Effect of Summer Ventilation on the Thermal Performance and Energy Efficiency of Buildings Utilizing Phase Change Materials

Abstract

:1. Introduction

2. Methodology

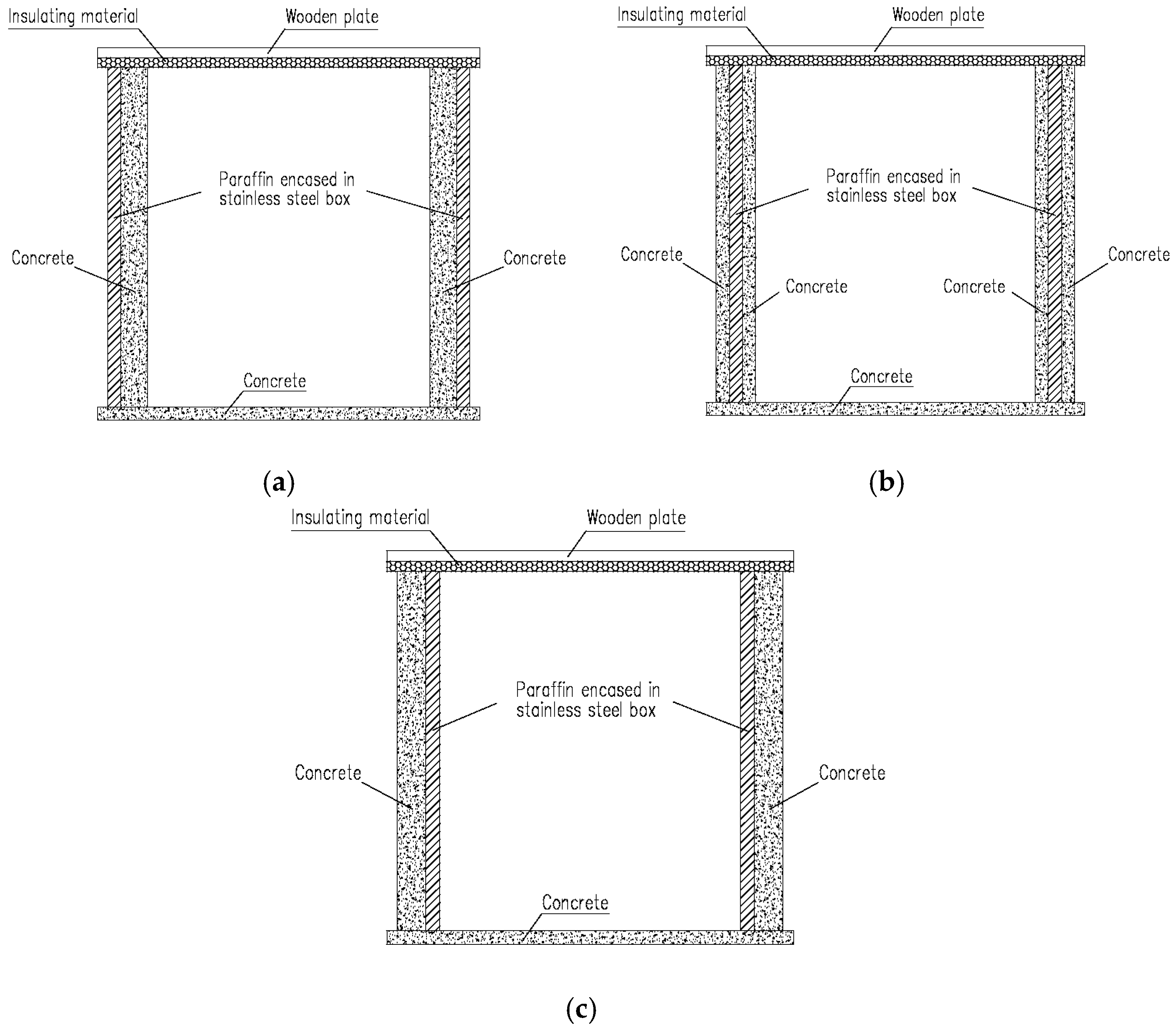

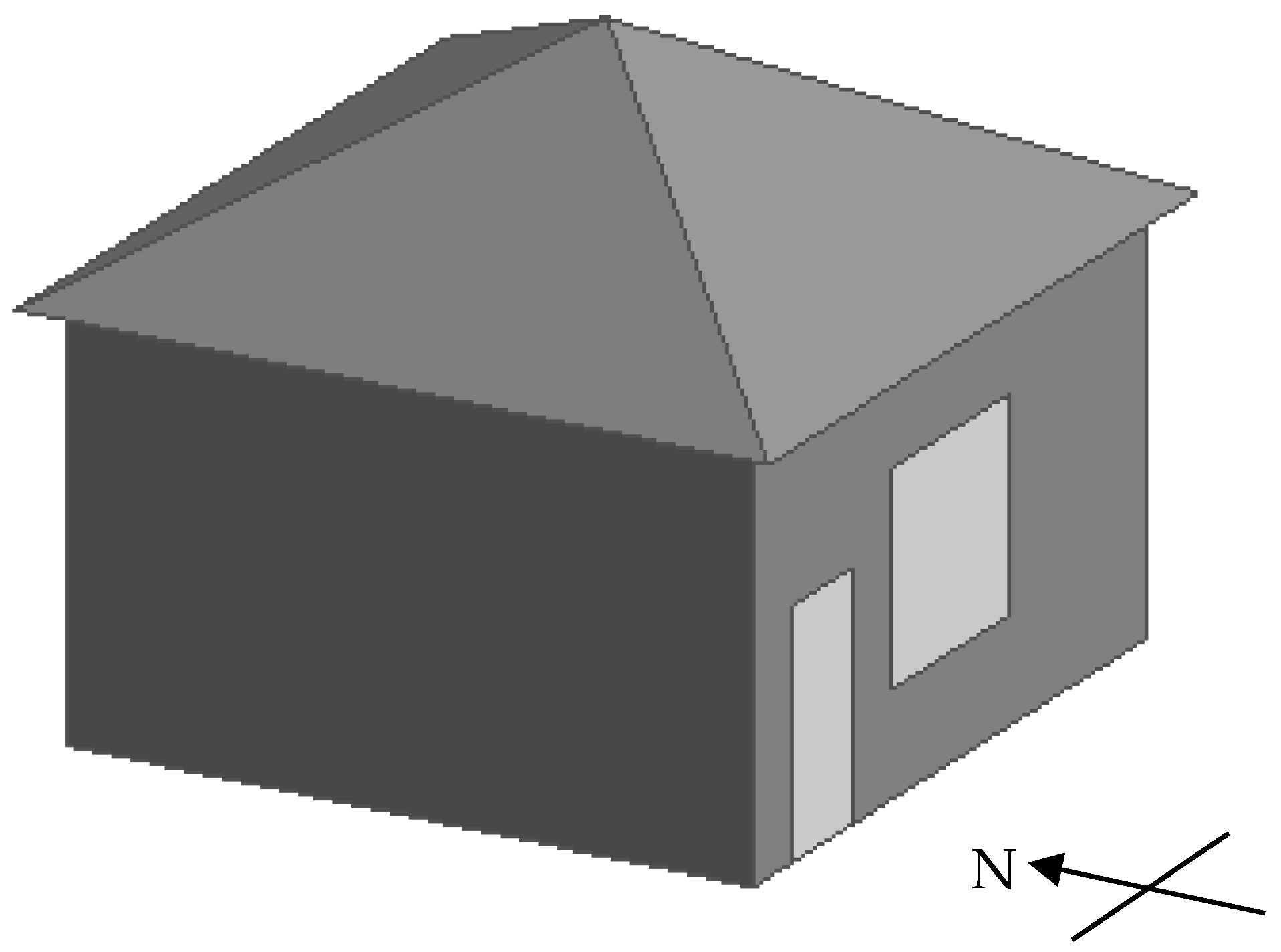

2.1. Modeling and Climate Regions

2.2. Determination of Energy Consumption for Building Cooling

3. Results and Discussion

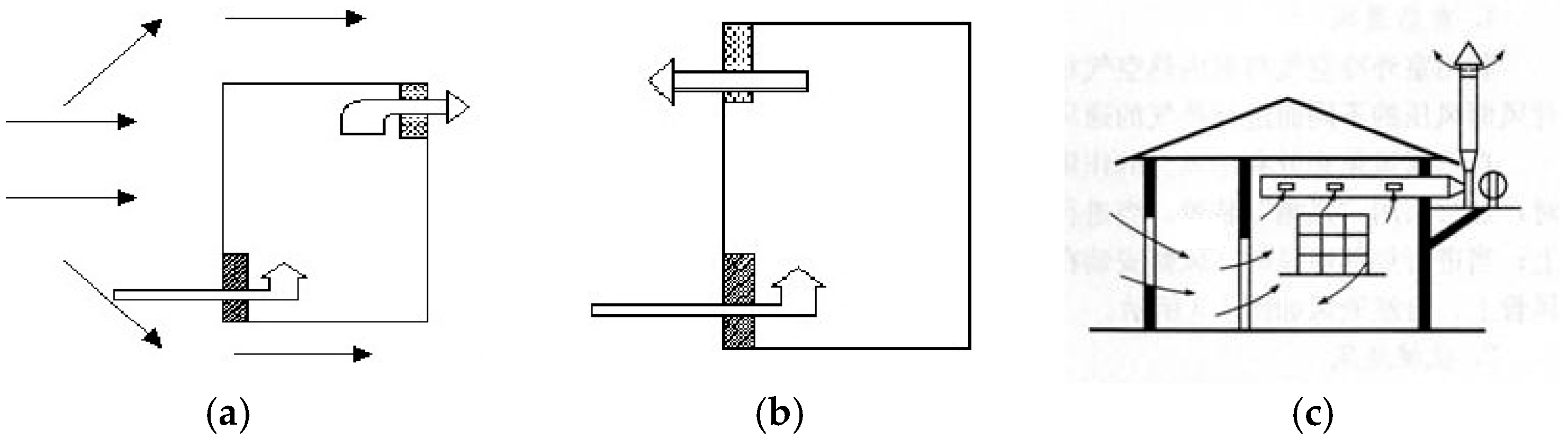

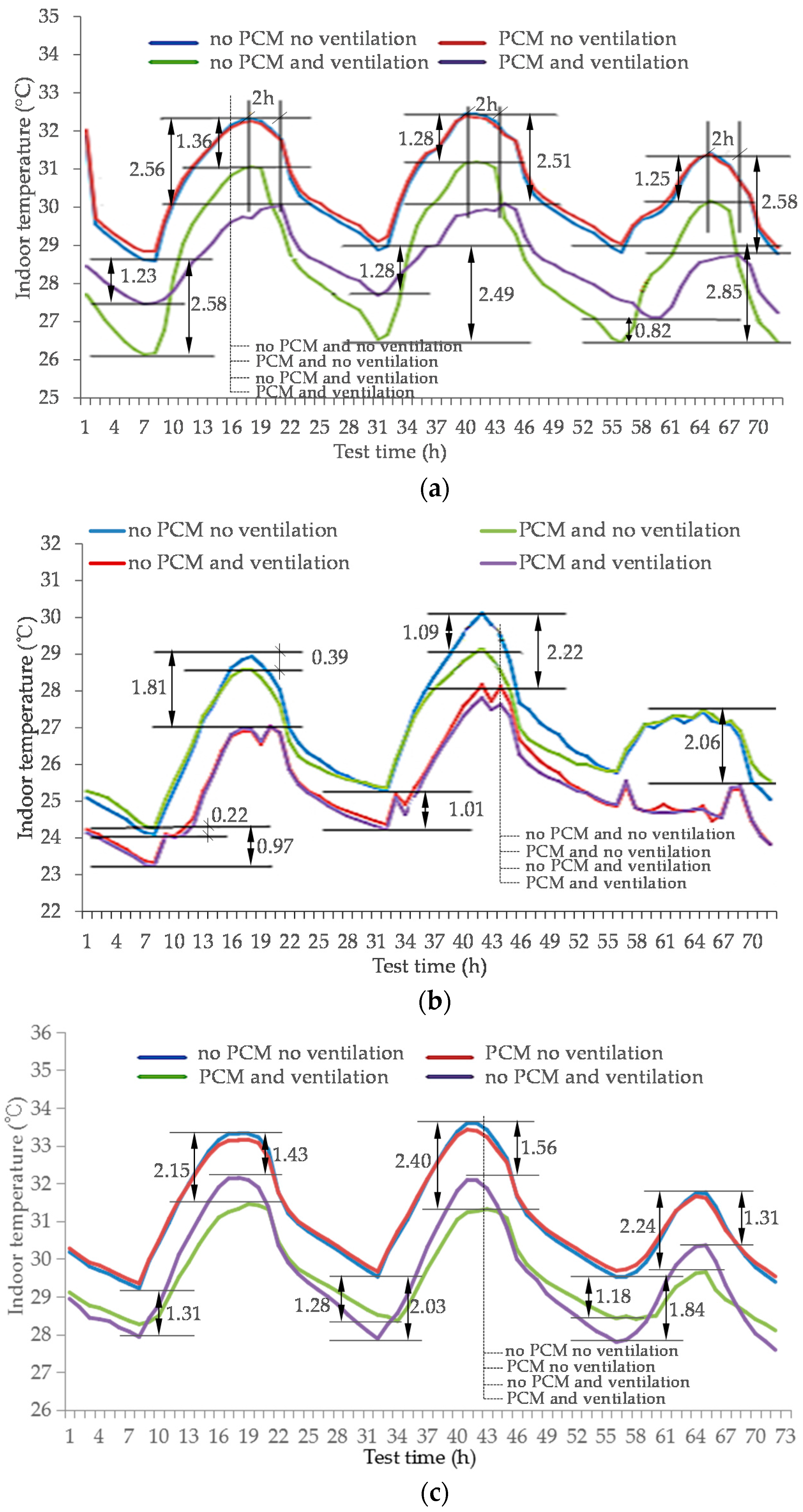

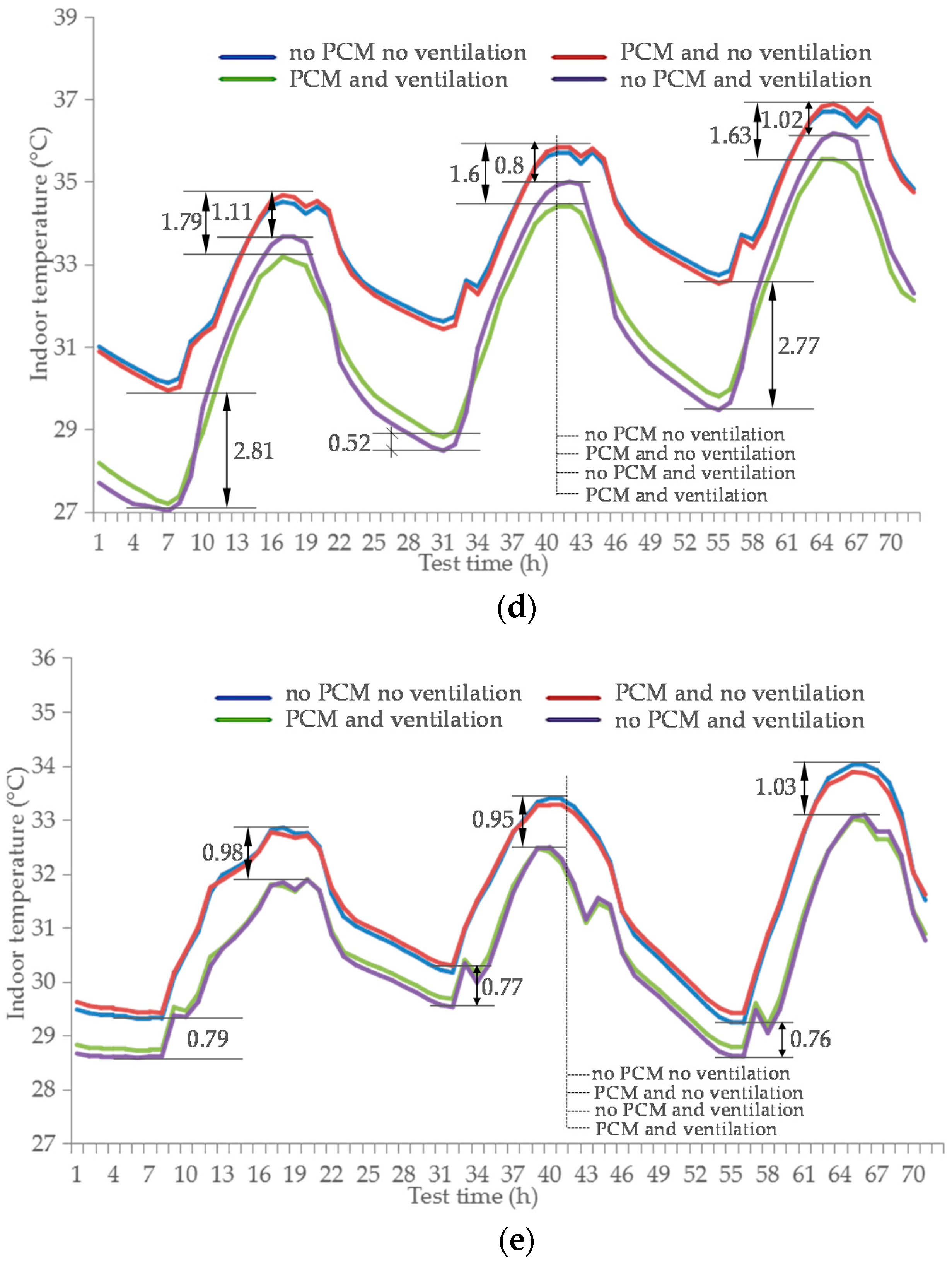

3.1. The Effect of Ventilation on Indoor Temperature

3.2. The Effect of Ventilation Period on Indoor Temperature and Energy Consumption

3.3. The Effect of Ventilation Quantity on Indoor Temperature and Energy Consumption

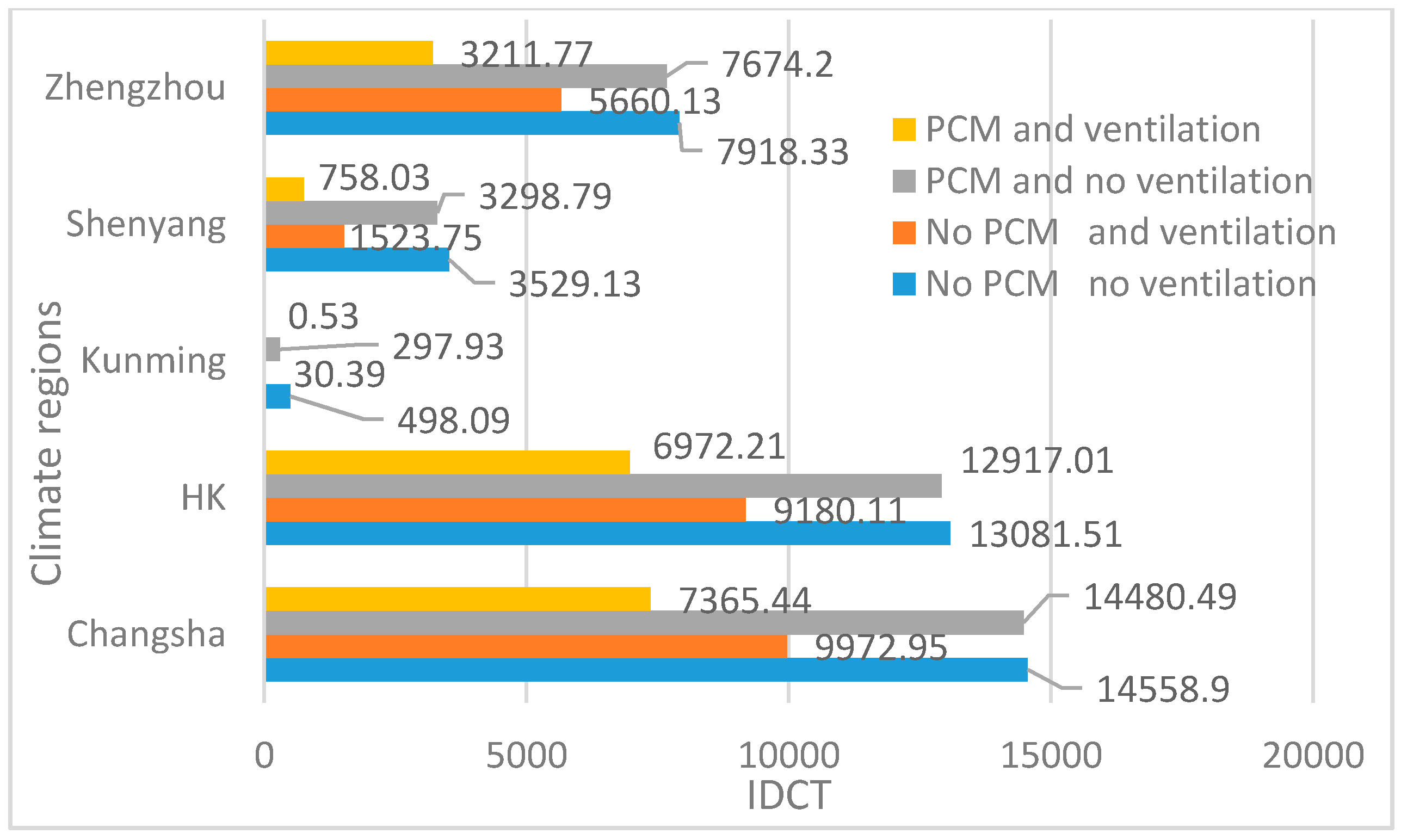

3.3.1. The Influence of Ventilation Quantity on Indoor Thermal Comfort of Buildings with PCM

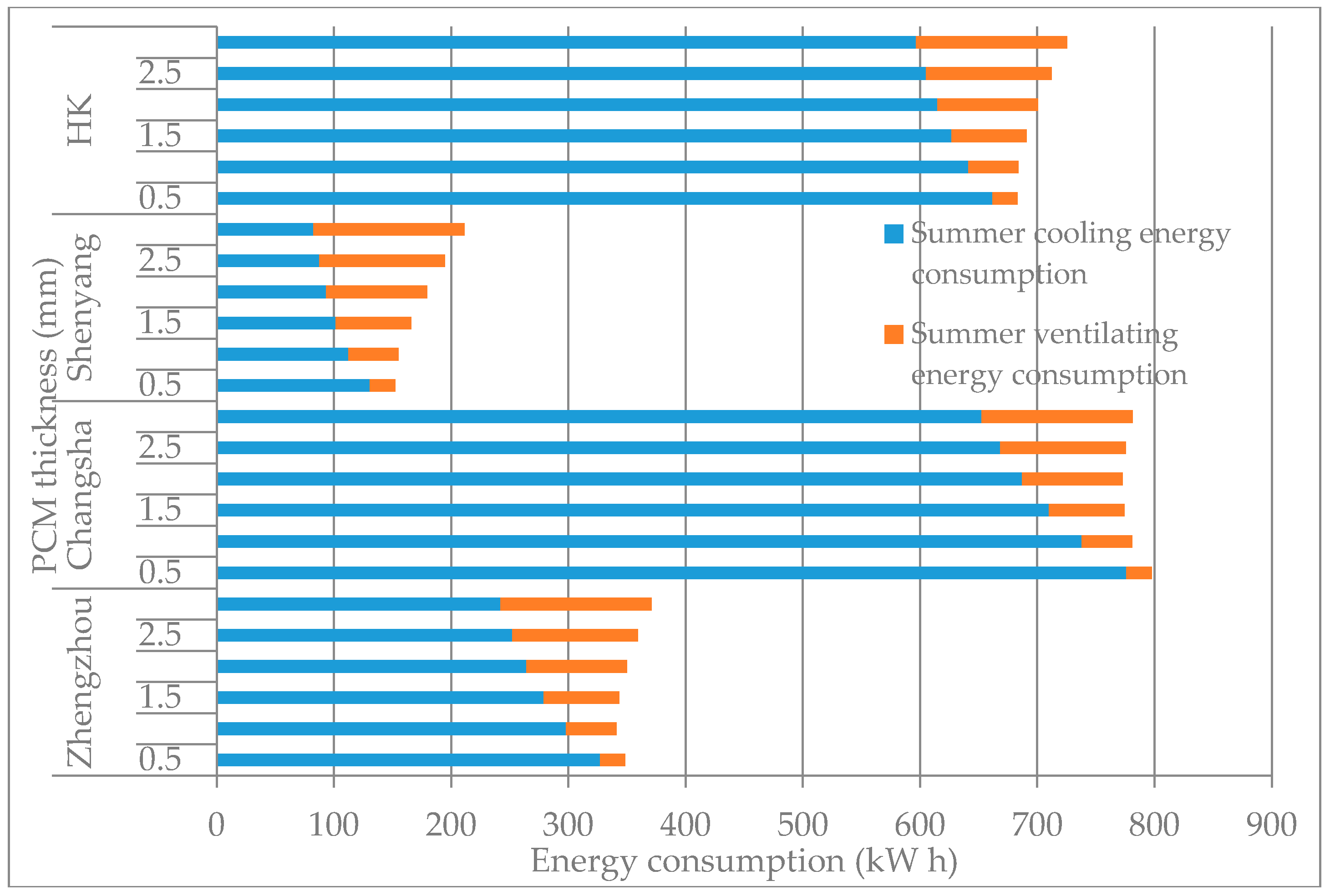

3.3.2. The Influence of Ventilation Quantity on Energy Consumption of Building with PCM

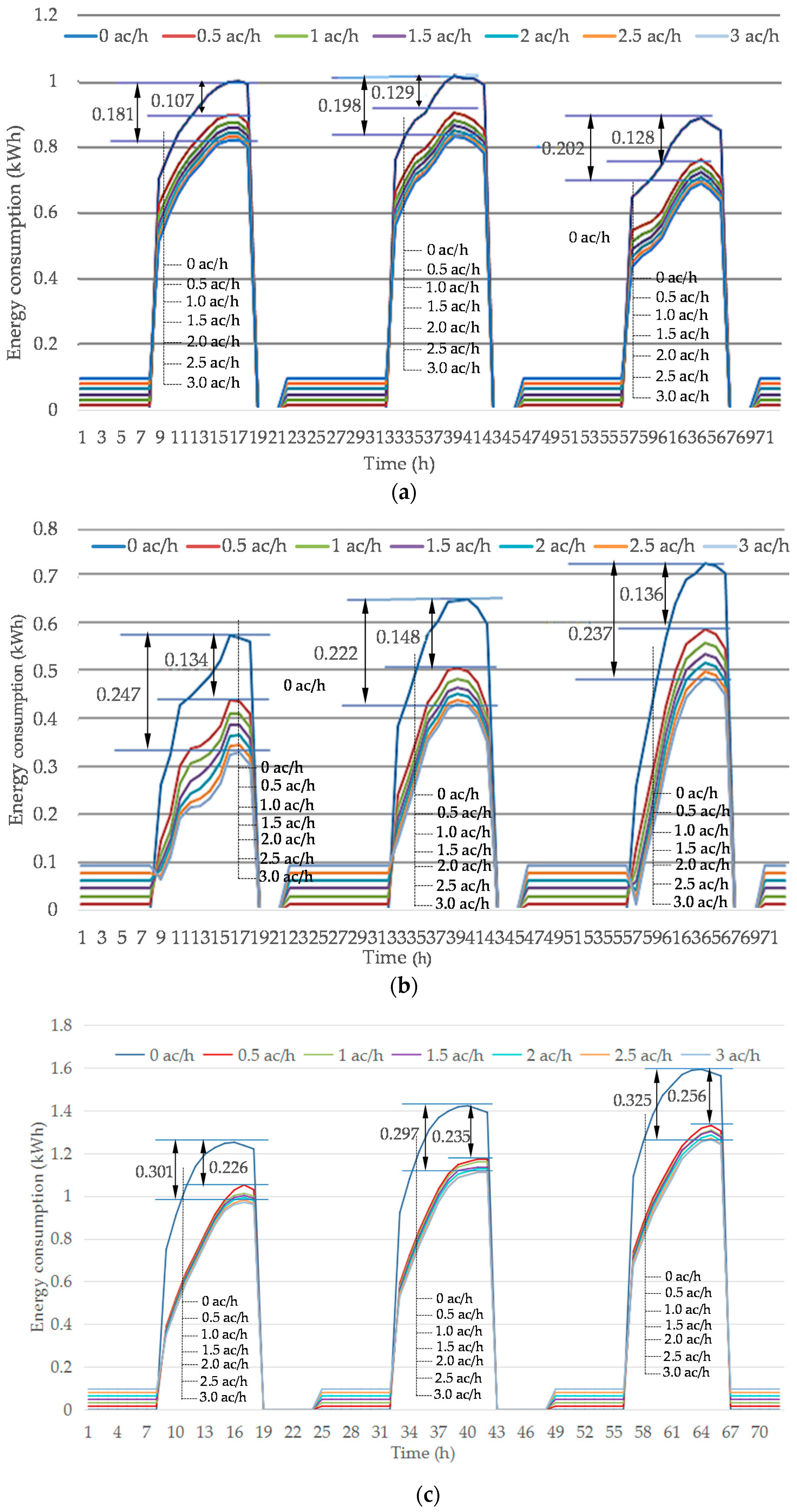

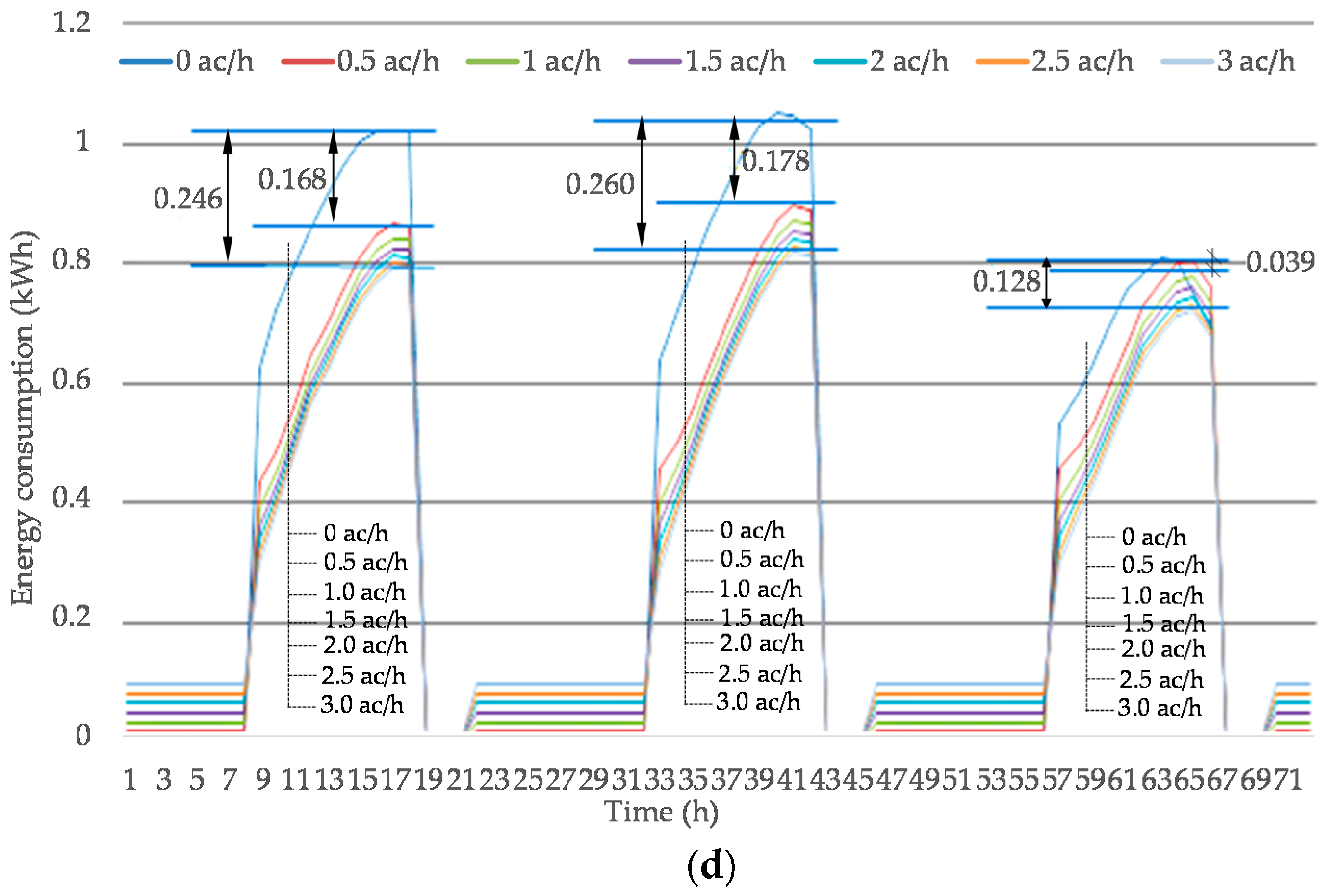

3.3.3. Influence of Ventilation Quantity on Shifting Peak Energy Consumption of Building with PCM

4. Conclusions and Recommendation

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Homod, R.Z.; Sahari, K.S.M.; Almurib, H.A.F.; Nagi, F.H. Rlf and ts fuzzy model identification of indoor thermal comfort based on pmv/ppd. Build. Environ. 2012, 49, 141–153. [Google Scholar] [CrossRef]

- Kumar, A.; Suman, B.M. Experimental evaluation of insulation materials for walls and roofs and their impact on indoor thermal comfort under composite climate. Build. Environ. 2013, 59, 635–643. [Google Scholar] [CrossRef]

- Ye, Y.Y.; Xu, P.; Mao, J.C. Energy performance of external versus internal shading devices in residential buildings. Appl. Mech. Mater. 2014, 672, 546–549. [Google Scholar] [CrossRef]

- Pérez-Lombard, L.; Ortiz, J.; Pout, C. A review on buildings energy consumption information. Energy Build. 2008, 40, 394–398. [Google Scholar] [CrossRef]

- Jiang, S.; Guo, J.; Yang, C.; Ding, Z.; Tian, L. Analysis of the relative price in china’s energy market for reducing the emissions from consumption. Energies 2017, 10, 656. [Google Scholar] [CrossRef]

- Wei, W.; He, L.-Y. China building energy consumption: Definitions and measures from an operational perspective. Energies 2017, 10, 582. [Google Scholar] [CrossRef]

- De Paola, M.; Arcuri, N.; Calabrò, V.; De Simone, M. Thermal and stability investigation of phase change material dispersions for thermal energy storage by t-history and optical methods. Energies 2017, 10, 354. [Google Scholar] [CrossRef]

- Soares, N.; Costa, J.J.; Gaspar, A.R.; Santos, P. Review of passive pcm latent heat thermal energy storage systems towards buildings’ energy efficiency. Energy Build. 2013, 59, 82–103. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Castellón, C.; Nogués, M.; Medrano, M.; Leppers, R.; Zubillaga, O. Use of microencapsulated pcm in concrete walls for energy savings. Energy Build. 2007, 39, 113–119. [Google Scholar] [CrossRef]

- Sharma, A.; Tyagi, V.V.; Chen, C.R.; Buddhi, D. Review on thermal energy storage with phase change materials and applications. Renew. Sustain. Energy Rev. 2009, 13, 318–345. [Google Scholar] [CrossRef]

- Cui, H.; Tang, W.; Qin, Q.; Xing, F.; Liao, W.; Wen, H. Development of structural-functional integrated energy storage concrete with innovative macro-encapsulated pcm by hollow steel ball. Appl. Energy 2017, 185, 107–118. [Google Scholar] [CrossRef]

- Memon, S.A. Phase change materials integrated in building walls: A state of the art review. Renew. Sustain. Energy Rev. 2014, 31, 870–906. [Google Scholar] [CrossRef]

- Alam, M.; Jamil, H.; Sanjayan, J.; Wilson, J. Energy saving potential of phase change materials in major australian cities. Energy Build. 2014, 78, 192–201. [Google Scholar] [CrossRef]

- Mazzeo, D.; Oliveti, G.; Arcuri, N. A method for thermal dimensioning and for energy behavior evaluation of a building envelope pcm layer by using the characteristic days. Energies 2017, 10, 659. [Google Scholar] [CrossRef]

- Regin, A.F.; Solanki, S.C.; Saini, J.S. An analysis of a packed bed latent heat thermal energy storage system using pcm capsules: Numerical investigation. Renew. Energy 2009, 34, 1765–1773. [Google Scholar] [CrossRef]

- Lo Brano, V.; Ciulla, G.; Piacentino, A.; Cardona, F. On the efficacy of pcm to shave peak temperature of crystalline photovoltaic panels: An fdm model and field validation. Energies 2013, 6, 6188–6210. [Google Scholar] [CrossRef] [Green Version]

- Wortman, D.N.; Christensen, C.B. Variable-base degree-day correction factors for energy savings calculations. In Proceedings of the ASHRAE Winter Meeting, Chicago, IL, USA, 27–30 January 1985; pp. 253–260. [Google Scholar]

- Tabares-Velasco, P.C.; Christensen, C.; Bianchi, M. Verification and validation of energyplus phase change material model for opaque wall assemblies. Build. Environ. 2012, 54, 186–196. [Google Scholar] [CrossRef]

- Meiss, A.; Padilla-Marcos, M.; Feijó-Muñoz, J. Methodology applied to the evaluation of natural ventilation in residential building retrofits: A case study. Energies 2017, 10, 456. [Google Scholar] [CrossRef]

- Park, J.; Choi, J.-I.; Rhee, G. Enhanced single-sided ventilation with overhang in buildings. Energies 2016, 9, 122. [Google Scholar] [CrossRef]

- Wang, P.; Li, D.; Huang, Y.; Zheng, X.; Wang, Y.; Peng, Z.; Ding, Y. Numerical study of solidification in a plate heat exchange device with a zigzag configuration containing multiple phase-change-materials. Energies 2016, 9, 394. [Google Scholar] [CrossRef]

- Qingyan, C.; Van, D.K.J. Accuracy―a program for combined problems of energy analysis, indoor airflow, and air quality. Ashrae Trans. 1988, 94, 196–214. [Google Scholar]

- Cui, H.; Memon, S.A.; Liu, R. Development, mechanical properties and numerical simulation of macro encapsulated thermal energy storage concrete. Energy Build. 2015, 96, 162–174. [Google Scholar] [CrossRef]

- Mi, X.; Liu, R.; Cui, H.; Memon, S.A.; Xing, F.; Lo, Y. Energy and economic analysis of building integrated with pcm in different cities of china. Appl. Energy 2016, 175, 324–336. [Google Scholar] [CrossRef]

- Shi, X.; Memon, S.A.; Tang, W.; Cui, H.; Xing, F. Experimental assessment of position of macro encapsulated phase change material in concrete walls on indoor temperatures and humidity levels. Energy Build. 2014, 71, 80–87. [Google Scholar] [CrossRef]

- Memon, S.A.; Cui, H.Z.; Zhang, H.; Xing, F. Utilization of macro encapsulated phase change materials for the development of thermal energy storage and structural lightweight aggregate concrete. Appl. Energy 2015, 139, 43–55. [Google Scholar] [CrossRef]

- Bonakdar, F.; Dodoo, A.; Gustavsson, L. Cost-optimum analysis of building fabric renovation in a swedish multi-story residential building. Energy Build. 2014, 84, 662–673. [Google Scholar] [CrossRef]

- China Academy of Building Research. Thermal Design Code for Civil Building (gb 50176–1993); MOC: Beijing, China, 1993. (In Chinese) [Google Scholar]

- EnergyPlus Weather Data. Available online: http://apps1.Eere.Energy.Gov/buildings/energyplus/cfm/weather_data3.Cfm (accessed on 30 October 2016).

- Chan, M.Y.; Burnett, J.; Chow, W.K. Energy use for ventilation systems in underground car parks. Build. Environ. 1998, 33, 303–314. [Google Scholar] [CrossRef]

- Lin, K.; Zhang, Y.; Jiang, Y. Simulation and designing of pcm wallboard rooms combined with night ventilation. Acta Energiae Sol. Sin. 2003, 24, 145–151. [Google Scholar]

| Building Elements | Construction (Outside to Inside) | U-Heat Transfer Coefficient 10−3 kW/(m2·K) |

|---|---|---|

| Roof | 10 mm Plastering, 40 mm Reinforced concrete, 100 mm XPS, 10 mm Plastering | 0.25 |

| PCM wall (south wall and east wall) | 10 mm Plastering, 79.5 mm XPS, 100 mm reinforced concrete, 10 mm PCM, 10 mm Plastering | 0.348 |

| Wall (east wall and north wall) | 10 mm Plastering, 79.5 mm XPS, 100 mm Reinforced concrete, 10 mm Plastering | 0.35 |

| Floor | 10 mm Plastering, 40 mm Reinforced concrete, 100 mm XPS, 10 mm Plastering | 0.25 |

| Climate Regions | Mean Temperature in | |

|---|---|---|

| Coldest Month | Hottest Month | |

| Severe Cold | ≤−10 °C | / |

| Cold | −10 °C–0 °C | / |

| Hot Summer & Cold Winter | 0 °C–10 °C | 25 °C–30 °C |

| Hot Summer & Warm Winter | >10 °C | 25 °C–29 °C |

| Mild (Temperate) | 0 °C–13 °C | 18 °C–25 °C |

| Items | Case 1 | Case 2 | Case 3 | Case 4 | Case 13 | Case 14 | Case 15 | Case 16 | Case 17 | Case 18 |

|---|---|---|---|---|---|---|---|---|---|---|

| 10 mm PCM | no | no | yes | yes | yes | |||||

| Ventilation | no | yes | no | yes | yes | |||||

| Ventilation quantities (ac/h) | 1 | 0.5 | 1 | 1.5 | 2 | 2.5 | 3 | |||

| Ventilation periods | 8:00~18:00 | 0:00~9:00 | ||||||||

| Items | Case 5 | Case 6 | Case 7 | Case 8 | Case 9 | Case 10 | Case 11 | Case 12 |

|---|---|---|---|---|---|---|---|---|

| 10 mm PCM | yes | |||||||

| ventilation | yes | |||||||

| Ventilation quantities (ac/h) | 1 | |||||||

| Ventilation periods | 0:00~3:00 | 3:00~6:00 | 6:00~9:00 | 9:00~12:00 | 12:00~15:00 | 15:00~18:00 | 18:00~21:00 | 21:00~24:00 |

| Sources | Equipment | People | Solar Radiation | ||||

|---|---|---|---|---|---|---|---|

| Changsha | Hong Kong | Kunming | Shenyang | Zhengzhou | |||

| Q—heat gain ( kW ) | 1258.62 | 1090.22 | 1771.82 | 2309.32 | 2073.64 | 1507.39 | 1483.06 |

| q—heat gain per hour (kW/h) | 0.144 | 0.124 | 0.202 | 0.264 | 0.237 | 0.172 | 0.169 |

| Changsha | Hong Kong | Kunming | Shenyang | Zhengzhou | |

|---|---|---|---|---|---|

| Original value (°C) | 28.000 | 28.000 | 28.000 | 28.000 | 28.000 |

| Modified value (°C) | 27.191 | 27.084 | 27.130 | 27.242 | 27.248 |

| Ventilation Periods | Case 5 | Case 6 | Case 7 | Case 8 | Case 9 | Case 10 | Case 11 | Case 12 | |

|---|---|---|---|---|---|---|---|---|---|

| 0:00–3:00 | 3:00–6:00 | 6:00–9:00 | 9:00–12:00 | 12:00–15:00 | 15:00–18:00 | 18:00–21:00 | 21:00–24:00 | ||

| Climate regions | Hong Kong | 10350.3 | 10388.7 | 10390.6 | 10421.6 | 10423.6 | 10410.3 | 10439.8 | 10428.8 |

| Kunming | 0.7 | 00.6 | 0.6 | 0.4 | 0.3 | 0.0 | 0.7 | 0.6 | |

| Shenyang | 1577.4 | 1577.9 | 1601.1 | 1654.3 | 1717.0 | 1746.4 | 1715.3 | 1632.1 | |

| Changsha | 11972.9 | 11910.9 | 11998.6 | 12115.2 | 12163.0 | 12143.6 | 12049.2 | 12056.0 | |

| Zhengzhou | 5186.5 | 5174.4 | 5186.9 | 5332.4 | 5424.5 | 5444.5 | 5398.4 | 5205.6 | |

| Ventilation Periods | Case 5 (kW h) | Case 6 (kW h) | Case 7 (kW h) | Case 8 (kW h) | Case 9 (kW h) | Case 10 (kW h) | Case 11 (kW h) | Case 12 (kW h) | |

|---|---|---|---|---|---|---|---|---|---|

| 0:00–3:00 | 3:00–6:00 | 6:00–9:00 | 9:00–12:00 | 12:00–15:00 | 15:00–18:00 | 18:00–21:00 | 21:00–24:00 | ||

| Climate regions | HK | 672.67 | 678.57 | 673.48 | 669.83 | 673.33 | 681.84 | 676.01 | 675.89 |

| Kunming | 0.09 | 0.08 | 0.07 | 0.06 | 0.04 | 0.01 | 0.09 | 0.09 | |

| Shenyang | 132.56 | 133.09 | 134.55 | 135.74 | 141.41 | 144.51 | 145.35 | 136.67 | |

| Changsha | 788.06 | 789.81 | 790.00 | 790.24 | 795.47 | 796.78 | 803.66 | 793.07 | |

| Zhengzhou | 359.16 | 357.42 | 361.61 | 362.60 | 370.48 | 372.92 | 374.58 | 358.39 | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Cui, H.; Tang, W.; Sang, G.; Wu, H. Effect of Summer Ventilation on the Thermal Performance and Energy Efficiency of Buildings Utilizing Phase Change Materials. Energies 2017, 10, 1214. https://doi.org/10.3390/en10081214

Zhang Y, Cui H, Tang W, Sang G, Wu H. Effect of Summer Ventilation on the Thermal Performance and Energy Efficiency of Buildings Utilizing Phase Change Materials. Energies. 2017; 10(8):1214. https://doi.org/10.3390/en10081214

Chicago/Turabian StyleZhang, Yi, Hongzhi Cui, Waiching Tang, Guochen Sang, and Hong Wu. 2017. "Effect of Summer Ventilation on the Thermal Performance and Energy Efficiency of Buildings Utilizing Phase Change Materials" Energies 10, no. 8: 1214. https://doi.org/10.3390/en10081214

APA StyleZhang, Y., Cui, H., Tang, W., Sang, G., & Wu, H. (2017). Effect of Summer Ventilation on the Thermal Performance and Energy Efficiency of Buildings Utilizing Phase Change Materials. Energies, 10(8), 1214. https://doi.org/10.3390/en10081214