Magnetron Sputter Epitaxy of High-Quality GaN Nanorods on Functional and Cost-Effective Templates/Substrates

Abstract

1. Introduction

2. Experimental Details

3. Results and Discussion

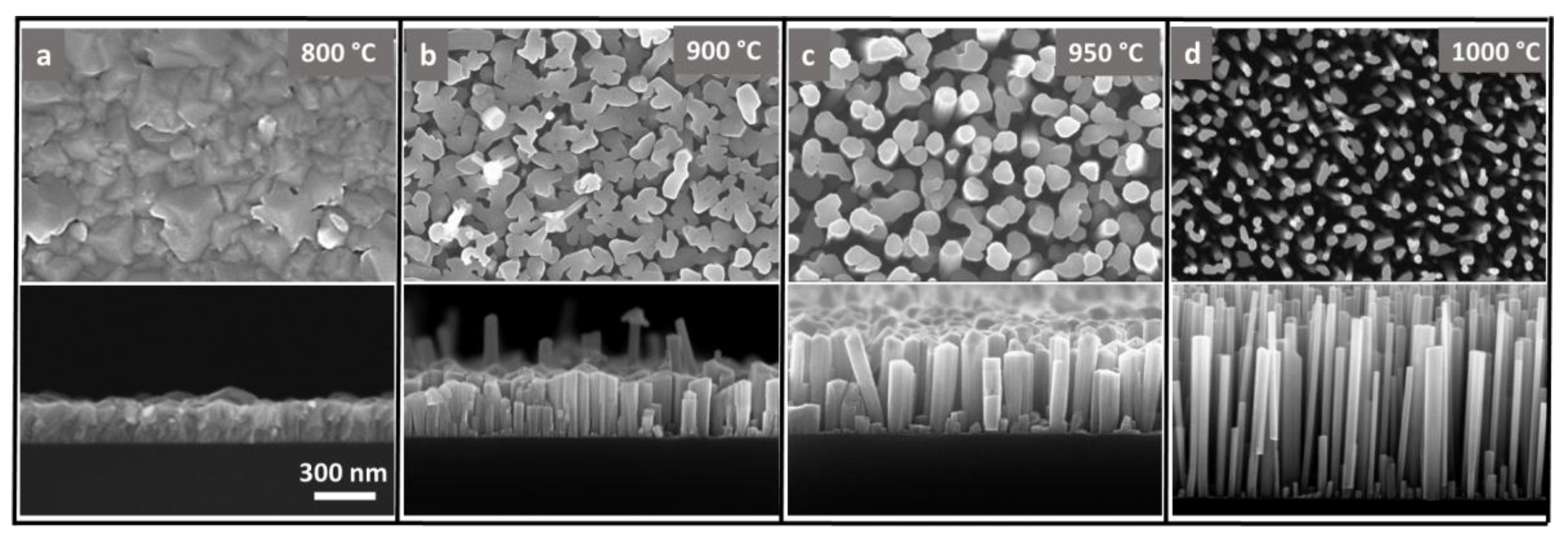

3.1. Growth of GaN NRs Directly onto Si Substrates

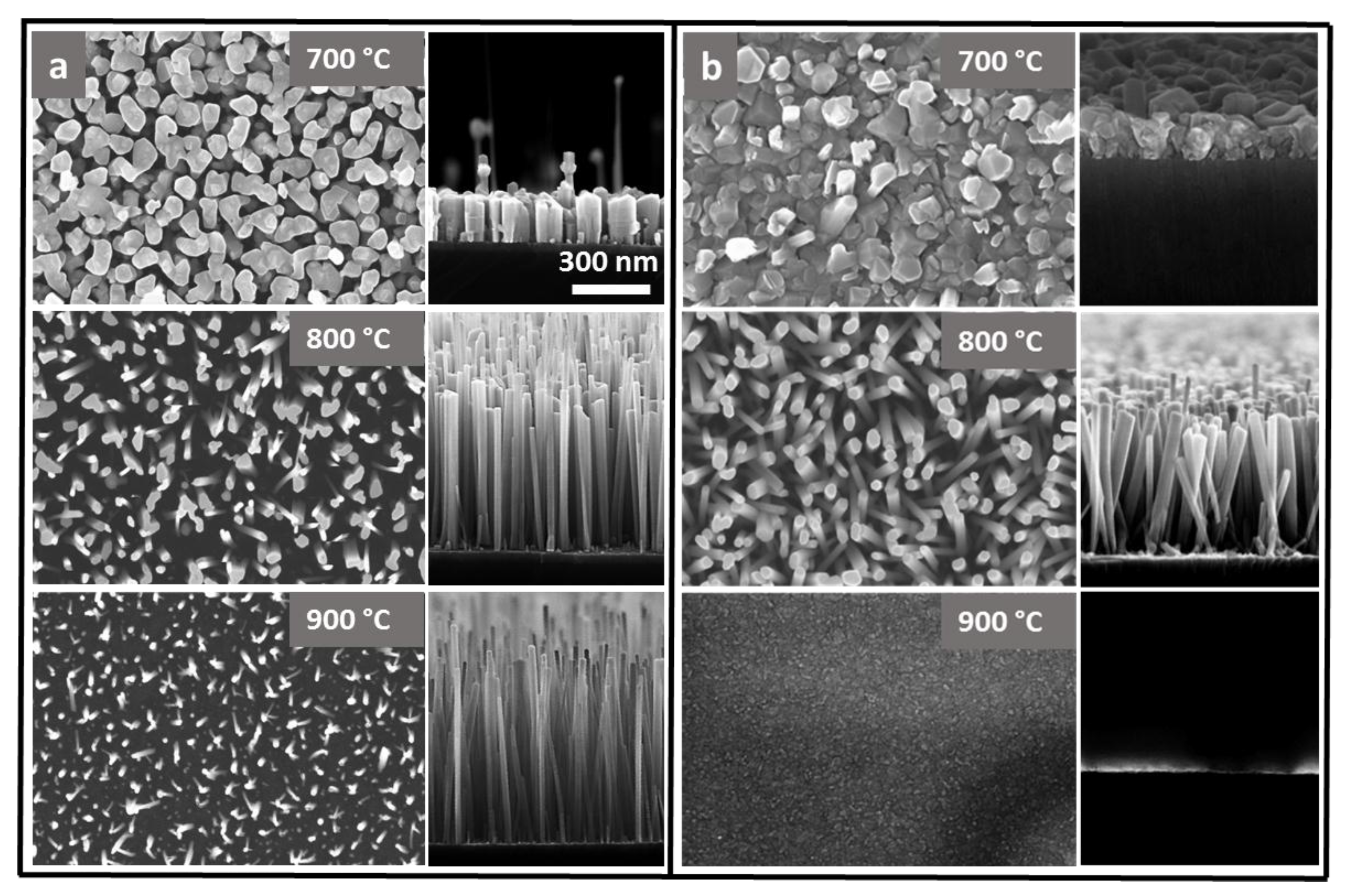

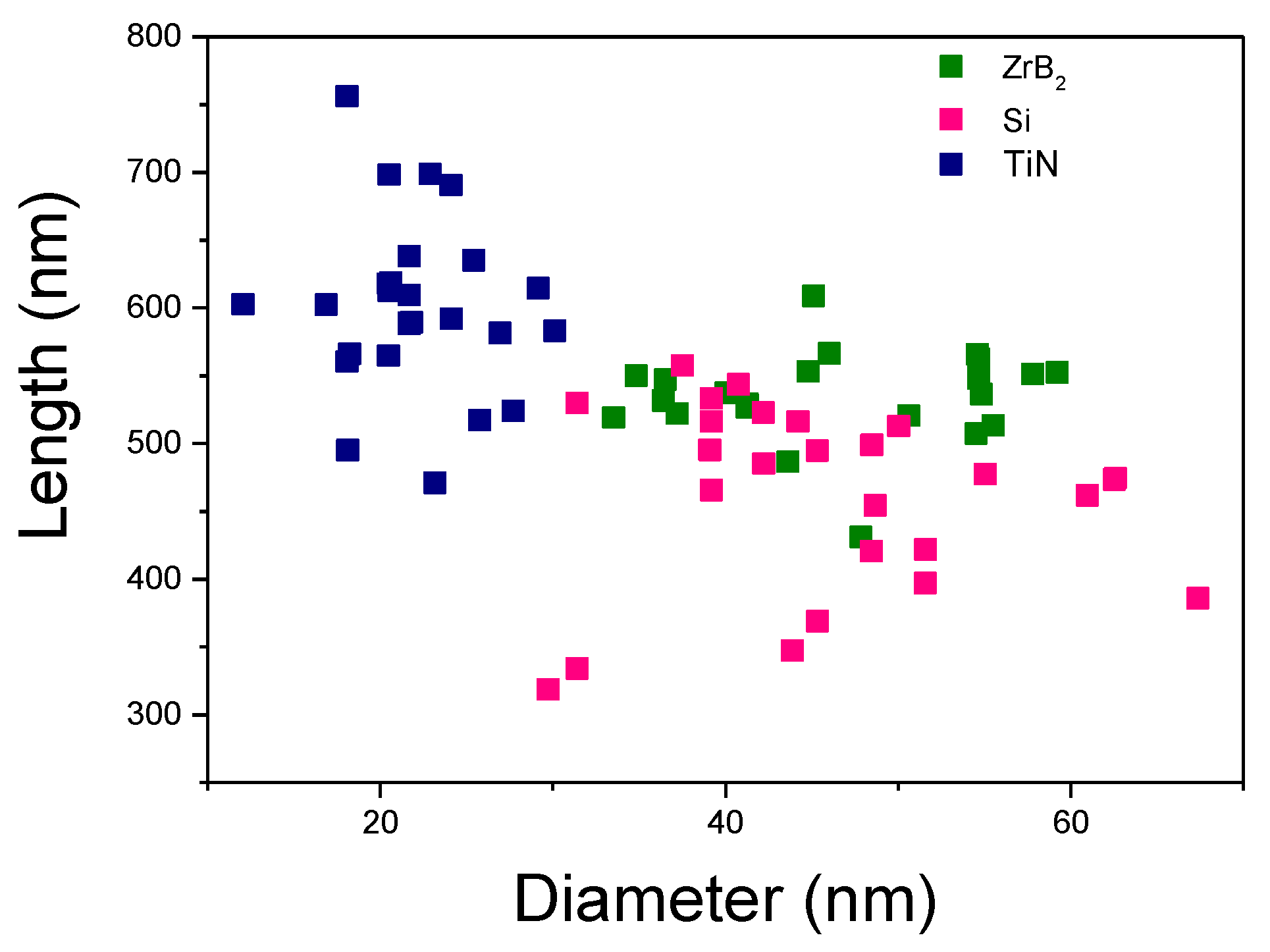

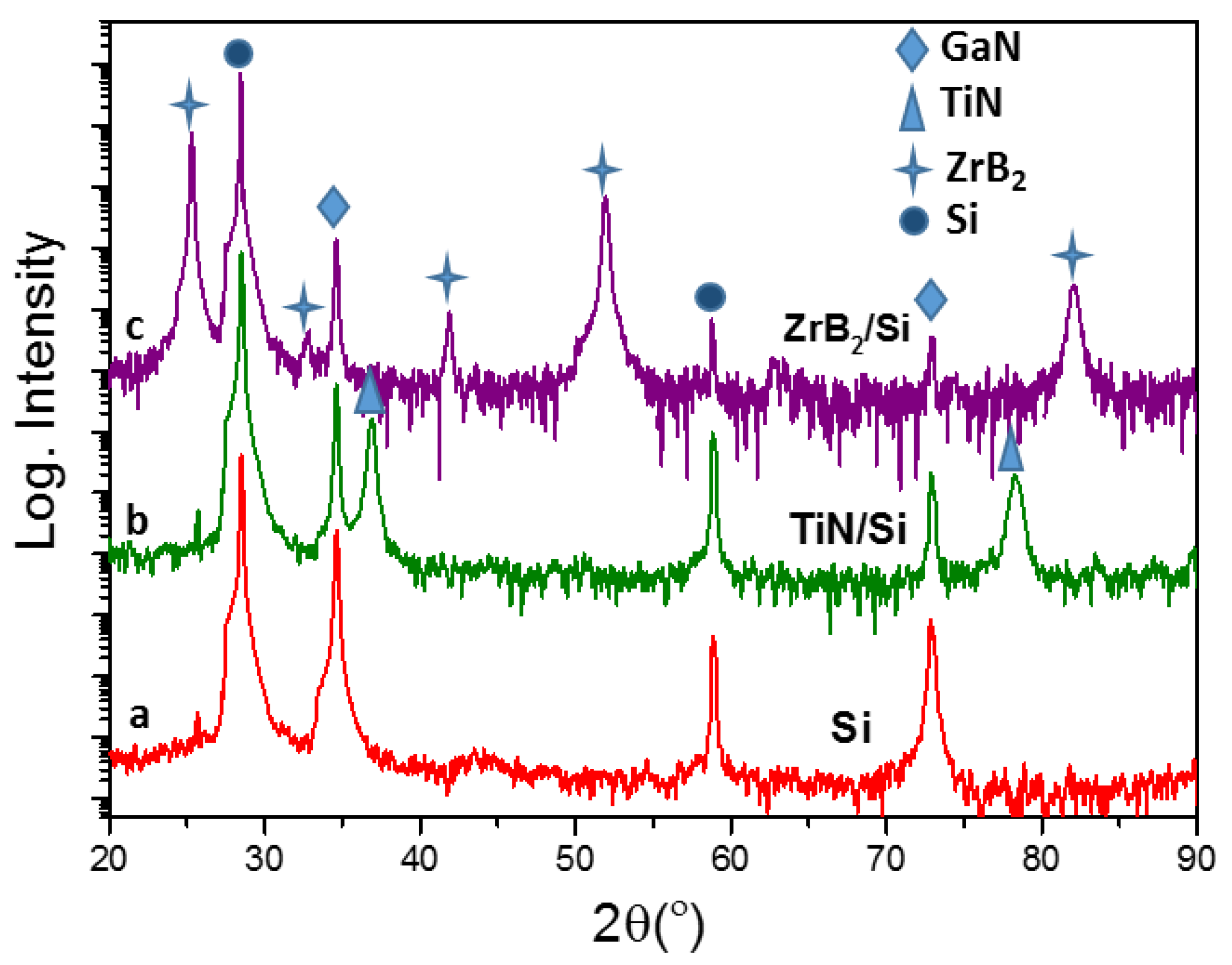

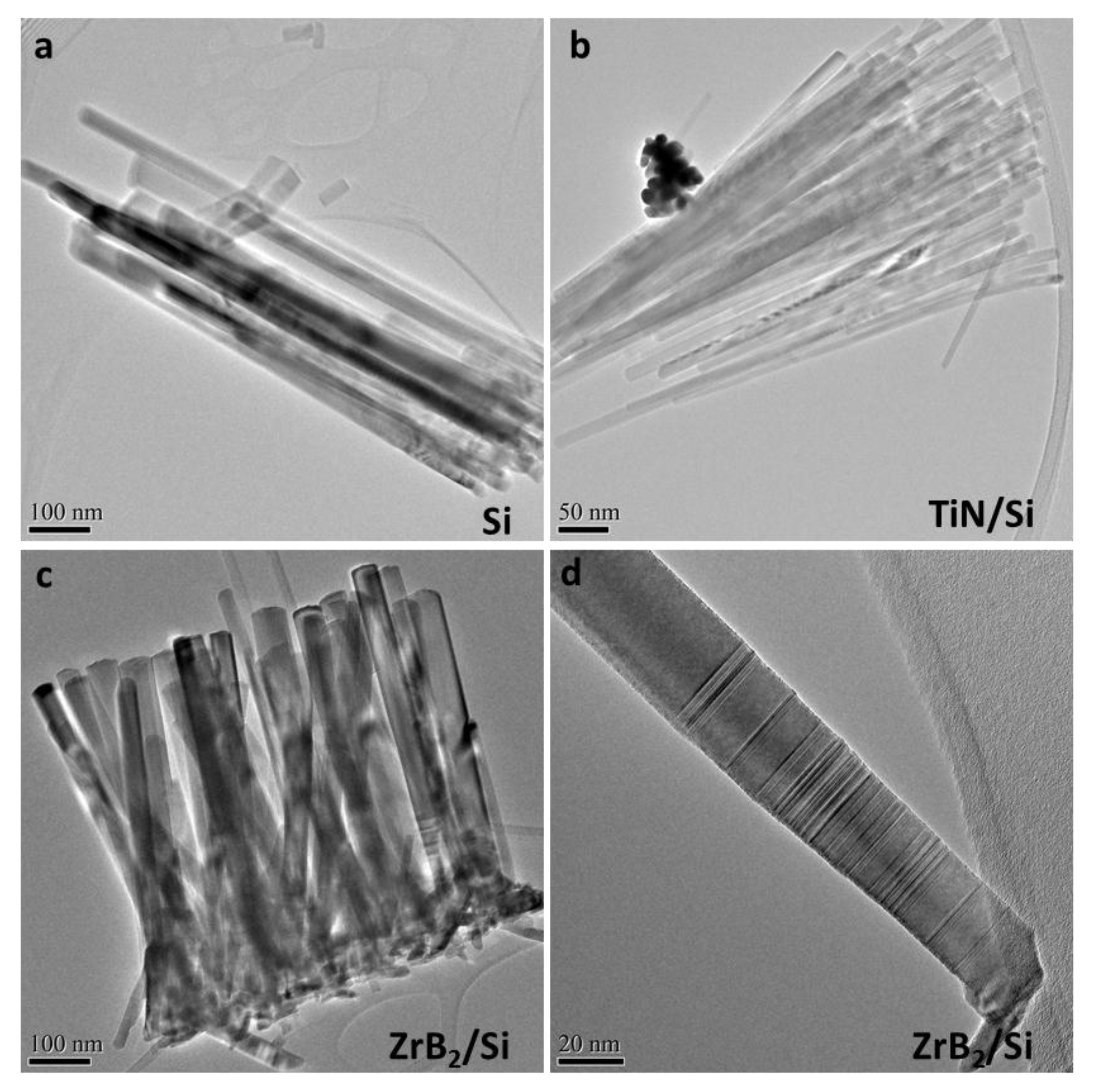

3.2. Growth of GaN NRs on TiN and ZrB2 Conductive Layers

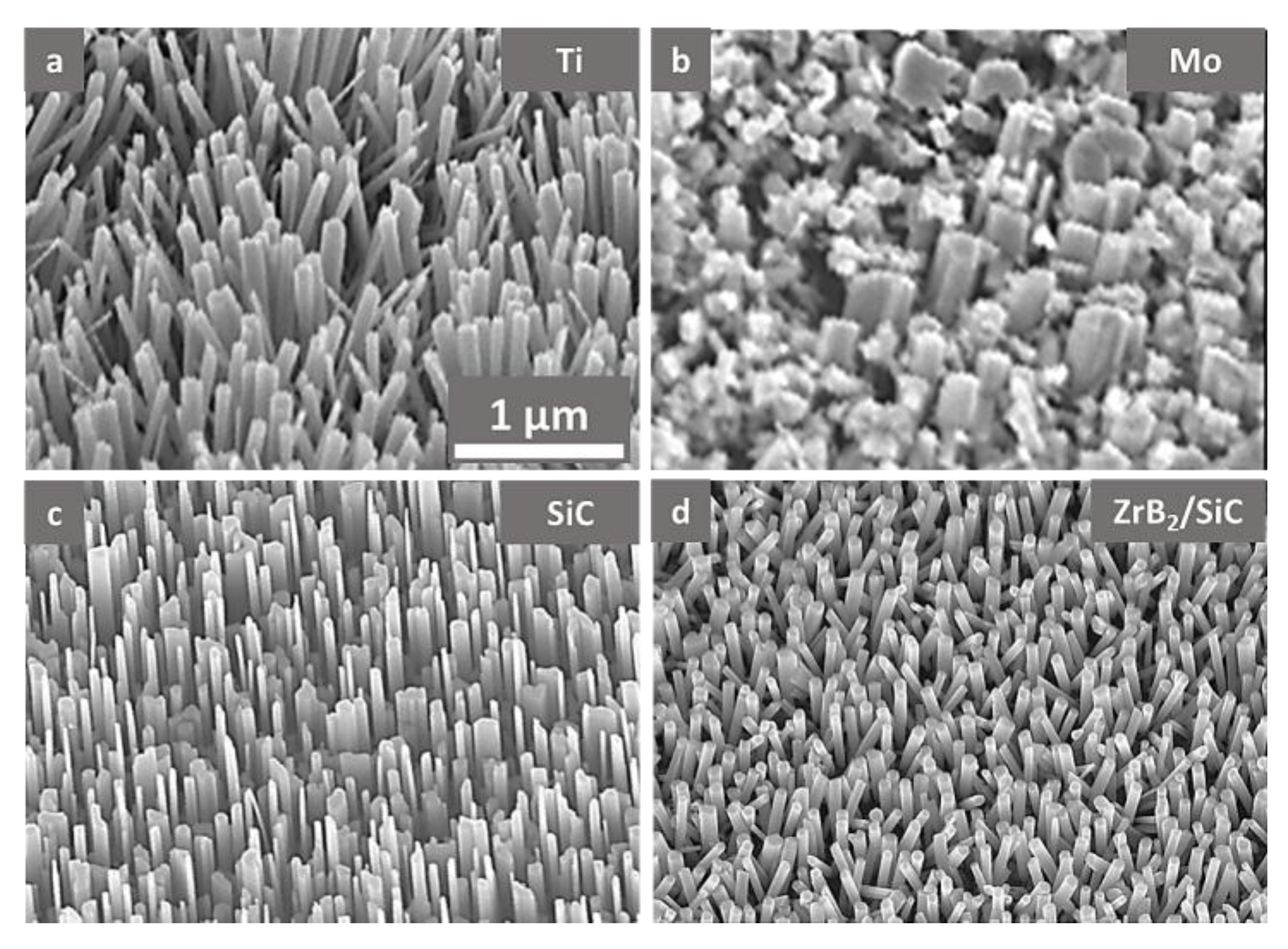

3.3. Growth of GaN NRs on Metal and SiC Templates/Substrates

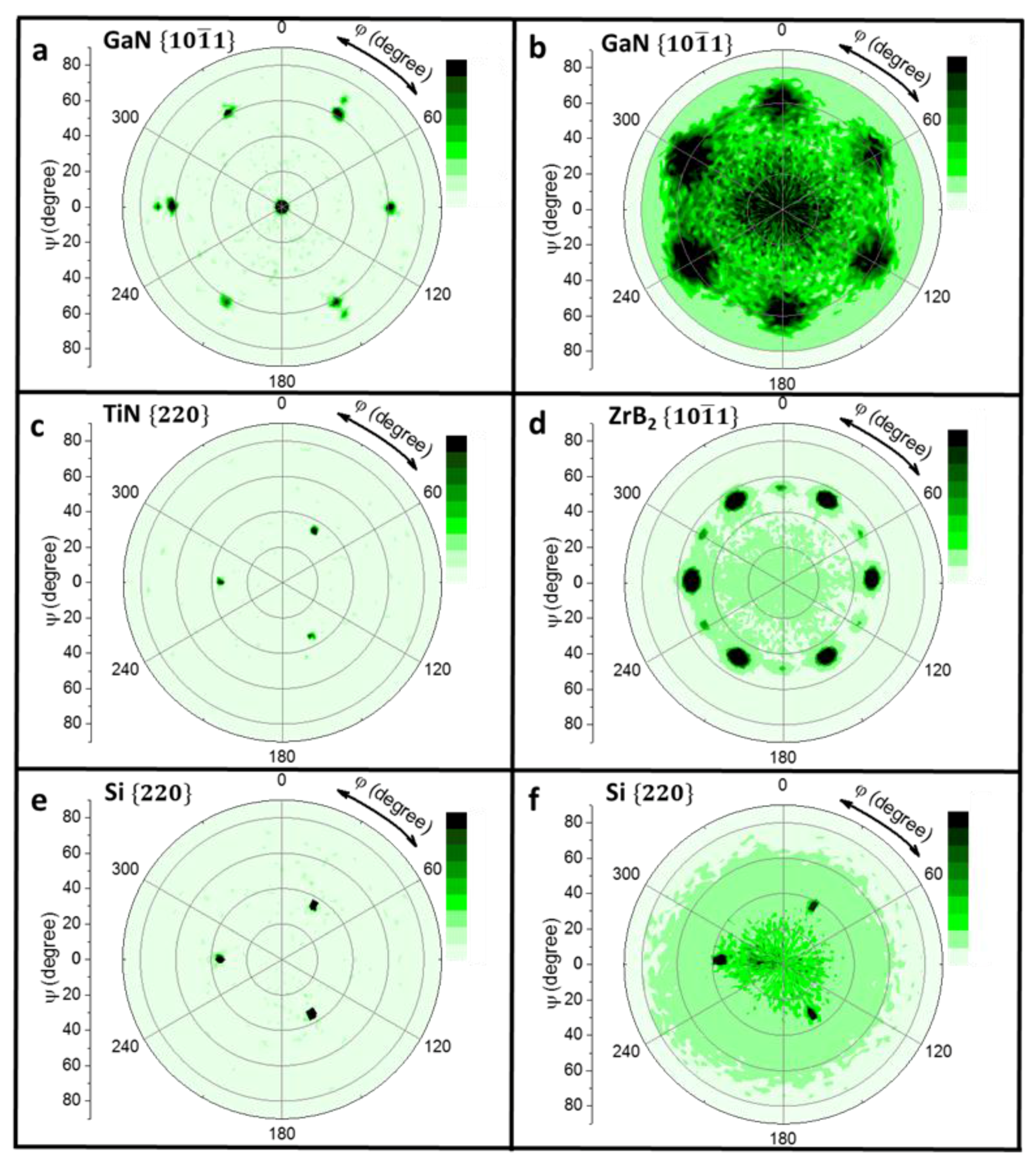

3.4. Structural Characterizations

3.5. Optical Properties

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Amano, H. Development of GaN-based blue LEDs and metalorganic vapor phase epitaxy of GaN and related materials. Prog. Cryst. Growth Charact. Mater. 2016, 62, 126–135. [Google Scholar] [CrossRef]

- Fujita, S. Wide-bandgap semiconductor materials: For their full bloom. Jpn. J. Appl. Phys. 2015, 54, 030101. [Google Scholar] [CrossRef]

- Viswanath, A.K. GaN nanostructure-based light emitting diodes and semiconductor lasers. J. Nanosci. Nanotechno. 2014, 14, 1947–1982. [Google Scholar] [CrossRef]

- Zhu, D.; Wallis, D.J.; Humphreys, C.J. Prospects of III-nitride optoelectronics grown on Si. Rep. Prog. Phys. 2013, 76, 106501. [Google Scholar] [CrossRef] [PubMed]

- Kukushkin, S.A.; Osipov, A.V.; Bessolov, V.N.; Medvedev, B.K.; Nevolin, V.K.; Tcarik, K.A. Substrates for epitaxy of gallium nitride: New materials and techniques. Rev. Adv. Mater. Sci. 2008, 17, 1–32. [Google Scholar]

- Gurnett, K.; Adams, T. Native substrates for GaN: the plot thickens. III-Vs Rev. 2006, 19, 39–41. [Google Scholar] [CrossRef]

- Li, G.; Wang, W.; Yang, W.; Lin, Y.; Wang, H.; Lin, Z.; Zhou, S. GaN-based light-emitting diodes on various substrates: A critical review. Rep. Prog. Phys. 2016, 79, 056501. [Google Scholar] [CrossRef] [PubMed]

- Liu, R.; Ponce, F.A.; Dadgar, A.; Krost, A. Atomic arrangement at the AlN/Si(111) interface. Appl. Phys. Lett. 2003, 83, 860–862. [Google Scholar] [CrossRef]

- Kamiyama, S.; Takanami, S.; Tomida, Y.; Iida, K.; Kawashima, T.; Fukui, S.; Iwaya, M.; Kinoshita, H.; Matsuda, T.; Yasuda, T.; et al. Violet and UV light-emitting diodes grown on ZrB2 substrate. Phys. Stat. Sol. (a) 2003, 200, 67–70. [Google Scholar] [CrossRef]

- Luther, B.P.; Mohney, S.E.; Jackson, T.N. Titanium and titanium nitride contacts to n-type gallium nitride. Semicond. Sci. Technol. 1998, 13, 1322–1327. [Google Scholar] [CrossRef]

- Piper, J. Galvanomagnetic effects in single-crystal ZrB2. Phys. Chem. Solids. 1966, 27, 1907–1915. [Google Scholar] [CrossRef]

- Johansson, B.O.; Sundgren, J.-E.; Greene, J.E. Growth and properties of single crystal TiN films deposited by reactive magnetron sputtering. J. Vac. Sci. Technol. A: Vac. Surf. Films 1985, 3, 303–307. [Google Scholar] [CrossRef]

- Sarwar, G.; Carnevale, S.D.; Yang, F.; Kent, T.F.; Jamison, J.J.; McComb, D.W.; Myers, R.C. Semiconductor nanowire light-emitting diodes grown on metal: A direction toward large-scale fabrication of nanowire devices. Small 2015, 11, 5402–5408. [Google Scholar] [CrossRef] [PubMed]

- Zhao, C.; Ng, T.K.; Wei, N.; Prabaswara, A.; Alias, M.S.; Janjua, B.; Shen, C.; Ooi, B.S. Facile formation of high-quality InGaN/GaN quantum-disks-in- nanowires on bulk-metal substrates for high-power light-emitters. Nano Lett. 2016, 16, 1056–1063. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, H.P.T.; Wang, Q.; Mi, Z. Phosphor-free InGaN/GaN dot-in-a-wire white light-emitting diodes on copper substrates. J. Electron. Mater. 2014, 43, 868–872. [Google Scholar] [CrossRef]

- Mandl, M.; Wang, X.; Schimpke, T.; Kölper, C.; Binder, M.; Ledig, J.; Waag, A.; Kong, X.; Trampert, A.; Bertram, F.; et al. Group III nitride core–shell nano- and microrods for optoelectronic applications. Phys. Status Solidi RRL 2013, 7, 800–814. [Google Scholar] [CrossRef]

- Kanga, M.S.; Lee, C.-H.; Park, J.B.; Yoo, H.; Yi, G.-C. Gallium nitride nanostructures for light-emitting diode applications. Nano Energy 2012, 1, 391–400. [Google Scholar] [CrossRef]

- Johnson, J.C.; Choi, H.-J.; Knutsen, K.P.; Schaller, R.D.; Yang, P.; Saykally, R.J. Single gallium nitride nanowire lasers. Nat. Mater. 2002, 1, 106–110. [Google Scholar] [CrossRef] [PubMed]

- Ko, S.-M.; Kim, J.-H.; Ko, Y.-H.; Chang, Y.H.; Kim, Y.-H.; Yoon, J.; Lee, J.Y.; Cho, Y.-H. Growth mechanism of catalyst-free and mask-free heteroepitaxial GaN submicrometer- and micrometer-sized rods under biaxial strain: Variation of surface energy and adatom kinetics. Cryst. Growth Des. 2012, 12, 3838–3844. [Google Scholar] [CrossRef]

- Li, E.; Cui, Z.; Fu, N.; Xu, R.; Ma, D. Growth and field emission of single-crystalline GaN nanowire with ropy morphology. Mater. Lett. 2015, 139, 426–428. [Google Scholar] [CrossRef]

- Cheng, H.; Li, J.; Wu, D.; Li, Y.; Wang, Z.; Wang, X.; Zheng, X. Effects of precursor-substrate distances on the growth of GaN nanowires. J. Nanomater. 2015, 16, 272–277. [Google Scholar] [CrossRef]

- Bertness, K.A.; Roshko, A.; Sanford, N.A.; Barker, J.M.; Davydov, A.V. Spontaneously grown GaN and AlGaN nanowires. J. Cryst. Growth 2006, 287, 522–527. [Google Scholar] [CrossRef]

- Ristic, J.; Calleja, E.; Fernandez-Garrido, S.; Cerutti, L.; Trampert, A.; Jahn, U.; Ploog, K.H. On the mechanisms of spontaneous growth of III-nitride nanocolumns by plasma-assisted molecular beam epitaxy. J. Cryst. Growth 2008, 310, 4035–4045. [Google Scholar] [CrossRef]

- Xiao, H.-D.; Liu, R.; Liu, J.-Q.; Lin, Z.-J.; Mei, L.-M. Growth process from amorphous GaN to polycrystalline GaN on Si (111) substrates. Vacuum 2009, 83, 1393–1396. [Google Scholar] [CrossRef]

- Serban, E.A.; Palisaitis, J.; Yeh, C.-C.; Hsu, H.-C.; Tsai, Y.-L.; Kuo, H.-C.; Junaid, M.; Hultman, L.; Persson, P.O.Å.; Birch, J.; et al. Selective-area growth of single-crystal wurtzite GaN nanorods on SiOx/Si(001) substrates by magnetron sputter epitaxy exhibiting single-mode lasing. Sci. Rep. 2017, submitted. [Google Scholar]

- Forsberg, M.; Serban, E.A.; Hsiao, C.-L.; Junaid, M.; Birch, J.; Pozina, G. Near band gap luminescence in hybrid organic-inorganic structures based on sputtered GaN nanorods. Sci. Rep. 2017, 7, 1170–1176. [Google Scholar] [CrossRef] [PubMed]

- Forsberg, M.; Serban, A.; Poenaru, I.; Hsiao, C.-L.; Junaid, M.; Birch, J.; Pozina, G. Stacking fault related luminescence in GaN nanorods. Nanotechnology 2015, 26, 355203–355211. [Google Scholar] [CrossRef] [PubMed]

- Junaid, M.; Chen, Y.-T.; Palisaitis, J.; Garbrecht, M.; Hsiao, C.-L.; Persson, P.O.Å.; Hultman, L.; Birch, J. Liquid-target reactive magnetron sputter epitaxy of high quality GaN(000) nanorods on Si(111). Mater. Sci. Semicond. Process. 2015, 39, 702–710. [Google Scholar] [CrossRef]

- Junaid, M.; Hsiao, C.-L.; Palisaitis, J.; Jensen, J.; Persson, P.O.Å.; Hultman, L.; Birch, J. Electronic-grade GaN(0001)/Al2O3(0001) grown by reactive DC-magnetron sputter epitaxy using a liquid Ga target. Appl. Phys. Lett. 2011, 98, 141915–141918. [Google Scholar] [CrossRef]

- Tengdelius, L.; Birch, J.; Lu, J.; Hultman, L.; Forsberg, U.; Janzen, E.; Högberg, H. Magnetron sputtering of epitaxial ZrB2 thin films on 4H-SiC(0001) and Si (111). Phys. Status Solidi A 2014, 211, 636–640. [Google Scholar] [CrossRef]

- Tengdelius, L.; Greczynski, G.; Chubarov, M.; Lu, J.; Forsberg, U.; Hultman, L.; Janzén, E.; Högberg, H. Stoichiometric, epitaxial ZrB2 thin films with low oxygen-content deposited by magnetron sputtering from a compound target: Effects of deposition temperature and sputtering power. J. Cryst. Growth 2015, 430, 55–62. [Google Scholar] [CrossRef]

- Johansson, J.; Svensson, C.P.; Martensson, T.; Samuelson, L.; Seifert, W. Mass transport model for semiconductor nanowire growth. J. Phys. Chem. B 2005, 109, 13567–13571. [Google Scholar] [CrossRef] [PubMed]

- Dubrovskii, V.G.; Cirlin, G.E.; Soshnikov, I.P.; Tonkikh, A.A.; Sibirev, N.V.; Samsonenko, Y.B.; Ustinov, V.M. Diffusion-induced growth of GaAs nanowhiskers during molecular beam epitaxy: Theory and experiment. Phys. Rev. B 2005, 71, 205325–205330. [Google Scholar] [CrossRef]

- Calabrese, G.; Corfdir, P.; Gao, G.; Pfüller, C.; Trampert, A.; Brandt, O.; Geelhaar, L.; Fernández-Garrido, S. Molecular beam epitaxy of single crystalline GaN nanowires on a flexible Ti foil. Appl. Phys. Lett. 2016, 108, 202101–202104. [Google Scholar] [CrossRef]

- Chen, Y.; Burgess, T.; An, X.; Mai, Y.-W.; Tan, H.H.; Zou, J.; Ringer, S.P.; Jagadish, C.; Liao, X. Effect of a high density of stacking faults on the Young’s modulus of GaAs nanowires. Nano Lett. 2016, 16, 1911. [Google Scholar] [CrossRef] [PubMed]

- Paiman, S.; Gao, Q.; Tan, H.H.; Jagadish, C.; Zhang, X.; Zou, J. Effects of growth rate on InP nanowires morphology and crystal structure. J. Cryst. Growth 2013, 383, 100–105. [Google Scholar] [CrossRef]

- Talin, A.A.; Wang, G.T.; Lai, E.; Anderson, R.J. Correlation of growth temperature, photoluminescence, and resistivity in GaN nanowires. Appl. Phys. Lett. 2008, 92, 093105–093107. [Google Scholar] [CrossRef]

- Upadhya, P.C.; Li, Q.; Wang, G.T.; Fischer, A.J.; Taylor, A.J.; Prasankumar, R.P. The influence of defect states on non-equilibrium carrier dynamics in GaN nanowires. Semicond. Sci. Technol. 2010, 25, 024017–024022. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Serban, E.A.; Palisaitis, J.; Junaid, M.; Tengdelius, L.; Högberg, H.; Hultman, L.; Persson, P.O.Å.; Birch, J.; Hsiao, C.-L. Magnetron Sputter Epitaxy of High-Quality GaN Nanorods on Functional and Cost-Effective Templates/Substrates. Energies 2017, 10, 1322. https://doi.org/10.3390/en10091322

Serban EA, Palisaitis J, Junaid M, Tengdelius L, Högberg H, Hultman L, Persson POÅ, Birch J, Hsiao C-L. Magnetron Sputter Epitaxy of High-Quality GaN Nanorods on Functional and Cost-Effective Templates/Substrates. Energies. 2017; 10(9):1322. https://doi.org/10.3390/en10091322

Chicago/Turabian StyleSerban, Elena Alexandra, Justinas Palisaitis, Muhammad Junaid, Lina Tengdelius, Hans Högberg, Lars Hultman, Per Ola Åke Persson, Jens Birch, and Ching-Lien Hsiao. 2017. "Magnetron Sputter Epitaxy of High-Quality GaN Nanorods on Functional and Cost-Effective Templates/Substrates" Energies 10, no. 9: 1322. https://doi.org/10.3390/en10091322

APA StyleSerban, E. A., Palisaitis, J., Junaid, M., Tengdelius, L., Högberg, H., Hultman, L., Persson, P. O. Å., Birch, J., & Hsiao, C.-L. (2017). Magnetron Sputter Epitaxy of High-Quality GaN Nanorods on Functional and Cost-Effective Templates/Substrates. Energies, 10(9), 1322. https://doi.org/10.3390/en10091322