Integrating Human Barriers in Human Reliability Analysis: A New Model for the Energy Sector

Abstract

1. Introduction

2. Literature Review

2.1. Traditional HRA: SPAR-H and HEART Methodologies

2.2. Human Factors as Safety Barriers

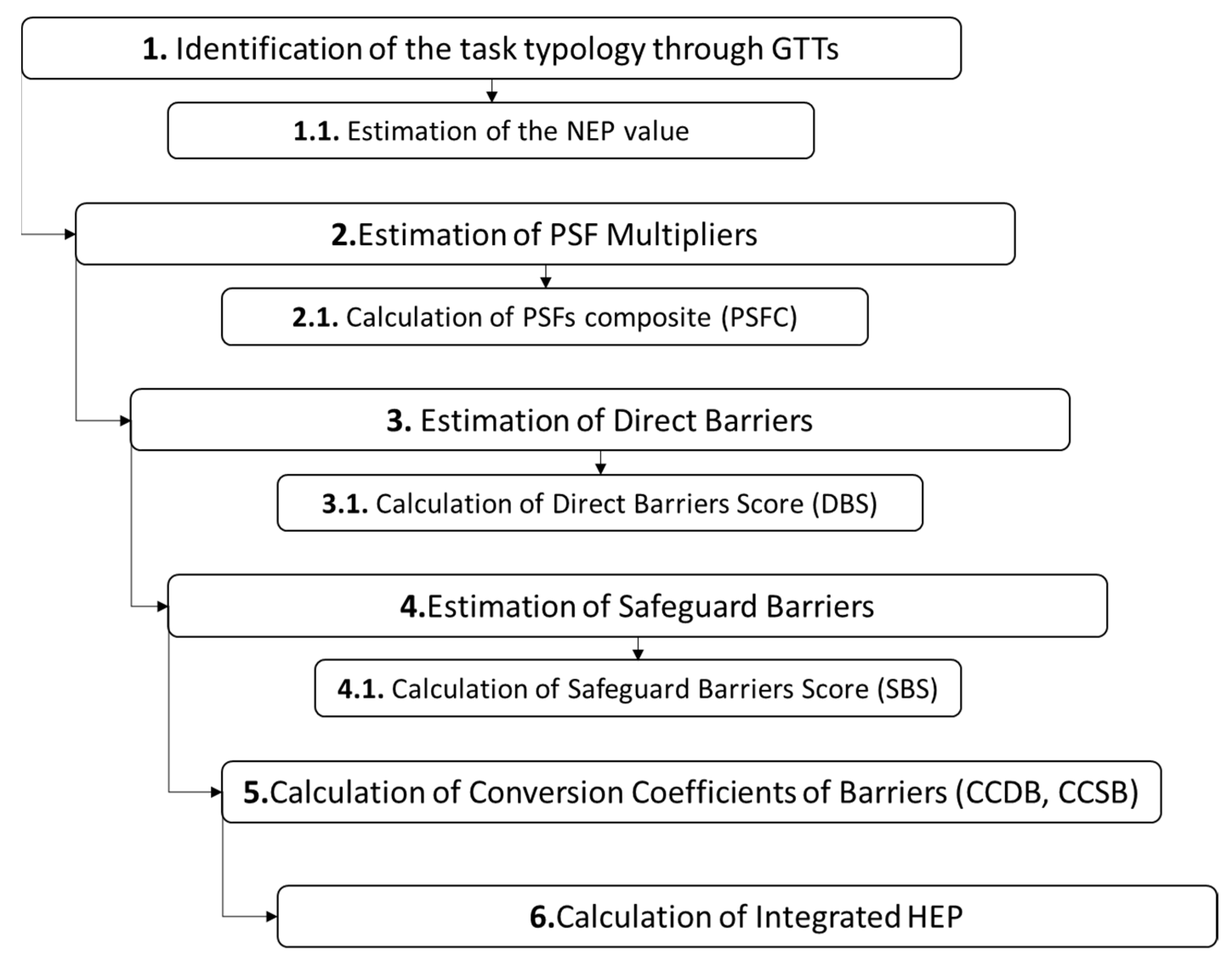

3. Development of the Methodology

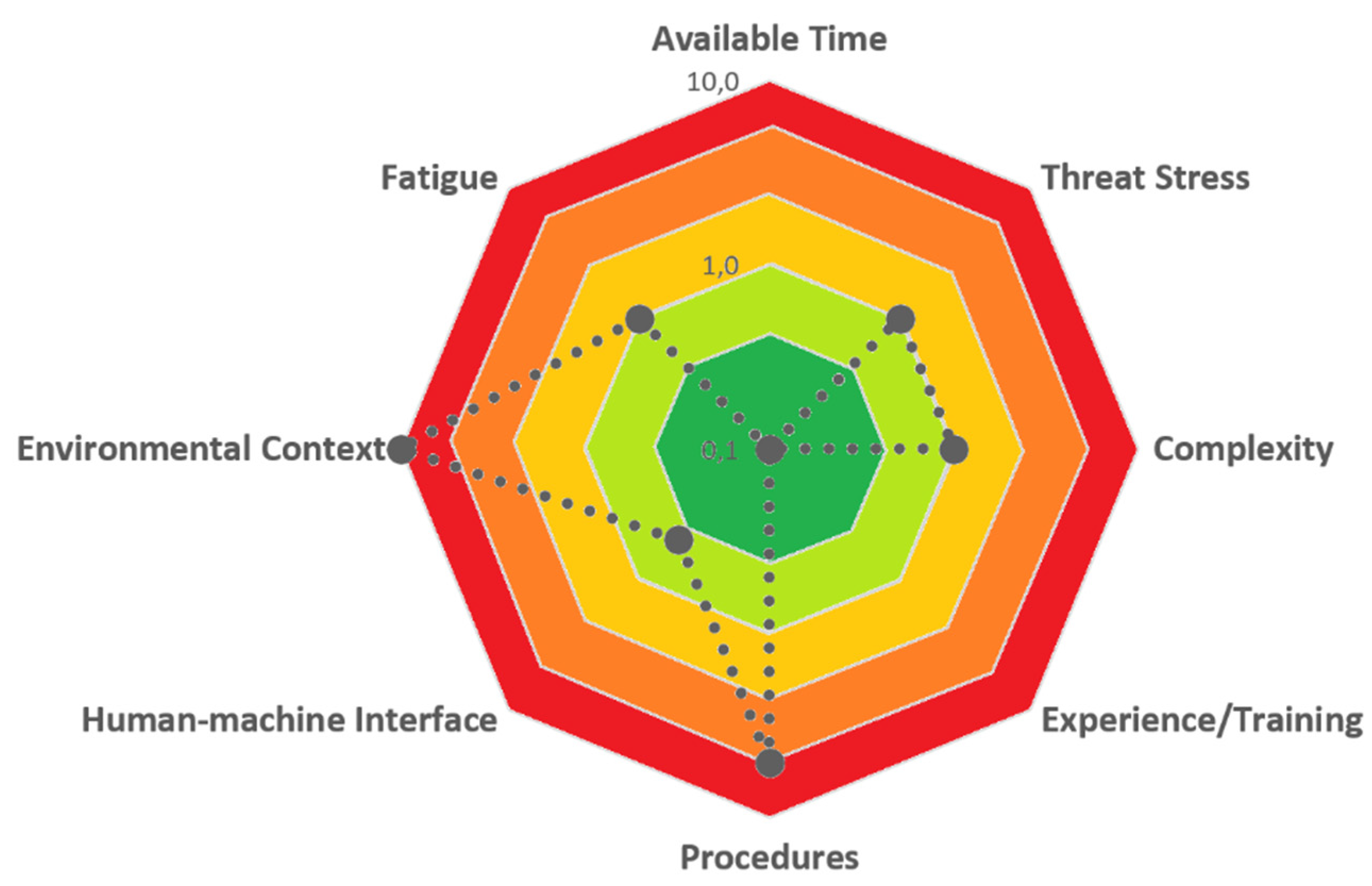

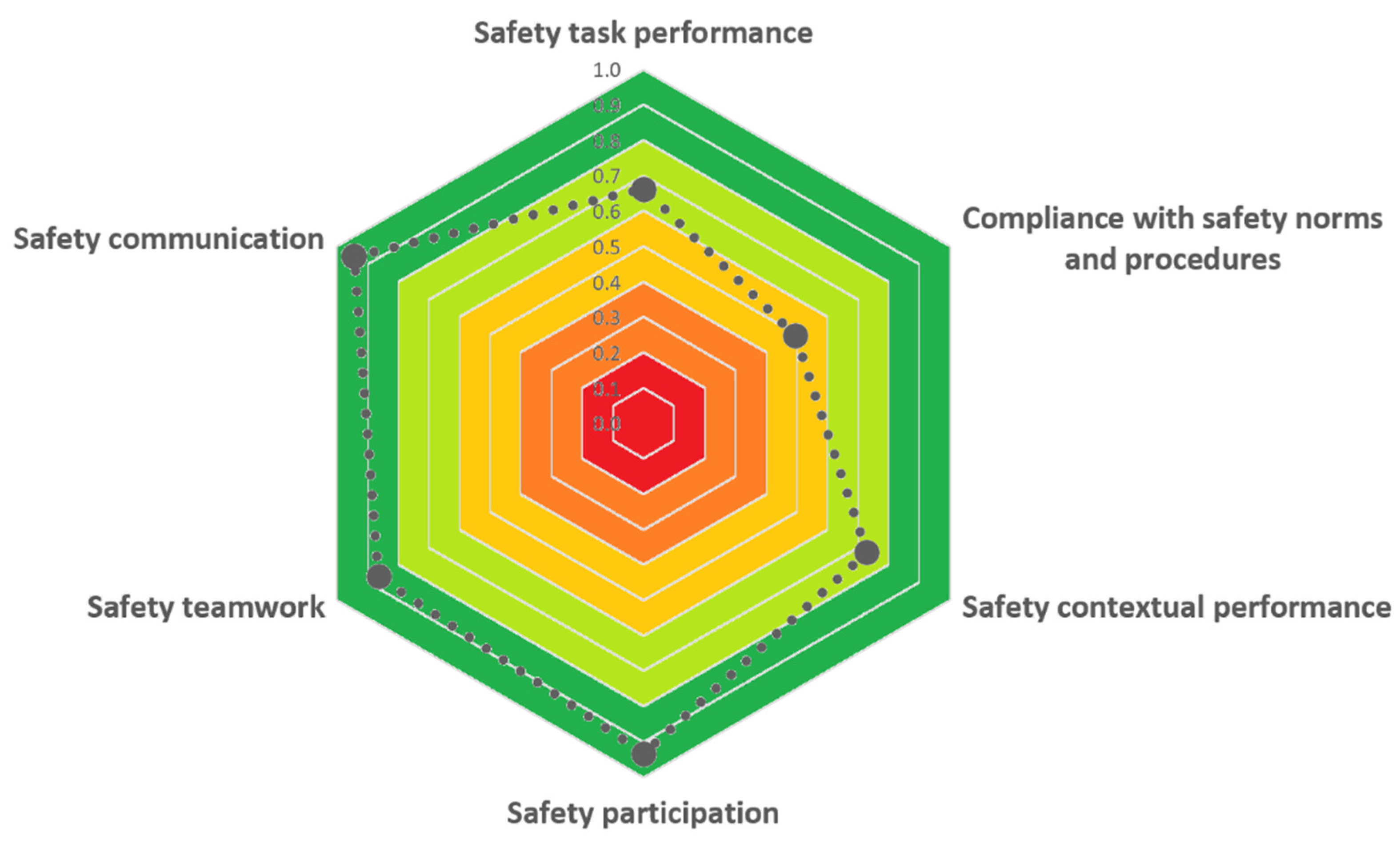

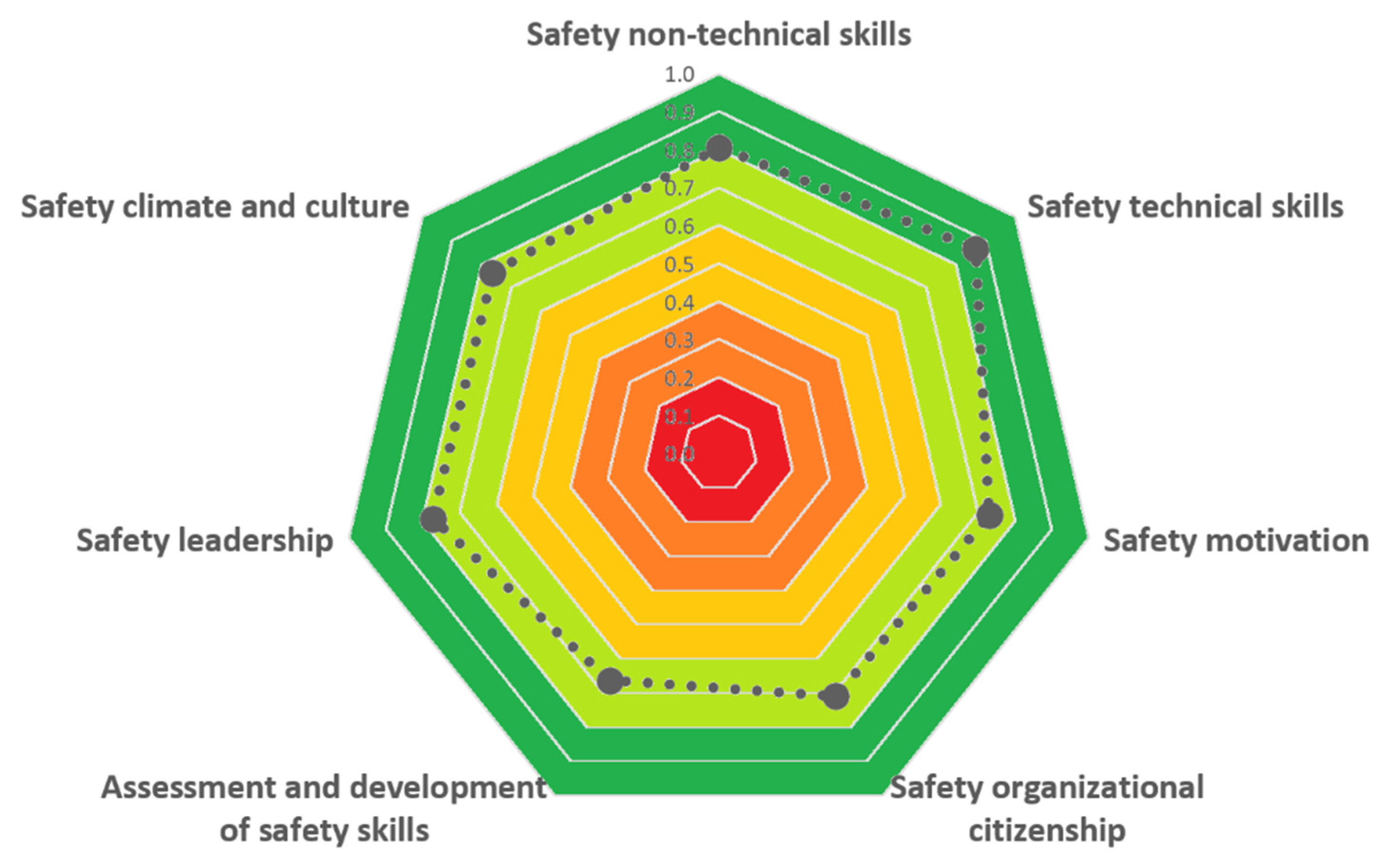

3.1. Human Barriers Dimensions

- (1)

- Dimension’s relevance as a barrier: To assess whether the dimension could be considered as a human safety barrier, the judges were asked the following question: “To what extent do you believe that the psychosocial dimension can positively influence workers’ safety behavior?”

- (2)

- Barrier category: To assess whether the dimension could be considered as a direct or safeguard barrier, the judges were asked the following question: “To what extent do you believe that the psychosocial dimension directly prevents workers from making errors during task execution?”

3.2. Estimating HEP including Barriers in the Analysis

4. Test Application of the Model

4.1. Method

4.2. Context and Task Description

4.3. Results of the Test

5. Discussion

Limitations and Further Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Reason, J. Human Error; Cambridge University Press: New York, NY, USA, 1990. [Google Scholar]

- Kariuki, S.; Löwe, K. Integrating human factors into process hazard analysis. Reliab. Eng. Syst. Saf. 2007, 92, 1764–1773. [Google Scholar] [CrossRef]

- Ren, J.; Jenkinson, I.; Wang, J.; Xu, D.-L.; Yang, J. A methodology to model causal relationships on offshore safety assessment focusing on human and organizational factors. J. Saf. Res. 2008, 39, 87–100. [Google Scholar] [CrossRef] [PubMed]

- Sexton, J.B.; Helmreich, R.L. Analyzing cockpit communications: The links between language, performance, error, and workload. Human Perf. Extreme Environ. 2000, 5, 63–68. [Google Scholar] [CrossRef] [PubMed]

- Mosleh, A.; Chang, J.; Chandler, F.; Marble, J.; Boring, R.; Gertman, D. Evaluation of current HRA methods for NASA use. In NASA HRA Methods Workshop; Kennedy Space Centre: Kennedy, FL, USA, 2006; pp. 16–18. [Google Scholar]

- Hou, L.-X.; Liu, R.; Liu, H.-C.; Jiang, S. Two decades on human reliability analysis: A bibliometric analysis and literature review. Ann. Nucl. Energy 2020, 151, 107969. [Google Scholar] [CrossRef]

- Galyean, W.J.; Whaley, A.M.; Kelly, D.L.; Boring, R.L. SPAR-H Step-by-Step Guidance; Idaho National Lab. (INL): Idaho Falls, ID, USA, 2011. [Google Scholar] [CrossRef][Green Version]

- Williams, J.C. A data-based method for assessing and reducing human error to improve operational performance. In Proceedings of the Conference Record for 1988 IEEE Fourth Conference on Human Factors and Power Plants, Monterey, CA, USA, 5–9 June 1988; pp. 436–450. [Google Scholar]

- Zhen, X.; Vinnem, J.E.; Yang, X.; Huang, Y. Quantitative risk modelling in the offshore petroleum industry: Integration of human and organizational factors. Ships Offshore Struct. 2019, 15, 1–18. [Google Scholar] [CrossRef]

- French, S.; Bedford, T.; Pollard, S.J.; Soane, E. Human reliability analysis: A critique and review for managers. Saf. Sci. 2011, 49, 753–763. [Google Scholar] [CrossRef]

- Mirzaei Aliabadi, M.; Esmaeili, R.; Mohammadfam, I.; Ashrafi, M. Human reliability analysis (HRA) using stand-ardized plant analysis risk-human (SPAR-H) and bayesian network (BN) for pipeline inspection gauges (PIG) operation: A case study in a gas transmission plant. Health Scope 2019, 8. [Google Scholar] [CrossRef]

- Abreu, J.M.; Hardy, N.; Pereira, F.C.; Zeifman, M. Modeling Human Reliability in the Power Grid Environment: An Application of the SPAR-H Methodology. Proc. Hum. Factors Ergon. Soc. Annu. Meet. 2015, 59, 662–666. [Google Scholar] [CrossRef]

- van de Merwe, K.; Øie, S.; Gould, K. The application of the SPAR-H method in managed-pressure drilling operations. In Proceedings of the Human Factors and Ergonomics Society Annual Meeting; Sage Publications: Los Angeles, CA, USA, 2012; Volume 56, pp. 2021–2025. [Google Scholar]

- Liu, J.; Zou, Y.; Wang, W.; Zhang, L.; Qing, T.; Zheng, T.; Ding, Q. A study on assigning performance shaping factors of the SPAR-H method for adequacy human reliability analysis of nuclear power plants. Int. J. Ind. Ergon. 2020, 81, 103051. [Google Scholar] [CrossRef]

- Wang, L.; Wang, Y.; Chen, Y.; Pan, X.; Zhang, W. Performance shaping factors dependence assessment through moderating and mediating effect analysis. Reliab. Eng. Syst. Saf. 2020, 202, 107034. [Google Scholar] [CrossRef]

- Di Bona, G.; Falcone, D.; Forcina, A.; Silvestri, L. Systematic Human Reliability Analysis (SHRA): A New Approach to Evaluate Human Error Probability (HEP) in a Nuclear Plant. Int. J. Math. Eng. Manag. Sci. 2020, 6, 345–362. [Google Scholar] [CrossRef]

- Kirwan, B.; Gibson, H.; Kennedy, R.; Edmunds, J.; Cooksley, G.; Umbers, I. Nuclear action reliability assessment (NARA): A data-based HRA tool. Saf. Reliab. 2005, 25, 38–45. [Google Scholar] [CrossRef]

- Kirwan, B.; Gibson, W. Controller Action Reliability Assessment (CARA) CARA User Manual; EUROCONTROL: Brussels, Belgium, 2009; pp. 1–70. [Google Scholar]

- Gibson, W.; Mills, A.; Smith, S.; Kirwan, B. Railway action reliability assessment, a railway-specific approach to human error quantification. In Rail Human Factors; Taylor & Francis: Oxfordshire, UK, 2013; pp. 671–676. [Google Scholar] [CrossRef]

- Akyuz, E.; Celik, M.; Cebi, S. A phase of comprehensive research to determine marine-specific EPC values in human error assessment and reduction technique. Saf. Sci. 2016, 87, 63–75. [Google Scholar] [CrossRef]

- Noroozi, A.; Abbassi, R.; MacKinnon, S.; Khan, F.; Khakzad, N. Effects of Cold Environments on Human Reliability Assessment in Offshore Oil and Gas Facilities. Hum. Factors J. Hum. Factors Ergon. Soc. 2013, 56, 825–839. [Google Scholar] [CrossRef]

- Mariani, M.G.; Vignoli, M.; Chiesa, R.; Violante, F.S.; Guglielmi, D. Improving Safety through Non-Technical Skills in Chemical Plants: The Validity of a Questionnaire for the Self-Assessment of Workers. Int. J. Environ. Res. Public Health 2019, 16, 992. [Google Scholar] [CrossRef]

- Karanikas, N.; Melis, D.J.; Kourousis, K.I. The Balance between Safety and Productivity and its Relationship with Human Factors and Safety Awareness and Communication in Aircraft Manufacturing. Saf. Health Work 2017, 9, 257–264. [Google Scholar] [CrossRef]

- Corrigan, S.; Kay, A.; Ryan, M.; Ward, M.; Brazil, B. Human factors and safety culture: Challenges and opportunities for the port environment. Saf. Sci. 2019, 119, 252–265. [Google Scholar] [CrossRef]

- Sklet, S. Safety barriers: Definition, classification, and performance. J. Loss Prev. Process Ind. 2006, 19, 494–506. [Google Scholar] [CrossRef]

- Hollnagel, E. Risk + barriers = safety? Saf. Sci. 2008, 46, 221–229. [Google Scholar] [CrossRef]

- Waterson, P. Designing for Human Reliability: Human Factors Engineering in the Oil, Gas and Process Industries. Policy Pract. Health Saf. 2017, 15, 82–83. [Google Scholar] [CrossRef]

- Reason, J. Human error: Models and management. BMJ 2000, 320, 768–770. [Google Scholar] [CrossRef] [PubMed]

- Larouzee, J.; Le Coze, J.-C. Good and bad reasons: The Swiss cheese model and its critics. Saf. Sci. 2020, 126, 104660. [Google Scholar] [CrossRef]

- Eurocontrol Experimental Centre. Revisiting the Swiss Cheese Model of Accidents. EEC Note. 13/06, October 2006. Available online: https://www.eurocontrol.int/sites/default/files/library/017_Swiss_Cheese_Model.pdf (accessed on 15 July 2021).

- Hu, Y. A Concise and Practical Barrier Model. Open J. Saf. Sci. Technol. 2019, 9, 93–111. [Google Scholar] [CrossRef]

- Khakzad, N.; Khan, F.; Amyotte, P. Dynamic safety analysis of process systems by mapping bow-tie into Bayesian network. Process Saf. Environ. Prot. 2013, 91, 46–53. [Google Scholar] [CrossRef]

- Yuan, Z.; Khakzad, N.; Khan, F.; Amyotte, P. Risk Analysis of Dust Explosion Scenarios Using Bayesian Networks. Risk Anal. 2014, 35, 278–291. [Google Scholar] [CrossRef]

- Cheliyan, A.S.; Bhattacharyya, S.K. Fuzzy event tree analysis for quantified risk assessment due to oil and gas leakage in offshore installations. Ocean Syst. Eng. 2018, 8, 41–55. [Google Scholar] [CrossRef]

- Williams, J.C.; Bell, J.L. Consolidation of the Generic Task Type database and concepts used in the Human Error Assessment and Reduction Technique (HEART). Saf. Reliab. 2016, 36, 245–278. [Google Scholar] [CrossRef]

- Laumann, K.; Rasmussen, M. Suggested improvements to the definitions of Standardized Plant Analysis of Risk-Human Reliability Analysis (SPAR-H) performance shaping factors, their levels and multipliers and the nominal tasks. Reliab. Eng. Syst. Saf. 2016, 145, 287–300. [Google Scholar] [CrossRef]

- Bye, A.; Laumann, K.; Taylor, C.; Rasmussen, M.; Øie, S.; van de Merwe, K.; Gould, K. Petro-HRA, a new method for human reliability analysis in the petroleum industry. In Proceedings of the 13th International Conference on Probabilistic Safety Assessment and Management (PSAM 13), Seoul, Korea, 2–7 October 2016. [Google Scholar]

- Hamer, R.; Waterson, P.; Jun, G.T. Human factors and nuclear safety since 1970—A critical review of the past, present and future. Saf. Sci. 2020, 133, 105021. [Google Scholar] [CrossRef]

- Newaz, M.T.; Davis, P.R.; Jefferies, M.; Pillay, M. Developing a safety climate factor model in construction research and practice: A systematic review identifying future directions for research. Eng. Constr. Arch. Manag. 2018, 25, 738–757. [Google Scholar] [CrossRef]

- Lynn, M.R. Determination and Quantification of Content Validity. Nurs. Res. 1986, 35, 382–386. [Google Scholar] [CrossRef] [PubMed]

- Lim, H.W.; Li, N.; Fang, D.; Wu, C. Impact of Safety Climate on Types of Safety Motivation and Performance: Multigroup Invariance Analysis. J. Manag. Eng. 2018, 34, 04018002. [Google Scholar] [CrossRef]

- Cigularov, K.P.; Chen, P.Y.; Rosecrance, J. The effects of error management climate and safety communication on safety: A multi-level study. Accid. Anal. Prev. 2010, 42, 1498–1506. [Google Scholar] [CrossRef] [PubMed]

- Xie, X.; Guo, D. Human factors risk assessment and management: Process safety in engineering. Process Saf. Environ. Prot. 2018, 113, 467–482. [Google Scholar] [CrossRef]

- Aven, T.; Hauge, S.; Sklet, S.; Vinnem, J.E. Methodology for incorporating human and organizational factors in risk analysis for offshore installations. Int. J. Mater. Struct. Rel. 2006, 4, 1–14. [Google Scholar]

- Vinnem, J.E.; Haugen, S.; Kongsvik, T.; Seljelid, J.; Steen, S.; Sklet, S.; Thomasssen, O. Operational safety condition-concept development. In Proceedings of the Presented at ESREL, Stavanger, Norway, 25–27 June 2007. [Google Scholar]

- Gran, B.A.; Nyheim, O.M.; Seljelid, J.; Vinnem, J.E. A BBN risk model of maintenance work on major process equipment on offshore petroleum installations. In Advances in Safety, Reliability and Risk Management; Berenguer, C., Grall, A., Soares, C.G., Eds.; CRC Press: Boca Raton, FL, USA, 2012; pp. 1249–1257. [Google Scholar]

| GTT | Definition | NEP |

|---|---|---|

| A | A totally unfamiliar task, performed at speed | 0.55 |

| B | Shift or restore the system to a new or original state on a single attempt without supervision | 0.26 |

| C | A complex task requiring a high level of comprehension and skill | 0.16 |

| D | Routine, highly practiced, a rapid task involving a relatively low level of skill | 0.02 |

| E | Restore or shift a system to original or new state following procedures, with some checking | 0.003 |

| F | Respond correctly to system command even when there is an augmented or automated supervisory system | 2 × 10−5 |

| PSF | Definition |

|---|---|

| Available time | The amount of time an operator or a crew has to diagnose and act to perform a task. |

| Threat Stress | The dangerousness of the task in terms of psychological and physical harm and operators’ adequacy of risk perception. |

| Complexity | How difficult the task is to perform in the given context. |

| Experience/Training | The experience and training of the operator(s) involved in the task. Included in this consideration are the years of experience of the individual or crew, and whether or not the operator/crew has been trained on the type of accident, the amount of time passed since training and the systems involved in the task and scenario. |

| Procedures | The existence, the quality and actual use of formal operating procedures for the tasks under consideration. |

| Human Machine Interfaces (HMI) | The equipment, displays and controls, layout, quality, and quantity of information available from instrumentation, and the interaction of the operator/crew with the equipment needed to carry out tasks. |

| Environmental Context | Physical conditions of the working environment (e.g., noise, temperature, brightness) in which the task is performed. |

| Fatigue | Whether or not the individual performing the task is physically and mentally fit to perform the task at the time. Things that may affect fitness include fatigue or sickness. |

| PSF | Level | Multiplier |

|---|---|---|

| Available Time | Inadequate time | 100 |

| Barely adequate time | 50 | |

| Limited time | 10 | |

| Nominal | 1 | |

| Extra Time | 0.1 | |

| Threat Stress | Very threatening | 5 |

| Moderately threatening | 2 | |

| Nominal | 1 | |

| Complexity | Overly complex | 50 |

| Moderately complex | 10 | |

| Nominal | 1 | |

| Simplified task | 0.1 | |

| Experience/Training | The mismatch between knowledge or skills and correct behavior | 100 |

| No experience/training | 50 | |

| Low experience/training | 15 | |

| Nominal | 1 | |

| Extensive experience/training | 0.1 | |

| Procedures | No procedures available or not used | 50 |

| Very poor procedures | 20 | |

| Poor procedures | 5 | |

| Adequate and followed procedures | 1 | |

| Exceptionally good and followed procedures | 0.5 | |

| HMI | Completely inadequate | 100 |

| Inadequate | 50 | |

| Barely adequate | 10 | |

| Adequate | 1 | |

| Specifically designed to ease the task | 0.5 | |

| Environmental Context | Environmental conditions do not allow to perform the task | 100 |

| Adverse conditions | 10 | |

| Nominal | 1 | |

| Fatigue | High | 100 |

| Moderate | 10 | |

| Nominal | 1 |

| Barrier Type | Dimension | Definition |

|---|---|---|

| Direct Barriers | Safety task performance | The quality of the operator’s performance in terms of safety in relation to a given task. |

| Compliance with safety norms and procedures | The set of activities that an operator needs to carry out to maintain high levels of safety while performing a task. It involves complying with safety norms, procedures and standards, using PPE. | |

| Safety contextual performance | The set of behaviors that grant the development of a safe environment at work. An example of performance is the operator’s active participation in safety briefings or safety cooperation behaviors among workers. | |

| Safety participation | Workers’ proactivity and efforts toward the improvement of safety at work and safety performances. | |

| Safety teamwork | Operators’ ability to work in teams pursuing goals while safely performing tasks. | |

| Safety communication | Quality and quantity of relevant safety information exchanges about safety in working teams. | |

| Safeguard Barriers | Non-Technical Safety skills | The set of cognitive, social and personal resource skills complementing technical skills and contributing to safe and efficient task performance (e.g., fatigue and stress management, safety awareness). |

| Technical Safety Skills | The set of technical skills that operators need to own to work safely. These skills vary as a function of the task to be performed and the operators’ role. | |

| Safety Motivation | Refers to workers’ willingness to spend energies and efforts to work safely. The worker may be intrinsically motivated to engage in safe behaviors or extrinsically motivated by external pressures from the organization. | |

| Safety organizational citizenship | Enlargement of workers’ role about safety without a formal acknowledgement of the acquired functions from the organization (e.g., through rewards). | |

| Assessment and development of safety skills | Evaluates the quality of organizational management of workers’ skills. It mainly focuses on how and how often organizations assess workers’ safety skills and their commitment to improving these. | |

| Safety Leadership | Evaluates the quality of members-leader interactions about safety. It involves the ability of leaders to promote safety behaviors among workers and improve the overall levels of safety in the working environment. | |

| Safety Climate and Culture | Refers to the set of workers’ perceptions about safety rules, norms and procedures, and the importance of safety in the working environment. |

| Level | Score |

|---|---|

| Yes | 1.00 |

| Rather Yes than No | 0.66 |

| Rather No than Yes | 0.33 |

| No | 0 |

| DBS | Conversion Coefficient |

|---|---|

| DBS ≥ 0.75 | 0.2 |

| 0.55 ≤ DBS 0.75 | 0.6 |

| 0.35 ≤ DBS 0.55 | 1.0 |

| 0.15 ≤ DBS 0.35 | 1.4 |

| DBS 0.15 | 1.8 |

| SBS | Conversion Coefficient |

|---|---|

| SBS ≥ 0.75 | 0.2 |

| 0.55 ≤ SBS 0.75 | 0.6 |

| 0.35 ≤ SBS 0.55 | 1.0 |

| 0.15 ≤ SBS 0.35 | 1.4 |

| SBS 0.15 | 1.8 |

| PSF | Selected Level | Multiplier |

|---|---|---|

| Available time | Extra Time | 0.1 |

| Threat Stress | Nominal | 1 |

| Complexity | Nominal | 1 |

| Experience/Training | Extensive experience/training | 0.1 |

| Procedures | Poor procedures | 5 |

| Human Machine Interfaces (HMI) | Specifically designed to ease the task | 0.5 |

| Environmental Context | Adverse condition | 10 |

| Fatigue | Nominal | 1 |

| Indicator | Evaluation | Score |

|---|---|---|

| Do workers pay attention and comply with safety norms and procedures even if they are not easy to apply? | Rather No than Yes | 0.33 |

| Do workers use the correct procedures to work safely? | Rather No than Yes | 0.33 |

| Do workers correctly use PPE in line with safety norms and procedures? | Yes | 1.00 |

| Do workers ensure the maximum respect of safety norms and procedures while working? | Rather No than Yes | 0.33 |

| Barrier total score | 0.50 |

| Variable | Score |

|---|---|

| Nominal Error Probability (NEP) | 0.02 |

| PSF Composite (PSFC) | 0.05 |

| Conversion Coefficient Direct Barriers (CCDB) | 0.2 |

| Conversion Coefficient Safeguard Barriers (CCSB) | 0.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guglielmi, D.; Paolucci, A.; Cozzani, V.; Mariani, M.G.; Pietrantoni, L.; Fraboni, F. Integrating Human Barriers in Human Reliability Analysis: A New Model for the Energy Sector. Int. J. Environ. Res. Public Health 2022, 19, 2797. https://doi.org/10.3390/ijerph19052797

Guglielmi D, Paolucci A, Cozzani V, Mariani MG, Pietrantoni L, Fraboni F. Integrating Human Barriers in Human Reliability Analysis: A New Model for the Energy Sector. International Journal of Environmental Research and Public Health. 2022; 19(5):2797. https://doi.org/10.3390/ijerph19052797

Chicago/Turabian StyleGuglielmi, Dina, Alessio Paolucci, Valerio Cozzani, Marco Giovanni Mariani, Luca Pietrantoni, and Federico Fraboni. 2022. "Integrating Human Barriers in Human Reliability Analysis: A New Model for the Energy Sector" International Journal of Environmental Research and Public Health 19, no. 5: 2797. https://doi.org/10.3390/ijerph19052797

APA StyleGuglielmi, D., Paolucci, A., Cozzani, V., Mariani, M. G., Pietrantoni, L., & Fraboni, F. (2022). Integrating Human Barriers in Human Reliability Analysis: A New Model for the Energy Sector. International Journal of Environmental Research and Public Health, 19(5), 2797. https://doi.org/10.3390/ijerph19052797