Firefighters’ Clothing Contamination in Fires of Electric Vehicle Batteries and Photovoltaic Modules—Literature Review and Pilot Tests Results

Abstract

:1. Introduction

2. Existing Guidelines and Practice in Firefighters’ PPC Maintenance

2.1. Standards of PPC Maintenance

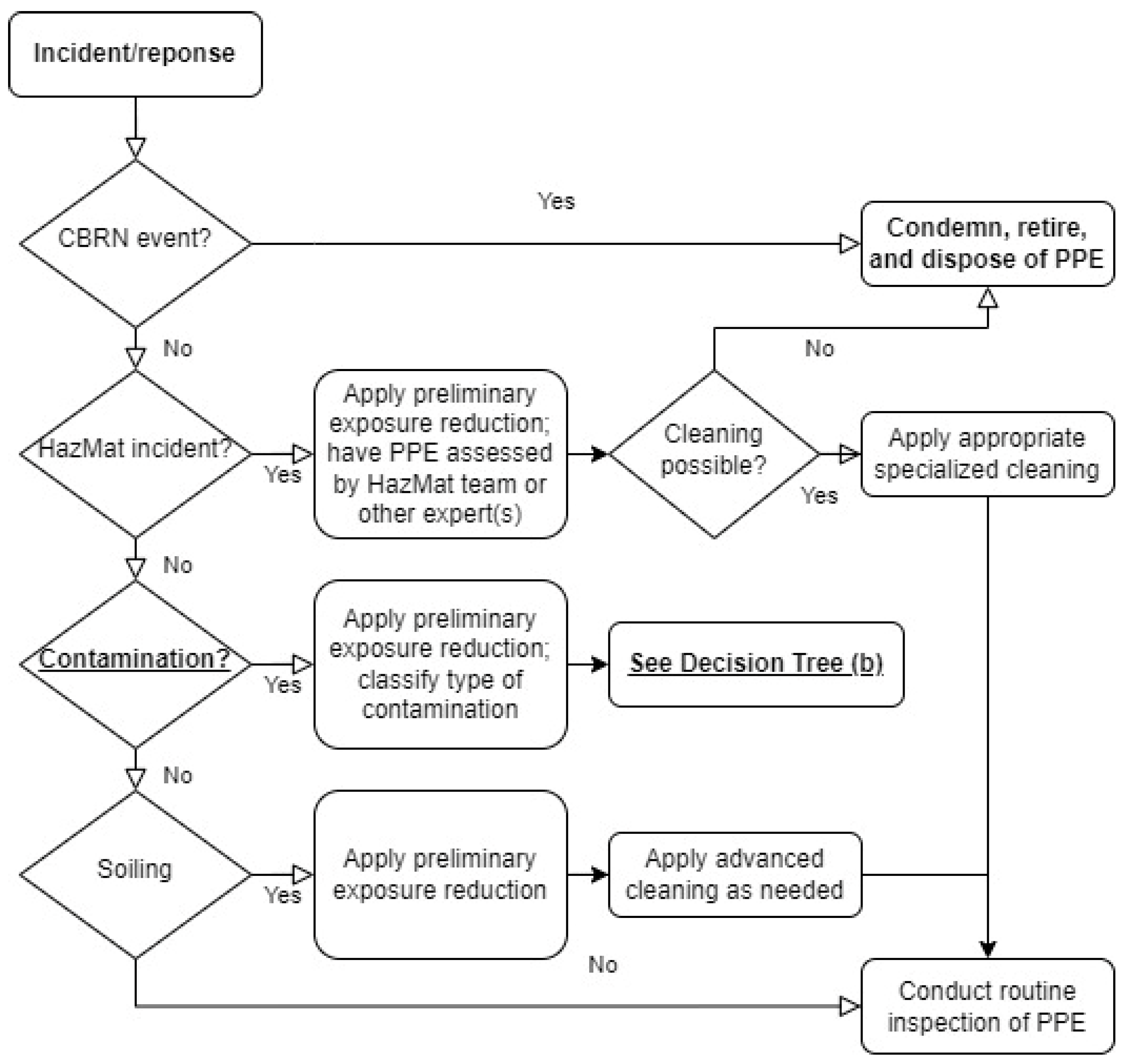

- NFPA 1851: 2020 Standard on Selection, Care, and Maintenance of Protective Ensembles for Structural Fire Fighting and Proximity Fire Fighting [29]—when it comes to Personal Protective Equipment (PPE) cleaning, this standard includes two tree diagrams to assist in the decision making on how to handle, clean, and dispose of PPE. PPE is a wider term that also includes PPC. The first decision tree (Figure 1) concerns general guidance, while the second decision tree (Figure 2), is specific to different types of contamination.As shown in Figure 1, the general decision path includes the type of event where PPE was used, especially if this was a chemical, biological, radiological, or nuclear (CBRN) event, and what classified it for retiring. The next step is an analysis of where the Hazardous Materials (HazMat) were detected. This determines whether cleaning is possible or not. The PPE classified for cleaning should be processed in a specialized service and be subject to a routine inspection. The third decision concerns other types of contamination. It suggests PPE should be secured to reduce the firefighters’ exposure to harmful substances, and the type of contamination should be classified as shown in Figure 2.The procedures presented in Figure 2 concern the following decision path when PPE is suspected to be contaminated. It consists of the verification of the presence of bulk chemicals and asbestos followed by appropriate action recommendations.The NFPA 1851 standard also provides an advanced PPE cleaning twice a year frequency recommendations, with one annual advanced inspection at least. New broad guidelines were also added for cleaning and sanitizing protective coats and pants, suggesting verification once each two years. However, an advanced inspection has been indicated at least annually (as opposed to year three in-service) or whenever a routine inspection may suggest potential damage. Considering the contaminants from PV installation and car battery fires, according to the NFPA 1851 decision tree, this type of incident should be treated as contamination with products of combustion, which is a very wide group of fires, including residential building fires, etc. However, it may be assumed that the types of substances in smoke may vary significantly. Although the verification of the cleaning procedure is mentioned in NFPA 1851, this means that the service provider is obliged to send contaminated samples for testing after advanced cleaning, and the result must provide at least 50% efficiency for removal of the average of all surrogate heavy metal contamination and semi-volatile organic compounds. Maximum level of contamination is not mentioned. The standard only indicated the fraction that needs to be disposed of.

- BS 8617: 2019 Personal protective equipment for firefighters—Cleaning, maintenance, and repair [30]—this standard establishes guidance for cleaning, maintenance, and repairing of different elements of firefighters’ PPE, in order to reduce the potential health and safety risks resulting from a poorly maintained, contaminated or damaged equipment. It includes inspection, testing, cleaning, decontamination, drying, repairs, replacement, retirement/disposal, recording, storage, and transportation, but without any detailed recommendations.

- EN 469: 2020 Protective clothing for firefighters—Performance requirements for protective clothing for firefighting [31]—this standard contains minimum performance requirements for protective clothing intended for use during firefighting operations, including construction, protection against heat and flame, mechanical and chemical properties, in terms of comfort of use and visibility, distinguishing between actions carried out outdoors and in buildings, in terms of protection against heat and flame.

- EN 13911: 2017 Protective clothing for firefighters—Requirements and test methods for fire hoods for firefighters [32]—this standard presents minimum safety requirements and test methods for a firefighters’ balaclava to be worn during rescue and firefighting operations to protect against the effects of heat and fire.

- EN ISO 15384: 2018/AMD 1: 2021 Protective clothing for firefighters—Laboratory test methods and performance requirements for wildland firefighting clothing + Amendment 1 [33]—this standard contains test methods and minimum performance requirements for PPC designed to protect the users’ body, excluding the head, hands, and feet, which is used in open-air firefighting and related activities. Wildland firefighting clothing refers to clothing which is used in open-air firefighting. However, this standard does not describe PPC maintenance procedures.

- ISO 23616: 2022 Cleaning, Inspection and Repair of Firefighters’ PPE [34]—this standard refers to requirements, guidance, and recommendations for PPE cleaning, inspection, and repairing. This standard excludes information concerning chemical protective clothing as well as CBRN protective clothing handling, apart from the information that once the PPE is used in a CBRN event, it should be secured and disposed of properly. It suggest periodical PPC washing and careful mechanical inspection of the clothing after this.

2.2. Cleaning and Decontamination Processes

2.3. Firefighters’ Protective Clothing Handling: Methods and Practices

3. Results of Firefighters’ Clothing Contamination from PV Module and Car Battery Fires

4. Conclusions and Future Directions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations and Short Forms

| AfPS | Ausschuss für Produktsicherheit (Committee for Product Safety) |

| AMD | Amendment |

| BS | British Standard |

| CBRN | Chemical, Biological, Radiological or Nuclear |

| DIN | Deutsches Institut für Normung (German institute for Standardization) |

| ECHA | European Chemicals Agency |

| EDX | Energy Dispersive X-ray Spectroscopy |

| EV | Electric Vehicles |

| EN | European Norm |

| EVA | Ethylene Vinyl Acetate |

| FR | Fire Resistant |

| FTIR-ATR | Fourier Transform Infrared—Attenuated Total Reflectance |

| HazMat | Hazardous Materials |

| ISO | International Organization for Standardization |

| LC/MS | Liquid Chromatography—Mass Spectrometry |

| LCO2 | Liquid CO2 |

| NFPA | National Fire Protection Association |

| OEKO-TEX® | Registered trade mark, representing the product labels and company certifications issued and other services provided by the International Association for Research and Testing in the Field of Textile and Leather Ecology |

| OETI | Institut fuer Oekologie, Technik und Innovation GmbH (Institute for Ecology, Technology and Innovation) |

| OSB | Oriented Strand Board |

| PE | Polyethylene |

| PPC | Personal Protective Clothing |

| PPE | Personal Protective Equipment |

| PU | Polyurethane |

| PV | Photovoltaic |

| PAHs | Polycyclic Aromatic Hydrocarbons |

| REACH | Registration, Evaluation, Authorisation and Restriction of Chemicals—European Union regulation |

| REM | Raster Electron Microscopic Analysis |

| VOCs | Volatile Organic Compounds |

| XRF | X-ray Fluorescence Analysis |

References

- Solar Continues to Break Installation Records, on Track for Terawatt Scale by 2022, Solar Power Europe. Available online: https://old.solarpowereurope.org/solar-continues-to-break-installation-records-on-track-for-terawatt-scale-by-2022/ (accessed on 30 May 2022).

- Nitta, N.; Wu, F.; Lee, J.T.; Yushin, G. Li-Ion Battery Materials: Present and Future. Mater. Today 2015, 18, 252–264. [Google Scholar] [CrossRef]

- Bisschop, R.; Willstrand, O.; Amon, F.; Rosengren, M. Fire Safety of Lithium-Ion Batteries in Road Vehicles; RISE Research Institutes of Sweden: Boras, Sweden, 2019. [Google Scholar] [CrossRef]

- Laukamp, H.; Bopp, G.; Grab, R.; Wittwer, C.; Haberlin, H.; van Heeckeren, B.; Phillip, S.; Reil, F.; Schmidt, H.; Sepanski, A.; et al. PV Hazard—Analysis and Assessment of Fire Incidents. In Proceedings of the 28th European Photovoltaic Solar Energy Conference and Exhibition, Paris, France, 30 September–4 October 2013. [Google Scholar]

- Sun, P.; Bisschop, R.; Niu, H.; Huang, X. A Review of Battery Fires in Electric Vehicles. Fire Technol. 2020, 56, 1361–1410. [Google Scholar] [CrossRef]

- Brzezinska, D.; Bryant, P. Performance-Based Analysis in Evaluation of Safety in Car Parks under Electric Vehicle Fire Conditions. Energies 2022, 15, 649. [Google Scholar] [CrossRef]

- Held, M.; Tuchschmid, M.; Zennegg, M.; Figi, R.; Schreiner, C.; Mellert, L.D.; Welte, U.; Kompatscher, M.; Hermann, M.; Nachef, L. Thermal Runaway and Fire of Electric Vehicle Lithium-Ion Battery and Contamination of Infrastructure Facility. Renew. Sustain. Energy Rev. 2022, 165, 112474. [Google Scholar] [CrossRef]

- Moskowitz, P.D.; Fthenakis, V.M. Toxic Materials Released from Photovoltaic Modules during Fires: Health Risks. Sol. Cells 1990, 29, 63–71. [Google Scholar] [CrossRef]

- Larsson, C.F. Lithium-Ion Battery Safety—Assessment by Abuse Testing, Fluoride Gas Emissions and Fire Propagation; Chalmers University of Technology: Göteborg, Sweden, 2017. [Google Scholar]

- Wang, Q.; Ping, P.; Zhao, X.; Chu, G.; Sun, J.; Chen, C. Thermal Runaway Caused Fire and Explosion of Lithium Ion Battery. J. Power Sources 2012, 208, 210–224. [Google Scholar] [CrossRef]

- Wang, Q.; Mao, B.; Stoliarov, S.I.; Sun, J. A Review of Lithium Ion Battery Failure Mechanisms and Fire Prevention Strategies. Prog. Energy Combust. Sci. 2019, 73, 95–131. [Google Scholar] [CrossRef]

- Feng, X.; Ouyang, M.; Liu, X.; Lu, L.; Xia, Y.; He, X. Thermal Runaway Mechanism of Lithium Ion Battery for Electric Vehicles: A Review. Energy Storage Mater. 2018, 10, 246–267. [Google Scholar] [CrossRef]

- Ouyang, D.; Chen, M.; Huang, Q.; Weng, J.; Wang, Z.; Wang, J. A Review on the Thermal Hazards of the Lithium-Ion Battery and the Corresponding Countermeasures. Appl. Sci. 2019, 9, 2483. [Google Scholar] [CrossRef] [Green Version]

- Cancelliere, P.; Liciotti, C.; Cardinali, M.; Puccia, V. Analysis of the Combustion Fumes and Gases Released during the Burning of Some C-Si PV Modules. In Proceedings of the 29th European Photovoltaic Solar Energy Conference and Exhibition, Amsterdam, The Netherlands, 22–26 September 2014; pp. 2259–2266. [Google Scholar] [CrossRef]

- Hull, T.R.; Paul, K.T. Bench-Scale Assessment of Combustion Toxicity—A Critical Analysis of Current Protocols. Fire Saf. J. 2007, 42, 340–365. [Google Scholar] [CrossRef]

- Song, G.; Wang, F. Firefighters’ Protective Clothing and Equipment. In Firefighter’s Clothing and Equipment: Performance, Protection, and Comfort; CRC Press: Boca Raton, FL, USA; Taylor & Francis Group: Abingdon, UK, 2019; pp. 26–60. [Google Scholar]

- Puszkarz, A.K.; Machnowski, W.; Błasińska, A. Modeling of Thermal Performance of Multilayer Protective Clothing Exposed to Radiant Heat. Heat Mass Transf. 2020, 56, 1767–1775. [Google Scholar] [CrossRef]

- Torvi, D.A.; George, V. Hadjisophocleus. Research in Protective Clothing for Firefighters: State of the Art and Future Directions. Fire Technol. 1999, 35, 111–130. [Google Scholar] [CrossRef]

- Fent, K.W.; Evans, D.E.; Booher, D.; Pleil, J.D.; Stiegel, M.A.; Horn, G.P.; Dalton, J. Volatile Organic Compounds Off-Gassing from Firefighters Personal Protective Equipment Ensembles after Use. J. Occup. Environ. Hyg. 2015, 12, 404–414. [Google Scholar] [CrossRef] [PubMed]

- Jakobsen, J.; Babigumira, R.; Danielsen, M.; Grimsrud, T.K.; Olsen, R.; Rosting, C.; Veierød, M.B.; Kjærheim, K. Work Conditions and Practices in Norwegian Fire Departments From 1950 Until Today: A Survey on Factors Potentially Influencing Carcinogen Exposure. Saf. Health Work 2020, 11, 509–516. [Google Scholar] [CrossRef] [PubMed]

- Pukkala, E.; Martinsen, J.I.; Weiderpass, E.; Kjaerheim, K.; Lynge, E.; Tryggvadottir, L.; Sparén, P.; Demers, P.A. Cancer Incidence among Firefighters: 45 Years of Follow-up in Five Nordic Countries. Occup. Environ. Med. 2014, 71, 398–404. [Google Scholar] [CrossRef]

- Jalilian, H.; Ziaei, M.; Weiderpass, E.; Rueegg, C.S.; Khosravi, Y.; Kjaerheim, K. Cancer Incidence and Mortality among Firefighters. Int. J. Cancer 2019, 145, 2639–2646. [Google Scholar] [CrossRef]

- Schaefer Solle, N.; Caban-Martinez, A.J.; Levy, R.A.; Young, B.A.; Lee, D.; Harrison, T.; Kobetz, E. Perceptions of Health and Cancer Risk among Newly Recruited Firefighters in South Florida. Am. J. Ind. Med. 2018, 61, 77–84. [Google Scholar] [CrossRef]

- Anderson, D.A.; Harrison, T.R.; Yang, F.; Wendorf Muhamad, J.; Morgan, S.E. Firefighter Perceptions of Cancer Risk: Results of a Qualitative Study. Am. J. Ind. Med. 2017, 60, 644–650. [Google Scholar] [CrossRef]

- Stec, A.A.; Dickens, K.E.; Salden, M.; Hewitt, F.E.; Watts, D.P.; Houldsworth, P.E.; Martin, F.L. Occupational Exposure to Polycyclic Aromatic Hydrocarbons and Elevated Cancer Incidence in Firefighters. Sci. Rep. 2018, 8, 2476. [Google Scholar] [CrossRef]

- Stec, A.; Wolffe, T.; Clinton, A. Minimising Firefighters’ Exposure to Toxic Fire Effluents. Interim Best Practice Report; University of Central Lancashire: Preston, UK, 2020. [Google Scholar]

- Fent, K.W.; Alexander, B.; Roberts, J.; Robertson, S.; Toennis, C.; Sammons, D.; Bertke, S.; Kerber, S.; Smith, D.; Horn, G. Contamination of Firefighter Personal Protective Equipment and Skin and the Effectiveness of Decontamination Procedures. J. Occup. Environ. Hyg. 2017, 14, 801–814. [Google Scholar] [CrossRef]

- Mayer, A.C.; Fent, K.W.; Bertke, S.; Horn, G.P.; Smith, D.L.; Kerber, S.; La Guardia, M.J. Firefighter Hood Contamination: Efficiency of Laundering to Remove PAHs and FRs. J. Occup. Environ. Hyg. 2019, 16, 129–140. [Google Scholar] [CrossRef] [PubMed]

- NFPA 1851; Standard on Selection, Care, and Maintenance of Protective Ensembles for Structural Fire Fighting and Proximity Fire Fighting. NFPA National Fire Codes Online; NFPA: Quincy, MA, USA, 2020.

- BS 8617: 2019; Personal Protective Equipment for Firefighters. Cleaning, Maintenance and Repair. Code of Practice. The British Standards Institution: London, UK, 2019.

- EN 469: 2020; Protective Clothing for Firefighters—Performance Requirements for Protective Clothing for Firefighting Activities. European Standards S.R.O.: Brussels, Belgium, 2020.

- EN 13911: 2017; Protective Clothing for Firefighters—Requirements and Test Methods for Fire Hoods for Firefighters. European Standards S.R.O.: Brussels, Belgium, 2017.

- EN ISO 15384:2018/AMD 1:2021; Protective Clothing for Firefighters—Laboratory Test Methods and Performance Requirements for Wildland Firefighting Clothing + Amendment 1. International Organization for Standardization: Geneva, Switzerland, 2021.

- ISO 23616:2022; Cleaning, Inspection and Repair of Firefighters’ PPE. International Organization for Standardization: Geneva, Switzerland, 2022.

- Johansson, I.; Somasundaran, P. Handbook for Cleaning/Decontamination of Surfaces; Elsevier: Amsterdam, The Netherlands, 2007; Volumes 1–2. [Google Scholar]

- Khan, A.W.; Kotta, S.; Ansari, S.H.; Ali, J.; Sharma, R.K. Recent Advances in Decontamination of Chemical Warfare Agents. Def. Sci. J. 2013, 63. [Google Scholar] [CrossRef]

- Supplement PPE & Materials for PPE. Standard 100 by OEKO—TEX (R). Available online: https://www.oeko-tex.com/importedmedia/downloadfiles/STANDARD_100_by_OEKO-TEX_R__-_Supplement_PPE___Materials_for_PPE_en.pdf (accessed on 20 August 2022).

- AfPS GS 2019:01 PAK; GS-Spezifikation “Prüfung Und Bewertung von Polyzyklischen Aromatischen Kohlenwasserstoffen (PAK) Bei Der Zuerkennung Des GS-Zeichens” Des Ausschusses Für Produktsicherheit. Bundesanstalt für Arbeitsschutz und Arbeitsmedizin (AfPS): Dortmund, Germany, 2019.

- ANNEX XVII TO REACH—Conditions of Restriction. In REACH—Regulation (EC) No 1907/2006 of the European Parliament and of the Council of 18 December 2006; ECHA: Helsinki, Finland, 2016.

- Laitinen, J.; Tuomi, T.; Vainiotalo, S.; Rantio, T.; Laaja, T.; Parshintsev, E.; Kiviranta, H.; Koponen, J.; Ruokojärvi, P.; Kemmeren, M.; et al. The Contamination and Decontamination of Fire Fighting Garments—Laboratory Tests. In Proceedings of the 8th European Conference on Protective Clothing. Upcoming Generation, Porto, Portugal, 7–9 May 2018. [Google Scholar]

- de Lucena, M.A.M.; Zapata, F.; Mauricio, F.G.M.; Ortega-Ojeda, F.E.; Quintanilla-López, M.G.; Weber, I.T.; Montalvo, G. Evaluation of an Ozone Chamber as a Routine Method to Decontaminate Firefighters’ PPE. Int. J. Environ. Res. Public Health 2021, 18, 10587. [Google Scholar] [CrossRef]

- Study Report on the Concentration of Harmful Substances in Urine Samples in Firefighters Wearing Contaminated PPE, PPE Cleaned by an Industrial Laundry and LCO2 Cleaned PPE; The University of Leuven: Leuven, Belgium, 2018.

- ISO 15797-2; Textiles—Industrial Washing and Finishing Procedures for Testing of Workwear. International Organization for Standardization: Geneva, Switzerland, 2017.

- Moutinho, H.R.; Johnston, S.; To, B.; Jiang, C.-S.; Xiao, C.; Hacke, P.; Moseley, J.; Tynan, J.; Dhere, N.G.; Al-Jassim, M.M. Development of Coring Procedures Applied to Si, CdTe, and CIGS Solar Panels. Sol. Energy 2018, 161, 235–241. [Google Scholar] [CrossRef]

- Riva, A.; Camino, G.; Fomperie, L.; Amigouët, P. Fire Retardant Mechanism in Intumescent Ethylene Vinyl Acetate Compositions. Polym. Degrad. Stab. 2003, 82, 341–346. [Google Scholar] [CrossRef]

- Nzereogu, P.U.; Omah, A.D.; Ezema, F.I.; Iwuoha, E.I.; Nwanya, A.C. Anode Materials for Lithium-Ion Batteries: A Review. Appl. Surf. Sci. Adv. 2022, 9, 100233. [Google Scholar] [CrossRef]

| Substance Type | Substance | Limit Values | |

|---|---|---|---|

| Direct Contact with the Skin | No Direct Contact to the Skin | ||

| Free and partially releasable formaldehyde | Formaldehyde (mg/kg) | 75.000 | 150.000 |

| Extractable heavy metals | Antimony (Sb) (mg/kg) | 30.000 | 30.000 |

| Arsenic (As) (mg/kg) | 0.200 | 0.200 | |

| Lead (Pb) (mg/kg) | 0.200 | 0.200 | |

| Cadmium (Cd) (mg/kg) | 0.100 | 0.100 | |

| Chromium (Cr) (mg/kg) | 1.000 | 1.000 | |

| Cobalt (Co) (mg/kg) | 1.000 | 1.000 | |

| Copper (Cu) 1 (mg/kg) | 50.000 | 50.000 | |

| Nickel (Ni) (mg/kg) | 1.000 | 1.000 | |

| Mercury (Hg) (mg/kg) | 0.020 | 0.020 | |

| Barium (Ba) (mg/kg) | 1000.000 | 1000.000 | |

| Selenium (Se) (mg/kg) | 100.000 | 100.000 | |

| Zinc (Zn) (mg/kg) | 750.000 | 750.000 | |

| Manganese (Mn) (mg/kg) | 90.000 | 90.000 | |

| Heavy metals (total content) | Arsenic (As) (mg/kg) | 100.000 | 100.000 |

| Cadmium (Cd) (mg/kg) | 40.000 | 40.000 | |

| Mercury (Hg) (mg/kg) | 0.500 | 0.500 | |

| Phthalates | Each phthalate (w%) | 0.010 | 0.010 |

| Sum of all phthalates (w%) | 0.025 | 0.025 | |

| Other chemical residues | Carcinogenic Arylamines (mg/kg) | 20.000 | 20.000 |

| Aniline (mg/kg) | 20.000 | 20.000 | |

| Benzene (mg/kg) | 1.000 | 1.000 | |

| Bisphenol A (mg/kg) | 100.000 | 100.000 | |

| Bisphenol B (mg/kg) | 1000.000 | 1000.000 | |

| Diazene-1,2-dicarboxamide (ADCA) (w%) | 0.100 | 0.100 | |

| Phenol (mg/kg) | 50.000 | 50.000 | |

| PAHs | Benzo(a)pyrene (mg/kg) | 1.000 | 1.000 |

| Benzo(e)pyrene (mg/kg) | 1.000 | 1.000 | |

| Benzo(a)anthracene (mg/kg) | 1.000 | 1.000 | |

| Chrysene (mg/kg) | 1.000 | 1.000 | |

| Benzo(b)fluoranthene (mg/kg) | 1.000 | 1.000 | |

| Benzo(j)fluoranthene (mg/kg) | 1.000 | 1.000 | |

| Benzo(k)fluoranthene (mg/kg) | 1.000 | 1.000 | |

| Dibenzo(a,h)anthracene (mg/kg) | 1.000 | 1.000 | |

| Naphthalene (mg/kg) | 2.000 | 2.000 | |

| Sum of 24 PAHs (mg/kg) | 10.000 | 10.000 | |

| VOCs and glycols | Methylethylketone (mg/kg) | 10.000 | 10.000 |

| Ethylbenzene (mg/kg) | 10.000 | 10.000 | |

| Xylene (mg/kg) | 10.000 | 10.000 | |

| Cyclohexanone (mg/kg) | 10.000 | 10.000 | |

| Styrene (mg/kg) | 10.000 | 10.000 | |

| Benzene (mg/kg) | 1.000 | 1.000 | |

| Toluene (mg/kg) | 10.000 | 10.000 | |

| Emission of volatiles | Formaldehyde [50-00-0] (mg/cm3) | 0.100 | 0.100 |

| Toluene [108-88-3] (mg/cm3) | 0.100 | 0.100 | |

| Styrene [100-42-3] (mg/cm3) | 0.005 | 0.005 | |

| Butadiene [106-99-0] (mg/cm3) | 0.002 | 0.002 | |

| Vinyl chloride [75-01-4] (mg/cm3) | 0.002 | 0.002 | |

| Aromatic hydrocarbons (mg/cm3) | 0.300 | 0.300 | |

| Organic volatiles (mg/cm3) | 0.500 | 0.500 | |

| Substance | Materials with Long-Term Skin Contact or Repeated Short-Term Skin Contact (mg/kg) | Materials with Short-Term Skin Contact (mg/kg) |

|---|---|---|

| Benzo(a)pyrene | <0.5 | <1 |

| Benzo(e)pyrene | <0.5 | <1 |

| Benzo(a)anthracene | <0.5 | <1 |

| Benzo(b)fluoranthene | <0.5 | <1 |

| Benzo(j)fluoranthene | <0.5 | <1 |

| Benzo(k)fluoranthene | <0.5 | <1 |

| Chrysene | <0.5 | <1 |

| Dibenzo(a,h)anthracene | <0.5 | <1 |

| Benzo(ghi)perylene | <0.5 | <1 |

| lndeno(1‚2,3-cd)pyrene | <0.5 | <1 |

| Phenanthrene, Pyrene, Anthracene, Fluoranthene, sum | <10 | <50 |

| Naphthalene | <2 | <10 |

| Sum of 15 PAHs | <10 | <50 |

| Test Number | Protective Clothing (Producer, Model) | Composition of the Clothing | Fire Source | Fire Space |

|---|---|---|---|---|

| Test 1 | Scantex, Garda | outer layer: 60% Nomex®, 40% viscose FR; membrane: 50% PE, 50% PU FR; thermal insulation: 100% Nomex®; liner: 50% Nomex®, 50% viscose FR | BAUER PV module BS-310-6MB5 99 × 164 cm | Open |

| Test 2 | Scantex, Garda | outer layer: 60% Nomex®, 40% viscose FR; membrane: 50% PE, 50% PU FR; thermal insulation: 100% Nomex®; liner: 50% Nomex®, 50% viscose FR | BAUER PV module BS-365-M6HBBGG 104 × 177 cm | Closed |

| Test 3 | Ballyclare, Xenon | outer layer: 93% Nomex®, 5% Kevlar, 2% antistatic; membrane: 100% Proline PTFE®; thermal insulation: 100% Duflot®; liner: 50% Kermel, 50% viscose FR | Ni-MH 50 Ah car battery | Closed |

| Material | Width (cm) | Length (cm) | Thickness (cm) | Number (pcs) |

|---|---|---|---|---|

| OSB | 4.5 | 45.0 | 2.0 | 14 |

| OSB | 6.0 | 60.0 | 2.0 | 14 |

| Pinewood | 4.5 | 55.0 | 1.5 | 4 |

| Kindling cubes | 2.1 | 2.4 | 1.2 | 7 |

| Substance Group | Detection Method/Standard Used | Test 1 | Test 2 | Test 3 |

|---|---|---|---|---|

| Soot residues, wt% | REM 1/EDX/FTIR-ATR 2 | <0.1 | 1.3 | 1.8 |

| Fats/oils/resins, wt% | FTIR-ATR 2 | <0.01 | 0.05 | <0.01 |

| Total PAHs, mg/kg | DIN EN 17132 3 | 240 | 364 | 670 |

| Formaldehyde 4, mg/kg | DIN EN ISO 14184 | 470 | 622 | 895 |

| Lithium, mg/kg | XRF 5 | <5 | <5 | 35 |

| Cobalt, mg/kg | XRF 5 | <5 | <5 | 24 |

| Organic phosphoric acid compounds 6, mg/kg | LC/MS 7 | <5 | 85 | 130 |

| Oligomer cyclic compound, mg/kg | ISO 15033 8 | 276 | 450 | 35 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szmytke, E.; Brzezińska, D.; Machnowski, W.; Kokot, S. Firefighters’ Clothing Contamination in Fires of Electric Vehicle Batteries and Photovoltaic Modules—Literature Review and Pilot Tests Results. Int. J. Environ. Res. Public Health 2022, 19, 12442. https://doi.org/10.3390/ijerph191912442

Szmytke E, Brzezińska D, Machnowski W, Kokot S. Firefighters’ Clothing Contamination in Fires of Electric Vehicle Batteries and Photovoltaic Modules—Literature Review and Pilot Tests Results. International Journal of Environmental Research and Public Health. 2022; 19(19):12442. https://doi.org/10.3390/ijerph191912442

Chicago/Turabian StyleSzmytke, Ewelina, Dorota Brzezińska, Waldemar Machnowski, and Szymon Kokot. 2022. "Firefighters’ Clothing Contamination in Fires of Electric Vehicle Batteries and Photovoltaic Modules—Literature Review and Pilot Tests Results" International Journal of Environmental Research and Public Health 19, no. 19: 12442. https://doi.org/10.3390/ijerph191912442

APA StyleSzmytke, E., Brzezińska, D., Machnowski, W., & Kokot, S. (2022). Firefighters’ Clothing Contamination in Fires of Electric Vehicle Batteries and Photovoltaic Modules—Literature Review and Pilot Tests Results. International Journal of Environmental Research and Public Health, 19(19), 12442. https://doi.org/10.3390/ijerph191912442