Physical and Compression Properties of Pellets Manufactured with the Biomass of Five Woody Tropical Species of Costa Rica Torrefied at Different Temperatures and Times

Abstract

:1. Introduction

2. Results

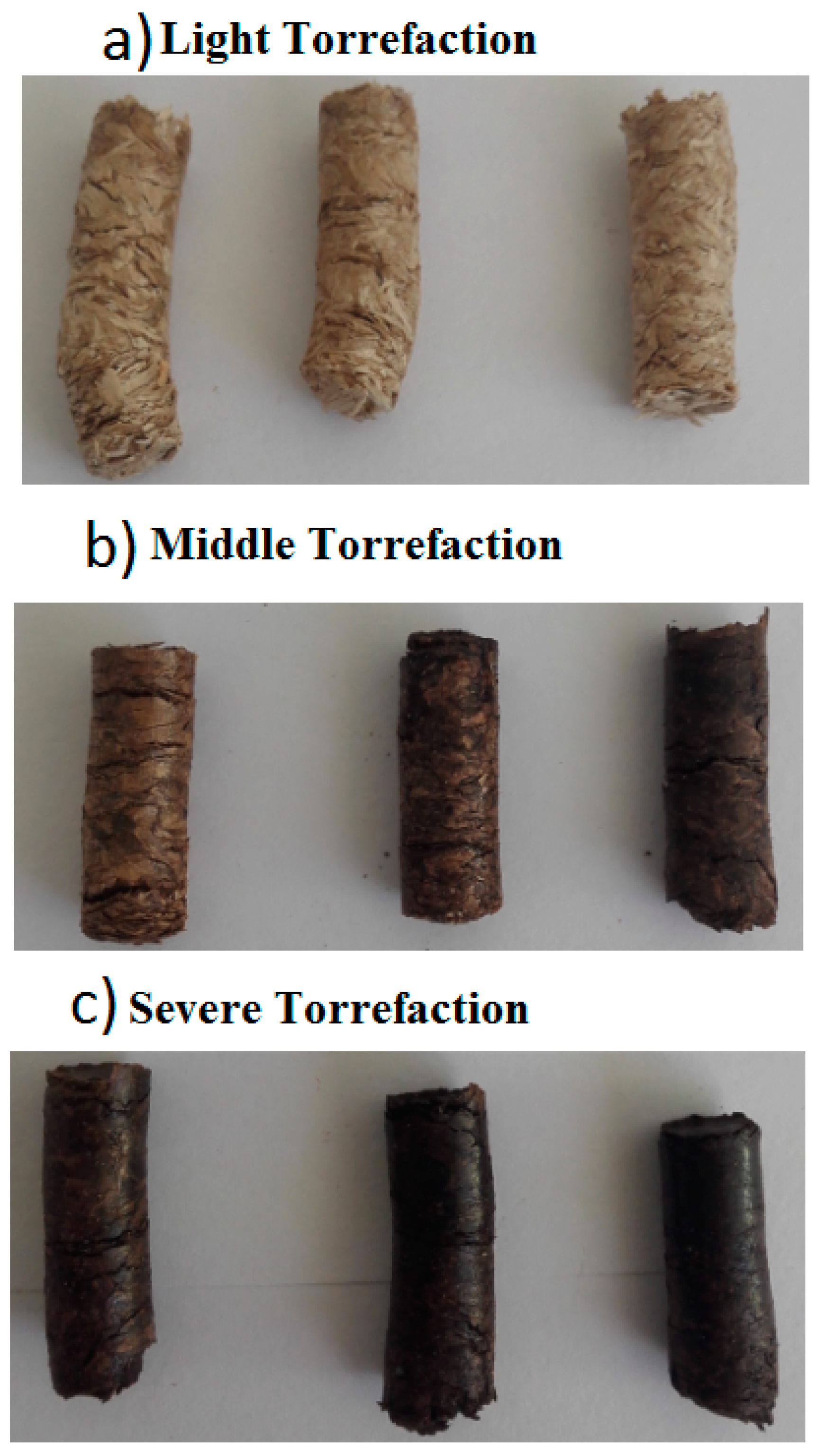

2.1. Pellet Appearance with Torrefied Biomass

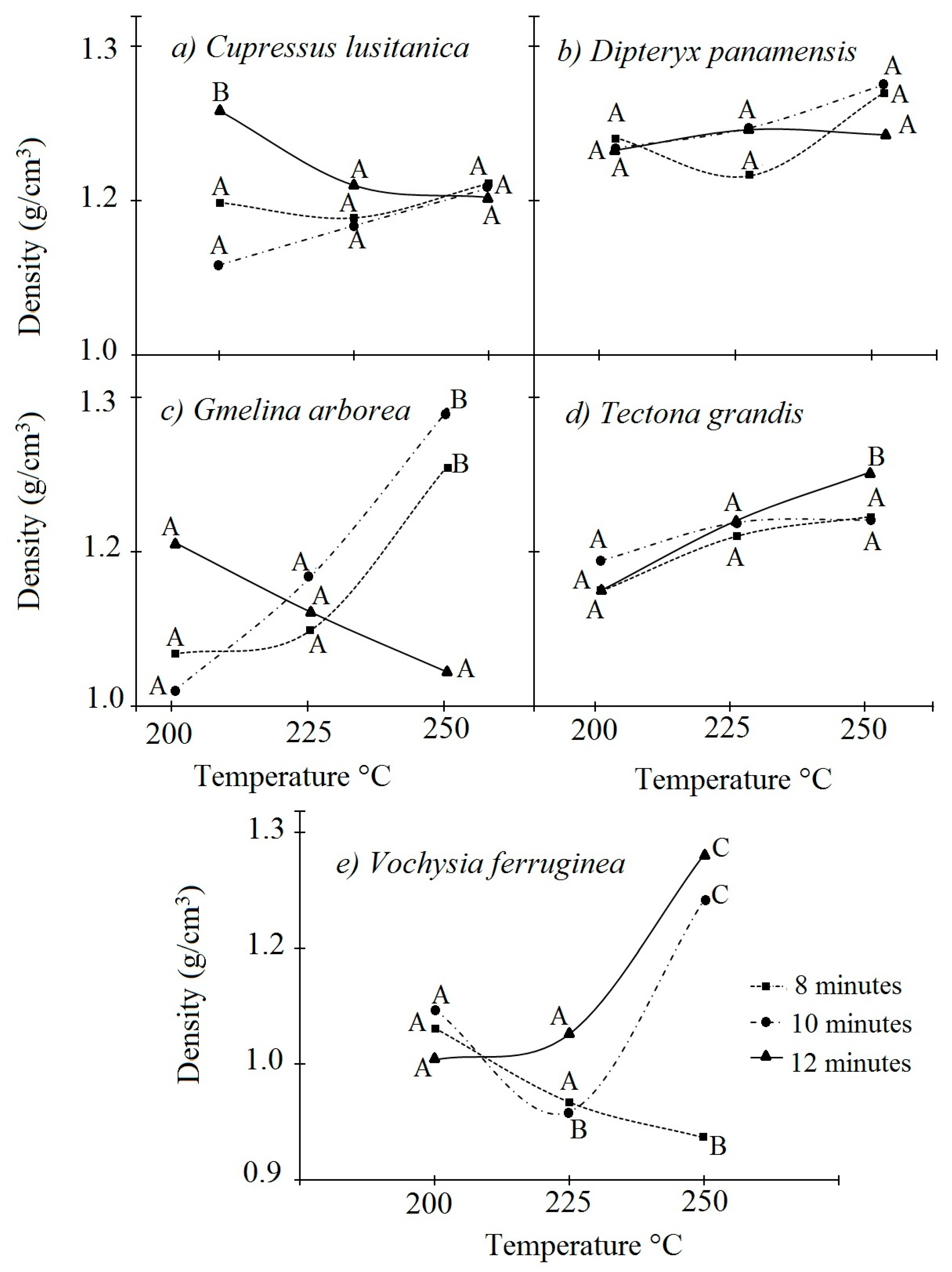

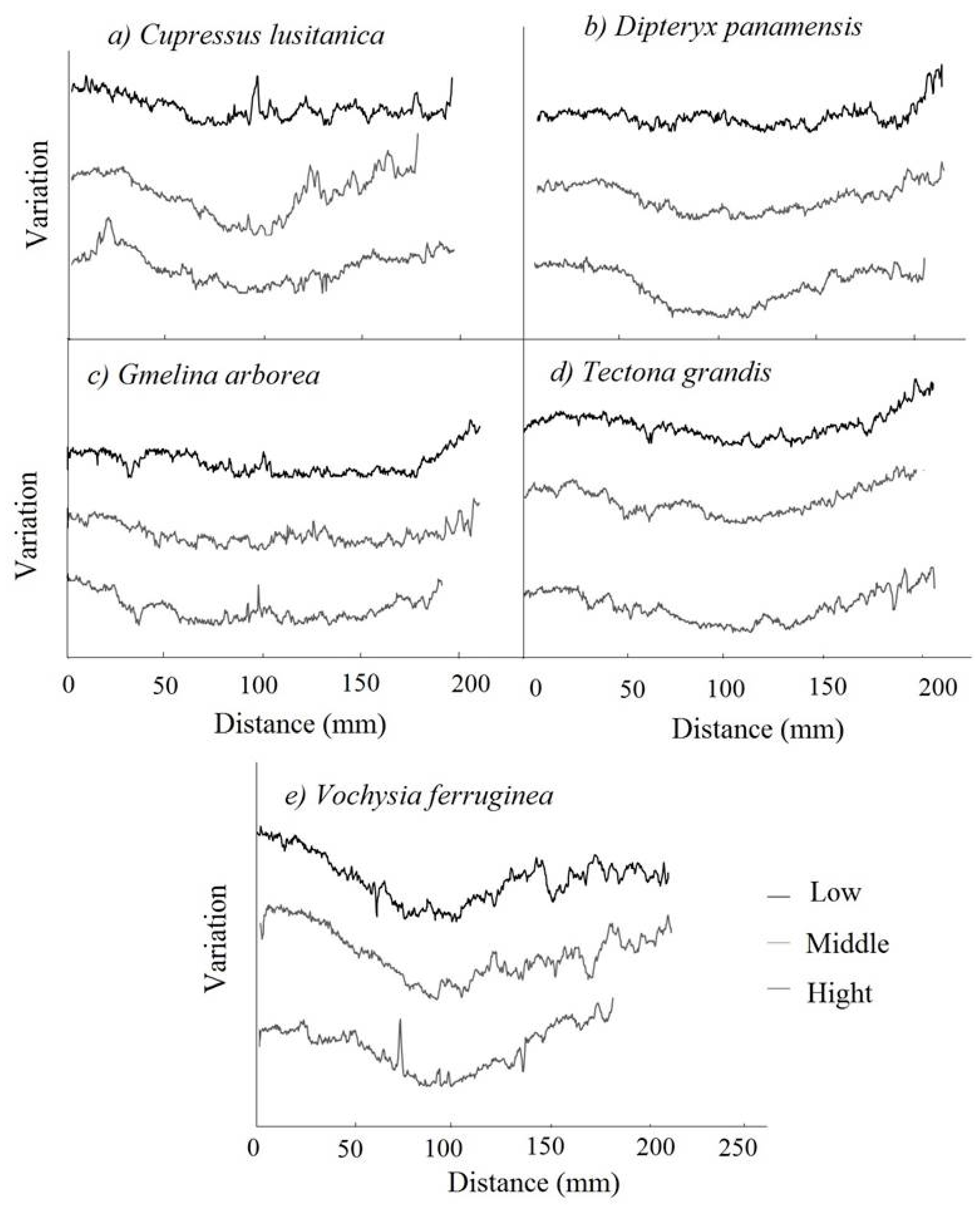

2.2. Pellet Density

2.3. Moisture Content and Moisture Absorption

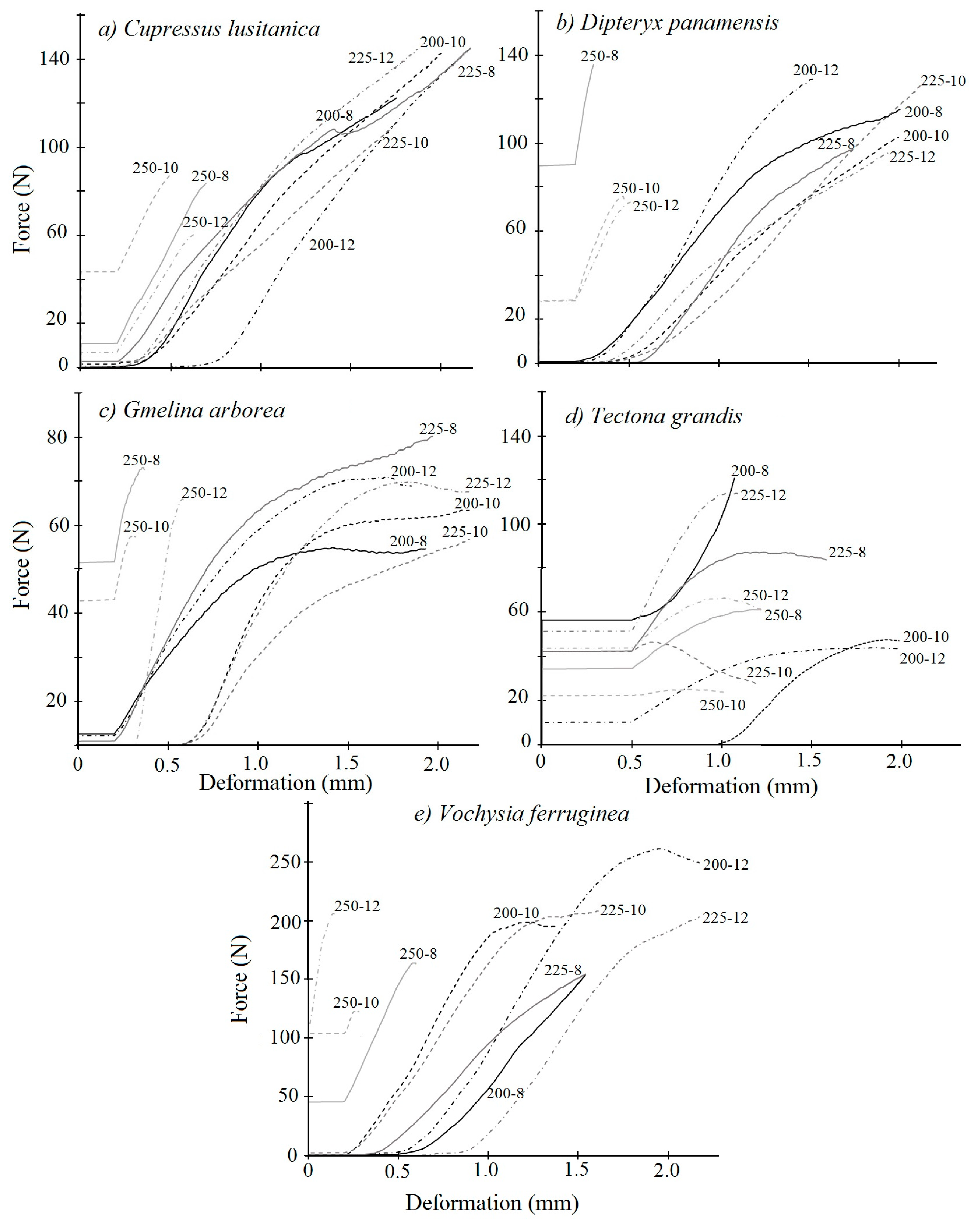

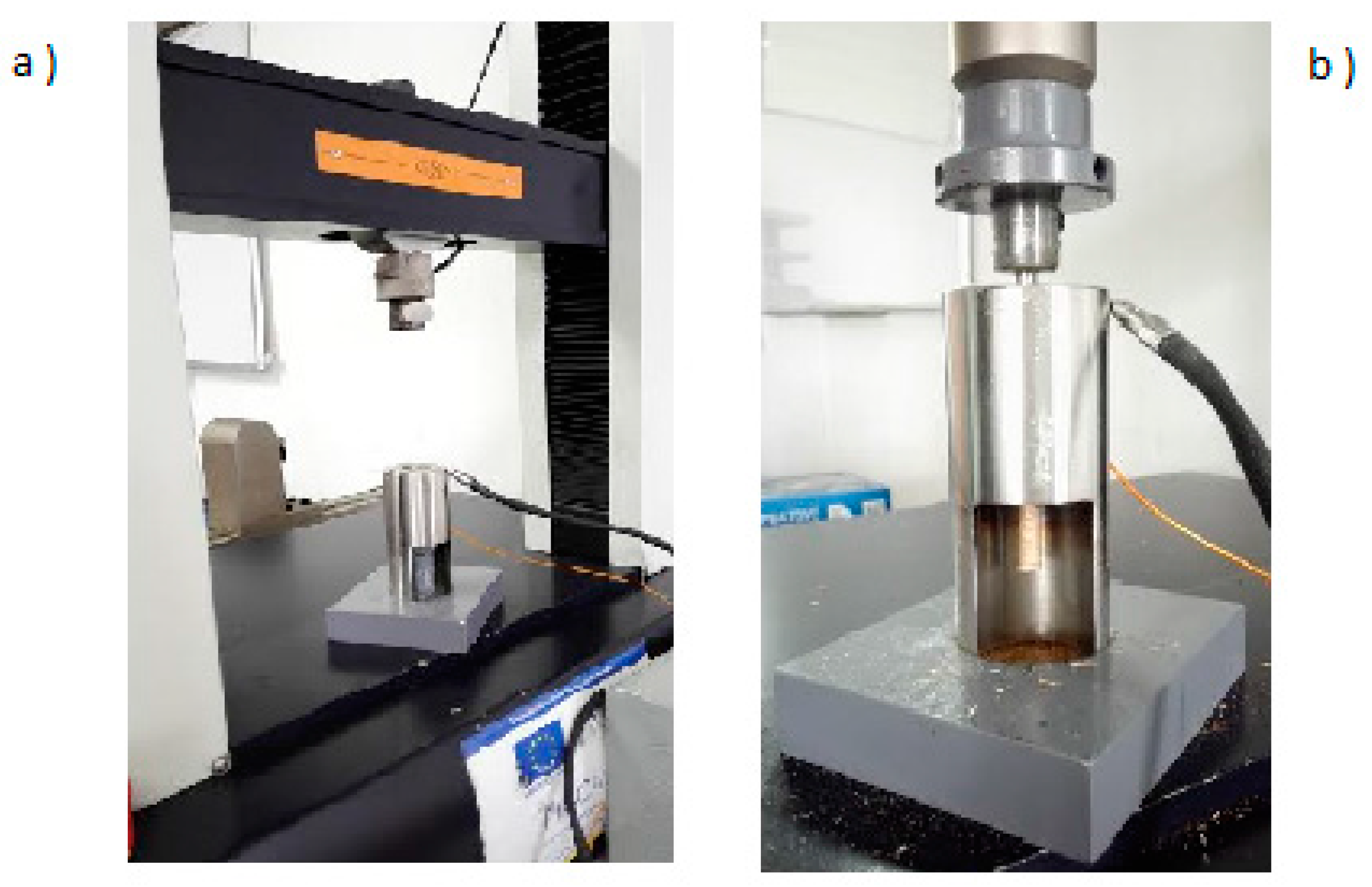

2.4. Compression Force

2.5. Effect of Different Properties of Pellets Made with Torrefied Biomass

3. Discussion

3.1. Appearance of Pellet with Torrefied Biomass

3.2. Pellet Density

3.3. Moisture Content and Moisture Absorption

3.4. Compression Force

3.5. Optimal Conditions for the Biomass Torrefaction of Reforestation Species

4. Materials and Methods

4.1. Provenance and Characteristics of the Material

4.2. Torrefaction Process

4.3. Pelletizing Process

4.4. Pellet Density and Variation by X-ray Densitometry

4.5. Water Absorption Percentage, Moisture Content, and Compression Force of the Pellets

4.6. Statistical Analysis

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Fournel, S.; Palacios, J.H.; Morissette, R.; Villeneuve, J.; Godbout, S.; Heitz, M.; Savoie, P. Influence of biomass properties on technical and environmental performance of a multi-fuel boiler during on-farm combustion of energy crops. Appl. Energy 2015, 141, 247–259. [Google Scholar] [CrossRef]

- Poddar, S.; Kamruzzaman, M.; Sujan, S.M.A.; Hossain, M.; Jamal, M.S.; Gafur, M.A.; Khanam, M. Effect of compression pressure on lignocellulosic biomass pellet to improve fuel properties: Higher heating value. Fuel 2014, 131, 43–48. [Google Scholar] [CrossRef]

- Kullander, S. Energy from biomass. Eur. Phys. J. Spec. Top. 2009, 176, 115–125. [Google Scholar] [CrossRef]

- Kim, S.; Dale, B.E. All biomass is local: The cost, volume produced, and global warming impact of cellulosic biofuels depend strongly on logistics and local conditions. Biofuels Bioprod. Biorefin. 2015, 9, 422–434. [Google Scholar] [CrossRef]

- Bahng, M.; Mukarakate, C.; Robichaud, D.; Nimlos, M. Current technologies for analysis of biomass thermochemical processing. Anal. Chim. Acta 2009, 651, 117–138. [Google Scholar] [CrossRef] [PubMed]

- Gokcol, C.; Dursunb, B.; Alboyaci, B.; Sunan, E. Importance of biomass energy as alternative to other sources in Turkey. Energy Policy 2009, 37, 424–431. [Google Scholar] [CrossRef]

- Wang, G.; Luo, Y.; Deng, J.; Kuang, J.; Zhang, Y. Pretreatment of biomass by torrefaction. Chin. Sci. Bull. 2011, 56, 1442–1448. [Google Scholar] [CrossRef]

- Medic, D.; Darr, M.; Shah, A.; Potter, B.; Zimmerman, J. Effects of torrefaction process parameters on biomass feedstock upgrading. Fuel 2012, 91, 147–154. [Google Scholar] [CrossRef]

- Proskurina, S.; Heinimö, J.; Schipfer, F.; Vakkilainen, E. Biomass for industrial applications: The role of torrefaction. Renew. Energy 2017, 111, 265–274. [Google Scholar] [CrossRef]

- Wu, M.; Schott, D.; Lodewijks, G. Physical properties of solid biomass. Biomass Bioenergy 2011, 35, 2093–2105. [Google Scholar] [CrossRef]

- Van der Stelt, M.; Gerhauser, H.; Kiel, J.; Ptasinski, K. Biomass upgrading by torrefaction for the production of biofuels: A review. Biomass Bioenergy 2011, 35, 3748–3762. [Google Scholar] [CrossRef]

- Chen, W.H.; Peng, J.; Bi, X.T. A state-of-the-art review of biomass torrefaction, densification and applications. Renew. Sustain. Energy Rev. 2015, 44, 847–866. [Google Scholar] [CrossRef]

- Du, S.W.; Chen, W.H.; Lucas, J.A. Pretreatment of biomass by torrefaction and carbonization for coal blend used in pulverized coal injection. Bioresour. Technol. 2014, 161, 333–339. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Liu, X.; Legros, R.; Bi, X.T.; Jim Lim, C.; Sokhansanj, S. Pelletization of torrefied sawdust and properties of torrefied pellets. Appl. Energy 2012, 93, 680–685. [Google Scholar] [CrossRef]

- Stelte, W.; Holm, J.; Sanadi, A.; Barsberg, S.; Ahrenfeldt, J.; Henriksen, U. Fuel pellets from biomass: The importance of the pelletizing pressure and its dependency on the processing conditions. Fuel 2011, 90, 3285–3290. [Google Scholar] [CrossRef] [Green Version]

- Tumuluru, J.S.; Wright, C.T.; Hess, J.R.; Kenney, K.L. A review of biomass densification systems to develop uniform feedstock commodities for bioenergy application. Biofuels Bioprod. Biorefin. 2011, 5, 683–707. [Google Scholar] [CrossRef]

- Filbakk, T.; Skjevrak, G.; Høibø, O.; Dibdiakova, J.; Jirjis, R. The influence of storage and drying methods for Scots pine raw material on mechanical pellet properties and production parameters. Fuel Process. Technol. 2011, 92, 871–878. [Google Scholar] [CrossRef]

- Kaliyan, N.; Morey, R.V. Factors affecting strength and durability of densified biomass products. Biomass Bioenergy 2009, 33, 337–359. [Google Scholar] [CrossRef]

- Wang, C.; Peng, J.; Li, H.; Bi, X.T.; Legros, R.; Lim, C.J.; Sokhansanj, S. Oxidative torrefaction of biomass residues and densification of torrefied sawdust to pellets. Bioresour. Technol. 2013, 127, 318–325. [Google Scholar] [CrossRef] [PubMed]

- Kotwaliwale, N.; Singh, K.; Kalne, A.; Jha, S.N.; Seth, N.; Kar, A. X-ray imaging methods for internal quality evaluation of agricultural produce. J. Food Sci. Technol. 2014, 51, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Tenorio, C.; Moya, R.; Tomazello-Filho, M.; Valaert, J. Application of the X-ray densitometry in the evaluation of the quality and mechanical properties of biomass pellets. Fuel Process. Technol. 2015, 132, 62–83. [Google Scholar] [CrossRef]

- Tenorio, C.; Moya, R.; Tomazello-Filho, M.; Valaert, J. Quality of pellets made from agricultural and forestry crops in Costa Rican tropical climates. BioResources 2015, 10, 482–498. [Google Scholar] [CrossRef]

- Arias, B.; Pevida, C.; Fermoso, J.; Plaza, M.G.; Rubiera, F.; Pis, J.J. Influence of torrefaction on the grindability and reactivity of woody biomass. Fuel Process. Technol. 2008, 89, 169–175. [Google Scholar] [CrossRef]

- Peng, J.H.; Bi, X.T.; Sokhansanj, S.; Lim, C.J. Torrefaction and densification of different species of softwood residues. Fuel 2013, 111, 411–421. [Google Scholar] [CrossRef]

- Gaitán-Álvarez, J.; Moya, R. Characteristics and properties of pellet fabricated with torrefacted biomass of Gmelina arborea and Dipterix panamensis at different time. Rev. Chapingo Ser. Cienc. For. Ambient. 2016, 23, 325–337. [Google Scholar] [CrossRef]

- Moya, R.; Rodríguez-Zúñiga, A.; Puente-Urbina, A. Thermogravimetric and devolatilisation analysis for five plantation species: Effect of extractives, ash compositions, chemical compositions and energy parameters. Thermochim. Acta 2017, 647, 36–46. [Google Scholar] [CrossRef]

- Tenorio, C.; Moya, R. Evaluation of different approaches for the drying of lignocellulose residues. BioResources 2012, 7, 3500–3514. [Google Scholar]

- Aragón-Garita, S.; Moya, R.; Bond, B.; Valaert, J.; Tomazello Filho, M. Production and quality analysis of pellets manufactured from five potential energy crops in the Northern Region of Costa Rica. Biomass Bioenergy 2016, 87, 84–95. [Google Scholar] [CrossRef]

- González-Peña, M.M.; Hale, M.D. Colour in thermally modified wood of beech, Norway spruce and Scots pine. Part 1: Colour evolution and colour changes. Holzforschung 2009, 63, 385–393. [Google Scholar] [CrossRef]

- Shang, L.; Nielsen, N.P.K.; Dahl, J.; Stelte, W.; Ahrenfeldt, J.; Holm, J.K.; Henriksen, U.B. Quality effects caused by torrefaction of pellets made from Scots pine. Fuel Process. Technol. 2012, 101, 23–28. [Google Scholar] [CrossRef]

- SawaiI, T.; Katayama, I.; Ida, T.; Imamura, H.; Kajimoto, T. Estimation of energy properties of torrefied Japanese cedar with colorimetric values. Mech. Eng. J. 2017, 4, 16–00320. [Google Scholar] [CrossRef]

- Mišljenović, N.; Bach, Q.V.; Tran, K.Q.; Salas-Bringas, C.; Skreiberg, Ø. Torrefaction influence on pelletability and pellet quality of Norwegian forest residues. Energy Fuels 2014, 28, 2554–2561. [Google Scholar] [CrossRef]

- Carone, A.; Pantaleo, A.; Pellerano, A. Influence of process parameters and biomass characteristics on the durability of pellets from the pruning residues of Olea europea L. Biomass Bioenergy 2011, 35, 402–410. [Google Scholar] [CrossRef]

- Cao, L.; Yuan, X.; Li, H.; Li, C.; Xiao, Z.; Jiang, L.; Zeng, G. Complementary effects of torrefaction and co-pelletization: Energy consumption and characteristics of pellets. Bioresour. Technol. 2015, 185, 254–262. [Google Scholar] [CrossRef] [PubMed]

- Peng, J.H.; Bi, H.T.; Sokhansanj, S.; Lim, J.C. A study of particle size effect on biomass torrefaction and densification. Energy Fuels 2012, 26, 3826–3839. [Google Scholar] [CrossRef]

- Phanphanich, M.; Mani, S. Impact of torrefaction on the grindability and fuel characteristics of forest biomass. Bioresour. Technol. 2011, 102, 1246–1253. [Google Scholar] [CrossRef] [PubMed]

- Pyle, O. Process for Producing Solid Industrial Fuel 1972. U.S. Patent 3950143A, 13 April 1976. [Google Scholar]

- Agar, D.A. A comparative economic analysis of torrefied pellet production based on state-of-the-art pellets. Biomass Bioenergy 2017, 97, 155–161. [Google Scholar] [CrossRef]

- Bissen, D. Biomass Densification, Document of Evaluation; Agricultural Utilization Research Institute, Zachry Energy Corporation: Minneapolis, MN, USA, 2009. [Google Scholar]

- Bergström, D.; Israelsson, S.; Öhman, M.; Dahlqvist, S.A.; Gref, R.; Boman, C.; Wästerlund, I. Effects of raw material particle size distribution on the characteristics of Scots pine sawdust fuel pellets. Fuel Process. Technol. 2008, 89, 1324–1329. [Google Scholar] [CrossRef]

- Larsson, S.H.; Thyrel, M.; Geladi, P.; Lestander, T.A. High quality biofuel pellet production from pre-compacted low density raw materials. Bioresour. Technol. 2008, 99, 7176–7182. [Google Scholar] [CrossRef] [PubMed]

- Kymäläinen, M.; Rautkari, L.; Hill, C.A. Sorption behaviour of torrefied wood and charcoal determined by dynamic vapour sorption. J. Mater. Sci. 2015, 50, 7673–7680. [Google Scholar] [CrossRef]

- Rudolfsson, M.; Borén, E.; Pommer, L.; Nordin, A.; Lestander, T. Combined effects of torrefaction and pelletization parameters on the quality of pellets produced from torrefied biomass. Appl. Energy 2017, 191, 414–424. [Google Scholar] [CrossRef]

- Acharjee, T.C.; Coronella, C.J.; Vasquez, V.R. Effect of thermal pretreatment on equilibrium moisture content of lignocellulosic biomass. Bioresour. Technol. 2011, 102, 4849–4854. [Google Scholar] [CrossRef] [PubMed]

- Kambo, H.S.; Dutta, A. Strength, storage, and combustion characteristics of densified lignocellulosic biomass produced via torrefaction and hydrothermal carbonization. Appl. Energy 2014, 135, 182–191. [Google Scholar] [CrossRef]

- Ahn, B.J.; Chang, H.S.; Lee, S.M.; Choi, D.H.; Cho, S.T.; Han, G.S.; Yang, I. Effect of binders on the durability of wood pellets fabricated from Larix kaemferi C. and Liriodendron tulipifera L. sawdust. Renew. Energy 2014, 62, 18–23. [Google Scholar] [CrossRef]

- Keipi, T.; Tolvanen, H.; Kokko, L.; Raiko, R. The effect of torrefaction on the chlorine content and heating value of eight woody biomass samples. Biomass Bioenergy 2014, 66, 232–239. [Google Scholar] [CrossRef]

- Chen, W.H.; Kuo, P.C. A study on torrefaction of various biomass materials and its impact on lignocellulosic structure simulated by a thermogravimetry. Energy 2010, 35, 2580–2586. [Google Scholar] [CrossRef]

- Nunes, L.J.R.; Matias, J.C.O.; Catalao, J.P.S. Wood pellets as a sustainable energy alternative in Portugal. Renew. Energy 2016, 85, 1011–1016. [Google Scholar] [CrossRef]

- Mani, S.; Tabil, L.G.; Sokhansanj, S. Effects of compressive force, particle size and moisture content on mechanical properties of biomass pellets from grasses. Biomass Bioenergy 2006, 30, 648–654. [Google Scholar] [CrossRef]

- Rhen, C.; Rolf, G.; Sjöström, M.; Wäterlund, I. Effects of raw material moisture content, densification pressure and temperature on some properties of Norway spruce pellets. Fuel Process. Technol. 2005, 87, 11–16. [Google Scholar] [CrossRef]

- Kumar, L.; Koukoulas, A.A.; Mani, S.; Satyavolu, J. Integrating torrefaction in the wood pellet industry: A Critical Review. Energy Fuels 2016, 31, 37–54. [Google Scholar] [CrossRef]

- Bridgeman, T.G.; Jones, J.M.; Shield, I.; Williams, P.T. Torrefaction of reed canary grass, wheat straw and willow to enhance solid fuel qualities and combustion properties. Fuel 2008, 87, 844–856. [Google Scholar] [CrossRef]

- Aarseth, K.A.; Prestlokken, E. Mechanical properties of feed Pellets: Weibull analysis. Biosyst. Eng. 2003, 84, 349–361. [Google Scholar] [CrossRef]

| Species | Temperature (°C) | Time (minutes) | Moisture Content (%) | Moisture Absorption (%) | Compression Force (N) | Density Variation (%) |

|---|---|---|---|---|---|---|

| Cupressus lusitanica | 200 | 8 | 2.71 A | 12.15 A | 929.09 A | 4.25 A |

| 10 | 3.44 A | 12.46 A | 609.21 B | 4.67 A | ||

| 12 | 1.28 B | 17.92 B | 323.20 C | 4.59 A | ||

| 225 | 8 | 1.65 B | 16.32 B | 416.83 C | 5.09 A | |

| 10 | 1.56 B | 12.22 A | 379.01 C | 5.25 A | ||

| 12 | 0.90 B | 11.58 A | 370.91 C | 6.42 B | ||

| 250 | 8 | 3.14 A | 10.34 A | 752.48 A | 4.31 A | |

| 10 | 0.96 B | 9.75 C | 819.17 A | 4.70 A | ||

| 12 | 1.73 B | 7.31 C | 672.33 B | 6.99 B | ||

| Dipteryx panamensis | 200 | 8 | 5.05 A | 10.08 A | 757.92 A | 3.81 A |

| 10 | 5.08 A | 9.22 A | 702.55 A | 2.84 A | ||

| 12 | 1.82 B | 9.41 A | 804.96 A | 3.00 A | ||

| 225 | 8 | 1.19 C | 11.76 B | 341.63 B | 3.35 A | |

| 10 | 1.19 C | 10.89 A | 407.86 B | 4.03 A | ||

| 12 | 0.73 C | 10.55 A | 409.95 B | 3.49 A | ||

| 250 | 8 | 0.67 C | 11.15 A | 832.50 A | 3.77 A | |

| 10 | 0.41 C | 9.28 A | 840.95 A | 4.47 A | ||

| 12 | 0.43 C | 7.19 C | 682.79 A | 4.66 A | ||

| Gmelina arborea | 200 | 8 | 4.19 A | 11.84 A | 579.62 A | 4.08 A |

| 10 | 5.51 A | 11.17 A | 497.68 A | 5.18 A | ||

| 12 | 3.98 A | 11.51 A | 582.56 A | 3.42 A | ||

| 225 | 8 | 2.69 B | 13.15 B | 191.78 B | 9.10 B | |

| 10 | 5.23 A | 11.44 A | 187.77 B | 3.22 A | ||

| 12 | 2.02 B | 11.82 A | 164.57 B | 3.74 A | ||

| 250 | 8 | 0.92 C | 12.09 A | 394.78 C | 4.72 A | |

| 10 | 2.35 B | 10.62 C | 457.50 C | 4.85 A | ||

| 12 | 2.71 B | 8.19 D | 332.06 C | 7.71 B | ||

| Tectona grandis | 200 | 8 | 3.93 A | 11.32 A | 296.59 A | 3.64 A |

| 10 | 4.64 A | 9.41 B | 268.53 A | 3.14 A | ||

| 12 | 1.68 B | 11.98 A | 250.78 A | 3.18 A | ||

| 225 | 8 | 2.15 B | 10.45 A | 620.32 B | 3.35 A | |

| 10 | 1.27 B | 10.12 A | 344.14 A | 3.92 A | ||

| 12 | 1.24 B | 10.74 A | 428.75 A | 3.56 A | ||

| 250 | 8 | 0.61 C | 9.82 A | 597.15 B | 3.62 A | |

| 10 | 2.25 B | 8.94 B | 506.88 B | 3.99 A | ||

| 12 | 1.18 C | 7.21 C | 589.91 B | 3.49 A | ||

| Vochysia ferruginea | 200 | 8 | 3.09 A | 9.82 A | 1052.41 A | 8.24 A |

| 10 | 3.68 A | 9.82 A | 1468.97 B | 8.26 A | ||

| 12 | 4.21 A | 9.69 A | 1434.28 B | 9.33 A | ||

| 225 | 8 | 0.87 B | 13.02 B | 623.97 C | 10.57 B | |

| 10 | 0.49 B | 11.26 A | 850.87 A | 12.55 B | ||

| 12 | 0.70 B | 9.92 A | 730.27 C | 11.18 B | ||

| 250 | 8 | 0.60 B | 9.46 A | 1388.33 B | 6.74 A | |

| 10 | 2.18 A | 10.30 A | 1162.28 A | 6.68 A | ||

| 12 | 3.08 A | 6.97 C | 867.46 A | 2.11 C |

| Cupressus Lusitanica | |||||

| Variables | Density | Coefficient of Variation | Compression Force | Moisture Absorption | Moisture Content |

| Density | 1.00 | - | - | - | - |

| Coefficient of variation | −0.32 ** | 1.00 | - | - | - |

| Compression force | 0.04 NS | −0.19 * | 1.00 | - | - |

| Moisture absorption | 0.14 NS | 0.04 NS | −0.33 ** | 1.00 | - |

| Moisture content | −0.16 * | −0.08 NS | 0.27 * | −0.14 NS | 1.00 |

| Dipteryx Panamensis | |||||

| Variables | Density | Coefficient of Variation | Compression Force | Moisture Absorption | Moisture Content |

| Density | 1.00 | - | - | - | - |

| Coefficient of variation | −0.18 * | 1.00 | - | - | - |

| Compression force | 0.21 * | 0.13 NS | 1.00 | - | - |

| Moisture absorption | −0.07 NS | −0.38 ** | −0.45 ** | 1.00 | - |

| Moisture content | −0.17 * | −0.31 ** | 0.15 NS | 0.04 NS | 1.00 |

| Gmelina Arborea | |||||

| Variables | Density | Coefficient of Variation | Compression Force | Moisture Absorption | Moisture Content |

| Density | 1.00 | - | - | - | - |

| Coefficient of variation | −0.21 * | 1.00 | - | - | - |

| Compression force | 0.17 * | −0.10 NS | 1.00 | - | - |

| Moisture absorption | 0.18 * | −0.10 NS | −0.06 NS | 1.00 | - |

| Moisture content | −0.42 ** | 1.10 NS | 0.42 ** | −0.15 NS | 1.00 |

| Tectona Grandis | |||||

| Variables | Density | Coefficient of Variation | Compression Force | Moisture Absorption | Moisture Content |

| Density | 1.00 | - | - | - | - |

| Coefficient of variation | −0.29 * | 1.00 | - | - | - |

| Compression force | 0.16 * | −0.03 NS | 1.00 | - | - |

| Moisture absorption | −0.01 NS | −0.16 * | −0.19 * | 1.00 | - |

| Moisture content | −0.27 * | 0.00 NS | −0.28 * | 0.09 NS | 1.00 |

| Vochysia Ferruginea | |||||

| Variables | Density | Coefficient of Variation | Compression Force | Moisture Absorption | Moisture Content |

| Density | 1.00 | - | - | - | - |

| Coefficient of variation | −0.55 ** | 1.00 | - | - | - |

| Compression force | −0.03 NS | −0.23 * | 1.00 | - | - |

| Moisture absorption | −0.37 ** | 0.39 ** | −0.24 * | 1.00 | - |

| Moisture content | 0.32 ** | −0.26 * | 0.32 ** | −0.19 * | 1.00 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gaitán-Alvarez, J.; Moya, R.; Puente-Urbina, A.; Rodriguez-Zuñiga, A. Physical and Compression Properties of Pellets Manufactured with the Biomass of Five Woody Tropical Species of Costa Rica Torrefied at Different Temperatures and Times. Energies 2017, 10, 1205. https://doi.org/10.3390/en10081205

Gaitán-Alvarez J, Moya R, Puente-Urbina A, Rodriguez-Zuñiga A. Physical and Compression Properties of Pellets Manufactured with the Biomass of Five Woody Tropical Species of Costa Rica Torrefied at Different Temperatures and Times. Energies. 2017; 10(8):1205. https://doi.org/10.3390/en10081205

Chicago/Turabian StyleGaitán-Alvarez, Johanna, Roger Moya, Allen Puente-Urbina, and Ana Rodriguez-Zuñiga. 2017. "Physical and Compression Properties of Pellets Manufactured with the Biomass of Five Woody Tropical Species of Costa Rica Torrefied at Different Temperatures and Times" Energies 10, no. 8: 1205. https://doi.org/10.3390/en10081205

APA StyleGaitán-Alvarez, J., Moya, R., Puente-Urbina, A., & Rodriguez-Zuñiga, A. (2017). Physical and Compression Properties of Pellets Manufactured with the Biomass of Five Woody Tropical Species of Costa Rica Torrefied at Different Temperatures and Times. Energies, 10(8), 1205. https://doi.org/10.3390/en10081205