Optimization of Municipal Waste Collection Routing: Impact of Industry 4.0 Technologies on Environmental Awareness and Sustainability

Abstract

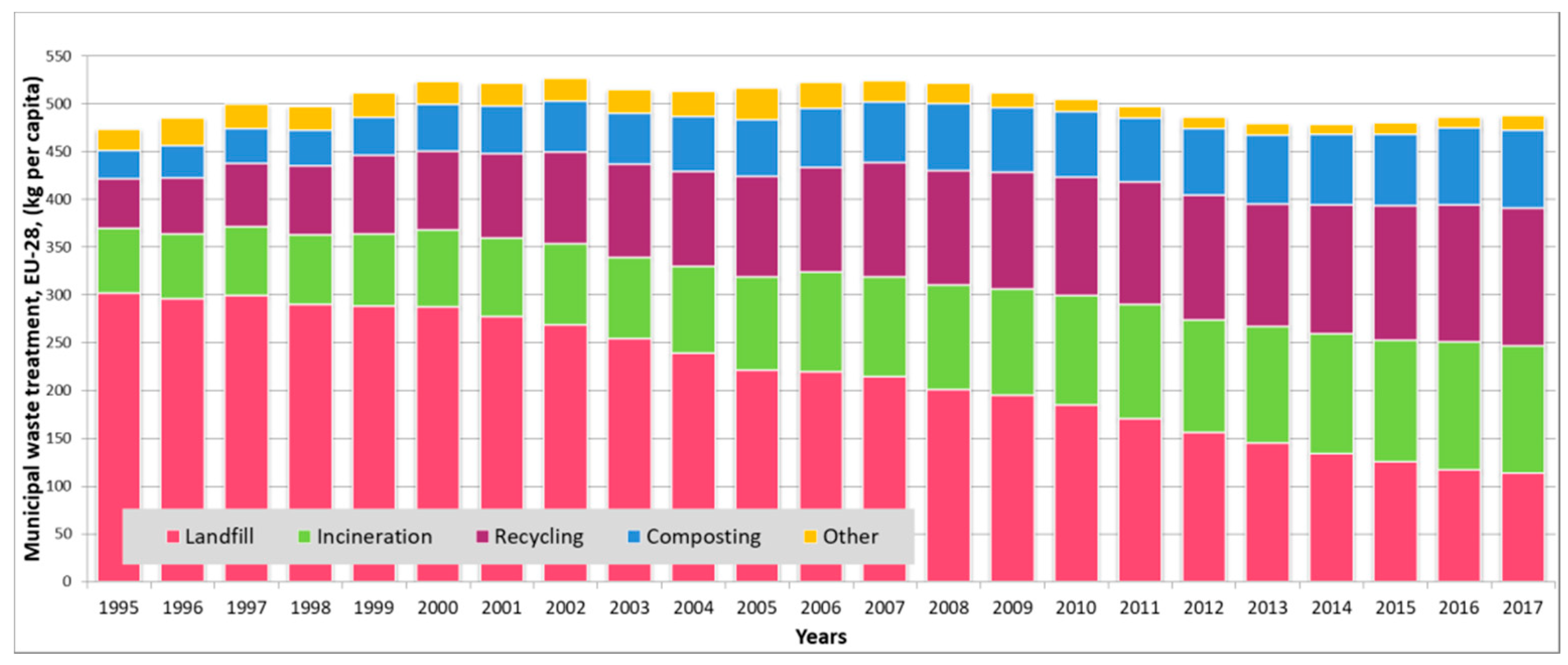

1. Introduction

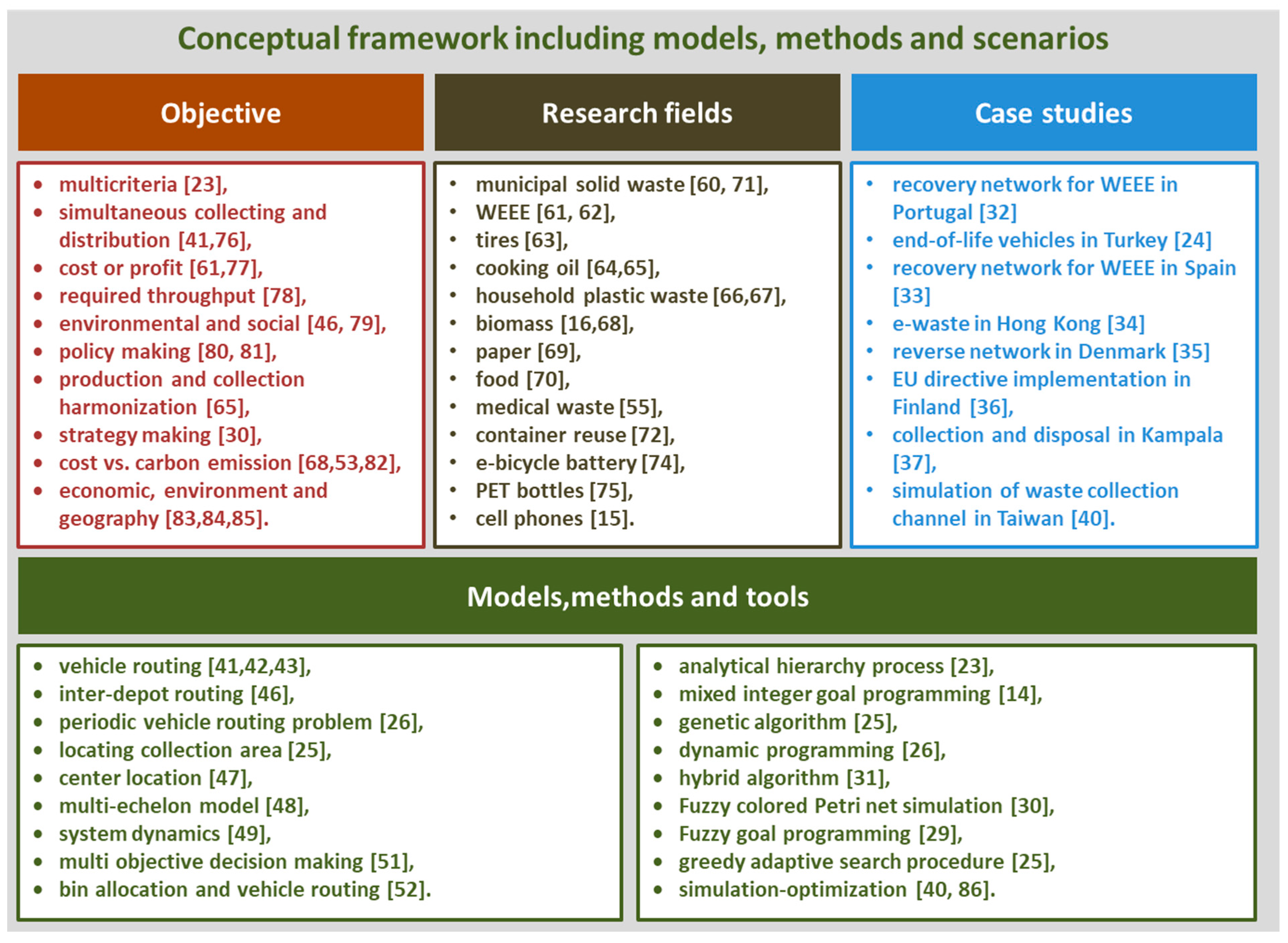

2. Literature Review

2.1. Conceptual Framework and Review Methodology

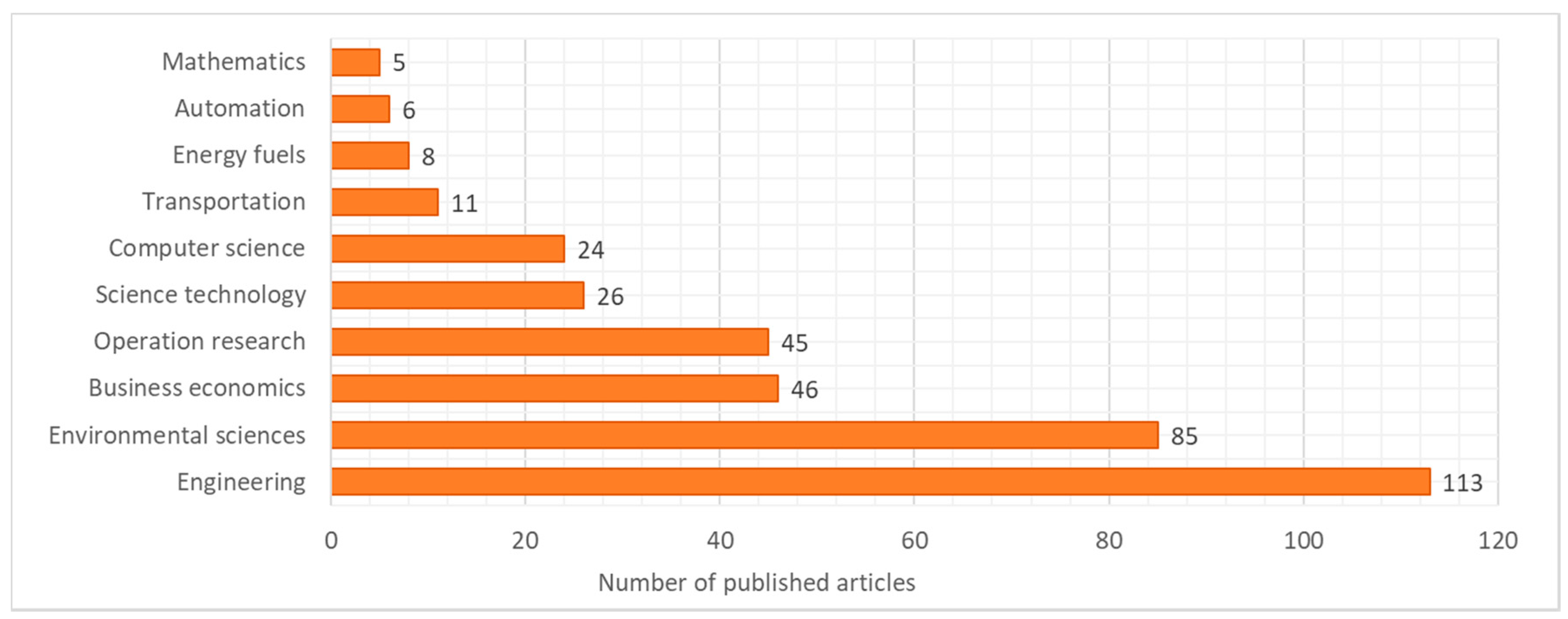

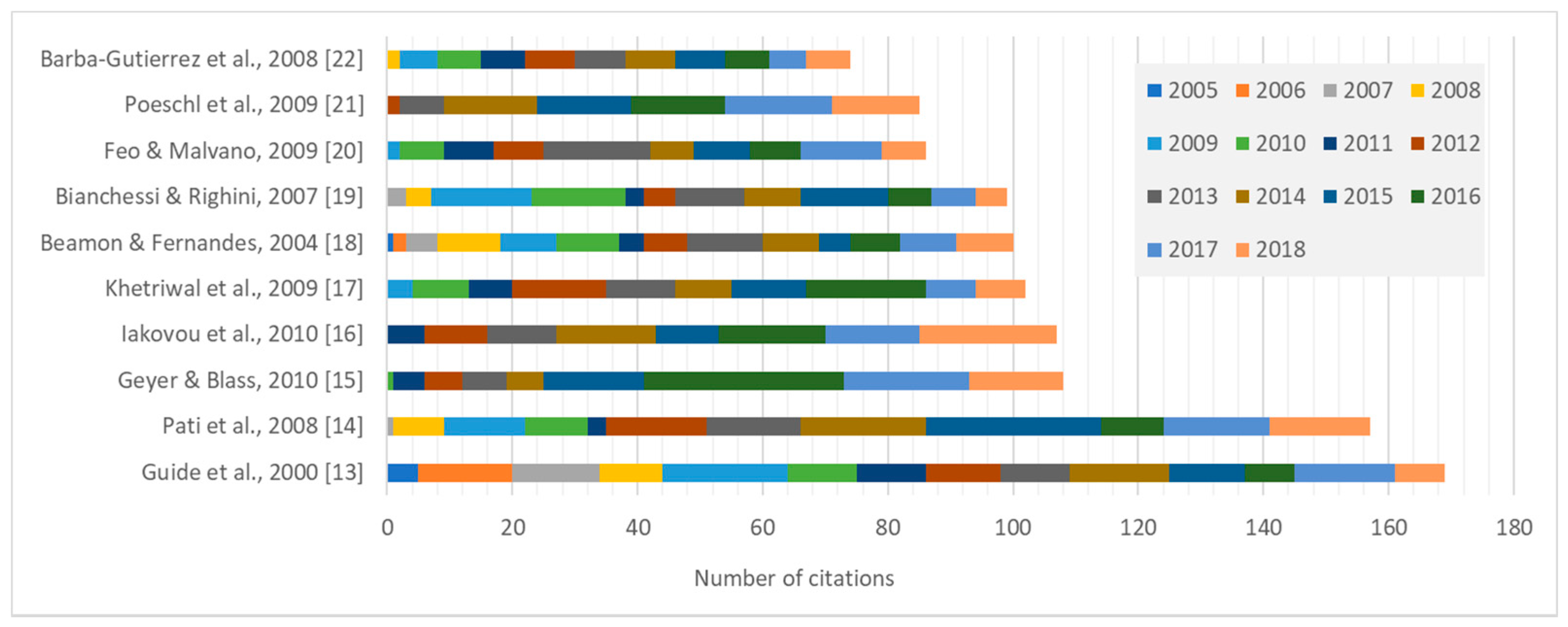

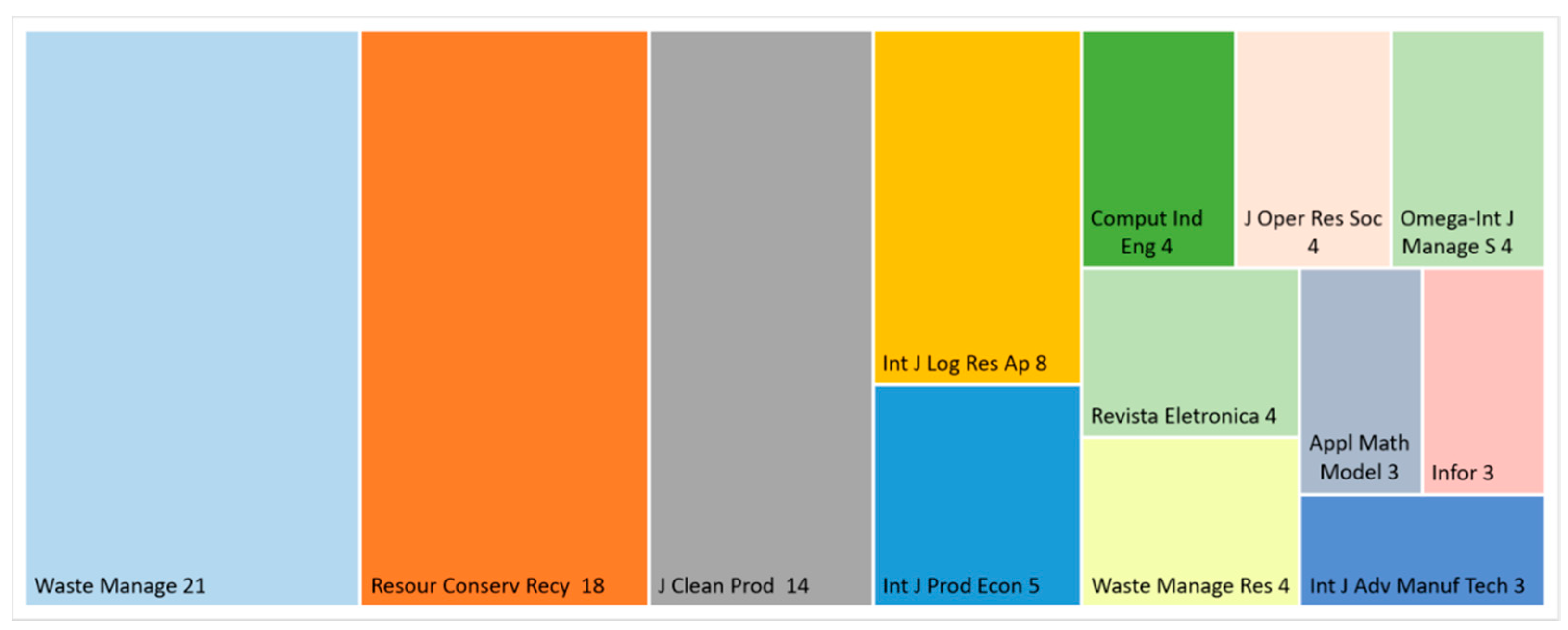

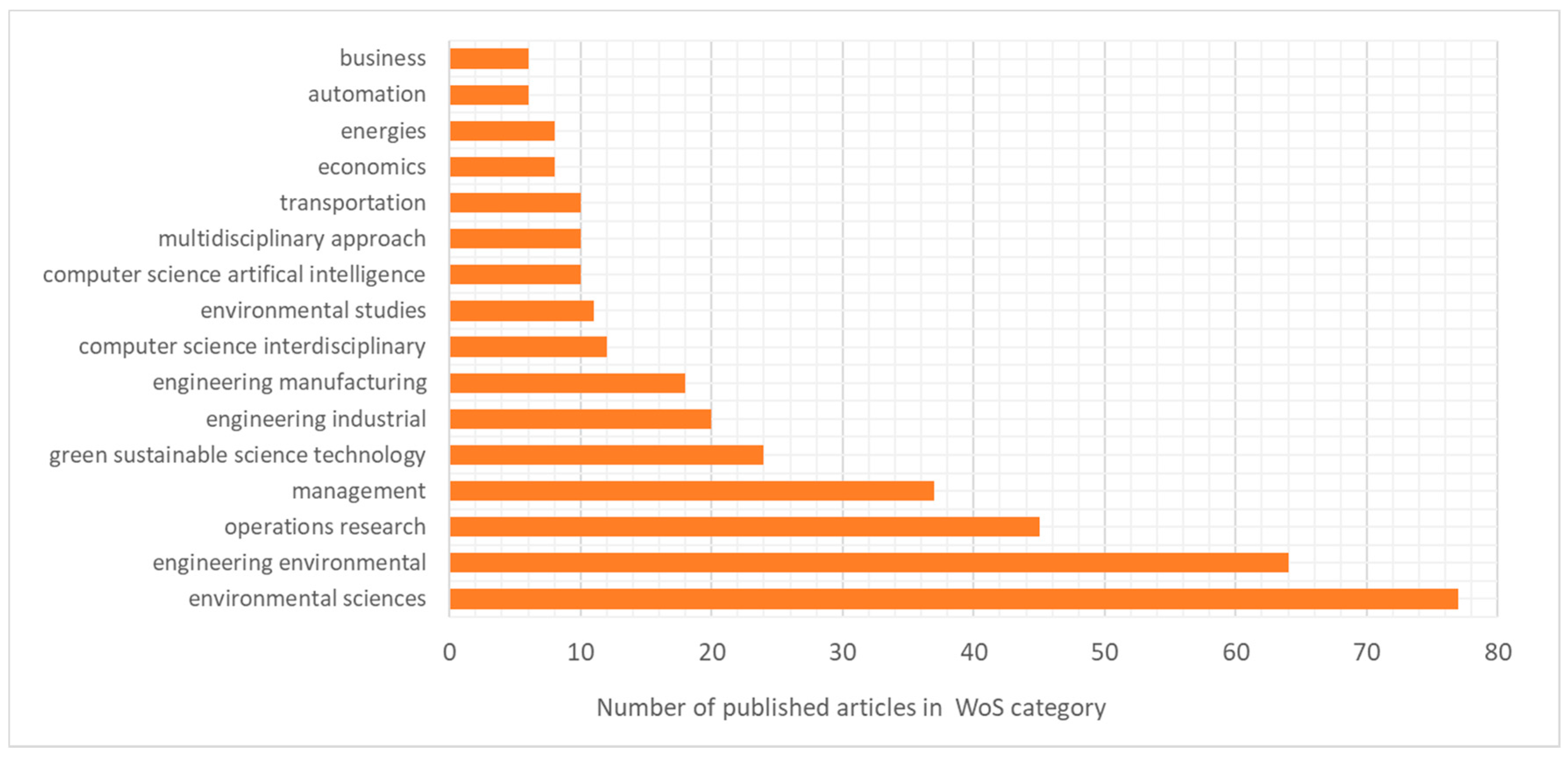

2.2. Descriptive Analysis

2.3. Content Analysis

2.4. Consequences of Literature Review

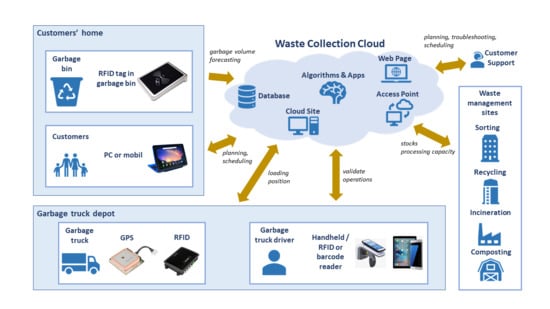

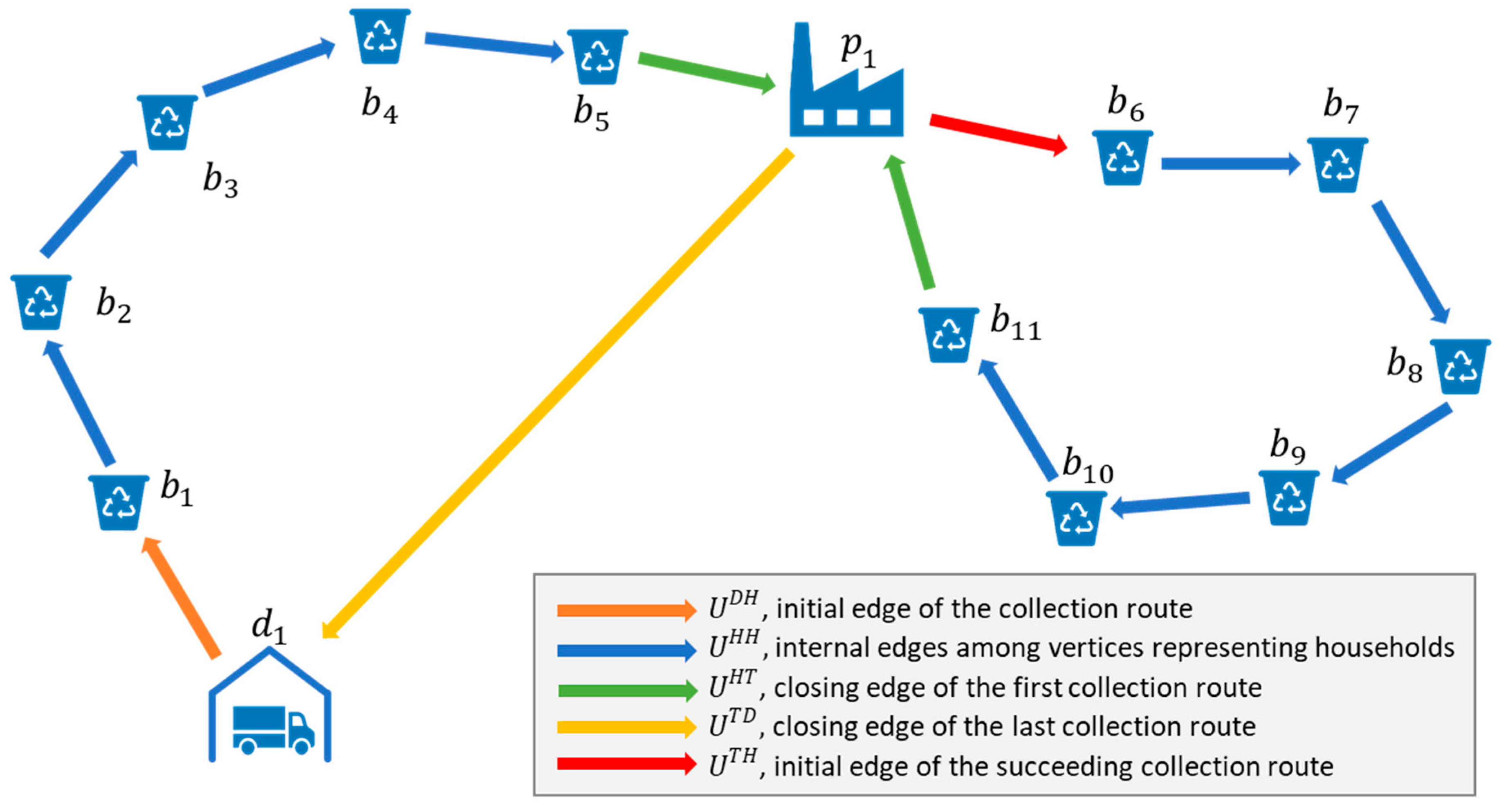

3. Model of Cyber-Physical Waste Collection System

- is the position of customer i where ;

- is the position of treatment site j where ; and,

- is the position of garbage truck depot k where .

4. Binary Bat Optimization Algorithm

5. Results and Discussions: Scenario Analysis of Cyber-Physical Waste Collection Systems Focusing on Environmental Awareness

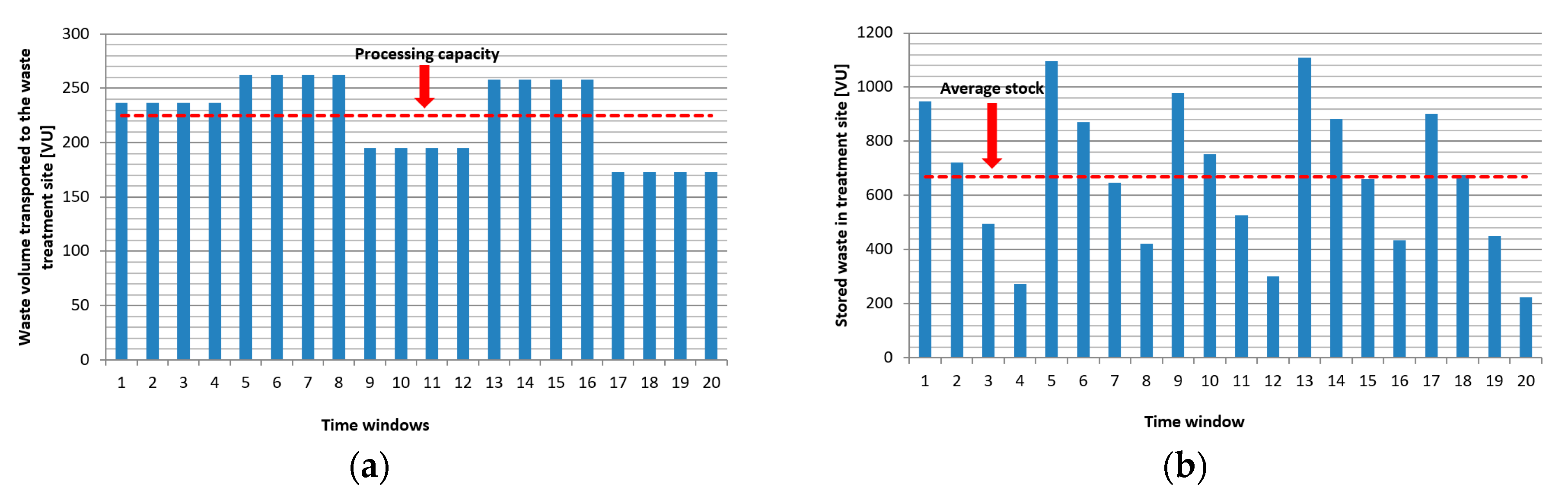

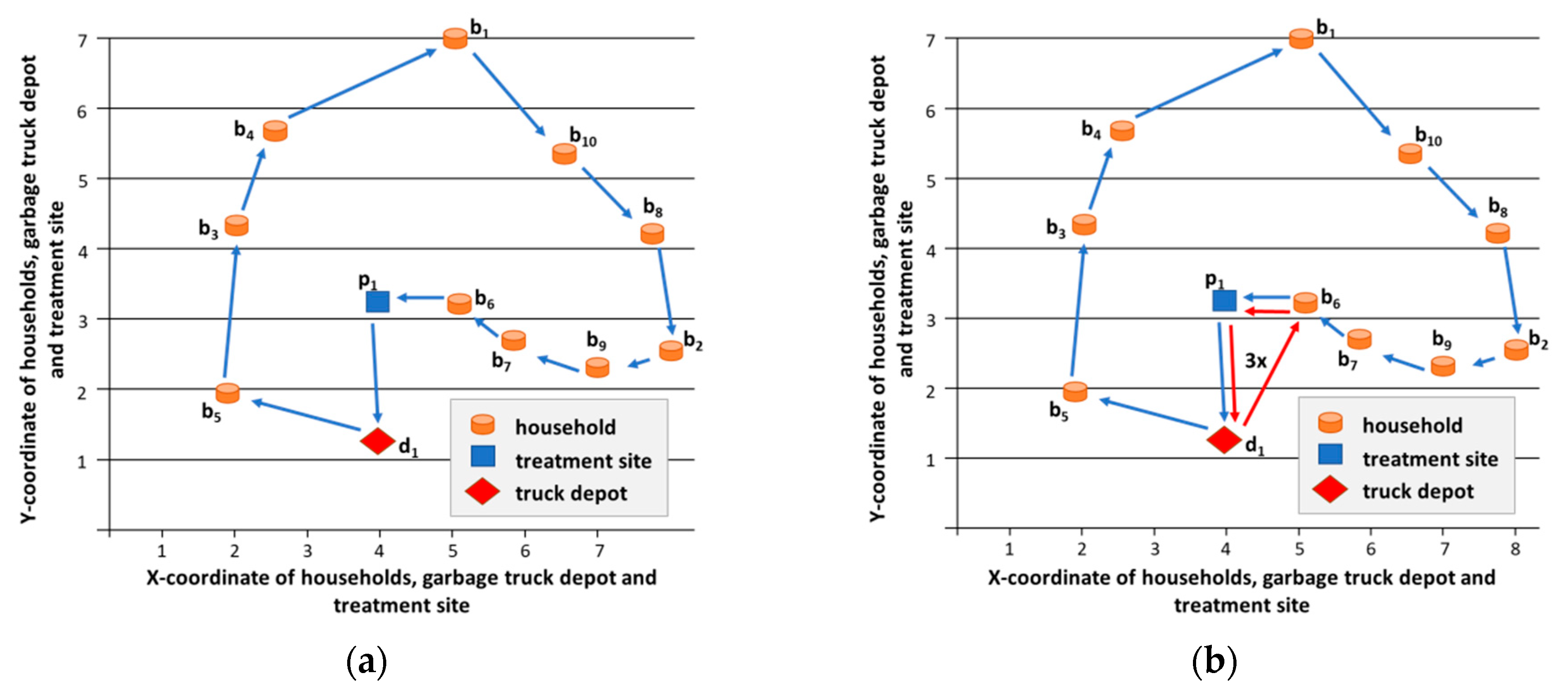

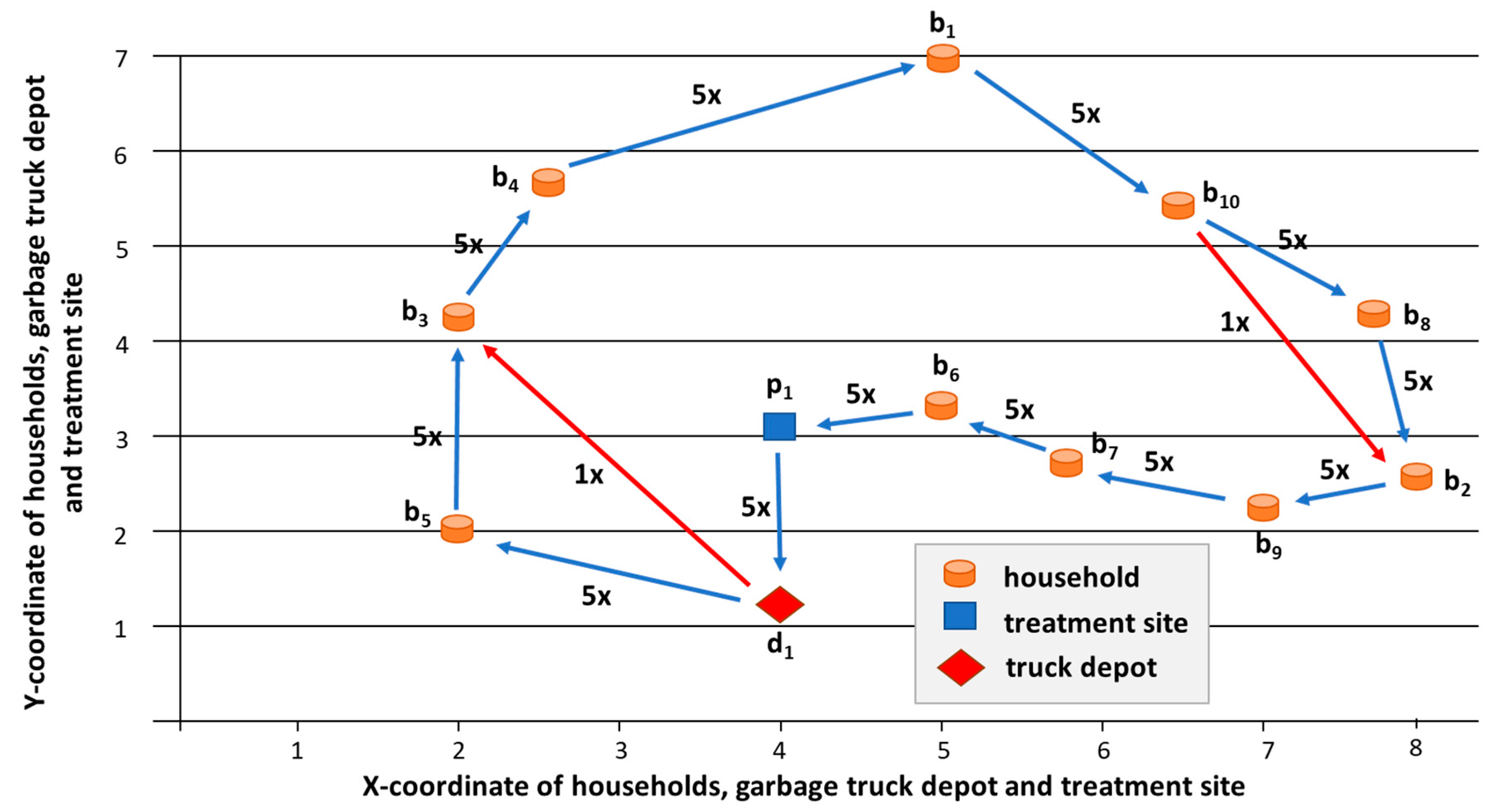

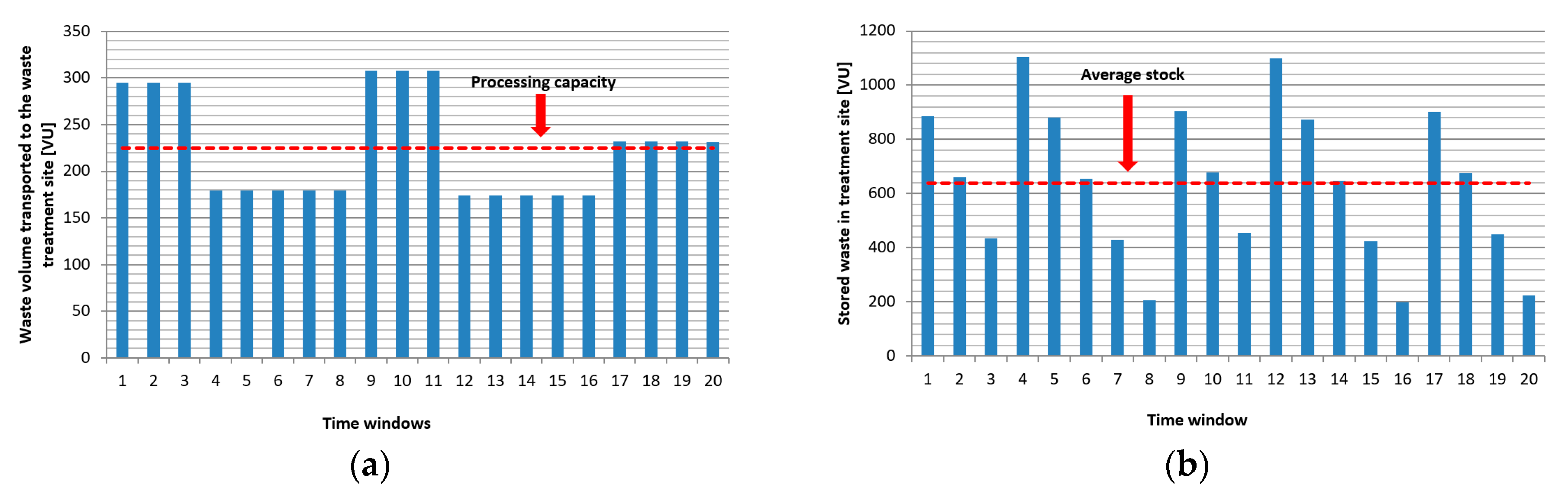

5.1. Scenario 1: Periodical Collection Routes in Conventional Waste Management System

5.2. Scenario 2: Dynamic Collection Route Scheduling in a Cyber-Physical Waste Management System

6. Discussion

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- World’s Population Increasingly Urban with More than Half Living in Urban Areas. Available online: http://www.un.org/en/development/desa/news/population/world-urbanization-prospects-2014.html (accessed on 14 January 2019).

- Velis, C.A.; Longhurst, P.J.; Drew, G.H.; Smith, R.; Pollard, S.J.T. Biodrying for mechanical-biological treatment of wastes: A review of process science and engineering. Bioresour. Technol. 2009, 100, 2747–2761. [Google Scholar] [CrossRef] [PubMed]

- Guo, S.S.; Nie, R.; Yu, Z. Syngas production from biomass gasification in China: A clean strategy for sustainable development. Energ. Source Part A 2019, 41, 911–917. [Google Scholar] [CrossRef]

- Shen, L.; Min, F.F.; Liu, L.Y.; Zhu, J.B.; Xue, C.G.; Cai, C.C.; Zhou, W.; Wang, C. Application of gaseous pyrolysis products of the waste cooking oil as coal flotation collector. Fuel 2019, 239, 446–451. [Google Scholar] [CrossRef]

- Baronti, C.; Curini, R.; D’Ascenzo, G.; Di Corcia, A.; Gentili, A.; Samperi, R. Monitoring natural and synthetic estrogens at activated sludge sewage treatment plants and in a receiving river water. Environ. Sci. Technol. 2000, 34, 5059–5066. [Google Scholar] [CrossRef]

- McKay, G. Dioxin characterisation, formation and minimisation during municipal solid waste (MSW) incineration: Review. Chem. Eng. J. 2002, 86, 343–368. [Google Scholar] [CrossRef]

- Municipal Waste Statistics. Eurostat. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php/Municipal_waste_statistics (accessed on 11 January 2019).

- Integrated Pollution Prevention and Control—Reference Document on the Best Available Techniques for Waste Incineration. Available online: http://eippcb.jrc.ec.europa.eu/reference/BREF/wi_bref_0806.pdf (accessed on 4 December 2018).

- Bányai, T. Real-Time Decision Making in First Mile and Last Mile Logistics: How Smart Scheduling Affects Energy Efficiency of Hyperconnected Supply Chain Solutions. Energies 2018, 11, 1833. [Google Scholar] [CrossRef]

- Brennan, L.; Owende, P. Biofuels from microalgae—A review of technologies for production, processing, and extractions of biofuels and co-products. Renew. Sustain. Energy Rev. 2010, 14, 557577. [Google Scholar] [CrossRef]

- Cronin, P.; Ryan, F.; Coughlan, M. Undertaking a literature review: A step-by-step approach. Br. J. Nurs. 2008, 17, 38–43. [Google Scholar] [CrossRef]

- Bonney, M.C. Trends in inventory management. Int. J. Prod. Econ. 1994, 35, 107–114. [Google Scholar] [CrossRef]

- Guide, V.D.R.; Jayaraman, V.; Srivastava, R.; Benton, W.C. Supply-chain management for recoverable manufacturing systems. Interfaces 2000, 30, 125–142. [Google Scholar] [CrossRef]

- Pati, R.K.; Vrat, P.; Kumar, P. A goal programming model for paper recycling system. Omega-Int. J. Manag. Sci. 2008, 36, 405–417. [Google Scholar] [CrossRef]

- Geyer, R.; Blass, V.D. The economics of cell phone reuse and recycling. Int. J. Adv. Manuf. Technol. 2010, 47, 515–525. [Google Scholar] [CrossRef]

- Iakovou, E.; Karagiannidis, A.; Vlachos, D.; Toka, A.; Malamakis, A. Waste biomass-to-energy supply chain management: A critical synthesis. Waste Manag. 2010, 30, 1860–1870. [Google Scholar] [CrossRef] [PubMed]

- Khetriwal, D.S.; Kraeuchi, P.; Widmer, R. Producer responsibility for e-waste management: Key issues for consideration—Learning from the Swiss experience. J. Environ. Manag. 2009, 90, 153–165. [Google Scholar] [CrossRef] [PubMed]

- Beamon, B.M.; Fernandes, C. Supply-chain network configuration for product recovery. Prod. Plan. Control 2004, 15, 270–281. [Google Scholar] [CrossRef]

- Bianchessi, N.; Righini, G. Heuristic algorithms for the vehicle routing problem with simultaneous pick-up and delivery. Comput. Oper. Res. 2007, 34, 578–594. [Google Scholar] [CrossRef]

- De Feo, G.; Malvano, C. The use of LCA in selecting the best MSW management system. Waste Manag. 2009, 29, 1901–1915. [Google Scholar] [CrossRef]

- Poeschl, M.; Ward, S.; Owende, P. Environmental impacts of biogas deployment—Part I: Life cycle inventory for evaluation of production process emissions to air. J. Clean. Prod. 2009, 24, 168–183. [Google Scholar] [CrossRef]

- Barba-Gutierrez, Y.; Adenso-Diaz, B.; Hopp, M. An analysis of some environmental consequences of European electrical and electronic waste regulation. Resour. Conserv. Recycl. 2008, 52, 481–495. [Google Scholar] [CrossRef]

- Barker, T.J.; Zabinsky, Z.B. A multicriteria decision making model for reverse logistics using analytical hierarchy process. Omega 2011, 39, 558–573. [Google Scholar] [CrossRef]

- Demirel, E.; Demirel, N.; Gokcen, H. A mixed integer linear programming model to optimize reverse logistics activities of end-of-life vehicles in Turkey. J. Clean Prod. 2016, 112, 2101–2113. [Google Scholar] [CrossRef]

- Bautista, J.; Pereira, J. Modeling the problem of locating collection areas for urban waste management. An application to the metropolitan area of Barcelona. Omega 2006, 34, 617–629. [Google Scholar] [CrossRef]

- Hemmelmayr, V.; Doerner, K.F.; Hartl, R.F.; Rath, S. A heuristic solution method for node routing based solid waste collection problems. J. Heuristics 2013, 19, 129–156. [Google Scholar] [CrossRef]

- Jalil, E.E.A.; Grant, D.B.; Nicholson, J.D.; Deutz, P. Reverse logistics in household recycling and waste systems: A symbiosis perspective. Supply Chain Manag. 2016, 21, 245–258. [Google Scholar] [CrossRef]

- Vahdani, B.; Tavakkoli-Moghaddam, R.; Jolai, F.; Baboli, A. Reliable design of a closed loop supply chain network under uncertainty: An interval fuzzy possibilistic chance-constrained model. Eng. Optimiz. 2013, 45, 745–765. [Google Scholar] [CrossRef]

- Subulan, K.; Tasan, A.S.; Baykasoglu, A. Designing an environmentally conscious tire closed-loop supply chain network with multiple recovery options using interactive fuzzy goal programming. Appl. Math. Model. 2015, 39, 2661–2702. [Google Scholar] [CrossRef]

- Hanafi, J.; Kara, S.; Kaebernick, H. Reverse logistics strategies for end-of-life products. Int. J. Logist. Manag. 2008, 19, 367–388. [Google Scholar] [CrossRef]

- Gruler, A.; Fikar, C.; Juan, A.A.; Hirsch, P.; Contreras-Bolton, C. Supporting multi-depot and stochastic waste collection management in clustered urban areas via simulation-optimization. J. Simul. 2017, 11, 11–19. [Google Scholar] [CrossRef]

- Gomes, M.I.; Barbosa-Povoa, A.P.; Novais, A.Q. Modelling a recovery network for WEEE: A case study in Portugal. Waste Manag. 2011, 31, 1645–1660. [Google Scholar] [CrossRef]

- Mar-Ortiz, J.; Adenso-Diaz, B.; Gonzalez-Velarde, J.L. Design of a recovery network for WEEE, collection: The case of Galicia, Spain. J. Oper. Res. Soc. 2011, 62, 1471–1484. [Google Scholar] [CrossRef]

- Chung, S.S.; Lau, K.Y.; Zhang, C. Generation of and control measures for e-waste in Hong Kong. Waste Manag. 2011, 31, 544–554. [Google Scholar] [CrossRef] [PubMed]

- Grunow, M.; Gobbi, C.; Alting, L. Designing the reverse network for WEEE in Denmark. Cirp Ann.-Manuf. Technol. 2009, 58, 391–394. [Google Scholar] [CrossRef]

- Yla-Mella, J.; Poikela, K.; Lehtinen, U.; Keiski, R.L.; Pongracz, E. Implementation of Waste Electrical and Electronic Equipment Directive in Finland: Evaluation of the collection network and challenges of the effective WEEE management. Resour. Conserv. Recycl. 2014, 86, 38–46. [Google Scholar] [CrossRef]

- Kinobe, J.R.; Bosona, T.; Gebresenbet, G.; Niwagaba, C.B.; Vinneras, B. Optimization of waste collection and disposal in Kampala city. Habitat Int. 2015, 49, 126–137. [Google Scholar] [CrossRef]

- Lee, C.K.; Chan, T.M. Development of RFID-based Reverse Logistics System. Expert Syst. Appl. 2009, 36, 9299–9307. [Google Scholar] [CrossRef]

- Gamberini, R.; Gebennini, E.; Rimini, B. An innovative container for WEEE collection and transport: Details and effects following the adoption. Waste Manag. 2009, 29, 2846–2858. [Google Scholar] [CrossRef] [PubMed]

- Yu, M.C.; Wu, P.S. A simulation study of the factors influencing the design of a waste collection channel in Taiwan. Int. J. Logist. Res. Appl. 2010, 13, 257–271. [Google Scholar] [CrossRef]

- Dell’Amico, M.; Righini, G.; Salani, M. A branch-and-price approach to the vehicle routing problem with simultaneous distribution and collection. Transp. Sci. 2006, 40, 235–247. [Google Scholar] [CrossRef]

- Bing, X.Y.; de Keizer, M.; Bloemhof-Ruwaard, J.M.; van der Vorst, J.G.A.J. Vehicle routing for the eco-efficient collection of household plastic waste. Waste Manag. 2014, 34, 719–729. [Google Scholar] [CrossRef]

- Cattaruzza, D.; Absi, N.; Feillet, D. Vehicle routing problems with multiple trips. 4OR-Q. J. Oper. Res. 2016, 14, 223–259. [Google Scholar] [CrossRef]

- Mar-Ortiz, J.; Gonzalez-Velarde, J.L.; Adenso-Diaz, B. Designing routes for WEEE collection: The vehicle routing problem with split loads and date windows. J. Heuristics 2013, 19, 103–127. [Google Scholar] [CrossRef]

- Aksen, D.; Kaya, O.; Salman, F.S.; Akca, Y. Selective and periodic inventory routing problem for waste vegetable oil collection. Optim. Lett. 2012, 6, 1063–1080. [Google Scholar] [CrossRef]

- Ramos, T.R.P.; Gomes, M.I.; Barbosa-Povoa, A.P. Planning a sustainable reverse logistics system: Balancing costs with environmental and social concerns. Omega 2014, 48, 60–74. [Google Scholar] [CrossRef]

- Alumur, S.A.; Tari, I. Collection Center Location with Equity Considerations in Reverse Logistics Networks. INFOR 2014, 52, 157–173. [Google Scholar] [CrossRef]

- Zhou, X.G.; Zhou, Y.H. Designing a multi-echelon reverse logistics operation and network: A case study of office paper in Beijing. Resour. Conserv. Recycl. 2015, 100, 58–69. [Google Scholar] [CrossRef]

- Golroudbary, S.R.; Zahraee, S.M. System dynamics model for optimizing the recycling and collection of waste material in a closed-loop supply chain. Simul. Model. Pract. Theory 2015, 53, 88–102. [Google Scholar] [CrossRef]

- Entezaminia, A.; Heydari, M.; Rahmani, D. A multi-objective model for multi-product multi-site aggregate production planning in a green supply chain: Considering collection and recycling centers. J. Manuf. Syst. 2016, 40, 63–75. [Google Scholar] [CrossRef]

- Achillas, C.; Aidonis, D.; Vlachokostas, C.; Moussiopoulos, N.; Banias, G.; Triantafillou, D. A multi-objective decision-making model to select waste electrical and electronic equipment transportation media. Resour. Conserv. Recycl. 2012, 66, 76–84. [Google Scholar] [CrossRef]

- Hemmelmayr, V.C.; Doerner, K.F.; Hartl, R.F.; Vigo, D. Models and Algorithms for the Integrated Planning of Bin Allocation and Vehicle Routing in Solid Waste Management. Transp. Sci. 2014, 48, 103–120. [Google Scholar] [CrossRef]

- Xu, Z.T.; Elomri, A.; Pokharel, S.; Zhang, Q.; Ming, X.G.; Liu, W.J. Global reverse supply chain design for solid waste recycling under uncertainties and carbon emission constraint. Waste Manag. 2017, 64, 358–370. [Google Scholar] [CrossRef]

- Entezaminia, A.; Heidari, M.; Rahmani, D. Robust aggregate production planning in a green supply chain under uncertainty considering reverse logistics: A case study. Int. J. Adv. Manuf. Tech. 2017, 90, 1507–1528. [Google Scholar] [CrossRef]

- Nolz, P.C.; Absi, N.; Feillet, D. A Stochastic Inventory Routing Problem for Infectious Medical Waste Collection. Networks 2014, 63, 82–95. [Google Scholar] [CrossRef]

- Ene, S.; Ozturk, N. Network modeling for reverse flows of end-of-life vehicles. Waste Manag. 2015, 38, 284–296. [Google Scholar] [CrossRef] [PubMed]

- Yu, H.; Solvang, W.D. A general reverse logistics network design model for product reuse and recycling with environmental considerations. Int. J. Adv. Manuf. Technol. 2016, 87, 2693–2711. [Google Scholar] [CrossRef]

- Kwak, M.; Behdad, S.; Zhao, Y.; Kim, H.; Thurston, D. E-Waste Stream Analysis and Design Implications. J. Mech. Des. 2011, 133, 101003. [Google Scholar] [CrossRef]

- Shakourloo, A.; Kazemi, A.; Javad, M.O.M. A new model for more effective supplier selection and remanufacturing process in a closed-loop supply chain. Appl. Math. Model. 2016, 40, 9914–9931. [Google Scholar] [CrossRef]

- Bing, X.Y.; Bloemhof, J.M.; Ramos, T.R.P.; Barbosa-Povoa, A.P.; Wong, C.Y.; van der Vorst, J.G.A.J. Research challenges in municipal solid waste logistics management. Waste Manag. 2016, 48, 584–592. [Google Scholar] [CrossRef] [PubMed]

- Dat, L.Q.; Doan, T.T.L.; Chou, S.Y.; Yu, V.F. Optimizing reverse logistic costs for recycling end-of-life electrical and electronic products. Expert Syst. Appl. 2012, 39, 6380–6387. [Google Scholar] [CrossRef]

- Kilic, H.S.; Cebeci, U.; Ayhan, M.B. Reverse logistics system design for the waste of electrical and electronic equipment (WEEE) in Turkey. Resour. Conserv. Recycl. 2015, 95, 120–132. [Google Scholar] [CrossRef]

- Fagundes, L.D.; Amorim, E.S.; Lima, R.D. Action Research in Reverse Logistics for End-Of-Life Tire Recycling. Syst. Pract. Act. Res. 2017, 30, 553–568. [Google Scholar] [CrossRef]

- Ramos, T.R.P.; Gomes, M.I.; Barbosa-Povoa, A.P. Planning waste cooking oil collection systems. Waste Manag. 2013, 33, 1691–1703. [Google Scholar] [CrossRef] [PubMed]

- Araujo, V.K.W.S.; Hamacher, S.; Scavarda, L.F. Economic assessment of biodiesel production from waste frying oils. Bioresour. Technol. 2010, 12, 4415–4422. [Google Scholar] [CrossRef] [PubMed]

- Bing, X.Y.; Bloemhof-Ruwaard, J.M.; van der Vorst, J.G.A.J. Sustainable reverse logistics network design for household plastic waste. Flex. Serv. Manuf. J. 2014, 26, 119–142. [Google Scholar] [CrossRef]

- Bing, X.Y.; Groot, J.J.; Bloemhof-Ruwaard, J.M.; van der Vorst, J.G.A.J. Multimodal network design for sustainable household plastic recycling. Int. J. Phys. Distrib. 2013, 43, 452–477. [Google Scholar] [CrossRef]

- Chiueh, P.T.; Lee, K.C.; Syu, F.S.; Lo, S.L. Implications of biomass pretreatment to cost and carbon emissions: Case study of rice straw and Pennisetum in Taiwan. Bioresour. Technol. 2012, 108, 285–294. [Google Scholar] [CrossRef] [PubMed]

- Pati, R.K.; Vrat, P.; Kumar, P. Economic analysis of paper recycling vis-a-vis wood as raw material. Int. J. Prod. Econ. 2006, 103, 489–508. [Google Scholar] [CrossRef]

- Grandhi, B.; Singh, J.A. What a Waste! A Study of Food Wastage Behavior in Singapore. J. Food Period. Mark. 2016, 22, 471–485. [Google Scholar] [CrossRef]

- Poldnurk, J. Optimisation of the economic, environmental and administrative efficiency of the municipal waste management model in rural areas. Resour. Conserv. Recycl. 2015, 97, 55–65. [Google Scholar] [CrossRef]

- Menesatti, P.; Canali, E.; Sperandio, G.; Burchi, G.; Devlin, G.; Costa, C. Cost and Waste Comparison of Reusable and Disposable Shipping Containers for Cut Flowers. Packag. Technol. Sci. 2012, 25, 203–215. [Google Scholar] [CrossRef]

- McLeod, F.N.; Cherrett, T.J.; Waterson, B.J. The scope for joint household/commercial waste collections: A case study. Int. J. Logist. Res. Appl. 2011, 14, 399–411. [Google Scholar] [CrossRef]

- Chen, F.; Yang, B.D.; Zhang, W.Y.; Ma, J.; Lv, J.; Yang, Y.J. Enhanced recycling network for spent e-bicycle batteries: A case study in Xuzhou, China. Waste Manag. 2017, 60, 660–665. [Google Scholar] [CrossRef] [PubMed]

- Kuczenski, B.; Geyer, R. PET bottle reverse logistics-environmental performance of California’s CRV program. Int. J. Life Cycle Assess. 2013, 18, 456–471. [Google Scholar] [CrossRef]

- Zacharias, J.; Zhang, B.J. Local distribution and collection for environmental and social sustainability—Tricycles in central Beijing. J. Transp. Geogr. 2015, 49, 9–15. [Google Scholar] [CrossRef]

- Batarti, R.; Jaber, M.Y.; Aijazzar, S.M. A profit maximization for a reverse logistics dual-channel supply chain with a return policy. Comput. Ind. Eng. 2017, 106, 58–82. [Google Scholar] [CrossRef]

- Figueiredo, J.N.; Mayerle, S.F. Designing minimum-cost recycling collection networks with required throughput. Transp. Res. E 2008, 44, 731–752. [Google Scholar] [CrossRef]

- Ghisolfi, V.; Chaves, G.D.L.D.; Siman, R.R.; Xavier, L.H. System dynamics applied to closed loop supply chains of desktops and laptops in Brazil: A perspective for social inclusion of waste pickers. Waste Manag. 2017, 60, 14–31. [Google Scholar] [CrossRef]

- Achillas, C.; Vlachokostas, C.; Aidonis, D.; Moussiopoulos, N.; Iakovou, E.; Banias, G. Optimising reverse logistics network to support policy-making in the case of Electrical and Electronic Equipment. Waste Manag. 2010, 30, 2592–2600. [Google Scholar] [CrossRef]

- Gamberini, R.; Gebennini, E.; Manzini, R.; Ziveri, A. On the integration of planning and environmental impact assessment for a WEEE transportation network-A case study. Resour. Conserv. Recycl. 2010, 54, 937–951. [Google Scholar] [CrossRef]

- Tao, Z.G.; Guang, Z.Y.; Hao, S.; Song, H.J.; Xin, D.G. Multi-period closed-loop supply chain network equilibrium with carbon emission constraints. Resour. Conserv. Recycl. 2015, 104, 354–365. [Google Scholar] [CrossRef]

- Accorsi, R.; Manzini, R.; Pini, C.; Penazzi, S. On the design of closed-loop networks for product life cycle management: Economic, environmental and geography considerations. J. Transp. Geogr. 2015, 48, 121–134. [Google Scholar] [CrossRef]

- Ramos, T.R.P.; Gomes, M.I.; Barbosa-Povoa, A.P. Economic and environmental concerns in planning recyclable waste collection systems. Transp. Res. E 2014, 62, 34–54. [Google Scholar] [CrossRef]

- Sarkar, B.; Ullah, M.; Kim, N. Environmental and economic assessment of closed-loop supply chain with remanufacturing and returnable transport items. Comput. Ind. Eng. 2017, 111, 148–163. [Google Scholar] [CrossRef]

- Zang, B.; Luo, Y.M.; Zhang, H.Y.; Li, G.X.; Zhang, F. Optimization for MSW logistics of new Xicheng and new Dongcheng districts in Beijing based on maximum capacity of transfer stations. J. Mater. Cycles Waste 2013, 15, 449–460. [Google Scholar] [CrossRef]

- Johansson, O.M. The effect of dynamic scheduling and routing in a solid waste management system. Waste Manag. 2006, 26, 875–885. [Google Scholar] [CrossRef] [PubMed]

- Elia, V.; Gnoni, M.G.; Tornese, F. Improving logistic efficiency of WEEE collection through dynamic scheduling using simulation modeling. Waste Manag. 2018, 72, 78–86. [Google Scholar] [CrossRef] [PubMed]

- Mes, M.; Schutten, M.; Rivera, A.P. Inventory routing for dynamic waste collection. Waste Manag. 2014, 34, 1564–1576. [Google Scholar] [CrossRef] [PubMed]

- Jouharaa, H.; Czajczyńska, D.; Ghazal, H.; Krzyżyńska, R.; Anguilano, L.; Reynolds, A.D.; Spencer, N. Municipal waste management systems for domestic use. Energy 2017, 139, 485–506. [Google Scholar] [CrossRef]

- Karaboga, D.; Basturk, B. A powerful and efficient algorithm for numerical function optimization: Artificial bee colony (ABC) algorithm. J. Glob. Optim. 2007, 39, 459–471. [Google Scholar] [CrossRef]

- Serapiao, A.B.S.; Correa, G.S.; Goncalves, F.B.; Carvalho, V.O. Combining K-Means and K-Harmonic with Fish School Search Algorithm for data clustering task on graphics processing units. Appl. Soft Comput. 2016, 41, 290–304. [Google Scholar] [CrossRef]

- Yang, X.S.; Gandomi, A.H. Bat algorithm: A novel approach for global engineering optimization. Eng. Comput. 2012, 29, 464–483. [Google Scholar] [CrossRef]

- Gandomi, A.H.; Alavi, A.H. Krill herd: A new bio-inspired optimization algorithm. Commun. Nonlinear Sci. 2012, 17, 4831–4845. [Google Scholar] [CrossRef]

- Bányai, Á.; Bányai, T.; Illés, B. Optimization of Consignment-Store-Based Supply Chain with Black Hole Algorithm. Complexity 2017, 2017, 6038973. [Google Scholar] [CrossRef]

- Kaveh, A.; Talatahari, S. Size optimization of space trusses using Big Bang-Big Crunch algorithm. Comput. Struct. 2009, 87, 1129–1140. [Google Scholar] [CrossRef]

- Mirjalili, S.; Hashim, S.Z.M.; Sardroudi, H.M. Training feedforward neural networks using hybrid particle swarm optimization and gravitational search algorithm. Appl. Math. Comput. 2012, 218, 11125–11137. [Google Scholar] [CrossRef]

- Fister, I.; Fister, I., Jr.; Yang, X.S.; Brest, J. A comprehensive review of firefly algorithms. Swarm. Evol. Comput. 2013, 13, 34–46. [Google Scholar] [CrossRef]

- Yang, X.S.; Karamanoglu, M.; He, X.S. Flower pollination algorithm: A novel approach for multiobjective optimization. Eng. Optim. 2014, 46, 1222–1237. [Google Scholar] [CrossRef]

- Santos, L.; Coutinho-Rodrigues, J.; Current, J.R. An improved ant colony optimization based algorithm for the capacitated arc routing problem. Transp. Res. B Methodol. 2010, 44, 246–266. [Google Scholar] [CrossRef]

- Pan, W.T. A new Fruit Fly Optimization Algorithm: Taking the financial distress model as an example. Knowl.-Based Syst. 2012, 26, 69–74. [Google Scholar] [CrossRef]

- Yang, X.S. A New Metaheuristic Bat-Inspired Algorithm. In Nature Inspired Cooperative Strategies for Optimization—Studies in Computational Intelligence, 1st ed.; González, J.R., Pelta, D.A., Cruz, C., Terrazas, G., Krasnogor, N., Eds.; Springer: Berlin/Heidelberg, Germany, 2010; Volume 284, pp. 65–74. [Google Scholar]

- Kongkaew, W. Bat algorithm in discrete optimization: A review of recent applications. Songklanakarin J. Sci. Technol. 2017, 39, 641–650. [Google Scholar] [CrossRef]

- Bányai, T.; Illés, B.; Bányai, Á. Smart Scheduling: An Integrated First Mile and Last Mile Supply Approach. Complexity 2018, 2018, 5180156. [Google Scholar] [CrossRef]

- Zhao, S.Z.; Suganthan, P.N.; Das, S. Self-adaptive differential evolution with modified multi-trajectory search for CEC’2010 large scale optimization. Lect. Notes Comput. Sci. 2010, 6466, 1–10. [Google Scholar] [CrossRef]

- Larsen, A.W.; Vrgoc, M.; Christensen, T.H. Diesel consumption in waste collection and transport and its environmental significance. Waste. Manag. Res. 2009, 27, 652–659. [Google Scholar] [CrossRef] [PubMed]

- Liang, J.; Liu, M. Network Design for Municipal Solid Waste Collection: A Case Study of the Nanjing Jiangbei New Area. Int. J. Environ. Res. Public Health 2018, 15, 2812. [Google Scholar] [CrossRef] [PubMed]

- Hettiarachchi, H.; Meegoda, J.N.; Ryu, S. Organic Waste Buyback as a Viable Method to Enhance Sustainable Municipal Solid Waste Management in Developing Countries. Int. J. Environ. Res. Public Health 2018, 15, 2483. [Google Scholar] [CrossRef] [PubMed]

- Kolnhofer-Derecskei, A.; Reicher, R.Z.; Szeghegyi, A. The X and Y Generations’ Characteristics Comparison. Acta Politec. Hung. 2017, 14, 107–125. [Google Scholar] [CrossRef]

- Kumar, S.; Smith, S.R.; Fowler, G.; Velis, C.; Kumar, J.; Arya, S.; Kumar, R.R.; Cheeseman, C. Challenges and opportunities associated with waste management in India. R. Soc. Open Sci. 2017, 4, 160764. [Google Scholar] [CrossRef] [PubMed]

- Yang, B.; Li, H.G. A novel dynamic timed fuzzy Petri nets modeling method with applications to industrial processes. Expert Syst. Appl. 2018, 97, 276–289. [Google Scholar] [CrossRef]

- Deng, Z.Y.; Zhang, J.; He, T.Q. Automatic Combination Technology of Fuzzy CPN for OWL-S Web Services in Supercomputing Cloud Platform. Int. J. Pattern Recognit. 2017, 31, 1759010. [Google Scholar] [CrossRef]

- Chen, H.K.; Chou, H.W.; Chiu, Y.C. On the modeling and solution algorithm for the reverse logistics recycling flow equilibrium problem. Transp. Res. C 2007, 15, 218–234. [Google Scholar] [CrossRef]

- Cannella, S.; Bruccoleri, M.; Framinan, J.M. Closed-loop supply chains: What reverse logistics factors influence performance? Int. J. Prod. Econ. 2016, 175, 35–49. [Google Scholar] [CrossRef]

- Reicher, R.; Komaromi, N.; Szeghegyi, A. The Possible Success Factors of Introduction of CRM System at Hungarian SMEs. Acta Politec. Hung. 2015, 12, 215–229. [Google Scholar] [CrossRef]

- Zhou, Z.Z.; Chi, Y.; Dong, J.; Tang, Y.J.; Ni, M.J. Model development of sustainability assessment from a life cycle perspective: A case study on waste management systems in China. J. Clean. Prod. 2019, 210, 1005–1014. [Google Scholar] [CrossRef]

- Xue, Y.Y.; Wen, Z.G.; Bressers, H.; Ai, N. Can intelligent collection integrate informal sector for urban resource recycling in China? J. Clean. Prod. 2019, 208, 307–315. [Google Scholar] [CrossRef]

- Han, Z.Y.; Zeng, D.; Li, Q.B.; Cheng, C.; Shi, G.Z.; Mou, Z.S. Public willingness to pay and participate in domestic waste management in rural areas of China. Resour. Conserv. Recycl. 2019, 140, 166–174. [Google Scholar] [CrossRef]

- Gu, F.; Zhang, W.J.; Guo, J.F.; Hall, P. Exploring “Internet plus Recycling”: Mass balance and life cycle assessment of a waste management system associated with a mobile application. Sci. Total Environ. 2019, 649, 172–185. [Google Scholar] [CrossRef] [PubMed]

- Sebastian, R.M.; Kumar, D.; Alappat, B.J. A technique to quantify incinerability of municipal solid waste. Resour. Conserv. Recycl. 2019, 140, 286–296. [Google Scholar] [CrossRef]

- Kundrák, J.; Molnár, V.; Deszpoth, I. MRR-based productivity decisions in hard machining. Wseas Trans. Environ. Dev. 2018, 14, 374–382. [Google Scholar]

- Meng, X.Y.; Tan, X.C.; Wang, Y.; Wen, Z.G.; Tao, Y.; Qian, Y. Investigation on decision-making mechanism of residents’ household solid waste classification and recycling behaviors. Resour. Conserv. Recycl. 2019, 140, 224–234. [Google Scholar] [CrossRef]

- Manzoor, F.; Wei, L.; Nurunnabi, M.; Subhan, Q.A.; Shah, S.I.A.; Fallatah, S. The impact of transformational leadership on job performance and CSR as mediator in SMEs. Sustainability 2019, 11, 436. [Google Scholar] [CrossRef]

| Benchmarking Function [102] | BHO 2 | GA 3 | HS 4 | BA 5 |

|---|---|---|---|---|

| Ackley | 3.66 × 10−7 | 4.67 × 10−6 | 1.28 × 10−7 | 1.84 × 10−8 |

| Bukin | 2.45 × 10−6 | 5.45 × 10−7 | 9.08 × 10−7 | 4.57 × 10−7 |

| Cross-in-tray | 8.55 × 10−9 | 7.32 × 10−9 | 6.98 × 10−8 | 1.04 × 10−6 |

| Easom | 1.18 × 10−5 | 2.09 × 10−4 | 8.18 × 10−9 | 6.73 × 10−9 |

| Eggholder | 5.50 × 10−7 | 3.12 × 10−7 | 1.98 × 10−8 | 8.11 × 10−8 |

| Himmelblau | 5.79 × 10−8 | 2.25 × 10−6 | 1.05 × 10−8 | 9.42 × 10−7 |

| Lévi | 1.20 × 10−6 | 7.34 × 10−8 | 3.12 × 10−8 | 6.54 × 10−5 |

| Matyas | 9.12 × 10−8 | 1.78 × 10−7 | 6.70 × 10−9 | 1.14 × 10−7 |

| Modified sphere | 2.21 × 10−8 | 1.93 × 10−6 | 2.40 × 10−8 | 4.25 × 10−7 |

| Three hump camel back | 1.51 × 10−6 | 4.17 × 10−8 | 7.79 × 10−10 | 5.79 × 10−9 |

| HH 2 | Sequence of Time Windows | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | |

| 1 | 15 | 19 | 14 | 23 | 39 | 40 | 36 | 28 | 11 | 36 | 18 | 11 | 19 | 33 | 37 | 27 | 40 | 27 | 25 | 11 |

| 2 | 10 | 35 | 24 | 19 | 40 | 30 | 26 | 0 | 26 | 19 | 32 | 20 | 7 | 27 | 24 | 40 | 10 | 4 | 2 | 21 |

| 3 | 40 | 25 | 4 | 38 | 39 | 6 | 33 | 30 | 9 | 14 | 14 | 15 | 17 | 13 | 13 | 6 | 1 | 25 | 18 | 6 |

| 4 | 36 | 12 | 37 | 37 | 39 | 38 | 11 | 12 | 37 | 4 | 7 | 18 | 33 | 10 | 33 | 2 | 14 | 30 | 20 | 38 |

| 5 | 27 | 38 | 21 | 35 | 35 | 31 | 22 | 17 | 18 | 23 | 1 | 14 | 3 | 23 | 29 | 27 | 23 | 8 | 24 | 14 |

| 6 | 1 | 3 | 36 | 35 | 35 | 30 | 15 | 39 | 8 | 37 | 12 | 21 | 36 | 26 | 39 | 32 | 23 | 7 | 3 | 38 |

| 7 | 33 | 1 | 29 | 35 | 29 | 16 | 29 | 35 | 31 | 30 | 23 | 0 | 37 | 21 | 41 | 28 | 8 | 32 | 9 | 9 |

| 8 | 21 | 1 | 31 | 9 | 16 | 13 | 32 | 36 | 35 | 20 | 23 | 34 | 42 | 34 | 32 | 35 | 31 | 8 | 11 | 22 |

| 10 | 33 | 10 | 4 | 22 | 38 | 28 | 30 | 14 | 33 | 15 | 1 | 22 | 32 | 40 | 27 | 32 | 20 | 6 | 5 | 30 |

| HH 2 | Sequence of Time Windows | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | |

| 1 | 15 | 34 | 48 | 71 | 39 | 79 | 115 | 143 | 11 | 47 | 65 | 76 | 19 | 52 | 89 | 116 | 40 | 67 | 92 | 103 |

| 2 | 10 | 45 | 69 | 88 | 40 | 70 | 96 | 96 | 26 | 45 | 77 | 97 | 7 | 34 | 58 | 98 | 10 | 14 | 16 | 37 |

| 3 | 40 | 65 | 69 | 107 | 39 | 45 | 78 | 108 | 9 | 23 | 37 | 52 | 17 | 30 | 43 | 49 | 1 | 26 | 44 | 50 |

| 4 | 36 | 48 | 85 | 122 | 39 | 77 | 88 | 100 | 37 | 41 | 48 | 66 | 33 | 43 | 76 | 78 | 14 | 44 | 64 | 102 |

| 5 | 27 | 65 | 86 | 121 | 35 | 66 | 88 | 105 | 18 | 41 | 42 | 56 | 3 | 26 | 55 | 82 | 23 | 31 | 55 | 69 |

| 6 | 1 | 4 | 40 | 75 | 35 | 65 | 80 | 119 | 8 | 45 | 57 | 78 | 36 | 62 | 101 | 133 | 23 | 30 | 33 | 71 |

| 7 | 33 | 34 | 63 | 98 | 29 | 45 | 74 | 109 | 31 | 61 | 84 | 84 | 37 | 58 | 99 | 127 | 8 | 40 | 49 | 58 |

| 8 | 21 | 22 | 53 | 62 | 16 | 29 | 61 | 97 | 35 | 55 | 78 | 112 | 42 | 76 | 108 | 143 | 31 | 39 | 50 | 72 |

| 9 | 33 | 43 | 47 | 69 | 38 | 66 | 96 | 110 | 33 | 48 | 49 | 71 | 32 | 72 | 99 | 131 | 20 | 26 | 31 | 61 |

| 10 | 37 | 69 | 97 | 134 | 28 | 31 | 57 | 62 | 7 | 40 | 56 | 89 | 10 | 35 | 68 | 75 | 39 | 52 | 54 | 68 |

| Routes | Route Length | Emission | |||||

|---|---|---|---|---|---|---|---|

| CO2 | SO2 | CO | HC | NOX | PM | ||

| Specific emissions in g/liter fuel consumption [106] | - | 2629 | 0.08 | 2.2 | 1.2 | 11.9 | 0.1 |

| Collection route with overloaded truck | 103.056 | 86698 | 2.63 | 72.56 | 39.58 | 392.44 | 3.29 |

| Collection route without overloaded truck | 118.420 | 99633 | 3.02 | 83.38 | 45.48 | 450.99 | 3.78 |

| Additional routes to eliminate overloading | 15.360 | 12935 | 0.39 | 10.82 | 5.90 | 58.55 | 0.49 |

| Routes | Route Length | Emission | |||||

|---|---|---|---|---|---|---|---|

| CO2 | SO2 | CO | HC | NOX | PM | ||

| 2nd, 4th and 5th collection routes without overloaded truck | 61.83 | 52019 | 1.58 | 43.53 | 23.74 | 235.46 | 1.97 |

| 1st collection route without overloaded truck | 20.37 | 17144 | 0.52 | 14.35 | 7.82 | 77.60 | 0.65 |

| 3rd collection route without overloaded truck | 19.91 | 16747 | 0.51 | 14.01 | 7.64 | 75.80 | 0.63 |

| Total collection route without overloaded truck | 102.11 | 85911 | 2.61 | 71.89 | 39.21 | 388.87 | 3.26 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bányai, T.; Tamás, P.; Illés, B.; Stankevičiūtė, Ž.; Bányai, Á. Optimization of Municipal Waste Collection Routing: Impact of Industry 4.0 Technologies on Environmental Awareness and Sustainability. Int. J. Environ. Res. Public Health 2019, 16, 634. https://doi.org/10.3390/ijerph16040634

Bányai T, Tamás P, Illés B, Stankevičiūtė Ž, Bányai Á. Optimization of Municipal Waste Collection Routing: Impact of Industry 4.0 Technologies on Environmental Awareness and Sustainability. International Journal of Environmental Research and Public Health. 2019; 16(4):634. https://doi.org/10.3390/ijerph16040634

Chicago/Turabian StyleBányai, Tamás, Péter Tamás, Béla Illés, Živilė Stankevičiūtė, and Ágota Bányai. 2019. "Optimization of Municipal Waste Collection Routing: Impact of Industry 4.0 Technologies on Environmental Awareness and Sustainability" International Journal of Environmental Research and Public Health 16, no. 4: 634. https://doi.org/10.3390/ijerph16040634

APA StyleBányai, T., Tamás, P., Illés, B., Stankevičiūtė, Ž., & Bányai, Á. (2019). Optimization of Municipal Waste Collection Routing: Impact of Industry 4.0 Technologies on Environmental Awareness and Sustainability. International Journal of Environmental Research and Public Health, 16(4), 634. https://doi.org/10.3390/ijerph16040634