A Sliding Surface-Regulated Current-Mode Pulse-Width Modulation Controller for a Digital Signal Processor-Based Single Ended Primary Inductor Converter-Type Power Factor Correction Rectifier

Abstract

:1. Introduction

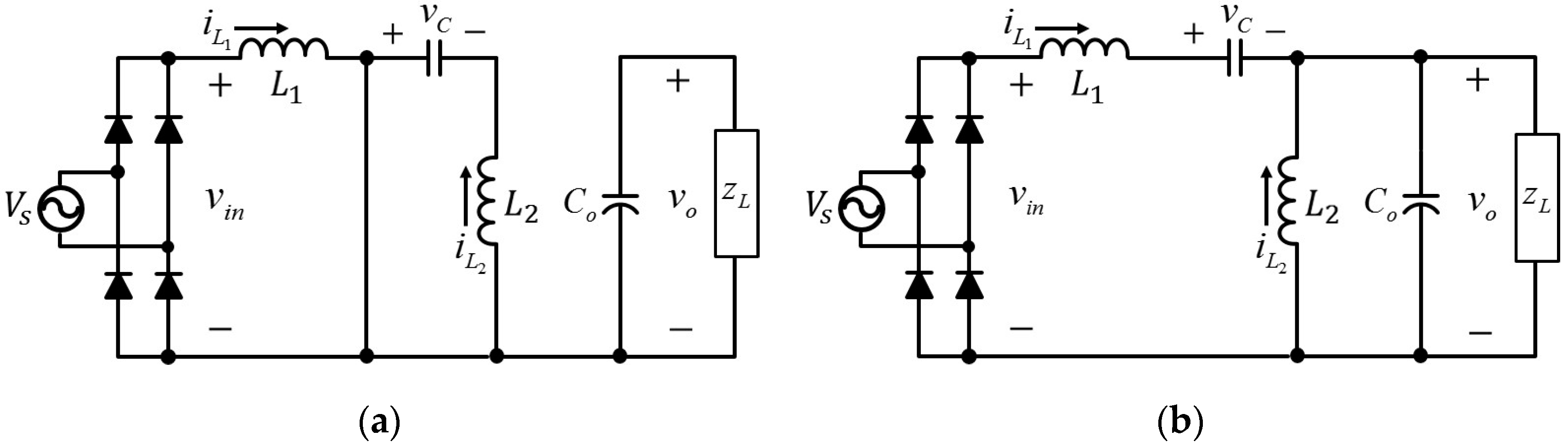

2. Modeling of Switch-Mode SEPIC-Type Rectifier

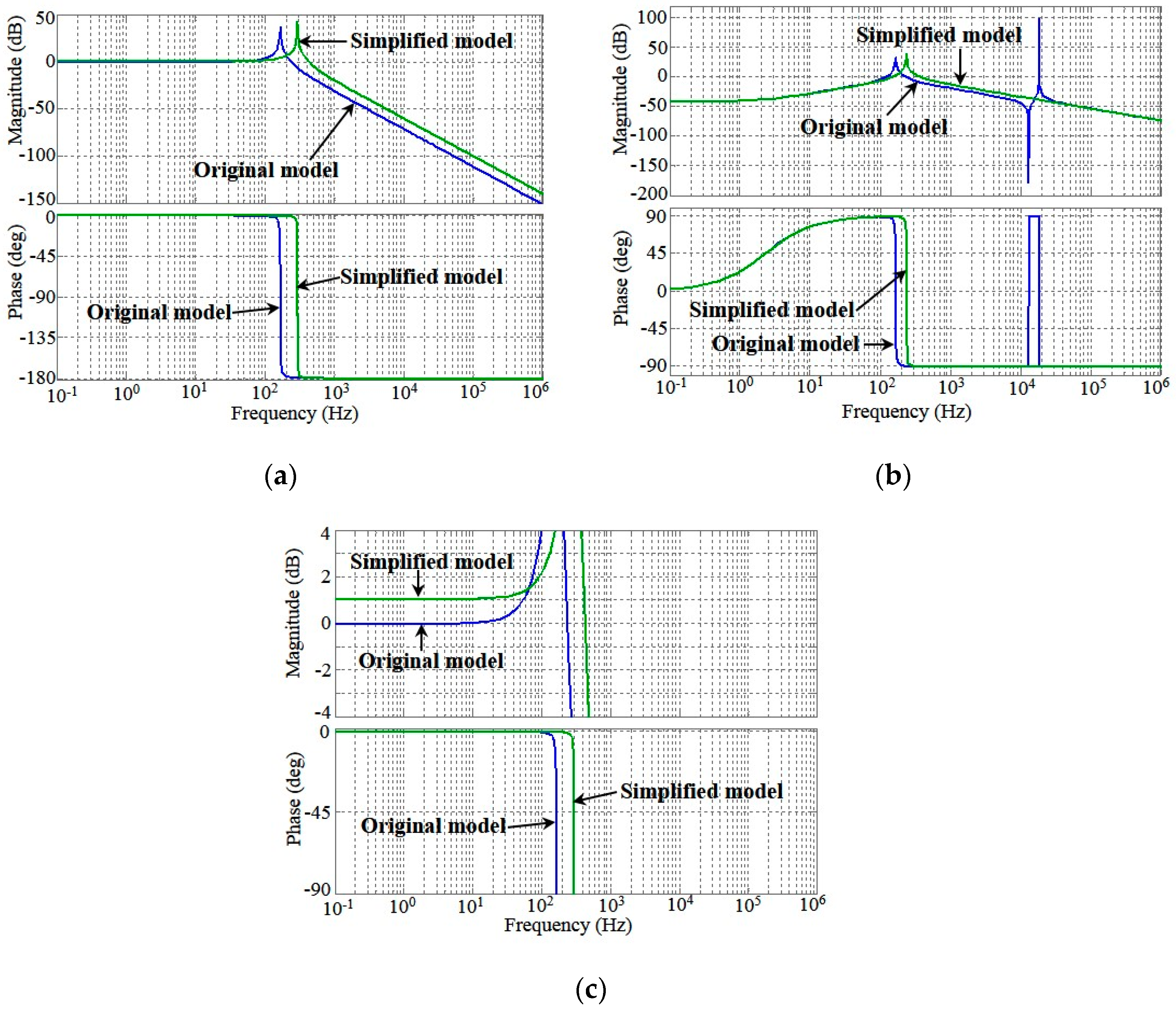

2.1. Full-Order State-Averaged Model

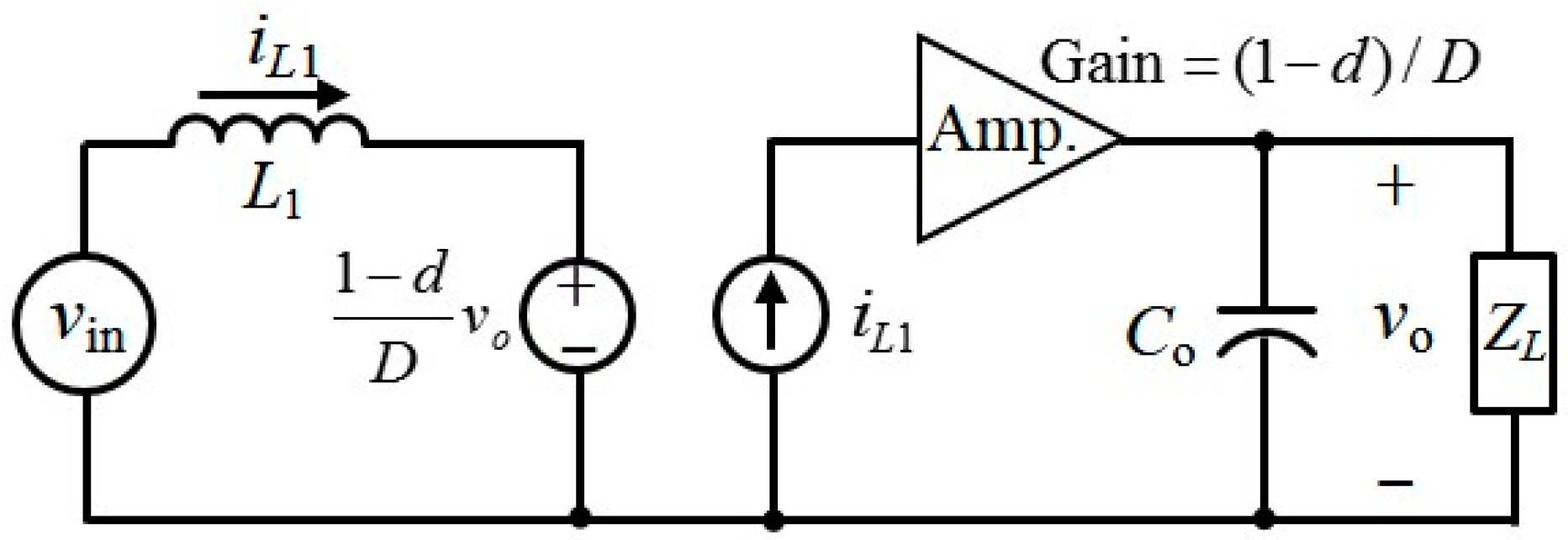

2.2. Simplified State-Averaged Model

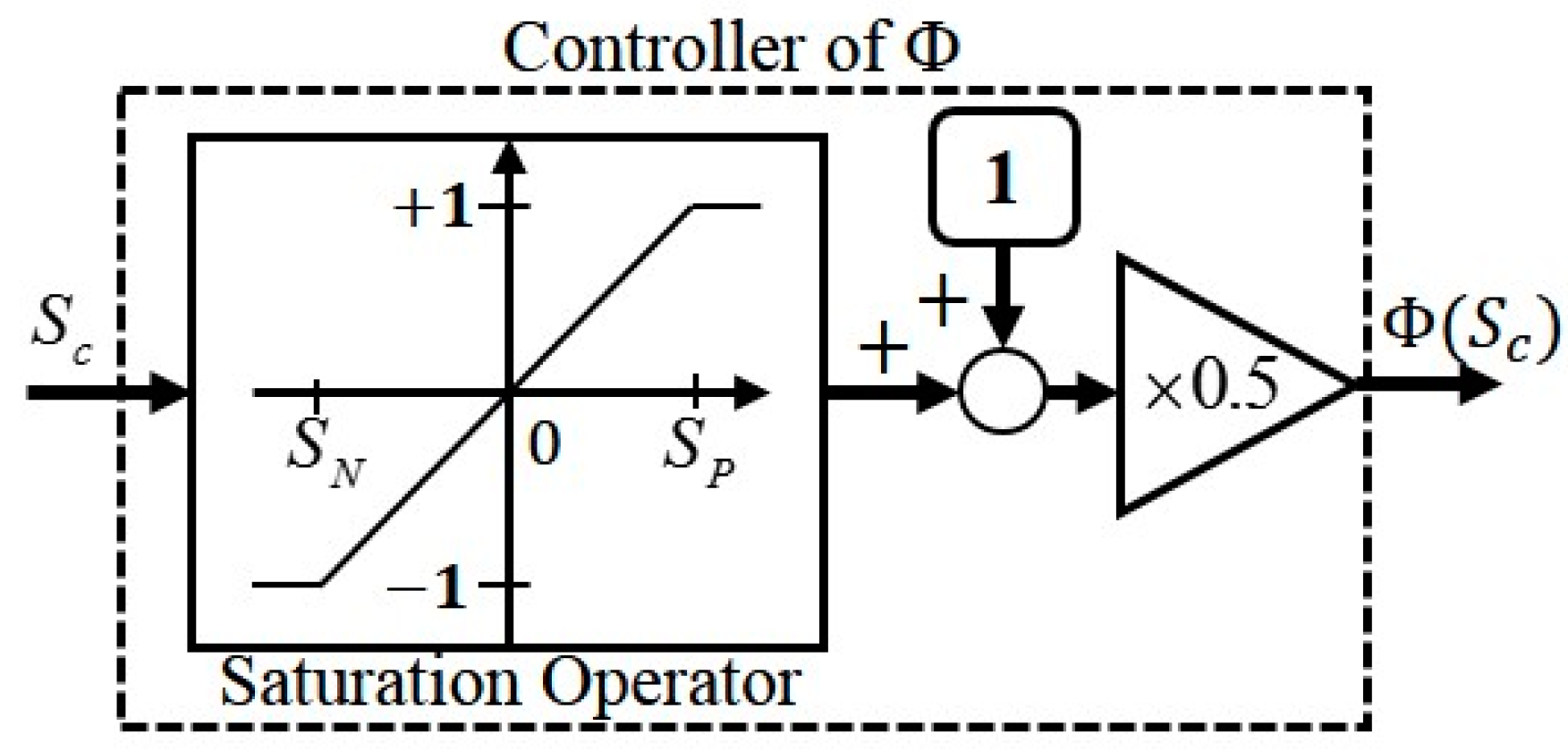

3. Sliding Surface-Regulated Current-Mode PWM Controller

3.1. Sliding-Mode Voltage Controller with Integral Sliding Surface

3.2. Sliding-Mode Current Controller with PFC

3.3. Stability Analysis of the PFC Rectifier

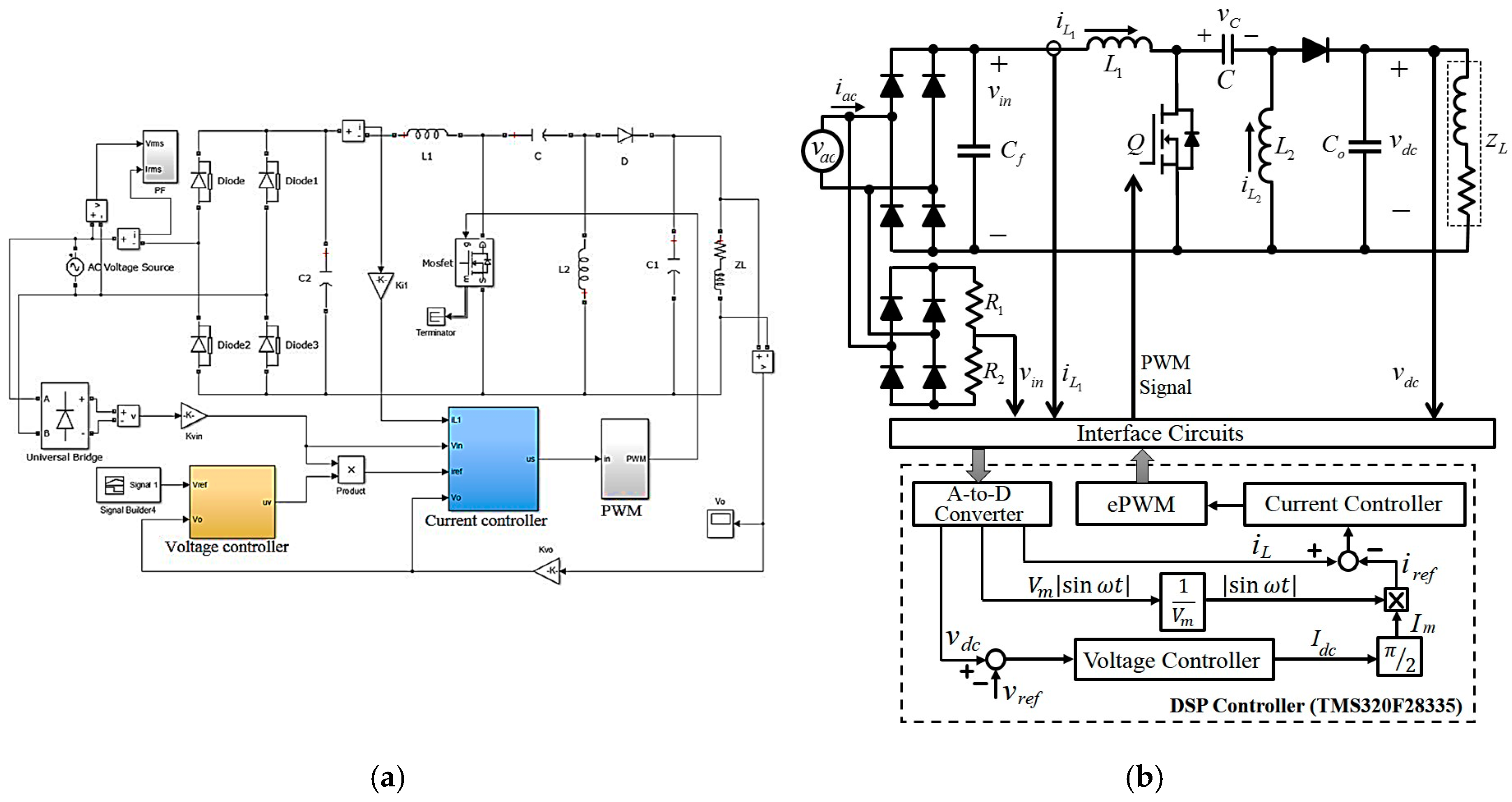

4. Simulation and Experimental Work

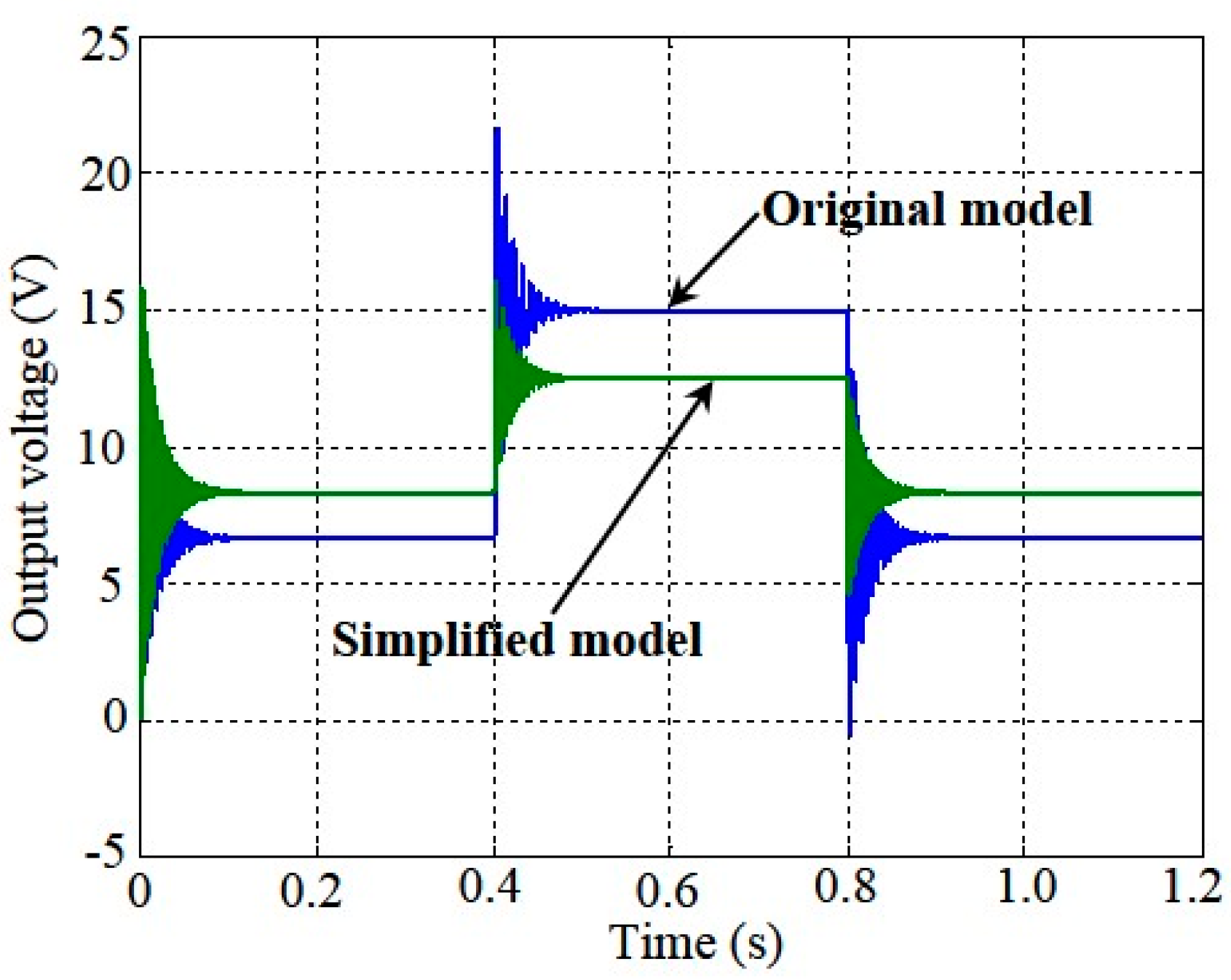

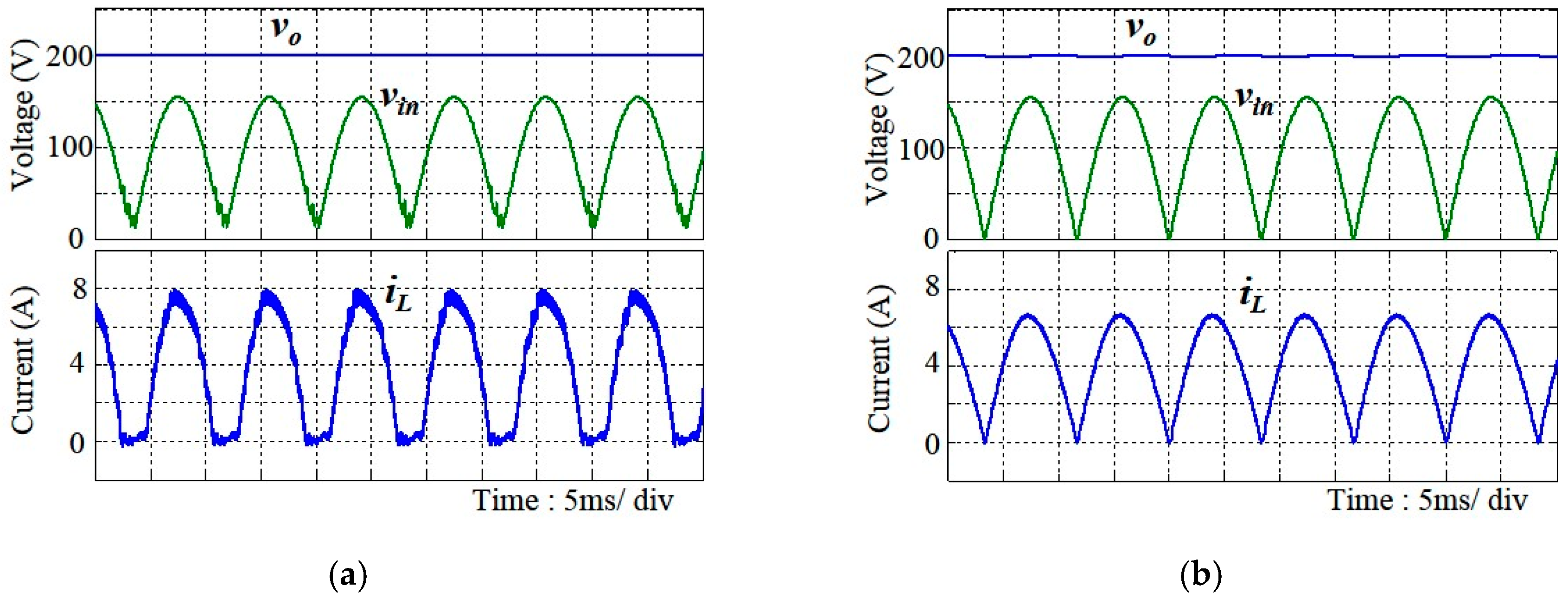

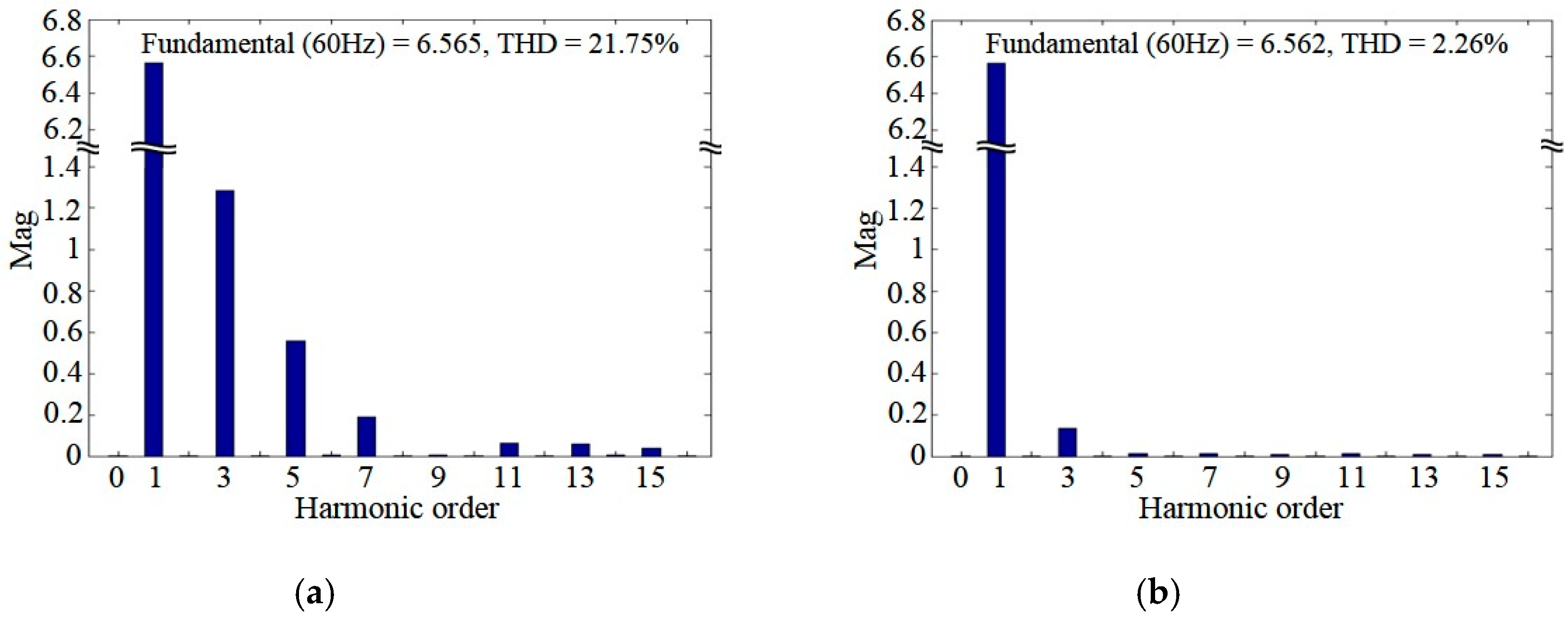

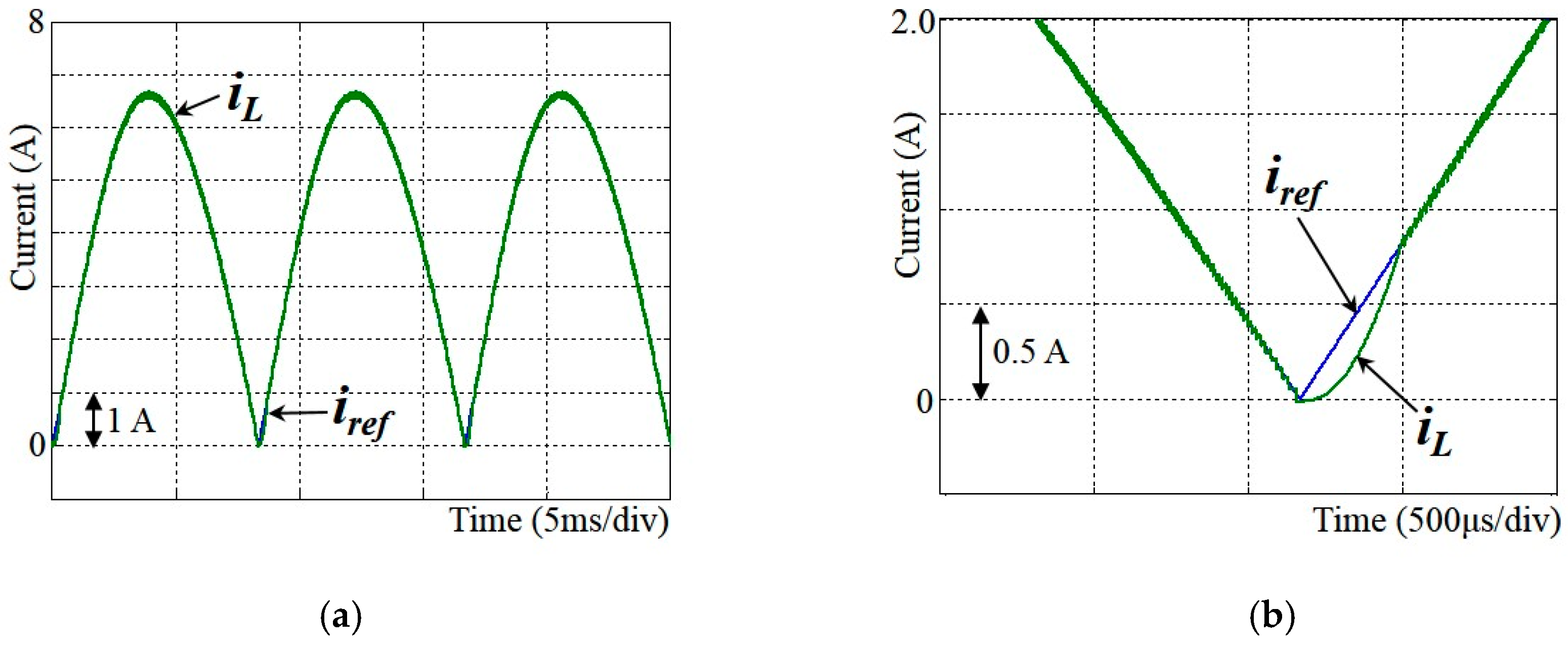

4.1. Simulation Results

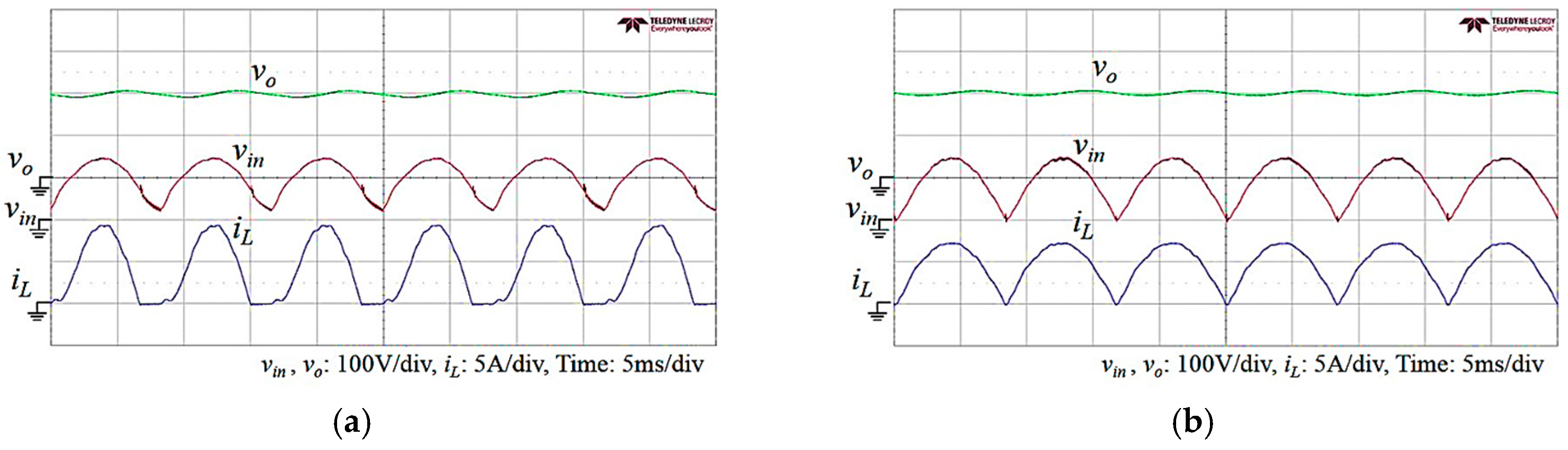

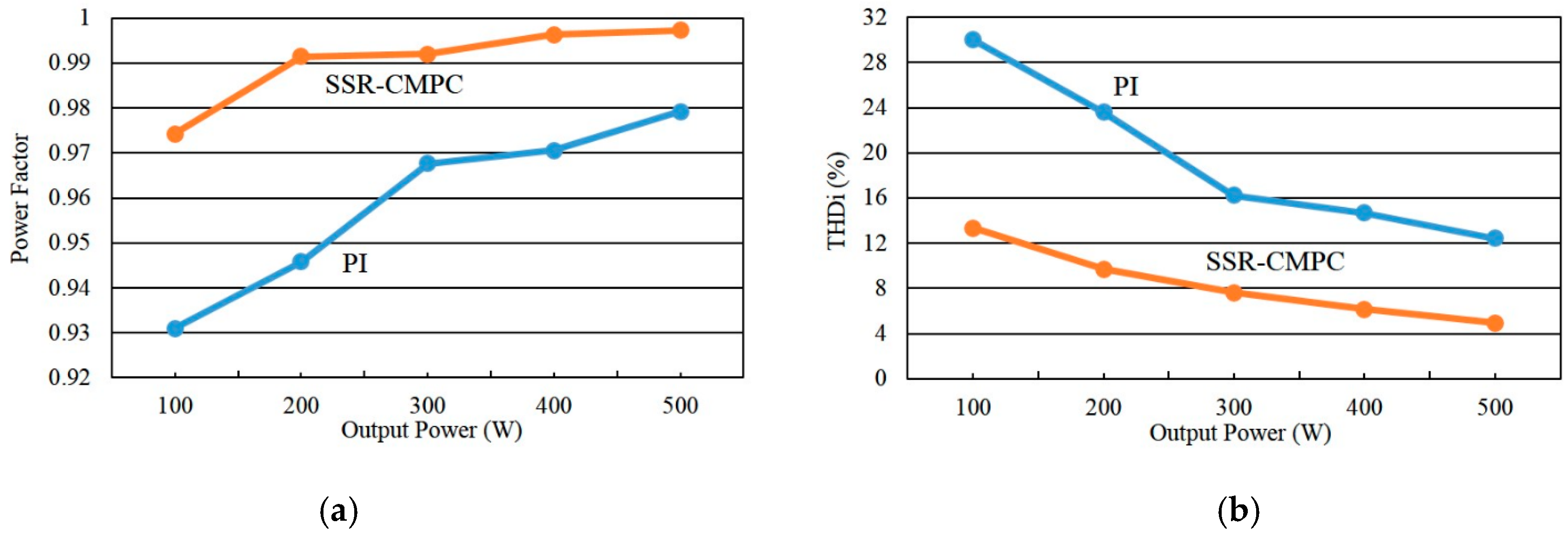

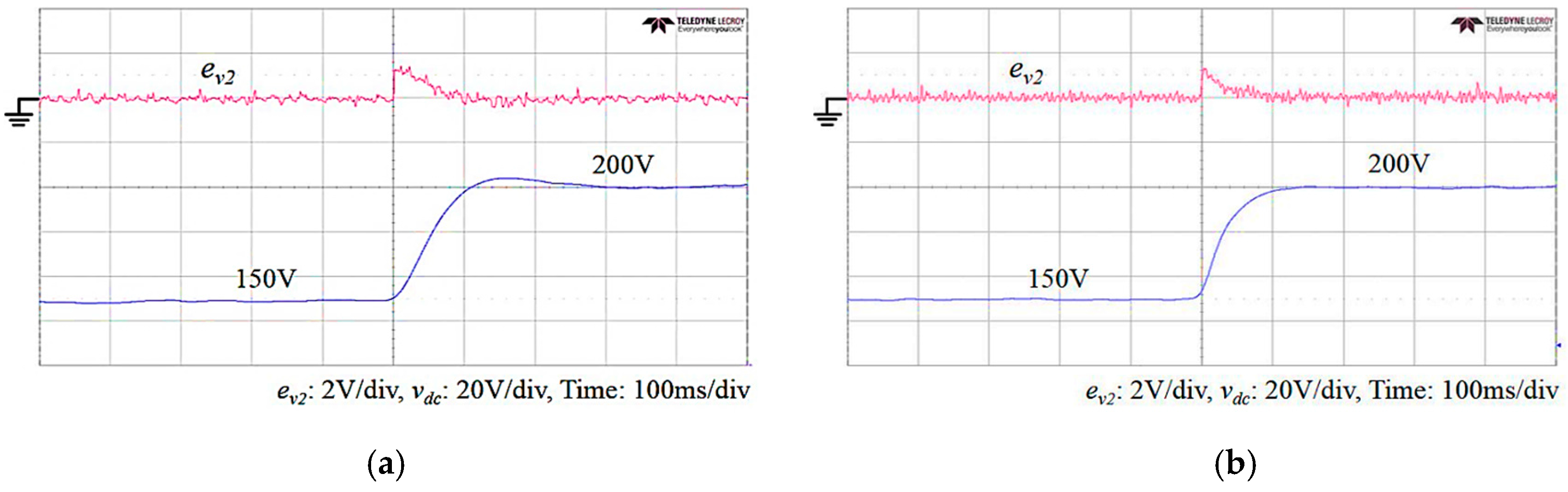

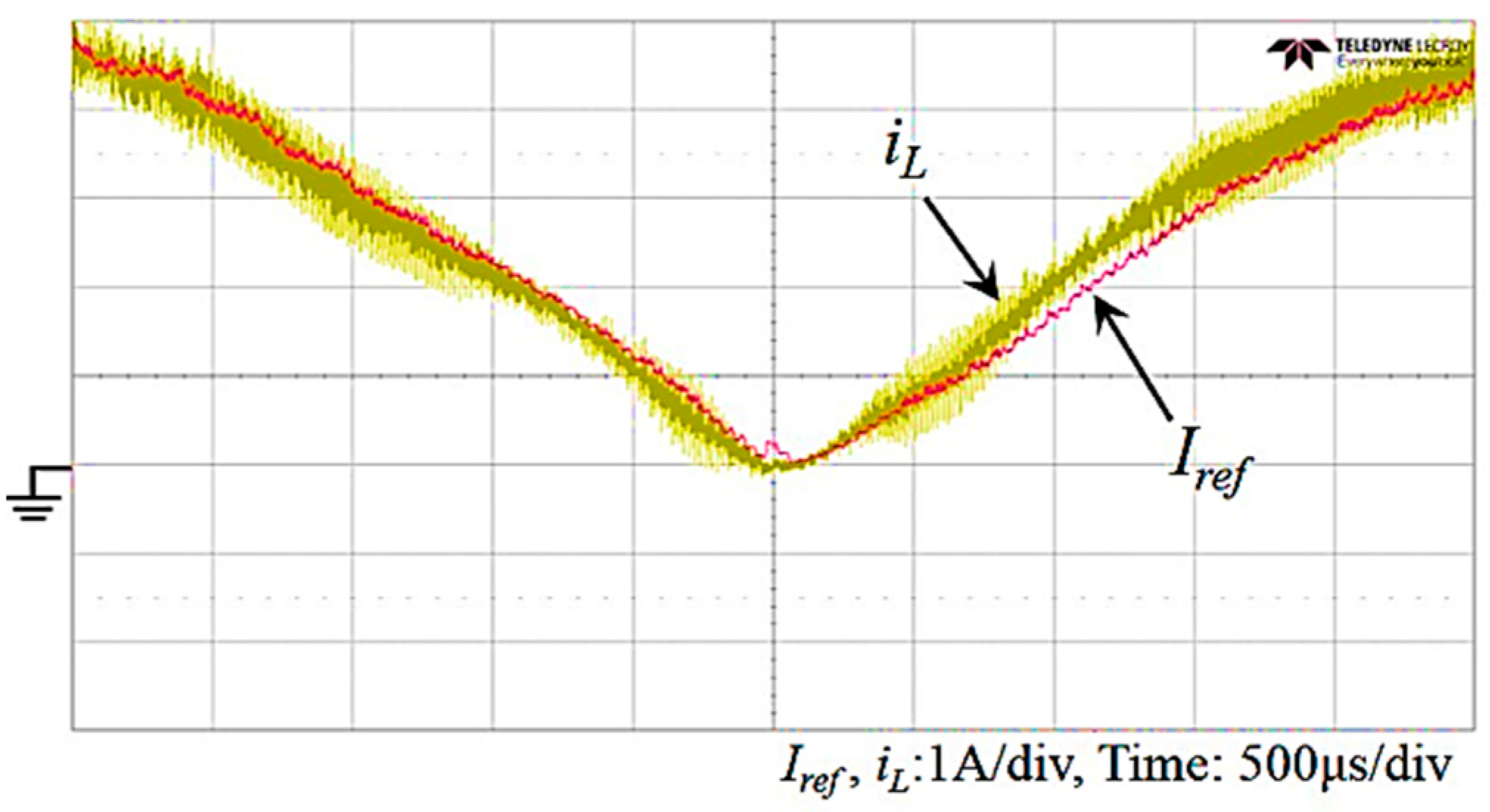

4.2. Experimental Results

4.3. Stability Analysis by Numerical Computation

5. Conclusions

Author Contributions

Conflicts of Interest

References

- Meng, T.; Yu, S.; Ben, H.Q.; Wei, G. A family of multilevel passive clamp circuits with coupled inductor suitable for single-phase isolated full-bridge boost PFC converter. IEEE Trans. Power Electron. 2014, 29, 4348–4356. [Google Scholar] [CrossRef]

- Wu, H.; He, X. Single phase three-level power factor correction circuit with passive lossless snubber. IEEE Trans. Power Electron. 2002, 17, 943–953. [Google Scholar]

- Zhang, J.; Zhao, C.; Zhao, S.; Wu, X. A Family of single-phase hybrid step-down PFC converters. IEEE Trans. Power Electron. 2017, 32, 5271–5281. [Google Scholar] [CrossRef]

- Ribeiro, H.S.; Borges, B.V. Analysis and design of a high-efficiency full-bridge single-stage converter with reduced auxiliary components. IEEE Trans. Power Electron. 2010, 25, 1850–1862. [Google Scholar] [CrossRef]

- Jang, Y.; Dillman, D.L.; Jovanovic, M.M. A new soft-switched PFC boost rectifier with integrated flyback converter for stand-by power. IEEE Trans. Power Electron. 2006, 21, 66–72. [Google Scholar] [CrossRef]

- Xie, X.; Zhao, C.; Lu, Q.; Liu, S. A novel integrated buck-flyback nonisolated PFC converter with high power factor. IEEE Trans. Ind. Electron. 2013, 60, 5603–5612. [Google Scholar] [CrossRef]

- Narimani, M.; Moschopoulos, G. A new single-phase single-stage three-level power factor correction AC-DC converter. IEEE Trans. Power Electron. 2012, 27, 2888–2899. [Google Scholar] [CrossRef]

- Ortman, M.S.; Soeiro, T.B.; Heldwein, M.L. High switches utilization single-phase PWM boost-type PFC rectifier topologies multiplying the switching frequency. IEEE Trans. Power Electron. 2014, 29, 5749–5760. [Google Scholar] [CrossRef]

- Tibola, G.; Barbi, I. Isolated three-phase high power factor rectifier based on the SEPIC converter operating in discontinuous conduction mode. IEEE Trans. Power Electron. 2013, 28, 4962–4969. [Google Scholar] [CrossRef]

- Cecati, C.; Dellaquila, A.; Liserre, M.; Ometto, A. A fuzzy-logic-based controller for active rectifier. IEEE Trans. Ind. Appl. 2003, 39, 105–112. [Google Scholar] [CrossRef]

- Kirawanich, P.; Connel, R.M.O. Fuzzy logic control of an active power line conditioner. IEEE Trans. Power Electron. 2004, 19, 1574–1585. [Google Scholar] [CrossRef]

- Tsang, K.M.; Chan, W.L. Adaptive control of power factor correction converter using nonlinear system identification. IEE Proc. Electr. Power Appl. 2005, 152, 627–633. [Google Scholar] [CrossRef]

- De Araujo Ribeiro, R.L.; de Azevedo, C.C.; de Sousa, R.M. A robust adaptive control strategy of active power filters for power-factor correction, harmonic compensation, and balancing of nonlinear loads. IEEE Trans. Power Electron. 2012, 27, 718–730. [Google Scholar] [CrossRef]

- Zaohong, Y.; Sen, P.C. Power factor correction circuits with robust Current control technique. IEEE Trans. Aerosp. Electron. Syst. 2002, 38, 1210–1219. [Google Scholar] [CrossRef]

- Chu, G.; Tse, C.K.; Wong, S.C.; Tan, S.C. A unified approach for the derivation of robust control for boost PFC converters. IEEE Trans. Power Electron. 2009, 24, 2531–2544. [Google Scholar] [CrossRef]

- Utkin, V. Sliding Modes in Control and Optimization; Springer-Verlag: New York, NY, USA, 1992. [Google Scholar]

- Utkin, V.; Guldner, J.; Shi, J. Sliding Mode Control in Electro-Mechanical Systems, 2nd ed.; CRC Press: Boca Ratom, FL, USA, 2009. [Google Scholar]

- Sabavovic, A. Variable structure systems with sliding modes in motion control—A Survey. IEEE Trans. Ind. Inf. 2011, 7, 212–223. [Google Scholar] [CrossRef]

- Alonge, F.; Cirrincione, M.; D’lppolito, F.; Pucci, M.; Sferlazza, A. Robust active disturbance rejection control of induction motor systems based on additional sliding-mode component. IEEE Trans. Ind. Electron. 2017, 64, 5608–5621. [Google Scholar] [CrossRef]

- Ye, J.; Malysz, P.; Emadi, A. A fixed-switching-frequency integral sliding mode current controller for switched reluctance motor drives. IEEE J. Emerg. Sel. Top. Power Electron. 2015, 3, 381–394. [Google Scholar]

- Ferrara, A.; Incremona, G.P. Design of an integral suboptimal second-order sliding mode controller for robust motion control of robot manipulator. IEEE Trans. Control Syst. Technol. 2015, 23, 2316–2325. [Google Scholar] [CrossRef]

- Shtessel, Y.; Baev, S.; Biglari, H. Unity power factor control in three-phase AC/DC boost converter using sliding modes. IEEE Trans. Ind. Electron. 2008, 55, 3874–3882. [Google Scholar] [CrossRef]

- Umamaheswari, M.G.; Uma, G.; Vijayalajshmi, K.M. Analysis and design of reduced-order sliding-mode controller for three-phase power factor correction using Cuk rectifiers. IET Power Electron. 2013, 6, 935–945. [Google Scholar] [CrossRef]

- Karaarslan, A.; Iskender, I. Average sliding control method applied on power factor correction converter for decreasing input current total harmonic distortion using digital signal processor. IET Power Electron. 2012, 5, 617–626. [Google Scholar] [CrossRef]

- Drakunov, S.V.; Reyhanoglu, M.; Singh, B. Sliding mode control of DC-DC power converters. IFAC Proc. 2009, 42, 237–242. [Google Scholar] [CrossRef]

- Wai, R.J.; Shih, L.C. Design of voltage tracking control for DC-DC boost converter via total sliding-mode technique. IEEE Trans. Ind. Electron. 2011, 58, 2502–2511. [Google Scholar] [CrossRef]

- Mohanty, P.R.; Panda, A.K. Fixed-frequency sliding-mode control scheme based on current control manifold for improved dynamic performance of boost PFC converter. IEEE J. Emerg. Sel. Top. Power Electron. 2017, 5, 576–586. [Google Scholar] [CrossRef]

- Chincholkar, S.H.; Chan, C.Y. Design of fixed-frequency pulse-width-modulation-based sliding-mode controllers for the quadratic boost converter. IEEE Trans. Circuits Syst. II Express Briefs 2017, 64, 51–55. [Google Scholar] [CrossRef]

- Guldemir, H. Study of sliding mode control of DC-DC buck converter. Energy Power Eng. 2011, 3, 401–406. [Google Scholar] [CrossRef]

- Martinez-Salamero, L.; Cid-Pastor, A.; El Aroudi, A.; Giral, R.; Calvente, J.; Ruiz-Magaz, G. Sliding-mode control of DC-DC switching converters. In Proceedings of the 18th IFAC World Congress, Milano, Italy, 28 August 2011; Volume 44, pp. 1910–1916. [Google Scholar]

- Shen, L.; Lu, D.D.-C.; Li, C. Adaptive sliding mode control method for DC-DC converters. IET Power Electron. 2015, 8, 1723–1732. [Google Scholar] [CrossRef]

- Chai, J.Y.; Liaw, C.M. Development of a switched-reluctance motor drive with PFC front end. IEEE Trans. Energy Convers. 2009, 24, 30–42. [Google Scholar] [CrossRef]

- Mohen, N.; Undeland, T.M.; Robbins, W.P. Power Electronics: Converters, Applications, and Design, 3rd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2003. [Google Scholar]

- Erickson, R.W.; Maksimovic, D. Fundamentals of Power Electronics, 2nd ed.; Kluwer Academic Publishers: Dordrecht, The Netherlands, 2001. [Google Scholar]

- Skogestad, S.; Postlethwaite, I. Multivariable Feedback Control: Analysis and Design, 2nd ed.; John Wiley & Sons: New York, NY, USA, 2005. [Google Scholar]

- Franklin, G.F.; Powell, J.D.; Emami-Naeini, A. Feedback Control of Dynamic Systems, 7th ed.; Pearson Education: Upper Saddle River, NJ, USA, 2015. [Google Scholar]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shieh, H.-J.; Chen, Y.-Z. A Sliding Surface-Regulated Current-Mode Pulse-Width Modulation Controller for a Digital Signal Processor-Based Single Ended Primary Inductor Converter-Type Power Factor Correction Rectifier. Energies 2017, 10, 1175. https://doi.org/10.3390/en10081175

Shieh H-J, Chen Y-Z. A Sliding Surface-Regulated Current-Mode Pulse-Width Modulation Controller for a Digital Signal Processor-Based Single Ended Primary Inductor Converter-Type Power Factor Correction Rectifier. Energies. 2017; 10(8):1175. https://doi.org/10.3390/en10081175

Chicago/Turabian StyleShieh, Hsin-Jang, and Ying-Zuo Chen. 2017. "A Sliding Surface-Regulated Current-Mode Pulse-Width Modulation Controller for a Digital Signal Processor-Based Single Ended Primary Inductor Converter-Type Power Factor Correction Rectifier" Energies 10, no. 8: 1175. https://doi.org/10.3390/en10081175

APA StyleShieh, H.-J., & Chen, Y.-Z. (2017). A Sliding Surface-Regulated Current-Mode Pulse-Width Modulation Controller for a Digital Signal Processor-Based Single Ended Primary Inductor Converter-Type Power Factor Correction Rectifier. Energies, 10(8), 1175. https://doi.org/10.3390/en10081175