1. Introduction

Climate change has led to more frequent extreme weather events, which have threatened economic activities such as agriculture, forestry, animal husbandry, and fishing [

1], aggravated the spread of diseases [

2], and threatened economic growth [

3] and public health [

4]. Many studies on climate change show that carbon dioxide emissions from energy consumption are the leading cause of climate change [

5]. Therefore, reducing carbon dioxide emissions has become a common concern of all countries to lessen the impact of climate-related disasters. However, considering the differences in the stages of economic development faced by developed and developing countries, different countries should play different roles in reducing carbon emissions [

6]. Although there are many disputes between developed and developing countries about the contributions of carbon emission reduction [

7], it is important to note that developing countries are currently playing an essential role in achieving carbon emission reduction and tackling climate change [

8].

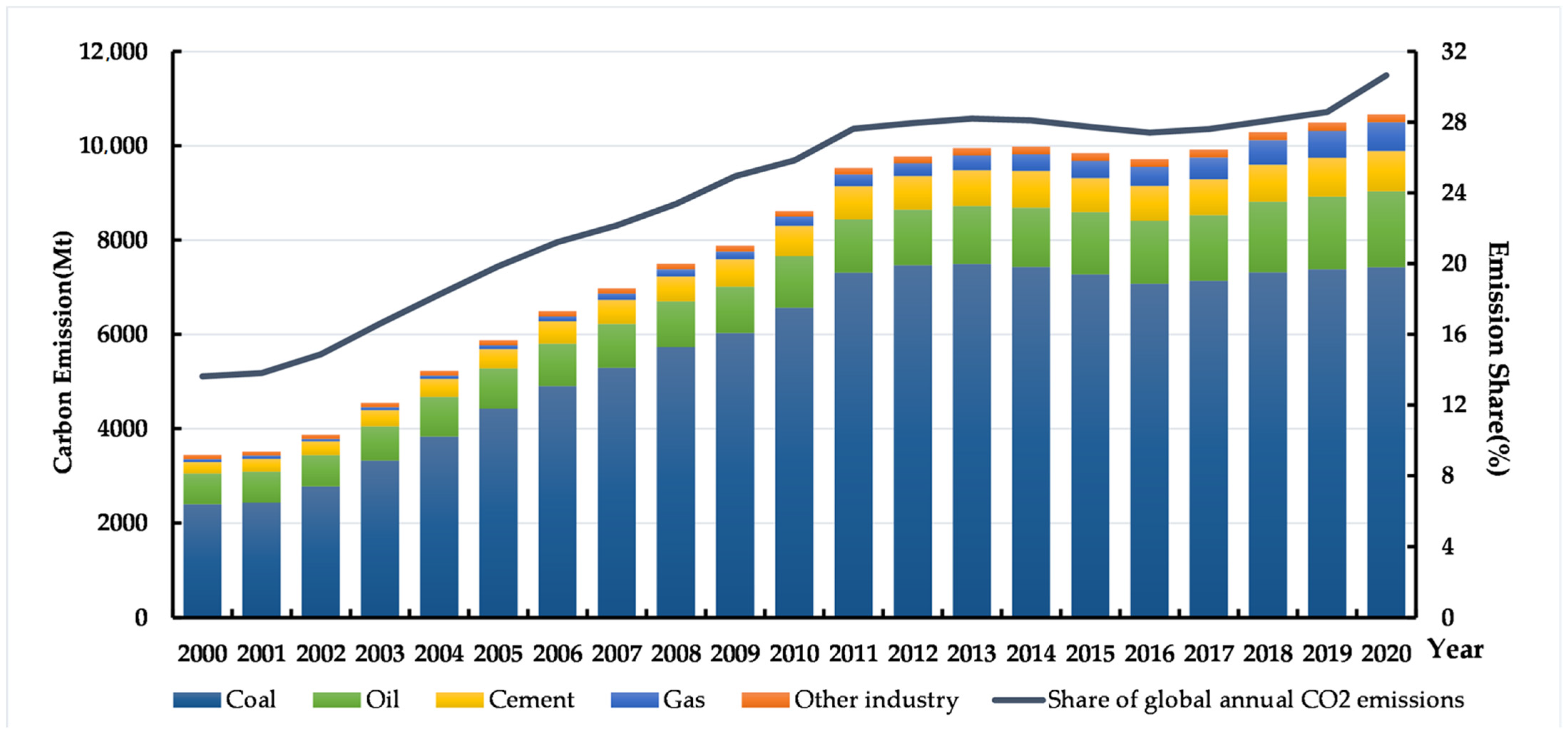

As the world’s biggest carbon emitter, China accounts for about 30% of the world’s carbon dioxide emissions, 90% of which are caused by fossil energy consumption [

9].

Figure 1 shows China’s CO

2 emissions by flue type and the share of global CO

2 emissions. Since the reform and opening-up, China’s industrial added value has increased approximately 60-fold from USD 96.05 billion in 1978 to USD 577 billion in 2020 (Constant 2015 USD) [

10]. The rapid outward development of China’s economy mainly relies on high investment and high energy consumption, resulting in a large amount of crude input of fossil energy, leading to a large amount of carbon dioxide emissions [

11]. At the same time, rapid economic growth has led to dramatic declines in environmental quality [

12]. To actively and effectively address the issue of climate change, at the general debate of the United Nations General Assembly in September 2020, President Xi Jinping declared that China would scale up its Nationally Determined Contributions (NDCs) by adopting more vigorous policies and measures and aims to have CO

2 emissions peak before 2030 and achieve carbon neutrality before 2060. The timespan from carbon peak to carbon neutrality that the Chinese government promised is much shorter than what many developed countries might take [

13]. Therefore, it is very challenging for the Chinese government to achieve these goals on time.

Much to our gratification, the rise of artificial intelligence injects new impetus into China’s economic growth and provides new solutions for improving China’s ecological environment [

14]. According to the statistics, China accounted for nearly one-fifth of global private investment funding in 2021, attracting USD 17 billion for AI (Artificial Intelligence) start-ups [

15]. Stanford University’s AI Index, which assesses AI advancements worldwide across various metrics in research, development, and economy, ranks China among the top three countries for global AI vibrancy. Facts have proved that China has built a solid foundation to support its AI economy [

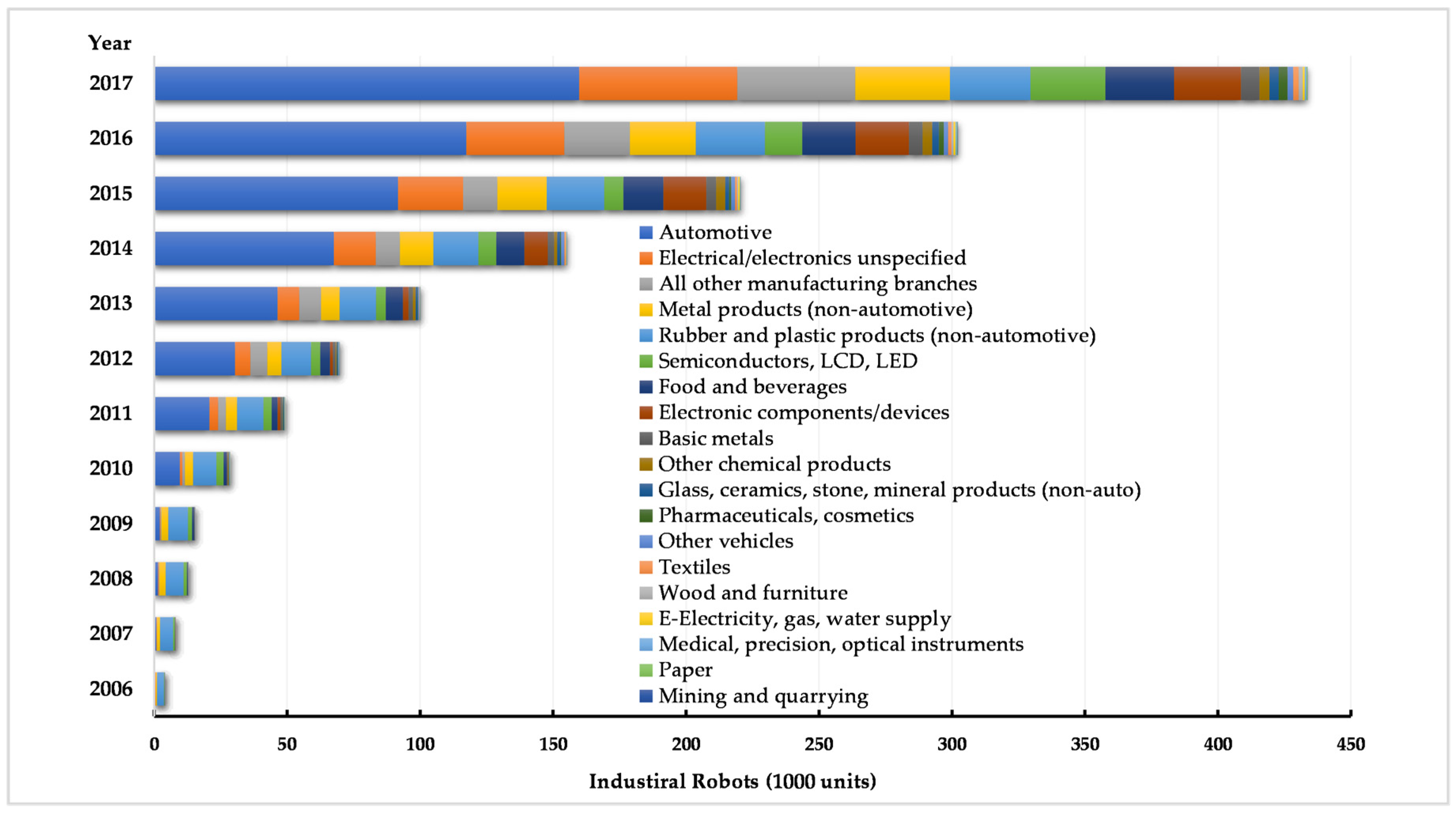

16]. The development of artificial intelligence has become a new trend in China’s current economic growth, and new industries represented by new information technologies such as big data, cloud computing, and mobile internet have formed. Then, while the information technology revolution promotes the vigorous development of intelligent manufacturing, can it bring about the dual effects of economy and ecology? Can it significantly improve the production efficiency of various industries and promote economic growth? Can it reduce energy consumption and achieve carbon emission reduction? Can it be an effective means to achieve carbon neutrality? It is worth studying whether intelligent manufacturing can reduce carbon emissions in industrial sectors and by what means to achieve carbon reduction in all industries. To this end, based on the industry data and robot production data from 2000 to 2017, this paper examines the impact of intelligent manufacturing on industrial carbon dioxide emissions and discusses its internal mechanism.

2. Literature Review

Progress in information technology has promoted extensive changes in the economic growth pattern and development structure. It also has significantly impacted how energy is produced and consumed in countries around the world. However, the effects of information technology on energy consumption are complex. On the one hand, information technology can reduce energy consumption in products and processes through its direct application, potentially offering considerable improvements in energy efficiency for the transport, buildings, and industry sectors. On the other hand, information technology will tend to increase electricity’s importance in the economy. The prevalence of more devices could cause significant net increases in energy use. At the same time, AI technologies based on big data and cloud computing are widely used in industry and profoundly impact electricity and energy use. Scholars have conducted many studies to assess the potential impact of information technology and AI on energy use.

2.1. Information Technology and Energy Consumption

Many scholars have studied fossil energy consumption in industrial production and found that intelligent manufacturing enabled by information technology can decrease the demand for fossil energy consumption and improve energy use efficiency. Schulte et al. (2016) used a cross-country cross-industry panel data set covering 13 years, 10 OECD countries, and 27 industries and found that information technology reduced total and non-electric energy demand, but electrical energy demand was not significantly affected [

17]. Usman et al. (2020) analyzed the impact of ICT (Information and Communication Technology) on economic performance and energy consumption in selected South Asian economies from 1990 to 2018. The study shows that in both the short and long term, ICT helped reduce India’s energy consumption and significantly improved the energy efficiency of Indian industries [

18]. Ishida et al. (2015) used the Autoregressive Distributed Lag (ARDL) boundary test approach to assessing the long-term relationship between ICT, energy consumption, and economic growth in Japan. The study shows that ICT investment can equally contribute to a modest reduction in Japan’s energy consumption but not to an increase in GDP (Gross Domestic Product) [

19]. Bastida et al. (2019) assessed the potential of ICT-based interventions in households to decrease electricity usage, and improve energy efficiency, finding that ICT-based effects on consumer behavior can reduce household final electricity consumption by 0–5% [

20].

A few scholars have found that progress in information technology has not always contributed to lower energy consumption. Saidi et al. (2017) investigated the impact of information communication technology (ICT) and economic growth on electricity consumption for a global panel of 67 countries using a dynamic panel data model. They found that ICT and economic growth increased electricity consumption [

21]. Zhou et al. (2018) used a three-tier structural decomposition analysis (SDA) approach to analyze the main drivers behind China’s change in energy intensity. They found that while higher energy efficiency in the ICT sectors led to a slight decrease in energy intensity, structural changes in ICT investments increased energy intensity. The spread of ICT products increased energy consumption in the production process [

22]. Lange et al. (2020) used an economic-environmental analytical model to discuss ICT’s direct and indirect effects on energy consumption and energy efficiency. The study showed that ICT brought additional energy consumption instead of saving energy. The energy-increasing impact of information technology (direct effect and economic growth) was more significant than the energy-reducing effect (energy efficiency improvement and sectoral changes) [

23].

2.2. Information Technology and Carbon Emissions

Excessive fossil energy consumption is the main reason for the continuous increase in carbon dioxide emissions [

24]. In addition to evaluating the direct impact of information technology progress on energy consumption, scholars have also focused directly on the effects of information technology on carbon emissions. Some scholars argue that advancements in information technology can reduce carbon emissions. Ozcan et al. (2018) used panel data to analyze the effect of information technology on CO

2 emissions in 20 emerging economies. The long-term parametric results showed that the more internet users a country has, the lower its emissions [

25]. Lu (2018) investigated the impact of information and communication technology (ICT) on carbon dioxide emissions using panel data from 12 Asian countries from 1993 to 2013. The results show that ICT negatively impacts carbon dioxide emissions [

26]. Other scholars argue that the advancements in information technology will increase carbon emissions. Belkhir et al. (2018) evaluated the global carbon footprint of the entire ICT industry. They pointed out that, if not controlled, the relative contribution of ICT GHGE (Greenhouse Gas Emissions) may increase from 1–1.6% in 2007 to 14% in 2040 [

27]. Park et al. (2018) used panel data from the European Union from 2001 to 2014 to examine the impact of the internet, financial development, economic growth, and trade openness on carbon dioxide emissions in selected EU (European Union) countries. The results show that electricity consumption due to Internet use positively and significantly impacts carbon emissions [

28].

2.3. Artificial Intelligence and Energy Consumption

With the rapid development of AI, scholars have also begun to pay attention to the impact of AI on carbon emissions. In contrast to the carbon reduction effect of ICT, scholars largely agree that intelligent manufacturing brought by AI applications suppresses carbon emissions. Liu et al. (2022) investigated the impact of AI on carbon intensity using China’s industrial sector data from 2005 to 2016. The empirical results show that AI significantly reduces carbon intensity, as measured by the number of robots adopted by industry and the number of academic AI-related papers [

29]. Similar to the findings of Liu et al. (2022), Li et al. (2022) empirically examined the carbon reduction effect of industrial robot applications based on the environmental Kuznets curve (EKC) model. They used data from a sample of 35 countries from 1993–2017, and the results also showed that the application of industrial robots significantly reduced carbon intensity [

30]. Chen et al. (2022) assessed AI’s impact on carbon emissions based on panel data from 270 Chinese cities from 2011 to 2017, using the Bartik’s method to quantify the data of Chinese manufacturing firms and robots. The findings show that AI has a significant inhibitory effect on carbon emission intensity and that the impact of AI on carbon emission reduction varies across cities of different sizes [

31].

The literature review shows that the existing studies mainly focus on three aspects. Firstly, more research focuses on the impact of information technology progress on fossil energy consumption. Most scholars believe technological progress can reduce energy consumption and improve energy use efficiency. A few scholars believe technological advancement has brought about economic expansion, increasing total energy consumption. Secondly, some studies focus directly on the impact of IT (Information Technology) progress on carbon emissions, but it is inconclusive whether IT progress has reduced carbon emissions. Thirdly, some studies have focused on the carbon reduction effect of AI, suggesting that intelligent manufacturing resulting from the applications of AI has curbed carbon emissions.

In summary, the existing research still has the following limitations. The current studies do not sufficiently explore the mechanism of carbon emission reduction achieved by the progress of information technology, and the studies on the impact of information technology progress on fossil energy consumption do not directly link fossil energy consumption with carbon emissions. However, these two problems are the core elements of the studies on the impact of intelligent manufacturing on carbon emission reduction in the industrial sectors. Given this, based on the industrial data and robot data from 2000 to 2017, this paper examines the impact of intelligent manufacturing on industrial carbon dioxide emissions and discusses its internal mechanism. The possible contributions are: first, analyzing the effect of intelligent manufacturing on emission reduction with industrial data and robot data; second, based on the overall assessment, this paper distinguishes high-carbon emission industries from low-carbon emission industries and high-intelligence industries from low-intelligence industries to examine the heterogeneous emission reduction effect of intelligent manufacturing. Third, to make up for the shortcomings of existing studies on the intrinsic mechanism of the impact of intelligent manufacturing on carbon emission reduction, this paper examines the effect of intelligent manufacturing on total fossil energy consumption and energy use efficiency. It also examines the intrinsic mechanism of intelligent manufacturing to achieve carbon emission reduction. The attempts and efforts in the above three aspects of this paper provide helpful supplements to existing studies.

3. Theoretical Analysis and Research Hypotheses

The application of information technology in production has promoted the rapid development of intelligent manufacturing in various industries [

32]. Can intelligent manufacturing brought by technological progress reduce carbon emissions in multiple industries to achieve carbon dioxide emission reduction?

Figure 2 shows the specific internal mechanism. Firstly, technological progress causes a rebound effect, affecting the industry’s carbon dioxide emission reduction [

33]. On the one hand, technological advancement has positive externalities. Technological progress can improve energy efficiency and save energy consumption, which is conducive to pushing the industry to reduce carbon dioxide emissions. On the other hand, technological progress has negative externalities. Technological progress will promote rapid economic growth, resulting in new demand for energy consumption and resistance to energy-saving energy consumption, which is not conducive to reducing carbon dioxide emissions in the industrial sectors. Secondly, the differences between industries will impact intelligent manufacturing’s carbon dioxide emission reduction [

34]. Different industries have different carbon emissions, and the impact of intelligent manufacturing on high-carbon and low-carbon emission industries may be heterogeneous, and various industries have different degrees of intelligence intensity, and the effect of intelligent manufacturing on industries with higher intelligence intensity and industries with lower intelligence intensity may also be heterogeneous [

35]. Combined with the above two levels of analysis, the rebound effect of technological progress and industry differences will affect the carbon emission reduction effect of intelligent manufacturing. So, it is uncertain whether intelligent manufacturing can promote carbon dioxide emission reduction in all industries. Therefore, we propose the first hypothesis:

Hypothesis 1. Intelligent manufacturing can significantly reduce CO2 emissions in the industrial sectors.

Carbon dioxide emissions are closely related to total energy consumption, the proportion of fossil energy, and energy efficiency [

36]. As the largest carbon dioxide emitter in the world, China is still in the process of industrialization, and energy-intensive industries still have a great demand for energy consumption [

37]. China’s total energy consumption is still high, and the fossil energy consumption is the primary source. Therefore, reducing fossil energy consumption and improving the efficiency of fossil energy use is an important way to achieve CO

2 reduction in the industrial sectors. Studies show China’s overall energy use efficiency lags behind developed countries [

38]. The information technology revolution can promote the flow of production factors from energy-intensive and emission-intensive industries to highly processed and technology-intensive industries, thereby reducing fossil energy consumption and improving energy efficiency [

39]. Enterprises can improve intelligent manufacturing through technological progress, thus reducing the cost of economic activities and improving production efficiency. The reduction of cost and improvement of production efficiency will also encourage enterprises to conduct technological research and development, thus enhancing the level of intelligent manufacturing, further reducing the demand for fossil energy consumption, and improving the efficiency of fossil energy use. It will have a dual effect on the industry’s fossil energy consumption, thus driving down carbon emissions. Moreover, the different levels of intelligent manufacturing in various industries will make them achieve different carbon emission reduction effects. Therefore, we have the second hypothesis:

Hypothesis 2. Intelligent manufacturing achieves carbon reduction in the industrial sectors by reducing fossil energy consumption and improving the energy use efficiency.

6. Mechanism Test of Intelligent Manufacturing to Achieve Emission Reduction Effect

The above analysis provides detailed evidence and rich robustness tests on China’s intelligent manufacturing’s carbon emission reduction effect. The findings fully demonstrate that the large-scale use of robots can reduce carbon dioxide emissions in the industry. Then, the question that makes us ponder is why intelligent manufacturing can achieve carbon emission reduction and its mechanism.

Changes in enterprise behavior can profoundly impact its carbon emissions. Therefore, we speculate that the mechanism underlying the significant reduction of carbon emissions by intelligent manufacturing focuses more on the impact of intelligent manufacturing on enterprise behavior. There are differences in the application of intelligent manufacturing among enterprises in different industries. Intelligent manufacturing can promote a rapid increase in output scale and a significant increase in revenue for IT-based enterprises. However, it raises the relative cost of energy-consumption-based traditional industries, leading to the risk of revenue loss for energy-consumption-based traditional enterprises under competitive market conditions. Under the loss risk constraint due to intelligent manufacturing, enterprises will adjust their energy use and efficiency.

We first examine the impact of intelligent manufacturing on enterprise income. The data on enterprise income are difficult to obtain, so in order to measure the impact of intelligent manufacturing on the income of enterprises in the industry, we choose two indicators, the number of enterprises in the industry with losses and the proportion of the number of enterprises with losses to the total number of enterprises, respectively, and the specific results are shown in

Table 11. Among them, columns (1) and (2) mainly examine the impact of intelligent manufacturing on the number of enterprises in the industry. The results show that intelligent manufacturing increases the number of enterprises in the market. Due to the increase in the number of enterprises, the competition within the industry increases, which leads to enterprises facing higher competitiveness. Columns (3)–(6) examine the effect of intelligent manufacturing on the number of loss–making enterprises and the share of the number of loss–making enterprises in the total number of enterprises. The results show that intelligent manufacturing exacerbates enterprises’ losses within traditional industries dominated by energy consumption. Thus, intelligent manufacturing forces firms to face the dual pressure of increased external competition and revenue losses.

Figure 2 shows that enterprises will change their energy use and efficiency. Therefore, we speculate that intelligent manufacturing can affect carbon emissions by reducing fossil energy consumption and improving energy use efficiency. Given this, we first analyze the relationship between intelligent manufacturing and energy consumption, and the specific results are shown in

Table 12. Among them, column (1) in

Table 12 mainly analyzes the impact of intelligent manufacturing on total energy consumption, and the results show that the improvement of intelligence level can reduce the energy consumption of the industry by about 7.48%, and this reduction effect is significant at the 5% confidence level. In addition to the analysis of total energy consumption, we also analyze different types of fossil energy consumption, including coal consumption, coke consumption, oil consumption, and natural gas consumption, as shown in columns (2)–(5) in

Table 12. From the results of the regression, we can see that the increase in the level of intelligent energy reduces the consumption of different types of fossil energy, but the impact of intelligent manufacturing on the total consumption of different types of fossil energy varies, with the most significant effect of intelligent manufacturing on reducing the total consumption of coal, the second most significant impact on the consumption of coke and natural gas, and the most negligible significant impact on the total consumption of oil.

In addition to energy consumption, improving energy efficiency is also an effective way to reduce carbon emissions. Therefore, to examine the impact of intelligent manufacturing on energy use efficiency, this paper uses intelligent manufacturing to regress the overall energy use efficiency and the three major fossil energy use efficiencies separately. The specific results are shown in

Table 13. Among them, column (1) is the ratio of total energy consumption to the total industrial output value, column (2) is the ratio of total energy consumption to industrial value–added, and columns (3)–(5) are the ratios of total coal, oil, and natural gas consumption to the total industrial output value, respectively. The results show that intelligent manufacturing is conducive to improving energy use efficiency and the efficiency of the three major fossil energy sources, and intelligent manufacturing has the most significant impact on improving the efficiency of coal use, followed by oil, and the most negligible impact on improving the efficiency of natural gas use. Through the above analysis, hypothesis 2 is tested, and intelligent manufacturing can reduce carbon emissions in the industry by reducing fossil energy consumption and improving the efficiency of fossil energy use.

In summary, intelligent manufacturing can inhibit fossil energy consumption and improve energy efficiency. It has the most apparent inhibitory effect on coal consumption and the most noticeable improvement in coal use efficiency. This variability in the impact of intelligent manufacturing on fossil energy may be related to China’s long–established coal-dominated energy consumption structure. Coal, oil, and gas are China’s primary source of fossil energy consumption and brings more than 90% of carbon emissions from the three primary fossil energy consumptions. The impact of intelligent manufacturing on coal–led fossil energy consumption is conducive to promoting the improvement and upgrading of China’s energy consumption structure, which further reduces fossil energy carbon emissions.

7. Conclusions

With the rapid development of information technology, the application of intelligent manufacturing has been promoted in various production fields. Intelligent manufacturing is essential in reducing carbon emissions and can effectively promote China’s goal of achieving a carbon peak by 2030 and carbon neutrality by 2060. Therefore, it is crucial to explore the impact of intelligent manufacturing on carbon emissions and its internal mechanism. Based on this, this paper uses industry data and robot data from 2000 to 2017 to test the impact of intelligent manufacturing on carbon emissions and analyze the effects of intelligent manufacturing on carbon emissions in heterogeneous industries. The study’s main conclusions are as follows: intelligent manufacturing positively impacts the industry’s total carbon emissions and carbon emissions per capita. Intelligent manufacturing can comprehensively reduce the carbon emissions from the consumption of the three primary fossil energies in the industrial sectors. Heterogeneity analysis shows that intelligent manufacturing can significantly reduce emissions in high-carbon emission industries than in low–carbon emission industries. Furthermore, intelligent manufacturing can reduce carbon emissions in industries with high-intelligence intensity but not in industries with low– intelligence intensity.

The mechanism analysis shows that intelligent manufacturing leads to the risk of loss for energy-based companies. Under the income loss constraint, enterprises will adjust the amount of energy used and energy efficiency. Intelligent manufacturing can significantly reduce the total consumption of various types of fossil energy. However, the degree of the reduction varies for different kinds of fossil energy. In general, intelligent manufacturing has the most apparent impact on reducing the total consumption of coal, followed by coke and natural gas consumption, and the most negligible effect on total oil consumption. Intelligent manufacturing is also conducive to improving the energy efficiency of the three primary fossil energies. It has the most obvious impact on improving coal use efficiency, followed by oil and natural gas. So, we can see that intelligent manufacturing can reduce carbon emissions by reducing fossil energy consumption and improving energy efficiency. The policy implications of the above conclusions are as follows.

- (1)

The government should use technological advances to drive production changes to ensure innovation-driven green development. Intelligent manufacturing can reduce the industry’s carbon emissions, so the potential for technological innovation needs to be further explored to provide a lasting driver for the green development of production. The government should further increase policy support and investment in innovative research and development to support enterprises in developing advanced energy-saving and environmental protection technologies, processes, and equipment. At the same time, relevant management departments should actively carry out pilot demonstrations in process intelligence, aggregating the multi-dimensional strength of manufacturing enterprises and research institutes to achieve interdisciplinary and cross-disciplinary collaborative research and support traditional industries to achieve carbon emission reduction with intelligent production.

- (2)

The government should focus on developing high-carbon emission and less intelligent–intensive industries and promote low carbonization with intelligent manufacturing. Intelligent manufacturing can comprehensively reduce carbon emissions from fossil energy consumption in the industry. However, due to the heterogeneity of its impact on carbon emission reduction in the industrial sectors and the current status of high energy consumption in China’s high carbon emission industries, less-intelligent intensive industries urgently need to upgrade industry technology and renewal industry equipment. Therefore, the government should control the development of high energy–consuming, heavy chemical industries and other high carbon emission enterprises and adjust their products and industrial structures. Less intelligent and less intensive enterprises should take the initiative to seek technological upgrading and transformation of production methods.

- (3)

The government should improve China’s energy consumption structure with intelligent manufacturing in the industrial sectors and gradually establish an energy system centered on renewable energy. As a sizeable coal-consuming country, China has formed an energy consumption structure dominated by coal consumption. Adopting targeted emission reduction policies is necessary to change this high–carbon emission energy consumption structure. Intelligent manufacturing has a significant effect on both reducing fossil energy consumption and improving fossil energy use efficiency. Therefore, it is necessary to use intelligent manufacturing to improve the energy consumption structure by improving energy efficiency and establishing a renewable energy–centered energy consumption system in light of the current situation of China’s energy consumption.