Fractionation and Extraction Optimization of Potentially Valuable Compounds and Their Profiling in Six Varieties of Two Nicotiana Species

Abstract

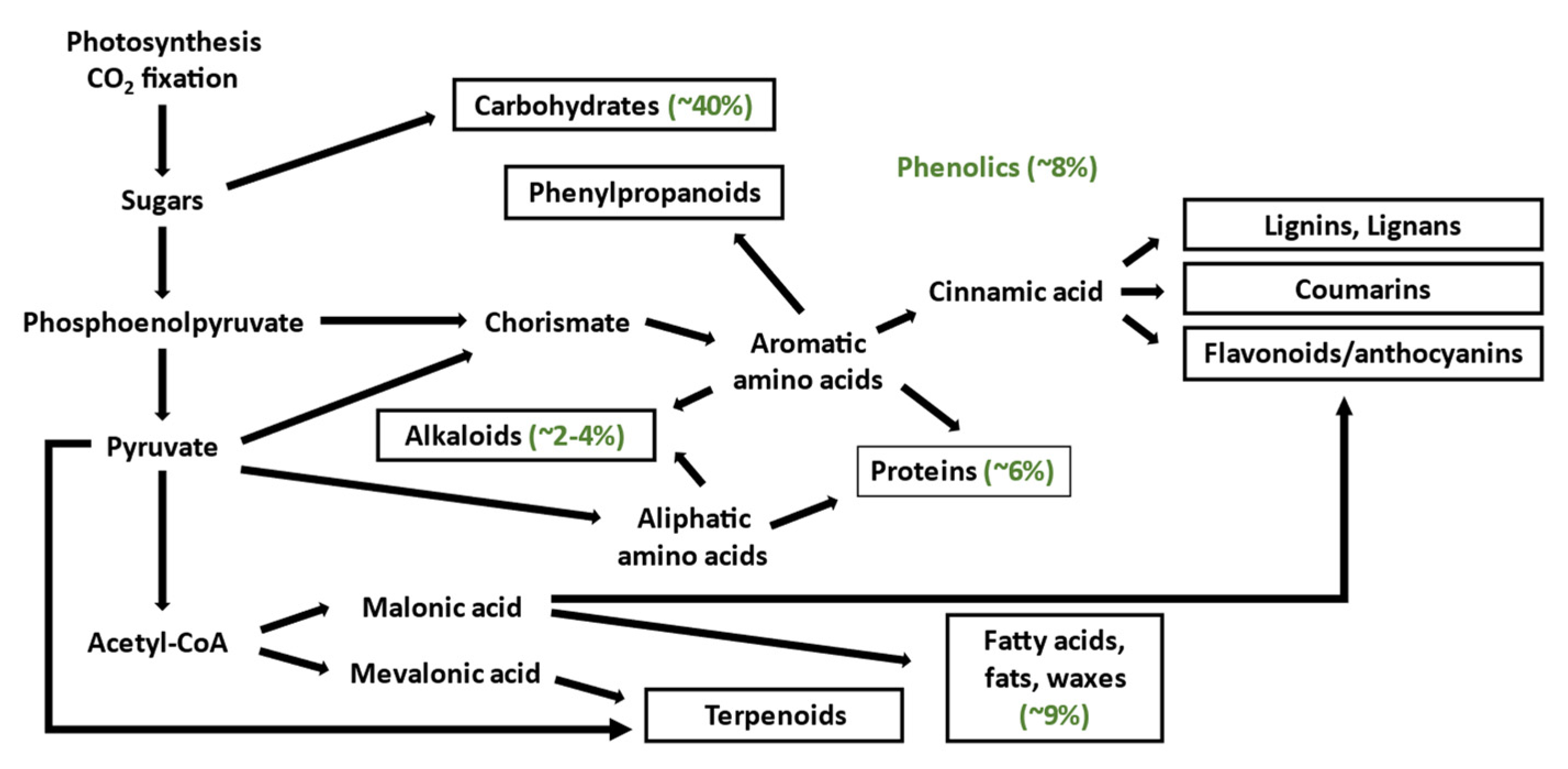

1. Introduction

1.1. Alkaloids

1.2. Rutin

1.3. Chlorogenic Acids

1.4. Ferulic Acid

1.5. Zeatin

1.6. Linoleic Acid

1.7. Neopytadiene

1.8. Experimental Approach

2. Results

2.1. Rapid Solubility Test of Potentially Valuable Compounds

2.2. Coverage by High-Resolution Microfractionation

2.3. Single Solvent Extraction Optimization

2.4. Profiling of Six Nicotiana Varieties for Potentially Valuable Compounds

2.5. Projected Yield of Potentially Valuable Compounds in Six Nicotiana Varieties

3. Discussion

4. Materials and Methods

4.1. Plant Sample Generation

4.2. Reagents and Chemicals

4.3. Rapid Solubility Test of Potentially Valuable Compounds

4.4. Microfractionation

4.5. Extraction Method Optimization

4.6. Solvent Extraction from Six Tobacco Varieties

4.7. Potentially Valuable Compound Quantification by LC-HR-MS

4.7.1. LC-HR-MS Method 1

4.7.2. LC-HR-MS Method 2

4.7.3. LC-HR-MS Method 3

4.7.4. LC-HR-MS Method 4

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Winter, J.C. Tobacco Use by Native North Americans: Sacred Smoke and Silent Killer; University of Oklahoma Press: Norman, OK, USA, 2000; Volume 236. [Google Scholar]

- Lamottke, K.; Ripoll, C.; Walczak, R. The Roots of Innovation. Eur. Biopharm. Rev. 2011, 15, 52–56. [Google Scholar]

- Sierro, N.; Battey, J.N.; Ouadi, S.; Bakaher, N.; Bovet, L.; Willig, A.; Goepfert, S.; Peitsch, M.C.; Ivanov, N.V. The tobacco genome sequence and its comparison with those of tomato and potato. Nat. Commun. 2014, 5, 3833. [Google Scholar] [CrossRef] [PubMed]

- Alan Rodgman, T.A.P. The Chemical Components of Tobacco and Tobacco Smoke. In The Chemical Components of Tobacco and Tobacco Smoke; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Nugroho, L.H.; Verpoorte, R. Secondary metabolism in tobacco. Plant Cell Tissue Organ Cult. 2002, 68, 105–125. [Google Scholar] [CrossRef]

- Lu, X.; Tang, K.; Li, P. Plant Metabolic Engineering Strategies for the Production of Pharmaceutical Terpenoids. Front. Plant Sci. 2016, 7, 1647. [Google Scholar] [CrossRef] [PubMed]

- Davis, D.L.; Nielsen, M.T. Tobacco: Production Chemistry and Technology; Blackwell Science: Oxford, UK, 1999. [Google Scholar]

- Fernandez-Pozo, N.; Menda, N.; Edwards, J.D.; Saha, S.; Tecle, I.Y.; Strickler, S.R.; Bombarely, A.; Fisher-York, T.; Pujar, A.; Foerster, H.; et al. The Sol Genomics Network (SGN)—From genotype to phenotype to breeding. Nucleic Acids Res. 2015, 43, D1036–D1041. [Google Scholar] [CrossRef]

- Sisson, V.; Severson, R. Alkaloid Composition of the Nicotiana Species. Beiträge Tab. Int. 1990, 14, 327. [Google Scholar] [CrossRef]

- Kaminski, K.P.; Bovet, L.; Laparra, H.; Lang, G.; De Palo, D.; Sierro, N.; Goepfert, S.; Ivanov, N.V. Alkaloid chemophenetics and transcriptomics of the Nicotiana genus. Phytochemistry 2020, 177, 112424. [Google Scholar] [CrossRef]

- Dewey, R.E.; Xie, J. Molecular genetics of alkaloid biosynthesis in Nicotiana tabacum. Phytochemistry 2013, 94, 10–27. [Google Scholar] [CrossRef]

- Katoh, A.; Uenohara, K.; Akita, M.; Hashimoto, T. Early Steps in the Biosynthesis of NAD in Arabidopsis Start with Aspartate and Occur in the Plastid. Plant Physiol. 2006, 141, 851–857. [Google Scholar] [CrossRef]

- Sinclair, S.J.; Murphy, K.J.; Birch, C.D.; Hamill, J.D. Molecular characterization of quinolinate phosphoribosyltransferase (QPRTase) in Nicotiana. Plant Mol. Biol. 2000, 44, 603–617. [Google Scholar] [CrossRef]

- DeBoer, K.D.; Dalton, H.L.; Edward, F.J.; Hamill, J.D. RNAi-mediated down-regulation of ornithine decarboxylase (ODC) leads to reduced nicotine and increased anatabine levels in transgenic Nicotiana tabacum L. Phytochemistry 2011, 72, 344–355. [Google Scholar] [CrossRef] [PubMed]

- Imanishi, S.; Hashizume, K.; Nakakita, M.; Kojima, H.; Matsubayashi, Y.; Hashimoto, T.; Sakagami, Y.; Yamada, Y.; Nakamura, K. Differential induction by methyl jasmonate of genes encoding ornithine decarboxylase and other enzymes involved in nicotine biosynthesis in tobacco cell cultures. Plant Mol. Biol. 1998, 38, 1101–1111. [Google Scholar] [CrossRef] [PubMed]

- Malmberg, R.L.; Watson, M.B.; Galloway, G.L.; Yu, W. Molecular Genetic Analyses of Plant Polyamines. Crit. Rev. Plant Sci. 1998, 17, 199–224. [Google Scholar] [CrossRef]

- Hibi, N.; Higashiguchi, S.; Hashimoto, T.; Yamada, Y. Gene expression in tobacco low-nicotine mutants. Plant Cell 1994, 6, 723–735. [Google Scholar] [CrossRef]

- Riechers, D.E.; Timko, M.P. Structure and expression of the gene family encoding putrescine N-methyltransferase in Nicotiana tabacum: New clues to the evolutionary origin of cultivated tobacco. Plant Mol. Biol. 1999, 41, 387–401. [Google Scholar] [CrossRef]

- Heim, W.G.; Sykes, K.A.; Hildreth, S.B.; Sun, J.; Lu, R.-H.; Jelesko, J.G. Cloning and characterization of a Nicotiana tabacum methylputrescine oxidase transcript. Phytochemistry 2007, 68, 454–463. [Google Scholar] [CrossRef]

- Katoh, A.; Shoji, T.; Hashimoto, T. Molecular Cloning of N -methylputrescine Oxidase from Tobacco. Plant Cell Physiol. 2007, 48, 550–554. [Google Scholar] [CrossRef]

- Deboer, K.D.; Lye, J.C.; Aitken, C.D.; Su, A.K.; Hamill, J.D. The A622 gene in Nicotiana glauca (tree tobacco): Evidence for a functional role in pyridine alkaloid synthesis. Plant Mol. Biol. 2009, 69, 299–312. [Google Scholar] [CrossRef]

- Kajikawa, M.; Hirai, N.; Hashimoto, T. A PIP-family protein is required for biosynthesis of tobacco alkaloids. Plant Mol. Biol. 2009, 69, 287–298. [Google Scholar] [CrossRef]

- Brent Friesen, J.; Leete, E. Nicotine synthase—an enzyme from nicotiana species which catalyzes the formation of (S)-nicotine from nicotinic acid and 1-methyl-δ’pyrrolinium chloride. Tetrahedron Lett. 1990, 31, 6295–6298. [Google Scholar] [CrossRef]

- Gavilano, L.B.; Siminszky, B. Isolation and Characterization of the Cytochrome P450 Gene CYP82E5v2 that Mediates Nicotine to Nornicotine Conversion in the Green Leaves of Tobacco. Plant Cell Physiol. 2007, 48, 1567–1574. [Google Scholar] [CrossRef] [PubMed]

- Lewis, R.S.; Bowen, S.W.; Keogh, M.R.; Dewey, R.E. Three nicotine demethylase genes mediate nornicotine biosynthesis in Nicotiana tabacum L.: Functional characterization of the CYP82E10 gene. Phytochemistry 2010, 71, 1988–1998. [Google Scholar] [CrossRef] [PubMed]

- Liedschulte, V.; Schwaar, J.D.; Laparra, H.; Vuarnoz, A.; Philippon, B.; Bakaher, N.; Sierro, N.; Bovet, L.; Lang, G.; Goepfert, S. Identification of CYP82E21 as a functional nicotine N-demethylase in tobacco flowers. Phytochemistry 2016, 131, 9–16. [Google Scholar] [CrossRef] [PubMed]

- Poupon, E.; Salame, R.; Yan, L.-H. Biomimetic Synthesis of Ornithine/Arginine and Lysine-Derived Alkaloids: Selected Examples. In Biomimetic Organic Synthesis; Wiley-VCH: Weinheim, Germany, 2011; pp. 1–60. [Google Scholar] [CrossRef]

- Leete, E.; Mueller, M.E. Biomimetic synthesis of anatabine from 2,5-dihydropyridine produced by the oxidative decarboxylation of baikiain. J. Am. Chem. Soc. 1982, 104, 6440–6444. [Google Scholar] [CrossRef]

- Leete, E.; Slattery, S.A. Incorporation of [2-14C]-and [6-14C]nicotinic acid into the tobacco alkaloids. Biosynthesis of anatabine and alpha, beta-dipyridyl. J. Am. Chem. Soc. 1976, 98, 6326–6330. [Google Scholar] [CrossRef] [PubMed]

- Solt, M.L.; Dawson, R.F.; Christman, D.R. Biosynthesis of Anabasine and of Nicotine by Excised Root Cultures of Nicotiana Glauca. Plant Physiol. 1960, 35, 887–894. [Google Scholar] [CrossRef]

- Bunsupa, S.; Komastsu, K.; Nakabayashi, R.; Saito, K.; Yamazaki, M. Revisiting anabasine biosynthesis in tobacco hairy roots expressing plant lysine decarboxylase gene by 15N-labeled lysine. Plant Biotechnol. 2014, 31, 511–518. [Google Scholar] [CrossRef]

- Shoji, T.; Hashimoto, T. Why does Anatabine, But not Nicotine, Accumulate in Jasmonate-Elicited Cultured Tobacco BY-2 Cells? Plant Cell Physiol. 2008, 49, 1209–1216. [Google Scholar] [CrossRef][Green Version]

- Bartholomeusz, T.A.; Bhogal, R.K.; Molinie, R.; Felpin, F.X.; Mathe-Allainmat, M.; Meier, A.C.; Drager, B.; Lebreton, J.; Roscher, A.; Robins, R.J.; et al. Nicotine demethylation in Nicotiana cell suspension cultures: N’-formylnornicotine is not involved. Phytochemistry 2005, 66, 2432–2440. [Google Scholar] [CrossRef]

- Botte, M.; Mabon, F.; Le Mouillour, M.; Robins, R.J. Biosynthesis of nornicotine in root cultures of Nicotiana alata does not involve oxidation at C-5′ of nicotine. Phytochemistry 1997, 46, 117–122. [Google Scholar] [CrossRef]

- Sun, B.; Zhang, F.; Zhou, G.J.; Chu, G.H.; Huang, F.F.; Wang, Q.M.; Jin, L.F.; Lin, F.C.; Yang, J. Genetic variation in alkaloid accumulation in leaves of Nicotiana. J. Zhejiang Univ. Sci. B 2013, 14, 1100–1109. [Google Scholar] [CrossRef] [PubMed]

- Kjsaki, T.; Tamaki, E. Phytochemical Studies on the tobacco alkaloids—X: Degradation of the tobacco alkaloids and their optical rotatory changes in tobacco plants. Phytochemistry 1966, 5, 293–300. [Google Scholar] [CrossRef]

- Leete, E.; Chedekel, M.R. Metabolism of nicotine in Nicotiana glauca. Phytochemistry 1974, 13, 1853–1859. [Google Scholar] [CrossRef]

- Tan, X.; Vrana, K.; Ding, Z.M. Cotinine: Pharmacologically Active Metabolite of Nicotine and Neural Mechanisms for Its Actions. Front. Behav. Neurosci. 2021, 15, 758252. [Google Scholar] [CrossRef]

- Rennick, A.; Kalakeche, R.; Seel, L.; Shepler, B. Nicotinic acid and nicotinamide: A review of their use for hyperphosphatemia in dialysis patients. Pharmacotherapy 2013, 33, 683–690. [Google Scholar] [CrossRef] [PubMed]

- Robins, R.J.; Hamill, J.D.; Parr, A.J.; Smith, K.; Walton, N.J.; Rhodes, M.J.C. Potential for use of nicotinic acid as a selective agent for isolation of high nicotine-producing lines of Nicotiana rustica hairy root cultures. Plant Cell Rep. 1987, 6, 122–126. [Google Scholar] [CrossRef]

- Fu, B.; Ji, X.; Zhao, M.; He, F.; Wang, X.; Wang, Y.; Liu, P.; Niu, L. The influence of light quality on the accumulation of flavonoids in tobacco (Nicotiana tabacum L.) leaves. J. Photochem. Photobiol. B 2016, 162, 544–549. [Google Scholar] [CrossRef]

- Winkel-Shirley, B. Biosynthesis of flavonoids and effects of stress. Curr. Opin. Plant Biol. 2002, 5, 218–223. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, S.; Wu, M.; Li, Z.; Liu, P.; Li, F.; Chen, Q.; Yang, A.; Yang, J. Evolutionary and functional analyses of the 2-oxoglutarate-dependent dioxygenase genes involved in the flavonoid biosynthesis pathway in tobacco. Planta 2018, 249, 543–561. [Google Scholar] [CrossRef]

- Sun, Y.; Li, W.; Wang, J.; Bi, J.; Su, S. Determination of rutin in cigarette tobacco, filters, mainstream smoke and burned ash of different branded cigarettes by high performance liquid chromatography. Molecules 2012, 17, 3751–3760. [Google Scholar] [CrossRef]

- Dias, M.I.; Sousa, M.J.; Alves, R.C.; Ferreira, I.C.F.R. Exploring plant tissue culture to improve the production of phenolic compounds: A review. Ind. Crops Prod. 2016, 82, 9–22. [Google Scholar] [CrossRef]

- Trantas, E.A.; Koffas, M.A.; Xu, P.; Ververidis, F. When plants produce not enough or at all: Metabolic engineering of flavonoids in microbial hosts. Front. Plant Sci. 2015, 6, 7. [Google Scholar] [CrossRef] [PubMed]

- Patel, K.; Patel, D.K. Chapter 26—The Beneficial Role of Rutin, A Naturally Occurring Flavonoid in Health Promotion and Disease Prevention: A Systematic Review and Update. In Bioactive Food as Dietary Interventions for Arthritis and Related Inflammatory Diseases, 2nd ed.; Watson, R.R., Preedy, V.R., Eds.; Academic Press: Cambridge, MA, USA, 2019; pp. 457–479. [Google Scholar] [CrossRef]

- Tamarkin, D.; Friedman, D.; Eini, M.; Berman, T.; Schuz, D. Foamable Vehicle and Vitamin and Flavonoid Pharmaceutical Compositions Thereof. U.S. Patent 20080069779A1, 9 October 2007. [Google Scholar]

- Tajik, N.; Tajik, M.; Mack, I.; Enck, P. The potential effects of chlorogenic acid, the main phenolic components in coffee, on health: A comprehensive review of the literature. Eur. J. Nutr. 2017, 56, 2215–2244. [Google Scholar] [CrossRef] [PubMed]

- Naveed, M.; Hejazi, V.; Abbas, M.; Kamboh, A.A.; Khan, G.J.; Shumzaid, M.; Ahmad, F.; Babazadeh, D.; FangFang, X.; Modarresi-Ghazani, F.; et al. Chlorogenic acid (CGA): A pharmacological review and call for further research. Biomed. Pharmacother. 2018, 97, 67–74. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Wang, J.; Ballevre, O.; Luo, H.; Zhang, W. Antihypertensive effects and mechanisms of chlorogenic acids. Hypertens. Res. 2012, 35, 370–374. [Google Scholar] [CrossRef] [PubMed]

- Liang, N.; Kitts, D.D. Role of Chlorogenic Acids in Controlling Oxidative and Inflammatory Stress Conditions. Nutrients 2015, 8, 16. [Google Scholar] [CrossRef]

- Luo, J.; He, W.; Li, X.; Ji, X.; Liu, J. Anti-acne vulgaris effects of chlorogenic acid by anti-inflammatory activity and lipogenesis inhibition. Exp. Dermatol. 2021, 30, 865–871. [Google Scholar] [CrossRef]

- Shifflett, J.R.; Watson, L.; McNally, D.J.; Bezabeh, D.Z. Analysis of the Polyphenols of Tobacco Using Pressurized Liquid Extraction (PLE) and Ultra Performance Liquid Chromatography With Electrospray Ionization—Tandem Mass Spectometric Detection (UPLC-ESI-MS/MS). Contrib. Tob. Nicotine Res. 2017, 27, 195–207. [Google Scholar] [CrossRef]

- Kwon, S.H.; Lee, H.K.; Kim, J.A.; Hong, S.I.; Kim, H.C.; Jo, T.H.; Park, Y.I.; Lee, C.K.; Kim, Y.B.; Lee, S.Y.; et al. Neuroprotective effects of chlorogenic acid on scopolamine-induced amnesia via anti-acetylcholinesterase and anti-oxidative activities in mice. Eur. J. Pharmacol. 2010, 649, 210–217. [Google Scholar] [CrossRef]

- Kitagawa, S.; Yoshii, K.; Morita, S.Y.; Teraoka, R. Efficient topical delivery of chlorogenic acid by an oil-in-water microemulsion to protect skin against UV-induced damage. Chem. Pharm. Bull. 2011, 59, 793–796. [Google Scholar] [CrossRef]

- Abraham, S.K.; Sarma, L.; Kesavan, P.C. Protective effects of chlorogenic acid, curcumin and beta-carotene against gamma-radiation-induced in vivo chromosomal damage. Mutat. Res. 1993, 303, 109–112. [Google Scholar] [CrossRef]

- Cho, A.S.; Jeon, S.M.; Kim, M.J.; Yeo, J.; Seo, K.I.; Choi, M.S.; Lee, M.K. Chlorogenic acid exhibits anti-obesity property and improves lipid metabolism in high-fat diet-induced-obese mice. Food Chem. Toxicol. 2010, 48, 937–943. [Google Scholar] [CrossRef] [PubMed]

- Zatorski, H.; Sałaga, M.; Zielińska, M.; Piechota-Polańczyk, A.; Owczarek, K.; Kordek, R.; Lewandowska, U.; Chen, C.; Fichna, J. Experimental colitis in mice is attenuated by topical administration of chlorogenic acid. Naunyn-Schmiedebergs Arch. Pharmacol. 2015, 388, 643–651. [Google Scholar] [CrossRef] [PubMed]

- Shin, H.S.; Satsu, H.; Bae, M.J.; Zhao, Z.; Ogiwara, H.; Totsuka, M.; Shimizu, M. Anti-inflammatory effect of chlorogenic acid on the IL-8 production in Caco-2 cells and the dextran sulphate sodium-induced colitis symptoms in C57BL/6 mice. Food Chem. 2015, 168, 167–175. [Google Scholar] [CrossRef]

- Chauhan, P.S.; Satti, N.K.; Sharma, V.K.; Dutt, P.; Suri, K.A.; Bani, S. Amelioration of inflammatory responses by chlorogenic acid via suppression of pro-inflammatory mediators. J. Appl. Pharm. Sci. 2011, 1, 67–75. [Google Scholar]

- Ghosh, S.; Basak, P.; Dutta, S.; Chowdhury, S.; Sil, P.C. New insights into the ameliorative effects of ferulic acid in pathophysiological conditions. Food Chem. Toxicol. 2017, 103, 41–55. [Google Scholar] [CrossRef] [PubMed]

- Zdunska, K.; Dana, A.; Kolodziejczak, A.; Rotsztejn, H. Antioxidant Properties of Ferulic Acid and Its Possible Application. Ski. Pharm. Physiol. 2018, 31, 332–336. [Google Scholar] [CrossRef]

- Bumrungpert, A.; Lilitchan, S.; Tuntipopipat, S.; Tirawanchai, N.; Komindr, S. Ferulic Acid Supplementation Improves Lipid Profiles, Oxidative Stress, and Inflammatory Status in Hyperlipidemic Subjects: A Randomized, Double-Blind, Placebo-Controlled Clinical Trial. Nutrients 2018, 10, 713. [Google Scholar] [CrossRef] [PubMed]

- Xia, W.; Veljkovic, E.; Koshibu, K.; Peitsch, M.C.; Hoeng, J. Neurobehavioral effects of selected tobacco constituents in rodents following subchronic administration. Eur. J. Pharmacol. 2019, 865, 172809. [Google Scholar] [CrossRef]

- Peres, D.D.; Sarruf, F.D.; de Oliveira, C.A.; Velasco, M.V.R.; Baby, A.R. Ferulic acid photoprotective properties in association with UV filters: Multifunctional sunscreen with improved SPF and UVA-PF. J. Photochem. Photobiol. B 2018, 185, 46–49. [Google Scholar] [CrossRef]

- Zhao, Z.; Moghadasian, M.H. Chemistry, natural sources, dietary intake and pharmacokinetic properties of ferulic acid: A review. Food Chem. 2008, 109, 691–702. [Google Scholar] [CrossRef] [PubMed]

- Buranov, A.U.; Mazza, G. Extraction and purification of ferulic acid from flax shives, wheat and corn bran by alkaline hydrolysis and pressurised solvents. Food Chem. 2009, 115, 1542–1548. [Google Scholar] [CrossRef]

- Gorinstein, S.; Lojek, A.; Číž, M.; Pawelzik, E.; Delgado-Licon, E.; Medina, O.J.; Moreno, M.; Salas, I.A.; Goshev, I. Comparison of composition and antioxidant capacity of some cereals and pseudocereals. Int. J. Food Sci. Technol. 2008, 43, 629–637. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, W.; Lan, Y.; Wang, K.; Wu, Y.; Zhong, X.; Ying, K.; Li, J.; Yang, G. Determination of 18 phenolic acids in tobacco and rhizosphere soil by ultra high performance liquid chromatography combined with triple quadrupole mass spectrometry. J. Sep. Sci. 2019, 42, 816–825. [Google Scholar] [CrossRef] [PubMed]

- Lampiasi, N.; Montana, G. An in vitro inflammation model to study the Nrf2 and NF-κB crosstalk in presence of ferulic acid as modulator. Immunobiology 2018, 223, 349–355. [Google Scholar] [CrossRef] [PubMed]

- San Miguel, S.M.; Opperman, L.A.; Allen, E.P.; Zielinski, J.; Svoboda, K.K. Bioactive antioxidant mixtures promote proliferation and migration on human oral fibroblasts. Arch. Oral Biol. 2011, 56, 812–822. [Google Scholar] [CrossRef]

- San Miguel, S.M.; Opperman, L.A.; Allen, E.P.; Zielinski, J.E.; Svoboda, K.K. Antioxidant combinations protect oral fibroblasts against metal-induced toxicity. Arch. Oral Biol. 2013, 58, 299–310. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, P.; Zhao, P.; Wang, D.; Zhang, Y.; Wang, J.; Chen, L.; Guo, W.; Gao, H.; Jiao, Y. Pretreatment of ferulic acid attenuates inflammation and oxidative stress in a rat model of lipopolysaccharide-induced acute respiratory distress syndrome. Int. J. Immunopathol. Pharm. 2018, 32, 394632017750518. [Google Scholar] [CrossRef]

- Chen, Y.; Xue, F.; Han, C.; Yang, H.; Han, L.; Li, K.; Li, J.; Xu, Q.; Li, Z.; Yuan, B.; et al. Ferulic acid ameliorated placental inflammation and apoptosis in rat with preeclampsia. Clin. Exp. Hypertens. 2019, 41, 524–530. [Google Scholar] [CrossRef]

- Yarmohammadi, F.; Rezaee, R.; Karimi, G. Natural compounds against doxorubicin-induced cardiotoxicity: A review on the involvement of Nrf2/ARE signaling pathway. Phytother. Res. 2021, 35, 1163–1175. [Google Scholar] [CrossRef]

- Mahmoud, A.M.; Hussein, O.E.; Hozayen, W.G.; Bin-Jumah, M.; Abd El-Twab, S.M. Ferulic acid prevents oxidative stress, inflammation, and liver injury via upregulation of Nrf2/HO-1 signaling in methotrexate-induced rats. Environ. Sci. Pollut. Res. Int. 2020, 27, 7910–7921. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Ren, K.; He, X.; Gong, J.; Hu, X.; Su, J.; Jin, Y.; Zhao, Z.; Zhu, Y.; Zou, C. Dynamic changes in physiological and biochemical properties of flue-cured tobacco of different leaf ages during flue-curing and their effects on yield and quality. BMC Plant Biol. 2019, 19, 555. [Google Scholar] [CrossRef] [PubMed]

- Rattan, S.I.; Sodagam, L. Gerontomodulatory and youth-preserving effects of zeatin on human skin fibroblasts undergoing aging in vitro. Rejuvenation Res. 2005, 8, 46–57. [Google Scholar] [CrossRef]

- Yang, B.; Ji, C.; Kang, J.; Chen, W.; Bi, Z.; Wan, Y. Trans-Zeatin inhibits UVB-induced matrix metalloproteinase-1 expression via MAP kinase signaling in human skin fibroblasts. Int. J. Mol. Med. 2009, 23, 555–560. [Google Scholar] [CrossRef] [PubMed]

- Sharma, P.; Joshi, T.; Joshi, T.; Chandra, S.; Tamta, S. In silico screening of potential antidiabetic phytochemicals from Phyllanthus emblica against therapeutic targets of type 2 diabetes. J. Ethnopharmacol. 2020, 248, 112268. [Google Scholar] [CrossRef]

- Choi, S.J.; Jeong, C.H.; Choi, S.G.; Chun, J.Y.; Kim, Y.J.; Lee, J.; Shin, D.H.; Heo, H.J. Zeatin prevents amyloid beta-induced neurotoxicity and scopolamine-induced cognitive deficits. J. Med. Food 2009, 12, 271–277. [Google Scholar] [CrossRef]

- Kim, M.J.; Choi, S.J.; Lim, S.T.; Kim, H.K.; Kim, Y.J.; Yoon, H.G.; Shin, D.H. Zeatin supplement improves scopolamine-induced memory impairment in mice. Biosci. Biotechnol. Biochem. 2008, 72, 577–581. [Google Scholar] [CrossRef]

- Grosskinsky, D.K.; Naseem, M.; Abdelmohsen, U.R.; Plickert, N.; Engelke, T.; Griebel, T.; Zeier, J.; Novak, O.; Strnad, M.; Pfeifhofer, H.; et al. Cytokinins mediate resistance against Pseudomonas syringae in tobacco through increased antimicrobial phytoalexin synthesis independent of salicylic acid signaling. Plant Physiol. 2011, 157, 815–830. [Google Scholar] [CrossRef]

- Grosskinsky, D.K.; Edelsbrunner, K.; Pfeifhofer, H.; van der Graaff, E.; Roitsch, T. Cis- and trans-zeatin differentially modulate plant immunity. Plant Signal Behav. 2013, 8, e24798. [Google Scholar] [CrossRef]

- Smigocki, A.; Neal, J.W., Jr.; McCanna, I.; Douglass, L. Cytokinin-mediated insect resistance in Nicotiana plants transformed with the ipt gene. Plant Mol. Biol. 1993, 23, 325–335. [Google Scholar] [CrossRef]

- Den Hartigh, L.J. Conjugated Linoleic Acid Effects on Cancer, Obesity, and Atherosclerosis: A Review of Pre-Clinical and Human Trials with Current Perspectives. Nutrients 2019, 11, 370. [Google Scholar] [CrossRef] [PubMed]

- Bjermo, H.; Iggman, D.; Kullberg, J.; Dahlman, I.; Johansson, L.; Persson, L.; Berglund, J.; Pulkki, K.; Basu, S.; Uusitupa, M.; et al. Effects of n-6 PUFAs compared with SFAs on liver fat, lipoproteins, and inflammation in abdominal obesity: A randomized controlled trial. Am. J. Clin. Nutr. 2012, 95, 1003–1012. [Google Scholar] [CrossRef] [PubMed]

- Koba, K.; Yanagita, T. Health benefits of conjugated linoleic acid (CLA). Obes. Res. Clin. Pract. 2014, 8, e525–e532. [Google Scholar] [CrossRef] [PubMed]

- Isman, M.B. Plant essential oils for pest and disease management. Crop Prot. 2000, 19, 603–608. [Google Scholar] [CrossRef]

- Silvestre, A.J.D.; Gandini, A. Chapter 2—Terpenes: Major Sources, Properties and Applications. In Monomers, Polymers and Composites from Renewable Resources; Belgacem, M.N., Gandini, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2008; pp. 17–38. [Google Scholar] [CrossRef]

- Leffingwell, J. Leaf Chemistry—Basic Chemical Constituents of Tobacco Leaf and Differences among Tobacco Types; Blackwell Science: Oxford, UK, 1999; pp. 265–284. [Google Scholar] [CrossRef]

- Rowland, R. Flue-cured tobacco. II. Neophytadiene. J. Am. Chem. Soc. 1957, 79, 5007–5010. [Google Scholar] [CrossRef]

- Palic, R.; Stojanović, G.; Alagić, S.; Nikolic, M.; Lepojevic, Z. Chemical composition and antimicrobial activity of the essential oil and CO2 extracts of the oriental tobacco, Prilep. Flavour Fragr. J. 2002, 17, 323–326. [Google Scholar] [CrossRef]

- Lalitharani, S.; Mohan, V.; Regini, G. GC-MS analysis of ethanolic extract of Zanthoxylum rhetsa (roxb.) dc spines. J. Herb. Med. Toxicol. 2010, 4, 1212–1217. [Google Scholar]

- Bhardwaj, M.; Sali, V.K.; Mani, S.; Vasanthi, H.R. Neophytadiene from Turbinaria ornata Suppresses LPS-Induced Inflammatory Response in RAW 264.7 Macrophages and Sprague Dawley Rats. Inflammation 2020, 43, 937–950. [Google Scholar] [CrossRef] [PubMed]

- Rebensburg, S.; Helfer, M.; Schneider, M.; Koppensteiner, H.; Eberle, J.; Schindler, M.; Gürtler, L.; Brack-Werner, R. Potent in vitro antiviral activity of Cistus incanus extract against HIV and Filoviruses targets viral envelope proteins. Sci. Rep. 2016, 6, 20394. [Google Scholar] [CrossRef]

- Li, R. Investigation of Irreversible Adsorption Behavior of Epirubicin on Silicagel Column. J. Univ. Hydraul. Electr. Eng./Yichang 2005, 27, 76–79. [Google Scholar]

- Client Success Stories. Available online: https://bicoll-group.com/technology/success-stories (accessed on 10 October 2022).

- Helleboid, S.; Haug, C.; Lamottke, K.; Zhou, Y.; Wei, J.; Daix, S.; Cambula, L.; Rigou, G.; Hum, D.W.; Walczak, R. The identification of naturally occurring neoruscogenin as a bioavailable, potent, and high-affinity agonist of the nuclear receptor RORα (NR1F1). J. Biomol. Screen 2014, 19, 399–406. [Google Scholar] [CrossRef] [PubMed]

- Lamottke, K. Slow Horses and Hidden Champions in the Drug Discovery Field. 2015. Available online: https://www.researchgate.net/publication/275464383_Slow_horses_and_hidden_champions_in_the_drug_discovery_field (accessed on 10 October 2022).

- Pezzuto, J.M. Plant-derived anticancer agents. Biochem. Pharmacol. 1997, 53, 121–133. [Google Scholar] [CrossRef]

| No. | Compounds | C6H14 | CH2Cl2 | CH2Cl2/ MeOH (4:1) | EtOH | MeOH | MeOH/ H2O (7:3) | H2O |

|---|---|---|---|---|---|---|---|---|

| 1 | Anatabine | 217 | 442 | 512 | 490 | 444 | 193 | 100 |

| 2 | Anabasine | NS | 10.3 | 70.0 | 97.0 | 103 | 109 | NS |

| 3 | Myosmine | 4.27 | 194 | 175 | 418 | 356 | 231 | 180 |

| 4 | Nicotinamide | NS | NS | 37.3 | 20.8 | 66.3 | 114 | 150 |

| 5 | Nicotinic acid | NS | NS | 3.98 | 3.51 | 6.71 | 2.85 | 3.10 |

| 6 | Cotinine | NS | 203 | 208 | 190 | 235 | 139 | 145 |

| 7 | Nornicotine | 358 | 422 | 412 | 396 | 428 | 418 | 416 |

| 8 | Zeatin | NS | NS | 0.61 | 0.56 | 2.28 | 3.03 | NS |

| 9 | Rutin | NS | NS | 3.82 | 6.67 | 49.0 | 0.52 | NS |

| 10 | Chlorogenic acid | NS | NS | 1.82 | 23.3 | 31.7 | 1.27 | 0.24 |

| 11 | Ferulic acid | NS | NS | 30.3 | 33.8 | 51.5 | 10.5 | NS |

| 12 | Solanesol | 42.0 | 235 | 203 | 3.31 | 0.51 | NS | NS |

| 13 | Zeaxanthin | NS | 0.29 | 0.49 | NS | NS | NS | NS |

| 14 | Lutein | NS | NS | 4.66 | NS | NS | NS | NS |

| 15 | Linoleic acid | 374 | 504 | 502 | 558 | 526 | NS | NS |

| 16 | Sclareol | 3.76 | 58.0 | 219 | 75.7 | 65.7 | 3.17 | NS |

| 17 | Ambroxide | 66.0 | 130 | 116 | 51.8 | 49.8 | NS | NS |

| 18 | Vitamin D3 | 104 | 100 | 212 | 74.3 | 113 | NS | NS |

| 19 | Vitamin E | 215 | 208 | 241 | 43.0 | 31.2 | 0.23 | NS |

| 20 | Squalene | 446 | 474 | 472 | 5.94 | 0.22 | NS | NS |

| 21 | Phytol | 470 | 432 | 416 | 430 | 408 | 0.32 | NS |

| 22 | Farnesol | 400 | 382 | 348 | 376 | 466 | 0.75 | NS |

| 23 | Neophytadiene | 486 | 486 | 482 | 57.5 | 4.08 | NS | NS |

| 24 | Linalool | 422 | 440 | 462 | 454 | 462 | 77.3 | 0.57 |

| 25 | Caryophyllene | 376 | 382 | 480 | 196 | 36.2 | NS | NS |

| 26 | Megastigmatrienone | 1.1 | 215 | 212 | 197 | 228 | 38.8 | NS |

| 27 | Borneol | 29.9 | 80.7 | 202 | 218 | 504 | 71.7 | NS |

| 28 | α-Pinene | 388 | 428 | 432 | 406 | 71.0 | NS | NS |

| 29 | Limonene | 442 | 398 | 388 | 392 | 394 | NS | NS |

| No. | Compounds | Virginia | Burley | Oriental |

|---|---|---|---|---|

| 1 | Nicotine | 1245 | 683 | 379 |

| 2 | Anatabine | 104 | 74.6 | 18.9 |

| 3 | Anabasine | 18.6 | 14.1 | 4.39 |

| 4 | Myosmine | 0.30 | 0.11 | 0.29 |

| 5 | Nicotinamide | 0.22 | 0.21 | 0.80 |

| 6 | Cotinine | 2.93 | 4.99 | 13.2 |

| 7 | Nornicotine | 34.4 | 37.0 | 63.5 |

| 8 | Norcotinine | 0.68 | 0.99 | 1.34 |

| 9 | Nicotinic acid | 5.16 | 6.73 | 6.41 |

| 10 | Chlorogenic acid | 1574 | 14.0 | 1109 |

| 11 | Cryptochlorogenic acid | 780 | 5.99 | 658 |

| 12 | Neochlorogenic acid | 473 | 4.72 | 446 |

| 13 | cis-Zeatin | 0.11 | 0.16 | 0.19 |

| 14 | trans-Zeatin | 2.04 | 3.37 | 0.97 |

| 15 | Ferulic acid | N/F | N/F | 0.10 |

| 16 | Isoferulic acid | 4.89 | 0.94 | 2.15 |

| 17 | Rutin | 2277 | 82.4 | 2129 |

| 18 | Xylitol | 481 | 37.1 | 110 |

| 19 | Ambroxide | N/F | 0.03 | 0.10 |

| 20 | Linoleic acid | 85.8 | 2.07 | N/F |

| 21 | α-Tocopherol | 283 | N/F | 0.21 |

| 22 | Vitamin D3 | N/F | N/F | N/F |

| No. | Compounds | Virginia | Burley | Oriental | |||

|---|---|---|---|---|---|---|---|

| Nonpolar | Polar | Nonpolar | Polar | Nonpolar | Polar | ||

| 1 | Nicotine | 196 | 1049 | 109 | 574 | 105 | 274 |

| 2 | Anatabine | 8.38 | 95.4 | 10.2 | 64.5 | 3.21 | 15.7 |

| 3 | Anabasine | 0.92 | 17.7 | 1.18 | 12.9 | 0.70 | 3.69 |

| 4 | Myosmine | 0.04 | 0.26 | 0.02 | 0.09 | 0.10 | 0.19 |

| 5 | Nicotinamide | 0.12 | 0.09 | 0.05 | 0.16 | 0.52 | 0.28 |

| 6 | Cotinine | 2.31 | 0.63 | 3.52 | 1.47 | 12.2 | 0.92 |

| 7 | Nornicotine | 1.85 | 32.5 | 1.99 | 35.0 | 4.44 | 59.0 |

| 8 | Norcotinine | 0.16 | 0.52 | 0.33 | 0.66 | 0.88 | 0.46 |

| 9 | Nicotinic acid | 2.88 | 2.28 | 2.21 | 4.52 | 4.46 | 1.95 |

| 10 | Chlorogenic acid | N/F | 1574 | N/F | 14.0 | N/F | 1109 |

| 11 | Cryptochlorogenic acid | N/F | 780 | N/F | 5.99 | N/F | 658 |

| 12 | Neochlorogenic acid | N/F | 473 | N/F | 4.72 | N/F | 446 |

| 13 | cis-Zeatin | N/F | 0.11 | N/F | 0.16 | N/F | 0.19 |

| 14 | trans-Zeatin | N/F | 2.04 | N/F | 3.37 | N/F | 0.97 |

| 15 | Ferulic acid | N/F | N/F | N/F | N/F | N/F | 0.10 |

| 16 | Isoferulic acid | N/F | 4.89 | N/F | 0.94 | N/F | 2.15 |

| 17 | Rutin | N/F | 2277 | N/F | 82.4 | N/F | 2129 |

| 18 | Xylitol | N/F | 481 | N/F | 37.1 | N/F | 110 |

| 19 | Ambroxide | N/F | N/F | 0.03 | N/F | 0.10 | N/F |

| 20 | Linoleic acid | 85.8 | N/F | 2.07 | N/F | N/F | N/F |

| 21 | α-Tocopherol | 283 | N/F | N/F | N/F | 0.21 | N/F |

| 22 | Vitamin D3 | N/F | N/F | N/F | N/F | N/F | N/F |

| Method | M1 | M2 | M3 | M4 | M5 | M6 | M7 | M8 | M9 | M10 | M11 | M12 | M13 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Base Method | BM1 | BM2 | BM1 | BM2 | BM1 | BM2 | BM1 | BM2 | BM1 | BM2 | BM1 | BM2 | BM3 | |

| Solvent | CH2Cl2 | CH2Cl2/MeOH (4:1, v/v) | CH2Cl2/MeOH (1:1, v/v) | CH2Cl2/MeOH (1:4, v/v) | MeOH | MeOH/H2O (9:1, v/v) | MeOH/H2O (7:3, v/v) | |||||||

| No. | Compound | |||||||||||||

| 1 | Nicotine | 8416 | 7093 | 22,432 | 24,480 | 29,515 | 31,401 | 33,803 | 28,978 | 33,228 | 38,819 | 36,101 | 36,775 | 47,827 |

| 2 | Anatabine | 18 | 19 | 232 | 261 | 270 | 319 | 264 | 332 | 231 | 357 | 283 | 369 | 450 |

| 3 | Anabasine | 20 | 24 | 274 | 311 | 332 | 364 | 327 | 385 | 289 | 408 | 354 | 408 | 542 |

| 4 | Myosmine | 5.28 | 5.04 | 8.50 | 7.19 | 8.34 | 6.04 | 6.80 | 6.26 | 4.15 | 6.63 | 4.42 | 6.67 | 13.82 |

| 5 | Nicotinamide | 0.69 | 1.16 | 2.73 | 2.80 | 2.84 | 3.09 | 2.74 | 3.11 | 2.33 | 3.46 | 2.65 | 3.07 | 4.09 |

| 6 | Cotinine | 135 | 231 | 159 | 152 | 70 | 141 | 44 | 133 | 38 | 139 | 40 | 50 | 72 |

| 7 | Nornicotine | 36 | 46 | 204 | 303 | 251 | 337 | 220 | 394 | 207 | 368 | 311 | 396 | 538 |

| 8 | Norcotinine | 5.08 | 8.58 | 4.58 | 7.53 | 4.60 | 3.95 | 4.12 | 4.07 | 3.57 | 4.27 | 3.89 | 2.87 | 3.92 |

| 9 | Nicotinic acid | 25.9 | 40.9 | 61.1 | 76.3 | 52.1 | 78.9 | 52.5 | 71.6 | 46.8 | 78.3 | 58.9 | 66.9 | 96.2 |

| 10 | cryptoCGA | N/F | N/F | 1253 | 5208 | 7957 | 21,192 | 11,518 | 29,854 | 9603 | 39,877 | 21,470 | 48,775 | 17,102 |

| 11 | neoCGA | N/F | N/F | 1193 | 5282 | 9017 | 25,057 | 13,972 | 38,252 | 10,746 | 52,038 | 23,618 | 61,684 | 16,901 |

| 12 | CGA | N/F | N/F | 4601 | 16,421 | 19,338 | 44,408 | 25,938 | 56,836 | 23,262 | 73,164 | 42,292 | 85,533 | 38,199 |

| 13 | trans-Zeatin | 2.6 | 3.5 | 72.0 | 88.6 | 92.5 | 100.9 | 105.2 | 109.2 | 105.2 | 121.9 | 131.6 | 134.6 | 43.0 |

| 14 | Rutin | 7 | 6 | 946 | 23,554 | 13,493 | 97,419 | 13,457 | 12,3712 | 8163 | 156,806 | 10,947 | 185,959 | 65,277 |

| 15 | Xylitol | 62 | 61 | 3474 | 3212 | 7260 | 6545 | 9950 | 8250 | 10,643 | 10,950 | 14,453 | 14,001 | 4938 |

| No. | Compound | Virginia | Burley | Oriental | NRT61 | NRT63 | B.M. |

|---|---|---|---|---|---|---|---|

| 1 | Nicotine | 34,609 | 37,162 | 18,055 | 76,696 | 62,926 | 94,150 |

| 2 | Anatabine | 1699 | 1544 | 287 | 663 | 606 | 622 |

| 3 | Anabasine | 281 | 242 | 61 | 738 | 733 | 833 |

| 4 | Myosmine | 6.69 | 13.13 | 13.24 | 11.00 | 11.29 | 13.23 |

| 5 | Nicotinamide | 2.50 | 1.65 | 10.61 | 4.87 | 4.34 | 5.36 |

| 6 | Cotinine | 34.8 | 116.4 | 103.4 | 59.8 | 69.8 | 46.3 |

| 7 | Nornicotine | 803 | 775 | 1138 | 967 | 962 | 909 |

| 8 | Norcotinine | 3.01 | 7.19 | 3.93 | 4.21 | 4.76 | 3.26 |

| 9 | Nicotinic acid | 87.3 | 179.8 | 55.7 | 68.8 | 77.1 | 97.4 |

| 10 | CGA | 118,846 | 1305 | 69,838 | 39,589 | 28,146 | 26,955 |

| 11 | Rutin | 224,699 | 7910 | 114,419 | 139,420 | 118,015 | 122,224 |

| 12 | Ferulic acid | 309 | 63 | 203 | 69 | 70 | 53 |

| 13 | Linoleic acid | 6496 | 2181 | 5821 | 2979 | 26,023 | 2967 |

| No. | Compound | Virginia | Burley | Oriental | NRT61 | NRT63 | B.M. |

|---|---|---|---|---|---|---|---|

| Total Dry Weight | 3288.91 | 5222.19 | 1700 | 2238.95 | 1433.6 | 1017.92 | |

| 1 | Nicotine | 113.83 | 194.07 | 30.69 | 171.72 | 90.21 | 95.84 |

| 2 | Anatabine | 5.59 | 8.06 | 0.49 | 1.48 | 0.87 | 0.63 |

| 3 | Anabasine | 0.92 | 1.26 | 0.10 | 1.65 | 1.05 | 0.85 |

| 4 | Myosmine | 0.02 | 0.07 | 0.02 | 0.02 | 0.02 | 0.01 |

| 5 | Nicotinamide | 0.01 | 0.01 | 0.02 | 0.01 | 0.01 | 0.01 |

| 6 | Cotinine | 0.11 | 0.61 | 0.18 | 0.13 | 0.10 | 0.05 |

| 7 | Nornicotine | 2.64 | 4.05 | 1.93 | 2.17 | 1.38 | 0.93 |

| 8 | Norcotinine | 0.01 | 0.04 | 0.01 | 0.01 | 0.01 | 0.00 |

| 9 | Nicotinic acid | 0.29 | 0.94 | 0.09 | 0.15 | 0.11 | 0.10 |

| 10 | CGA | 390.87 | 6.81 | 118.72 | 88.64 | 40.35 | 27.44 |

| 11 | Rutin | 739.01 | 41.31 | 194.51 | 312.15 | 169.19 | 124.41 |

| 12 | Ferulic acid | 1.02 | 0.33 | 0.35 | 0.15 | 0.10 | 0.05 |

| 13 | Linoleic acid | 21.36 | 11.39 | 9.90 | 6.67 | 37.31 | 3.02 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Laszlo, C.; Kaminski, K.; Guan, H.; Fatarova, M.; Wei, J.; Bergounioux, A.; Schlage, W.K.; Schorderet-Weber, S.; Guy, P.A.; Ivanov, N.V.; et al. Fractionation and Extraction Optimization of Potentially Valuable Compounds and Their Profiling in Six Varieties of Two Nicotiana Species. Molecules 2022, 27, 8105. https://doi.org/10.3390/molecules27228105

Laszlo C, Kaminski K, Guan H, Fatarova M, Wei J, Bergounioux A, Schlage WK, Schorderet-Weber S, Guy PA, Ivanov NV, et al. Fractionation and Extraction Optimization of Potentially Valuable Compounds and Their Profiling in Six Varieties of Two Nicotiana Species. Molecules. 2022; 27(22):8105. https://doi.org/10.3390/molecules27228105

Chicago/Turabian StyleLaszlo, Csaba, Kacper Kaminski, Haifeng Guan, Maria Fatarova, Jianbing Wei, Alexandre Bergounioux, Walter K. Schlage, Sandra Schorderet-Weber, Philippe A. Guy, Nikolai V. Ivanov, and et al. 2022. "Fractionation and Extraction Optimization of Potentially Valuable Compounds and Their Profiling in Six Varieties of Two Nicotiana Species" Molecules 27, no. 22: 8105. https://doi.org/10.3390/molecules27228105

APA StyleLaszlo, C., Kaminski, K., Guan, H., Fatarova, M., Wei, J., Bergounioux, A., Schlage, W. K., Schorderet-Weber, S., Guy, P. A., Ivanov, N. V., Lamottke, K., & Hoeng, J. (2022). Fractionation and Extraction Optimization of Potentially Valuable Compounds and Their Profiling in Six Varieties of Two Nicotiana Species. Molecules, 27(22), 8105. https://doi.org/10.3390/molecules27228105