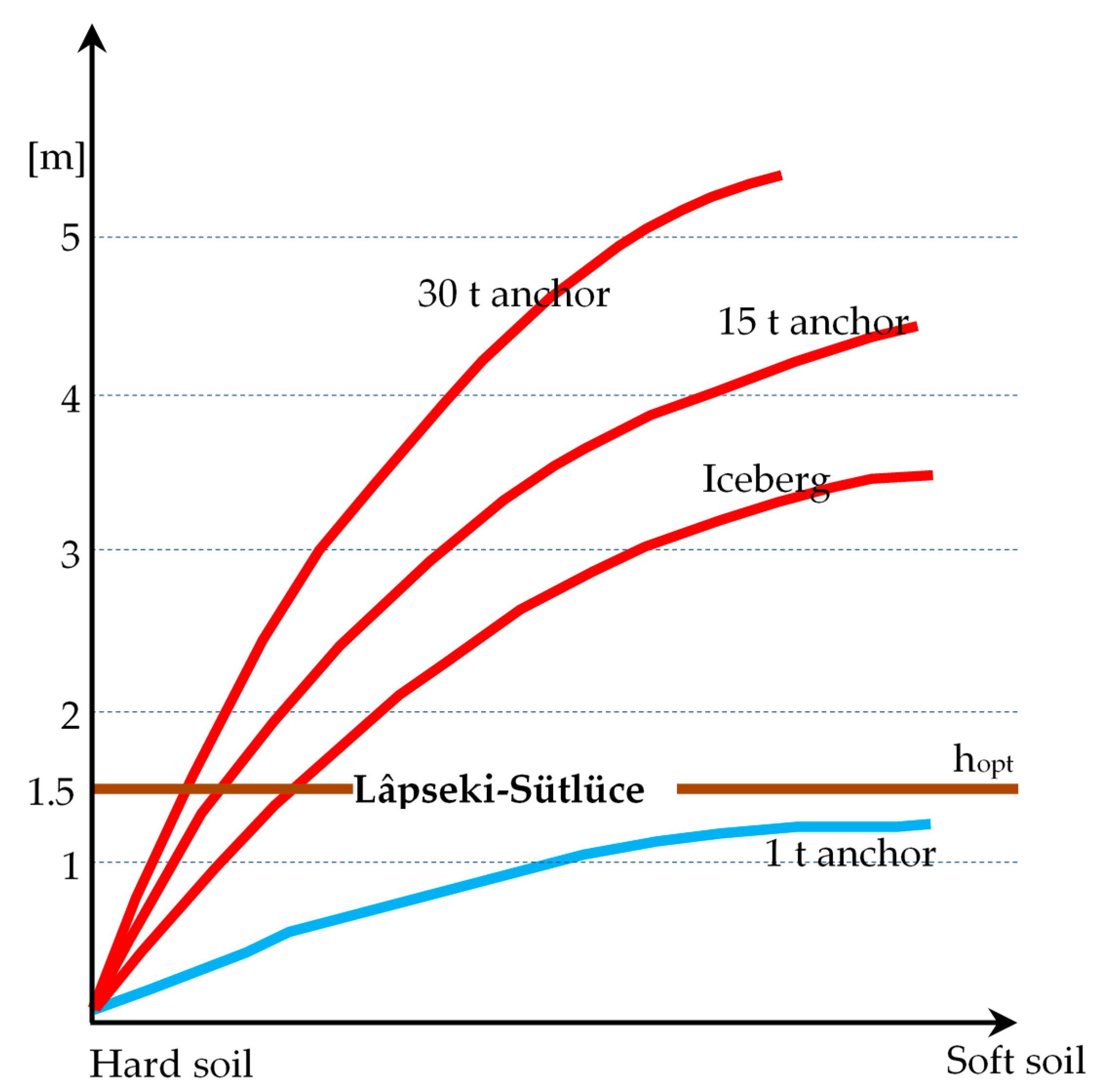

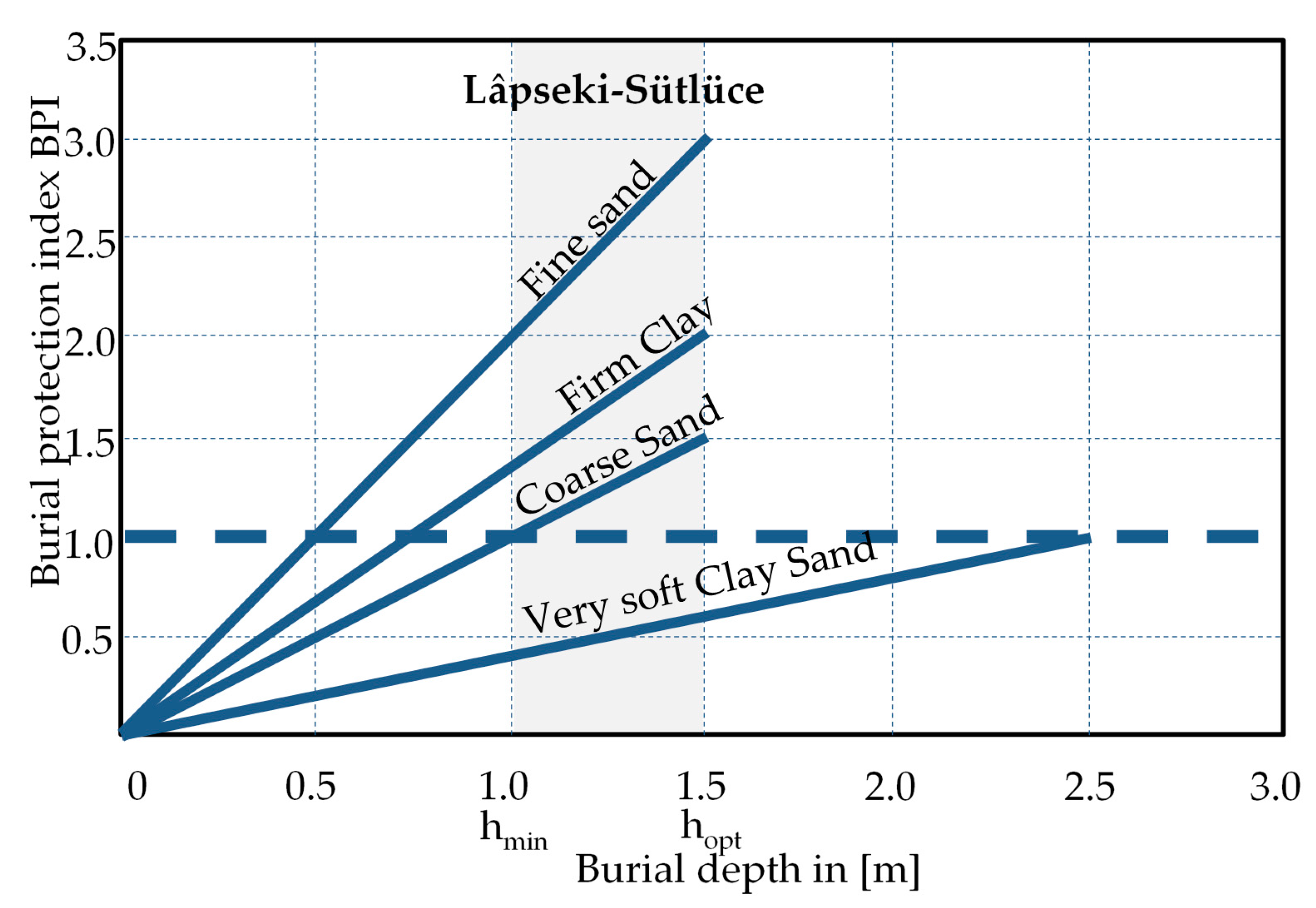

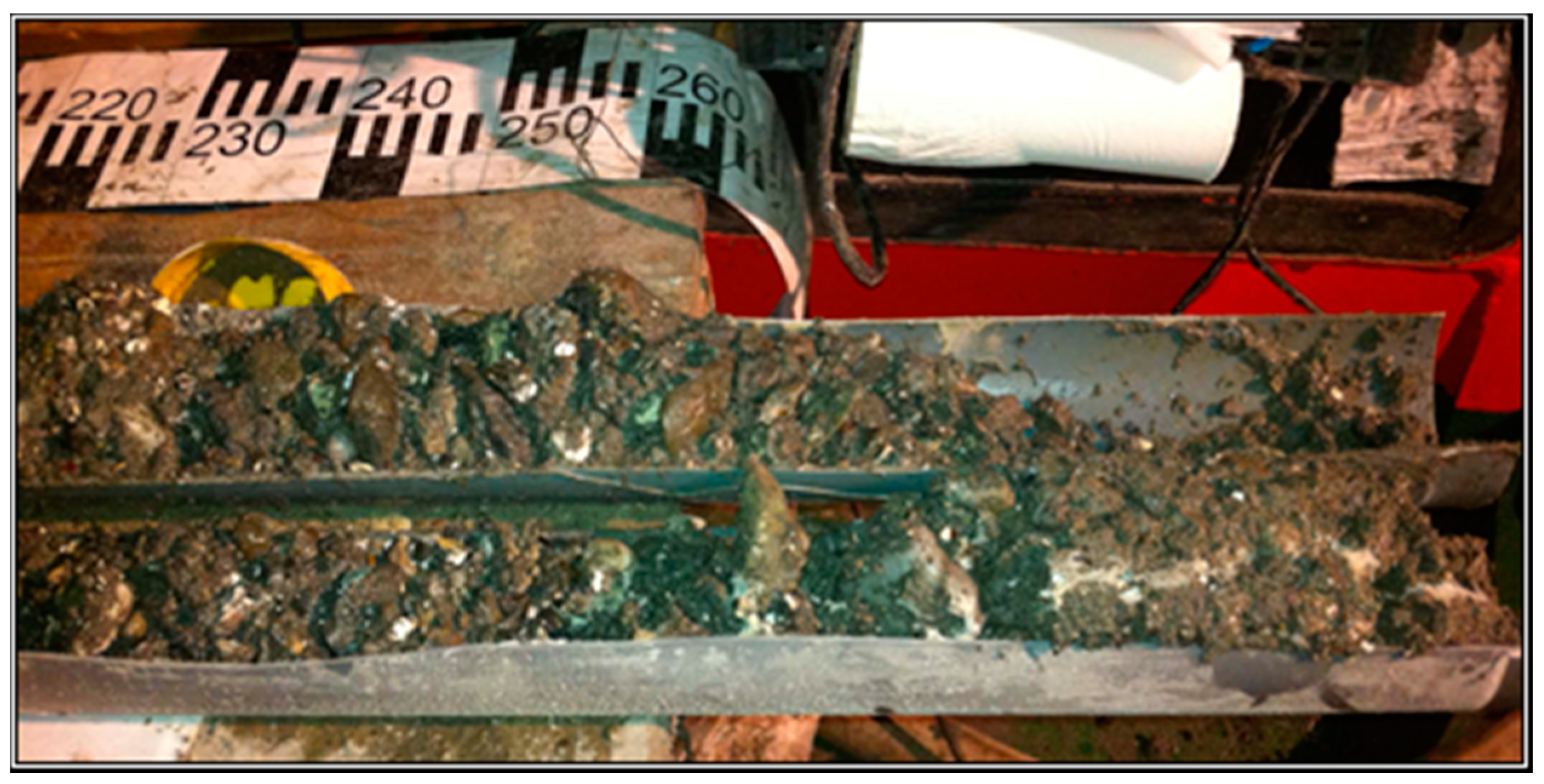

4. Assessment of Lâpseki–Sütlüce Optimal Burial Depth

- ➢

- BPI = 0 Assumes that the cable is surface laid;

- ➢

- BPI = 1 Depth of burial consistent with protecting a cable from normal fishing gear only;

- ➢

- BPI = 2 Depth of burial gives protection from anchors up to approximately 2 t. This may be suitable for normal fishing activity, but would not be for larger ships (e.g., large container ships, tankers);

- ➢

- BPI = 3 Depth of burial sufficient to protect from anchors of all but the largest ships.

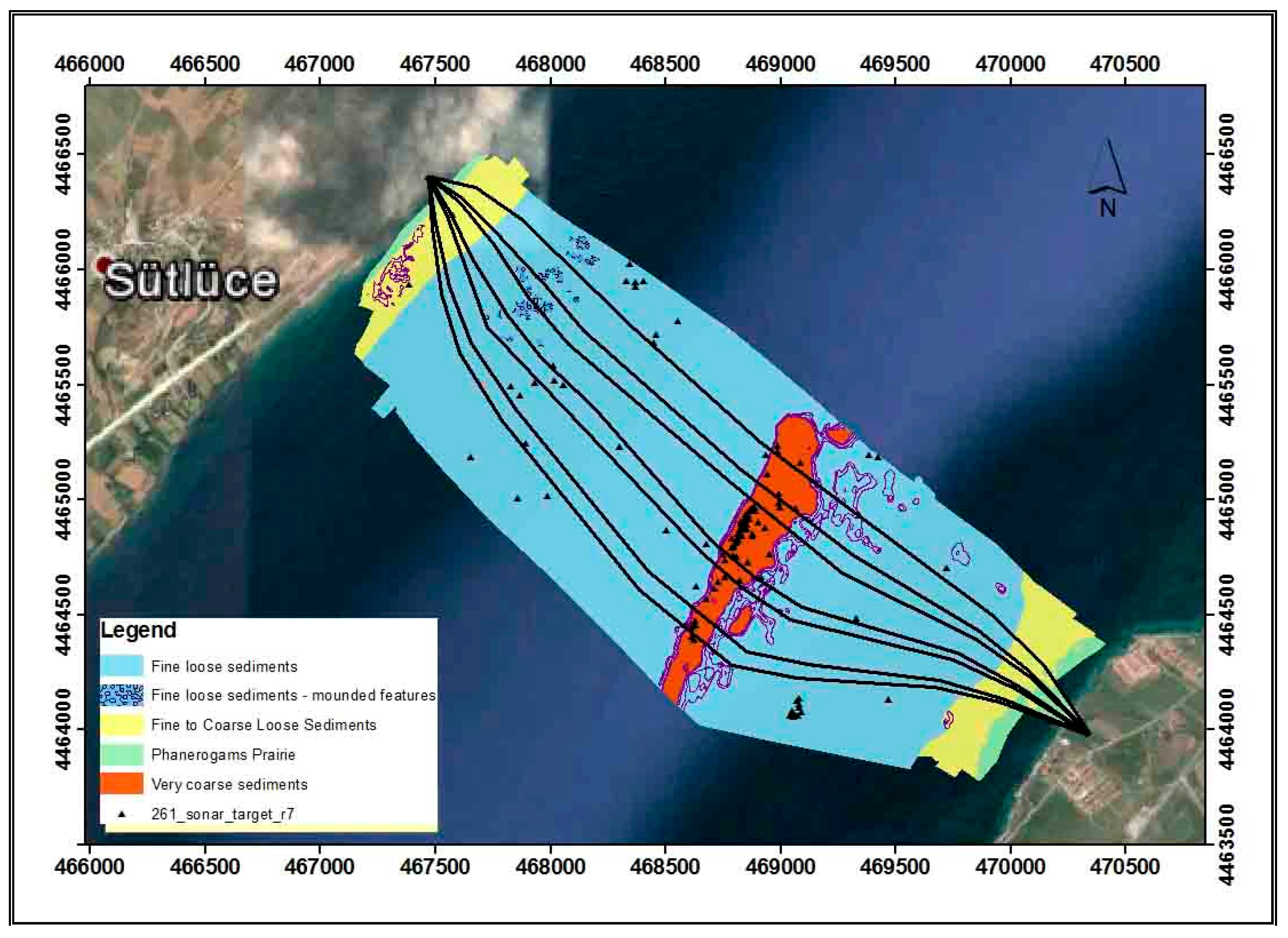

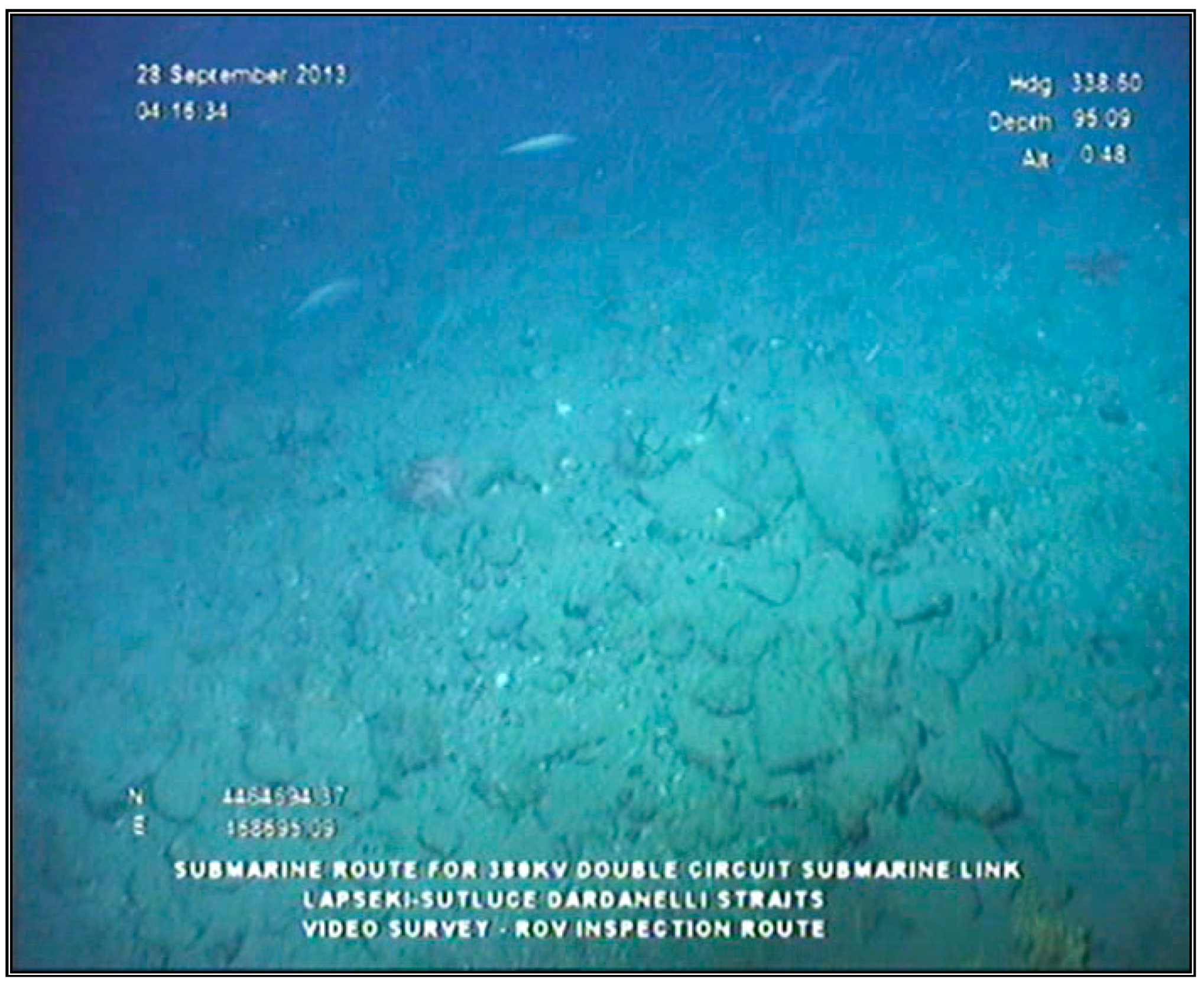

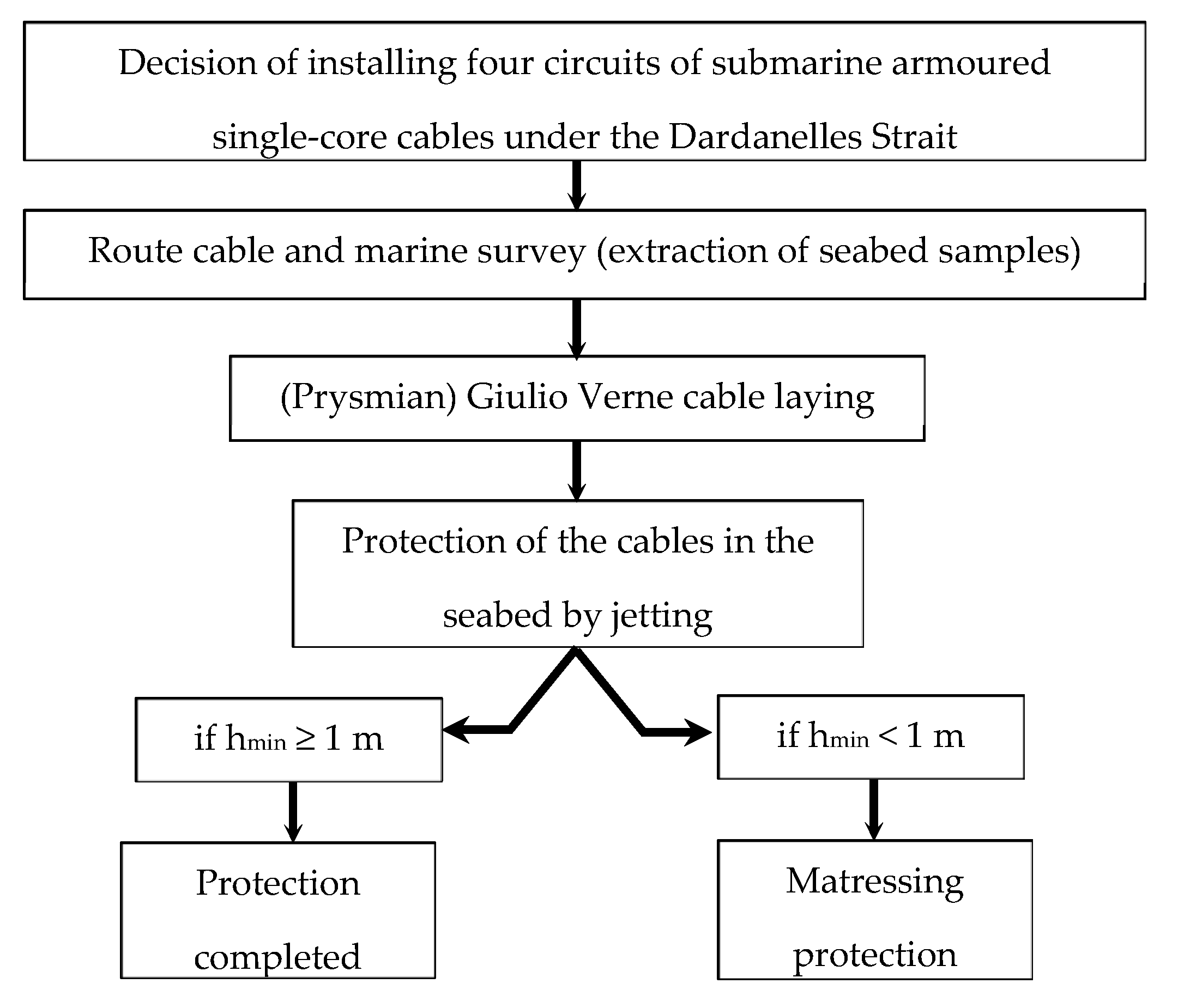

5. Verification of the Consistency of the Installation Choices of Lâpseki–Sütlüce

- ➢

- A desktop study;

- ➢

- A topographic survey at both landings from the shoreline to the sea/land joint bay area;

- ➢

- A near-shore bathymetric survey;

- ➢

- AN offshore marine survey.

- Rough sea bottom, which may cause free spans, abrasion, or sidewall pressure on the cable;

- Steep slopes (less than 15–20% is recommended);

- Natural obstacles like boulders or even human past activities as wrecks, scrap, etc;

- Areas where waves, high water currents, high tidal range, soil movements, or ice may cause problems (it is not the case of the Lâpseki–Sütlüce submarine link);

- Cable crossings and other cables or services nearby (as it is the case of the Lâpseki–Sütlüce submarine cables);

- Too shallow water depth for cable laying, protection, and repair;

- Too hard or too soft seabed;

- Areas of existing and future marine activities like shipping channels, fishing areas.

6. Conclusions

Author Contributions

Conflicts of Interest

References

- Iliceto, F.; Gubernali, A.; Yildir, K.; Durukan, Y. Special Protection System in the interface between the Turkish and ENTSO-E power systems to counteract propagation of major disturbances. In Proceedings of the 43rd International Conference on Large High Voltage Electric Systems 2010, Cigré 2010, Paris, France, 22–27 August 2010. [Google Scholar]

- Iliceto, F.; Gatta, F.M.; Cinieri, E.; Asan, G. TRVs across circuit breakers of series compensated lines: Status with present technology and analysis for the Turkish 420-kV grid. In Proceedings of the 1991 IEEE Power Engineering Society Transmission and Distribution Conference, Dallas, TX, USA, 22–27 September 1991. [Google Scholar]

- Zhang, Z.; Voloh, I.; Cardenas, J.; Antiza, I.; Iliceto, F. Inter-area oscillation detection by modern digital relays. In Proceedings of the International Conference on Advanced Power System Automation and Protection, Beijing, China, 16–20 October 2011; pp. 1396–1401. [Google Scholar]

- Bui-Van, Q.; Gallon, F.; Iliceto, F.; Janssen, A.L.J.; Middleton, B.; Waldron, M. Long-distance AC power transmission and shunt/series compensation overview and experiences. In Proceedings of the 41st International Conference on Large High Voltage Electric Systems 2006, Cigré 2006, Paris, France, 27 August–1 September 2006. [Google Scholar]

- Balanuye, I.; Köksal, F.; Ozan, N.; Özdemirci, E.; Iliceto, F.; Colla, L.; Kuljaca, N.; Kurkcu, F. 400 kV AC—2 × 1000 MW submarine cable crossing of the Dardanelles strait in Turkey. In Proceedings of the Cigré, Paris, France, 21–26 August 2016. Paper B1-310. [Google Scholar]

- Benato, R.; Paolucci, A. EHV AC Undergrounding Electrical Power: Performance and Planning; Series: Power Systems; Springer: Berlin/Heidelberg, Germany, 2010; Volume 47, ISBN 978-1-84882-866-7. [Google Scholar] [CrossRef]

- Benato, R.; Paolucci, A. Operating capability of AC EHV mixed lines with overhead and cables links. Electr. Power Syst. Res. 2008, 78, 584–594. [Google Scholar] [CrossRef]

- Benato, R.; Paolucci, A. Operating Capability of Long AC EHV Transmission Cables. Electr. Power Syst. Res. 2005, 75, 17–27. [Google Scholar] [CrossRef]

- Benato, R.; Napolitano, D. State-space model for availability assessment of EHV OHL–UGC mixed power transmission link. Electr. Power Syst. Res. 2013, 99, 45–52. [Google Scholar] [CrossRef]

- Benato, R. Multiconductor Analysis of Underground Power Transmission Systems: EHV AC Cables. Electr. Power Syst. Res. 2009, 79, 27–38. [Google Scholar] [CrossRef]

- Benato, R.; Sessa, S.D.; de Zan, R.; Guarniere, M.R.; Lavecchia, G.; Labini, P.S. Different Bonding Types of Scilla-Villafranca (Sicily-Calabria) 43 km Double-Circuit AC 380 kV Submarine-Land Cable. IEEE Trans. Ind. Appl. 2015, 51, 5050–5057. [Google Scholar] [CrossRef]

- Benato, R.; Lauria, S.; Gatta, F.M.; Colla, L.; Rebolini, M.; Renaud, F. Steady-State and Transient EHV AC Cable Shunt Reactive Compensation Assessment. In Proceedings of the Cigré 2010, Paris, France, 22–27 August 2010. Paper C4-109. [Google Scholar]

- Benato, R.; del Brenna, M.; di Mario, C.; Lorenzoni, A.; Zaccone, E. A New procedure to compare the social costs of EHV-HV overhead lines and underground XLPE cables. In Proceedings of the Cigré 2006, Paris, France, 21–26 August 2006. Paper B1-301. [Google Scholar]

- Colla, L.; Gatta, F.M.; Geri, A.; Lauria, S.; Maccioni, M. Steady-state operation of Very Long EHV AC Cable Lines. In Proceedings of the 2009 IEEE Bucharest Power Tech Conference, Bucharest, Romania, 28 June–2 July 2009. Paper n. 634. [Google Scholar]

- Benato, R.; Colla, L.; Sessa, S.D.; Marelli, M. Review of high current rating insulated cable solutions. Electr. Power Syst. Res. 2016, 133, 36–41. [Google Scholar] [CrossRef]

- Benato, R.; Sessa, S.D.; Guglielmi, F.; Partal, E.; Tleis, N. Ground Return Current Behaviour in High Voltage Alternating Current Insulated Cables. Energies 2014, 7, 8116–8131. [Google Scholar] [CrossRef]

- Lauria, S.; Gatta, F.M.; Colla, L. Shunt compensation of EHV Cables and Mixed Overhead-Cable Lines. In Proceedings of the 2007 IEEE Lausanne Power Tech Conference, Lausanne, Switzerland, 1–5 July 2007. Paper n. 562. [Google Scholar]

- Colla, L.; Iliceto, F.; Gatta, F.M.; Lauria, S. Design and operation of EHV transmission lines including long insulated cable and overhead sections. In Proceedings of the IEEE International Power Engineering Conference, Singapore, 29 November–2 December 2005. Paper TM-3.6J. [Google Scholar]

- Benato, R.; Sessa, S.D.; Guglielmi, F. Determination of Steady-State and Faulty Regimes of Overhead Lines by Means of Multiconductor Cell Analysis (MCA). Energies 2012, 5, 2771–2793. [Google Scholar] [CrossRef]

- Benato, R.; Sessa, S.D.; Guglielmi, F.; Partal, E.; Tleis, N. Zero sequence behaviour of a double-circuit overhead line. Electr. Power Syst. Res. 2014, 116, 419–426. [Google Scholar] [CrossRef]

- Benato, R.; Paolucci, A. Multiconductor cell analysis of skin effect in Milliken type cables. Electr. Power Syst. Res. 2012, 90, 99–106. [Google Scholar] [CrossRef]

- Matis, M. The Protection of Undersea Cables: A Global Security Threat; United States Army War College: Carlisle, PA, USA, 2012. [Google Scholar]

- Protection of submarine cables by placement “underground”. Electr. Eng. 1938, 57, 204–205. [CrossRef]

- Worzyk, T. Submarine Power Cables: Design, Installation, Repair, Environmental Aspects; Power Systems Series; Springer: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Recommended Practice DNV-RP-J301 Subsea Power Cables in Shallow Water Renewable Energy Applications. February 2014. Available online: https://rules.dnvgl.com/docs/pdf/DNV/codes/docs/2014-02/RP-J301.pdf (accessed on 13 September 2016).

- Working Group B1.21. Cigré Technical Brochure #398: Third-Party Damage to Underground and Submarine Cables; CIGRE: Paris, France, 2009; ISBN 978-2-85873-085-8. [Google Scholar]

- IEEE Standards 1120: IEEE Guide for the Planning, Design, Installation, and Repair of Submarine Power Cable Systems; IEEE: New York, NY, USA, 2005; ISBN 0-7381-4473-8 SS95271.

- Working Group B1.43. Cigré Technical Brochure #623: Recommendations for Mechanical Testing of Submarine Cables; CIGRE: Paris, France, 2015; ISBN 978-2-85873-326-2. [Google Scholar]

- Department for Business Enterprise and Regulatory Reform (BERR). Review of Cabling Techniques and Environmental Effects Applicable to the Offshore Wind Farm Industry; Technical Report; BERR: London, UK, 2008. [Google Scholar]

- Cigré Working Group 21.06. Methods to Prevent Mechanical Damage to Submarine Cables. In Proceedings of the Cigré 1986, Paris, France, 27 August–4 September 1986. [Google Scholar]

- Allan, P.G. Geotechnical Aspects of Submarine Cables. In Proceedings of the IBC Conference on Subsea Geotechnics, Aberdeen, UK, 18–19 November 1998. [Google Scholar]

- Arnaud, U.; Bazzi, G.; Valenza, D. Advantages and disadvantages of embedment to prevent external mechanical damages to submarine cables. IEEE Trans. Power Deliv. 1990, 5, 54–57. [Google Scholar] [CrossRef]

- Candas, M.; Meric, O.S. The Application of Ultra High Voltage in the World. J. Power Energy Eng. 2015, 3, 453–457. [Google Scholar] [CrossRef]

- Oldervoll, F.; Jensen, G.; Slåtten, S.A.; Elders, J.; Kaldhussæter, E. The Olslofjord Project—The world’s first installed 420 kV submarine cable connection combining SCFF cables and XLPE cables with flexible factory joints. In Proceedings of the 9th International Conference on Insulated Cables, Jicable’15, Versailles, France, 21–25 June 2015. Paper B1.6. [Google Scholar]

- Da Silva, J.C.V.; de Araujo Andrade, M.; Bedia, M., Jr. Electrical Optical Power Cable. In Proceedings of the 57th International Wire & Cable Symposium, Providence, RI, USA, 9–12 November 2008; pp. 479–483. [Google Scholar]

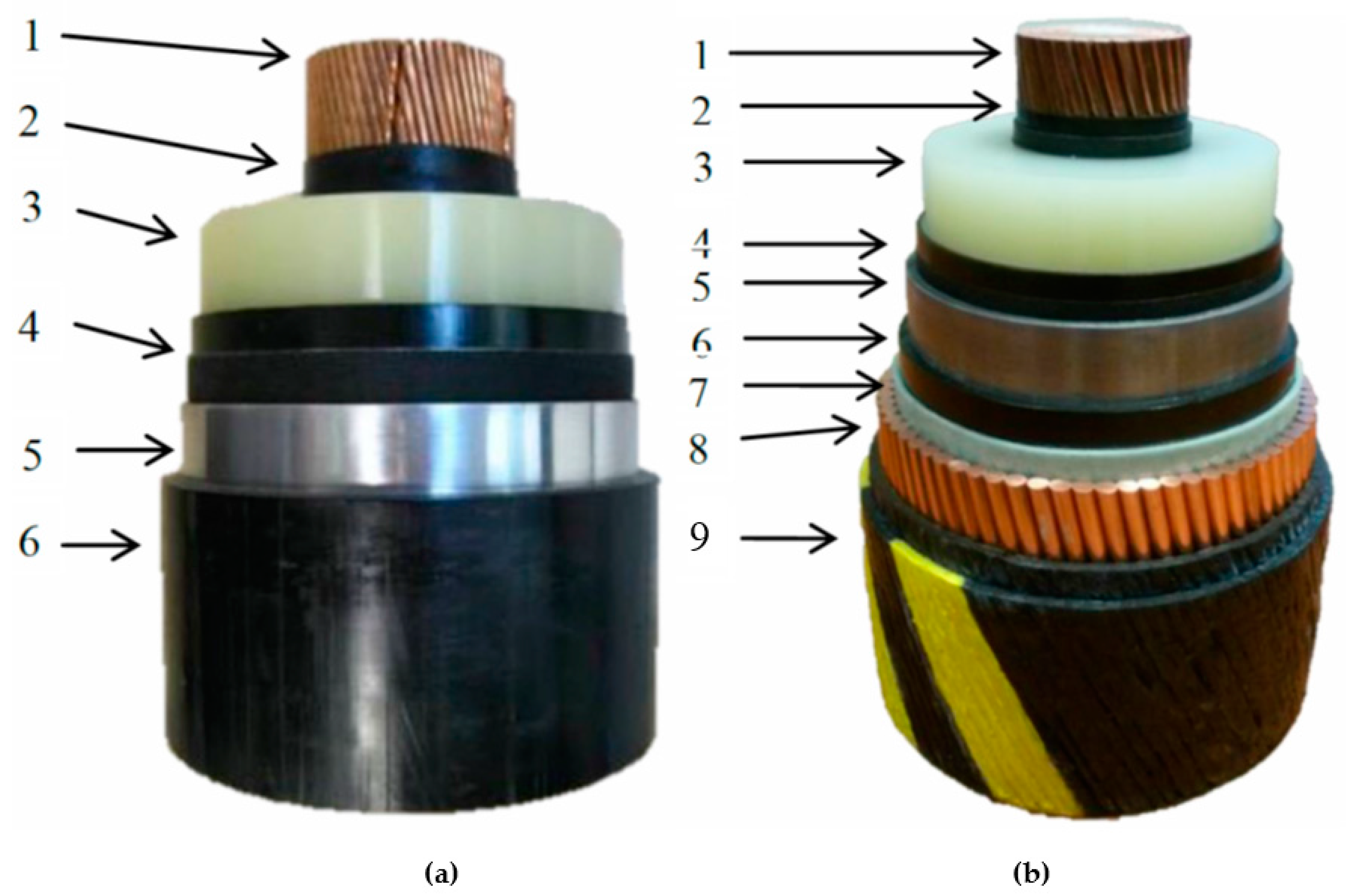

| Land Cable | Submarine Cable | ||||

|---|---|---|---|---|---|

| N | Description | Nominal Diameter mm | N | Description | Nominal Diameter mm |

| 1 | Copper conductor M-type watertight | 58 | 1 | Copper conductor with aluminium central rod watertight | 52.6 |

| 2 | Conductor Screen | 61.6 | 2 | Conductor Screen | 55.6 |

| 3 | XLPE insulation | 116.7 | 3 | XLPE insulation | 112.6 |

| 4 | Insulation Screen | 119.8 | 4 | Insulation Screen | 115.6 |

| 5 | Longitudinally Welded Al screen | 124 | 5 | Extruded lead screen | 124.1 |

| 6 | PE outer sheath | 137.4 | 6 | PE sheath | 131.1 |

| - | 7 | Bedding | 133.1 | ||

| 8 | Copper round wires armour | 144.9 | |||

| 9 | Serving | 153 | |||

| Factor | Hydro Jetting | Ploughing | Mechanical Cutting |

|---|---|---|---|

| Range of suitable soil conditions | M | H | M |

| Uneven bathymetry | H | M | L |

| High currents | L | H | H |

| Low underwater visibility, high turbidity | L | H | L |

| Very shallow water | L (2) | H | M |

| Simultaneous lay and burial (SLB) | M | H | L |

| Post-lay burial (PLB) | H | L (3) | M (3) |

| Manoeuvrability | H | L | M |

| Multipass capability | H | L (4) | M (4) |

| Ability to bury bundled cables | H | M | M |

| Ability to bury loops or repair joints | M | - | - |

| Safety of cable during burial operation | H | L (5) | M |

| Suitability in close proximity to infrastructure | H | L | M |

| Backfill quality | M | H | L |

| Environmental benignity | M | H | M |

| Rate of progress | M | H | L |

| Availability of suitable vessels | H | M (6) | H |

| Mobilisation layout flexibility | H | L | M |

| Ease of catenary/tow line management | H | M | H |

| Category | Cover Depth (m) | Seabed Conditions | Protection |

|---|---|---|---|

| A | >1.50 | fine sediments (soft clay/silt) and/or coarse sediments (loose to dense sand) with thickness >1.65 m | jetting |

| B | 1.00–1.50 | fine sediments (soft to firm clay/silt) and/or coarse sediments (loose to dense sand/fine gravel) with thickness 1.15–1.65 m | |

| C | 0.75–1.00 | fine sediments (soft to firm clay/silt) and/or coarse sediments (loose to dense sand/fine gravel) with thickness 0.90–1.15 m | |

| D | variable | Subcropping/outcropping very coarse sediments (loose gravel/pebbles/cobbles/possible boulders) | jetting attempt + other protection |

| P | approx. 0.50 | Cymodocea nodosa prairie | microtrenching |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Benato, R.; Balanuye, İ.; Köksal, F.; Ozan, N.; Özdemirci, E. Installation of XLPE-Insulated 400 kV Submarine AC Power Cables under the Dardanelles Strait: A 4 GW Turkish Grid Reinforcement. Energies 2018, 11, 164. https://doi.org/10.3390/en11010164

Benato R, Balanuye İ, Köksal F, Ozan N, Özdemirci E. Installation of XLPE-Insulated 400 kV Submarine AC Power Cables under the Dardanelles Strait: A 4 GW Turkish Grid Reinforcement. Energies. 2018; 11(1):164. https://doi.org/10.3390/en11010164

Chicago/Turabian StyleBenato, Roberto, İbrahim Balanuye, Fatih Köksal, Nurhan Ozan, and Ercüment Özdemirci. 2018. "Installation of XLPE-Insulated 400 kV Submarine AC Power Cables under the Dardanelles Strait: A 4 GW Turkish Grid Reinforcement" Energies 11, no. 1: 164. https://doi.org/10.3390/en11010164

APA StyleBenato, R., Balanuye, İ., Köksal, F., Ozan, N., & Özdemirci, E. (2018). Installation of XLPE-Insulated 400 kV Submarine AC Power Cables under the Dardanelles Strait: A 4 GW Turkish Grid Reinforcement. Energies, 11(1), 164. https://doi.org/10.3390/en11010164