Determination of the Optimum Heat Transfer Coefficient and Temperature Rise Analysis for a Lithium-Ion Battery under the Conditions of Harbin City Bus Driving Cycles

Abstract

:1. Introduction

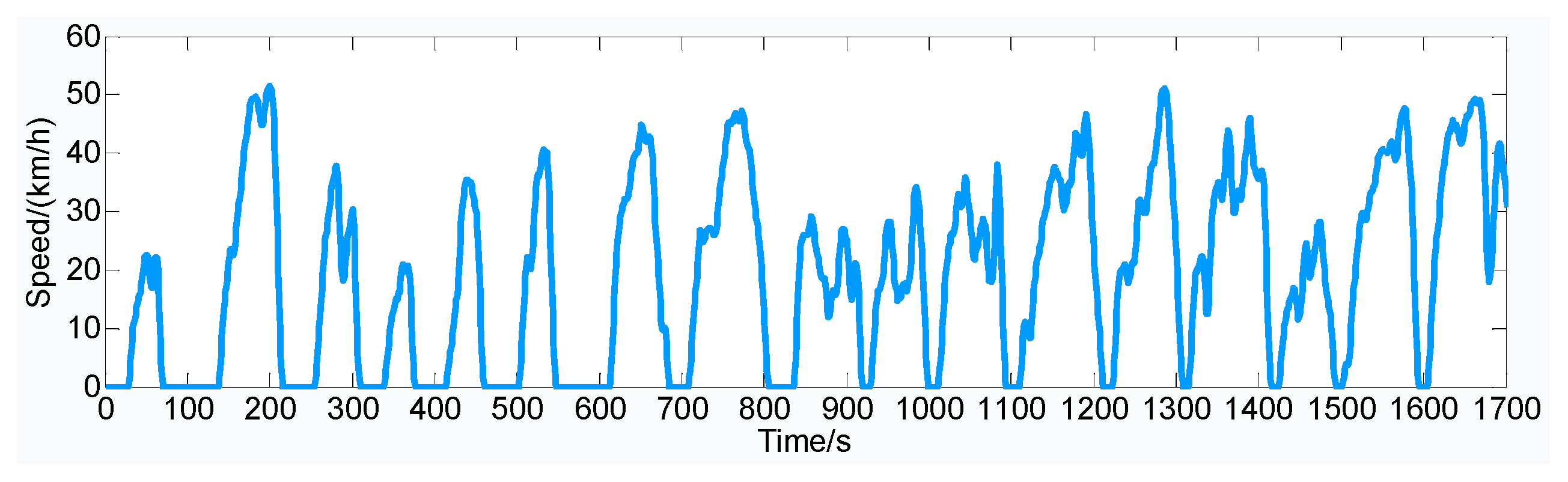

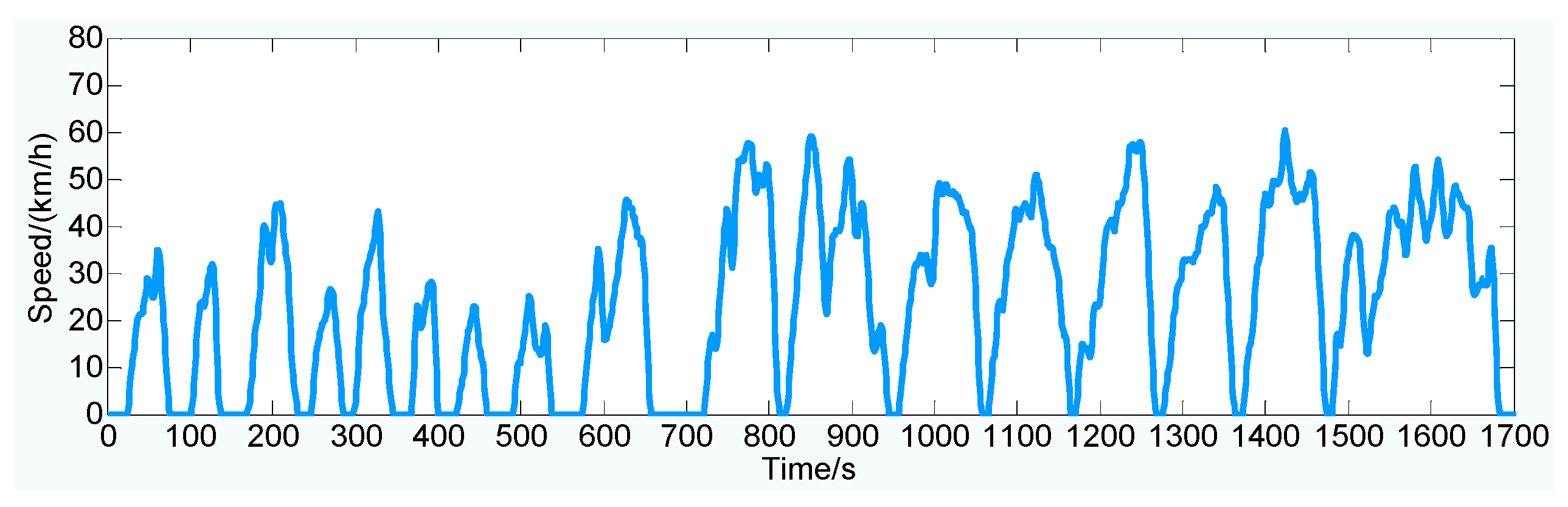

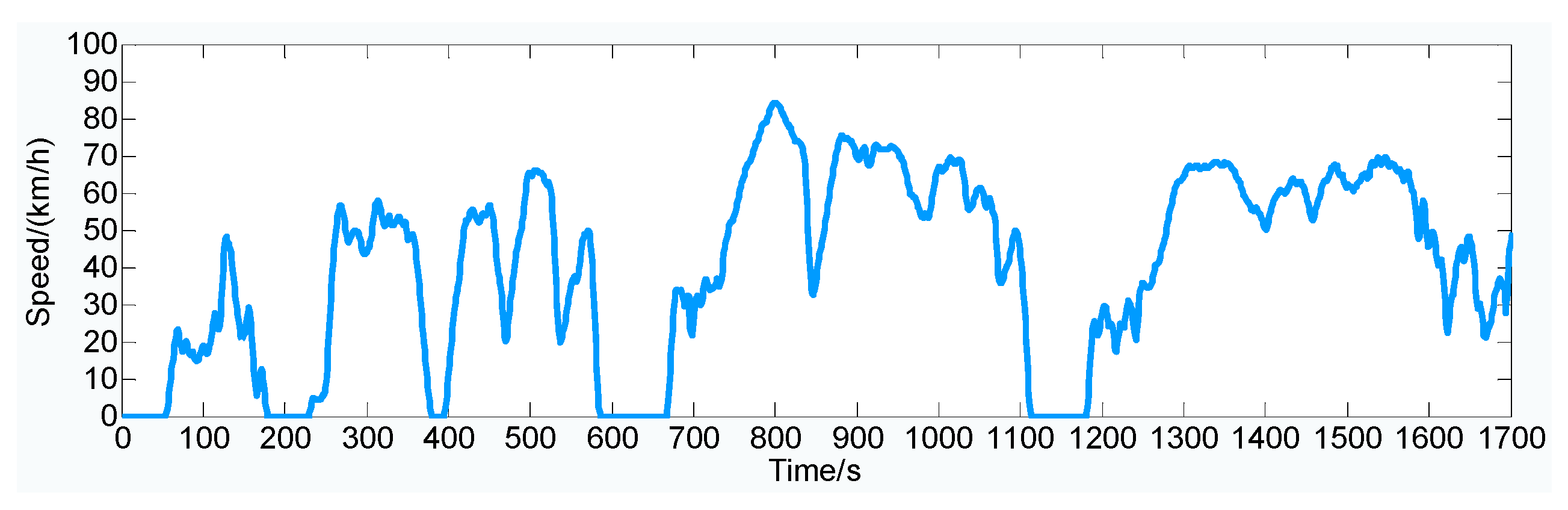

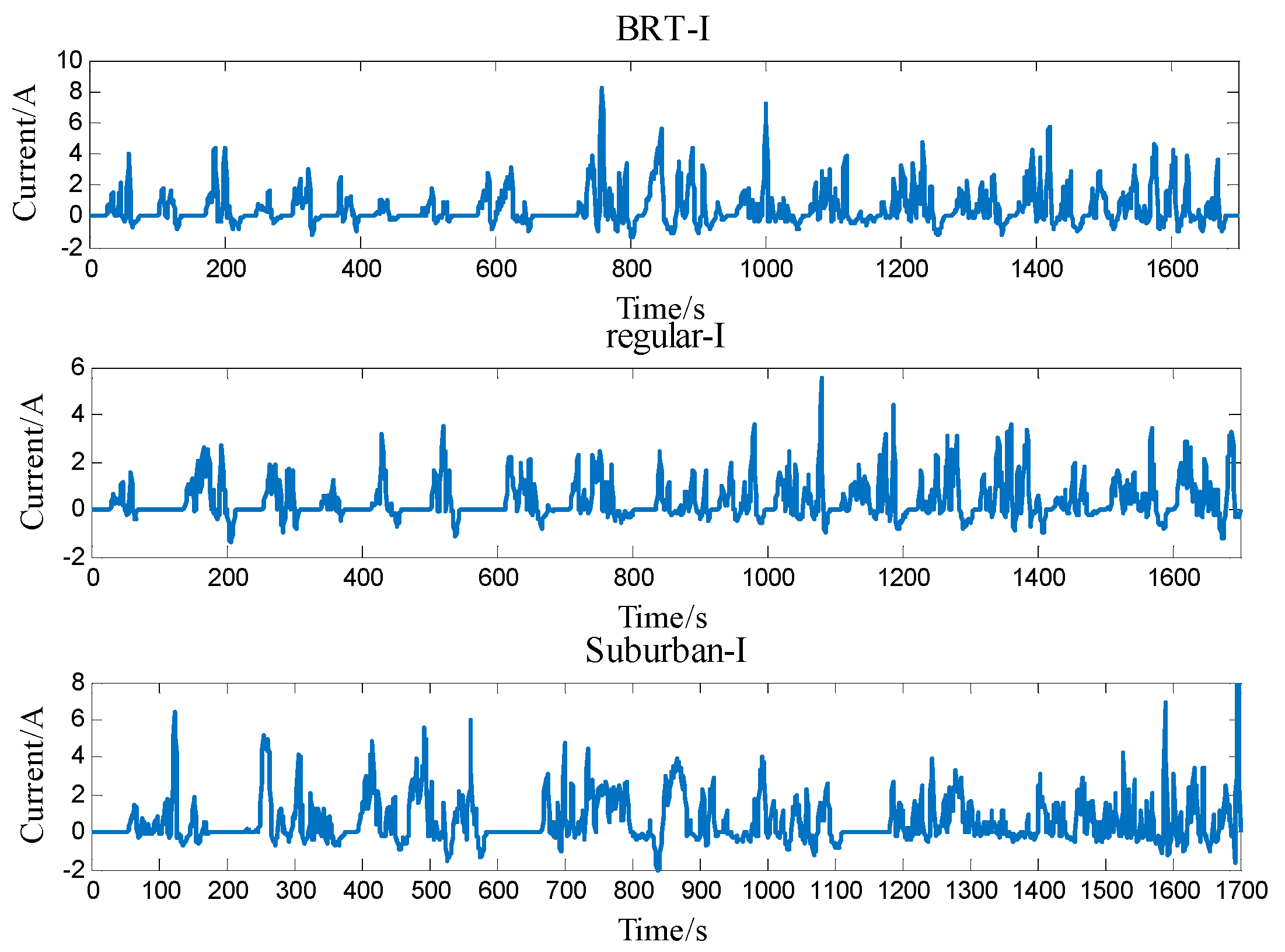

2. Selection and Calculation of the Test Cycles

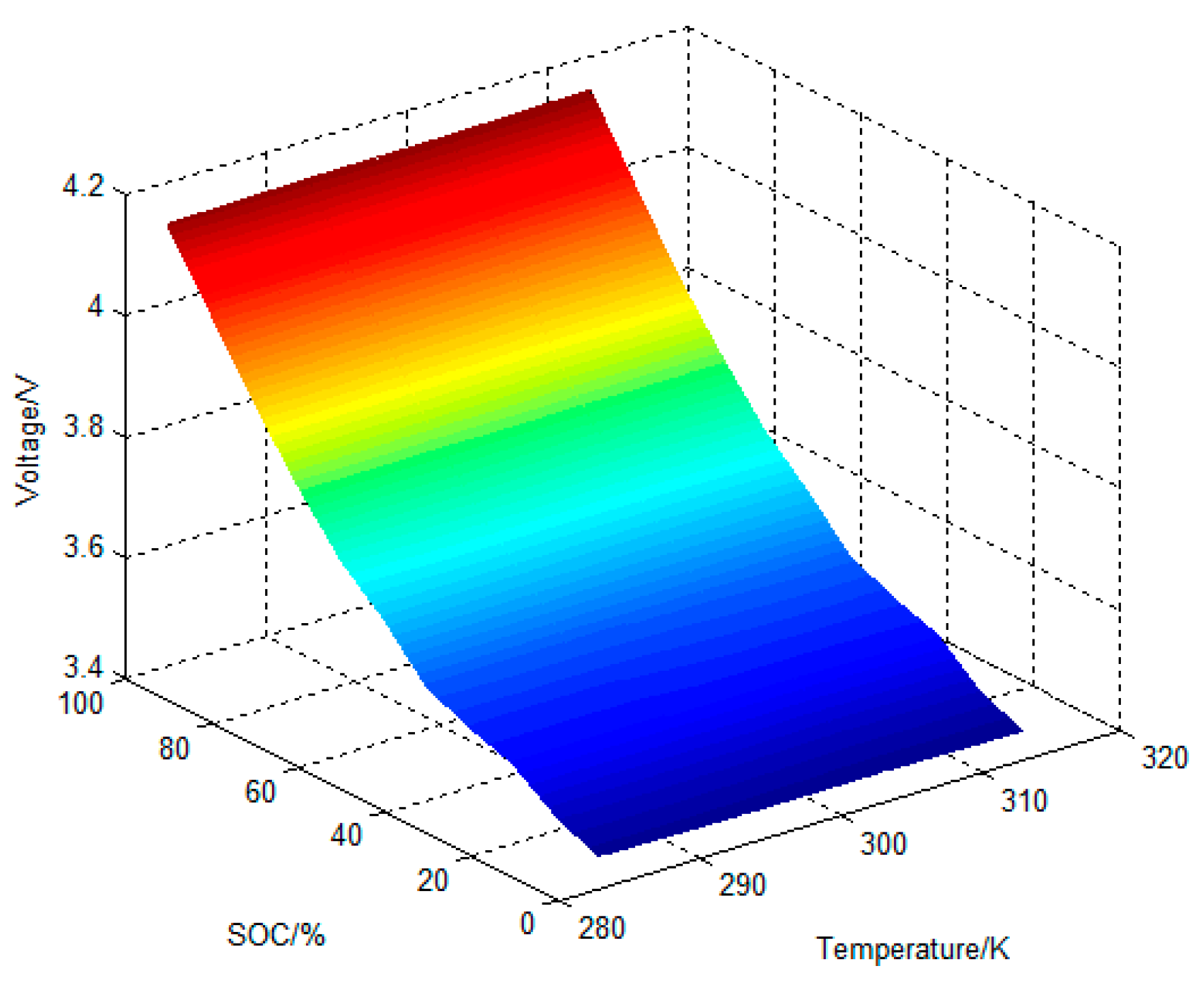

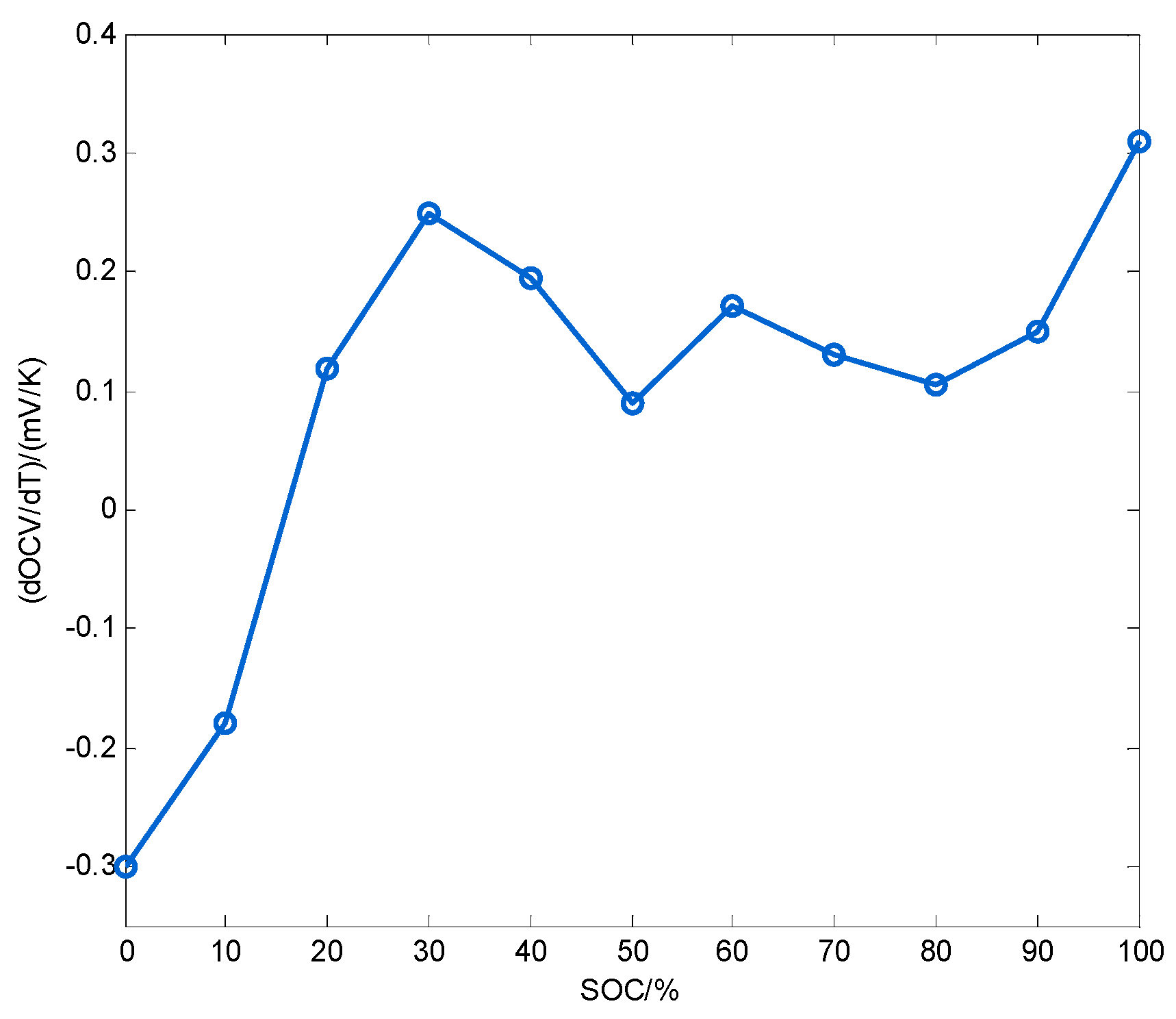

3. Establishment and Verification of the Thermal Model

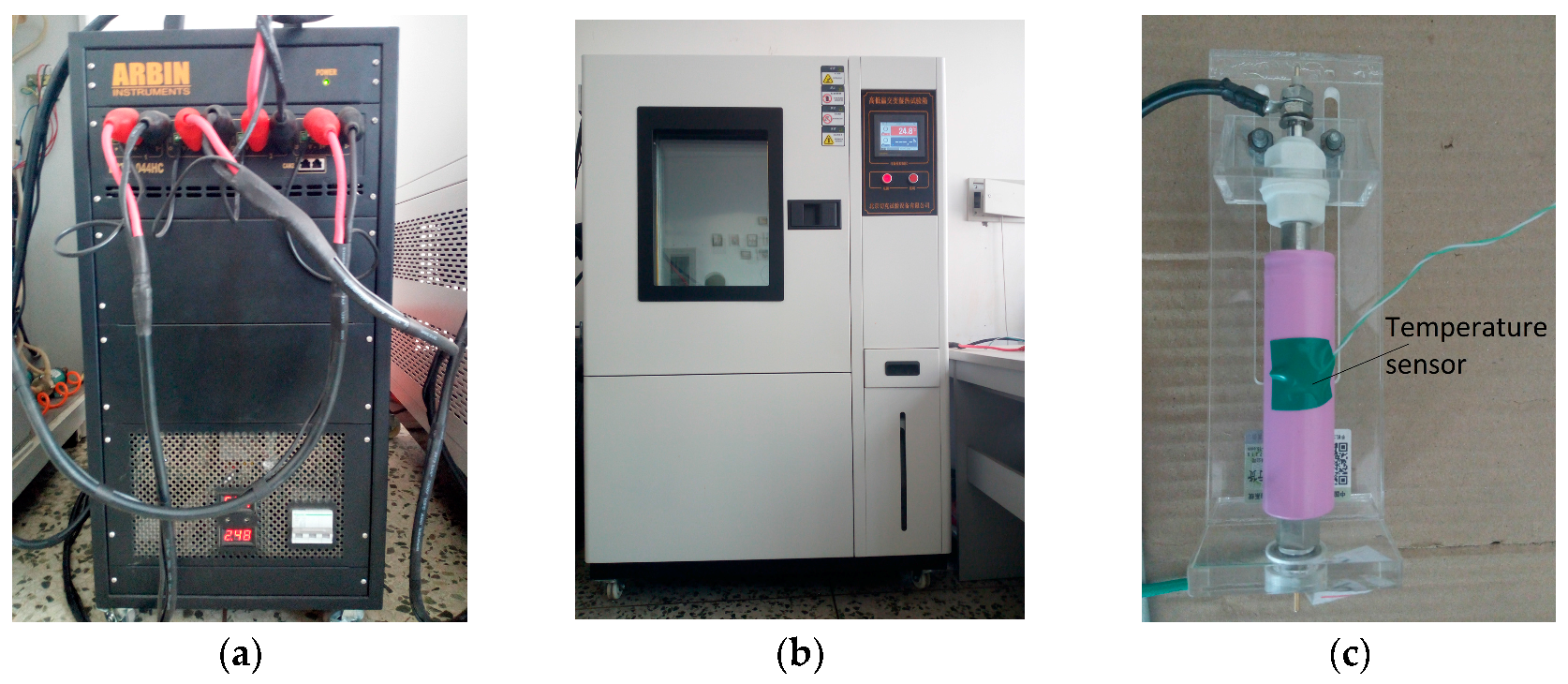

3.1. Simulation Model Building

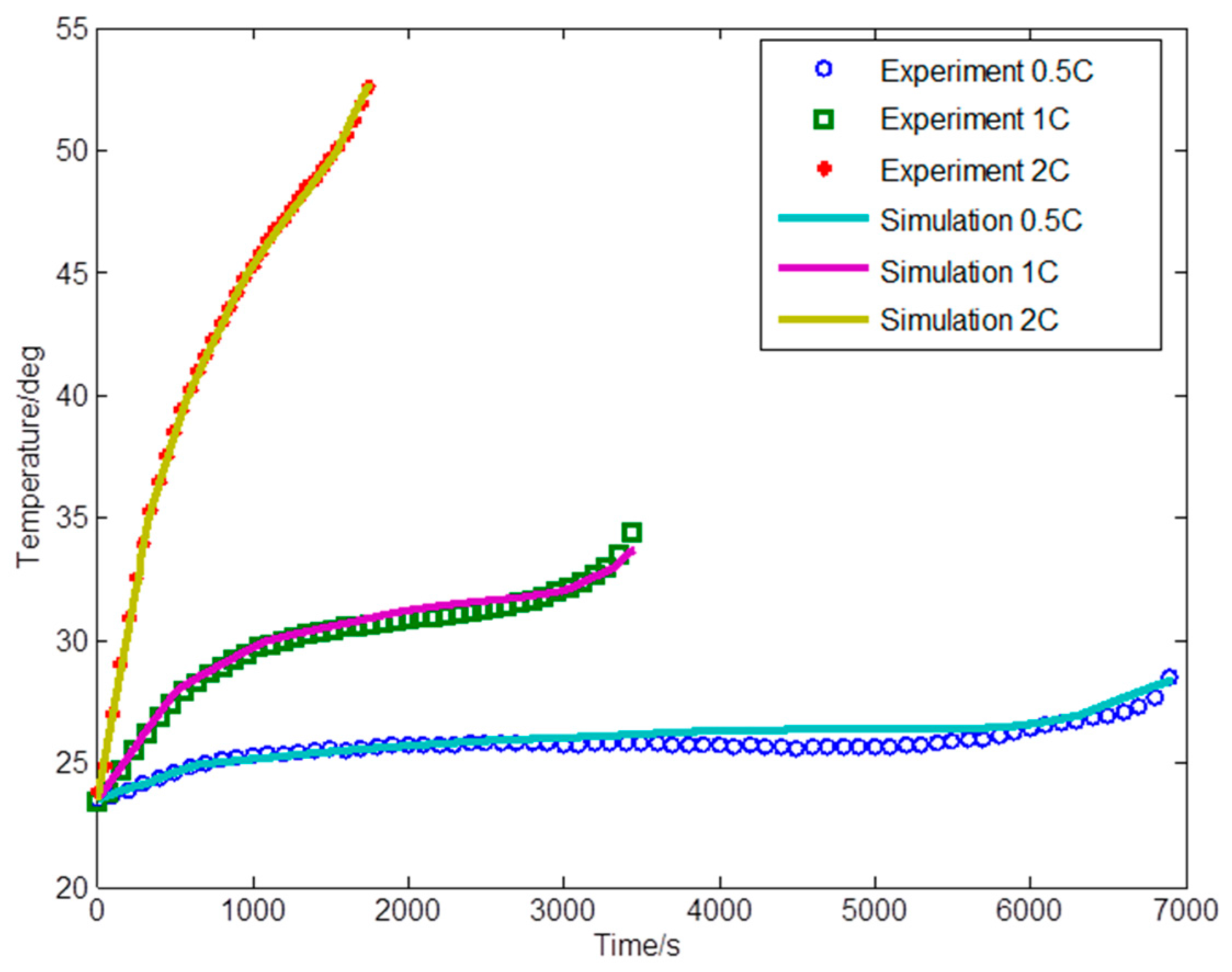

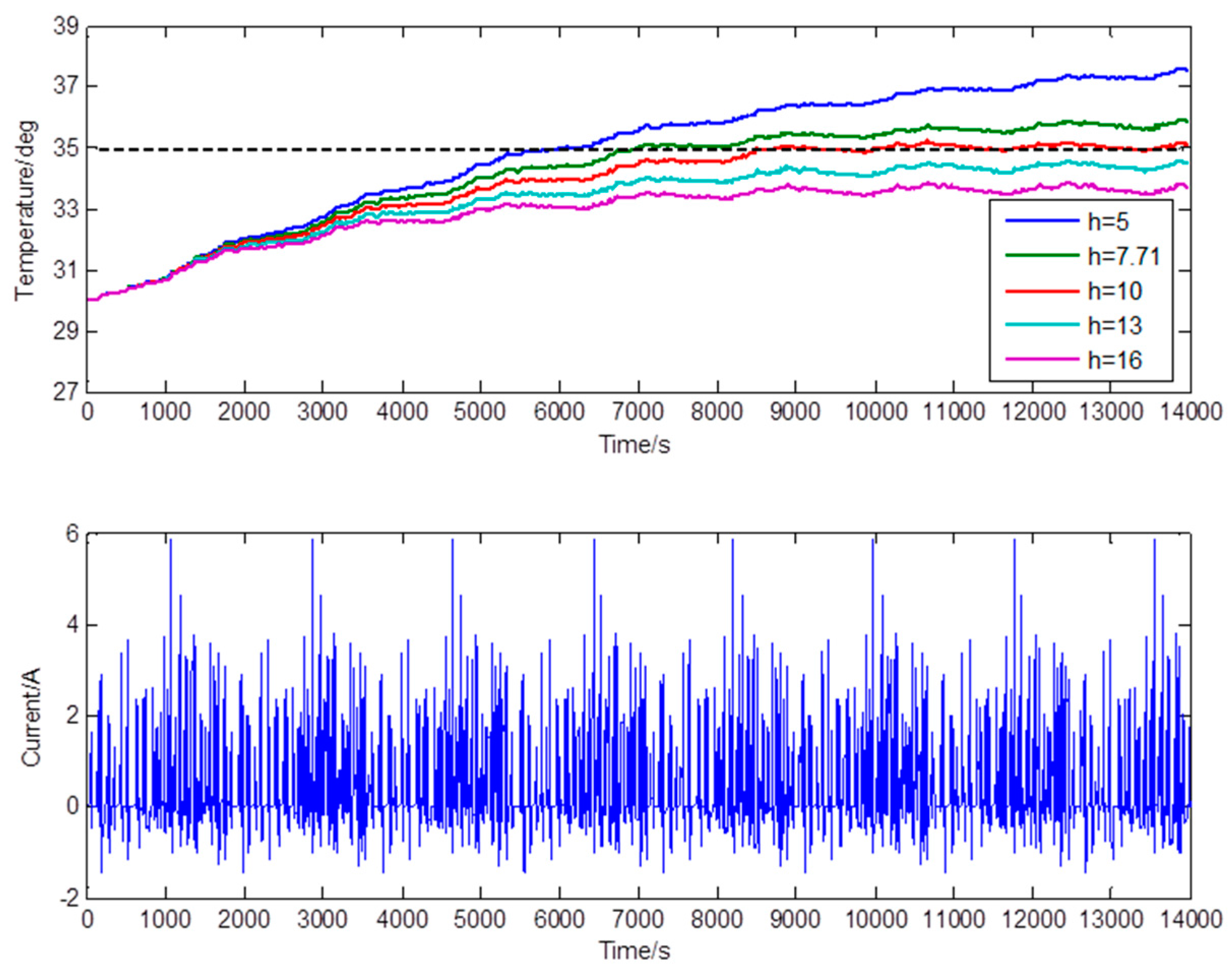

3.2. Simulation Model Verification

4. Results and Discussion

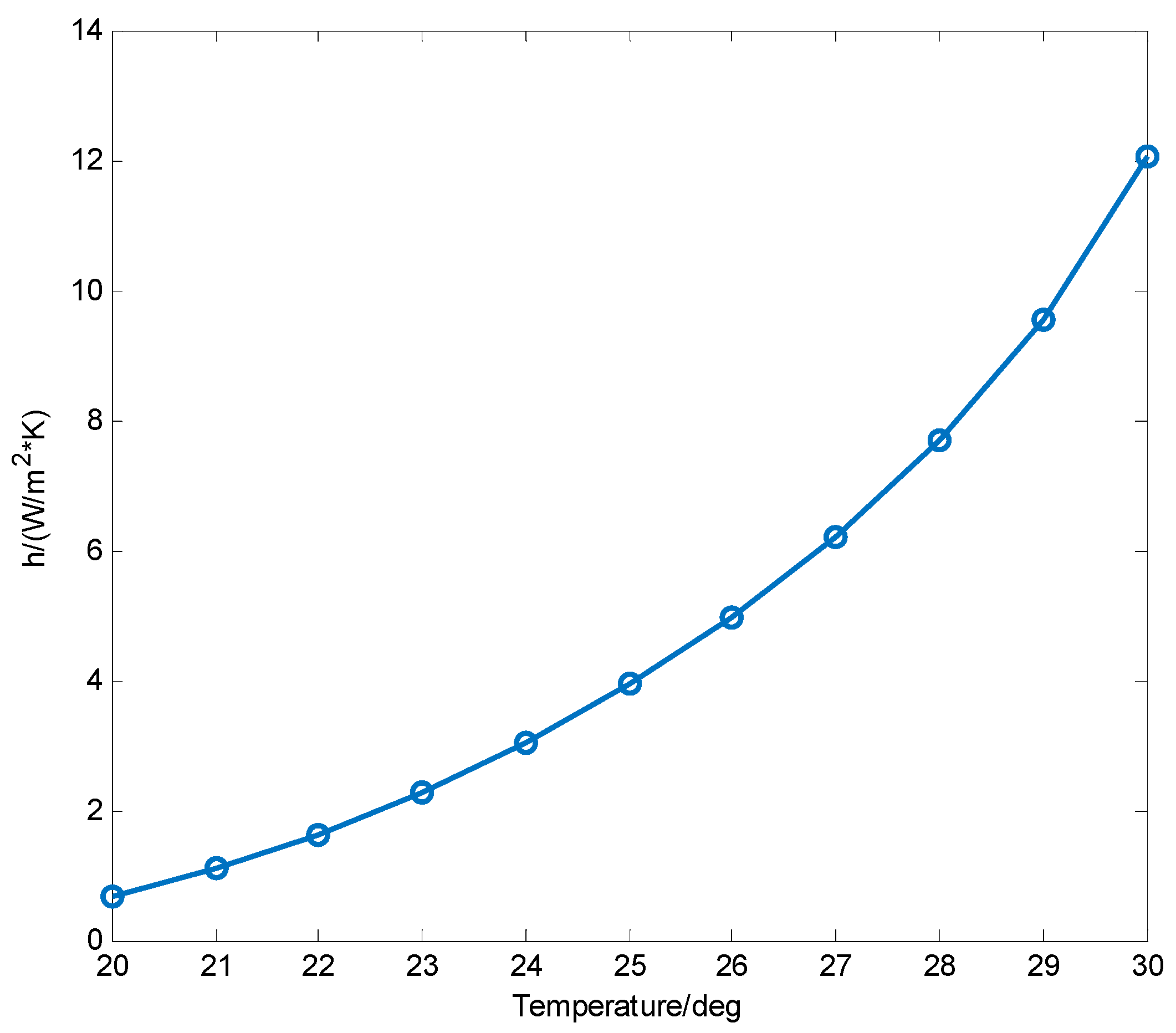

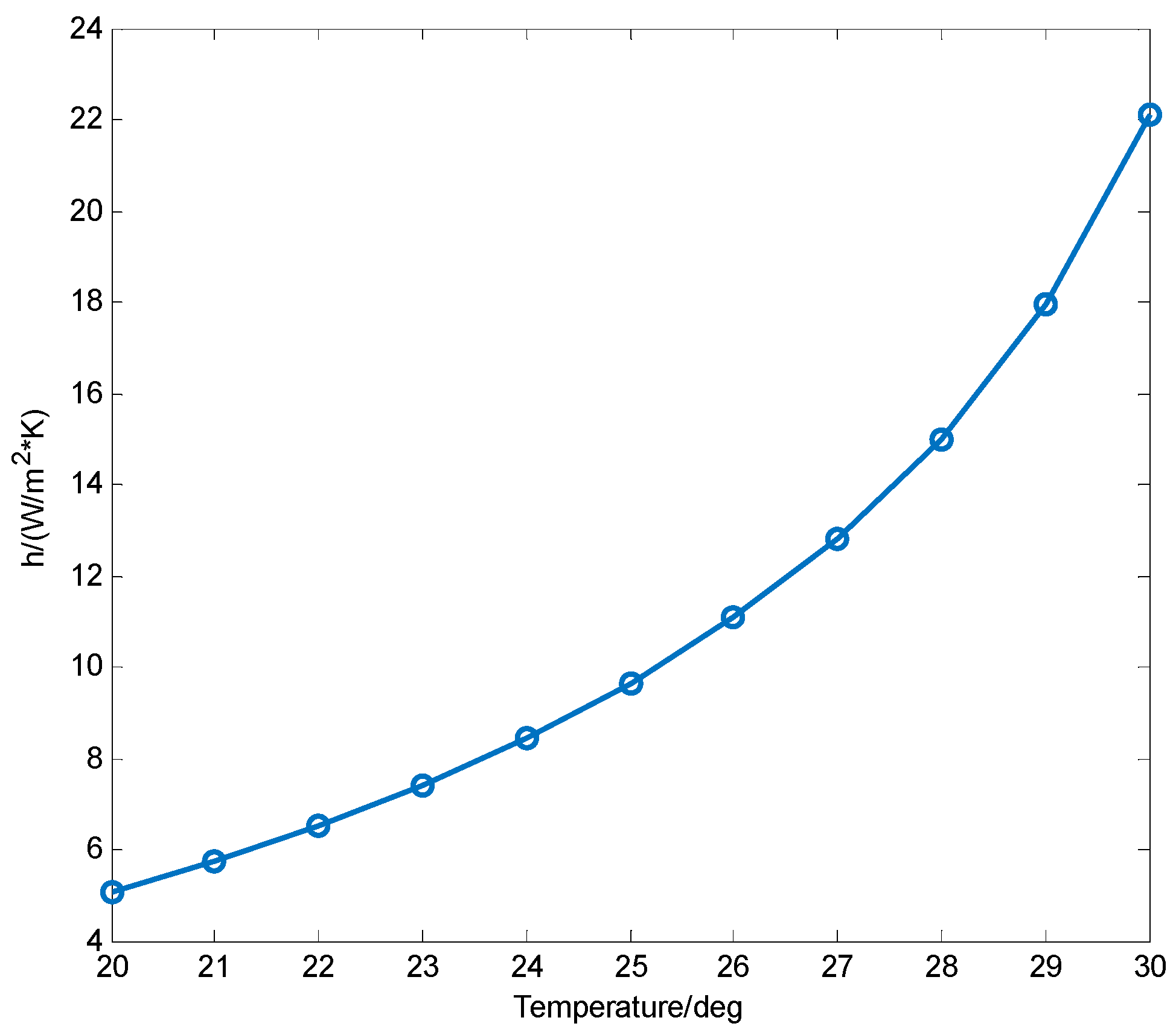

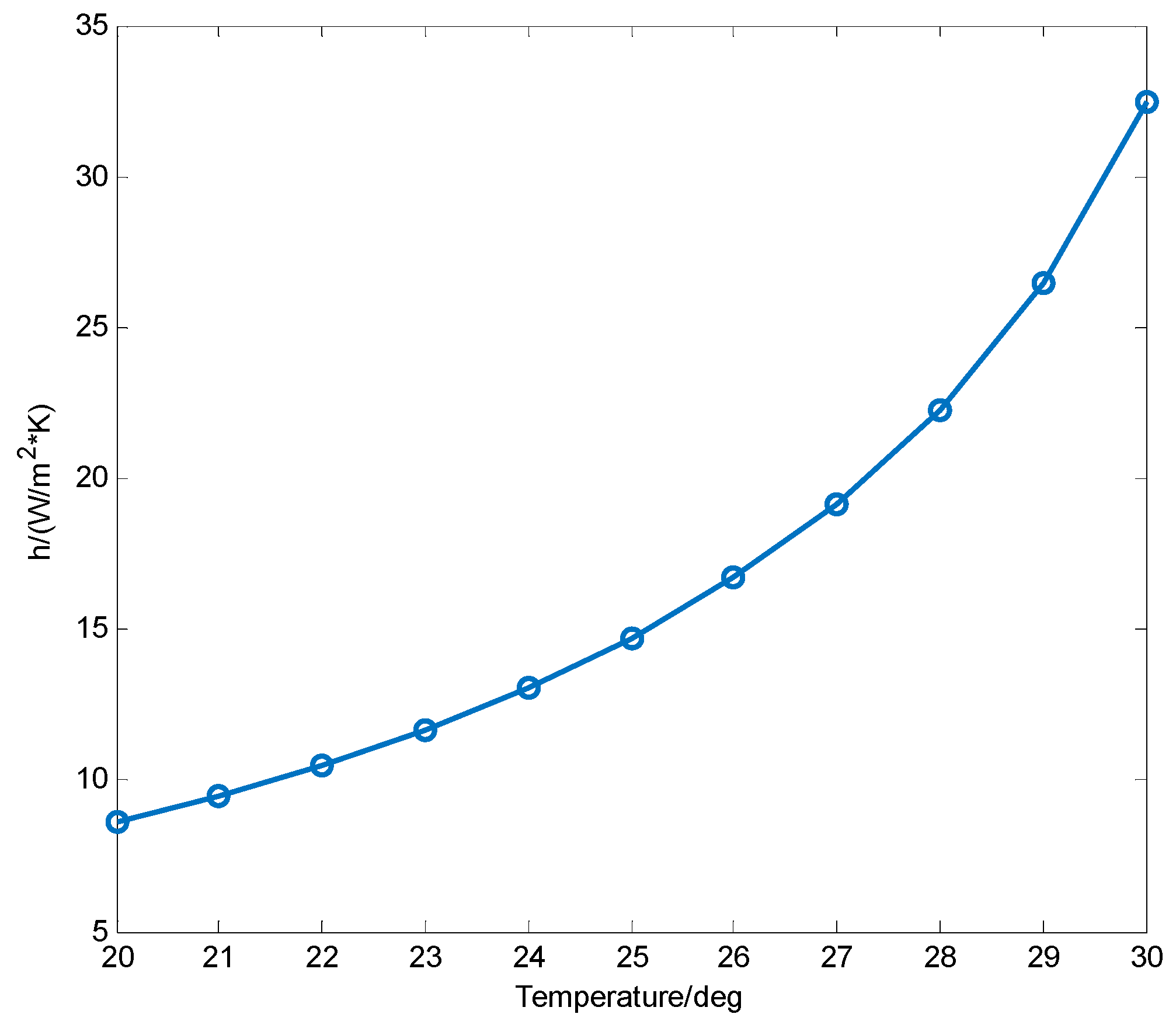

4.1. Optimum Heat Transfer Coefficient Analysis

4.2. Temperature Rise Analysis

4.2.1. Multiple Linear Regression Analysis

4.2.2. Significance Test of Regression Equation

5. Conclusions

- (1)

- Based on a lumped parameter thermal model, the thermal behavior of the cells was predicted, with different ambient temperature, heat transfer coefficient, and battery current values. The simulation and experimental results show that the model can accurately predict the change in the battery temperature, where the prediction error is less than 1 °C. In addition, in order to keep the temperature of the battery below 35 °C, the quantitative relationship between the optimum heat transfer coefficient and the ambient temperature of the battery was obtained. The results show that the heat transfer coefficient is the cubic power function of the ambient temperature, i.e., when the ambient temperature is 30 °C, the heat transfer coefficient should be at least 12 W/m2K under the operation conditions of the regular lines, 22 W/m2K under the operation conditions of the BRT lines, and 32 W/m2K under the operation conditions of the suburban lines.

- (2)

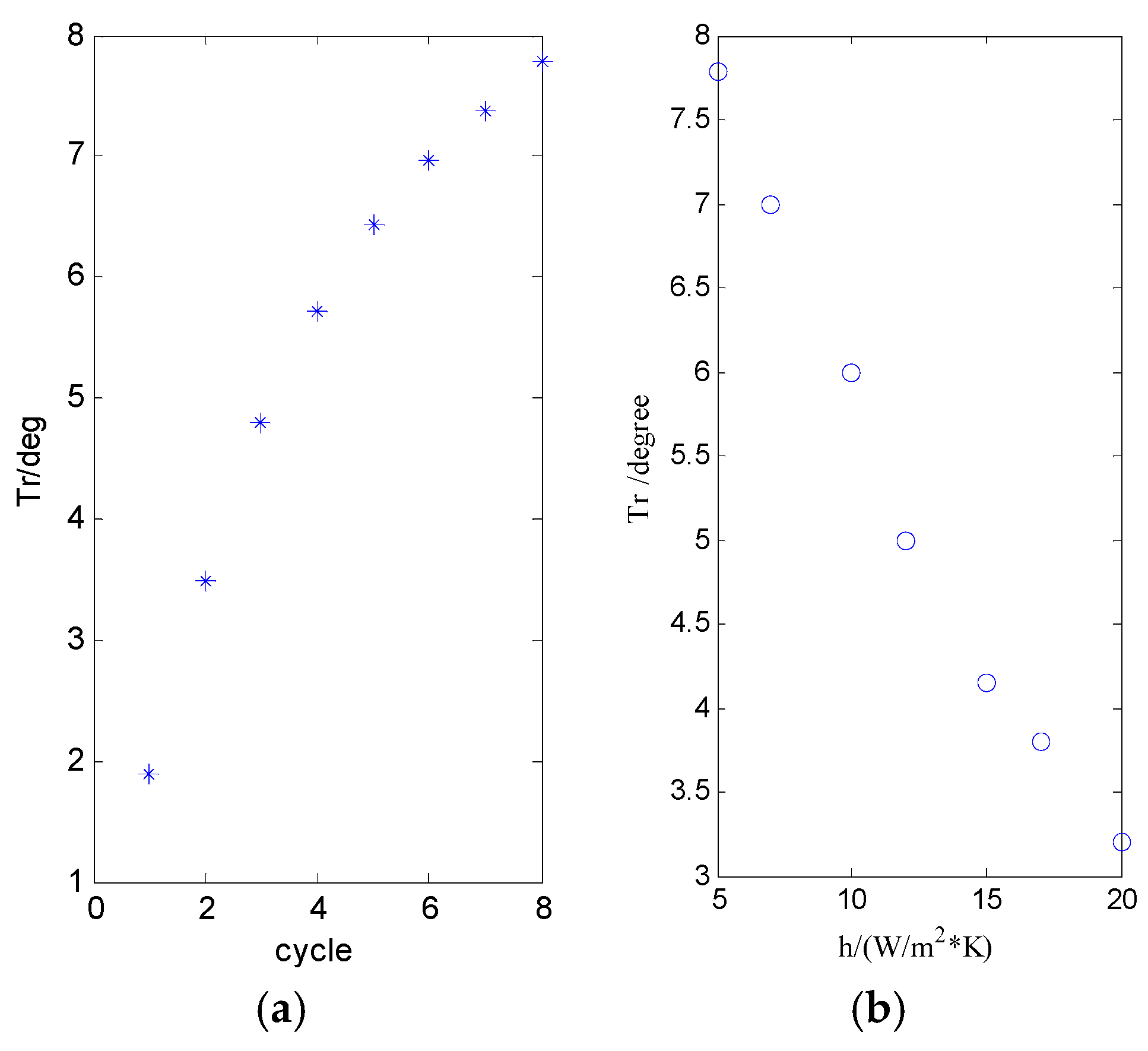

- When the ambient temperature is 30 °C, the relationship between the temperature rise (Tr), the number of cycles (c), and the heat transfer coefficient (h) under three Harbin bus cycles was investigated. The results show that the temperature rise (Tr) and the number of cycles (c), and the temperature rise (Tr) and the heat transfer coefficient (h) of the battery are approximately linear.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Chacko, S.; Charmer, S. Concept development and CAE for EV battery thermal management. In Proceedings of the IMechE Conference VTMS10 2011, Gaydon, UK, 15–19 May 2011. C1305-028. [Google Scholar]

- Yu, Q.; Xiong, R.; Lin, C.; Shen, W.; Deng, J. Lithium-ion battery parameters and state-of-charge joint estimation based on h infinity and unscented kalman filters. IEEE Trans. Veh. Technol. 2017, 66, 8693–8701. [Google Scholar] [CrossRef]

- Tourani, A.; White, P.; Ivey, P. A multi scale multi-dimensional thermo electrochemical modelling of high capacity lithium-ion cells. J. Power Sources 2014, 255, 360–367. [Google Scholar] [CrossRef]

- Lin, C.; Xu, S.; Li, Z.; Li, B.; Chang, G.; Liu, J. Thermal analysis of large-capacity LiFePO4 power batteries for electric vehicles. J. Power Sources 2015, 294, 633–642. [Google Scholar] [CrossRef]

- Jiang, F.; Peng, P.; Sun, Y. Thermal analyses of LiFePO4/graphite battery discharge processes. J. Power Sources 2013, 243, 181–194. [Google Scholar] [CrossRef]

- Du, S.; Jia, M.; Cheng, Y.; Tang, Y.; Zhang, H.; Ai, L.; Zhang, K.; Lai, Y. Study on the thermal behaviors of power lithium iron phosphate (LFP) aluminum-laminated battery with different tab configurations. Int. J. Therm. Sci. 2015, 89, 327–336. [Google Scholar] [CrossRef]

- Saw, L.H.; Somasundaram, K.; Ye, Y.; Tay, A.A.O. Electro-thermal analysis of Lithium Iron Phosphate battery for electric vehicles. J. Power Sources 2014, 249, 231–238. [Google Scholar] [CrossRef]

- Chacko, S.; Chung, Y.M. Thermal modelling of Li-ion polymer battery for electric vehicle drive cycles. J. Power Sources 2012, 213, 296–303. [Google Scholar] [CrossRef]

- Zou, C.; Manzie, C.; Nesic, D. A Framework for simplification of pde-based lithium-ion battery models. IEEE Trans. Control Syst. Technol. 2016, 24, 1594–1609. [Google Scholar] [CrossRef]

- Zou, C.; Hu, X.; Wei, Z.; Tang, X. Electrothermal dynamics-conscious lithium-ion battery cell-level charging management via state-monitored predictive control. Energy 2017, 141, 250–259. [Google Scholar] [CrossRef]

- Tourani, A.; White, P.; Ivey, P. Analysis of electric and thermal behaviour of lithium-ion cells in realistic driving cycles. J. Power Sources 2014, 268, 301–314. [Google Scholar] [CrossRef]

- Zhang, J.; Bin, W.U.; Zhe, L.I. Thermal modeling and thermal design of lithium-ion batteries for automotive application: Status and prospects. J. Integr. Technol. 2014, 3, 18–26. [Google Scholar]

- Jiaqiang, E.; Long, Y.; Wang, S. Thermal simulation on dynamic lithium-ion battery during charge and its grey relational analysis. J. Cent. South Univ. 2013, 44, 998–1005. [Google Scholar]

- Wu, X.; Lv, S. Determination of the optimum heat transfer coefficient for power battery thermal management system under the operation conditions of Harbin city bus driving cycles. In Proceedings of the International Symposium on Electric Vehicles, Stockholm, Sweden, 26–29 July 2017. [Google Scholar]

- Chen, C.; Xiong, R.; Shen, W. A lithium-ion battery-in-the-loop approach to test and validate multi-scale dual h infinity filters for state of charge and capacity estimation. IEEE Trans. Power Electron. 2018, 33, 332–342. [Google Scholar] [CrossRef]

- Wu, X.; Hu, C.; Du, J. Development of a driving cycle for city bus in Harbin of China. Int. J. Electr. Hybrid Veh. 2015, 7, 104–119. [Google Scholar] [CrossRef]

- Li, W.; Wang, J.; Yang, H.; Gu, Y.; Yang, H.; He, X. A Synchronverter-based V2G smart charging and discharging control strategy for electric vehicles. Proc. CSEE 2017, 37, 544–556. [Google Scholar]

- Song, Z.; Hofmann, H.; Li, J.; Hou, J.; Han, X.; Ouyang, M. Energy management strategies comparison for electric vehicles with hybrid energy storage system. Appl. Energy 2014, 134, 321–331. [Google Scholar] [CrossRef]

- Du, S.L.; Lai, Y.Q.; Jia, M.; Cheng, Y.; Zhang, H.L.; Zhang, K.; Liu, Y.X. Electrothermal characteristics simulation of cylindrical automotive lithium-ion battery. Chin. J. Nonferrous Met. 2014, 24, 1823–1830. [Google Scholar]

- Saw, L.H.; Ye, Y.; Tay, A.A.O. Electrochemical–thermal analysis of 18650 Lithium Iron Phosphate cell. Energy Convers. Manag. 2013, 75, 162–174. [Google Scholar] [CrossRef]

- Sun, J.; Wei, G.; Pei, L.; Lu, R.; Song, K.; Wu, C.; Zhu, C. Online internal temperature estimation for lithium-ion batteries based on kalman filter. Energies 2015, 8, 4400–4415. [Google Scholar] [CrossRef]

- Xiong, R.; Tian, J.; Mu, H.; Wang, C. A systematic model-based degradation behavior recognition and health monitoring method for lithium-ion batteries. Appl. Energy 2017. [Google Scholar] [CrossRef]

- Zou, C.; Manzie, C.; Nešić, D.; Kallapur, A.G. Multi-time-scale observer design for state-of-charge and state-of-health of a lithium-ion battery. J. Power Sources 2016, 335, 121–130. [Google Scholar] [CrossRef]

- Xiong, R.; Yu, Q.; Wang, L.Y.; Lin, C. A novel method to obtain the open circuit voltage for the state of charge of lithium ion batteries in electric vehicles by using H infinity filter. Appl. Energy 2017. [Google Scholar] [CrossRef]

- Ye, Y.; Shi, Y.; Tay, A.A.O. Electro-thermal cycle life model for lithium iron phosphate battery. J. Power Sources 2012, 217, 509–518. [Google Scholar] [CrossRef]

- Li, J.; Cheng, Y.; Jia, M.; Tang, Y.; Lin, Y.; Zhang, Z.; Liu, Y. An electrochemical-thermal model based on dynamic responses for lithium iron phosphate battery. J. Power Sources 2014, 255, 130–143. [Google Scholar] [CrossRef]

- Ye, Y.; Shi, Y.; Cai, N.; Lee, J.; He, X. Electro-thermal modeling and experimental validation for lithium ion battery. J. Power Sources 2012, 199, 227–238. [Google Scholar] [CrossRef]

- Melcher, A.; Ziebert, C.; Rohde, M.; Seifert, H. Modeling and simulation the thermal runaway behavior of cylindrical li-ion cells—Computing of critical parameter. Energies 2016, 9, 292. [Google Scholar] [CrossRef]

- Xu, M.; Zhang, Z.; Wang, X.; Jia, L.; Yang, L. A pseudo three-dimensional electrochemical-thermal model of a prismatic LiFePO4 battery during discharge process. Energy 2015, 80, 303–317. [Google Scholar] [CrossRef]

- Lai, Y.; Du, S.; Ai, L.; Ai, L.; Cheng, Y.; Tang, Y.; Jia, M. Insight into heat generation of lithium ion batteries based on the electrochemical-thermal model at high discharge rates. Int. J. Hydrogen Energy 2015, 40, 13039–13049. [Google Scholar] [CrossRef]

- Xiong, R.; Zhang, Y.; He, H.; Zhou, X.; Pecht, M.G. A double-scale, particle-filtering, energy state prediction algorithm for lithium-ion batteries. IEEE Trans. Ind. Electron. 2017, PP, 1. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| Mass/g | 45 |

| Radius/mm | 9 |

| Height/mm | 65 |

| Nominal capacity/Ah | 2.6 |

| Nominal voltage/V | 3.6 |

| Charge cutoff voltage/V | 4.2 |

| Discharge cutoff voltage/V | 2.75 |

| Average Speed (km/h) | Maximum Speed (km/h) | Maximum Acceleration (m/s2) | Maximum Deceleration (m/s2) | ||

|---|---|---|---|---|---|

| Regular lines | 19.17 | 51.4 | 1.33 | −1.61 | |

| BRT lines | 24.73 | 60.4 | 1.5 | −1.72 | |

| Suburban lines | 40.44 | 84.2 | 2.5 | −1.89 | |

| Parameter | Value |

|---|---|

| Length*width*height/m | 11.98*2.55*3.2 |

| curb weight/kg | 13,400 |

| Full load weight/kg | 18,000 |

| Minimum ground clearance/mm | 130 |

| Maximum braking distance/m | 10 |

| Minimum turning diameter/m | 24 |

| Tires | 275/70R22.5 |

| Curb quality/kg | 13,400 + 200 |

| Bearing quality/kg | 4300 |

| Windward area/m2 | 7.83 |

| Wheel rolling radius/m | 0.478 |

| Air resistance coefficient | 0.75 |

| Rolling resistance coefficient | 0.0076 + 0.000056ua |

| Air density/(kg/m3) | 1.23 |

| Main gear ratio | 6.2 |

| Total efficiency of the transmission system | 0.96 |

| Material | ki (W m−1 K−1) | ρi (kg m−3) | cp,i (J kg−1 K−1) |

|---|---|---|---|

| Separator [26] | 0.334 | 1009 | 1978.16 |

| Negative electrode | 1.04 [25,26,27] | 1347.33 [28] | 1437.4 [28] |

| Positive electrode | 1.58 [28] | 2328.5 [28] | 1269.21 [28] |

| Al [29] | 160 | 2700 | 903 |

| Cu [29] | 400 | 8900 | 385 |

| can [19] | 44.5 | 7850 | 475 |

| Arbin battery test system | Voltage range: 0 V–5 V Current range: 0 A –50 AVoltage accuracy: full-range ±0.5‰ FSR Current accuracy: full-range ±0.1‰ FSR Number of channels: 4 |

| Thermostat | Temperature range: −40–+150 °C Temperature error: <0.5 °C Chamber size: 0.5 m*0.5 m*0.6 m |

| Pico temperature acquisition device | Sensor type: K type thermocouple Temperature accuracy: ±0.2% reading and ±0.5 °C Conversion time: 100 ms resolution ratio: 20 bit Number of channels: 8 |

| r2 | Sy | ||

|---|---|---|---|

| Regular lines | 0.9347 | 0.3193 | |

| BRT lines | 0.9505 | 0.4523 | |

| Suburban lines | 0.8917 | 0.6978 | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, X.; Lv, S.; Chen, J. Determination of the Optimum Heat Transfer Coefficient and Temperature Rise Analysis for a Lithium-Ion Battery under the Conditions of Harbin City Bus Driving Cycles. Energies 2017, 10, 1723. https://doi.org/10.3390/en10111723

Wu X, Lv S, Chen J. Determination of the Optimum Heat Transfer Coefficient and Temperature Rise Analysis for a Lithium-Ion Battery under the Conditions of Harbin City Bus Driving Cycles. Energies. 2017; 10(11):1723. https://doi.org/10.3390/en10111723

Chicago/Turabian StyleWu, Xiaogang, Siyu Lv, and Jizhong Chen. 2017. "Determination of the Optimum Heat Transfer Coefficient and Temperature Rise Analysis for a Lithium-Ion Battery under the Conditions of Harbin City Bus Driving Cycles" Energies 10, no. 11: 1723. https://doi.org/10.3390/en10111723

APA StyleWu, X., Lv, S., & Chen, J. (2017). Determination of the Optimum Heat Transfer Coefficient and Temperature Rise Analysis for a Lithium-Ion Battery under the Conditions of Harbin City Bus Driving Cycles. Energies, 10(11), 1723. https://doi.org/10.3390/en10111723