Analysis of Roadheader for Breaking Rock Containing Holes under Confining Pressures

Abstract

:1. Introduction

2. Basic Theory of LS-DYNA

3. Establishment of the Rock Breaking Model

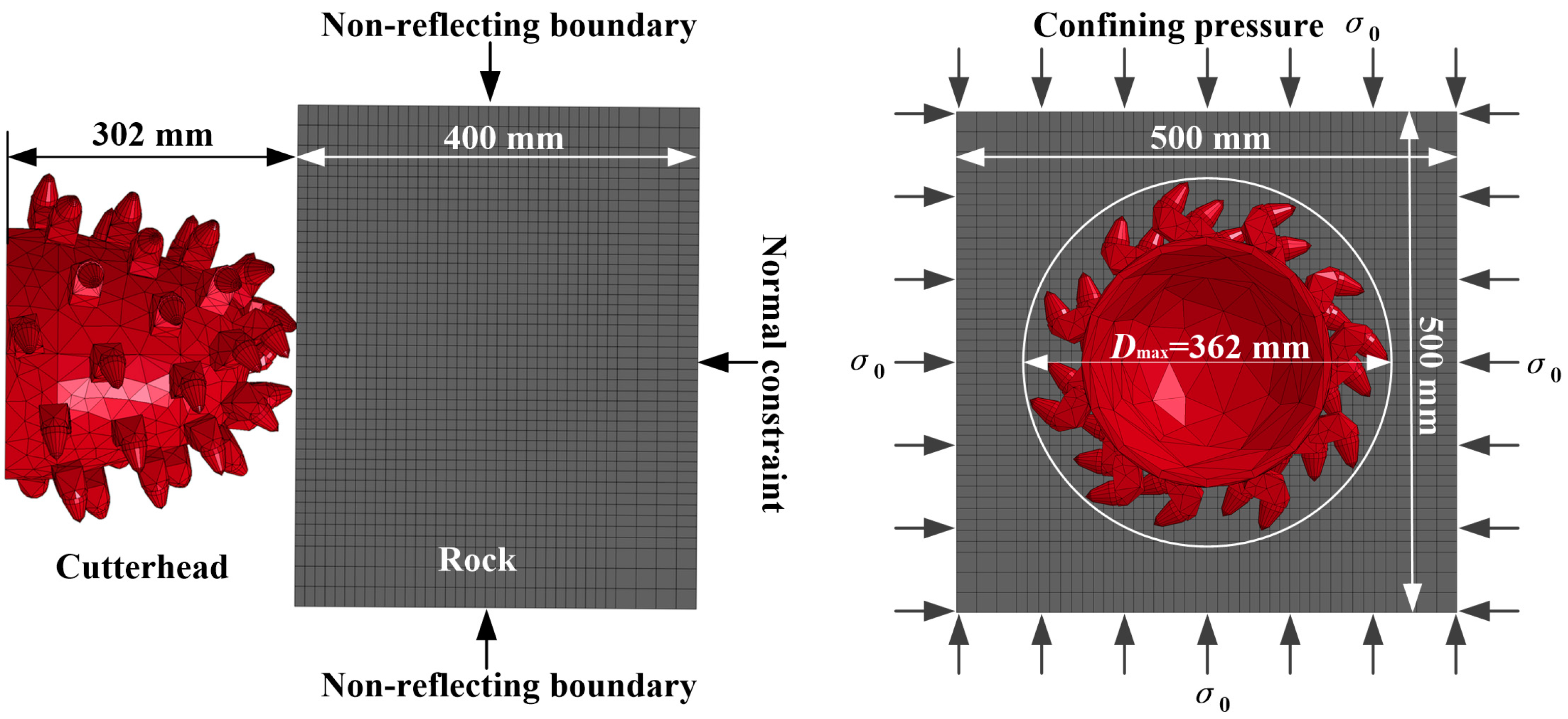

3.1. Material Model and Boundary Conditions

3.2. Contact and Failure Criterion

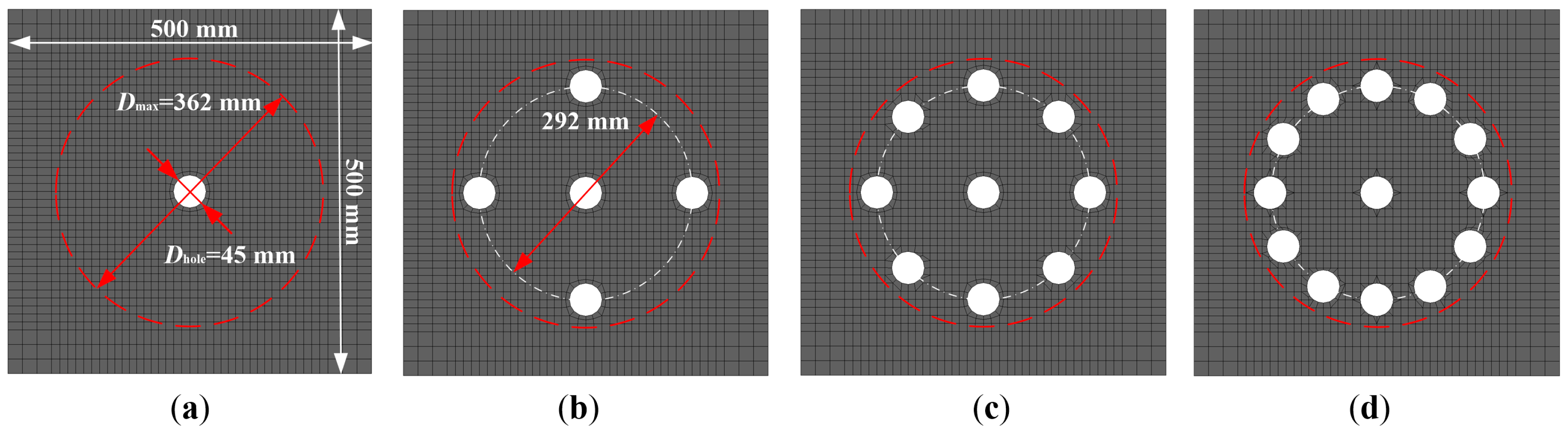

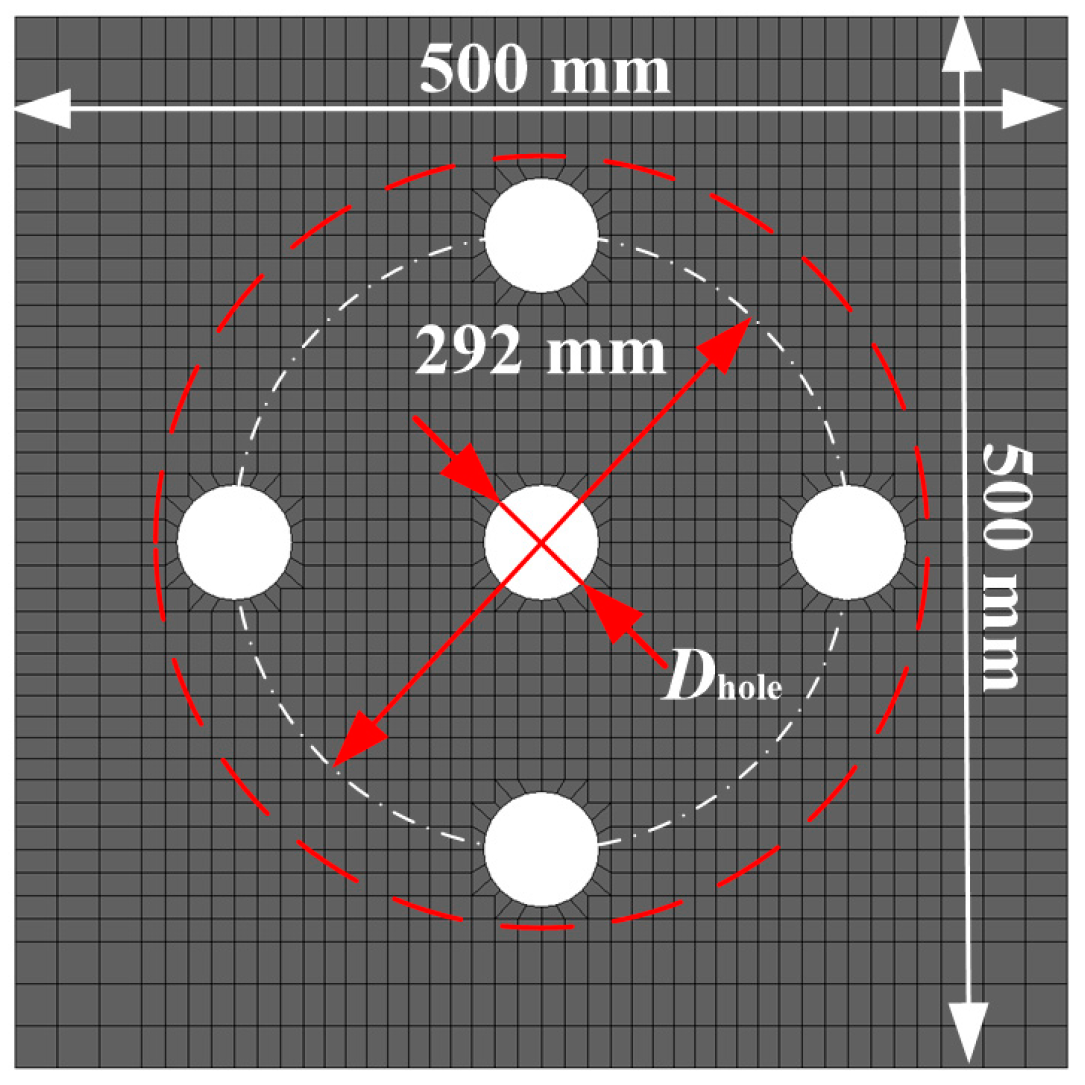

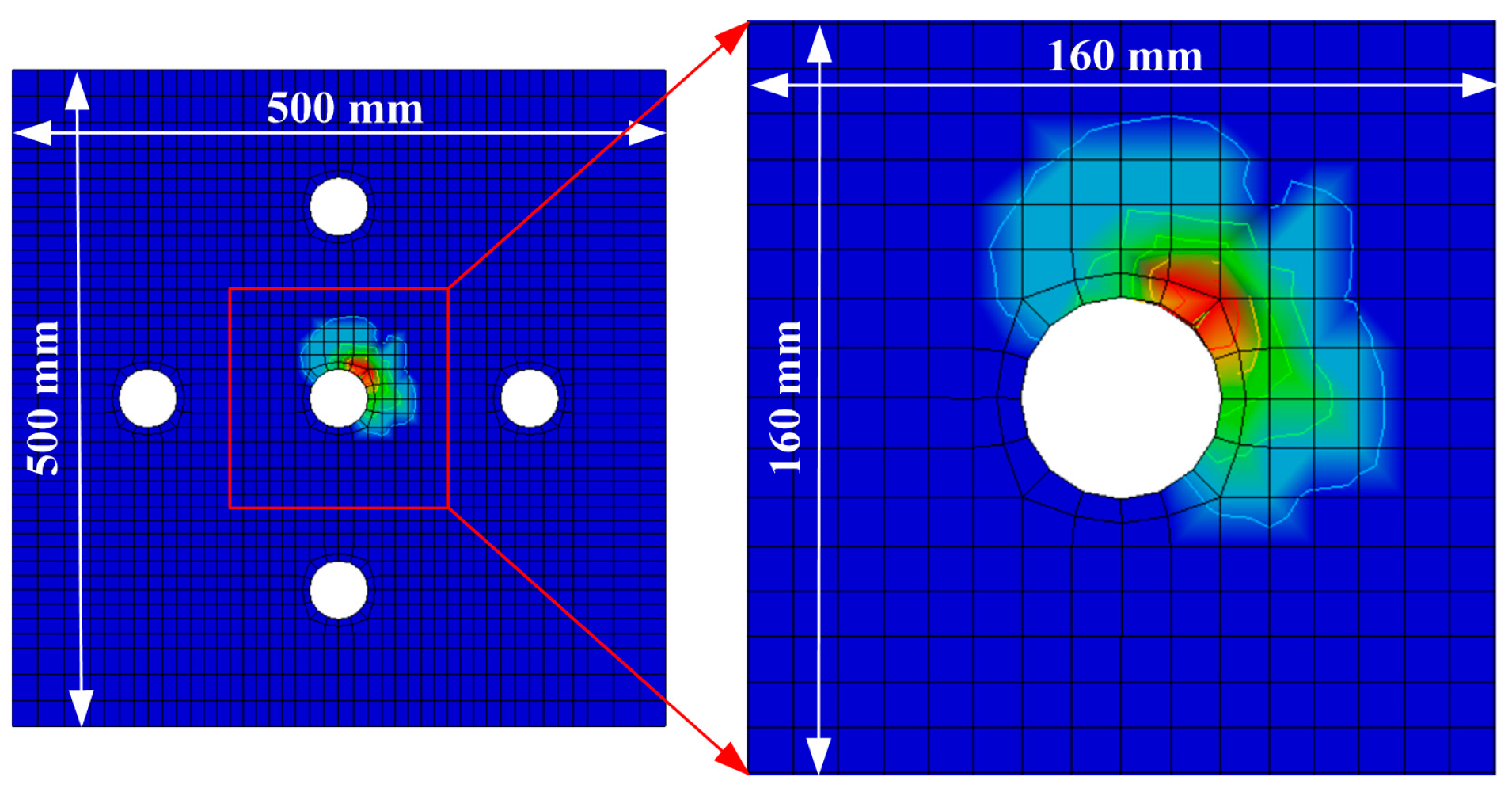

3.3. Rock Model Design

3.4. Motion Parameters of Cutterhead

4. Verification of the Numerical Model

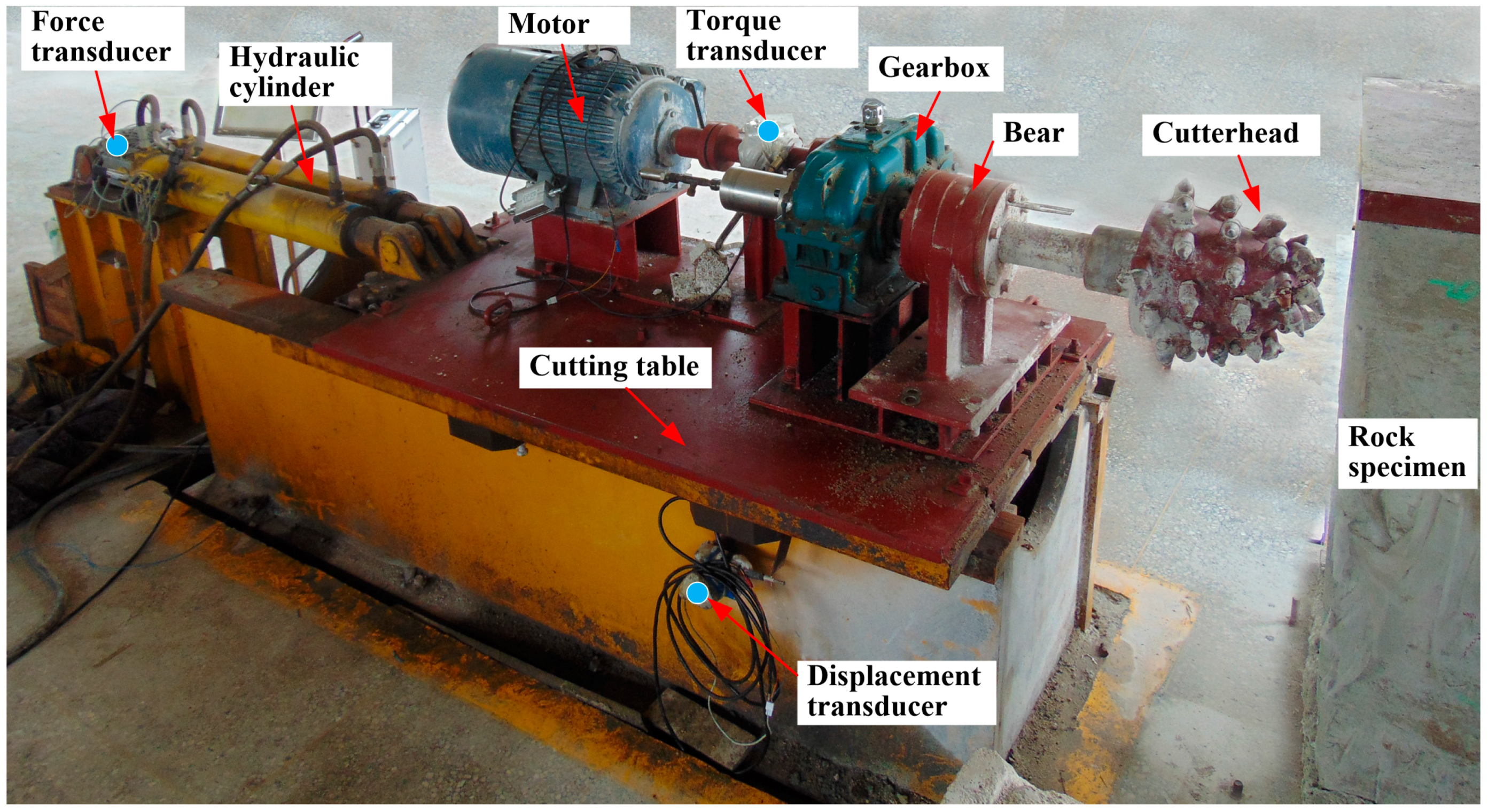

4.1. Experiment Procedures

4.2. Comparison between Experimental and Numerical Results

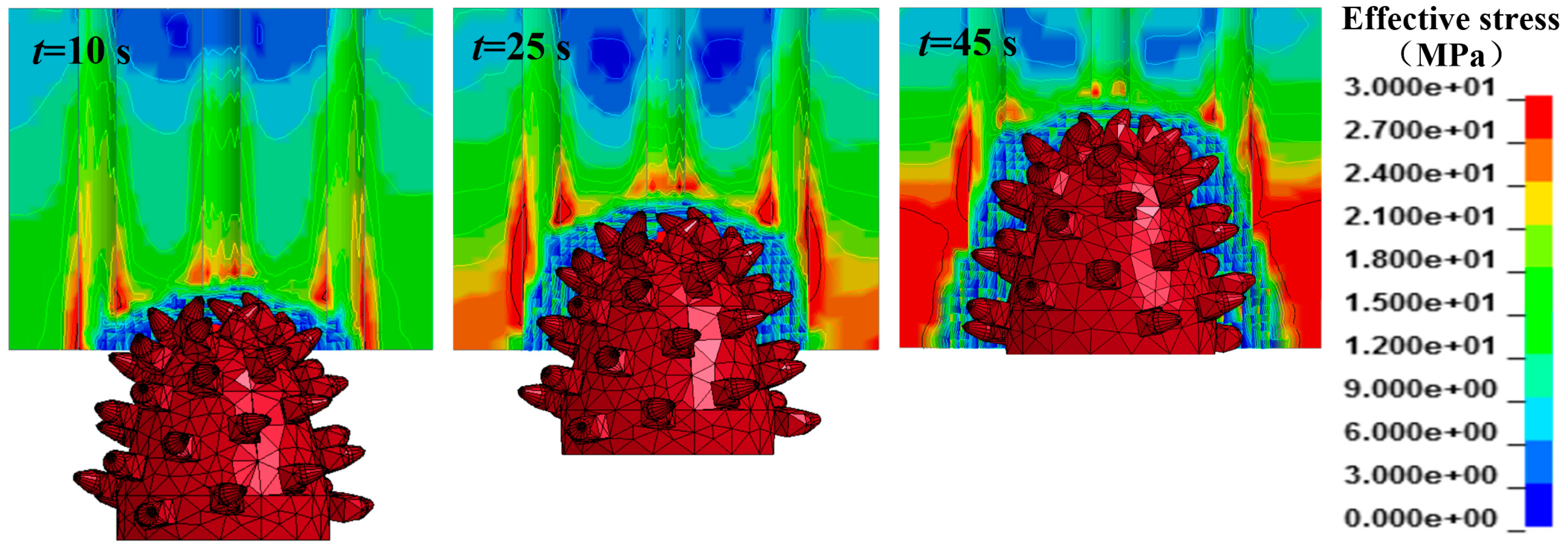

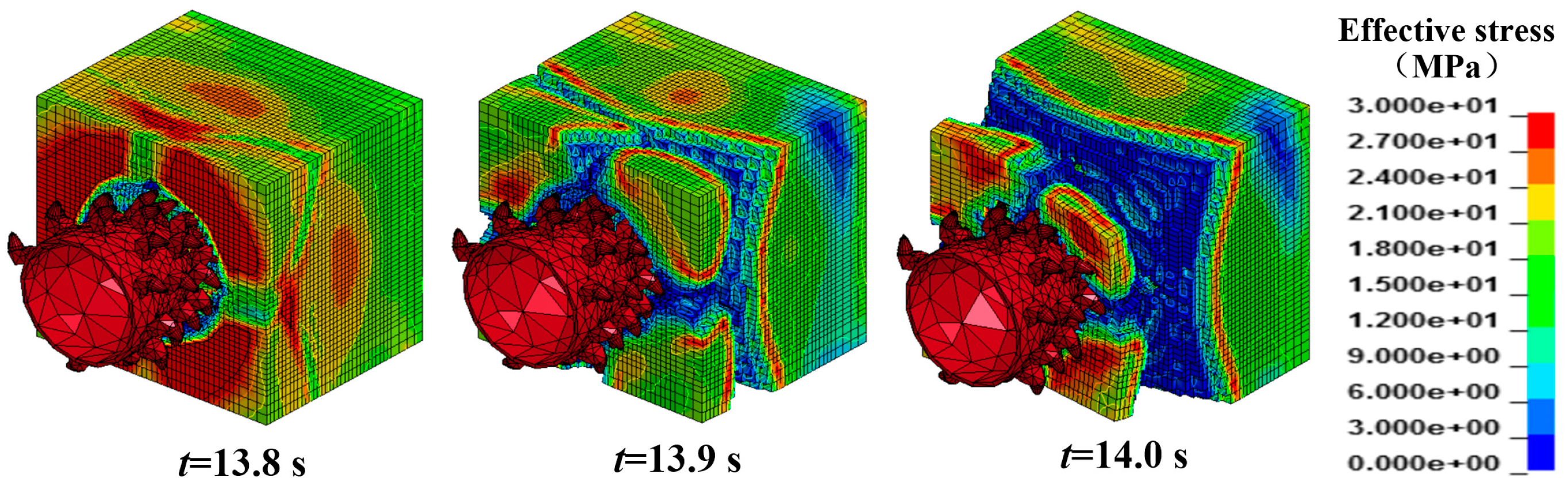

5. Numerical Results and Discussion

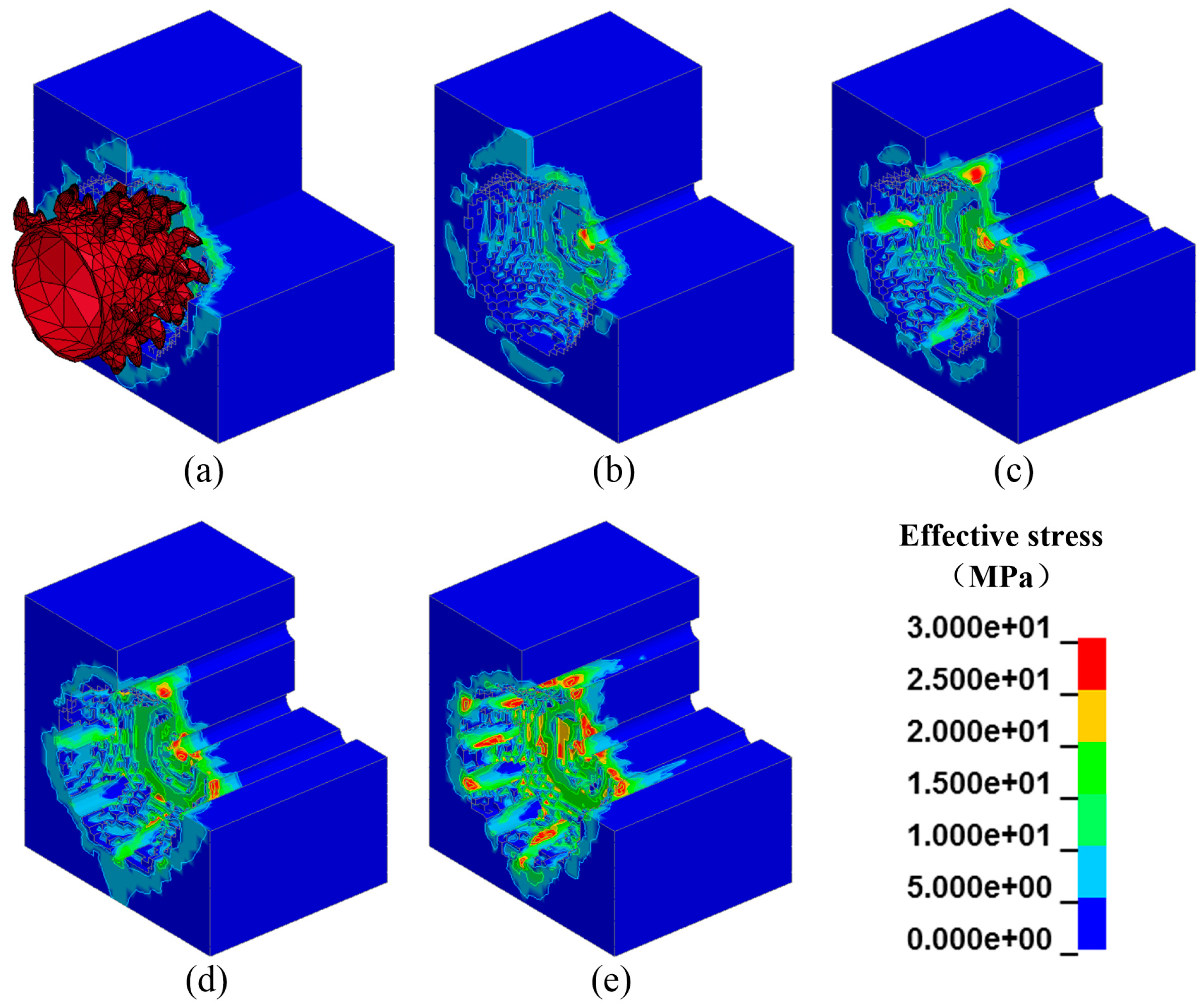

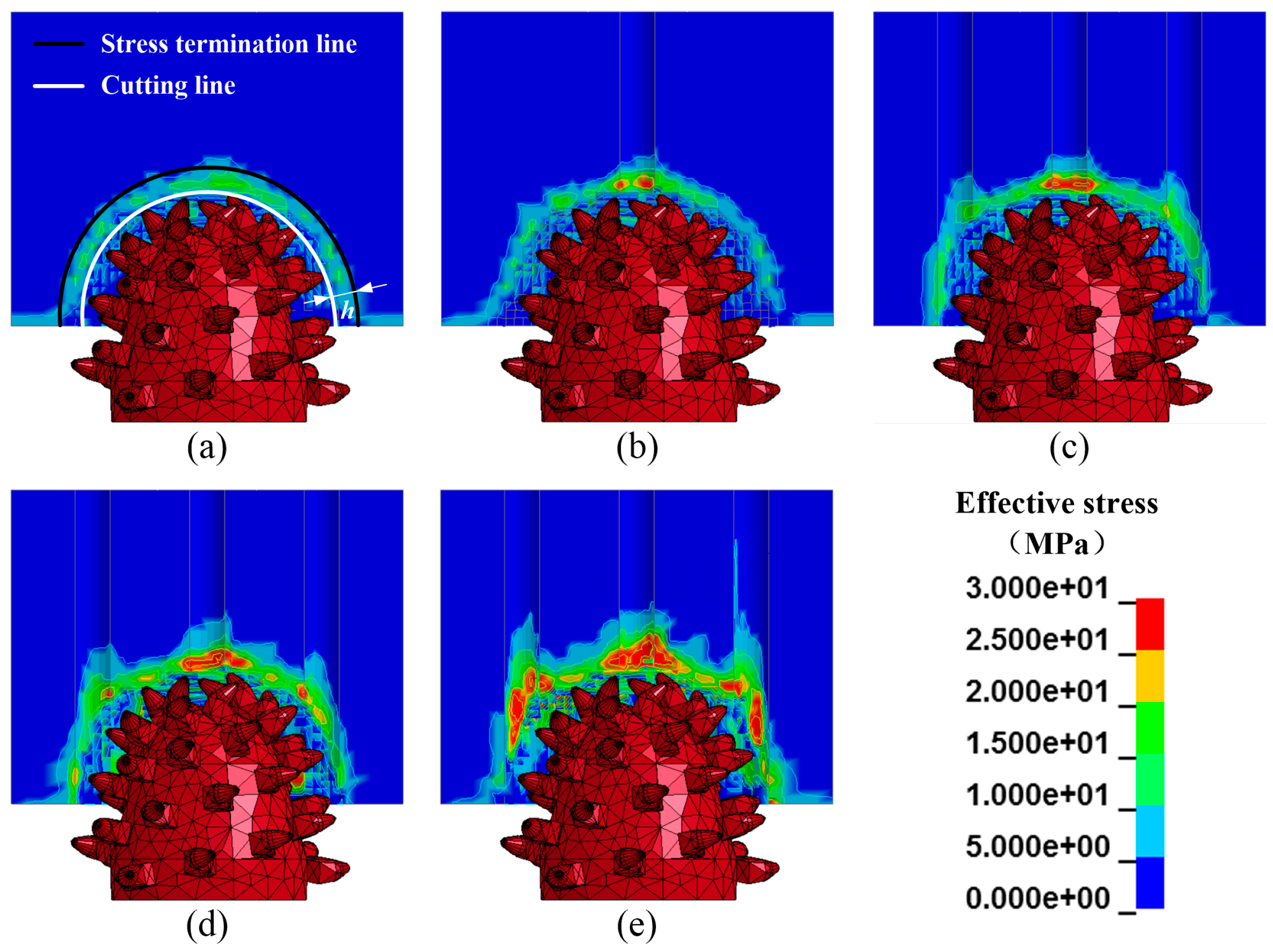

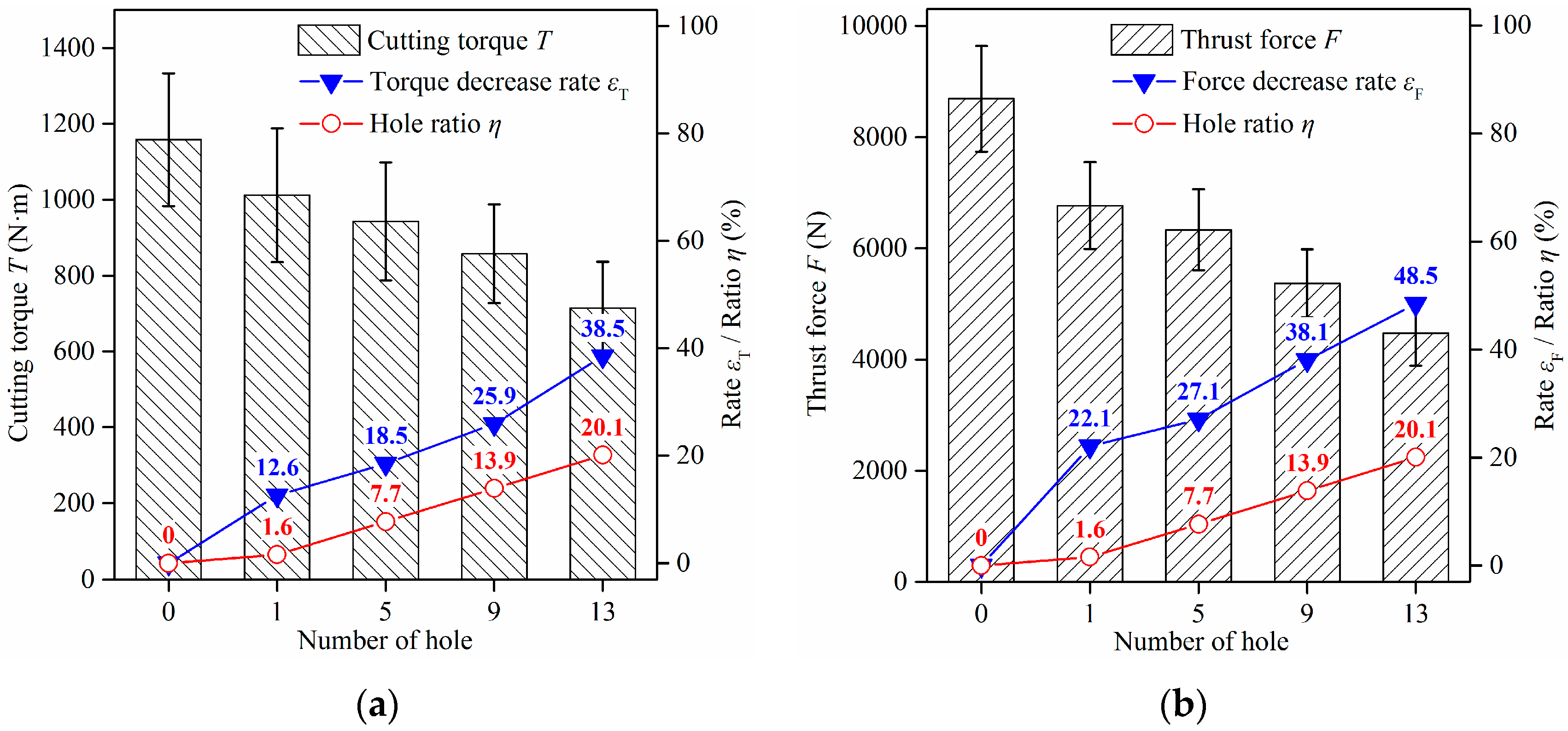

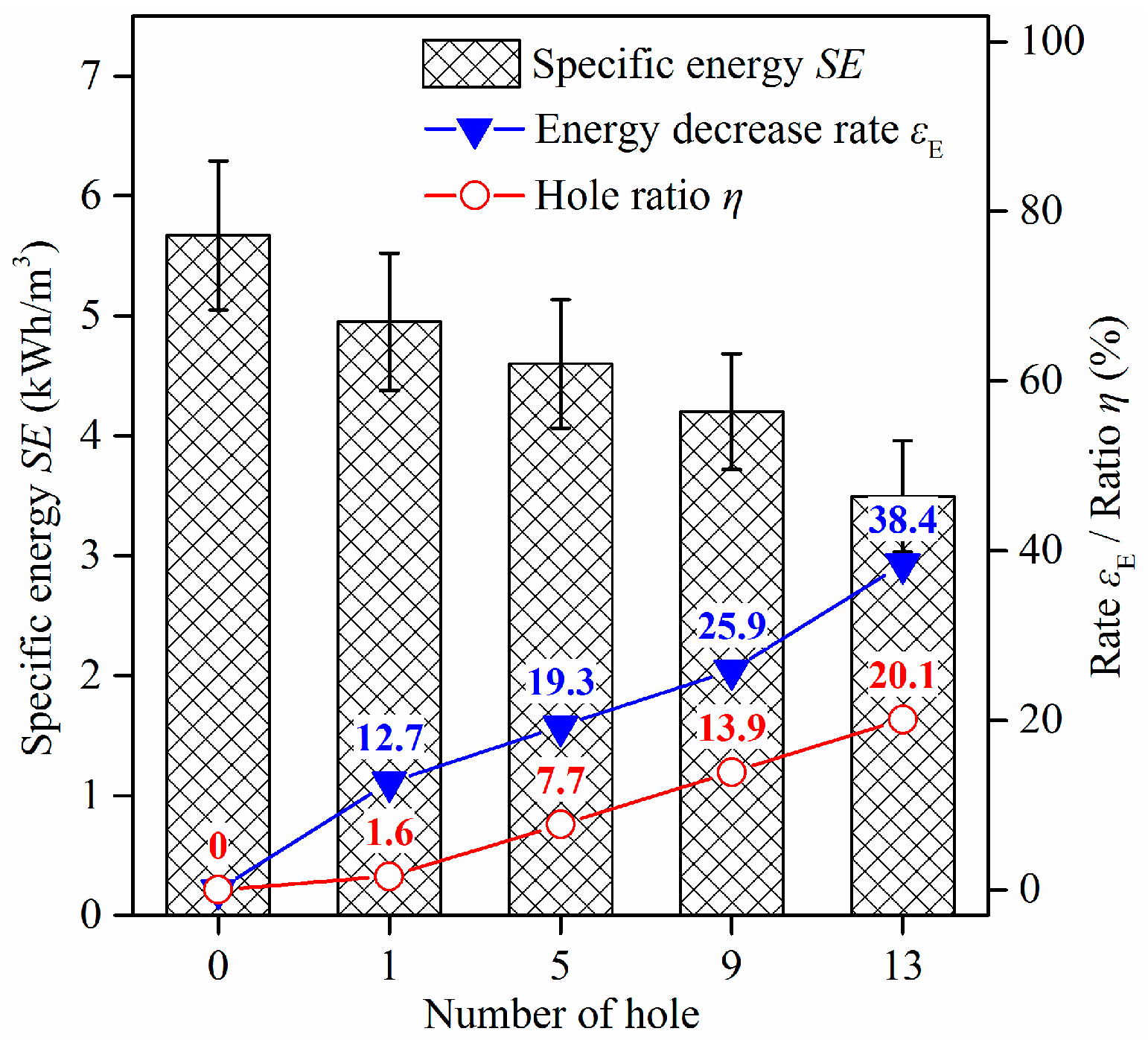

5.1. Effect of Hole Number on Rock Fragmentation

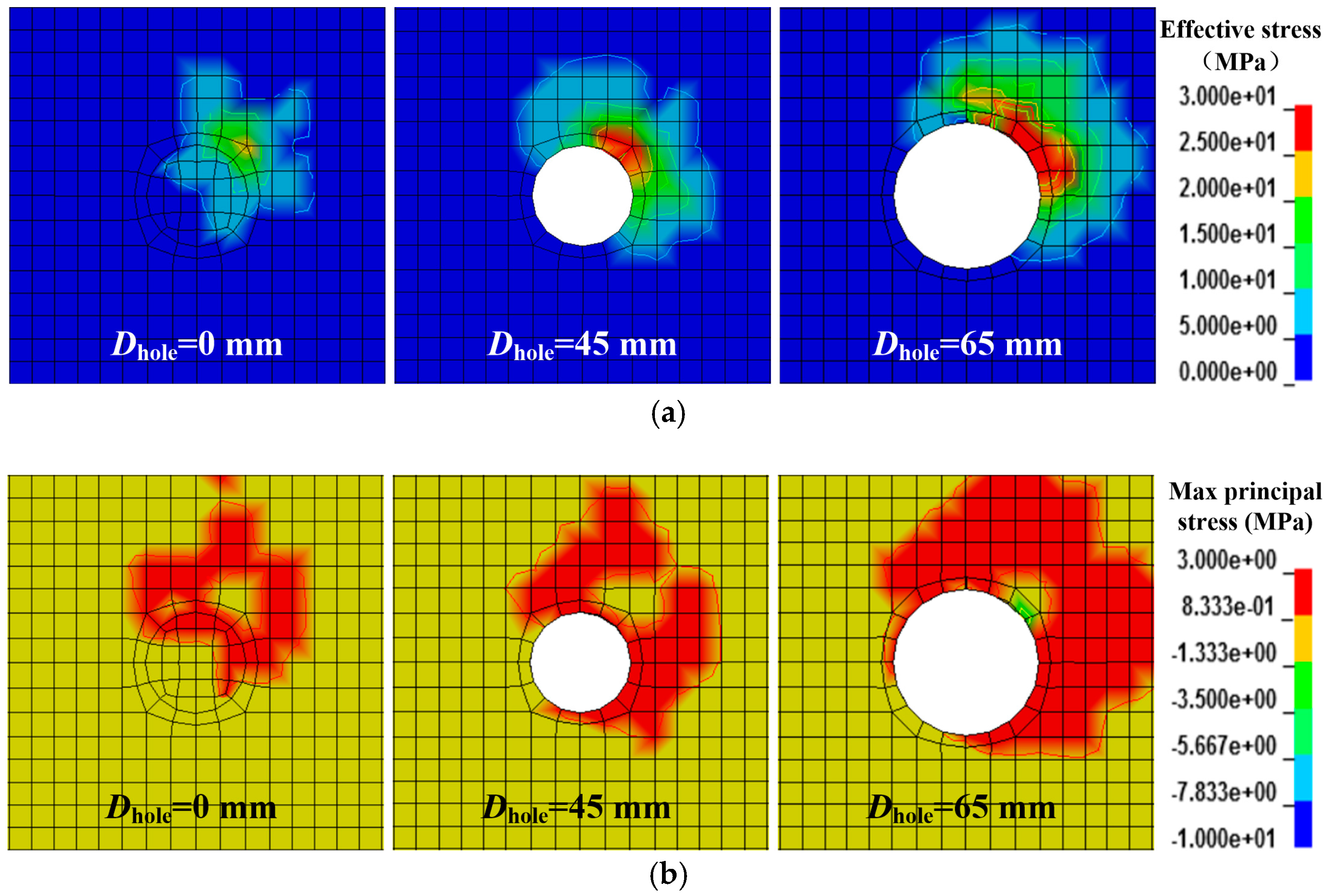

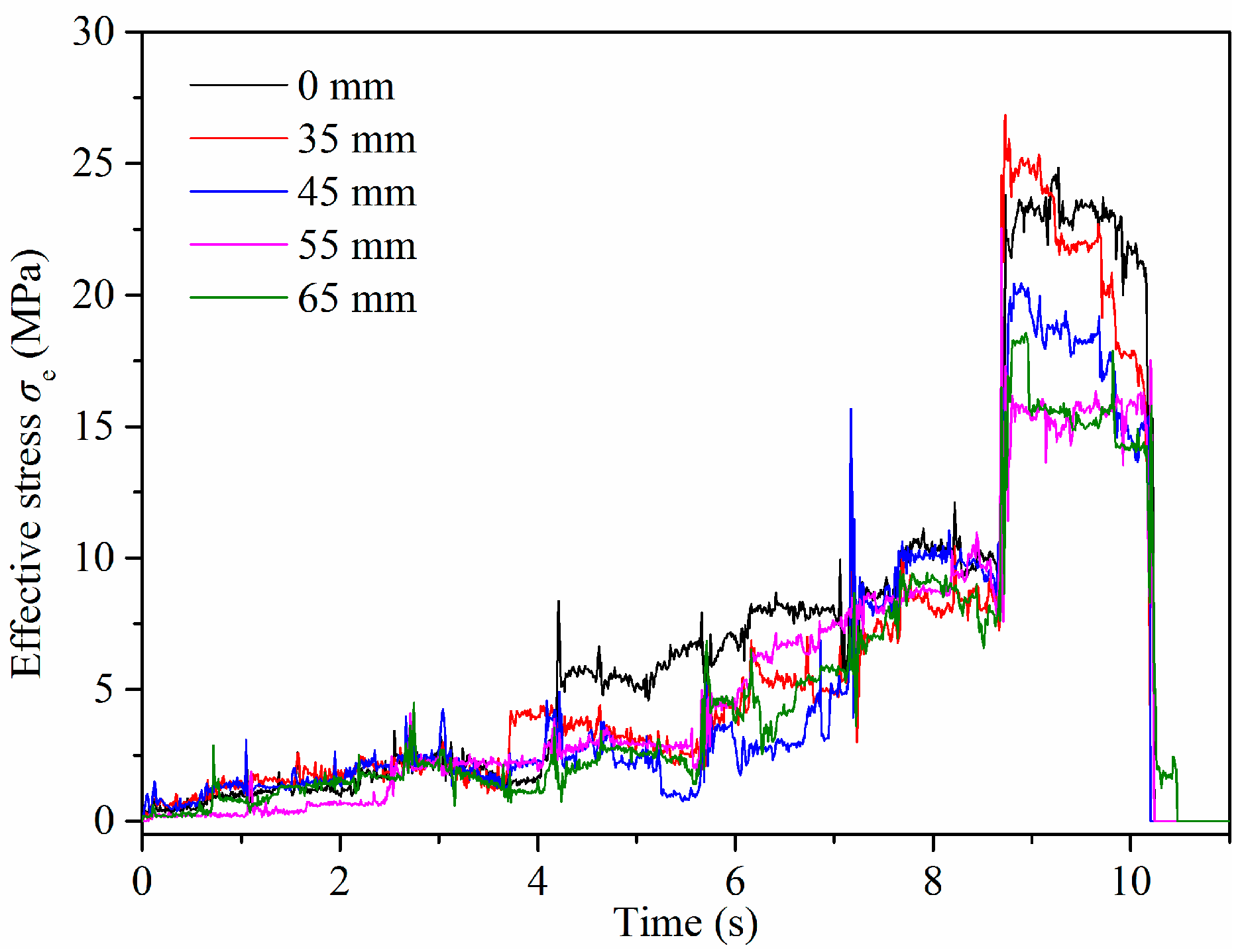

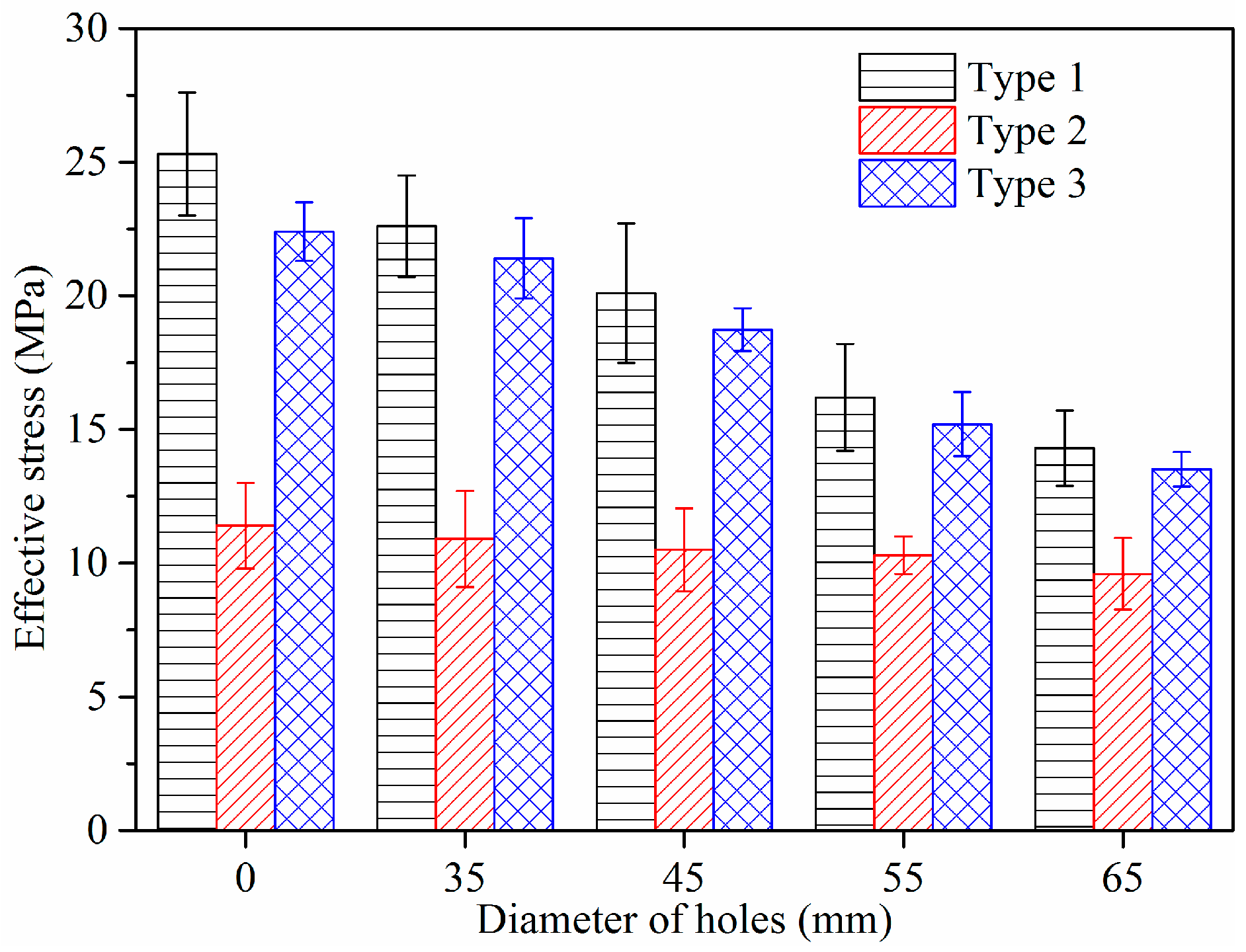

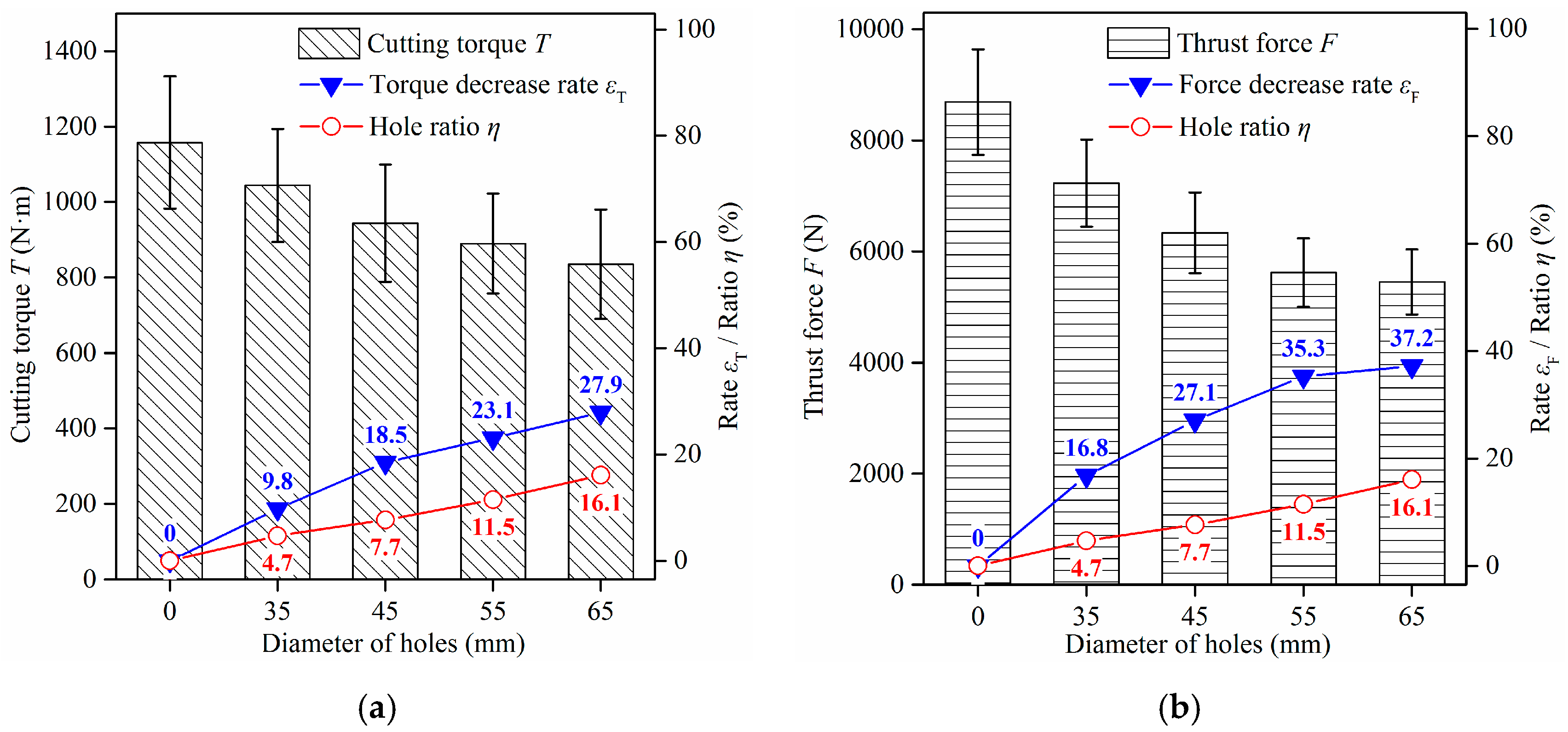

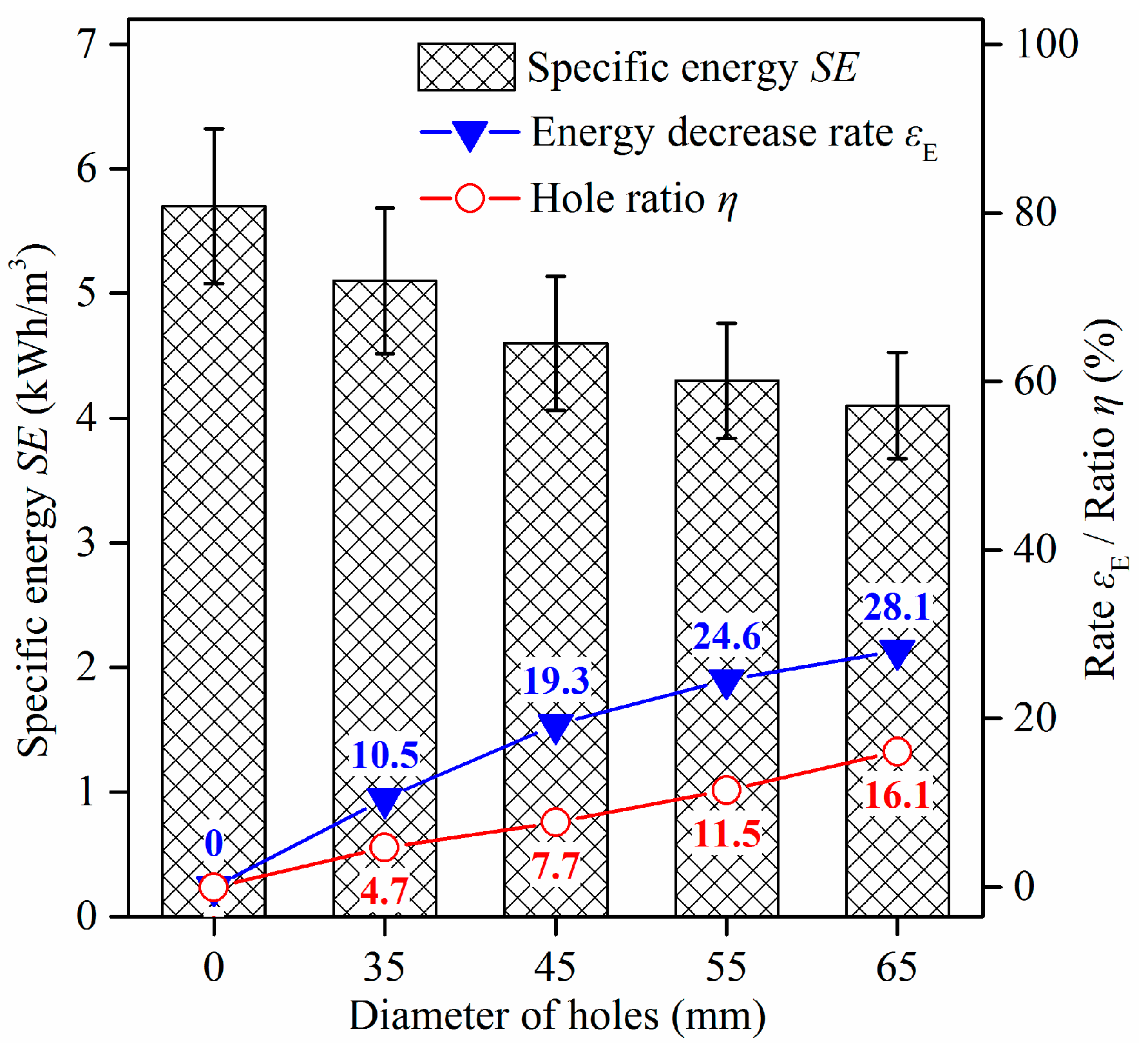

5.2. Effect of Hole Size on Rock Fragmentation

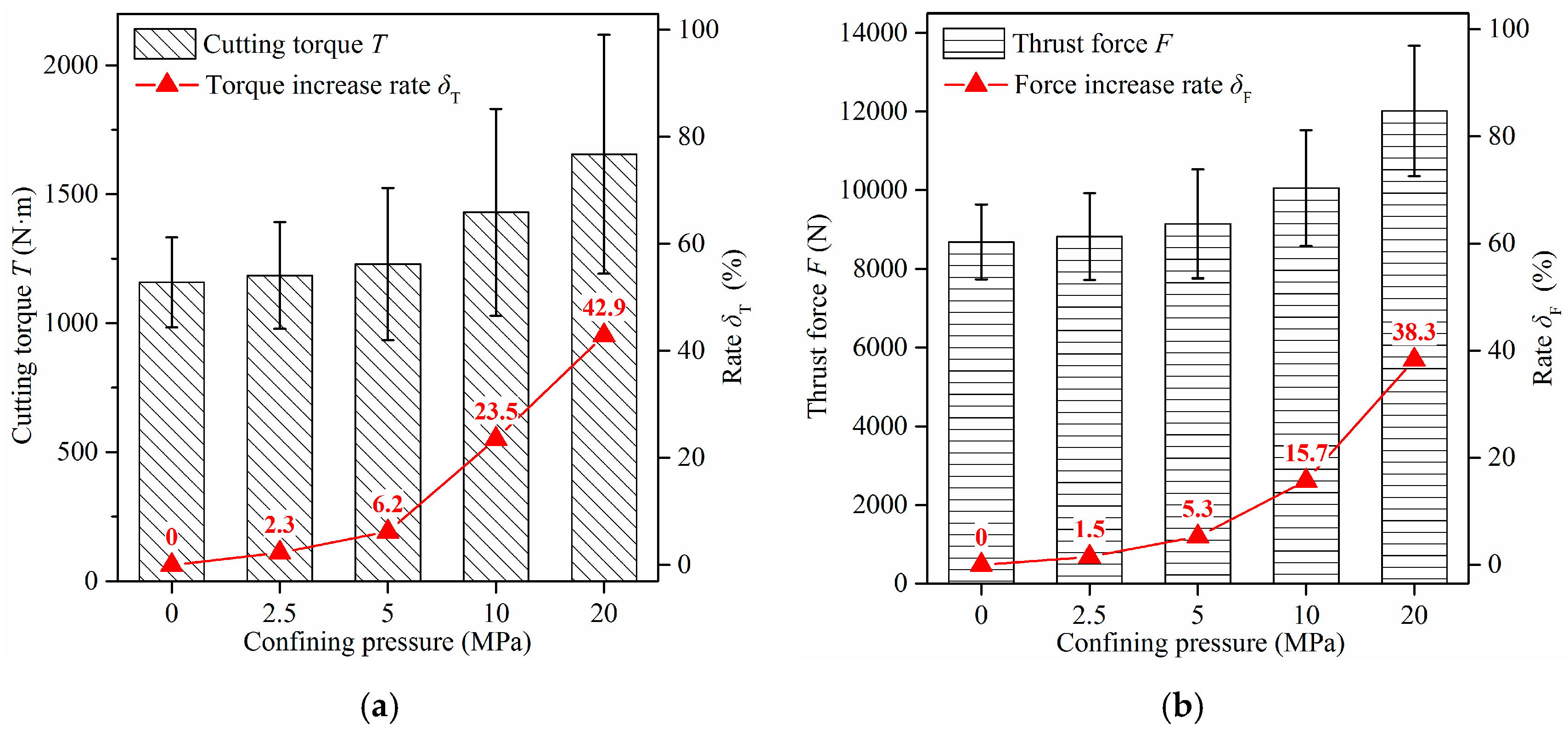

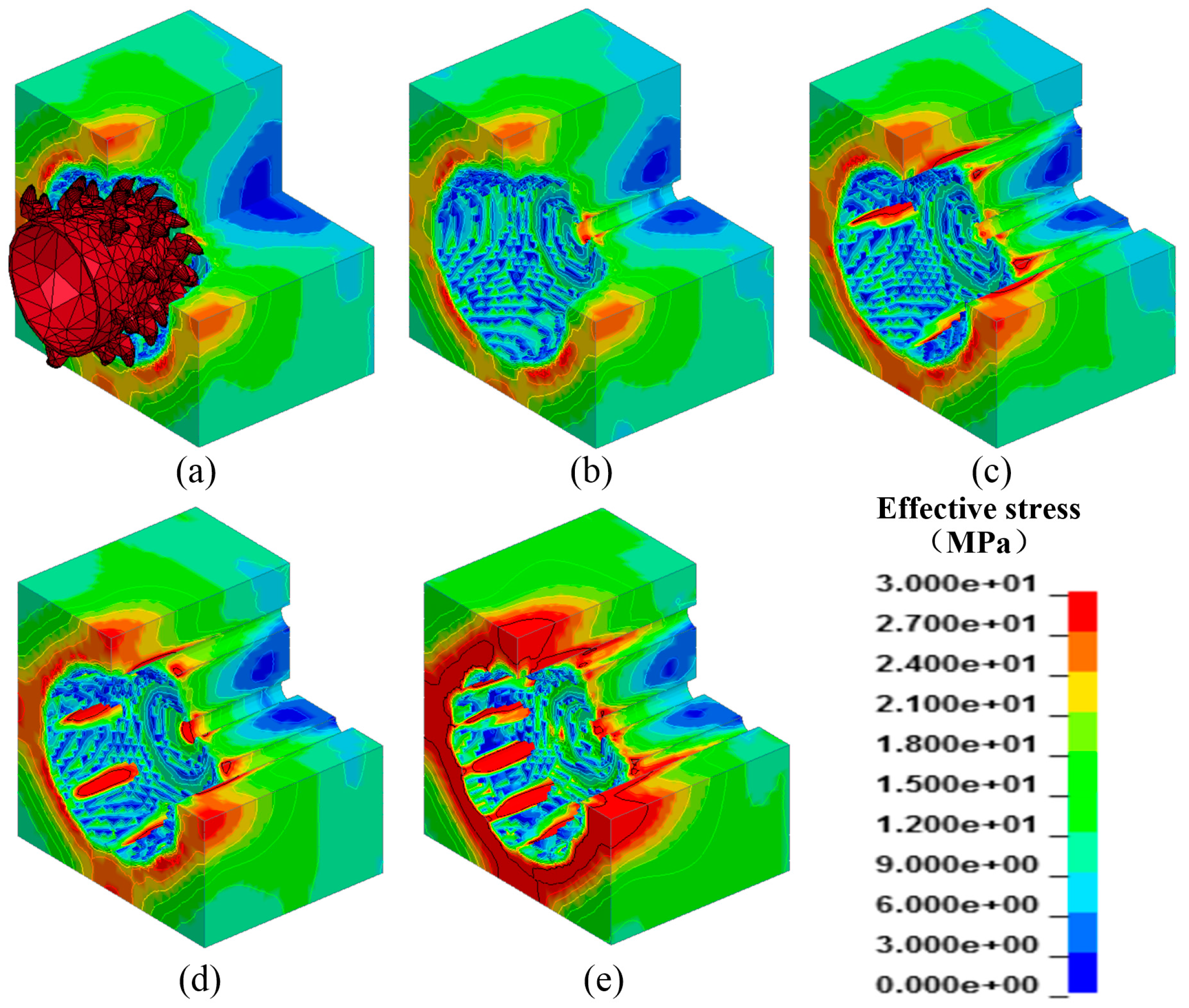

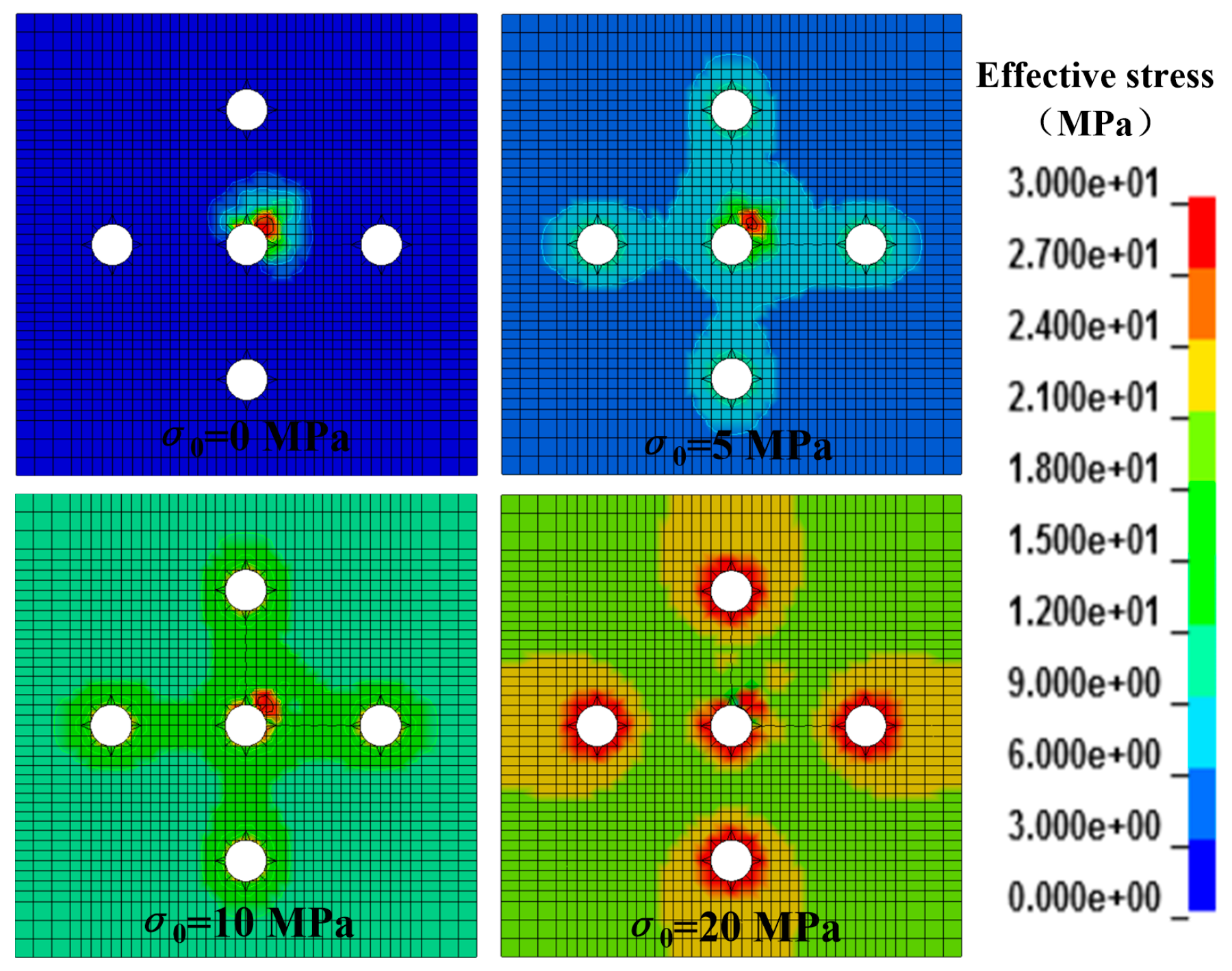

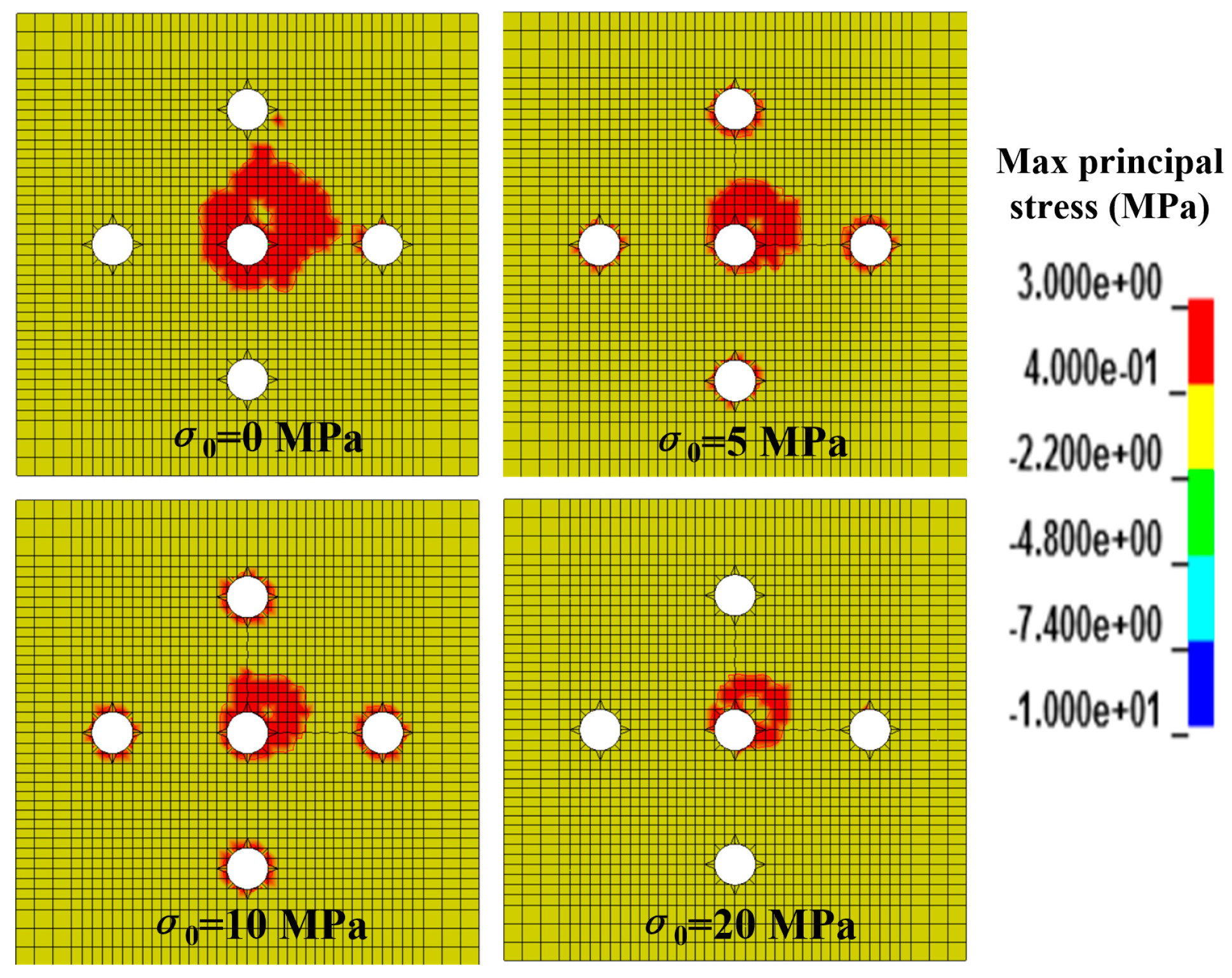

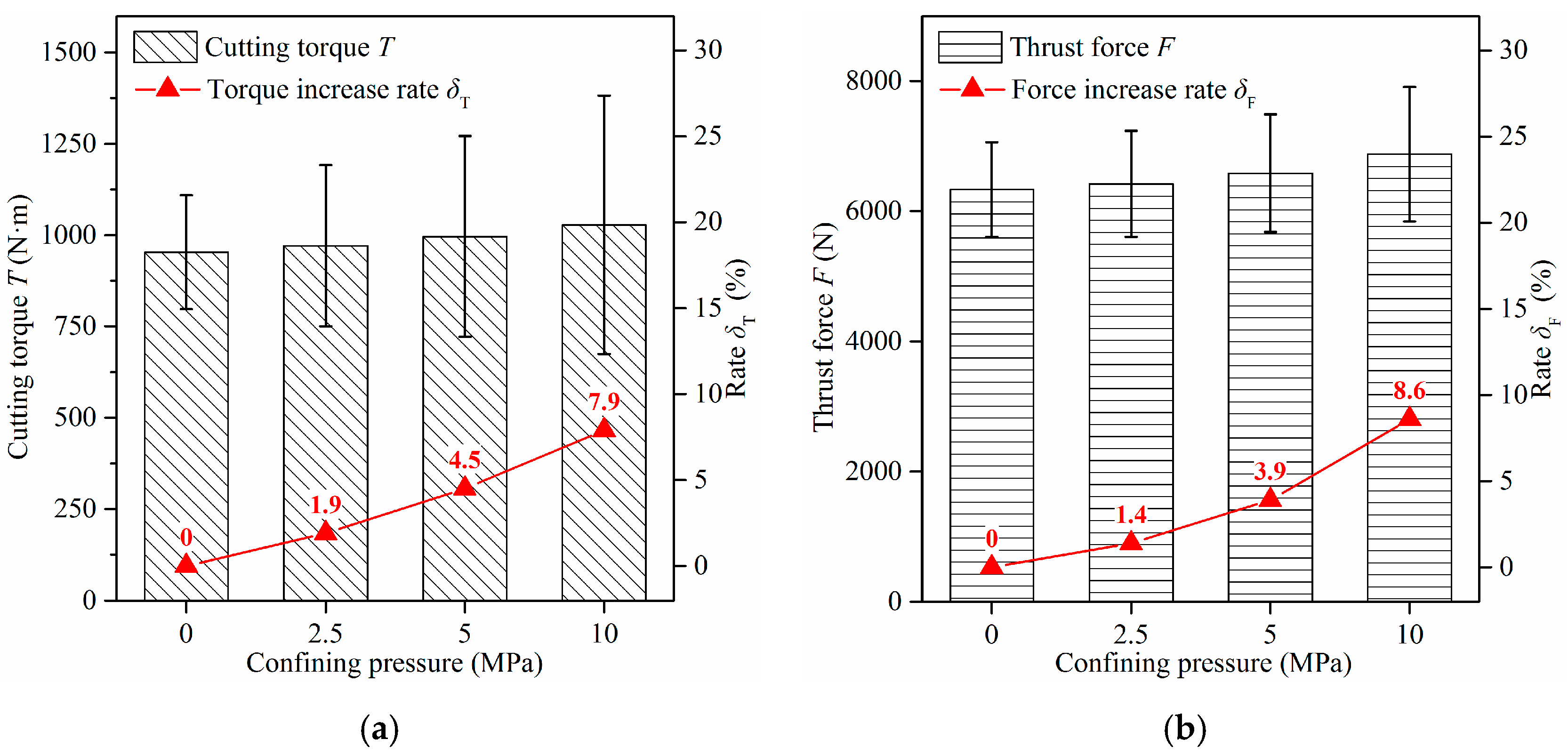

5.3. Effect of Confining Pressure on Rock Fragmentation

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lu, Y.; Xiao, S.; Ge, Z.; Zhou, Z.; Deng, K. Rock-breaking properties of multi-nozzle bits for tree-type drilling in underground coal mines. Energies 2016, 9, 249. [Google Scholar] [CrossRef]

- He, M. Present State and Perspective of Rock Mechanics in Deep Mining Engineering; Science Press Beijing: Beijing, China, 2004; pp. 88–94. [Google Scholar]

- Wang, Z.; Dou, L.; Li, J.; Kang, K.; Feng, L. Numerical investigation of damage risks of roadway surrounding rocks under oblique incident dynamic loads. Shock Vib. 2017, 2017, 6298372. [Google Scholar] [CrossRef]

- Neil, D.; Ozdemir, L. Considerations for Development of Hard Rock Roadheaders. Available online: http://emi.mines.edu/UserFiles/File/earthMechanics/roadheader/roadheader1.pdf (accessed on 25 July 2017).

- Bilgin, N.; Copur, H.; Balci, C. Mechanical Excavation in Mining and Civil Industries; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Bilgin, N.; Dincer, T.; Copur, H.; Erdogan, M. Some geological and geotechnical factors affecting the performance of a roadheader in an inclined tunnel. Tunn. Undergr. Space Technol. 2004, 19, 629–636. [Google Scholar] [CrossRef]

- Gehring, K. Design criteria for TBM’s with respect to real rock pressure. In Proceedings of the Tunnel Boring Machines—Trends in Design & Construction of Mechanized Tunnelling, International Lecture Series TBM Tunnelling Trends, Hagenberg, Austria, 14–15 December 1996; pp. 43–53. [Google Scholar]

- Bilgin, N.; Tuncdemir, H.; Balci, C.; Copur, H.; Eskikaya, S. A Model to Predict the Performance of Tunneling Machines under Stressed Conditions. Available online: https://www.researchgate.net/profile/Hakan_Tuncdemir/publication/242759738_A_Model_to_Predict_The_Performance_of_tunnelling_Machines_Under_Stressed_Conditions/links/00b495293ccf942bd3000000.pdf (accessed on 25 July 2017).

- Yin, L.; Gong, Q.; Ma, H.; Zhao, J.; Zhao, X. Use of indentation tests to study the influence of confining stress on rock fragmentation by a TBM cutter. Int. J. Rock Mech. Min. Sci. 2014, 72, 261–276. [Google Scholar] [CrossRef]

- Ma, H.; Gong, Q.; Wang, J.; Yin, L.; Zhao, X. Study on the influence of confining stress on TBM performance in granite rock by linear cutting test. Tunn. Undergr. Space Technol. 2016, 57, 145–150. [Google Scholar] [CrossRef]

- Ma, H.; Yin, L.; Ji, H. Numerical study of the effect of confining stress on rock fragmentation by TBM cutters. Int. J. Rock Mech. Min. Sci. 2011, 48, 1021–1033. [Google Scholar] [CrossRef]

- Huang, J.; Zhang, Y.; Zhu, L.; Wang, T. Numerical simulation of rock cutting in deep mining conditions. Int. J. Rock Mech. Min. Sci. 2016, 84, 80–86. [Google Scholar] [CrossRef]

- Li, X.; Wang, S.; Malekian, R.; Hao, S.; Li, Z. Numerical simulation of rock breakage modes under confining pressures in deep mining: An experimental investigation. IEEE Access 2016, 4, 5710–5720. [Google Scholar] [CrossRef]

- Gnirk, P.; Cheatham, J., Jr. An experimental study of single bit-tooth penetration into dry rock at confining pressures 0 to 5000 psi. Soc. Pet. Eng. J. 1965, 5, 117–130. [Google Scholar] [CrossRef]

- Chen, L.; Labuz, J. Indentation of rock by wedge-shaped tools. J. Rock Mech. Min. Sci. 2006, 43, 1023–1033. [Google Scholar] [CrossRef]

- Huang, H.; Detournay, E. Discrete element modeling of tool-rock interaction II: Rock indentation. Int. J. Numer. Anal. Methods Geomech. 2013, 37, 1930–1947. [Google Scholar] [CrossRef]

- Huang, H.; Lecampion, B.; Detournay, E. Discrete element modeling of tool-rock interaction I: Rock cutting. Int. J. Numer. Anal. Methods Geomech. 2013, 37, 1913–1929. [Google Scholar] [CrossRef]

- Innaurato, N.; Oggeri, C.; Oreste, P.P.; Vinai, R. Experimental and numerical studies on rock breaking with TBM tools under high stress confinement. Rock Mechan. Rock Eng. 2007, 40, 429–451. [Google Scholar] [CrossRef]

- Cook, N.; Hood, M.; Tsai, F. Observations of Crack Growth in Hard Rock Loaded by an Indenter; Elsevier: Amsterdam, The Netherlands, 1984; pp. 97–107. [Google Scholar]

- Liu, H.; Kou, S.; Lindqvist, P.-A.; Tang, C. Numerical simulation of the rock fragmentation process induced by indenters. J. Rock Mech. Min. Sci. 2002, 39, 491–505. [Google Scholar] [CrossRef]

- Li, X.; Li, H.; Liu, Y.; Zhou, Q.; Xia, X. Numerical simulation of rock fragmentation mechanisms subject to wedge penetration for TBMs. Tunn. Undergr. Space Technol. 2016, 53, 96–108. [Google Scholar] [CrossRef]

- Jespersen, C.; MacLaughlin, M.; Hudyma, N. Strength, deformation modulus and failure modes of cubic analog specimens representing macroporous rock. J. Rock Mech. Min. Sci. 2010, 47, 1349–1356. [Google Scholar] [CrossRef]

- Lee, H.; Jeon, S. An experimental and numerical study of fracture coalescence in pre-cracked specimens under uniaxial compression. Int. J. Solids Struct. 2011, 48, 979–999. [Google Scholar] [CrossRef]

- Lin, P.; Wong, R.H.; Tang, C. Experimental study of coalescence mechanisms and failure under uniaxial compression of granite containing multiple holes. Int. J. Rock Mech. Min. Sci. 2015, 77, 313–327. [Google Scholar] [CrossRef]

- Long, R.; Sun, S.; Lian, Z. Research on the hard-rock breaking mechanism of hydraulic drilling impact tunneling. Math. Probl. Eng. 2015, 2015, 153648. [Google Scholar] [CrossRef]

- Wong, R.H.; Lin, P. Numerical study of stress distribution and crack coalescence mechanisms of a solid containing multiple holes. Int. J. Rock Mech. Min. Sci. 2015, 79, 41–54. [Google Scholar] [CrossRef]

- He, J.; Zhang, Z.; Li, X. Numerical analysis on the formation of fracture network during the hydraulic fracturing of shale with pre-existing fractures. Energies 2017, 10, 736. [Google Scholar] [CrossRef]

- Fourmeau, M.; Kane, A.; Hokka, M. Experimental and numerical study of drill bit drop tests on Kuru granite. Phil. Trans. R. Soc. A 2017, 375, 20160176. [Google Scholar] [CrossRef] [PubMed]

- Menezes, P.L.; Lovell, M.R.; Avdeev, I.V.; Higgs, C.F. Studies on the formation of discontinuous rock fragments during cutting operation. Int. J. Rock Mech. Min. Sci. 2014, 71, 131–142. [Google Scholar] [CrossRef]

- Hallquist, J.O. LS-DYNA Theory Manual; Livermore Software Technology Corporation: Livermore, CA, USA, 2006; Volume 3, pp. 25–31. [Google Scholar]

- Xie, L.; Lu, W.; Zhang, Q.; Jiang, Q.; Wang, G.; Zhao, J. Damage evolution mechanisms of rock in deep tunnels induced by cut blasting. Tunn. Undergr. Space Technol. 2016, 58, 257–270. [Google Scholar] [CrossRef]

- Yankelevsky, D.Z. Resistance of a concrete target to penetration of a rigid projectile-revisited. International J. Impact Eng. 2017, 106, 30–43. [Google Scholar] [CrossRef]

- Schwer, L.E.; Murray, Y.D. Continuous Surface Cap Model for Geomaterial Modeling: A New LS-DYNA Material Type. Available online: http://www.dynalook.com/international-conf-2002/Session_16-3.pdf (accessed on 25 July 2017).

- Jiang, H.; Zhao, J. Calibration of the continuous surface cap model for concrete. Finite Elem. Anal. Des. 2015, 97, 1–19. [Google Scholar] [CrossRef]

- Meléndez, C.; Miguel, P.F.; Pallarés, L. A simplified approach for the ultimate limit state analysis of three-dimensional reinforced concrete elements. Eng. Struct. 2016, 123, 330–340. [Google Scholar] [CrossRef]

- Jaime, M.C.; Zhou, Y.; Lin, J.-S.; Gamwo, I.K. Finite element modeling of rock cutting and its fragmentation process. Int. J. Rock Mech. Min. Sci. 2015, 80, 137–146. [Google Scholar] [CrossRef]

- Jiang, H.; Chorzepa, M.G. An effective numerical simulation methodology to predict the impact response of pre-stressed concrete members. Eng. Fail. Anal. 2015, 55, 63–78. [Google Scholar] [CrossRef]

- Li, W.; Zhang, D.; Li, M. Failure criteria of gas-infiltrated sandy shale based on the effective stress principle. Energies 2016, 9, 972. [Google Scholar] [CrossRef]

- Fowell, R.; McFeat-Smith, I. Factors influencing the cutting performance of a selective tunnelling machine. In Proceedings of the Tunnelling Symposium, London, UK, 1–5 March 1976; Volume 76, pp. 301–309. [Google Scholar]

| Material | ρ | E | µ | σC | σT | α | β | γ | θ | X0 | D1 | D2 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (kg/m3) | (GPa) | - | (MPa) | (MPa−1) | (MPa−2) | |||||||

| Rock | 2532 | 15.4 | 0.19 | 28.6 | 2.7 | 7.71 | 0.054 | 2.97 | 0.34 | 70.14 | 6.11 × 10−4 | 2.23 × 10−6 |

| Cutterhead | 7800 | 200 | 0.25 | - | - | - | - | - | - | - | - | - |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Du, C.; Jiang, H.; Liu, K. Analysis of Roadheader for Breaking Rock Containing Holes under Confining Pressures. Energies 2017, 10, 1154. https://doi.org/10.3390/en10081154

Liu Z, Du C, Jiang H, Liu K. Analysis of Roadheader for Breaking Rock Containing Holes under Confining Pressures. Energies. 2017; 10(8):1154. https://doi.org/10.3390/en10081154

Chicago/Turabian StyleLiu, Zenghui, Changlong Du, Hongxiang Jiang, and Kai Liu. 2017. "Analysis of Roadheader for Breaking Rock Containing Holes under Confining Pressures" Energies 10, no. 8: 1154. https://doi.org/10.3390/en10081154

APA StyleLiu, Z., Du, C., Jiang, H., & Liu, K. (2017). Analysis of Roadheader for Breaking Rock Containing Holes under Confining Pressures. Energies, 10(8), 1154. https://doi.org/10.3390/en10081154