A Comprehensive Review of the Effects of Different Simulated Environmental Conditions and Hybridization Processes on the Mechanical Behavior of Different FRP Bars

Abstract

:1. Introduction

2. Materials Properties for Fabricating FRP Bars

2.1. Composite Fibers

2.2. Resin

3. Different Simulated Environments and Their Effects on the Mechanical Properties of FRP Bars

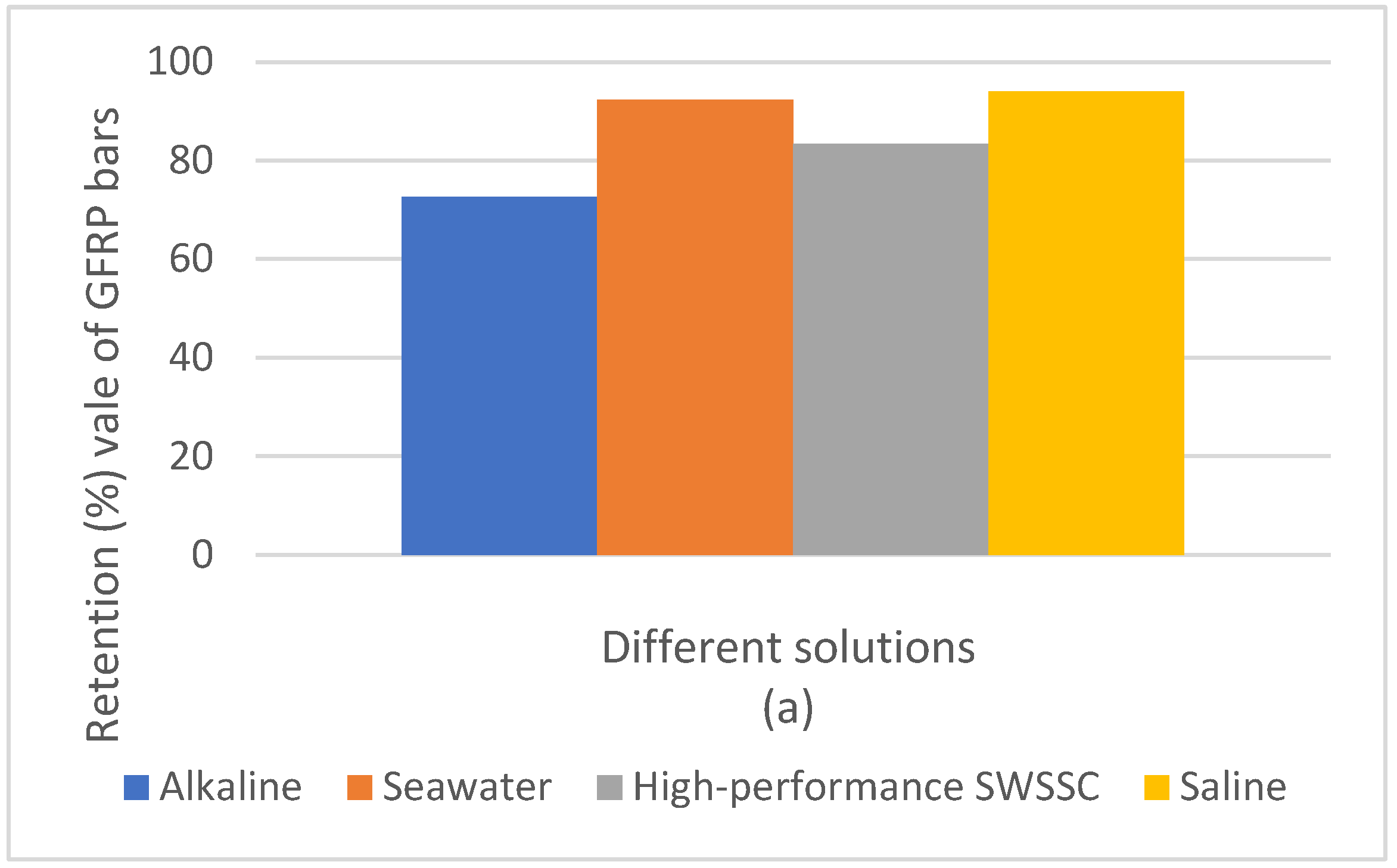

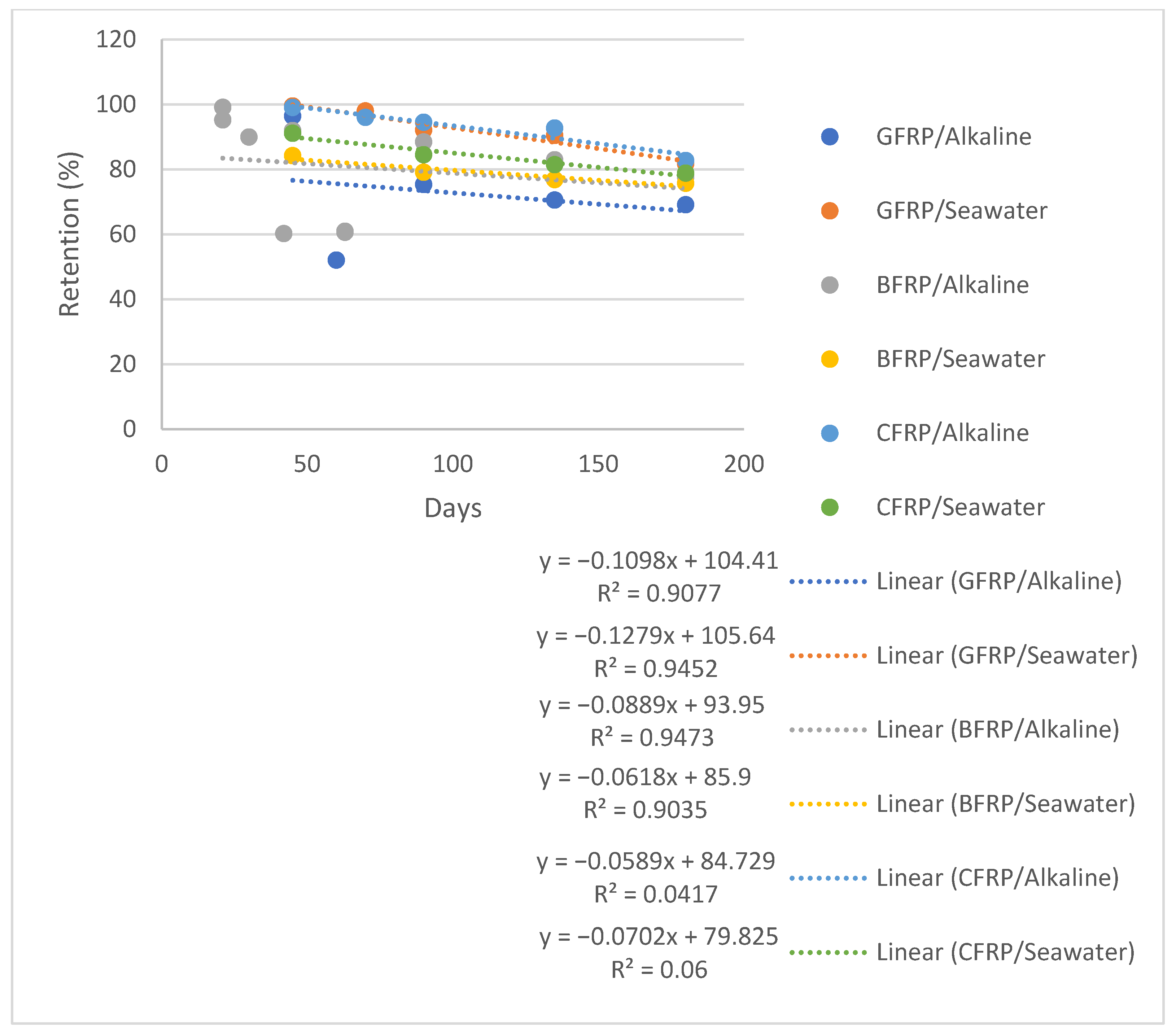

3.1. Behavior of FRP Bars under Tension

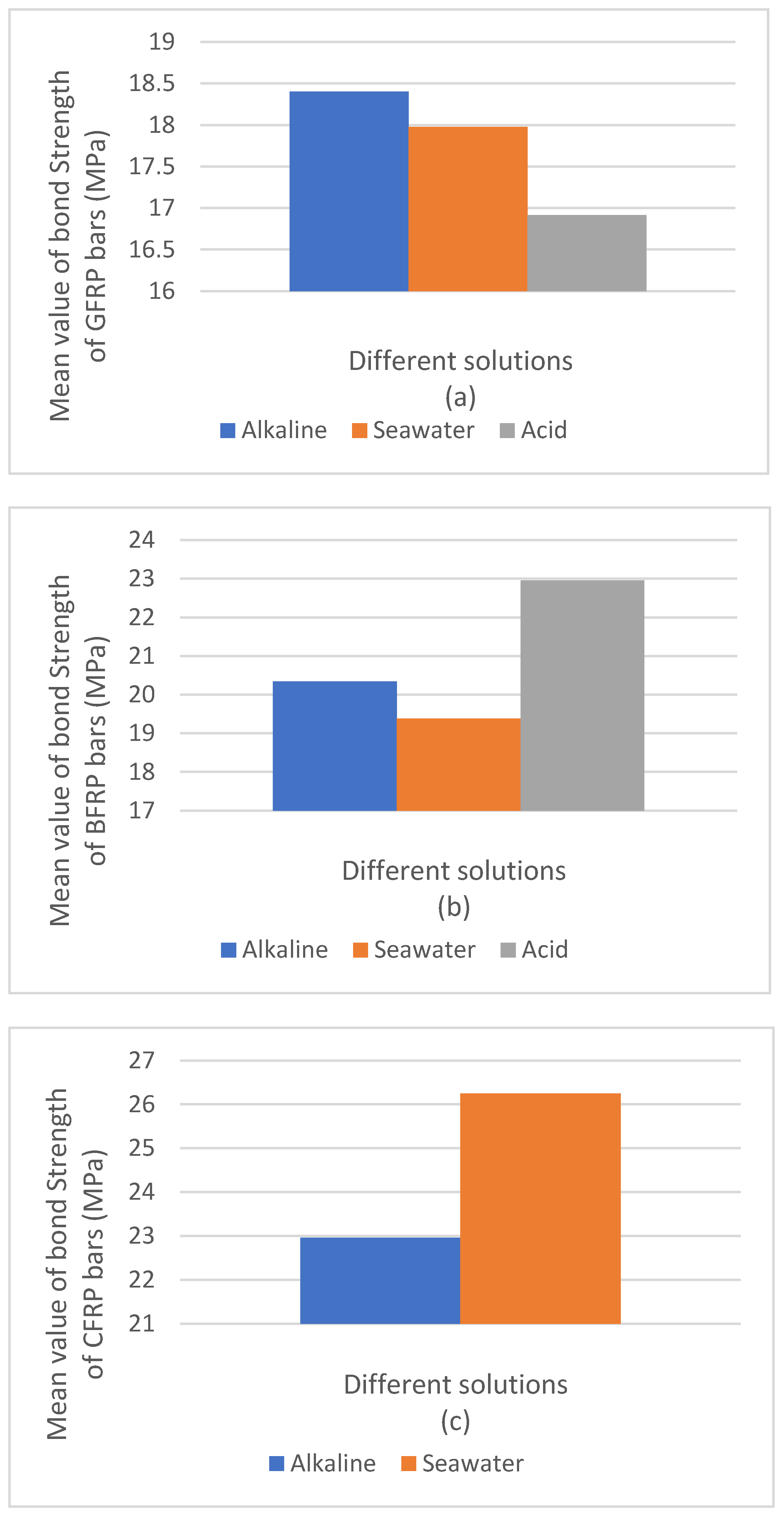

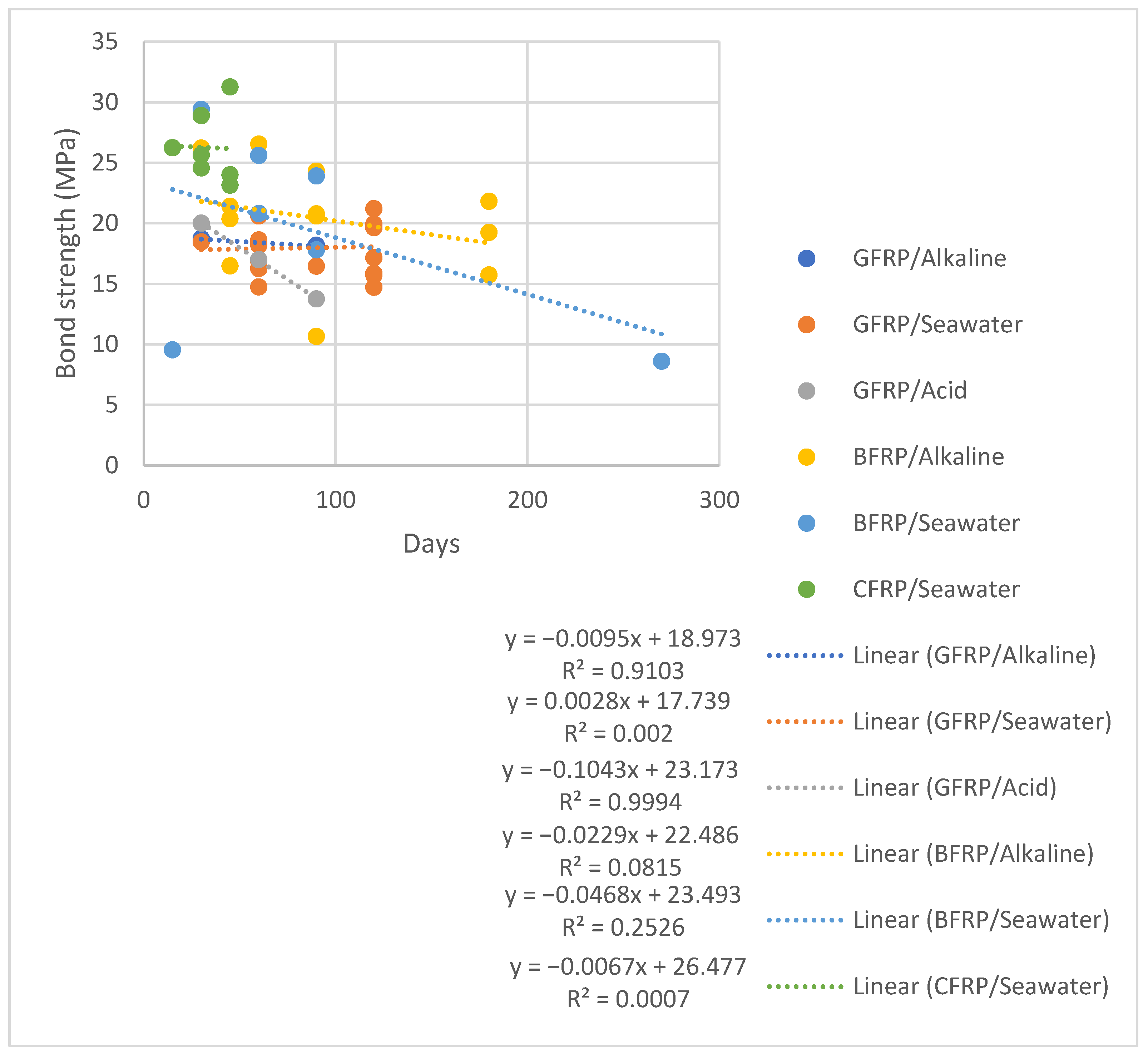

3.2. Bonding of FRP Bars to the Concrete

4. Influence of Hybridization on Mechanical Properties of Composite Bars

4.1. Hybrid Effect on the Tensile Strength of FRP Bars

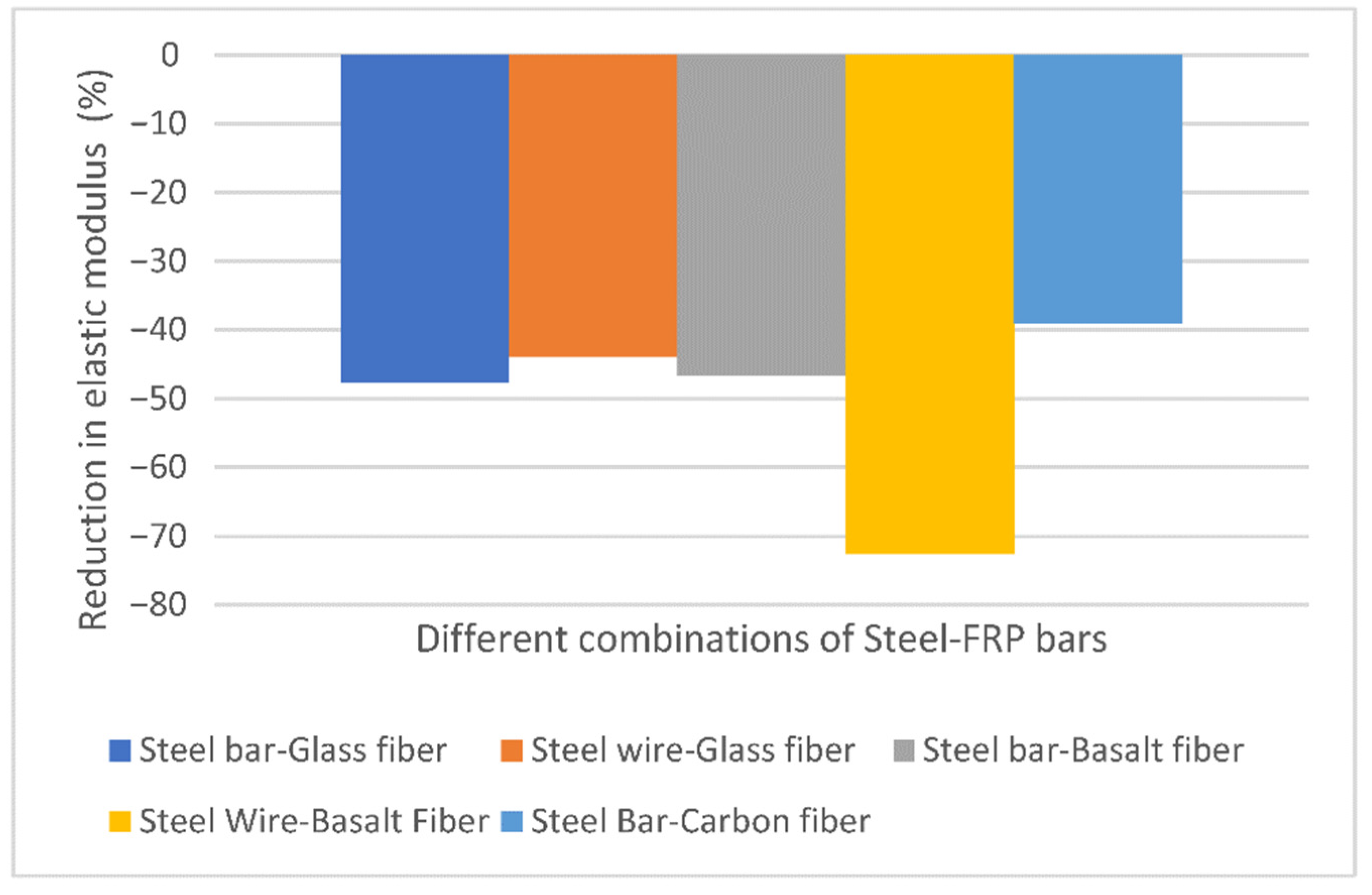

4.2. Hybrid Effect on the Modulus of Elasticity of FRP Bars

4.3. Effects of Environmental Conditions on Hybrid Bars

5. Conclusions and Research Needs

5.1. Conclusions

- In terms of tensile strength, CFRP bars are more resistant to alkaline solutions, in comparison to different FRP bars. Moreover, considering seawater and saline solutions, GFRP bars show more durability.

- Alkaline solutions have a greater effect on the bond strength of CFRP bars than seawater solutions. In addition, the bond strength of BFRP bars in alkaline and seawater solutions was almost equal to approximately 20 MPa, which was less than their bond strength in acid solutions. As for GFRP bars, they were more resistant to alkaline solutions than to seawater and acid solutions.

- When fabricating hybrid composite fibers, the type of fibers used highly affects the elastic modulus. For a high elastic modulus, carbon fibers are recommended; however, for a low elastic modulus, glass and basalt are preferred.

- Using the hybridization process can improve the tensile strength of fabricated hybrid FRP bars by up to approximately 210%, in comparison with steel bars (ST37). On the other hand, this process has an adverse effect on the elastic modulus of fabricated hybrid FRP bars and can reduce this mechanical behavior by up to approximately 70%, compared with steel bars’ (ST37) elastic modulus.

- When it comes to hybrid composite bars made up of steel, the volume of the steel material has a great influence on the final mechanical behavior. The more steel used, the greater the ductility of the hybrid composite bars, as observed under tensile tests. Using steel material for fabricating hybrid composite bars generally has a positive effect on the elastic modulus of these bars. This behavior stems from the high elastic modulus of steel materials in comparison with composite fibers.

- Steel materials can have an adverse effect on the ultimate tensile strength of hybrid composite bars because composite fibers have a higher tensile strength than steel material.

- Tensile tests in the literature indicate that hybridization can improve the ductility of composite bars. Such an increase in their ductility can be attributed to using different materials in one cross-sectional area of the hybrid composite bars. Furthermore, hybridization improves the elastic modulus of composite bars and when steel is used the elastic modulus is linearly proportional to the steel’s volume.

- Hybrid composite bars that were fabricated by steel materials show great pseudo-ductile behavior, in comparison to hybrid composite bars composed of composite fibers only. However, the former group shows lower durability compared to the latter group because of the presence of steel in their cross-sectional area.

- In the case of resin, epoxy and vinyl ester resins have a higher elastic modulus and tensile strength, respectively. Current data also denotes that vinyl ester and epoxy have better performance regarding their degradation level.

5.2. Research Needs

- Only a limited number of studies have investigated the effects of different environmental conditions on the compressive behavior of different FRP bars.

- The performance of FRP bars in cyclic loads, along with harsh environmental conditions remains obscure.

- The effects of the bar size and diameter on the bond and tensile behavior of FRP bars subjected to different solutions remains unclear.

- The influence of different fibers, such as aramid fibers, on the mechanical behavior of hybrid FRP bars remains unclear.

- The effects of the steel bars and steel wire diameter on the elastic and the tensile strength of hybrid FRP bars have not been completely investigated.

- The effects of environmental solutions on the durability of hybrid FRP bars are still obscure.

- The mechanical behaviors of FRP bars are deeply influenced by the types of fibers, the manufacturing process, and the types of resin, etc. These agents cause uncertainties in the final mechanical behavior of FRP bars. More research should be conducted to produce FRP bars with the same mechanical behavior. Using probabilistic models and machine learning methods can accommodate these uncertainties and provide further insight into the behavior of FRP bars that are subjected to simulated environmental conditions [114,115].

Author Contributions

Funding

Informed Consent Statement

Conflicts of Interest

References

- Ahmed, A.; Guo, S.; Zhang, Z.; Shi, C.; Zhu, D. A review on durability of fiber reinforced polymer (FRP) bars reinforced seawater sea sand concrete. Constr. Build. Mater. 2020, 256, 119484. [Google Scholar] [CrossRef]

- Tawfik, T.A.; Aly Metwally, K.; EL-Beshlawy, S.A.; Al Saffar, D.M.; Tayeh, B.A.; Soltan Hassan, H. Exploitation of the nanowaste ceramic incorporated with nano silica to improve concrete properties. J. King Saud Univ. Eng. Sci. 2020, 33, 581–588. [Google Scholar] [CrossRef]

- Zeyad, A.M.; Khan, A.H.; Tayeh, B.A. Durability and strength characteristics of high-strength concrete incorporated with volcanic pumice powder and polypropylene fibers. J. Mater. Res. Technol. 2020, 9, 806–813. [Google Scholar] [CrossRef]

- Agwa, I.S.; Omar, O.M.; Tayeh, B.A.; Abdelsalam, B.A. Effects of using rice straw and cotton stalk ashes on the properties of lightweight self-compacting concrete. Constr. Build. Mater. 2020, 235, 117541. [Google Scholar] [CrossRef]

- Alexander, M.; Beushausen, H. Durability, service life prediction, and modelling for reinforced concrete structures-review and critique. Cem. Concr. Res. 2019, 122, 17–29. [Google Scholar] [CrossRef]

- Almusallam, T.H.; Elsanadedy, H.M.; Al-Salloum, Y.A.; Alsayed, S.H. Experimental and numerical investigation for the flexural strengthening of RC beams using near-surface mounted steel or GFRP bars. Constr. Build. Mater. 2013, 40, 145–161. [Google Scholar] [CrossRef]

- Kassem, C.; Farghaly, A.S.; Benmokrane, B. Evaluation of flexural behavior and serviceability performance of concrete beams reinforced with FRP bars. J. Compos. Constr. 2011, 15, 682–695. [Google Scholar] [CrossRef]

- Kazemian, M.; Sedighi, S.; Ramezanianpour, A.A.; Bahman-Zadeh, F.; Ramezanianpour, A.M. Effects of cyclic carbonation and chloride ingress on durability properties of mortars containing Trass and Pumice natural pozzolans. Struct. Concr. 2021, 22, 2704–2719. [Google Scholar] [CrossRef]

- Yan, F.; Lin, Z.; Yang, M. Bond mechanism and bond strength of GFRP bars to concrete: A review. Compos. Part B Eng. 2016, 98, 56–69. [Google Scholar] [CrossRef]

- Cui, Z.; Alipour, A. Concrete cover cracking and service life prediction of reinforced concrete structures in corrosive environments. Constr. Build. Mater. 2018, 159, 652–671. [Google Scholar] [CrossRef]

- Wang, J.; Li, L.; Zhang, X.G.; Zhao, Y. A Prediction Model for Concrete Cracks due to Chloride-Induced Corrosion. Adv. Mater. Sci. Eng. 2020, 2020, 1049258. [Google Scholar] [CrossRef] [Green Version]

- Otieno, M.; Beushausen, H.; Alexander, M. Chloride-induced corrosion of steel in cracked concrete—Part I: Experimental studies under accelerated and natural marine environments. Cem. Concr. Res. 2016, 79, 373–385. [Google Scholar] [CrossRef]

- Otieno, M.; Beushausen, H.; Alexander, M. Chloride-induced corrosion of steel in cracked concrete—Part II: Corrosion rate prediction models. Cem. Concr. Res. 2016, 79, 386–394. [Google Scholar] [CrossRef]

- Boschmann Käthler, C.; Angst, U.M.; Ebell, G.; Elsener, B. Chloride-induced reinforcement corrosion in cracked concrete: The influence of time of wetness on corrosion propagation. Corros. Eng. Sci. Technol. 2020, 56, 1–10. [Google Scholar] [CrossRef]

- Andrade, C. Propagation of reinforcement corrosion: Principles, testing and modelling. Mater. Struct. Constr. 2019, 52, 2. [Google Scholar] [CrossRef] [Green Version]

- Andrade, C. Linear propagation models of deterioration processes of concrete. Corros. Eng. Sci. Technol. 2020, 55, 283–288. [Google Scholar] [CrossRef]

- Mirdarsoltany, M.; Rahai, A.; Hatami, F. Experimental Investigation on the Ductility of Concrete Deep Beams Reinforced with Basalt-Carbon and Basalt-Steel Wire Hybrid Composite Bars. Shock Vib. 2021, 2021, 6866993. [Google Scholar] [CrossRef]

- Bezuidenhout, S.R.; van Zijl, G.P.A.G. Corrosion propagation in cracked reinforced concrete, toward determining residual service life. Struct. Concr. 2019, 20, 2183–2193. [Google Scholar] [CrossRef]

- Otieno, M.B.; Beushausen, H.D.; Alexander, M.G. Modelling corrosion propagation in reinforced concrete structures—A critical review. Cem. Concr. Compos. 2011, 33, 240–245. [Google Scholar] [CrossRef]

- Zhu, W.; François, R.; Zhang, C.; Zhang, D. Propagation of corrosion-induced cracks of the RC beam exposed to marine environment under sustained load for a period of 26 years. Cem. Concr. Res. 2018, 103, 66–76. [Google Scholar] [CrossRef]

- Michel, A.; Otieno, M.; Stang, H.; Geiker, M.R. Propagation of steel corrosion in concrete: Experimental and numerical investigations. Cem. Concr. Compos. 2016, 70, 171–182. [Google Scholar] [CrossRef]

- Ahmadi, B.; Ramezanianpour, A.A.; Sobhani, J. Rebar corrosion in cracked RC prisms located in harsh marine environment. Mag. Concr. Res. 2014, 66, 1007–1019. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, J.; Zhao, Y.; Tang, L.; Xing, F. Time-dependent probability assessment for chloride induced corrosion of RC structures using the third-moment method. Constr. Build. Mater. 2015, 76, 232–244. [Google Scholar] [CrossRef]

- Homayoonmehr, R.; Ramezanianpour, A.A.; Mirdarsoltany, M. Influence of metakaolin on fresh properties, mechanical properties and corrosion resistance of concrete and its sustainability issues: A review. J. Build. Eng. 2021, 44, 103011. [Google Scholar] [CrossRef]

- Moradi-Marani, F.; Shekarchi, M.; Dousti, A.; Mobasher, B. Investigation of corrosion damage and repair system in a concrete jetty structure. J. Perform. Constr. Facil. 2010, 24, 294–301. [Google Scholar] [CrossRef]

- Valipour, M.; Pargar, F.; Shekarchi, M.; Khani, S.; Moradian, M. In situ study of chloride ingress in concretes containing natural zeolite, metakaolin and silica fume exposed to various exposure conditions in a harsh marine environment. Constr. Build. Mater. 2013, 46, 63–70. [Google Scholar] [CrossRef]

- Montemor, M.F.; Simões, A.M.P.; Ferreira, M.G.S. Chloride-induced corrosion on reinforcing steel: From the fundamentals to the monitoring techniques. Cem. Concr. Compos. 2003, 25, 491–502. [Google Scholar] [CrossRef] [Green Version]

- Ye, H.; Fu, C.; Tian, Y.; Jin, N. Chloride-Induced Steel Corrosion in Concrete Under Service Loads; Springer: Singapore, 2020. [Google Scholar]

- Zhang, D.; Zeng, Y.; Fang, M.; Jin, W. Service life prediction of precast concrete structures exposed to chloride environment. Adv. Civ. Eng. 2019, 2019, 3216328. [Google Scholar] [CrossRef]

- Liang, M.T.; Huang, R.; Jheng, H.Y. Reconsideration for a study of the effect of chloride binding on service life predictions. J. Mar. Sci. Technol. 2011, 19, 531–540. [Google Scholar] [CrossRef]

- Safehian, M.; Ramezanianpour, A.A. Assessment of service life models for determination of chloride penetration into silica fume concrete in the severe marine environmental condition. Constr. Build. Mater. 2013, 48, 287–294. [Google Scholar] [CrossRef]

- Dousti, A.; Rashetnia, R.; Ahmadi, B.; Shekarchi, M. Influence of exposure temperature on chloride diffusion in concretes incorporating silica fume or natural zeolite. Constr. Build. Mater. 2013, 49, 393–399. [Google Scholar] [CrossRef]

- Khaghanpour, R.; Dousti, A.; Shekarchi, M. Prediction of Cover Thickness Based on Long-Term Chloride Penetration in a Marine Environment. J. Perform. Constr. Facil. 2017, 31, 04016070. [Google Scholar] [CrossRef]

- Stoiber, N.; Hammerl, M.; Kromoser, B. Cradle-to-gate life cycle assessment of CFRP reinforcement for concrete structures: Calculation basis and exemplary application. J. Clean. Prod. 2021, 280, 124300. [Google Scholar] [CrossRef]

- Badogiannis, E.; Aggeli, E.; Papadakis, V.G.; Tsivilis, S. Evaluation of chloride-penetration resistance of metakaolin concrete by means of a diffusion—Binding model and of the k-value concept. Cem. Concr. Compos. 2015, 63, 1–7. [Google Scholar] [CrossRef]

- Valipour, M.; Shekarchi, M.; Arezoumandi, M. Chlorine diffusion resistivity of sustainable green concrete in harsh marine environments. J. Clean. Prod. 2017, 142, 4092–4100. [Google Scholar] [CrossRef]

- Adesina, A.; de Azevedo, A.R.G.; Amin, M.; Hadzima-Nyarko, M.; Agwa, I.S.; Zeyad, A.M.; Tayeh, B.A. Fresh and mechanical properties overview of alkali-activated materials made with glass powder as precursor. Clean. Mater. 2022, 3, 100036. [Google Scholar] [CrossRef]

- Saif, M.S.; El-Hariri, M.O.R.; Sarie-Eldin, A.I.; Tayeh, B.A.; Farag, M.F. Impact of Ca+ content and curing condition on durability performance of metakaolin-based geopolymer mortars. Case Stud. Constr. Mater. 2022, 16, e00922. [Google Scholar] [CrossRef]

- Ramezani, M. Performance of composite connections strengthened with CFRP laminate. Mag. Civ. Eng. 2021, 106, 10614. [Google Scholar] [CrossRef]

- Ramezani, M.; Dehghani, A.; Sherif, M.M. Carbon nanotube reinforced cementitious composites: A comprehensive review. Constr. Build. Mater. 2022, 315, 125100. [Google Scholar] [CrossRef]

- Ramezani, M.; Kim, Y.H.; Sun, Z. Mechanical properties of carbon-nanotube-reinforced cementitious materials: Database and statistical analysis. Mag. Concr. Res. 2020, 72, 1047–1071. [Google Scholar] [CrossRef]

- Ramezani, M.; Kim, Y.H.; Sun, Z. Modeling the mechanical properties of cementitious materials containing CNTs. Cem. Concr. Compos. 2019, 104, 103347. [Google Scholar] [CrossRef]

- Kamboozia, N.; Mousavi Rad, S.; Saed, S.A. Laboratory Investigation of the Effect of Nano-ZnO on the Fracture and Rutting Resistance of Porous Asphalt Mixture under the Aging Condition and Freeze–Thaw Cycle. J. Mater. Civ. Eng. 2022, 34, 04022052. [Google Scholar] [CrossRef]

- Mirdarsoltany, M.; Rahai, A.; Hatami, F.; Homayoonmehr, R.; Abed, F. Investigating tensile behavior of sustainable basalt–carbon, basalt–steel, and basalt–steel-wire hybrid composite bars. Sustainability 2021, 13, 10735. [Google Scholar] [CrossRef]

- El Refai, A.; Ammar, M.A.; Masmoudi, R. Bond performance of basalt fiber-reinforced polymer bars to concrete. J. Compos. Constr. 2015, 19, 04014050. [Google Scholar] [CrossRef]

- Ceroni, F. Experimental performances of RC beams strengthened with FRP materials. Constr. Build. Mater. 2010, 24, 1547–1559. [Google Scholar] [CrossRef]

- Ma, G.; Huang, Y.; Aslani, F.; Kim, T. Tensile and bonding behaviours of hybridized BFRP–steel bars as concrete reinforcement. Constr. Build. Mater. 2019, 201, 62–71. [Google Scholar] [CrossRef]

- Won, J.P.; Park, C.G. Effect of environmental exposure on the mechanical and bonding properties of hybrid FRP reinforcing bars for concrete structures. J. Compos. Mater. 2006, 40, 1063–1076. [Google Scholar] [CrossRef]

- Nanni, A.; De Luca, A.; Jawaheri Zadeh, H. Reinforced Concrete with FRP Bars; CRC Press: London, UK, 2014. [Google Scholar] [CrossRef]

- Robert, M.; Benmokrane, B. Combined effects of saline solution and moist concrete on long-term durability of GFRP reinforcing bars. Constr. Build. Mater. 2013, 38, 274–284. [Google Scholar] [CrossRef]

- Achillides, Z.; Pilakoutas, K. Bond behavior of fiber reinforced polymer bars under direct pullout conditions. J. Compos. Constr. 2004, 8, 173–181. [Google Scholar] [CrossRef]

- Rafi, M.M.; Nadjai, A.; Ali, F.; Talamona, D. Aspects of behaviour of CFRP reinforced concrete beams in bending. Constr. Build. Mater. 2008, 22, 277–285. [Google Scholar] [CrossRef]

- Issa, M.S.; Metwally, I.M.; Elzeiny, S.M. Influence of fibers on flexural behavior and ductility of concrete beams reinforced with GFRP rebars. Eng. Struct. 2011, 33, 1754–1763. [Google Scholar] [CrossRef]

- Etman, E.E.S. Innovative hybrid reinforcement for flexural members. J. Compos. Constr. 2011, 15, 2–8. [Google Scholar] [CrossRef]

- Wu, Z.; Wang, X.; Wu, G. Basalt FRP composite as reinforcements in infrastructure. In Proceedings of the Seventeenth Annual International Conference Compossites Engineering, New Orleans, LA, USA, 26–31 July 2009; Volume 26, p. 4. [Google Scholar]

- Kara, I.F.; Ashour, A.F. Flexural performance of FRP reinforced concrete beams. Compos. Struct. 2012, 94, 1616–1625. [Google Scholar] [CrossRef] [Green Version]

- Li, S.; Guo, S.; Yao, Y.; Jin, Z.; Shi, C.; Zhu, D. The effects of aging in seawater and SWSSC and strain rate on the tensile performance of GFRP/BFRP composites: A critical review. Constr. Build. Mater. 2021, 282, 122534. [Google Scholar] [CrossRef]

- Morales, C.N.; Claure, G.; Emparanza, A.R.; Nanni, A. Durability of GFRP reinforcing bars in seawater concrete. Constr. Build. Mater. 2021, 270, 121492. [Google Scholar] [CrossRef]

- Mirdarsoltany, M.; Rahai, A.; Hatami, F. Tensile behavior of GFRP hybrid composite bars in RC structures. Solid State Technol. 2021, 64, 4955–4961. [Google Scholar]

- Won, J.-P.; Park, C.-G.; Lee, S.-J.; Hong, B.-T. Durability of hybrid frp reinforcing bars in concrete structures exposed to marine environments. Int. J. Struct. Eng. 2013, 4, 63–74. [Google Scholar] [CrossRef]

- Deitz, D.H.; Harik, I.E.; Gesund, H. Physical properties of glass fiber reinforced polymer rebars in compression. J. Compos. Constr. 2003, 7, 363–366. [Google Scholar] [CrossRef]

- Systems, S. SP Systems Guide to Composites. 2016. Available online: https://composites.ugent.be/home_made_composites/documentation/SP_Composites_Guide.pdf (accessed on 1 June 2022).

- Benmokrane, B.; Ali, A.H.; Mohamed, H.M.; ElSafty, A.; Manalo, A. Laboratory assessment and durability performance of vinyl-ester, polyester, and epoxy glass-FRP bars for concrete structures. Compos. Part B Eng. 2017, 114, 163–174. [Google Scholar] [CrossRef] [Green Version]

- Benmokrane, B.; Elgabbas, F.; Ahmed, E.A.; Cousin, P. Characterization and Comparative Durability Study of Glass/Vinylester, Basalt/Vinylester, and Basalt/Epoxy FRP Bars. J. Compos. Constr. 2015, 19, 04015008. [Google Scholar] [CrossRef]

- Benmokrane, B.; Mohamed, H.M.; Manalo, A.; Cousin, P. Evaluation of Physical and Durability Characteristics of New Headed Glass Fiber–Reinforced Polymer Bars for Concrete Structures. J. Compos. Constr. 2017, 21, 04016081. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Davalos, J.F.; Ray, I.; Kim, H.Y. Accelerated aging tests for evaluations of durability performance of FRP reinforcing bars for concrete structures. Compos. Struct. 2007, 78, 101–111. [Google Scholar] [CrossRef]

- Uomoto, T.; Mutsuyoshi, H.; Katsuki, F.; Misra, S. Use of Fiber Reinforced Polymer Composites as Reinforcing Material for Concrete. J. Mater. Civ. Eng. 2002, 14, 191–209. [Google Scholar] [CrossRef]

- Benmokrane, B.; Wang, P.; Ton-That, T.M.; Rahman, H.; Robert, J.-F. Durability of Glass Fiber-Reinforced Polymer Reinforcing Bars in Concrete Environment. J. Compos. Constr. 2002, 6, 143–153. [Google Scholar] [CrossRef]

- Gowripalan, N.; Mohamed, H.M. Chloride-ion induced corrosion of galvanized and ordinary steel reinforcement in high-performance concrete. Cem. Concr. Res. 1998, 28, 1119–1131. [Google Scholar] [CrossRef]

- Papadakis, V.G. Effect of supplementary cementing materials on concrete resistance against carbonation and chloride ingress. Cem. Concr. Res. 2000, 30, 291–299. [Google Scholar] [CrossRef]

- El-Nemr, A.; Ahmed, E.A.; Barris, C.; Benmokrane, B. Bond-dependent coefficient of glass- and carbon-FRP bars in normal- and high-strength concretes. Constr. Build. Mater. 2016, 113, 77–89. [Google Scholar] [CrossRef]

- ASTM D7205/D7205M-21; Standard Test Method for Tensile Properties of Fiber Reinforced Polymer Matrix Composite Bars. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D7913/D7913M; Standard Test Method for Bond Strength of Fiber-Reinforced Polymer Matrix Composite Bars to Concrete by Pullout Testing. ASTM International (ASTM): West Conshohocken, PA, USA, 2020; Volume 14, pp. 1–9. [CrossRef]

- Wu, G.; Dong, Z.-Q.; Wang, X.; Zhu, Y.; Wu, Z.-S. Prediction of Long-Term Performance and Durability of BFRP Bars under the Combined Effect of Sustained Load and Corrosive Solutions. J. Compos. Constr. 2015, 19, 04014058. [Google Scholar] [CrossRef]

- Elgabbas, F.; Ahmed, E.A.; Benmokrane, B. Physical and mechanical characteristics of new basalt-FRP bars for reinforcing concrete structures. Constr. Build. Mater. 2015, 95, 623–635. [Google Scholar] [CrossRef]

- Chinaka, E.; Shokouhian, M.; Head, M.; Efe, S. An experimental investigation of bond strength of AFRP bars with self-consolidating concrete. Civ. Eng. Des. 2019, 1, 148–160. [Google Scholar] [CrossRef]

- Tello NA, H.; Abdelrahman, M.; El Tonsy, S.; Weheda, F.; Abed, F.H. Effect of Harsh Environmental Exposure on the Flexural Performance of BFRP-RC Beams. In 2020 Advances in Science and Engineering Technology International Conferences (ASET); IEEE: Piscataway, NJ, USA, 2020; pp. 1–5. [Google Scholar]

- Alkhraisha, H.; Mhanna, H.; Tello, N.; Abed, F. Serviceability and flexural behavior of concrete beams reinforced with basalt fiber-reinforced polymer (BFRP) bars exposed to harsh conditions. Polymers 2020, 12, 2110. [Google Scholar] [CrossRef] [PubMed]

- Okamoto, T.; Matsubara, S.; Tanigaki, M.; Hasuo, K. Practical application and performance of PPC beams reinforced with braided FRP bars. Spec. Publ 1993, 138, 875–894. [Google Scholar]

- Rifai MAl El-Hassan, H.; El-Maaddawy, T.; Abed, F. Durability of basalt FRP reinforcing bars in alkaline solution and moist concrete environments. Constr. Build. Mater. 2020, 243, 118258. [Google Scholar] [CrossRef]

- Wang, Z.; Zhao, X.L.; Xian, G.; Wu, G.; Singh Raman, R.K.; Al-Saadi, S.; Haque, A. Long-term durability of basalt- and glass-fibre reinforced polymer (BFRP/GFRP) bars in seawater and sea sand concrete environment. Constr. Build. Mater. 2017, 139, 467–489. [Google Scholar] [CrossRef]

- Ellis, D.S.; Tabatabai, H.; Nabizadeh, A. Residual tensile strength and bond properties of GFRP bars after exposure to elevated temperatures. Materials 2018, 11, 346. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, Z.; Zhao, X.L.; Xian, G.; Wu, G.; Raman, R.K.S.; Al-Saadi, S. Effect of sustained load and seawater and sea sand concrete environment on durability of basalt- and glass-fibre reinforced polymer (B/GFRP) bars. Corros. Sci. 2018, 138, 200–218. [Google Scholar] [CrossRef]

- Lu, C.; Ni, M.; Chu, T.; He, L. Comparative Investigation on Tensile Performance of FRP Bars after Exposure to Water, Seawater, and Alkaline Solutions. J. Mater. Civ. Eng. 2020, 32, 04020170. [Google Scholar] [CrossRef]

- Wu, G.; Wang, X.; Wu, Z.; Dong, Z.; Xie, Q. Degradation of basalt FRP bars in alkaline environment. Sci. Eng. Compos. Mater. 2015, 22, 649–657. [Google Scholar] [CrossRef]

- Brown, V.L.; Bartholomew, C.L. FRP reinforcing bars in reinforced concrete members. ACI Mater. J. 1993, 90, 34–39. [Google Scholar] [CrossRef]

- Toutanji, H.; Deng, Y. Deflection and crack-width prediction of concrete beams reinforced with glass FRP rods. Constr. Build. Mater. 2003, 17, 69–74. [Google Scholar] [CrossRef]

- Murphy, M.; O’mahony, M.; Lycett, C.; Jamieson, I. Recycled polymers for use as bitumen modifiers. J. Mater. Civ. Eng. 2001, 13, 306–314. [Google Scholar] [CrossRef] [Green Version]

- Yan, F.; Lin, Z. New strategy for anchorage reliability assessment of GFRP bars to concrete using hybrid artificial neural network with genetic algorithm. Compos. Part B Eng. 2016, 92, 420–433. [Google Scholar] [CrossRef] [Green Version]

- Sharaky, I.A.; Torres, L.; Baena, M.; Miàs, C. An experimental study of different factors affecting the bond of NSM FRP bars in concrete. Compos. Struct. 2013, 99, 350–365. [Google Scholar] [CrossRef]

- Nanni, A.; Boothby, T.E.; Bakis, C.E. Test Methods for FRP-Concrete Systems Subjected to Mechanical Loads: State of the Art Review. J. Reinf. Plast. Compos. 1995, 14, 524–558. [Google Scholar] [CrossRef]

- Benmokrane, B.; Tighiouart, B. Bond strength and load distribution of composite GFRP reinforcing bars in concrete. Mater. J. 1996, 93, 254–259. [Google Scholar]

- Kachlakev, D.I.; Lundy, J.R. Bond strength study of hollow composite rebars with different micro structure. In Proceedings of the Second International Conference on Composites in Infrastructure National Science Foundation, Tucson, AZ, USA, 5–7 January 1998. [Google Scholar]

- El Refai, A.; Abed, F.; Altalmas, A. Bond Durability of Basalt Fiber–Reinforced Polymer Bars Embedded in Concrete under Direct Pullout Conditions. J. Compos. Constr. 2015, 19, 04014078. [Google Scholar] [CrossRef]

- Abed, F.; Elmesalami, N. Bond-Dependent Coefficient of GFRP Bars in Concrete Beams. In Proceedings of the 2019 Advances in Science and Engineering Technology International Conferences (ASET), Dubai, United Arab Emirates, 26 March–10 April 2019; pp. 1–5. [Google Scholar]

- Emparanza, A.R.; de Caso YBasalo, F.; Kampmann, R.; Usabiaga, I.A. Evaluation of the bond-to-concrete properties of GFRP rebars in marine environments. Infrastructures 2018, 3, 44. [Google Scholar] [CrossRef] [Green Version]

- Altalmas, A.; El Refai, A.; Abed, F. Bond degradation of basalt fiber-reinforced polymer (BFRP) bars exposed to accelerated aging conditions. Constr. Build. Mater. 2015, 81, 162–171. [Google Scholar] [CrossRef]

- Hassan, M.; Benmokrane, B.; ElSafty, A.; Fam, A. Bond durability of basalt-fiber-reinforced-polymer (BFRP) bars embedded in concrete in aggressive environments. Compos. Part B Eng. 2016, 106, 262–272. [Google Scholar] [CrossRef]

- Dong, Z.; Wu, G.; Xu, B.; Wang, X.; Taerwe, L. Bond durability of BFRP bars embedded in concrete under seawater conditions and the long-term bond strength prediction. Mater. Des. 2016, 92, 552–562. [Google Scholar] [CrossRef]

- Yang, Y.; Li, Z.; Zhang, T.; Wei, J.; Yu, Q. Bond-Slip Behavior of Basalt Fiber Reinforced Polymer Bar in Concrete Subjected to Simulated Marine Environment: Effects of BFRP Bar Size, Corrosion Age, and Concrete Strength. Int. J. Polym. Sci. 2017, 2017, 16–24. [Google Scholar] [CrossRef]

- Seo, D.-W.; Park, K.-T.; You, Y.-J.; Kim, H.-Y. Enhancement in Elastic Modulus of GFRP Bars by Material Hybridization. Engineering 2013, 5, 865–869. [Google Scholar] [CrossRef] [Green Version]

- Seo, D.W.; Park, K.T.; You, Y.J.; Lee, S.Y. Experimental Investigation for Tensile Performance of GFRP-Steel Hybridized Rebar. Adv. Mater. Sci. Eng. 2016, 2016, 9401427. [Google Scholar] [CrossRef] [Green Version]

- Sun, Z.Y.; Yang, Y.; Qin, W.H.; Ren, S.T.; Wu, G. Experimental study on flexural behavior of concrete beams reinforced by steel-fiber reinforced polymer composite bars. J. Reinf. Plast. Compos. 2012, 31, 1737–1745. [Google Scholar] [CrossRef]

- You, Y.J.; Park, Y.H.; Kim, H.Y.; Park, J.S. Hybrid effect on tensile properties of FRP rods with various material compositions. Compos. Struct. 2007, 80, 117–122. [Google Scholar] [CrossRef]

- Cui, Y.-H.; Tao, J. A new type of ductile composite reinforcing bar with high tensile elastic modulus for use in reinforced concrete structures. Can. J. Civ. Eng. 2009, 36, 672–675. [Google Scholar] [CrossRef]

- Won, J.P.; Park, C.G.; Jang, C.I. Tensile fracture and bond properties of ductile hybrid FRP reinforcing bars. Polym. Polym. Compos. 2007, 15, 9–16. [Google Scholar] [CrossRef]

- Hwang, J.-H.; Seo, D.-W.; Park, K.-T.; You, Y.-J. Experimental Study on the Mechanical Properties of FRP Bars by Hybridizing with Steel Wires. Engineering 2014, 06, 365–373. [Google Scholar] [CrossRef]

- Liang, Y.; Sun, C.; Ansari, F. Acoustic Emission Characterization of Damage in Hybrid Fiber-Reinforced Polymer Rods. J. Compos. Constr. 2004, 8, 70–78. [Google Scholar] [CrossRef]

- Correia, L.; Cunha, F.E.M.; Mota, C.; Fangueiro, R.; Nunes, J.P. Pseudo-Ductile Braided Composite Rods (BCRs) Produced by Braidtrusion. In Proceedings of the European Conference on Composite Materials (ECCM), Munich, Germany, 26–30 June 2016. [Google Scholar]

- Zhou, Y.; Gao, H.; Hu, Z.; Qiu, Y.; Guo, M.; Huang, X.; Hu, B. Ductile, durable, and reliable alternative to FRP bars for reinforcing seawater sea-sand recycled concrete beams: Steel/FRP composite bars. Constr. Build. Mater. 2021, 269, 121264. [Google Scholar] [CrossRef]

- Dong, Z.; Wu, G.; Xu, Y. Experimental study on the bond durability between steel-FRP composite bars (SFCBs) and sea sand concrete in ocean environment. Constr. Build. Mater. 2016, 115, 277–284. [Google Scholar] [CrossRef]

- Dong, Z.; Wu, G.; Zhao, X.L.; Zhu, H.; Lian, J. Bond durability of steel-FRP composite bars embedded in seawater sea-sand concrete under constant bending and shearing stress. Constr. Build. Mater. 2018, 192, 808–817. [Google Scholar] [CrossRef]

- Szmigiera, E.D.; Protchenko, K.; Urba ski, M.; Garbacz, A. Mechanical properties of hybrid FRP bars and nano-hybrid FRP bars. Arch. Civ. Eng. 2019, 65, 97–110. [Google Scholar] [CrossRef] [Green Version]

- Ramezani, M.; Kim, Y.H.; Sun, Z. Probabilistic model for flexural strength of carbon nanotube reinforced cement-based materials. Compos. Struct. 2020, 253, 112748. [Google Scholar] [CrossRef]

- Ramezani, M.; Kim, Y.H.; Sun, Z. Elastic modulus formulation of cementitious materials incorporating carbon nanotubes: Probabilistic approach. Constr. Build. Mater. 2021, 274, 122092. [Google Scholar] [CrossRef]

| Fiber Type | Density (kg/m3) | Tensile Strength (MPa) | Young Modulus (GPA) | Ultimate Tensile Strain (%) | Thermal Expansion Coefficient (10−6/°C) | Poisson’s Coefficient |

|---|---|---|---|---|---|---|

| E-glass | 2500 | 3450 | 72.4 | 2.4 | 5 | 0.22 |

| S-glass | 2500 | 4580 | 85.5 | 3.3 | 2.9 | 0.22 |

| Alkali resistant glass | 2270 | 1800–3500 | 70–76 | 2.0–3.0 | - | - |

| ECR | 2620 | 3500 | 80.5 | 4.6 | 6 | 0.22 |

| Carbon (high modulus) | 1950 | 2500–4000 | 350–650 | 0.5 | −1.2–0.1 | 0.20 |

| Carbon (high strength) | 1750 | 3500 | 240 | 1.1 | −0.6–0.2 | 0.20 |

| Aramid (Kevlar 29) | 1440 | 2760 | 62 | 4.4 | −2.0 longitudinal 59 radial | 0.35 |

| Aramid (Kevlar 49) | 1440 | 3620 | 124 | 2.2 | −2.0 longitudinal 59 radial | 0.35 |

| Aramid (Kevlar 149) | 1440 | 3450 | 175 | 1.4 | −2.0 longitudinal 59 radial | 0.35 |

| Aramid (Technora H) | 1390 | 3000 | 70 | 4.4 | −6.0 longitudinal 59 radial | 0.35 |

| Aramid (SVM) | 1430 | 3800–4200 | 130 | 3.5 | - | - |

| Basalt (Albarrie) | 2800 | 4840 | 89 | 3.1 | 8 | - |

| Property | Matrix | ||

|---|---|---|---|

| Polyester | Epoxy | Vinyl Ester | |

| Density (kg/m3) | 1200–1400 | 1200–1400 | 1150–1350 |

| Tensile strength (MPa) | 34.5–104 | 55–130 | 73–81 |

| Longitudinal modulus (GPa) | 2.1–3.45 | 2.75–4.10 | 3.0–3.5 |

| Poisson’s coefficient | 0.35–0.39 | 0.38–0.40 | 0.36–0.39 |

| Thermal expansion coefficient (10−6/°C)) | 55–100 | 45–65 | 50–75 |

| Moisture content (%) | 0.15–0.60 | 0.08–0.15 | 0.14–0.30 |

| Type | Bar Diameter (mm) | Solution | Days | Tensile Strength (MPa) | Ref. | Retention (%) |

|---|---|---|---|---|---|---|

| GFRP | 9.53 | Seawater | 70 | 754 | [66] | 98 |

| GFRP | 9.53 | Alkaline | 60 | 482 | [66] | 52 |

| GFRP | 6 | High-performance seawater sea sand concrete | 63 | 1036 | [81] | 97.9 |

| GFRP | 6 | Normal seawater sea sand concrete | 42 | 728 | [81] | 68.7 |

| GFRP | 19 | - | - | 633.8 | [82] | 98 |

| GFRP | 19 | - | - | 535.7 | [82] | 83 |

| GFRP | 12.7 | Saline solution | 60 | 781 | [50] | 99 |

| GFRP | 12.7 | Saline solution | 365 | 702 | [50] | 89 |

| GFRP | 6 | High-performance seawater sea sand concrete/20% | 42 | 988 | [83] | 93.7 |

| GFRP | 6 | High-performance seawater sea sand concrete/20% | 63 | 617 | [83] | 58.6 |

| GFRP | 8 | Alkaline | 45 | 1359.8 | [84] | 96.4 |

| GFRP | 8 | Alkaline | 90 | 1061.4 | [84] | 75.3 |

| GFRP | 8 | Alkaline | 135 | 994.7 | [84] | 70.5 |

| GFRP | 8 | Alkaline | 180 | 974.8 | [84] | 69.1 |

| GFRP | 8 | Seawater | 45 | 1402.6 | [84] | 99.5 |

| GFRP | 8 | Seawater | 90 | 1298.1 | [84] | 92.09 |

| GFRP | 8 | Seawater | 135 | 1275.2 | [84] | 90.4 |

| GFRP | 8 | Seawater | 180 | 1152.9 | [84] | 81.7 |

| BFRP | 6 | High-performance seawater sea sand concrete | 21 | 1341 | [81] | 99.3 |

| BFRP | 6 | Normal seawater sea sand concrete | 63 | 352 | [81] | 26 |

| BFRP | 6 | Alkaline | 21 | 1385 | [74] | 99.1 |

| BFRP | 6 | Alkaline | 63 | 852 | [74] | 60.9 |

| BFRP | 6 | Deionized water | 42 | 1320 | [74] | 94.4 |

| BFRP | 6 | Salt | 42 | 1320 | [74] | 94.4 |

| BFRP | 6 | Acid | 42 | 1301 | [74] | 93.1 |

| BFRP | 7 | Alkaline | 42 | 1012 | [75] | 60.2 |

| BFRP | 8 | Alkaline | 30 | 1409 | [75] | 89.9 |

| BFRP | 6 | Alkaline | 63 | 802 | [85] | 60.58 |

| BFRP | 12 | Alkaline | 21 | 1036 | [85] | 95.18 |

| BFRP | 6 | High-performance seawater sea sand concrete/20% | 42 | 1276 | [83] | 94 |

| BFRP | 6 | High-performance seawater sea sand concrete/40% | 63 | 586 | [83] | 43.2 |

| BFRP | 8 | Alkaline | 45 | 1194.7 | [84] | 91.9 |

| BFRP | 8 | Alkaline | 90 | 1148.9 | [84] | 88.4 |

| BFRP | 8 | Alkaline | 135 | 1078.5 | [84] | 82.9 |

| BFRP | 8 | Alkaline | 180 | 1008.6 | [84] | 77.6 |

| BFRP | 8 | Seawater | 45 | 1095.2 | [84] | 84.2 |

| BFRP | 8 | Seawater | 90 | 1028.5 | [84] | 79.1 |

| BFRP | 8 | Seawater | 135 | 998.7 | [84] | 76.8 |

| BFRP | 8 | Seawater | 180 | 984.8 | [84] | 75.7 |

| CFRP | 3 | Alkaline | 70 | 2476 | [66] | 96 |

| CFRP | 8 | Alkaline | 45 | 2059 | [84] | 99.03 |

| CFRP | 8 | Alkaline | 90 | 1966.6 | [84] | 94.5 |

| CFRP | 8 | Alkaline | 135 | 1928.8 | [84] | 92.7 |

| CFRP | 8 | Alkaline | 180 | 1720.5 | [84] | 82.7 |

| CFRP | 8 | Seawater | 45 | 1894.9 | [84] | 91.1 |

| CFRP | 8 | Seawater | 90 | 1758.7 | [84] | 84.5 |

| CFRP | 8 | Seawater | 135 | 1692.5 | [84] | 81.4 |

| CFRP | 8 | Seawater | 180 | 1638.3 | [84] | 78.8 |

| FRP Type | Bar Diameter (mm) and Sizing Shape | Solution | Temperature | Days | Mean Value of Bond Strength (MPa) | Ref. |

|---|---|---|---|---|---|---|

| GFRP | 10, Sand coating | Seawater | 23 | 60 | 14.73 | [96] |

| GFRP | 10, Sand coating | Seawater | 40 | 60 | 18.44 | [96] |

| GFRP | 10, Sand coating | Seawater | 60 | 60 | 16.29 | [96] |

| GFRP | 10, Sand coating | Seawater | 23 | 120 | 15.7 | [96] |

| GFRP | 10, Sand coating | Seawater | 40 | 120 | 14.7 | [96] |

| GFRP | 10, Sand coating | Seawater | 60 | 120 | 15.85 | [96] |

| GFRP | 10, Helical wrap | Seawater | 23 | 60 | 16.26 | [96] |

| GFRP | 10, Helical wrap | Seawater | 40 | 60 | 16.84 | [96] |

| GFRP | 10, Helical wrap | Seawater | 60 | 60 | 18.17 | [96] |

| GFRP | 10, Helical wrap | Seawater | 23 | 120 | 19.9 | [96] |

| GFRP | 10, Helical wrap | Seawater | 40 | 120 | 19.63 | [96] |

| GFRP | 10, Helical wrap | Seawater | 60 | 120 | 17.15 | [96] |

| GFRP | 10, Lugs | Seawater | 23 | 60 | 18.62 | [96] |

| GFRP | 10, Lugs | Seawater | 40 | 60 | 20.71 | [96] |

| GFRP | 10, Lugs | Seawater | 60 | 60 | 20.59 | [96] |

| GFRP | 10, Lugs | Seawater | 23 | 120 | 21.2 | [96] |

| GFRP | 10, Lugs | Seawater | 40 | 120 | 19.68 | [96] |

| GFRP | 10, Lugs | Seawater | 60 | 120 | 19.93 | [96] |

| GFRP | 12, Ribbed | Seawater | 60 | 30 | 18.46 | [97] |

| GFRP | 12, Ribbed | Seawater | 60 | 60 | 18.22 | [97] |

| GFRP | 12, Ribbed | Seawater | 60 | 90 | 16.44 | [97] |

| GFRP | 12, Ribbed | Alkaline | 60 | 30 | 18.74 | [97] |

| GFRP | 12, Ribbed | Alkaline | 60 | 60 | 18.3 | [97] |

| GFRP | 12, Ribbed | Alkaline | 60 | 90 | 18.17 | [97] |

| GFRP | 12, Ribbed | Acid | 60 | 30 | 20 | [97] |

| GFRP | 12, Ribbed | Acid | 60 | 60 | 17 | [97] |

| GFRP | 12, Ribbed | Acid | 60 | 90 | 13.74 | [97] |

| BFRP | 12, Deformed surface | Alkaline | 40 | 45 | 16.48 | [98] |

| BFRP | 12, Deformed surface | Alkaline | 50 | 45 | 21.4 | [98] |

| BFRP | 12, Deformed surface | Alkaline | 60 | 45 | 20.37 | [98] |

| BFRP | 12, Deformed surface | Alkaline | 40 | 90 | 10.64 | [98] |

| BFRP | 12, Deformed surface | Alkaline | 50 | 90 | 20.59 | [98] |

| BFRP | 12, Deformed surface | Alkaline | 60 | 90 | 20.78 | [98] |

| BFRP | 12, Deformed surface | Alkaline | 40 | 180 | 15.72 | [98] |

| BFRP | 12, Deformed surface | Alkaline | 50 | 180 | 19.24 | [98] |

| BFRP | 12, Deformed surface | Alkaline | 60 | 180 | 21.81 | [98] |

| BFRP | 12, Sand-coated | Tap water | 80 | 60 | 29.4 | [97] |

| BFRP | 12, Sand-coated | Seawater | 60 | 30 | 29.4 | [97] |

| BFRP | 12, Sand-coated | Seawater | 60 | 60 | 25.6 | [97] |

| BFRP | 12, Sand-coated | Seawater | 60 | 90 | 23.9 | [97] |

| BFRP | 12, Sand-coated | Alkaline | 60 | 30 | 26.2 | [97] |

| BFRP | 12, Sand-coated | Alkaline | 60 | 60 | 26.53 | [97] |

| BFRP | 12, Sand-coated | Alkaline | 60 | 90 | 24.3 | [97] |

| BFRP | 12, Sand-coated | Acid | 60 | 30 | 23.22 | [97] |

| BFRP | 12, Sand-coated | Acid | 60 | 60 | 22.92 | [97] |

| BFRP | 12, Sand-coated | Acid | 60 | 90 | 22.74 | [97] |

| BFRP | 8, Sand-coated | Seawater | 40 | 15 | 9.54 | [99] |

| BFRP | 8, Twined | Artificial seawater | 40 | 60 | 20.8 | [100] |

| BFRP | 8, Twined | Artificial seawater | 40 | 90 | 17.8 | [100] |

| BFRP | 13, Ribbed | Artificial seawater | 50 | 270 | 8.6 | [99] |

| CFRP | 8, Ribbed | Seawater | 25 | 30 | 24.56 | [99] |

| CFRP | 8, Ribbed | Seawater | 25 | 45 | 24.01 | [99] |

| CFRP | 8, Ribbed | Seawater | 40 | 15 | 26.24 | [99] |

| CFRP | 8, Ribbed | Seawater | 40 | 30 | 28.9 | [99] |

| CFRP | 8, Ribbed | Seawater | 40 | 45 | 31.25 | [99] |

| CFRP | 8, Ribbed | Seawater | 55 | 30 | 25.64 | [99] |

| CFRP | 8, Ribbed | Seawater | 55 | 45 | 23.13 | [99] |

| Materials | Steel to FRP Ratio | Diameter | Tensile Strength (MPa) | Improvement in Tensile Strength | Elastic Modulus (GPa) | Reduction in Elastic Modulus | Ref. | |

|---|---|---|---|---|---|---|---|---|

| Core | Crust | |||||||

| Steel rod | Glass | 9.2 | 13 | 1122.7 | 203.43 | 76.5 | −61.75 | [107] |

| Steel rod | Glass | 29.2 | 13 | 1269.7 | 243.16 | 94.9 | −52.55 | [107] |

| Steel rod | Glass | 51 | 13 | 1258.8 | 240.22 | 111.2 | −44.4 | [107] |

| Steel rod | Glass | 76.2 | 13 | 833.9 | 125.38 | 148.2 | −25.9 | [107] |

| Steel wire | Glass | 9.8 | 13 | 1150.3 | 210.89 | 62.6 | −68.7 | [107] |

| Steel wire | Glass | 31.8 | 13 | 1245.4 | 236.59 | 99.8 | −50.1 | [107] |

| Steel wire | Glass | 57 | 13 | 1323.2 | 257.62 | 126.9 | −36.55 | [107] |

| Steel wire | Glass | 70.3 | 13 | 1156.4 | 212.54 | 157.3 | −21.35 | [107] |

| Steel rebar | Glass | 57.2 | 13 | 669.5 | 80.95 | 110.1 | −44.95 | [107] |

| Steel wire | Glass | 10.9 | 16 | 1232.7 | 233.16 | 58.5 | −70.75 | [107] |

| Steel wire | Glass | 36.9 | 16 | 1238.6 | 234.76 | 97.2 | −51.4 | [107] |

| Steel wire | Glass | 60.2 | 16 | 1283.1 | 246.78 | 143.3 | −28.35 | [107] |

| Steel wire | Glass | 70.1 | 16 | 1361.8 | 268.05 | 155.1 | −22.45 | [107] |

| Steel rebar | Glass | 36.6 | 16 | 779.5 | 110.68 | 100.4 | −49.8 | [107] |

| Steel rebar | GFRP | 63.2 | 16 | 596.5 | 61.22 | 146.8 | −26.6 | [107] |

| Steel–Glass | Carbon–Twaron | - | 10 | 628 | 69.73 | 142.11 | −28.945 | [105] |

| Glass | Carbon | - | 9.5 | 1191 | 221.89 | - | - | [108] |

| Steel rebar | Glass | 9.5 | 13 | 762.1 | 105.97 | 53.7 | −73.15 | [101] |

| Dispersed Steel wire | Glass | 30.8 | 13 | 688.2 | 86.00 | 98.3 | −50.85 | [101] |

| Steel rebar | Glass | 47.9 | 13 | 715.4 | 93.35 | 133.2 | −33.4 | [101] |

| Steel wire | Glass | 25 | 19 | 1217.9 | 229.16 | 90.8 | −54.6 | [102] |

| Steel wire | Glass | 42.3 | 19 | 1197.2 | 223.57 | 123.2 | −38.4 | [102] |

| Steel wire | Glass | 66.3 | 19 | 781.8 | 111.30 | 118.5 | −40.75 | [102] |

| Steel rebar | Glass | 24.7 | 19 | 899.6 | 143.14 | 88.8 | −55.6 | [102] |

| Steel rebar | Glass | 45.9 | 19 | 537.7 | 45.32 | 120.7 | −39.65 | [102] |

| Steel rebar | Glass | 67.9 | 19 | 466.6 | 26.11 | 148.2 | −25.9 | [102] |

| Carbon | Glass | - | 12.7 | 1281 | 246.22 | 80.4 | −59.8 | [104] |

| Glass | Carbon | - | 12.7 | 1083 | 192.70 | 78.9 | −60.55 | [104] |

| Dispersed Carbon | Glass | - | 12.7 | 1045 | 182.43 | 62.4 | −68.8 | [104] |

| Steel | Glass | 33.3 | 4 | 705.1 | 90.57 | 81.1 | −59.45 | [109] |

| Steel | Glass | 66.6 | 4 | 699.53 | 89.06 | 99.4 | −50.3 | [109] |

| Steel | Basalt | 66.6 | 4 | 779.66 | 110.72 | 110.4 | −44.8 | [109] |

| Steel | Basalt | 76 | 12 | 492.8 | 33.19 | 129.17 | −35.415 | [47] |

| Carbon | Aramid | - | - | 800 | 116.22 | 63 | −68.5 | [47] |

| Carbon | Glass | - | - | 550 | 48.65 | 43 | −78.5 | [47] |

| Carbon | Aramid–Glass | - | - | 503 | 35.95 | 37 | −81.5 | [47] |

| Steel bar | Basalt | 56.2 | 10 | 798.6 | 115.84 | 88 | −56 | [44] |

| Steel wire | Basalt | 28.2 | 10 | 1027 | 177.57 | 55 | −72.5 | [44] |

| Carbon | Basalt | - | 10 | 869.7 | 135.05 | 106 | −47 | [44] |

| Steel | Glass | 56.2 | 10 | 798.6 | 115.84 | 96.41 | −51.795 | [59] |

| Steel | Carbon | - | 10 | 950 | 156.76 | 129 | −35.5 | [110] |

| Steel | Carbon | - | 14 | 825 | 122.97 | 132 | −34 | [110] |

| Steel | Glass | - | 10 | 662 | 78.92 | 92 | −54 | [110] |

| Steel | Carbon | - | 12 | 716 | 93.51 | 112 | −44 | [110] |

| Steel | Carbon | - | 14 | 706 | 90.81 | 119 | −40.5 | [110] |

| Steel | Glass | - | 12 | 623 | 68.38 | 77 | −61.5 | [110] |

| Steel | Carbon | - | 16 | 700 | 89.19 | 118 | −41 | [110] |

| Steel | Basalt | - | 12.5 | 480.9 | 29.97 | 97.8 | −51.1 | [111] |

| Steel | Basalt | - | 15 | 718 | 94.05 | 108.9 | −45.55 | [112] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mirdarsoltany, M.; Abed, F.; Homayoonmehr, R.; Alavi Nezhad Khalil Abad, S.V. A Comprehensive Review of the Effects of Different Simulated Environmental Conditions and Hybridization Processes on the Mechanical Behavior of Different FRP Bars. Sustainability 2022, 14, 8834. https://doi.org/10.3390/su14148834

Mirdarsoltany M, Abed F, Homayoonmehr R, Alavi Nezhad Khalil Abad SV. A Comprehensive Review of the Effects of Different Simulated Environmental Conditions and Hybridization Processes on the Mechanical Behavior of Different FRP Bars. Sustainability. 2022; 14(14):8834. https://doi.org/10.3390/su14148834

Chicago/Turabian StyleMirdarsoltany, Mohammadamin, Farid Abed, Reza Homayoonmehr, and Seyed Vahid Alavi Nezhad Khalil Abad. 2022. "A Comprehensive Review of the Effects of Different Simulated Environmental Conditions and Hybridization Processes on the Mechanical Behavior of Different FRP Bars" Sustainability 14, no. 14: 8834. https://doi.org/10.3390/su14148834

APA StyleMirdarsoltany, M., Abed, F., Homayoonmehr, R., & Alavi Nezhad Khalil Abad, S. V. (2022). A Comprehensive Review of the Effects of Different Simulated Environmental Conditions and Hybridization Processes on the Mechanical Behavior of Different FRP Bars. Sustainability, 14(14), 8834. https://doi.org/10.3390/su14148834