A Rapid Method to Noninvasively Measure the Viscoelastic Properties of Synthetic Polymers Using Mechanical Vibrations and Photonics

Abstract

1. Introduction

2. Materials and Methods

2.1. Specimen Preparation

2.2. Measurement of Tensile Stress–Strain Curves of Silicone in Uniaxial Tension

2.3. Measurement of Polymer Elastic Modulus (Stiffness) and Sample Image

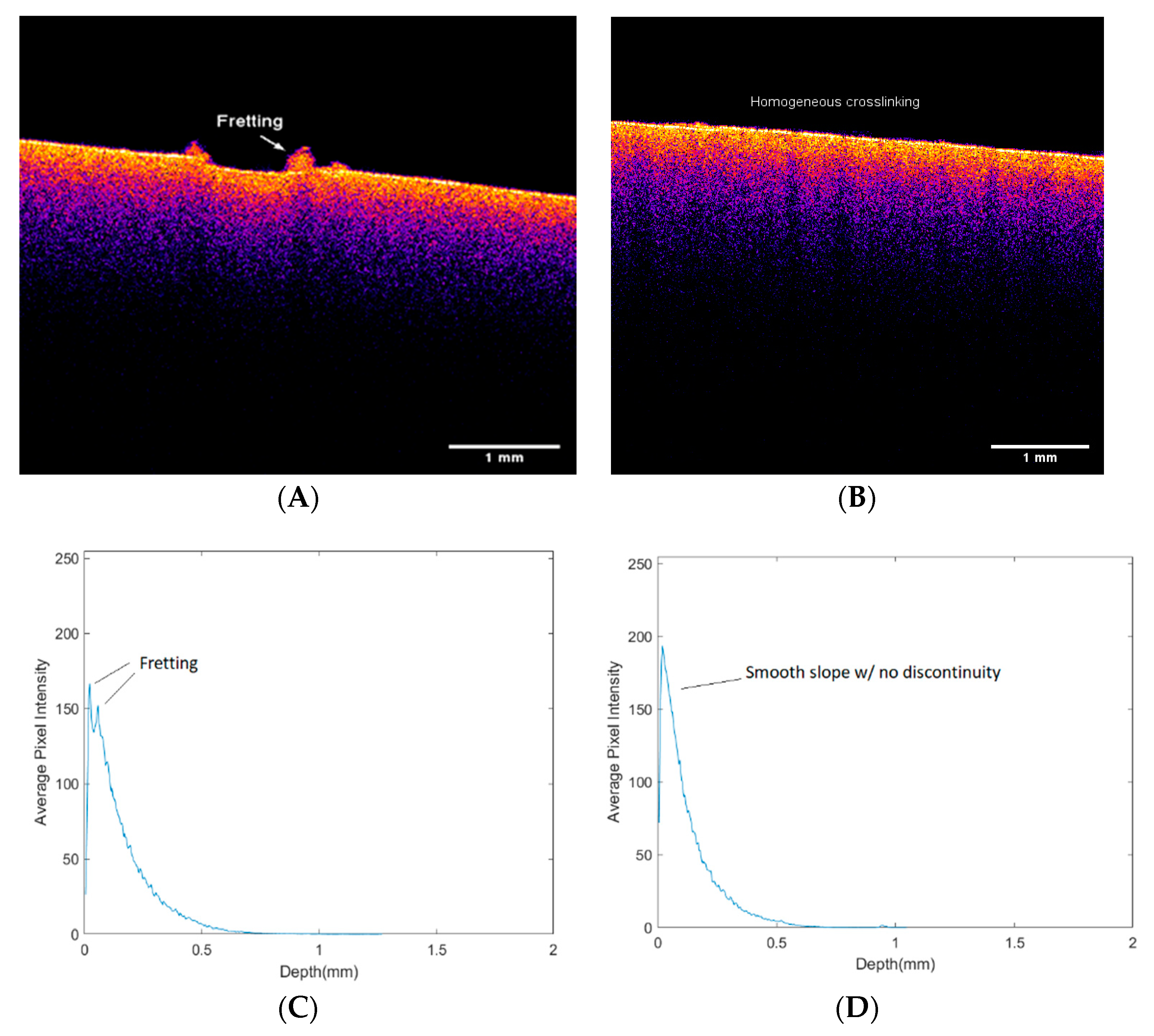

2.3.1. OCT Images of Filled Silicone Polymers

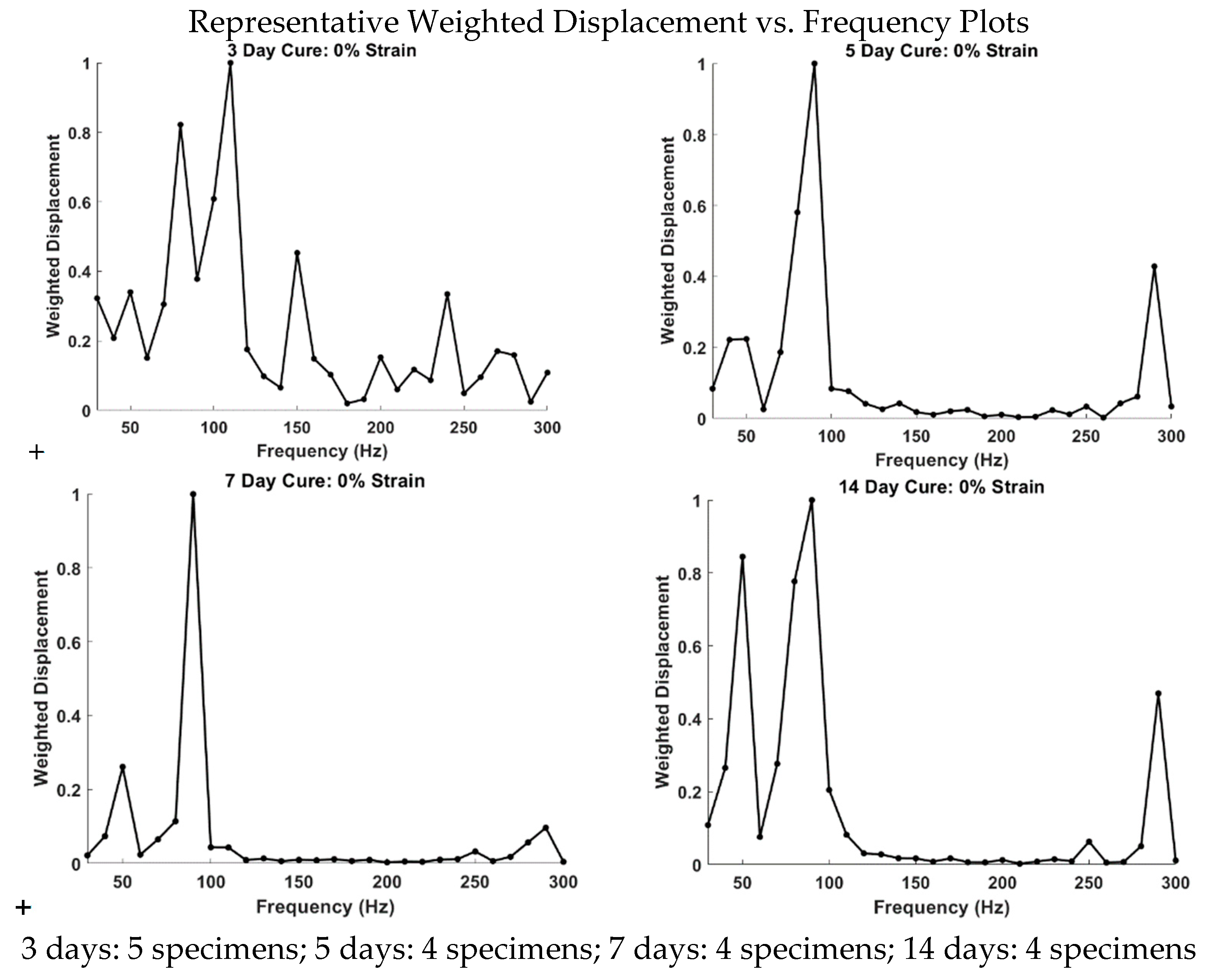

2.3.2. Measurement of Resonant Frequency and the Elastic Modulus

2.3.3. Measurement of Loss Modulus

2.4. Soft Polymeric Materials

3. Results

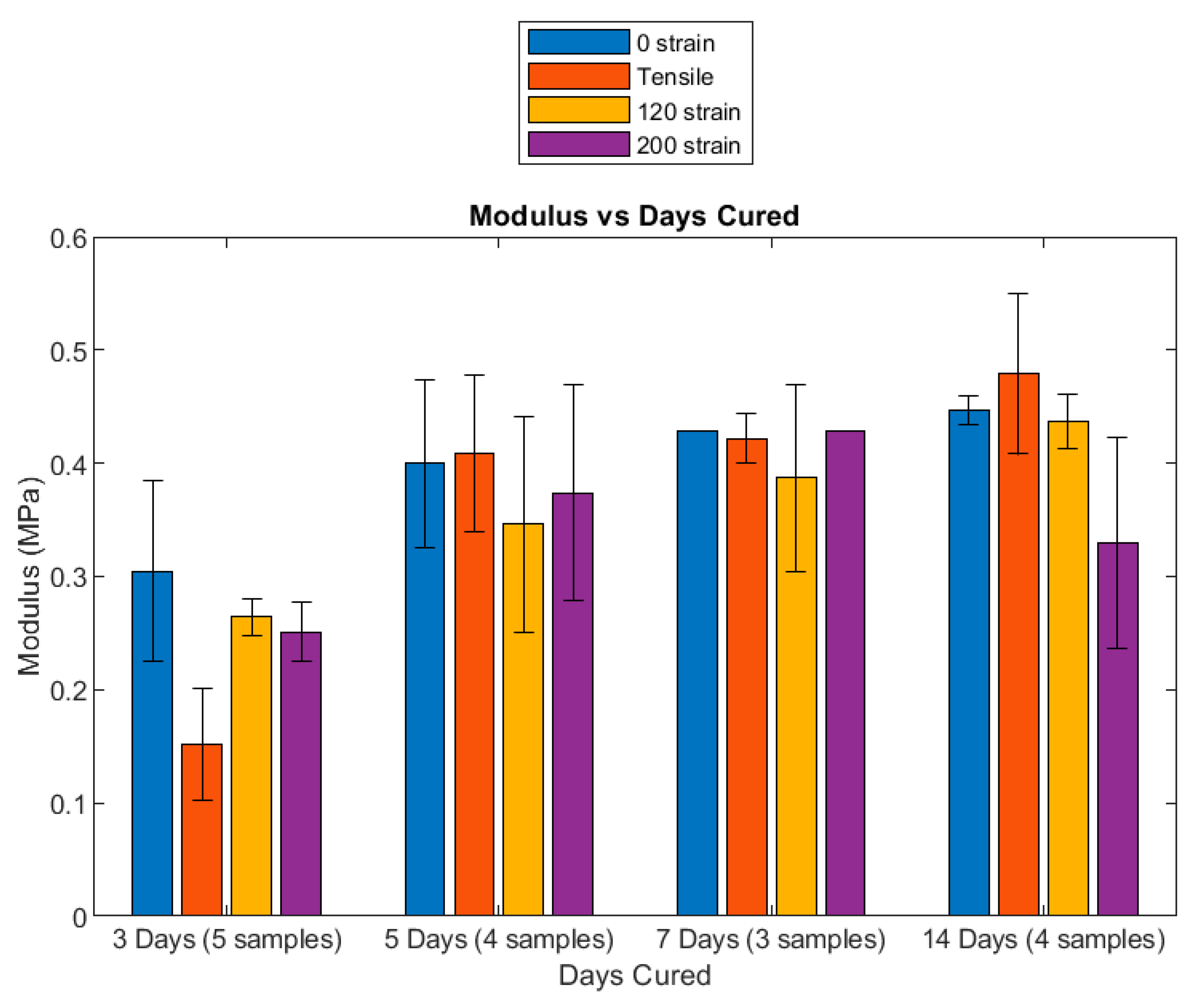

3.1. Characterization of Filled Silicone Polymers

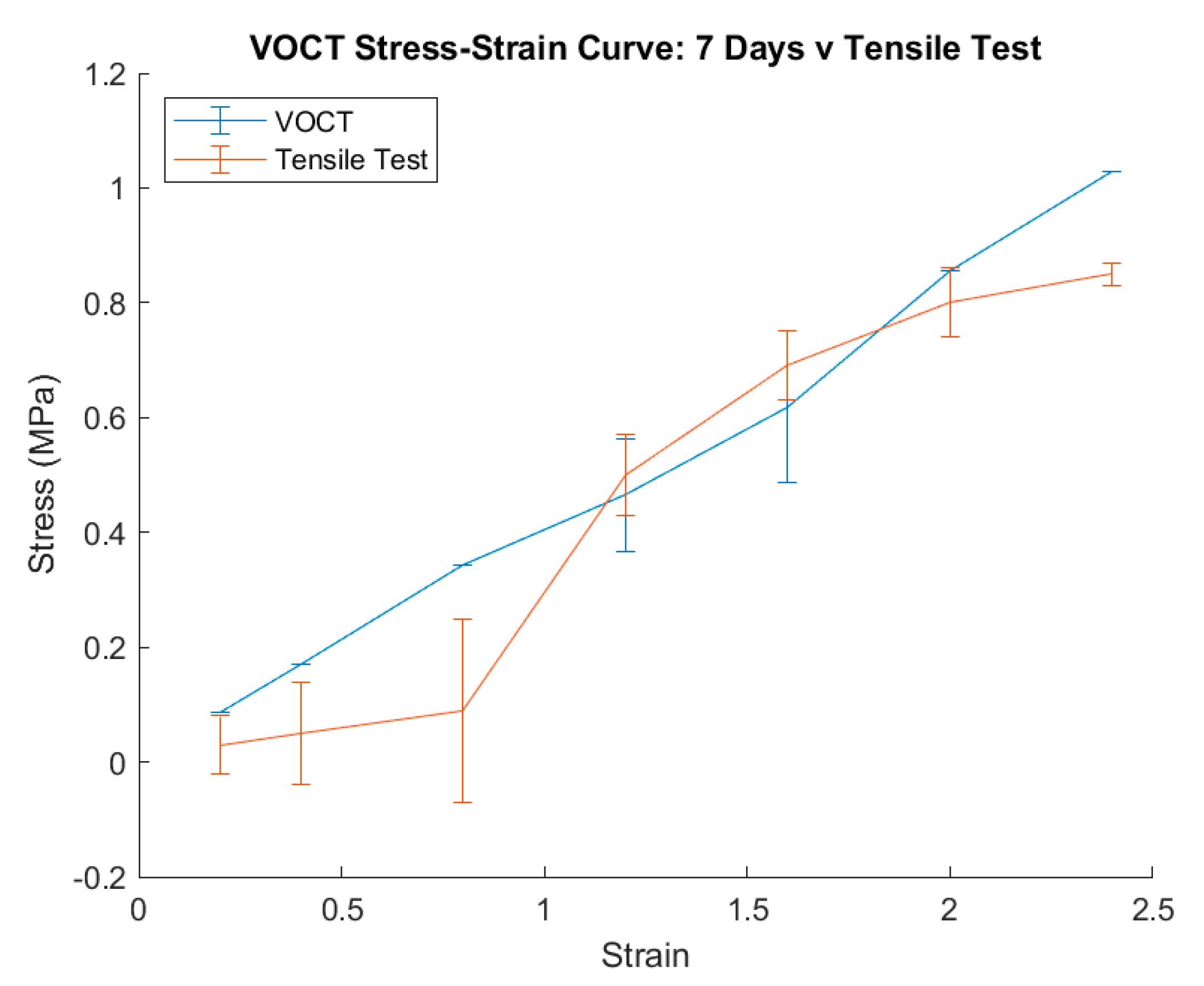

3.2. Tensile and VOCT Stress–Strain Curves of Silicone Specimens

3.3. Sample Inhomogeneity Detection Using VOCT

3.4. Loss Modulus as a Percent of Elastic Modulus

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Silver, F.H.; Shah, R.G.; Silver, L.L. The Use of Vibrational Optical Coherence Tomography in Matching Host Tissue and Implant Mechanical Properties. Biomater. Med. Appl. 2019, 2. [Google Scholar] [CrossRef]

- Silver, F.H.; Deshmukh, T.; Benedetto, D.; Kelkar, N. Mechano-vibrational spectroscopy of skin: Are changes in collagen and vascular tissue components early signs of basal cell carcinoma formation? Ski. Res. Technol. 2020, 27, 227–233. [Google Scholar] [CrossRef] [PubMed]

- Dunn, M.D.; Silver, F.H. Viscoelastic Behavior of Human Connective Tissues: Relative Contribution of Viscous and Elastic Components. Connect. Tissue Res. 1983, 12, 59–70. [Google Scholar] [CrossRef] [PubMed]

- Sotomayor-Del-Moral, J.A.; Pascual-Francisco, J.B.; Susarrey-Huerta, O.; Resendiz-Calderon, C.D.; Gallardo-Hernández, E.A.; Farfan-Cabrera, L.I. Moral of viscoelastic poisson’s ratio of engineering elastomers via DIC-based creep testing. Polymer 2022, 14, 1837. [Google Scholar] [CrossRef] [PubMed]

- Tirella, A.; Mattei, G.; Ahluwalia, A. Strain rate viscoelastic analysis of soft and highly hydrated biomaterials. J. Biomed. Mater. Res. Part A 2014, 102, 3352–3360. [Google Scholar] [CrossRef] [PubMed]

- Zhu, F.; Yasin, S.; Hussain, M. Dynamic oscillatory shear testing is used to investigate polymeric viscoelastic behavior. Viscoelastic Rheological Behaviors of Polypropylene and LMPP Blends. Polymers 2021, 13, 3485. [Google Scholar] [CrossRef] [PubMed]

- Yamashita, J.; Li, X.; Furman, B.; Rawis, H.R.; Wang, X.; Agrawal, C.M. Collagen and bone viscoelasticity: A dynamic mechanical analysis. J. Biomed. Mater. Res. 2002, 63, 31–36. [Google Scholar] [CrossRef] [PubMed]

- Chan, R.W. Nonlinear viscoelastic characterization of human vocal fold tissues under large-amplitude oscillatory shear (LAOS). J. Rheol. 2018, 62, 695–712. [Google Scholar] [CrossRef] [PubMed]

- Desrochers, J.M.W.; Amrein, M.W.; Matyas, J.R.; Desrochers, J. Viscoelasticity of the articular cartilage surface in early osteoarthritis. Osteoarthr. Cartil. 2012, 20, 413–421. [Google Scholar] [CrossRef] [PubMed]

- Griffin, D.J.; Vicari, J.; Buckley, M.R.; Silverberg, J.L.; Cohen, I.; Bonassar, L.J. Effects of Enzymatic Treatments on the Depth-Dependent Viscoelastic Shear Properties of Articular Cartilage. J. Orthop. Res. 2014, 32, 1652–1657. [Google Scholar] [CrossRef] [PubMed]

- Han, H.; Frank, E.; Greene, J.; Lee, H.-Y.; Grodzinsky, A.; Ortiz, L. Time-Dependent Nanomechanics of Cartilage. Biophys. J. 2011, 100, 1846–1854. [Google Scholar] [CrossRef] [PubMed]

- Hong, X.; Ramkumar, A.; Kemerer, T.S.; Deng, C.X.; Stegemann, J.P. Multimode ultrasound viscoelastography for three-dimensional interrogation of microscale mechanical properties in heterogeneous biomaterials. J. Biomater. 2018, 178, 11–22. [Google Scholar] [CrossRef] [PubMed]

- Miri, A.K.; Heris, H.K.; Mongeau, L.; Fa Miri, F.J. Nanoscale Viscoelasticity of Extracellular Matrix Proteins in Soft Tissues: A Multiscale Approach. J. Mech. Behav. Biomed. Mater. 2014, 30, 196–204. [Google Scholar] [CrossRef] [PubMed]

- Norberg, C.; Filippone, G.; Andreopoulos, F.; Best, T.M.; Baraga, M.; Alicia RJackson, A.R.; Travascio, F. Viscoelastic and equilibrium shear properties of human meniscus: Relationship with tissue structure and composition. J. Biomech. 2021, 120, 110343. [Google Scholar] [CrossRef] [PubMed]

- Shah, R.G.; Devore, D.; Pierce, M.C.; Silver, F.H. Vibrational analysis of implants and tissues: Calibration and spectroscopy of multi-component materials. J. Biomed. Mater. Res.—Part A 2017, 105, 1666–1671. [Google Scholar] [CrossRef]

- Silver, F.H.; Kelkar, N.; Deshmukh, T.; Ritter, N.; Ryan, N.; Nadiminiti, H. Characterization of the biomechanical properties of skin using vibrational optical coherence tomography: Do changes in the biomechanical properties of skin stroma reflect structural changes in the extracellular matrix of cancerous lesions? Biomolecules 2021, 11, 1712. [Google Scholar] [CrossRef] [PubMed]

- Silver, F.H.; Kelkar, N.; Desmukh, T.; Horvath, I.; Shah, R.G. Mechano-Vibrational Spectroscopy of Tissues and Materials Using Vibrational Optical Coherence Tomography: A New Non-Invasive and Non-Destructive Technique. Recent Prog. Mater. 2020, 2, 010. [Google Scholar] [CrossRef]

- Shabana, A.A. Theory of Vibration, 3rd ed.; Springer: Berlin/Heidelberg, Germany, 2019; pp. 338–342. [Google Scholar]

- Silver, F.H.; Shah, R.G.; Benedetto, D.; Dular, A.; Kirn, T. Virtual Biopsy and Physical Characterization of Tissues, Biofilms, Implants, and Viscoelastic Liquids Using Vibrational Optical Coherence Tomography. World J. Mech. 2019, 9, 1–16. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Silver, F.H.; Gonzalez-Mercedes, M.; Mesica, A. A Rapid Method to Noninvasively Measure the Viscoelastic Properties of Synthetic Polymers Using Mechanical Vibrations and Photonics. Photonics 2022, 9, 925. https://doi.org/10.3390/photonics9120925

Silver FH, Gonzalez-Mercedes M, Mesica A. A Rapid Method to Noninvasively Measure the Viscoelastic Properties of Synthetic Polymers Using Mechanical Vibrations and Photonics. Photonics. 2022; 9(12):925. https://doi.org/10.3390/photonics9120925

Chicago/Turabian StyleSilver, Frederick H., Michael Gonzalez-Mercedes, and Arielle Mesica. 2022. "A Rapid Method to Noninvasively Measure the Viscoelastic Properties of Synthetic Polymers Using Mechanical Vibrations and Photonics" Photonics 9, no. 12: 925. https://doi.org/10.3390/photonics9120925

APA StyleSilver, F. H., Gonzalez-Mercedes, M., & Mesica, A. (2022). A Rapid Method to Noninvasively Measure the Viscoelastic Properties of Synthetic Polymers Using Mechanical Vibrations and Photonics. Photonics, 9(12), 925. https://doi.org/10.3390/photonics9120925