Analysis of Hygrothermal Microclimatic (HTM) Parameters in Specific Food Storage Environments in Slovakia

Abstract

1. Introduction

- Although individual factors can be qualified and quantified separately, HTM is a complex of variables in interaction with each other.

- Assessment of the HTM is a function of exposure time and type of work activity.

- There are different individual reactions of people to the qualitative and quantitative effects of HTM factors.

- The effects of HTM can be somewhat “mitigated” by human adaptation or acclimatization.

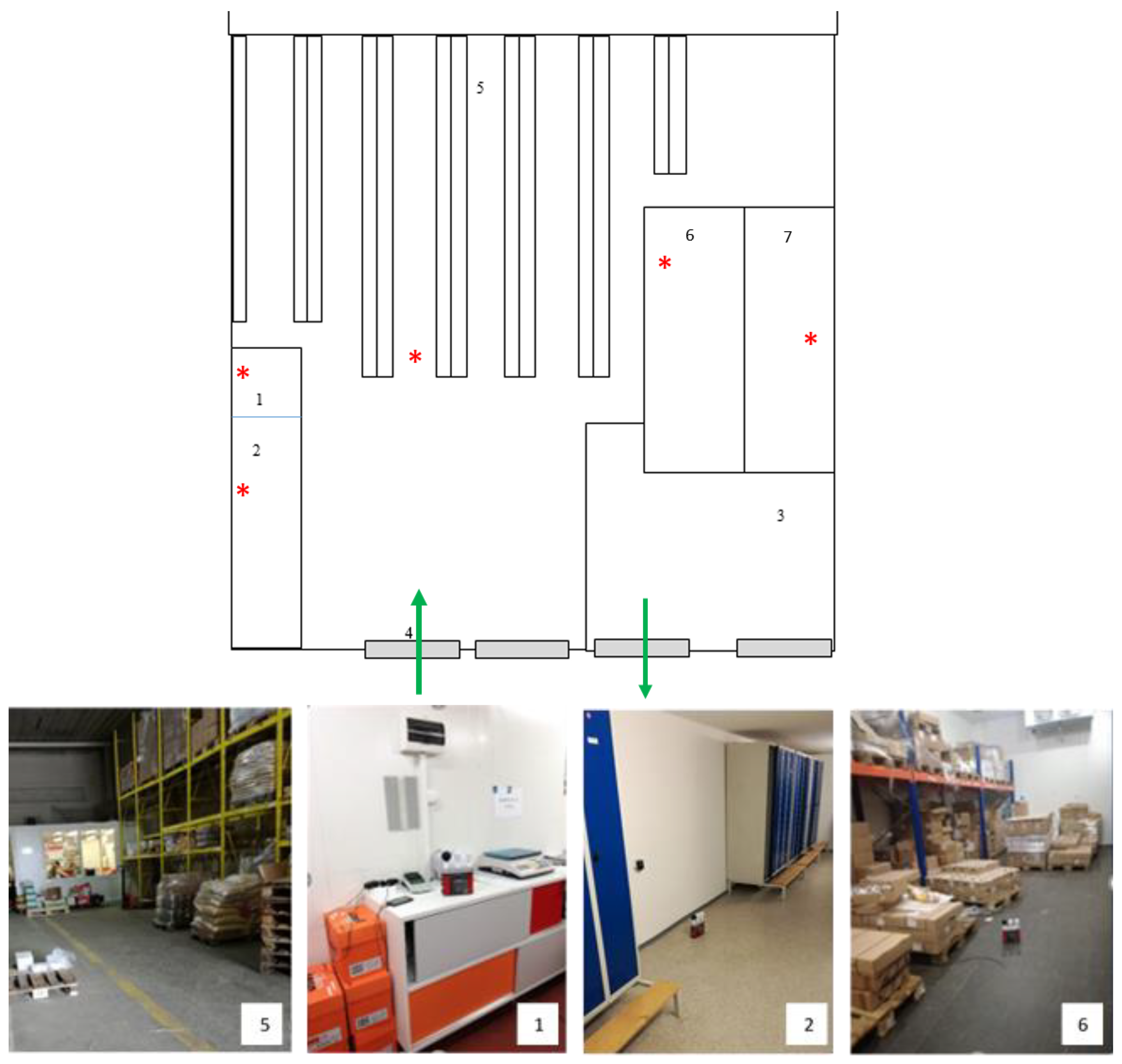

2. Materials and Methods

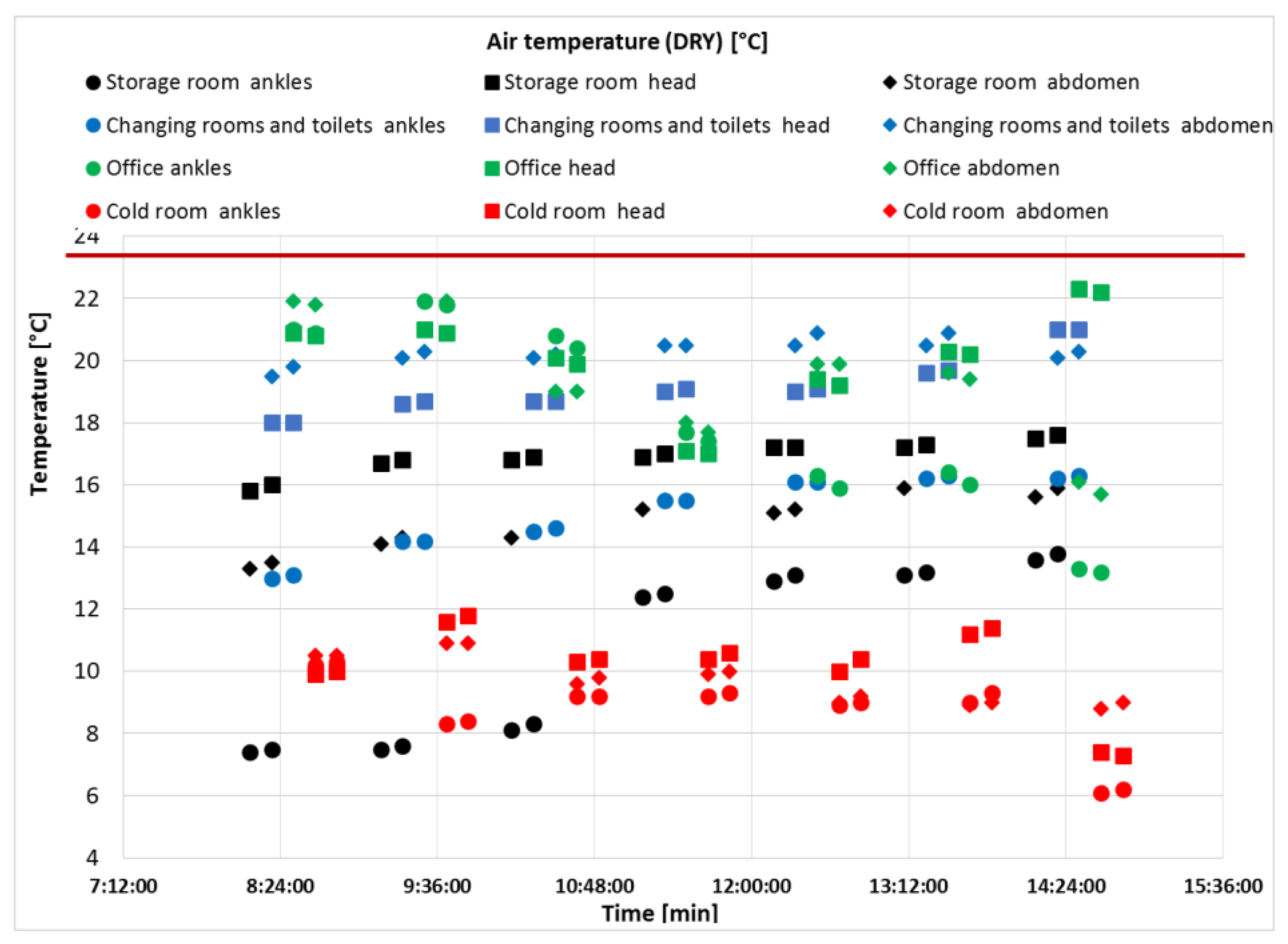

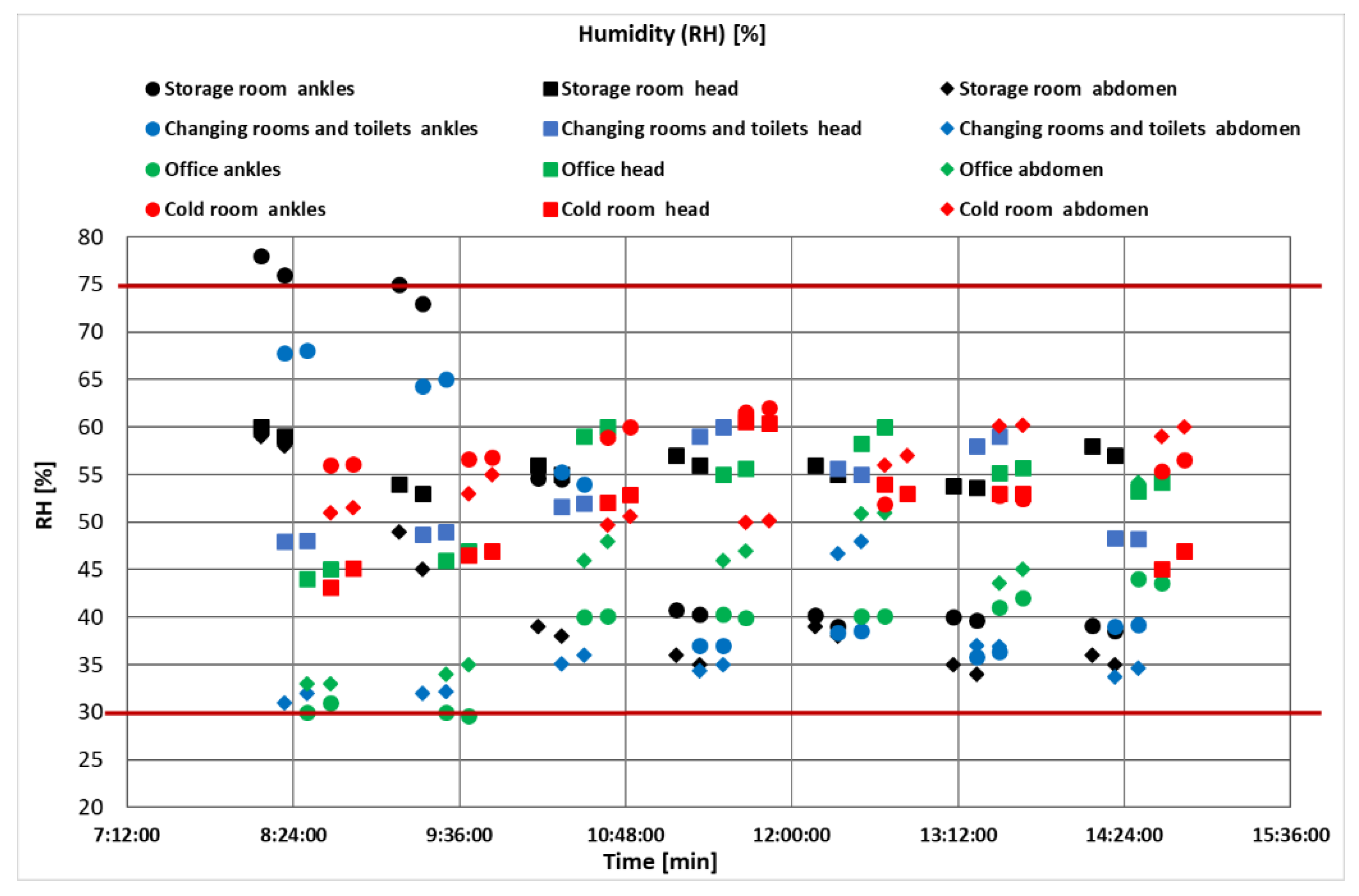

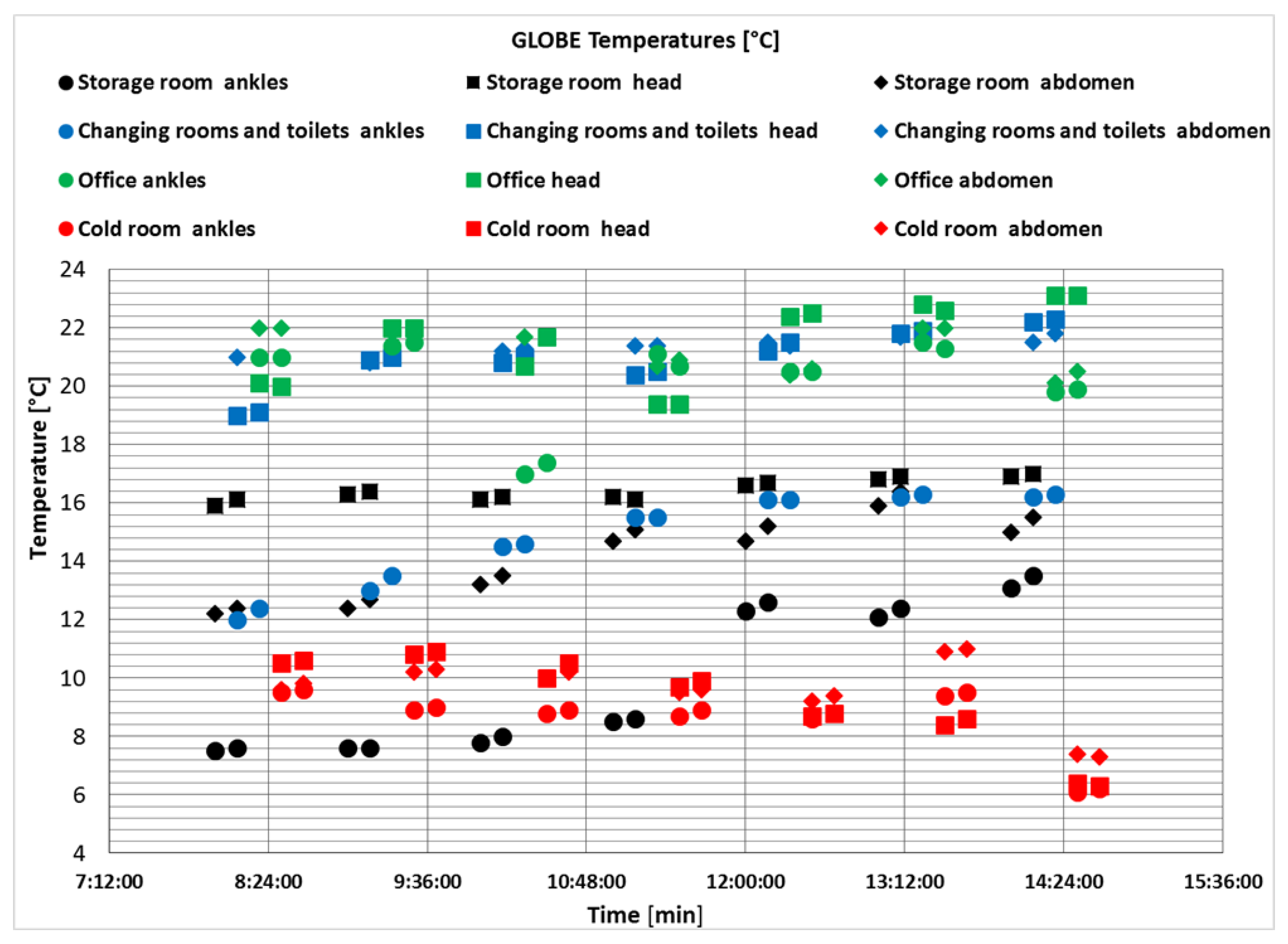

3. Results

4. Discussion

Statistical Evaluation of the Average Measured Values of Microclimatic Conditions in Food Storage

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- SEA. Report of Environment in Slovak Republic for 2015. Available online: https://www.enviroportal.sk/uploads/spravy/sprava-2015-final-ep.pdf (accessed on 1 April 2016).

- SEA. Report of Environment in Slovak Republic for 2016. Available online: https://www.enviroportal.sk/uploads/report/8142.pdf (accessed on 1 April 2017).

- SEA. Report of Environment in Slovak Republic for 2017. Available online: https://www.enviroportal.sk/uploads/report/6961.pdf (accessed on 1 April 2018).

- Tureková, I.; Marková, I. Indoor of Buildings, 1st ed.; Constantine the Philosopher University in Nitra: Nitra, Slovakia, 2018; 150p. (In Slovak) [Google Scholar]

- Loveček, T.; Ristvej, J.; Sventeková, E.; Šiser, A.; Veľas, A. Research of competencies of crisis and security managers. In Proceedings of the 3rd International Conference Economic, Business Management and Educational Innovation (EBMEI 2016), Prague, Czech Republic, 10–11 May 2016; Singapore Management & Sports Science Inst.: Singapore, 2016; pp. 172–177. [Google Scholar]

- Slamková, E.; Dulina, Ľ.; Tabaková, M. Ergonomic in Industry, 1st ed.; GEORG: Žilina, Slovakia, 2010. (in Slovak) [Google Scholar]

- de Freitas, C.R.; Grigorieva, E.A. A comprehensive catalogue and classification of human thermal climate indices. Int. J. Biometeorol. 2015, 59, 109–120. [Google Scholar] [CrossRef]

- Goldman, R.F. Standards for human exposure to heat. In Environmental Ergonomics; Mekjavic, I.B., Banister, E.W., Morrison, J.B., Eds.; Taylor & Francis: Philadelphia, PA, USA, 1988; pp. 99–138. [Google Scholar]

- Havenith, G.; Fiala, D. Thermal indices and thermophysiological modeling for heat stress. Compr. Physiol. 2011, 6, 255–302. [Google Scholar]

- Lee, D.H. Seventy-five years of searching for a heat index. Environ. Res. 1980, 22, 331–356. [Google Scholar] [CrossRef]

- Parsons, K.C.; Fox, J.G.; Metz, B. The Commission of the European Communities Seminar on heat stress indices. Ergonomics 1995, 38, 1–5. [Google Scholar] [CrossRef]

- Bethea, D.; Parsons, K. The Development of a Practical Heat Stress Assessment Methodology for Use in UK Industry (Research Report 008); Department of Human Sciences, Loughborough University: Loughborough, UK, 2002. [Google Scholar]

- d’Ambrosio Alfano, F.R.; Palella, B.I.; Riccio, G. Thermal environment assessment reliability using temperature–humidity indices. Ind. Health 2011, 49, 95–106. [Google Scholar] [CrossRef] [PubMed]

- d’Ambrosio Alfano, F.R.; Malchaire, J.; Palella, B.I.; Riccio, G. WBGT Index Revisited After 60 Years of Use. Ann. Occup. Hyg. 2014, 58, 955–970. [Google Scholar]

- ISO 7243. Hot Environments—Estimation of the Heat Stress on Working Man, Based on the WBGT-Index (wet Bulb Globe Temperature); International Organization for Standardization: Geneva, Switzerland, 1989. [Google Scholar]

- ISO 7933. Ergonomics of the Thermal Environment—Analytical Determination and Interpretation of Heat Stress Using Calculation of the Predicted Heat Strain; International Organization for Standardization: Geneva, Switzerland, 2004. [Google Scholar]

- ANSI/ASHRAE Standard 55: 2017. Thermal Environmental Conditions for Human Occupancy; ASHRAE Headquarters: Atlanta, GA, USA, 2017. [Google Scholar]

- Çengel, Y.A.; Boles, M.A. Thermodynamics: An Engineering Approach, 8th ed.; McGraw-Hill Education: New York, NY, USA, 2015. [Google Scholar]

- Nicol, F.; Humphreys, M. Adaptive thermal comfort and sustainable thermal standards for buildings. Energy Build. 2002, 34, 563–572. [Google Scholar] [CrossRef]

- ISO 7730. Moderate Thermal Environments—Determination of the PMV and PPD Indices and Specification of the Conditions for Thermal Comfort; International Organization for Standardization: Geneva, Switzerland, 1994. [Google Scholar]

- Fanger, P.O. Thermal Comfort. Analysis and Applications in Environmental Engineering; Danish Technical Press: Copenhagen, Denmark, 1970; 244p. [Google Scholar]

- Pourshaghaghy, A.; Omidvari, M. Examination of thermal comfort in a hospital using PMV-PPD model. Appl. Ergon. 2012, 43, 1089–1095. [Google Scholar] [CrossRef]

- Homod, R.Z.; Sahari, K.S.M.; Almurib, H.A.F.; Nagi, F.H. RLF and TS fuzzy model identification of indoor thermal comfort based on PMV/PPD. Build. Environ. 2012, 49, 141–153. [Google Scholar] [CrossRef]

- Wei, S.; Li, M.; Lin, W.; Sun, Y. Parametric studies and evaluations of indoor thermal environment in wet season using a field survey and PMV–PPD method. Energy Build. 2010, 42, 799–806. [Google Scholar] [CrossRef]

- Cheung, T.; Schiavon, S.; Parkinson, T.; Li, P.; Bragerb, G. Analysis of the accuracy on PMV—PPD model using the ASHRAE Global Thermal Comfort Database II. Build. Environ. 2019, 153, 205–217. [Google Scholar] [CrossRef]

- Humphreys, M.A.; Nicol, J.F.; Raja, I.A. Field studies of indoor thermal comfort and the progress of the adaptive approach. Adv. Build. Energy Res. 2007, 1, 55–88. [Google Scholar] [CrossRef]

- Brager, G.S.; De Dear, R.J. Thermal adaptation in the built environment: A literature review. Energy Build. 1998, 27, 83–96. [Google Scholar] [CrossRef]

- De Dear, R.; Brager, G.S. Developing an Adaptive Model of Thermal Comfort and Preference; Center for Environmental Design Research, UC Berkeley: Berkeley, CA, USA, 1998. [Google Scholar]

- Huang, L.; Zhu, Y.; Ouyang, Q.; Cao, B. A study on the effects of thermal, luminous, and acoustic environments on indoor environmental comfort in offices. Build. Environ. 2012, 49, 304–309. [Google Scholar] [CrossRef]

- Gajic, D.; Stupar, D.; Antunovic, B.; Jankovic, A. Determination of the energy performance indicator of kindergartens through design, measured and recommended parameters. Energy Build. 2019, 204, 109511. [Google Scholar] [CrossRef]

- Fabozzi, M.; Dama, A. Field study on thermal comfort in naturally ventilated and air-conditioned university classrooms. Indoor Built Environ. 2019. [Google Scholar] [CrossRef]

- Rodriguez, C.M.; Coronado, M.C.; Medina, J.M. Classroom-comfort-data: A method to collect comprehensive information on thermal comfort in school classrooms. Methodsx 2019, 6, 2698–2718. [Google Scholar] [CrossRef]

- Chen, K. A Review on Thermal Comfort Evaluation of Head-Worn Devices. In Advances in Ergonomics in Design (AHFE 2018); Rebelo, F., Soares, M.M., Eds.; Book Series: Advances in Intelligent Systems and Computing; Springer: Cham, Switzerland, 2019; Volume 777, pp. 590–598. [Google Scholar] [CrossRef]

- Höppe, P.; Martinac, I. Indoor climate and air quality. Int. J. Biometeorol. 1998, 42, 1–7. [Google Scholar] [CrossRef]

- Kumar, A.; Suman, B.M. Experimental evaluation of insulation materials for walls and roofs and their impact on indoor thermal comfort under composite climate. Build. Environ. 2013, 59, 635–643. [Google Scholar] [CrossRef]

- Bernatíková, Š.; Malý, S. Reakce lidského organismu na tepelnou zátěž. Spektrum 2009, 1, 78–80. (In Czech) [Google Scholar]

- De Turck, S.; Laverge, J.; Van Den Bossche, N. Personal HVAC: A Simulation Based Feasibility Study. Ph.D. Dissertation, Faculty of Engineering and Architecture, Ghent University, Ghent, Belgium, 2018. Available online: https://lib.ugent.be/catalog/rug01:002495100 (accessed on 21 March 2020).

- Decree of the Ministry of Health of the Slovak Republic no. 99/2016 Coll. on Protection of Health Against Heat and Cold Stress at Work; Ministry of Health of the Slovak Republic: Bratislava, Slovak Republic, 2016; 6p. (In Slovakia) [Google Scholar]

- Decree of the Ministry of Health of the Slovak Republic 259/2008 Coll. on the Details of the Requirements for the Indoor Environment of Buildings and the Minimum Requirements for Lower-Standard Apartments and Buildings; Ministry of Health of the Slovak Republic: Bratislava, Slovak Republic, 2008; 11p. (In Slovakia) [Google Scholar]

- Zare, S.; Shirvan, H.E.; Hemmatjo, R.; Nadri, F.; Jahani, Y.; Jamshidzadeh, K.; Paydar, P. A comparison of the correlation between heat stress indices (UTCI, WBGT, WBDT, TSI) and physiological parameters of workers in Iran. Weather Clim. Extrem. 2019, 26, 100213. [Google Scholar] [CrossRef]

- Heo, S.; Bell, M.L. Heat waves in South Korea: Differences of heat wave characteristics by thermal indices. J. Expo. Environ. Epidemol. 2019, 29, 790–805. [Google Scholar] [CrossRef] [PubMed]

- Virgílio, A.; Oliveira, M.; Gaspar, A.R.; Raimundo, A.M.; Quintela, D.A. Assessment of thermal environments: Working conditions in the portuguese glass industry. Ind. Health 2018, 56, 62–77. [Google Scholar]

- Cheng, Y.-T.; Lung, S.-C.C.; Hwang, J.-S. New approach to identifying proper thresholds for a heat warning system using health risk increments. Environ. Res. 2019, 170, 282–292. [Google Scholar]

- Ladomerský, J.; Balog, K.; Martinka, J.; Hroncová, E.; Dibdiaková, J. The Environmental and Energy Potential of Incinerating Various Biomass Mixtures. Adv. Mater. Res. 2014, 1001, 114–117. [Google Scholar] [CrossRef]

- Fang, Z.; Feng, X.; Xu, X.; Zhou, X.; Lin, Z.; Ji, Y. Investigation into the thermal comfort of conditions by different seasonal field surveys in China, Guangzhou. Int. J. Biometeorol. 2019, 63, 1357–1368. [Google Scholar] [CrossRef]

- Drahoš, R.; Drahoš, M. Zdravotné aspekty tepelno-vlhkostnej mikroklímy pri práci (Health Aspects of Heat-Moisture Microclimate at Work). Available online: http://www.d2r.sk/texty/zdravotne_aspekty_mikroklimy.pdf (accessed on 28 March 2015). (In Slovak).

- Epstein, Y.; Moran, D.S. Thermal comfort and the heat stress indices. Ind. Health 2006, 44, 388–398. [Google Scholar] [CrossRef]

- Moran, D.S.; Pandolf, K.B.; Shapiro, Y.; Heled, Y.; Shani, Y.; Mathew, W.T.; Gonzalez, R.R. An environmental stress index (ESI) as a substitute for the wet bulb globe temperature (WBGT). J. Therm. Biol. 2001, 26, 427–431. [Google Scholar] [CrossRef]

- Makovická-Osvaldová, L. Risk Management at Occupational Safety and Health. In Proceedings of the International Scientific Conference; Technical University in Brtislava: Bratislava, Slovak Republic, 2014; pp. 57–60. [Google Scholar]

- ACGIH. TLVs and BELs. Threshold Limit Values for Chemicals Substances and Physical Agents and Biological Exposure Indices; ACGIH Signature Publications: Cinncinati, OH, USA, 2004; pp. 168–176. [Google Scholar]

- US Department of Labor. OSHA. Technical Manual (OTM) (TED 01-00-015) Section III; Heat Stress, US Department of Labor: Washington, DC, USA, 1999; Chapter 4. [Google Scholar]

- AIHA. Heat exchange and human tolerence limits. In Heating and Cooling for Man Industry, 2nd ed.; American Industrial Hygiene Association: Arkon, OH, USA, 1975; pp. 5–28. [Google Scholar]

- Zhang, H.; Arens, E.; Huizenga, C.H.; Han, T. Thermal sensation and comfort models for non-uniform and transient environments: Part I: Local sensation of individual body parts. Build. Environ. 2010, 45, 380–388. [Google Scholar] [CrossRef]

- OOFŽP/268/2013. Odborné Usmernenie Ministerstva Zdravotníctva Slovenskej Republiky, Ktorým sa Upravuje Postup pri Meraní a Hodnotení Tepelno-Vlhkostnej Mikroklímy Expert Guideline of the Ministry of Health of the Slovak Republic Regulating the Procedure for Measurement and Evaluation of Thermal-Humidity Microclimate; Ministry of Health of the Slovak Republic: Bratislava, Slovak Republic, 2013; 14p. (In Slovakia) [Google Scholar]

- ISO 7726:1998. Ergonomics of the Thermal Environment. Instruments for Measuring Physical Quantities; International Organization for Standardization: Geneva, Switzerland, 1998. [Google Scholar]

- Frič, M.; Šaligová, D.; Chovancová, L. Meranie a hodnotenie tepelno-vlhkostnej mikroklímy v pracovnom prostredí (Measurement and evaluation of thermal-moisture microclimate in working environment). In Životné podmienky a zdravie: Zborník vedeckých prác (In Living Conditions and Health: Proceedings of scientific papers); Úrad verejného zdravotníctva (Public Health Authority): Bratislava, Slovak Republic, 2015; pp. 265–272. (In Slovak) [Google Scholar]

- Kraliková, R.; Sokolová, D. Experimental measurments and evaluation of indoor microclimate conditions. Acta Univ. Cibiniensis Tech. Ser. 2015, 66, 79–84. [Google Scholar] [CrossRef][Green Version]

- Ondrejková, Ľ. Záťaž teplom a chladom pri práci v nových legislatívnych úpravách (Heat and Cold Load at Work in New Legislation). Available online: https://www.mzdovecentrum.sk/clanok-z-titulky/zataz-teplom-a-chladom-pri-praci-v-novych-legislativnych-upravach-10.htm (accessed on 20 June 2016).

- Králikova, R.; Sokolova, H.; Wessely, E. Thermal Environment Evaluation According to Indices in Industrial Workplaces. Procedia Eng. 2014, 69, 158–167. [Google Scholar] [CrossRef]

- Decree 28167/2007-OL. Food Code of the Slovak Republic; Of the Ministry of Agriculture of the Slovak Republic and the Ministry of Health of the Slovak Republic: Bratislava, Slovak Republic, 2007. [Google Scholar]

- Jokl, M.V. Thermal Comfort and Optimum. Humidity Part 1. Acta Polytech. 2002, 42, 12–24. [Google Scholar]

- Lan, L.; Wargocki, P.; Lian, Z. Quantitative measurement of productivity loss due to thermal discomfort. Energy Build. 2011, 43, 1057–1062. [Google Scholar] [CrossRef]

- Sakoia, T.; Mochida, T. Concept of the equivalent wet bulb globe temperature index for indicating safe thermal occupational environments. Build. Environ. 2013, 67, 167–178. [Google Scholar] [CrossRef]

- Litti, G. Methods and criteria for energy environmental retrofitting of historic and heritage buildings: Diagnosis and Assessment. Ph.D. Dissertation, Faculty of Applied Engineering Sciences, EMIB Energy and Materials in Infrastructure and Buildings, University of Antwerp, Atwerp, Belgium, 2018; 375p. [Google Scholar]

- Balocco, C.; Petrone, G.; Maggi, O.; Pasquariello, G.; Albertini, A.; Pasquarella, C. Indoor microclimatic study for Cultural Heritage protection and preventive conservation in the Palatina Library. J. Cult. Herit. 2016, 22, 956–967. [Google Scholar] [CrossRef]

- Lucchi, E. Multidisciplinary risk-based analysis for supporting the decision making process on conservation, energy efficiency, and human comfort in museum buildings. Review. J. Cult. Herit. 2016, 22, 1079–1089. [Google Scholar] [CrossRef]

- Al horr, Y.; Arif, M.; Katafygiotou, M.; Mazroei, A.; Kaushik, A.; Elsarrag, E. Impact of indoor environmental quality on occupant well-being and comfort: A review of the literature. Int. J. Sustain. Built Environ. 2016, 5, 1–11. [Google Scholar] [CrossRef]

- CEN Standard EN 15251: 2007. Indoor Environmental Input Parameters for Design and Assessment of Energy Performance of Buildingsaddressing Indoor Air Quality, Thermal Environment, Lighting and Acoustics; Comité Européen de Normalisation: Brussels, Belgium, 2007. [Google Scholar]

| Place of Measurement | Walls | Floor | Celing | Heating | Lighting |

|---|---|---|---|---|---|

| Storage room (11 × 17 × 6 m) | Brick | Non-washable flooring | Roofing | Without heaters | Fluor lamps Glass surfaces |

| Changing rooms and toilets inside the warehouse (3.5 × 9 × 2.6 m) | Brick walls with washable cladding | Washable flooring | Brick ceiling with plaster | Local heat sources | Fluor lamps Glass surfaces |

| Office in the warehouse (6 × 4 × 2.6 m) | Brick | Washable flooring | Brick ceiling with plaster | Local heat sources | Fluor lamps Glass surfaces |

| Cold room refrigerator in the warehouse | Brick walls with washable cladding | Washable flooring | Brick ceiling with plaster | Air conditioning unit | Fluor lamps |

| Location | Functions * | Measured Quantities of Hygrothermal Microclimate | tg/to | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| GLOBE tg (°C) | WBGTi (°C) | WBGT0 (°C) | tr,m | to | |||||||||

| Ankles | Torso | Head | Ankles | Torso | Head | Ankles | Torso | Head | (°C) | (°C) | (%) | ||

| Warehouse | Ā | 11.9 | 16.15 | 17.4 | 5.7 | 10.1 | 13.3 | 7.4 | 10.2 | 13.3 | 3.16 | ||

| R2 | 4.692 | 0.58 | 0.156 | 2.212 | 0.568 | 0.236 | 2.932 | 0.788 | 0.188 | ||||

| ΔA | 2.166 | 0.761 | 0.394 | 1.487 | 0.754 | 0.486 | 1.712 | 0.888 | 0.434 | ||||

| var | 19.691 | 5.252 | 2.405 | 19.830 | 7.461 | 3.632 | 23.139 | 8.702 | 3.260 | ||||

| Φ | 15.15 | 10.3 | 10.3 | 15.85 | 14.47 | ||||||||

| Office | Ā | 20.2 | 21.9 | 21.3 | 13.4 | 15.1 | 16.2 | 13.3 | 14.8 | 16.54 | 8.64 | ||

| R2 | 2.197 | 1.856 | 0.266 | 1.433 | 0.445 | 0.968 | 2.032 | 0.642 | 0.558 | ||||

| ΔA | 1.482 | 1.362 | 0.516 | 1.197 | 0.667 | 0.983 | 1.415 | 6.073 | 0.747 | ||||

| var | 7.331 | 6.220 | 2.418 | 8.948 | 4.415 | 6.073 | 10.717 | 5.392 | 4.517 | ||||

| Φ | 21.10 | 15.0 | 14.8 | 23.69 | 19.28 | ||||||||

| Changing rooms | Ā | 15.4 | 21.2 | 21.3 | 10.6 | 14.28 | 15.9 | 9.6 | 14.6 | 15.8 | 6.68 | ||

| R2 | 7.04 | 0.509 | 0.086 | 3.450 | 0.0656 | 0.452 | 4.489 | 1.202 | 0.556 | ||||

| ΔA | 2.635 | 0.509 | 0.294 | 1.857 | 0.256 | 0.672 | 2.119 | 1.096 | 0.745 | ||||

| var | 17.229 | 3.364 | 1.376 | 18.464 | 1.793 | 4.228 | 22.025 | 7.479 | 4.719 | ||||

| Φ | 19.33 | 13.4 | 13.2 | 21.18 | 18.01 | ||||||||

| Cold room refrigerator | Ā | 9.1 | 10.2 | 10.9 | 6.6 | 7.3 | 8.2 | 6.6 | 7.3 | 8.3 | 1.28 | ||

| R2 | 0.106 | 0.346 | 0.922 | 0.204 | 0. 285 | 1.589 | 0.225 | 0.265 | 1.678 | ||||

| ΔA | 0.326 | 0.588 | 0.960 | 0.451 | 0.534 | 1.261 | 0.475 | 0.515 | 1.295 | ||||

| var | 3.561 | 5.747 | 9.740 | 6.843 | 7.340 | 15.226 | 7.218 | 7.079 | 15.533 | ||||

| Φ | 10.10 | 7.4 | 7.4 | 10.3 | 9.97 | ||||||||

| Work classification derived from [26,27] | 15–25 | ||||||||||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marková, I.; Tureková, I.; Jaďuďová, J.; Hroncová, E. Analysis of Hygrothermal Microclimatic (HTM) Parameters in Specific Food Storage Environments in Slovakia. Int. J. Environ. Res. Public Health 2020, 17, 2092. https://doi.org/10.3390/ijerph17062092

Marková I, Tureková I, Jaďuďová J, Hroncová E. Analysis of Hygrothermal Microclimatic (HTM) Parameters in Specific Food Storage Environments in Slovakia. International Journal of Environmental Research and Public Health. 2020; 17(6):2092. https://doi.org/10.3390/ijerph17062092

Chicago/Turabian StyleMarková, Iveta, Ivana Tureková, Jana Jaďuďová, and Emília Hroncová. 2020. "Analysis of Hygrothermal Microclimatic (HTM) Parameters in Specific Food Storage Environments in Slovakia" International Journal of Environmental Research and Public Health 17, no. 6: 2092. https://doi.org/10.3390/ijerph17062092

APA StyleMarková, I., Tureková, I., Jaďuďová, J., & Hroncová, E. (2020). Analysis of Hygrothermal Microclimatic (HTM) Parameters in Specific Food Storage Environments in Slovakia. International Journal of Environmental Research and Public Health, 17(6), 2092. https://doi.org/10.3390/ijerph17062092