One of the major challenges currently faced in the transportation sector is how to decrease the dependency on fossil fuels and thus reduce the emission of greenhouse gases. As electric vehicles (EVs) have the advantage of eliminating the automobile exhaust and offer an ultimate solution for sustainable personal mobility [

1,

2], EVs seem to be one of the best future alternatives for the automotive industry and transportation [

3]. However, the limited operational range of EVs is a major drawback which is mostly affected by the battery management system and motor drive system. As the motor drive system is the main power source of EVs, the efficiency of the drive system will directly influence their mileage endurance. Compared with induction motors (IMs) and switched reluctance motors (SRMs) [

4,

5], permanent magnet synchronous motors (PMSMs) with their advantage of high power density and high efficiency, can decrease the energy consumption and improve the operational mileage of EVs [

6,

7,

8], therefore, the PMSM direct drive system has been widely applied in EVs for transportation.

The optimization of the electromagnetic structure and control strategy of PMSMs has been widely discussed in recent years. There are several PMSM control strategies, such as

id = 0 control, maximum torque per ampere (MTPA) control, maximum speed per voltage (MSPV) control, unity power factor (UPF) control, loss model control (LMC) and etc. [

9,

10,

11,

12,

13,

14,

15,

16,

17,

18,

19,

20,

21,

22,

23,

24]. The

id = 0 control is the most conventional vector control method used in PMSM drive systems. In [

9,

10,

11], the finite element method (FEM) is used to calculate the motor loss, and the

id = 0 control is used to drive the PMSM system to verify the performance of a PMSM. By keeping the motor current in the

d-axis at zero, the

id = 0 control can make the electromagnetic torque and

q-axis motor current proportional, and will not damage the magnetic properties of the permanent magnet. However, in [

12], the

id = 0 control method could not minimize the stator current in the interior of a PMSM in which the

d-axis magnetic inductance is not equal to

q-axis magnetic inductance, and could not achieve minimum copper loss in IPMSMs. Compared with other control strategies, the MTPA control method can take advantage of the reluctance torque of the motor, by which the stator current is decreased [

13,

14,

15,

16]. In [

16], the improved MTPA control takes the core saturation and cross coupling of the

d- and

q-axis magnetic flux into account, and the motor performance was optimized with the consideration of the impact of various temperatures. The MTPA control can obtain the minimum stator current and achieve the least copper loss below the rated speed. Meanwhile, the MSPV control can optimize the stator voltage and obtain the optimal stator iron below rated torque [

17]. However, as the losses of a PMSM are comprised of copper loss and iron loss, both the MTPA control method and MSPV control method only consider part of the total motor loss, and ignore the coupling relationship between copper loss and iron loss. Therefore, neither the MTPA control strategy nor the MSPV control strategy will achieve the maximum motor efficiency in PMSMs [

18]. The UPF control can keep the power factor of PMSMs to one and decrease the energy consumption in the power transfer process [

19,

20,

21]. In Ref. [

21], a PMSM drive system with small DC-link capacitor applied UPF control to stabilize the motor driving and decrease the energy loss on the input side. As the UPF control does not take into consideration the power loss in PMSMs, the motor efficiency will not always achieve the maximum value under UPF control. The LMC can optimize both copper loss and iron loss by the PMSM loss model and improve the motor efficiency of the PMSM system [

22,

23,

24]. In Ref. [

23], the motor iron loss is calculated by the iron loss resistance, and both the iron loss and copper loss are optimized. The LMC enables the drivetrain to operate safely at the maximum attainable performance limits. In Ref. [

24], the Bertotti iron loss formula is used to analyze the stator iron loss, and iron loss is verified by the FEM model. Based on the loss model, the proposed control method fully considers the cross effect and iron loss, and can maximize the efficiency of PMSMs. However, these recent optimized motor efficiency control strategies only focus on the optimization of the motor loss, and neglect the coupling relationship between motor loss and inverter loss. Therefore, as the inverter loss is an important part of system loss in the PMSM system for transportation, these motor control strategies will not achieve the maximum system efficiency.

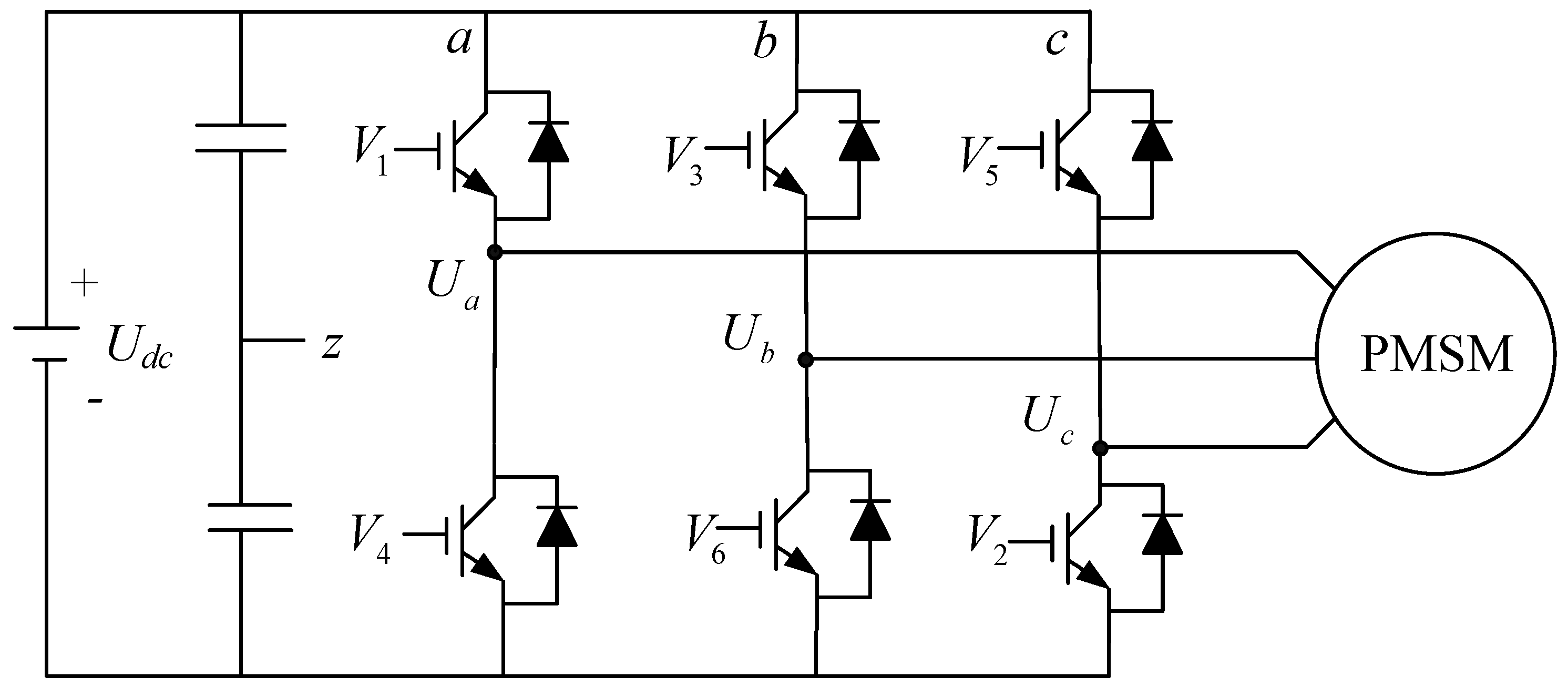

There are also many control strategies for three-phase half-bridge inverters in the PMSM drive system [

25]. Modern methods about three-phase inverters such as selected harmonic elimination pulse width modulation (SHEPWM) [

26], current harmonic distortion minimization PWM (CHMPWM) [

27], harmonic injection PWM (HIPWM) [

28], space vector pulse width modulation (SVPWM) [

29], etc., always focus on the modulation optimization to decrease the harmonic components of the output voltage in the three-phase inverter. In Ref. [

26], a method of smooth transition between different SHEPWMs is proposed to adapt to the SPMSMs and IPMSMs, by which smooth transition of current is guaranteed and the harmonic current is reduced. In Ref. [

27], considering the saliency ratio and load angle constraints, a new current harmonic evaluation index is proposed, and based on it, the improved CHMPWM guarantees good performance of both current THD and the specific order current harmonics. All these control strategies ignore the coupling relationship between motor loss and inverter loss. As the inverter loss is an important part of the efficient performance in the PMSM drive system, the efficiency optimization of the three-phase inverter will directly improve the power loss of a PMSM system. Therefore, to acquire a higher system efficiency of a PMSM drive system, The PWM control strategy must take consideration both harmonic components of output voltage and the power loss of power devices in the three-phase bridge inverter.

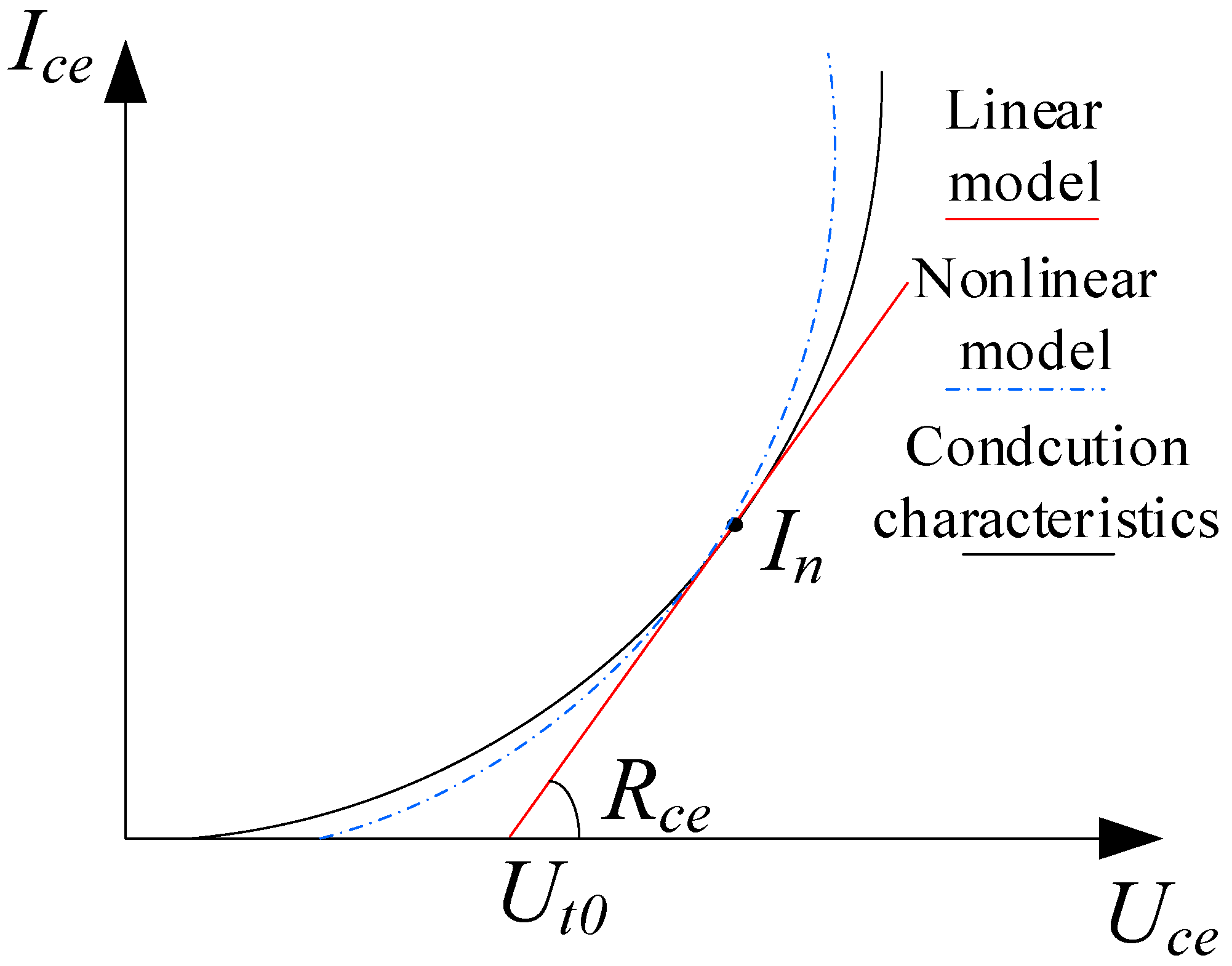

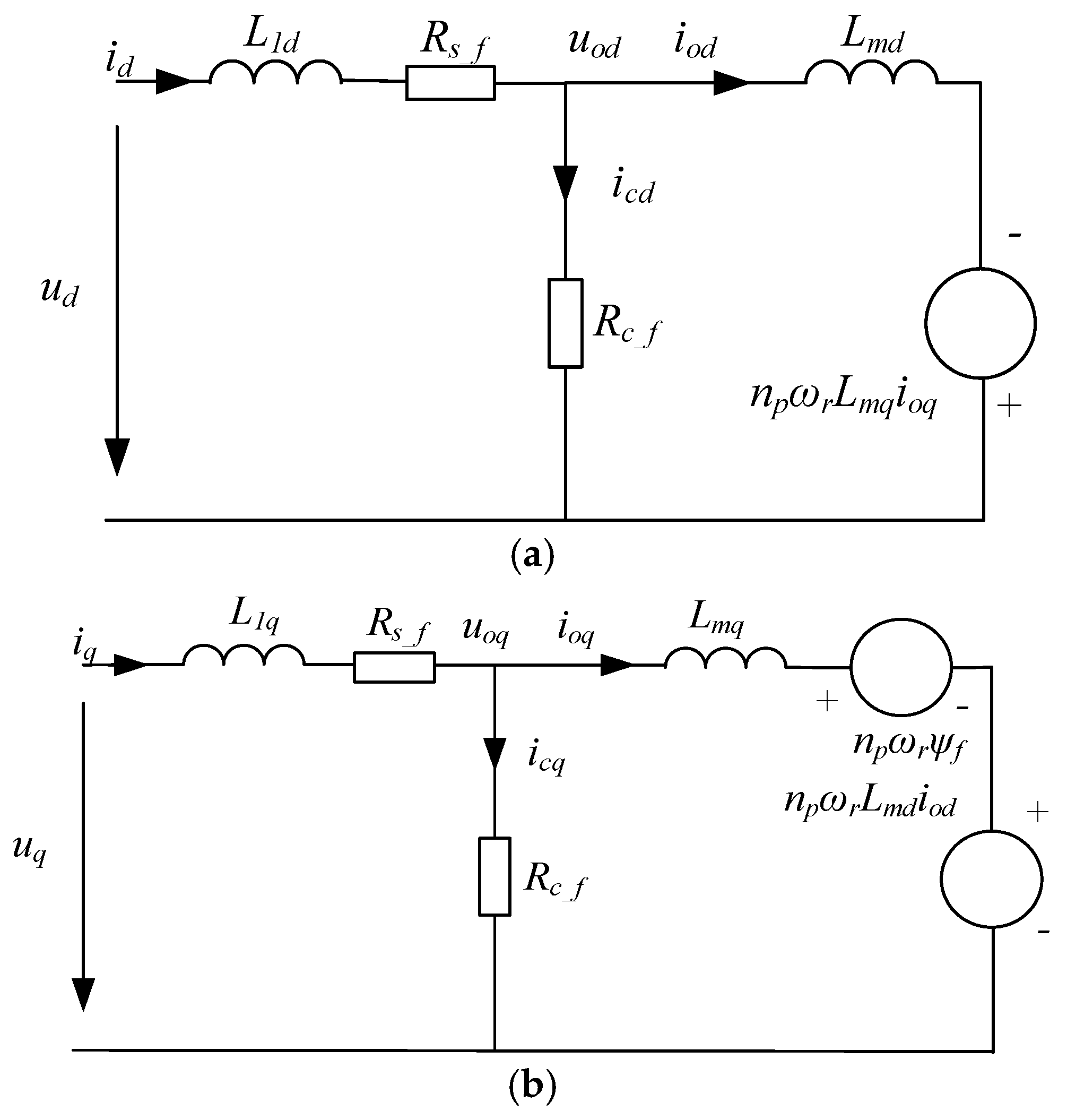

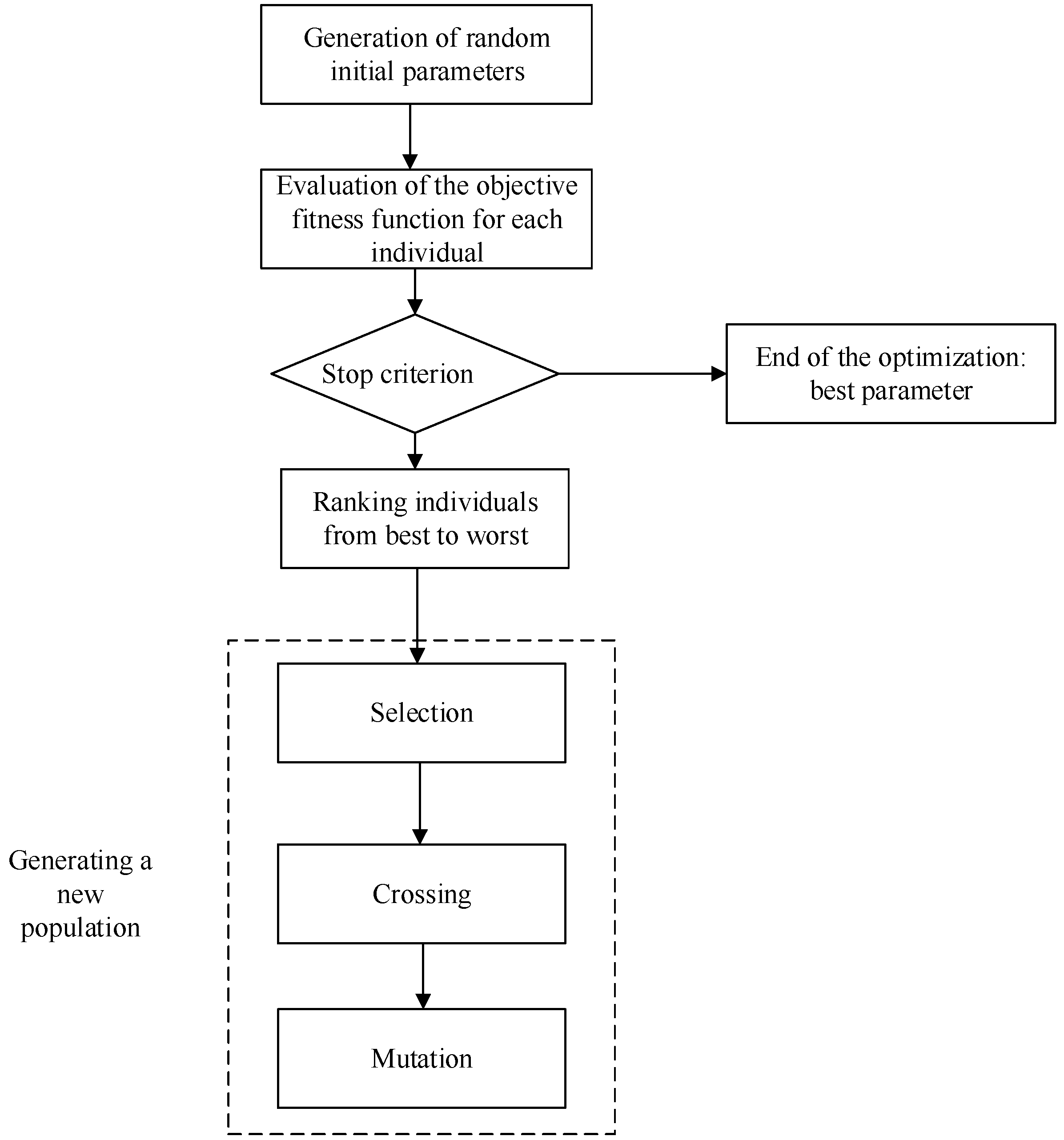

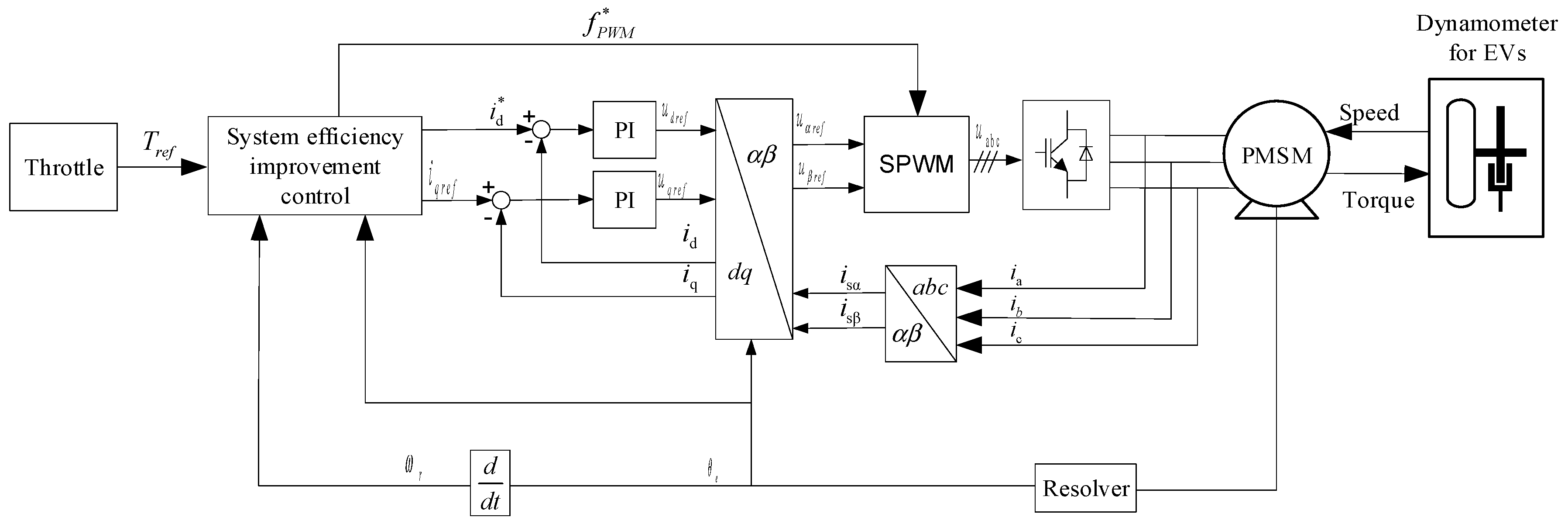

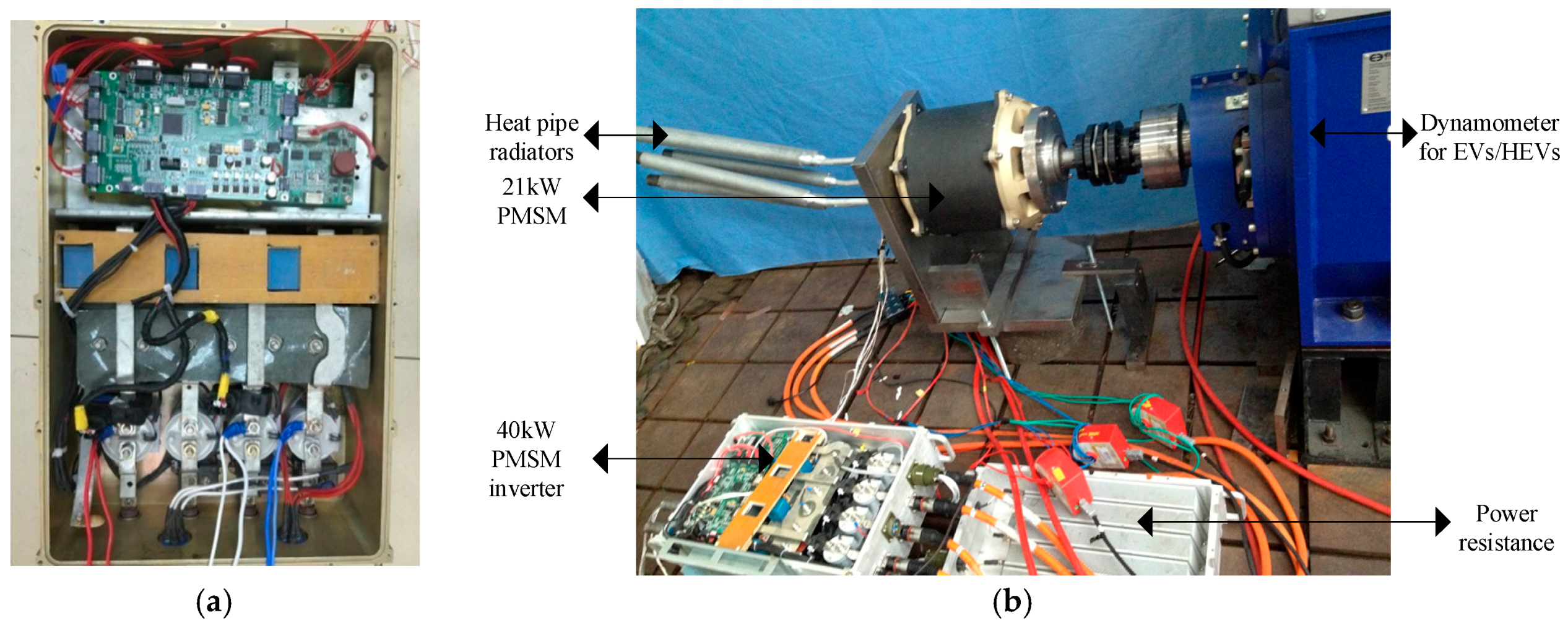

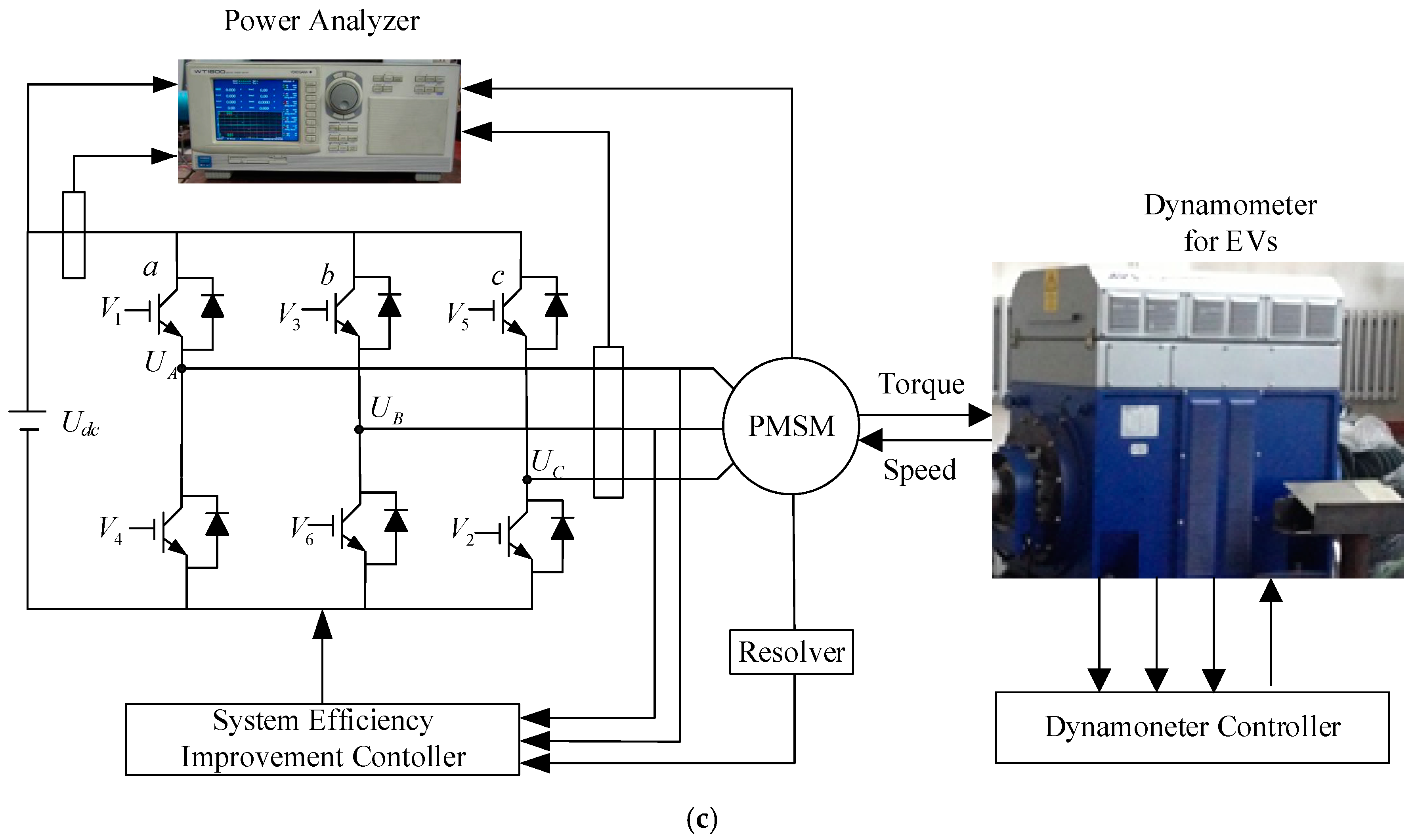

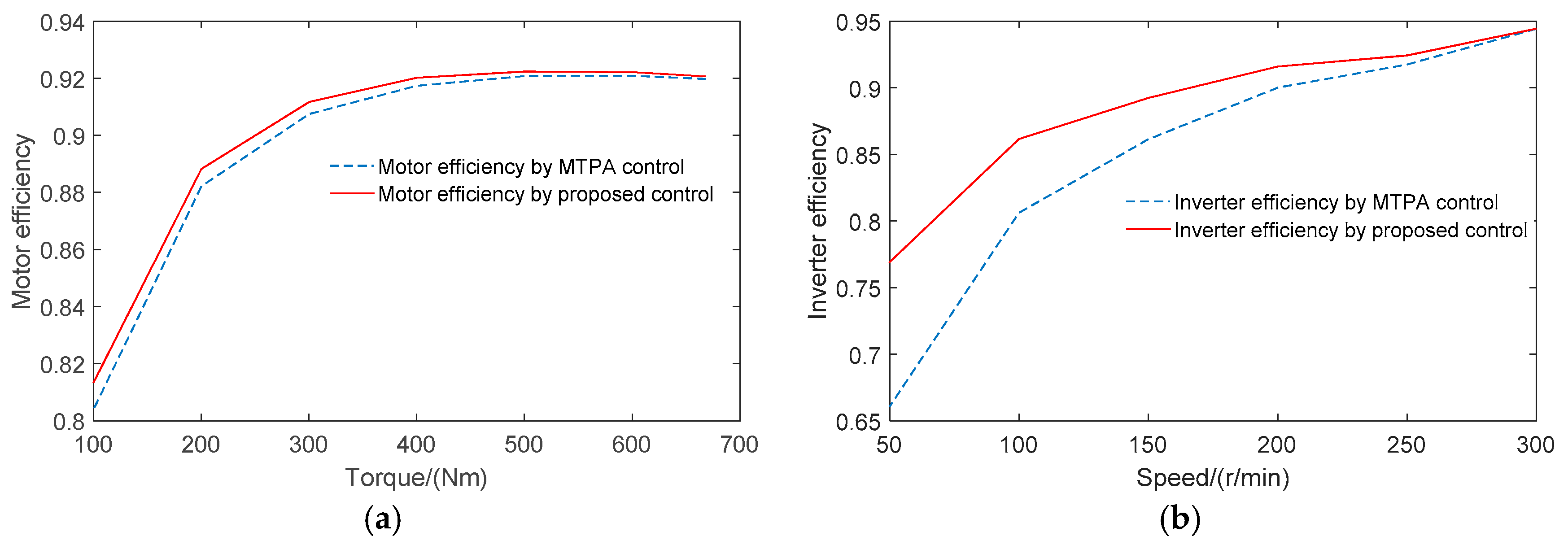

This paper proposes a novel efficiency control strategy to improve the power loss of PMSM drive systema, which can optimize both motor and inverter losses. An accurate nonlinear loss model of a three-phase half-bridge inverter is built to predict the conduction loss and switch loss exactly in the sine-wave PMSM system. This paper applies the double Fourier integral analysis to analytically calculate the fundamental component and harmonics of the inverter output voltage, by which a global motor loss model of the PMSM is established. The global motor loss model can take consideration of both the fundamental motor loss and harmonic motor loss, which shows the coupling relationship between motor loss and inverter loss. Based on the nonlinear inverter loss and global motor loss model, the proposed efficiency optimization control strategy can optimize the motor current and PWM frequency together, by which the PMSM drive system can achieve higher system efficiency compared with traditional control strategies. The loss reduction effect is tested and verified by experiments.