Breakdown Voltage and Its Influencing Factors of Thermally Aged Oil-Impregnated Paper at Pulsating DC Voltage

Abstract

1. Introduction

2. Experiments

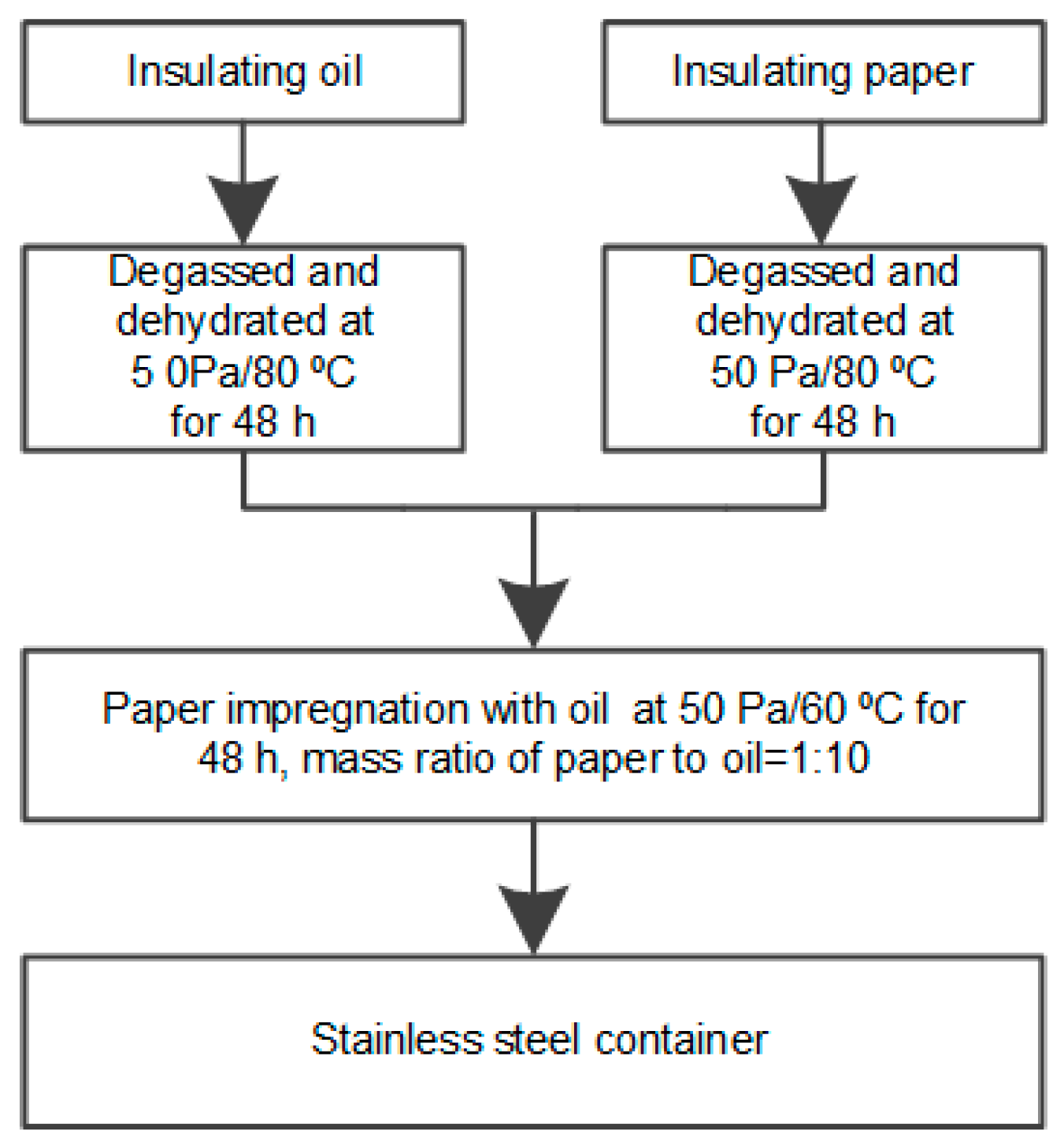

2.1. Accelerated Thermal Aging Experiments

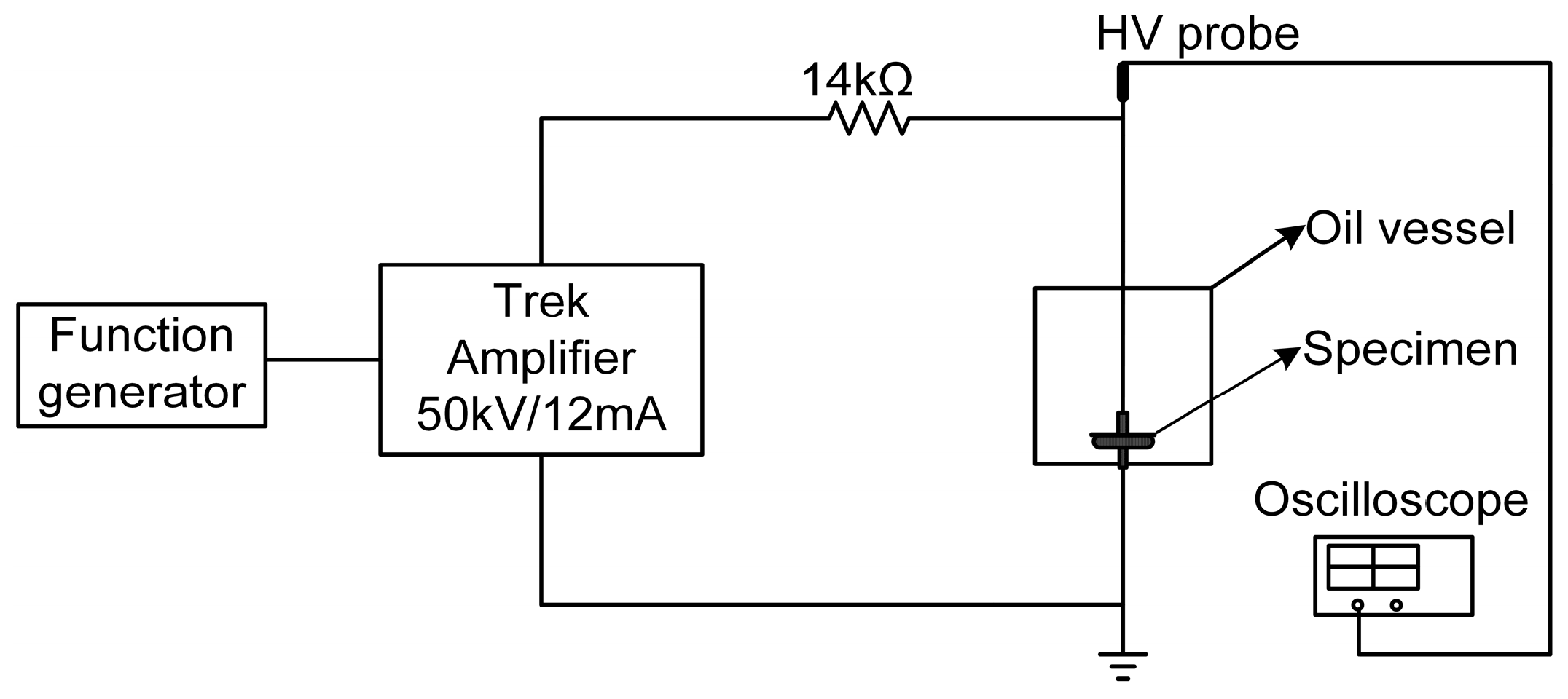

2.2. Experimetnal Setup for Breakdown Voltage Test

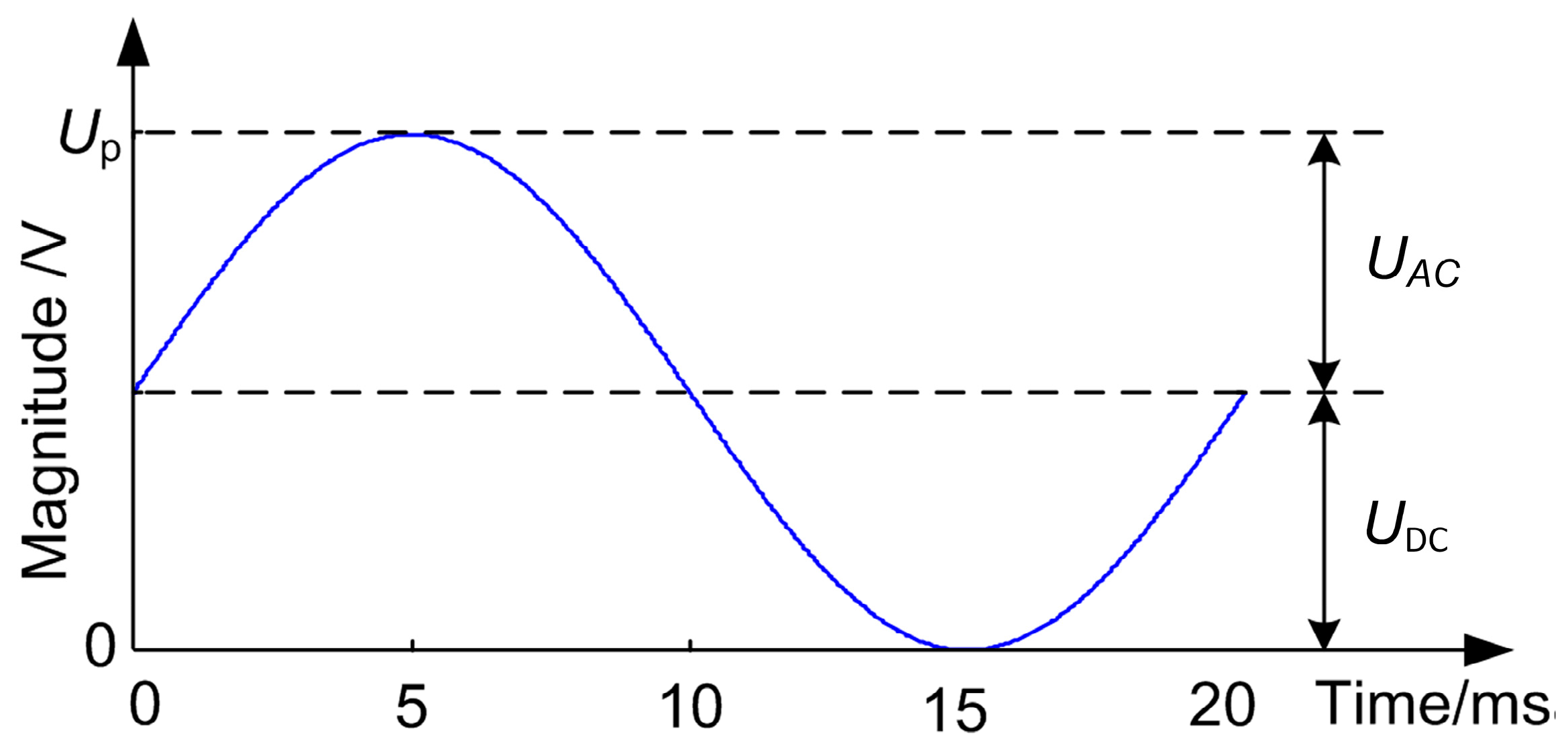

2.3. Breakdown Voltage Test

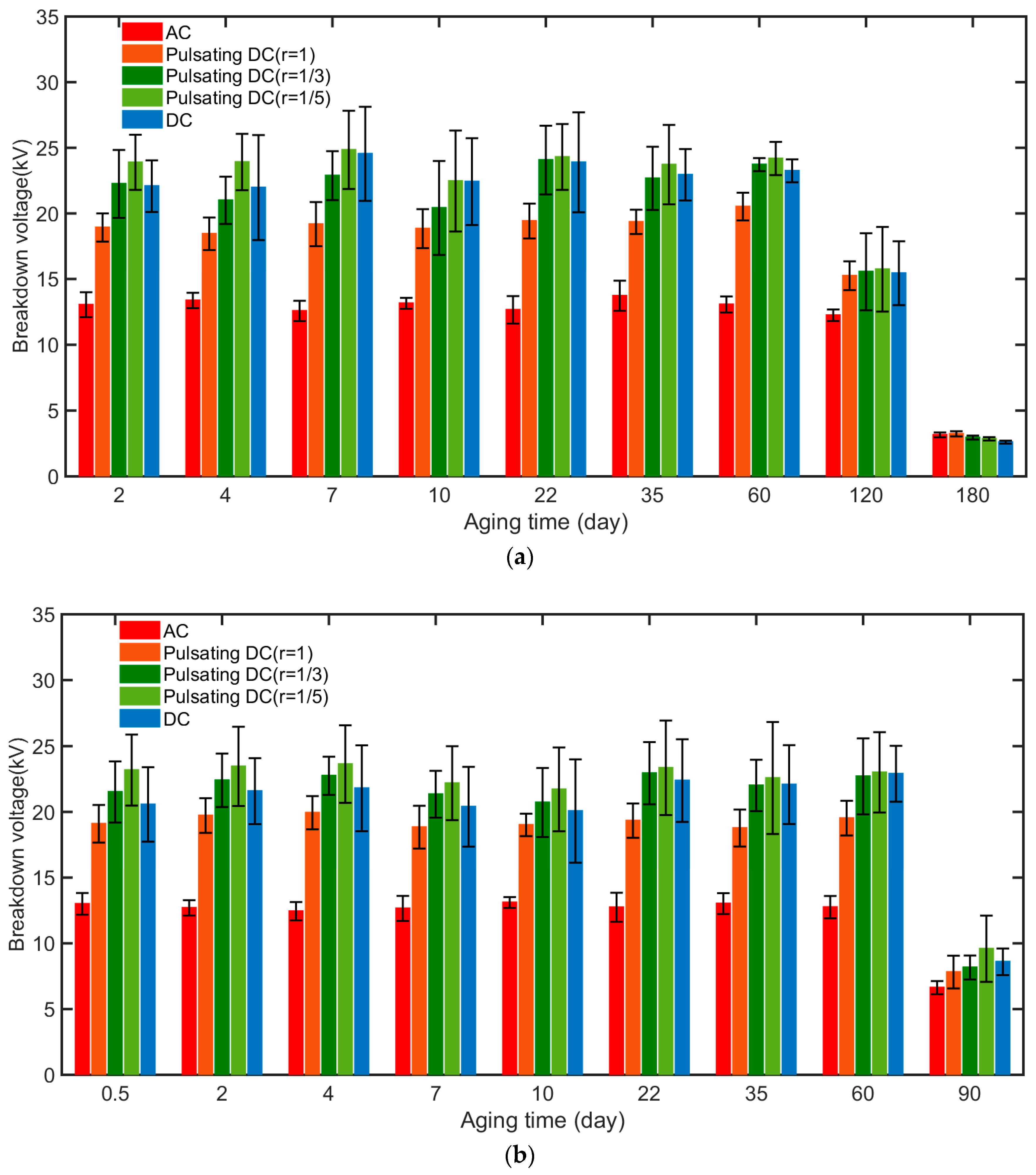

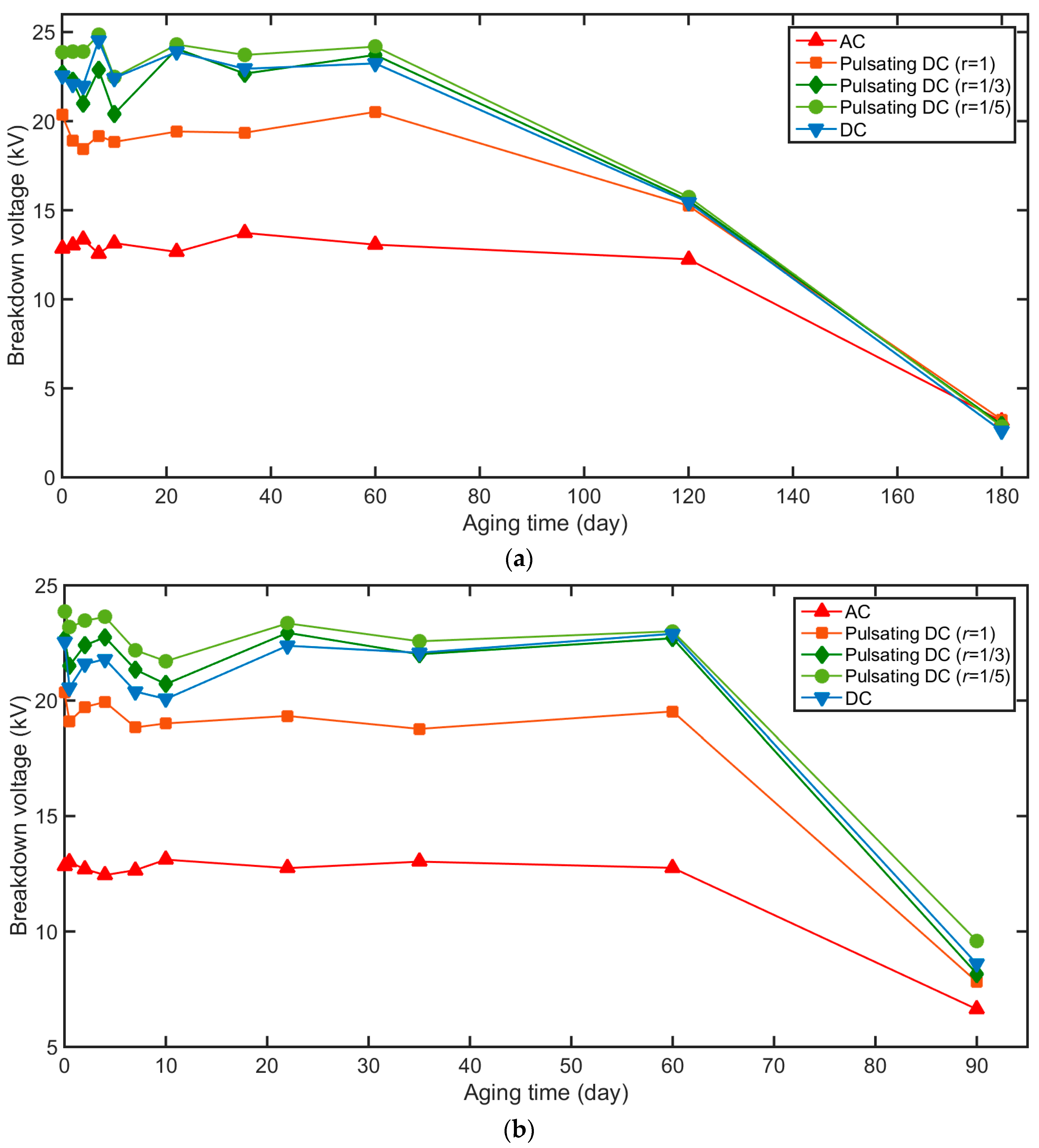

3. Breakdown Voltage of Thermally Aged OIP

4. Discussion

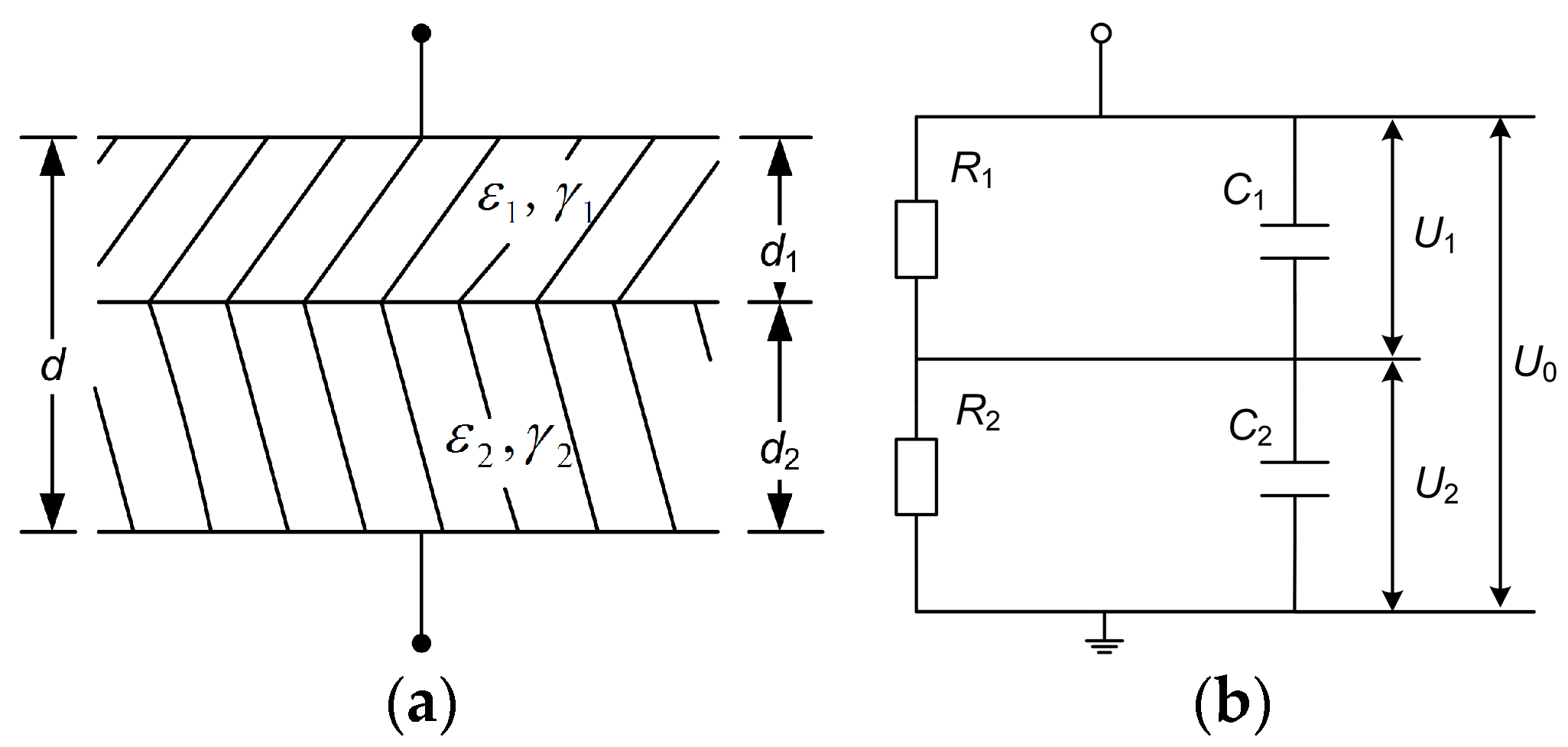

4.1. Difference in Magnitude of Breakdown Voltage at Different Voltage Waveforms

4.2. Possible Influencing Factors for Variation of Breakdown Voltage Versus Aging Time

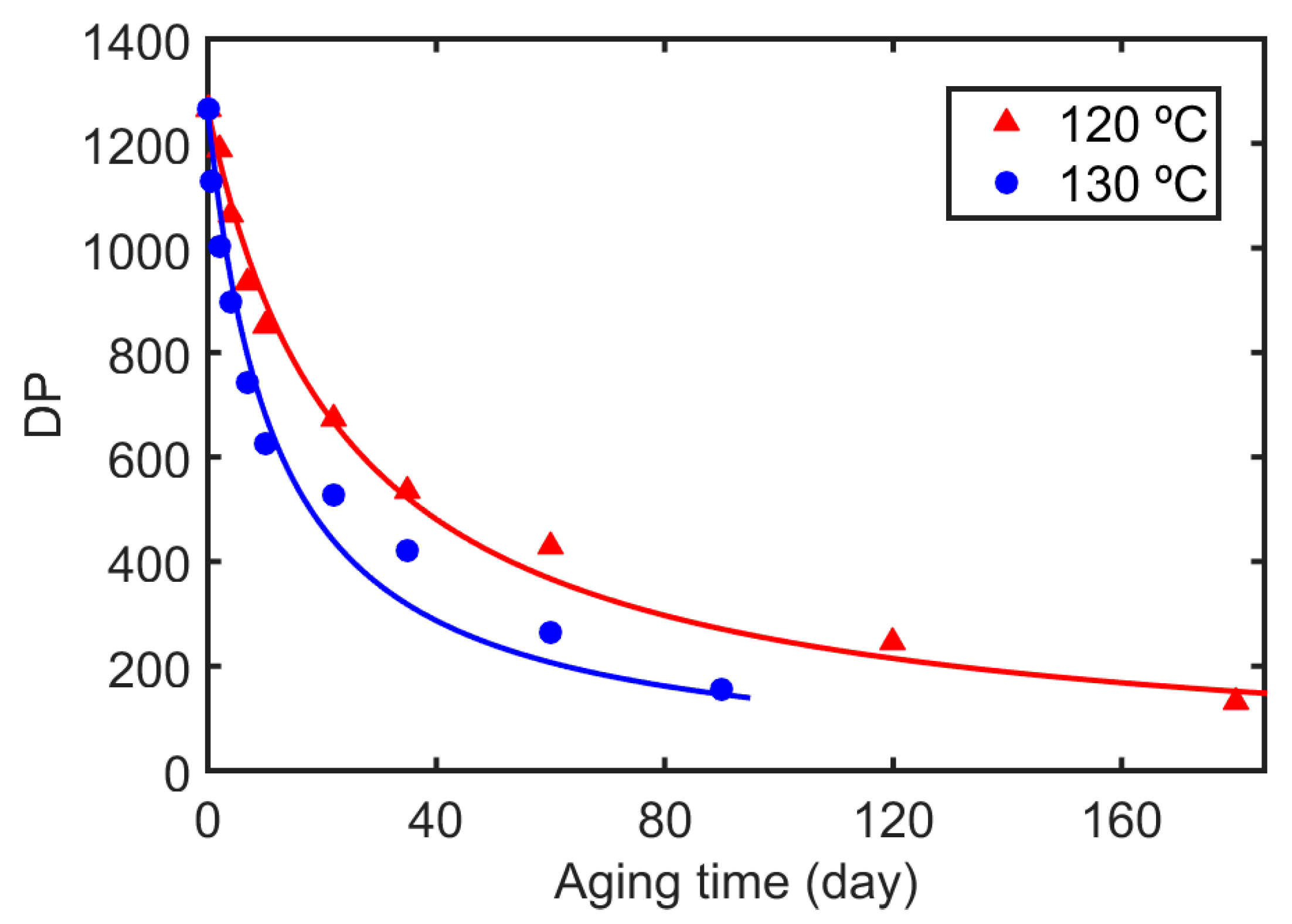

4.2.1. DP of Paper

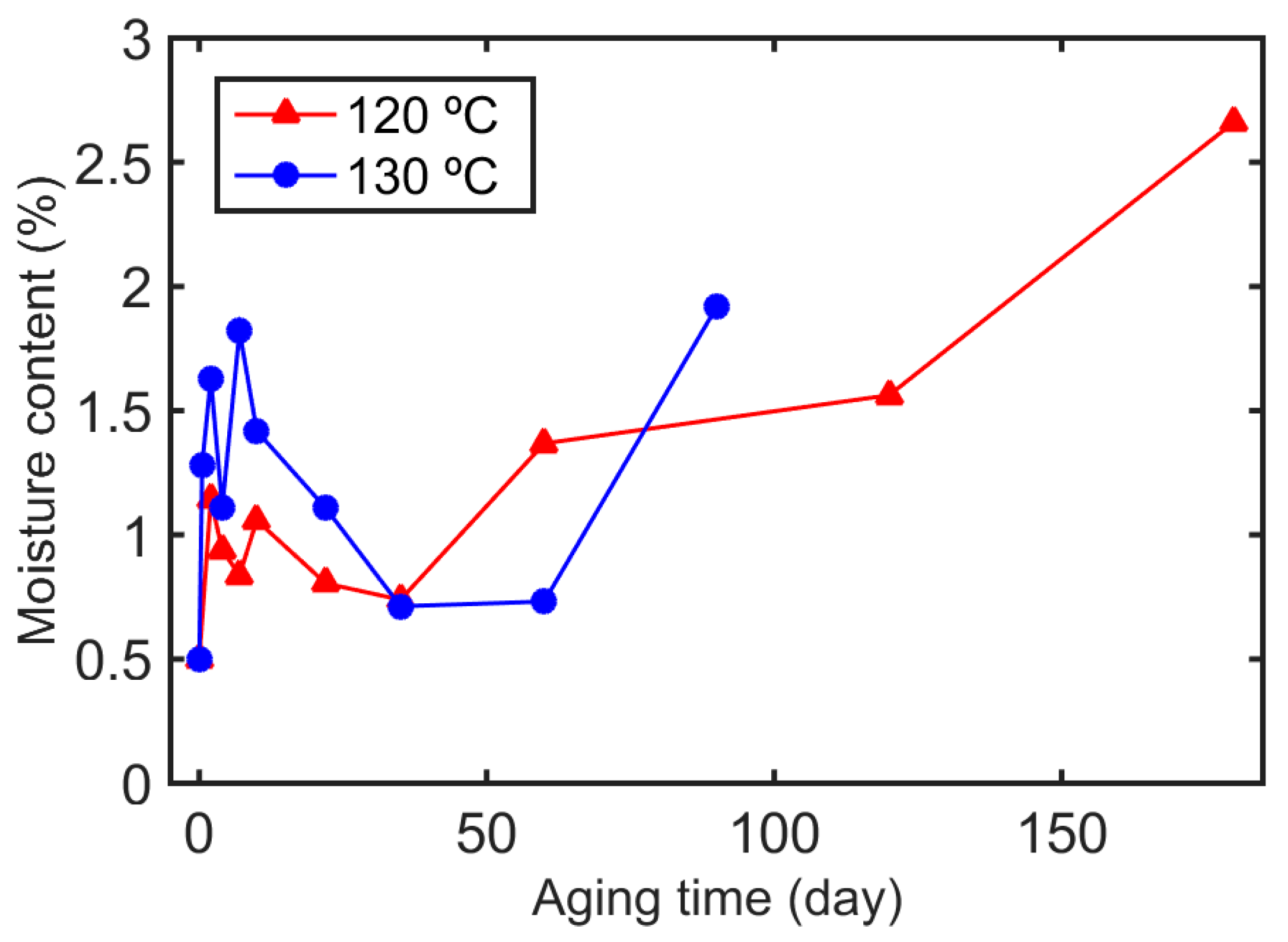

4.2.2. Moisture Content

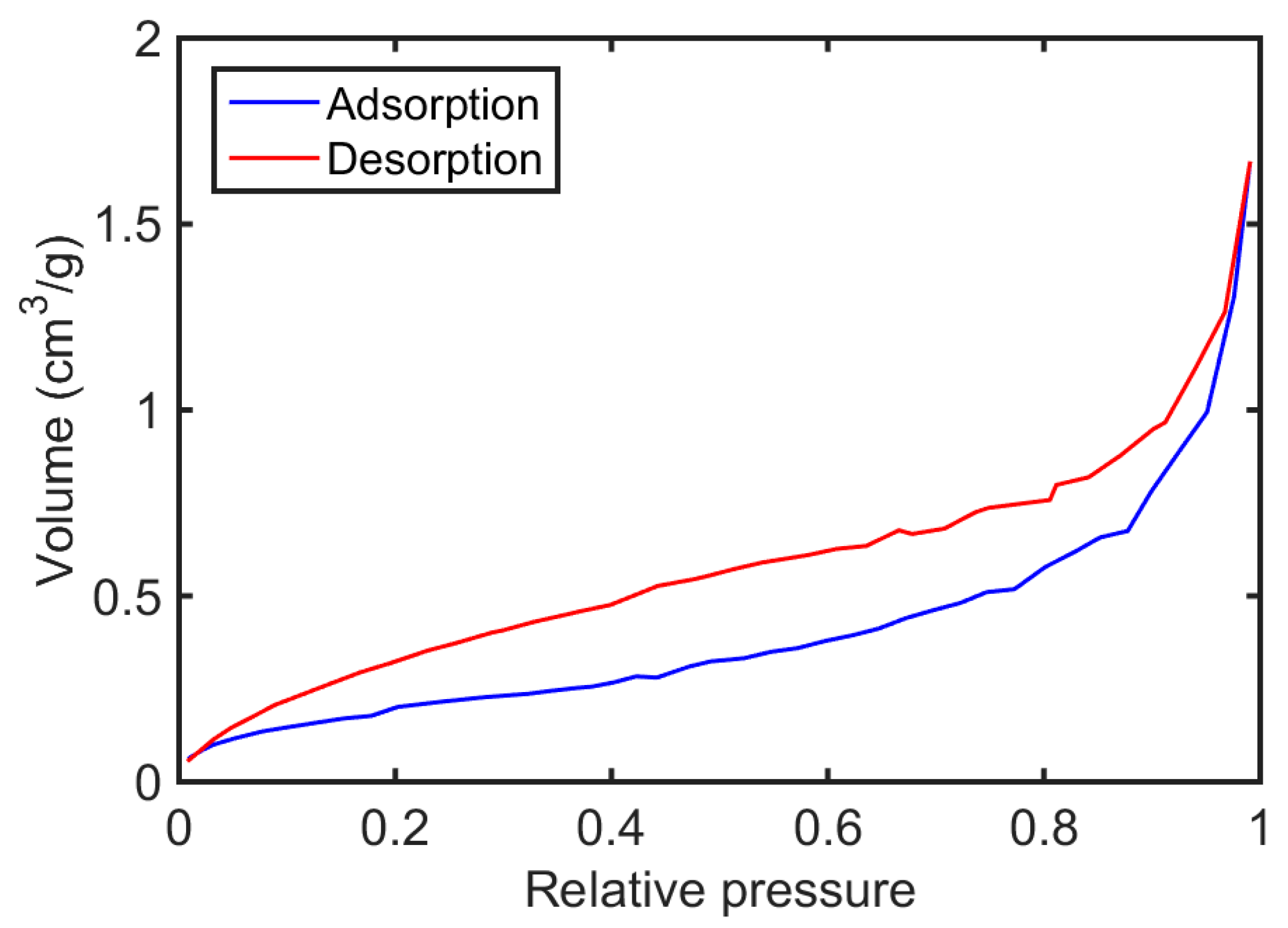

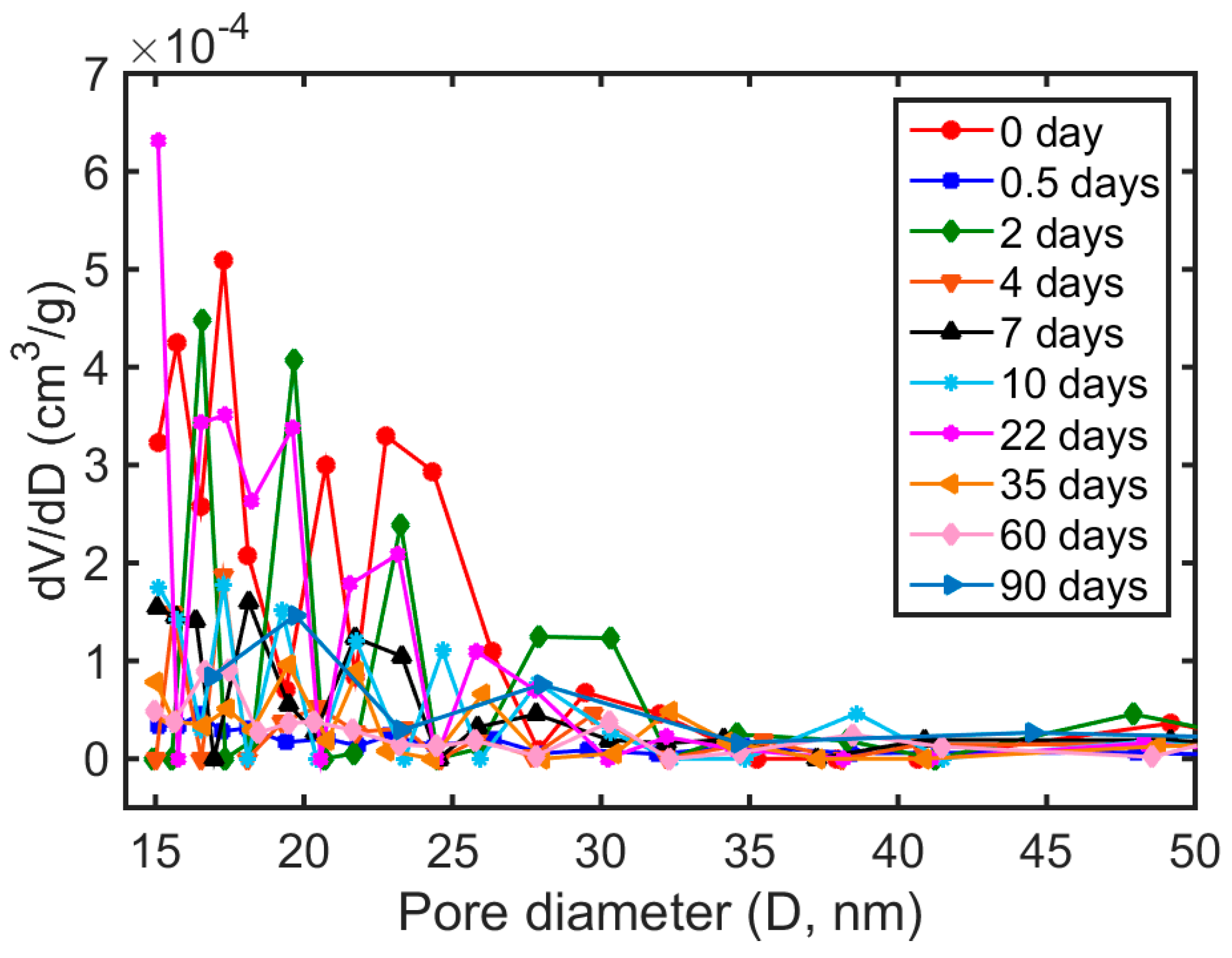

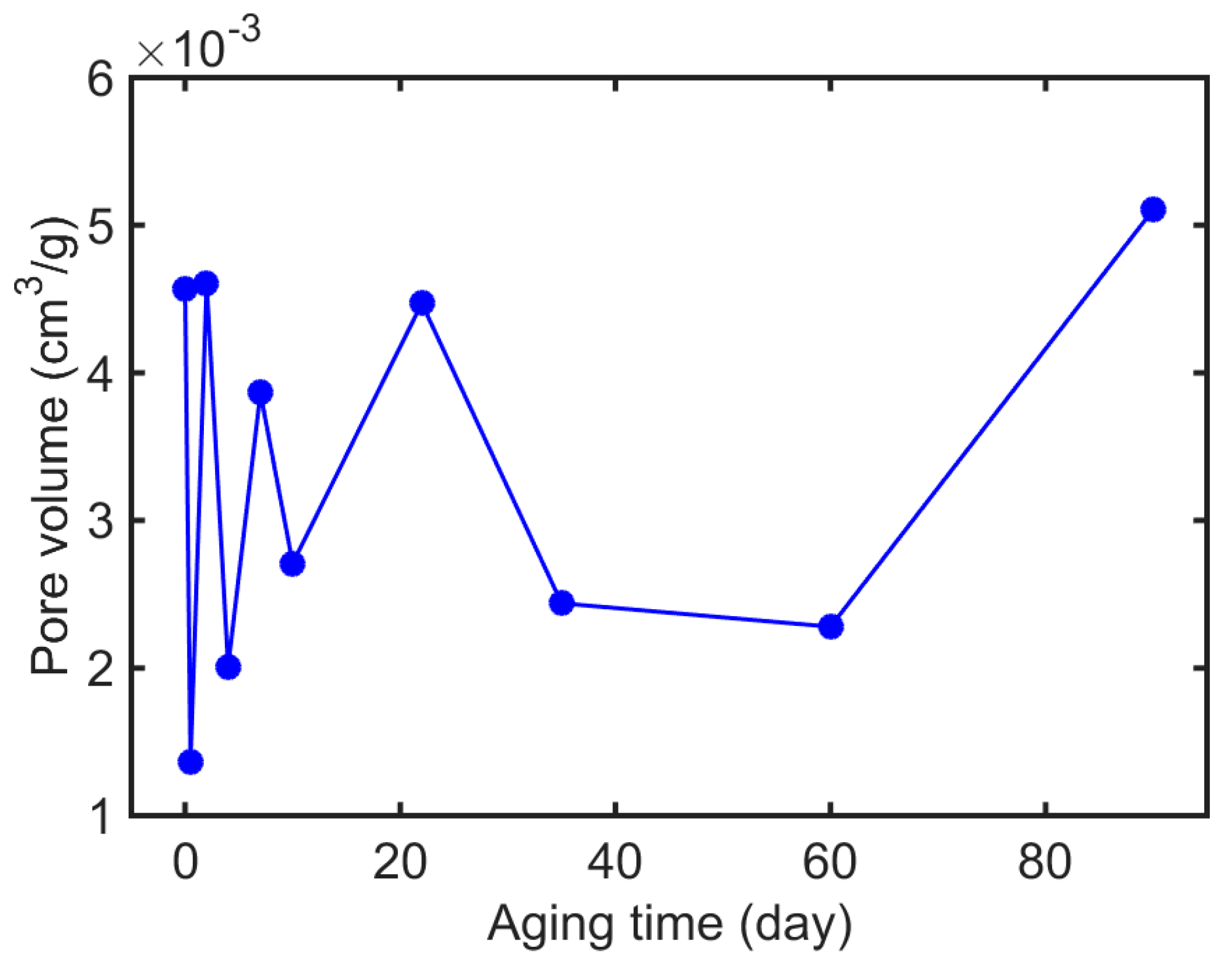

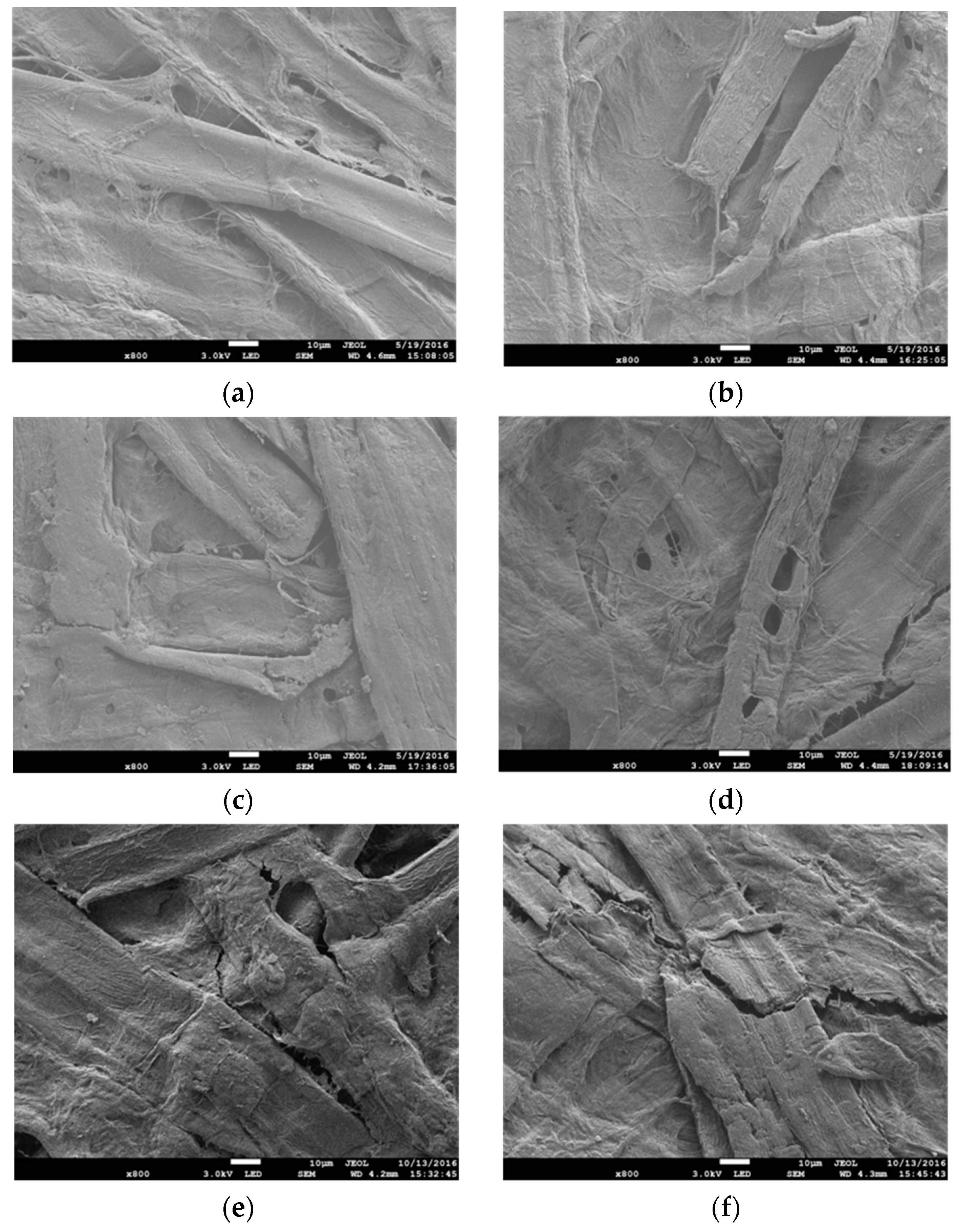

4.2.3. Oil Absorption Ability of Paper Associated with Pores and Cracks

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kohtoh, M.; Kaneko, S.; Okabe, S.; Amimoto, T. Aging effect on electrical characteristics of insulating oil in field transformer. IEEE Trans. Dielectr. Electr. Insul. 2009, 16, 1698–1706. [Google Scholar] [CrossRef]

- Prevost, T.A.; Oommen, T.V. Cellulose insulation in oil-filled power transformers: Part I—history and development. IEEE Electr. Insul. Mag. 2006, 22, 28–35. [Google Scholar] [CrossRef]

- Oommen, T.V.; Prevost, T.A. Cellulose insulation in oil-filled power transformers: Part II maintaining insulation integrity and life. IEEE Electr. Insul. Mag. 2006, 22, 5–14. [Google Scholar] [CrossRef]

- Saha, T.K. Review of modern diagnostic techniques for assessing insulation condition in aged transformers. IEEE Trans. Dielectr. Electr. Insul. 2003, 10, 903–917. [Google Scholar] [CrossRef]

- Bao, L.; Li, J.; Zhang, J.; Li, X.; Li, X. Influences of temperature on partial discharge behavior in oil-paper bounded gas cavity under pulsating DC voltage. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 1482–1490. [Google Scholar] [CrossRef]

- Li, J.; He, Z.; Grzybowski, S. Electrical aging lifetime model of oil-impregnated paper under pulsating DC voltage influenced by temperature. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 1992–1997. [Google Scholar] [CrossRef]

- Zhou, Y.X.; Jin, F.B.; Huang, M.; Le, T.H.; Huang, J.W.; Liu, Z.H.; Lu, L.C. Effects of thermal aging on creepage discharge in oil- impregnated pressboard under combined AC-DC voltage. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 2737–2746. [Google Scholar] [CrossRef]

- Qi, B.; Zhao, X.; Li, C.; Wu, H. Electric field distribution in oil-pressboard insulation under AC-DC combined voltages. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 1935–1941. [Google Scholar] [CrossRef]

- Nazemi, M.H.; Hinrichsen, V. Experimental investigations on partial discharge characteristics of water droplets on polymeric insulating surfaces at AC, DC and combined AC-DC voltages. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 2261–2270. [Google Scholar] [CrossRef]

- Qi, B.; Wei, Z.; Li, C.; Gao, Y.; Zhang, X. Influences of Different Ratios of AC-DC Combined Voltage on Internal Gas Cavity Discharge in Oil-Pressboard Insulation. IEEE Trans. Power Deliv. 2016, 31, 1026–1033. [Google Scholar] [CrossRef]

- Abdelmalik, A.A. Analysis of thermally aged insulation paper in a natural ester-based dielectric fluid. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 2408–2414. [Google Scholar] [CrossRef]

- Sun, P.; Sima, W.; Yang, M.; Wu, J. Influence of thermal aging on the breakdown characteristics of transformer oil impregnated paper. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 3373–3381. [Google Scholar] [CrossRef]

- Huaqiang, L.; Yaning, Z.; Lisheng, Z.; Qinxue, Y.; Xu, L.; Guangqi, L.; Mori, S.; Yamada, S. The DC breakdown of mineral insulating oil and oil-pressboard. In Proceedings of the 2013 Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Shenzhen, China, 20–23 October 2013; pp. 929–931. [Google Scholar]

- Lianwei, B.; Jian, L.; Jinzhuang, L.; Zhiman, H.; Yan, W. Electrical breakdown characteristics of oil-paper insulation under pulsating voltage. In Proceedings of the 2012 International Conference on High Voltage Engineering and Application (ICHVE), Shanghai, China, 17–20 September 2012; pp. 484–488. [Google Scholar]

- Wang, Z.; Pang, L.; Wang, T.; Yang, H.; Zhang, Q.; Li, J. Breakdown characteristics of oil-paper insulation under lightning impulse waveforms with oscillations. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 2620–2627. [Google Scholar] [CrossRef]

- Vandermaar, A.J.; Wang, M.; Neilson, J.B.; Srivastava, K.D. The electrical breakdown characteristics of oil-paper insulation under steep front impulse voltages. IEEE Trans. Power Deliv. 1994, 9, 1926–1935. [Google Scholar] [CrossRef]

- Sima, W.; Hua, J.; Yang, M.; Wu, J. Impact of time parameters of lightning impulse on the breakdown characteristics of oil paper insulation. High Volt. 2016, 1, 18–24. [Google Scholar] [CrossRef]

- Sima, W.; Wu, J.; Sun, P.; Yang, M.; Hua, J. Breakdown characteristics of oil-impregnated paper and influential factors for damped alternating oscillation waveforms. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 2079–2087. [Google Scholar] [CrossRef]

- Bao, L.; Li, J.; Zhang, J.; Li, X. Electrical Breakdown Properties of Oil-paper Insulation under Pulsating Voltage Influenced by Temperature. J. Electr. Eng. Technol. 2016, 11, 1735–1743. [Google Scholar] [CrossRef]

- Chen, Q.; Chi, M.; Gao, Y.; Wei, X.; Wang, Y.; Zhang, S. Breakdown Characteristics and Its Mathematical Model of Oil-pressboard Insulation Under Compound Electric Field. Proc. CSEE 2013, 33, 170–176. [Google Scholar]

- Liao, R.; Hao, J.; Chen, G.; Ma, Z.; Yang, L. A comparative study of physicochemical, dielectric and thermal properties of pressboard insulation impregnated with natural ester and mineral oil. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 1626–1637. [Google Scholar] [CrossRef]

- Tang, C.; Liao, R.; Huang, F.; Y, L.; Zhu, M. The Breakdown Voltage of Power Transformer Insulation Paper After Thermal Aging. Trans. China Electrotech. Soc. 2010, 25, 1–8. [Google Scholar]

- Electric Strength of Insulating Materials. Test Methods, Tests at Power Frequencies; IEC 60243:2013; BSI: London, UK, 2013.

- Shroff, D.H.; Stannett, A.W. A review of paper aging in power transformers. IEE Proc. C Gener. Transm. Distrib. 1985, 132, 312–319. [Google Scholar] [CrossRef]

- Emsley, A.M.; Heywood, R.J.; Ali, M.; Xiao, X. Degradation of cellulosic insulation in power transformers. Part 4: Effects of ageing on the tensile strength of paper. IEE Proc. Sci. Meas. Technol. 2000, 147, 285–290. [Google Scholar] [CrossRef]

- Takahashi, E.; Tsutsumi, Y.; Okuyama, K.; Ogata, F. Partial discharge characteristics of oil-immersed insulation systems under DC, combined AC-DC and DC reversed polarity voltage. IEEE Trans. Power Appar. Syst. 1976, 95, 411–420. [Google Scholar] [CrossRef]

- Emsley, A. The kinetics and mechanisms of degradation of cellulosic insulation in power transformers. Polym. Degrad. Stab. 1994, 44, 343–349. [Google Scholar] [CrossRef]

- Oommen, T.V. Moisture Equilibrium Charts for Transformer Insulation Drying Practice. IEEE Trans. Power Apper. Syst. 1984, PAS-103, 3062–3067. [Google Scholar] [CrossRef]

- Tang, Y.; Wu, D.; Chen, S.; Zhang, F.; Jia, J.; Feng, X. Highly reversible and ultra-fast lithium storage in mesoporous graphene-based TiO2/SnO2 hybrid nanosheets. Energy Environ. Sci. 2013, 6, 2447–2451. [Google Scholar] [CrossRef]

- Li, Y.; Li, Z.; Shen, P.K. Simultaneous Formation of Ultrahigh Surface Area and Three-Dimensional Hierarchical Porous Graphene-Like Networks for Fast and Highly Stable Supercapacitors. Adv. Mater. 2013, 25, 2474–2480. [Google Scholar] [CrossRef] [PubMed]

| Thermal Aging Temperatures (°C) | Aging Time (Day) |

|---|---|

| 120 | 2, 4, 7, 10, 22, 35, 60, 120, 180 |

| 130 | 0.5, 2, 4, 7, 10, 22, 35, 60, 90 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Wang, F.; Li, J.; Ran, H.; Li, X.; Fu, Q. Breakdown Voltage and Its Influencing Factors of Thermally Aged Oil-Impregnated Paper at Pulsating DC Voltage. Energies 2017, 10, 1411. https://doi.org/10.3390/en10091411

Zhang J, Wang F, Li J, Ran H, Li X, Fu Q. Breakdown Voltage and Its Influencing Factors of Thermally Aged Oil-Impregnated Paper at Pulsating DC Voltage. Energies. 2017; 10(9):1411. https://doi.org/10.3390/en10091411

Chicago/Turabian StyleZhang, Jing, Feipeng Wang, Jian Li, Hehuan Ran, Xudong Li, and Qiang Fu. 2017. "Breakdown Voltage and Its Influencing Factors of Thermally Aged Oil-Impregnated Paper at Pulsating DC Voltage" Energies 10, no. 9: 1411. https://doi.org/10.3390/en10091411

APA StyleZhang, J., Wang, F., Li, J., Ran, H., Li, X., & Fu, Q. (2017). Breakdown Voltage and Its Influencing Factors of Thermally Aged Oil-Impregnated Paper at Pulsating DC Voltage. Energies, 10(9), 1411. https://doi.org/10.3390/en10091411