The Safe Use of Pesticides: A Risk Assessment Procedure for the Enhancement of Occupational Health and Safety (OHS) Management

Abstract

1. Introduction

2. Legislative Framework

- Provide a documented risk assessment report, demonstrating that the employer has taken into account all the risks derived from the use of pesticides;

- The risk assessment of the activities related with the use of pesticides should consider the worst situation of exposure for each activity;

- All the phases of the process should be considered, starting from handling, preparation of the mixture, setting of the application equipment, mixing, loading, and application, up to the final operations related to the equipment cleaning and maintenance, as well as dealing with the management of the cleaning water and the pesticide residues;

- The risk assessment has to take into account the hazardous properties of the pesticides, the information on health and safety provided by the safety sheet of each product, the level of exposure, and the duration of the exposure, as well as any occupational exposure limit values or biological limit values associated with each product;

- The preventive and protective measure applied, as well as the re-entry safety periods for each type of application have to be defined.

3. Background Analysis

- I represents the intensity score level, i.e., the exposure level of the operator;

- MIX indicates the exposure during the mixing/preparation activities;

- APPL indicates the exposure during the pesticide application activity;

- REPAIR stands for the exposure during the repair/maintenance/regulation operations of the equipment for pesticide application; and

- PPE refers the personal protective equipment used (e.g., eye glasses, gloves, etc.).

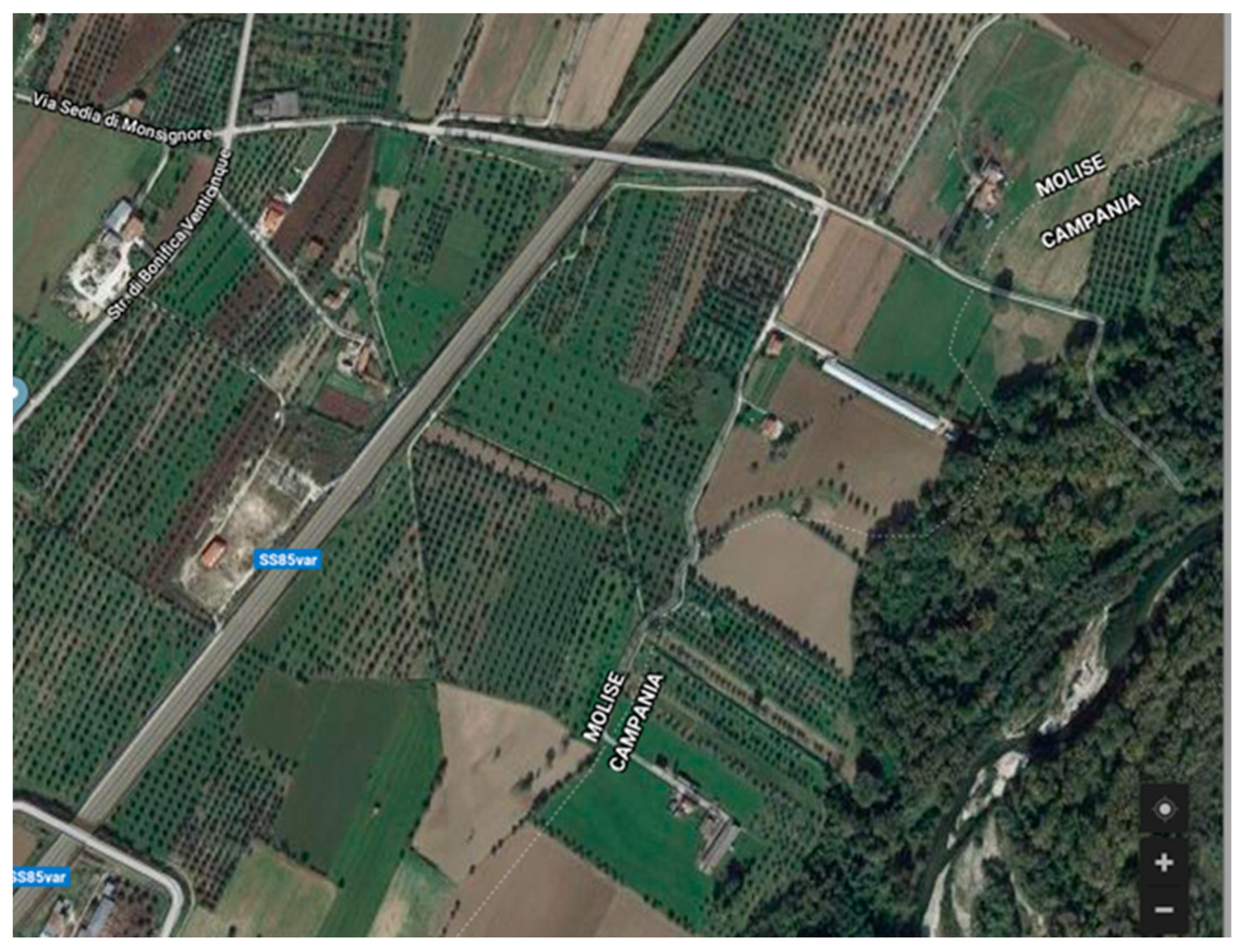

- An assessment of the risks to safety and health at work is reported, including those facing the workers exposed to chemical risks;

- The protective measures to be taken as well as the personal protective equipment to be used are defined; and

- The specific training of operators and the related mandatory certificates are listed.

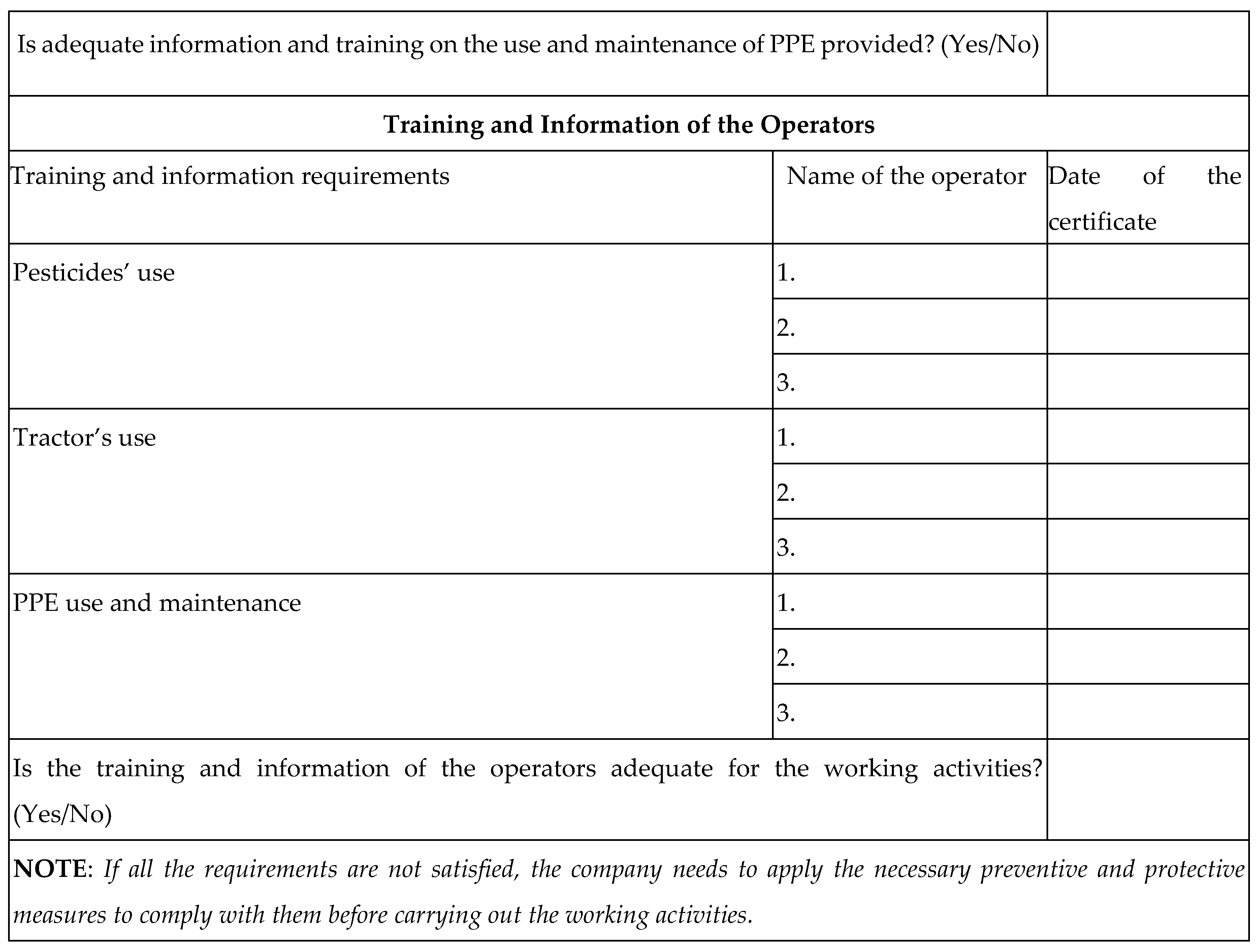

4. Materials and Methods

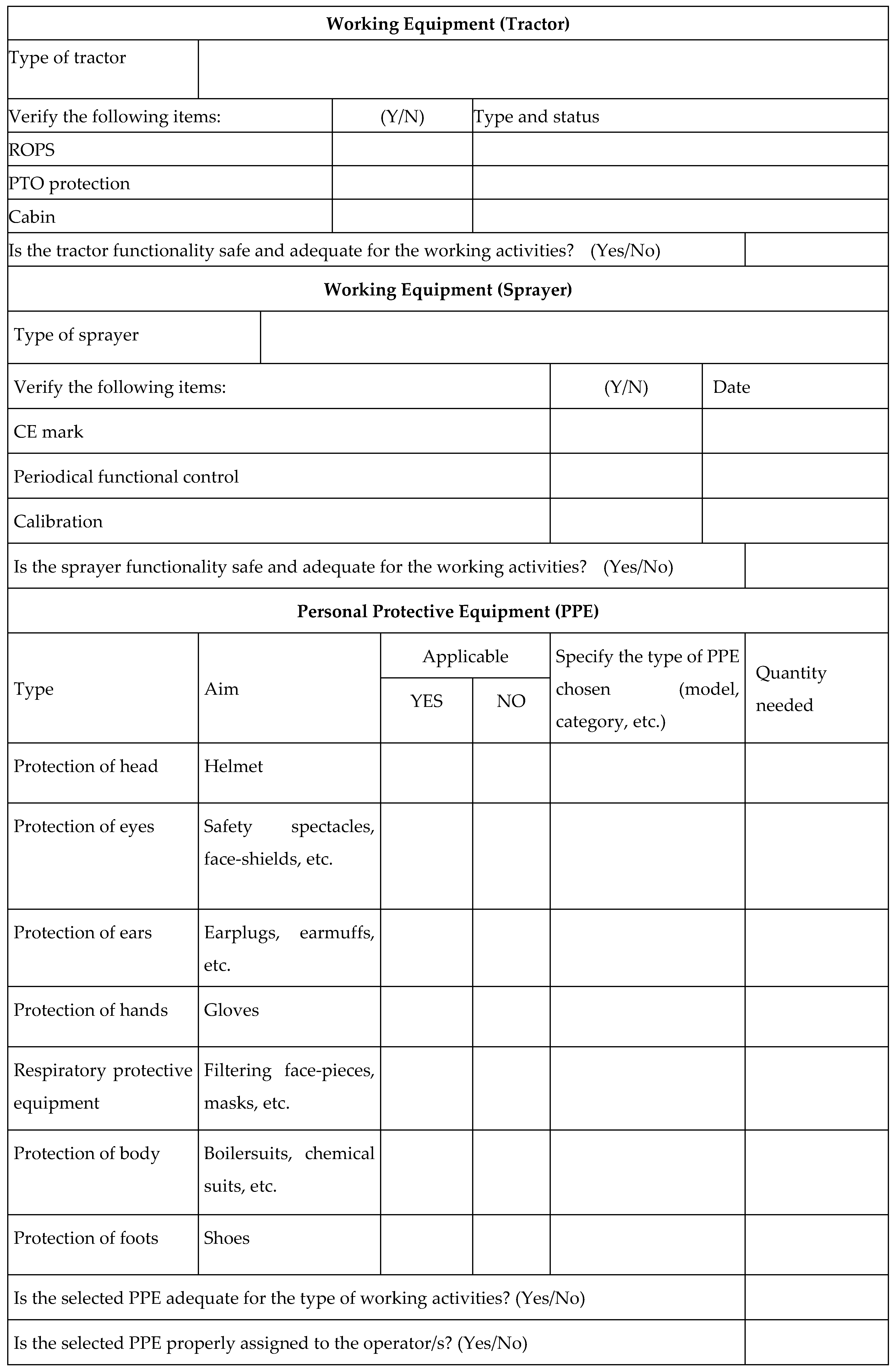

4.1. Preliminary Assessment

- Professional information and training of the operator and the related certification as the pesticides’ professional user;

- Machinery conformity (tractor and pesticide application equipment);

- Selection of the proper pesticides depending on the company needs;

- Functional calibration of the application equipment;

- Definition of working procedures for the pesticides’ application;

- Selection of the proper PPE based on the type of pesticides and machinery used; and

- Conformity with the health surveillance requisites.

4.2. Chemical Risk Assessment

4.2.1. Evaluation of the Possible Exposure

4.2.2. Evaluation of the Toxicity Level

4.2.3. Definition of the Risk Level

4.3. Improvement Options

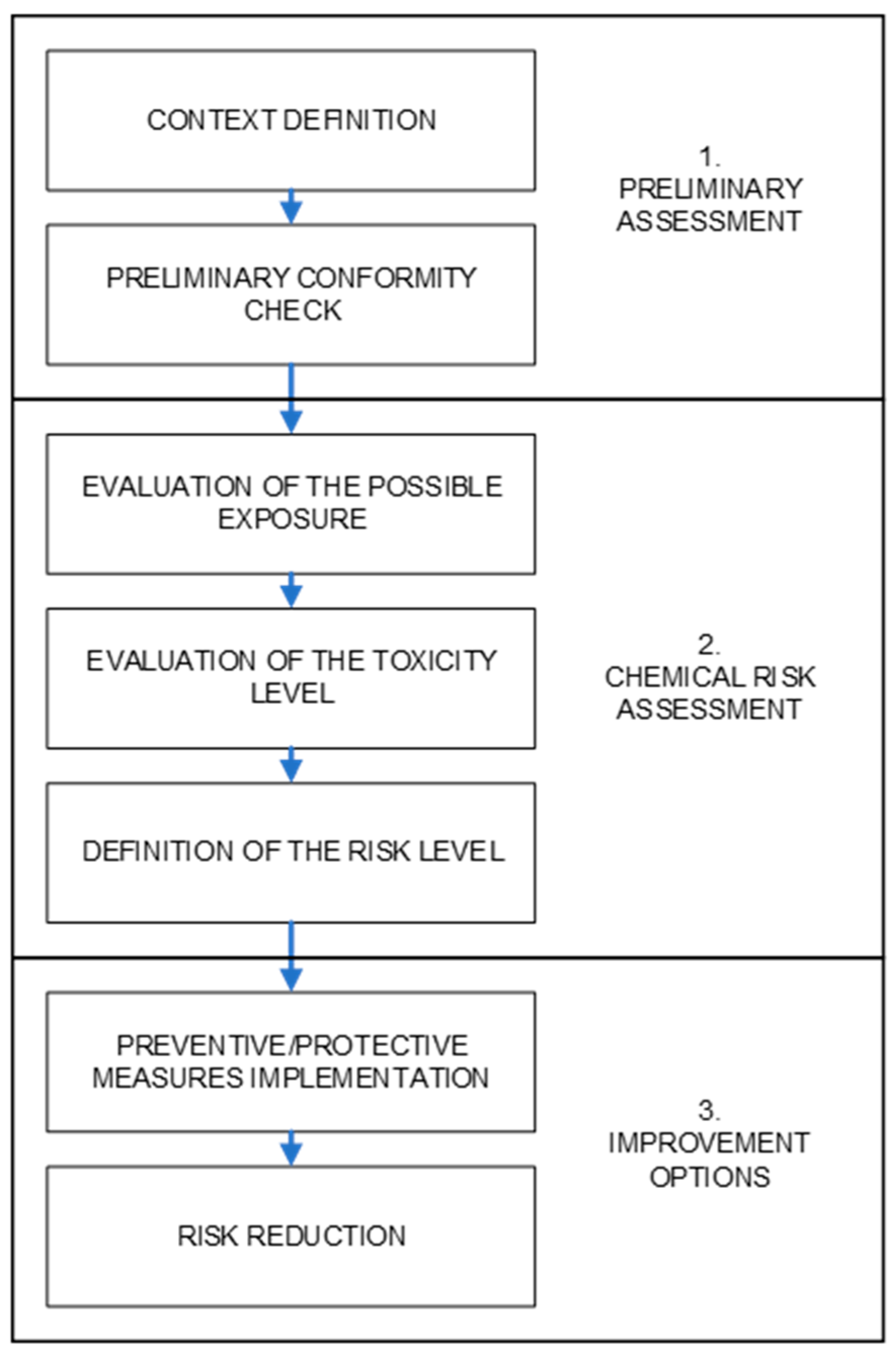

5. Case Study

5.1. Preliminary Assessment

- Product “A” against the “olive fly”: a synthetic pyrethroid is used, whose active principle is based on the presence of deltamethrin (whose concentration derived from the SDS is 1.51 %). As far as the quantity of product is concerned, the use of 0.9 L of pesticide was estimated for 1000 L of water (i.e., the company uses 0.45 L of product A per hectare). The re-entry time is fixed in 3 days after the treatment.

- Product “B” against the “olive peacock spot”: a copper compound is used, i.e., a tribasic copper sulfate (whose concentration derived from the SDS is 24%). The needed quantity was estimated in 3.0 L per 1000 L of water (i.e., the company uses 1.5 L of product B per hectare). The re-entry time is fixed in 20 days after the treatment.

5.2. Evaluation of the Possible Exposure Level

5.3. Evaluation of the Toxicity Level

5.4. Evaluation of the Risk Level

5.5. Improvement Options

6. Discussion

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

References

- Machado, S.C.; Martins, I. Risk assessment of occupational pesticide exposure: Use of endpoints and surrogates. Regul. Toxicol. Pharmacol. 2018, 98, 276–283. [Google Scholar] [CrossRef] [PubMed]

- Möhring, N.; Gaba, S.; Finger, R. Quantity based indicators fail to identify extreme pesticide risks. Sci. Total Environ. 2019, 646, 503–523. [Google Scholar] [CrossRef]

- Lamichhane, J.R. Pesticide use and risk reduction in European farming systems with IPM: An introduction to the special issue. Crop Prot. 2017, 97, 1–6. [Google Scholar] [CrossRef]

- Skevas, T.; Lansink, A.O.; Stefanou, S.E. Designing the emerging EU pesticide policy: A literature review. NJAS-Wagening. J. Life Sci. 2013, 64, 95–103. [Google Scholar] [CrossRef]

- Directive 2009/127/EC of the European Parliament and of the Council of 21 October 2009 Amending Directive 2006/42/EC with Regard to Machinery for Pesticide Application. Available online: http://data.europa.eu/eli/dir/2009/127/oj (accessed on 7 November 2018).

- Regulation (EC) No. 1107/2009 of the European Parliament and of the Council of 21 October 2009 Concerning the Placing of Plant Protection Products on the Market and Repealing Council Directives 79/117/EEC and 91/414/EEC. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32009R1107 (accessed on 7 November 2018).

- Regulation (EC) No. 1272/2008 of the European Parliament and of the Council of 16 December 2008 on Classification, Labelling and Packaging of Substances and Mixtures, Amending and Repealing Directives 67/548/EEC and 1999/45/EC, and Amending Regulation (EC) No. 1907/2006. Available online: https://eur-lex.europa.eu/eli/reg/2008/1272/oj (accessed on 7 November 2018).

- Briggs, D.J. A framework for integrated environmental health impact assessment of systemic risks. Environ. Health 2008, 7, 61. [Google Scholar] [CrossRef]

- Handford, C.E.; Elliott, C.T.; Campbell, K.A. Review of the global pesticide legislation and the scale of challenge in reaching the global harmonization of food safety standards. Integr. Environ. Assess. Manag. 2015, 11, 525–536. [Google Scholar] [CrossRef]

- Dugger-Webster, A.; LePrevost, C.E. Following pesticide labels: A continued journey toward user comprehension and safe use. Curr. Opin. Environ. Sci. Health 2018, 4, 19–26. [Google Scholar] [CrossRef]

- PANE (Pesticide Action Network Europe). NAP Best Practice—Sustainable use of pesticides: Implementing a National Action Plan. 2010. Available online: https://www.pan-europe.info/old/Resources/Reports/NAP_best_practice.pdf (accessed on 7 November 2018).

- Cunha, J.P.; Chueca, P.; Garcerá, C.; Moltó, E. Risk assessment of pesticide spray drift from citrus applications with air-blast sprayers in Spain. Crop Prot. 2012, 42, 116–123. [Google Scholar] [CrossRef]

- Biocca, M.; Pochi, D.; Fanigliulo, R.; Gallo, P.; Pulcini, P.; Marcovecchio, F.; Perrino, C. Evaluating a filtering and recirculating system to reduce dust drift in simulated sowing of dressed seed and abraded dust particle characteristics. Pest Manag. Sci. 2017, 73, 1134–1142. [Google Scholar] [CrossRef] [PubMed]

- Alix, A.; Capri, E. Modern Agriculture in Europe and the Role of Pesticides. Adv. Chem. Pollut. Environ. Manag. Prot. 2018, 2, 1–22. [Google Scholar] [CrossRef]

- Lechenet, M.; Makowski, D.; Py, G.; Munier-Jolain, N. Profiling farming management strategies with contrasting pesticide use in France. Agric. Syst. 2016, 149, 40–53. [Google Scholar] [CrossRef]

- Hillocks, R.J. Farming with fewer pesticides: EU pesticide review and resulting challenges for UK agriculture. Crop Prot. 2012, 31, 85–93. [Google Scholar] [CrossRef]

- Thomas, K.W.; Dosemeci, M.; Coble, J.B.; Hoppin, J.A.; Sheldon, L.S.; Chapa, G.; Croghan, C.W.; Jones, A.; Knott, C.E.; Lynch, C.F.; et al. Assessment of a pesticide exposure intensity algorithm in the agricultural health study. J. Expo. Sci. Environ. Epidemiol. 2010, 20, 559–569. [Google Scholar] [CrossRef] [PubMed]

- Coble, J.; Thomas, K.W.; Hines, C.J.; Hoppin, J.A.; Dosemeci, M.; Curwin, B.; Lubin, J.; Beane Freeman, L.E.; Blair, A.; Alavanja, M.C. An updated algorithm for estimation of pesticide exposure intensity in the Agricultural Health Study. Int. J. Environ. Res. Public Health 2011, 8, 4608–4622. [Google Scholar] [CrossRef]

- Thouvenin, I.; Bouneb, F.; Mercier, T. Operator dermal exposure and protection provided by personal protective equipment and working coveralls during mixing/loading, application and sprayer cleaning in vineyards. Int. J. Occup. Saf. Ergon. 2017, 23, 229–239. [Google Scholar] [CrossRef]

- Reffstrup, T.K.; Larsen, J.C.; Meyer, O. Risk assessment of mixtures of pesticides. Current approaches and future strategies. Regul. Toxic. Pharmacol. 2010, 56, 174–192. [Google Scholar] [CrossRef] [PubMed]

- Wong, H.L.; Garthwaite, D.G.; Ramwell, C.T.; Brown, C.D. Assessment of exposure of professional agricultural operators to pesticides. Sci. Total Environ. 2018, 619, 874–882. [Google Scholar] [CrossRef]

- Lu, J.L.D. Occupational safety of farmers in the vegetable industry. Int. J. Occup. Saf. Ergon. 2011, 17, 445–453. [Google Scholar] [CrossRef]

- Databases for Vibration Machines, Umeå University, Department of Public Health and Clinical Medicine. Available online: http://www.vibration.db.umu.se/Default.aspx?lang=en (accessed on 5 January 2019).

- Hand-Arm Vibration Database, PAF. Available online: https://www.portaleagentifisici.it/fo_hav_list_macchinari_avanzata.php?lg=EN&page=0 (accessed on 5 January 2019).

- Fargnoli, M.; De Minicis, M.; Tronci, M. Design Management for Sustainability: An integrated approach for the development of sustainable products. J. Eng. Technol. Manag. 2014, 34, 29–45. [Google Scholar] [CrossRef]

- Carpenter, D.O.; Arcaro, K.; Spink, D.C. Understanding the human health effects of chemical mixtures. Environ. Health Perspect. 2002, 110, 25–42. [Google Scholar] [CrossRef]

- Kim, K.H.; Kabir, E.; Jahan, S.A. Exposure to pesticides and the associated human health effects. Sci. Total Environ. 2017, 575, 525–535. [Google Scholar] [CrossRef]

- Nguyen, T.-H.-Y.; Bertin, M.; Bodin, J.; Fouquet, N.; Bonvallot, N.; Roquelaure, Y. Multiple Exposures and Co-exposures to Occupational Hazards among Agricultural Workers: A Systematic Review of Observational Studies. Saf. Health Work 2018, 9, 239–240. [Google Scholar] [CrossRef] [PubMed]

- Damalas, C.A.; Eleftherohorinos, I.G. Pesticide exposure, safety issues, and risk assessment indicators. Int. J. Environ. Res. Pub. Health 2011, 8, 1402–1419. [Google Scholar] [CrossRef]

- Lewis, K.A.; Tzilivakis, J.; Warner, D.J.; Green, A. An international database for pesticide risk assessments and management. Hum. Ecol. Risk Assess. Int. J. 2016, 22, 1050–1064. [Google Scholar] [CrossRef]

- Maroni, M.; Fait, A.; Colosio, C. Risk assessment and management of occupational exposure to pesticides. Toxicol. Lett. 1999, 107, 145–153. [Google Scholar] [CrossRef]

- Zhang, C.; Guanming, S.; Shen, J.; Hu, R.F. Productivity effect and overuse of pesticide in crop production in China. J. Integr. Agric. 2015, 14, 1903–1910. [Google Scholar] [CrossRef]

- Sharifzadeh, M.S.; Abdollahzadeh, G.; Damalas, C.A.; Rezaei, R. Farmers’ Criteria for Pesticide Selection and Use in the Pest Control Process. Agriculture 2018, 8, 24. [Google Scholar] [CrossRef]

- Damalas, C.A.; Georgiou, E.B.; Theodorou, M.G. Pesticide use and safety practices among Greek tobacco farmers: A survey. Int. J. Environ. Health Res. 2006, 16, 339–348. [Google Scholar] [CrossRef] [PubMed]

- Ye, M.; Beach, J.; Martin, J.; Senthilselvan, A. Occupational pesticide exposures and respiratory health. Int. J. Environ. Res. Pub. Health 2013, 10, 6442–6471. [Google Scholar] [CrossRef]

- Fargnoli, M.; Lombardi, M.; Haber, N.; Puri, D. The Impact of Human Error in the Use of Agricultural Tractors: A Case Study Research in Vineyard Cultivation in Italy. Agriculture 2018, 8, 82. [Google Scholar] [CrossRef]

- Damalas, C.A.; Abdollahzadeh, G. Farmers’ use of personal protective equipment during handling of plant protection products: Determinants of implementation. Sci. Total Environ. 2016, 571, 730–736. [Google Scholar] [CrossRef] [PubMed]

- Hashemi, S.M.; Hosseini, S.M.; Hashemi, M.K. Farmers’ perceptions of safe use of pesticides: Determinants and training needs. Int. Arch. Occup. Environ. Health 2012, 85, 57–66. [Google Scholar] [CrossRef] [PubMed]

- Abbassy, M.M.S. Farmer’s Knowledge, Attitudes and Practices, and their Exposure to Pesticide Residues after Application on the Vegetable and Fruit Crops. Case Study: North of Delta, Egypt. J. Environ. Anal. Toxicol. 2017, 7, 2161-0525. [Google Scholar] [CrossRef]

- Caffaro, F.; Cavallo, E. Comprehension of safety pictograms affixed to agricultural machinery: A survey of users. J. Saf. Res. 2015, 55, 151–158. [Google Scholar] [CrossRef] [PubMed]

- Lichtenberg, B.; Mischke, U.; Scherf, S.; Röver, M.; Martin, S. Hazard and risk based allocation of safety instructions to operators handling pesticides. J. für Verbraucherschutz und Lebensmittelsicherheit 2015, 10, 373–384. [Google Scholar] [CrossRef]

- Vitali, M.; Protano, C.; Del Monte, A.; Ensabella, F.; Guidotti, M. Operative modalities and exposure to pesticides during open field treatments among a group of agricultural subcontractors. Arch. Environ. Contam. Toxic. 2009, 57, 193–202. [Google Scholar] [CrossRef]

- Cividino, S.R.S.; Pergher, G.; Gubiani, R.; Moreschi, C.; Da Broi, U.; Vello, M.; Rinaldi, F. Definition of a Methodology for Gradual and Sustainable Safety Improvements on Farms and Its Preliminary Applications. Agriculture 2018, 8, 7. [Google Scholar] [CrossRef]

- Lombardi, M.; Fargnoli, M. Prioritization of hazards by means of a QFD-based procedure. Int. J. Saf. Secur. Eng. 2018, 8, 342–353. [Google Scholar] [CrossRef]

- Cecchini, M.; Colantoni, A.; Monarca, D.; Cossio, F.; Riccioni, S. Survey on the status of enforcement of European directives on health and safety at work in some farms of central Italy. Chem. Eng. Trans. 2017, 58, 103–108. [Google Scholar] [CrossRef]

- Vassie, L.; Tomàs, J.M.; Oliver, A. Health and safety management in UK and Spanish SMEs: A comparative study. J. Saf. Res. 2000, 31, 35–43. [Google Scholar] [CrossRef]

- Micheli, G.J.; Cagno, E. Dealing with SMEs as a whole in OHS issues: Warnings from empirical evidence. Saf. Sci. 2010, 48, 729–733. [Google Scholar] [CrossRef]

- Fargnoli, M.; Lombardi, M.; Haber, N.; Guadagno, F. Hazard Function Deployment: A QFD based tool for the assessment of working tasks–A practical study in the construction industry. Int. J. Occup. Saf. Ergon. 2018, 1–53. [Google Scholar] [CrossRef] [PubMed]

- Maroni, M.; Colosio, C.; Ferioli, A.; Fait, A. Biological monitoring of pesticide exposure: A review. Introduction. Toxicology 2000, 143, 1–118. [Google Scholar] [CrossRef] [PubMed]

- Aktar, W.; Sengupta, D.; Chowdhury, A. Impact of pesticides use in agriculture: Their benefits and hazards. Interdiscip. Toxicol. 2009, 2, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Garcia, F.P.; Ascencio, S.Y.C.; Oyarzun, J.C.G.; Hernandez, A.C.; Alavarado, P.V. Pesticides: Classification, uses and toxicity. Measures of exposure and genotoxic risks. J. Res. Environ. Sci. Toxicol. 2012, 1, 279–293. [Google Scholar]

- Barr, D.B. Biomonitoring of exposure to pesticides. J. Chem. Health Saf. 2008, 15, 20–29. [Google Scholar] [CrossRef]

- Anwar, W.A. Biomarkers of human exposure to pesticides. Environ. Health Perspect. 1997, 105, 801–806. [Google Scholar] [CrossRef] [PubMed]

- Colosio, C.; Rubino, F.M.; Alegakis, A.; Ariano, E.; Brambilla, G.; Mandic-Rajcevic, S.; Metruccio, F.; Minoia, C.; Moretto, A.; Somaruga, C.; et al. Integration of biological monitoring, environmental monitoring and computational modelling into the interpretation of pesticide exposure data: Introduction to a proposed approach. Toxicol. Lett. 2012, 213, 49–56. [Google Scholar] [CrossRef]

- Harris, S.A.; Sass-Kortsak, A.M.; Corey, P.N.; Purdham, J.T. Pesticide exposures in professional turf applicators, job titles, and tasks performed: Implications of exposure measurement error for epidemiologic study design and interpretation of results. Am. J. Ind. Med. 2005, 48, 205–216. [Google Scholar] [CrossRef]

- Marquart, J.; Brouwer, D.H.; Gijsbers, J.H.J.; Links, I.H.M.; Warren, N.; Van Hemmen, J.J. Determinants of dermal exposure relevant for exposure modelling in regulatory risk assessment. Ann. Occup. Hyg. 2003, 47, 599–607. [Google Scholar] [CrossRef]

- Van Hemmen, J.J. EUROPOEM, a predictive occupational exposure database for registration purposes of pesticides. Appl. Occup. Environ. Hyg. 2001, 16, 246–250. [Google Scholar] [CrossRef]

- Machera, K.; Tsakirakis, A.; Charistou, A.; Anastasiadou, P.; Glass, C.R. Dermal exposure of pesticide applicators as a measure of coverall performance under field conditions. Ann. Occup. Hyg. 2009, 53, 573–584. [Google Scholar] [CrossRef] [PubMed]

- Dick, F.D.; Semple, S.E.; Van Tongeren, M.; Miller, B.G.; Ritchie, P.; Sherriff, D.; Cherrie, J.W. Development of a task-exposure matrix (TEM) for pesticide use (TEMPEST). Ann. Occup. Hyg. 2010, 54, 443–452. [Google Scholar] [CrossRef]

- EFSA (European Food Safety Authority). Guidance on the assessment of exposure of operators, workers, residents and bystanders in risk assessment for plant protection products. EFSA J. 2014, 12, 3874. [Google Scholar] [CrossRef]

- Ellis, M.C.B.; van den Berg, F.; van de Zande, J.C.; Kennedy, M.C.; Charistou, A.N.; Arapaki, N.S.; Butler, A.H.; Machera, K.A.; Jacobs, C.M. The BROWSE model for predicting exposures of residents and bystanders to agricultural use of pesticides: Comparison with experimental data and other exposure models. Biosyst. Eng. 2017, 154, 122–136. [Google Scholar] [CrossRef]

- Sumon, K.A.; Rico, A.; Ter Horst, M.M.; Van den Brink, P.J.; Haque, M.M.; Rashid, H. Risk assessment of pesticides used in rice-prawn concurrent systems in Bangladesh. Sci. Total Environ. 2016, 568, 498–506. [Google Scholar] [CrossRef] [PubMed]

- Protano, C.; Guidotti, M.; Vitali, M. Performance of different work clothing types for reducing skin exposure to pesticides during open field treatment. Bull. Environ. Contam. Toxicol. 2009, 83, 115–119. [Google Scholar] [CrossRef]

- Rubino, F.M.; Mandic-Rajcevic, S.; Ariano, E.; Alegakis, A.; Bogni, M.; Brambilla, G.; De Paschale, G.; Firmi, A.; Minoia, C.; Micoli, G.; et al. Farmers’ exposure to herbicides in North Italy: Assessment under real-life conditions in small-size rice and corn farms. Toxicol. Lett. 2012, 210, 189–197. [Google Scholar] [CrossRef]

- Sieber, W.K., Jr.; Sundin, D.S.; Frazier, T.M.; Robinson, C.F. Development, use, and availability of a job exposure matrix based on national occupational hazard survey data. Am. J. Ind. Med. 1991, 20, 163–174. [Google Scholar] [CrossRef]

- Perry, M.J.; Marbella, A.; Layde, P.M. Nonpersistent pesticide exposure self-report versus biomonitoring in farm pesticide applicators. Ann. Epidemiol. 2006, 16, 701–707. [Google Scholar] [CrossRef]

- Baldi, I.; Carles, C.; Blanc-Lapierre, A.; Fabbro-Peray, P.; Druet-Cabanac, M.; Boutet-Robinet, E.; Soulat, J.M.; Bouvier, G.; Lebailly, P.; Barrau, M.; et al. A French crop-exposure matrix for use in epidemiological studies on pesticides: PESTIMAT. J. Expos. Sci. Environ. Epidemiol. 2017, 27, 56–63. [Google Scholar] [CrossRef] [PubMed]

- Alavanja, M.C.; Sandler, D.P.; McMaster, S.B.; Zahm, S.H.; McDonnell, C.J.; Lynch, C.F.; Pennybacker, M.; Rothman, N.; Dosemeci, M.; Bond, A.E.; et al. The Agricultural Health Study. Environ. Health Perspect. 1996, 104, 362. [Google Scholar] [CrossRef]

- Dosemeci, M.; Alavanja, M.C.; Rowland, A.S.; Mage, D.; Zahm, S.H.; Rothman, N.; Lubin, J.H.; Hoppin, J.A.; Sandler, D.P.; Blair, A. A quantitative approach for estimating exposure to pesticides in the Agricultural Health Study. Ann. Occup. Hyg. 2002, 46, 245–260. [Google Scholar] [CrossRef] [PubMed]

- Blair, A.; Thomas, K.; Coble, J.; Sandler, D.P.; Hines, C.J.; Lynch, C.F.; Knott, C.; Purdue, M.P.; Zahm, S.H.; Alavanja, M.C.; et al. Impact of pesticide exposure misclassification on estimates of relative risks in the Agricultural Health Study. Occup. Environ. Med. 2011, 68, 537–541. [Google Scholar] [CrossRef]

- Christensen, K.; Christensen, C.H.; Wright, J.M.; Galizia, A.; Glenn, B.S.; Scott, C.S.; Mall, J.K.; Bateson, T.F.; Murphy, P.A.; Cooper, G.S. The use of epidemiology in risk assessment: Challenges and opportunities. Hum. Ecol. Risk Assess. Int. J. 2015, 21, 1644–1663. [Google Scholar] [CrossRef]

- Garzia, N.A.; Spinelli, J.J.; Gotay, C.C.; Teschke, K. Literature review: Dermal monitoring data for pesticide exposure assessment of farm workers. J. Agromed. 2018, 23, 187–214. [Google Scholar] [CrossRef] [PubMed]

- Mandic-Rajcevic, S.; Rubino, F.M.; Ariano, E.; Cottica, D.; Neri, S.; Colosio, C. Environmental and biological monitoring for the identification of main exposure determinants in vineyard mancozeb applicators. J. Expo. Sci. Environ. Epidemiol. 2018, 28, 289–296. [Google Scholar] [CrossRef] [PubMed]

- Van der Mark, M.; Vermeulen, R.; Nijssen, P.C.; Mulleners, W.M.; Sas, A.M.; van Laar, T.; Brouwer, M.; Huss, A.; Kromhout, H.; Kromhout, H. Occupational exposure to pesticides and endotoxin and Parkinson disease in the Netherlands. Occup. Environ. Med. 2014, 71, 757–764. [Google Scholar] [CrossRef]

- Negatu, B.; Vermeulen, R.; Mekonnen, Y.; Kromhout, H. A method for semi-quantitative assessment of exposure to pesticides of applicators and re-entry workers: An application in three farming systems in Ethiopia. Ann. Occup. Hyg. 2016, 60, 669–683. [Google Scholar] [CrossRef] [PubMed]

- ISSA (International Social Security Association). Assess your accident risk yourself! Risk evaluation at workplace. In Brochure of the International Section Machine and System Safety, Mannheim; ISSA: Geneva, Switzerland, 2000; ISBN 92-843-2130-1. [Google Scholar]

- Regione Lombardia, Regional Decree n. 4580 of 29 April 2010 Concerning Good Practices of Pesticides’ Use in Agriculture (In Italian: Decreto della Direzione Generale della Sanità n. 4580 del 29 Aprile 2010—Buona Pratica dell’Utilizzo dei Fitofarmaci in Agricoltura). Available online: http://www.consultazioniburl.servizirl.it/storicoBurl/burl/ElencoBollettini.aspx (accessed on 7 November 2018).

- Cavallo, E.; Ferrari, E.; Bollani, L.; Coccia, M. Attitudes and behaviour of adopters of technological innovations in agricultural tractors: A case study in Italian agricultural system. Agric. Sys. 2014, 130, 44–54. [Google Scholar] [CrossRef]

- Balsari, P.; Oggero, G.; Marucco, P. Pesticide application horticultural and floricultural farms of Liguria Region: Current situation and results of one year of sprayer inspections. Julius-Kühn-Archiv 2010, 426, 82–88. [Google Scholar]

- Cividino, S.R.S.; Pergher, G.; Zucchiatti, N.; Gubiani, R. Agricultural Health and Safety Survey in Friuli Venezia Giulia. Agriculture 2018, 8, 9. [Google Scholar] [CrossRef]

- Bevan, R.; Brown, T.; Matthies, F.; Sams, C.; Jones, K.; Hanlon, J.; La Vedrine, M. Human biomonitoring data collection from occupational exposure to pesticides—Final Report. EFSA Support. Publ. 2017, 14, 1–207. [Google Scholar] [CrossRef]

- World Health Organization (WHO). The WHO Recommended Classification of Pesticides by Hazard and Guidelines to Classification. Available online: https://www.who.int/ipcs/publications/pesticides_hazard_2009.pdf (accessed on 5 January 2019).

- Likert, R. A Technique for the Measurement of Attitudes. Archives of Psychology; The Science Press: New York, NY, USA, 1932. [Google Scholar]

- ISO/IEC 31010: 2009, Risk Management—Risk Assessment Techniques; Edition 1.0; International Electrotechnical Commission: Geneve, Switzerland, 2009; ISBN 2-8318-1068-2.

- Allahyari, M.S.; Damalas, C.A.; Ebadattalab, M. Farmers’ technical knowledge about integrated pest management (IPM) in olive production. Agriculture 2017, 7, 101. [Google Scholar] [CrossRef]

- Fargnoli, M.; De Minicis, M.; Di Gravio, G. Knowledge Management integration in Occupational Health and Safety systems in the construction industry. Int. J. Prod. Dev. 2011, 14, 165–185. [Google Scholar] [CrossRef]

- Rijal, J.P.; Regm, R.; Ghimire, R.; Puri, K.D.; Gyawaly, S.; Poudel, S. Farmers’ Knowledge on Pesticide Safety and Pest Management Practices: A Case Study of Vegetable Growers in Chitwan, Nepal. Agriculture 2018, 8, 16. [Google Scholar] [CrossRef]

- Guarascio, M.; Lombardi, M. Massi, F.; Risk Analysis in handling and storage of petroleum products. Am. J. Appl. Sci. 2013, 10, 965–978. [Google Scholar] [CrossRef]

- Colosio, C.; Mandic-Rajcevic, S.; Godderis, L.; van der Laan, G.; Hulshof, C.; van Dijk, F. Workers’ health surveillance: Implementation of the Directive 89/391/EEC in Europe. Occup. Med. 2017, 67, 574–578. [Google Scholar] [CrossRef] [PubMed]

- Damalas, C.A.; Koutroubas, S.D. Farmers’ behaviour in pesticide use: A key concept for improving environmental safety. Curr. Opin. Environ Sci. Health 2018, 4, 27–30. [Google Scholar] [CrossRef]

- Damalas, C.A.; Koutroubas, S.D. Farmers’ training on pesticide use is associated with elevated safety behavior. Toxics 2017, 5, 19. [Google Scholar] [CrossRef]

- Voss, C.; Tsikriktsis, N.; Frohlich, M. Case research in operations management. Int. J. Oper. Prod. Manag. 2002, 22, 195–219. [Google Scholar] [CrossRef]

- Yin, R.K. Case Study Research: Design and Methods, 4th ed.; Sage: Thousand Oaks, CA, USA, 2008; ISBN 1412960991. [Google Scholar]

- Kayyar, M.; Ameri, F.; Summers, J.D. A case study of the development of a design enabler tool to support frame analysis for Wright Metal Products, a US SME. Int. J. Comput. Aided Eng. Technol. 2012, 4, 321–339. [Google Scholar] [CrossRef]

- Acquavella, J.F.; Alexander, B.H.; Mandel, J.S.; Burns, C.J.; Gustin, C. Exposure misclassification in studies of agricultural pesticides: Insights from biomonitoring. Epidemiology 2006, 17, 69–74. [Google Scholar] [CrossRef] [PubMed]

| Main Legislative Source | Italian Legislation | Context | Main Issues |

|---|---|---|---|

| Directive 89/391/EEC | Decree 81/2008 | Occupational health and safety (OHS) of professional workers | Specific risk assessment of working activities related to the use of chemical products; Specific information and training of the operators that use pesticides; Provision of safe working equipment and specific personal protective equipment (PPE). |

| Directive 2009/128/EC | Decree 150/2012 and National Action Plan (NAP) | Sustainable use of pesticides | Certified information and training of the users, distributors, and advisors; Certified inspection of pesticide application equipment in professional use; Documented regular calibrations and technical checks of the pesticide application equipment; Proper handling and storage of pesticides and treatment of their packaging and remnants; Implementation of practices and products allowing low pesticide-input pest management. |

| Directive 2006/42/EC | Decree 17/2010 | Machinery safety | Specific essential health and safety requirements for the construction and maintenance of machinery for pesticide application. |

| Regulation (EC) no. 1272/2008 | Classification, labelling, and packaging of substances and mixtures | New type of classification and labelling of hazardous substances. | |

| Regulation (EC) no. 1907/2006 | Registration, evaluation, authorization and restriction of chemicals | New requirements for safety data sheets (containing information concerning hazards, first-aid measures, handling and storage, personal protection, etc.) | |

| Factors | Criteria |

|---|---|

| MIX | Number of loadings; concentration of the active principle; type of formulation; duration of mixing and loading |

| APPL | Use rate; application pressure; treated area; interventions on machines during application; condition of the equipment; duration of the application |

| REPAIR | Maintenance of the equipment; duration of the maintenance |

| MIX = (LOAD × CONC) × COMP | ||

|---|---|---|

| LOAD | Number of loads per day | Score |

| 1 | 0.5 | |

| 2–5 | 1 | |

| >5 | 2 | |

| CONC | Concentration of the active principle | Score |

| <50% | 0.5 | |

| 50–90% | 1 | |

| >90% | 2 | |

| COMP | Type of formulation/compound | Score |

| Soluble bags | 0.5 | |

| Granules/liquid | 1 | |

| Powder | 2 | |

| APPL = [(DOSE × SURF × BAR) ×TRACT] + INT + EQUIP | ||

|---|---|---|

| DOSE | Quantity of pesticide used (kg/ha) | Score |

| <0.1 | 1 | |

| 0.1–2.5 | 2 | |

| >2.5 | 3 | |

| SURF | Application surface (ha) | Score |

| <3 | 0.5 | |

| 3–10 | 1 | |

| 10–20 | 2 | |

| >20 | 3 | |

| BAR | Application pressure/type of equipment (bar) | Score |

| <3 | 1 | |

| 3–5 | 2 | |

| 5–10 | 3 | |

| >10 | 4 | |

| TRACT | Type of tractor used to operate the pesticide application equipment | Score |

| Without cabin | 3 | |

| With a non air-conditioned cabin | 2 | |

| With an air-conditioned cabin | 1 | |

| With an air-conditioned cabin equipped with activated carbon filters | 0 | |

| INT | Number of in-field interventions to calibrate the equipment | Score |

| 0 | 0 | |

| 1–2 | 1 | |

| >2 | 2 | |

| EQUIP | Condition of the application equipment | Score |

| Good | 0 | |

| Not good | 8 | |

| REPAIR | Equipment Maintenance Operations | Score |

| Maintenance operations are carried out by a different person | 0 | |

| Maintenance operations are carried out by the operator | 30 |

| RE-ENTRY = (DOSE × H/D) × EARL | ||

|---|---|---|

| H/D | Plants height/foliage density | score |

| Low/Low | 1 | |

| Low/High | 2 | |

| High/Low | 3 | |

| High/High | 4 | |

| EARL | Time before re-entering in the field after the pesticide application in order to carry out other activities | score |

| >2 days | 0 | |

| 1–2 days (24–48 h) | 1.5 | |

| PPEs | Condition of PPE | Score |

| Good | 0.5 | |

| Not good | 1 | |

| SKILL | Experience/Skills of the Operator in Using Pesticides | Score |

| >5 year | 0.25 | |

| 1–5 years | 0.5 | |

| <1 year | 1 | |

| FREQ | Number of Days Per Year Dedicated to the Use of Pesticides | Score |

| <5 | 0.5 | |

| 5–10 | 1 | |

| 10–20 | 2 | |

| >20 | 3 |

| Exposure Level (Iexp) | |

|---|---|

| Score | Meaning |

| ≤5 | Very low level of possible exposure |

| 6–15 | Low level of possible exposure |

| 16–30 | Medium level of possible exposure |

| 31–50 | High level of possible exposure |

| ≥51 | Very high level of possible exposure |

| Code | Hazard Statement | Toxicity Index (Itox) |

|---|---|---|

| H302 | Harmful if swallowed | 1 |

| H319 | Causes serious eye irritation | |

| H335 | May cause respiratory irritation | |

| H315 | Causes skin irritation | |

| EUH066 | Repeated exposure may cause skin dryness or cracking | |

| H332 | Harmful if inhaled | 2 |

| H312 | Harmful in contact with skin | |

| H301 | Toxic if swallowed | |

| H314 | Causes severe skin burns and eye damage | |

| H318 | Causes serious eye damage | |

| H331 | Toxic if inhaled | 3 |

| H300 | Toxic in contact with skin | |

| H317 | May cause an allergic skin reaction | |

| H336 | May cause drowsiness or dizziness | |

| H330 | Fatal if inhaled | 4 |

| H310 | Fatal in contact with skin | |

| H334 | May cause allergy or asthma symptoms or breathing difficulties if inhaled | |

| H361f | Suspected of damaging fertility | |

| H360Fd | May damage fertility. May damage the unborn child | |

| H362 | May cause harm to breast-fed children | |

| H304 | May be fatal if swallowed and enters airways | |

| H371 | May cause damage to organs | |

| H373 | May cause damage to organs prolonged or repeated exposure | 5 |

| H370 | Causes damage to organs | |

| H351 | Suspected of causing cancer | |

| H372 | Causes damage to organs through prolonged or repeated exposure | |

| H360F | May damage fertility | |

| H340 | May cause genetic defects | |

| H360D | May damage the unborn child |

| RE | Level | Meaning |

|---|---|---|

| ≤15 | I | Acceptable level of exposure risk |

| 16–60 | II | Medium level of exposure risk |

| 61–150 | III | High level of exposure risk |

| ≥151 | IV | Unacceptable level of exposure risk |

| Exposure Risk Level (RE) | Improvement Measures |

|---|---|

| Level I | No additional interventions are required. |

| Level II | Update information and training activities; verify the adequacy and the condition of PPE. Verify the adequacy of the pesticides used. |

| Level III | Update information and training activities; verify the adequacy and the condition of PPE. Verify the adequacy of the pesticides used and the possibility of selecting less hazardous products, providing specific biological/environmental monitoring. Verify the adequacy and the condition of the pesticide application equipment and its maintenance operations. Update the operative procedures and instructions and carry out a new risk assessment. |

| Level IV | The adequacy of the pesticides used needs to be verified and the use of less hazardous products should be considered. A specific biological/environmental monitoring, as well as the operators’ health surveillance have to be implemented. Verify the selection of PPE and its condition as well as the adequacy of operative procedures and instructions. Verify the adequacy and the condition of the pesticide application equipment and its maintenance operations. Carry out a new risk assessment. |

| Code | Product “A” | Product “B” | ||

|---|---|---|---|---|

| 1. MIX | 1.1 | LOAD | 1 | 1 |

| 1.2 | CONC | 0.5 | 0.5 | |

| 1.3 | COMP | 1 | 1 | |

| 1.4 | tM | 0.042 (20 min) | 0.042 (20 min) | |

| 2. APPL | 2.1 | DOSE | 2 | 2 |

| 2.2 | SURF | 0.5 | 0.5 | |

| 2.3 | BAR | 4 | 4 | |

| 2.4 | TRACT | 2 | 2 | |

| 2.5 | INT | 0 | 0 | |

| 2.6 | EQUIP | 0 | 0 | |

| 2.7 | tA | 0.312 (2.5 h) | 0.312 (2.5 h) | |

| 3. REPAIR | 3.1 | REPAIR | 30 | 30 |

| 3.2 | tR | 0.125 (1 h) | 0.125 (1 h) | |

| 4. REENTRY | 2.1 | DOSE | 2 | 2 |

| 4.1 | H/D | 3 | 3 | |

| 4.2 | EARL | 1.5 | 1.5 | |

| 4.3 | tRE | 0.042 (20 min) | 0.042 (20 min) | |

| 5. PPE | 0.5 | 0.5 | ||

| 6. SKIL | 0.5 | 0.5 | ||

| 7. FREQ | 1 | 2 | ||

| Iexp | 2.036 | 4.073 | ||

| Code | Hazard Statement | Toxicity Index (Itox) |

|---|---|---|

| Product “A” | ||

| H302 | Harmful if swallowed | 1 |

| H315 | Causes skin irritation | 1 |

| H301 | Toxic if swallowed | 2 |

| H318 | Causes serious eye damage | 2 |

| H331 | Toxic if inhaled | 3 |

| H317 | May cause an allergic skin reaction | 3 |

| Product “B” | ||

| H302 | Harmful if swallowed | 1 |

| H319 | Causes serious eye irritation | 1 |

| H315 | Causes skin irritation | 1 |

| H317 | May cause an allergic skin reaction | 3 |

| H330 | Fatal if inhaled | 4 |

| H372 | Causes damage to organs through prolonged or repeated exposure | 5 |

| Iexp | Itox | RE | Level | |

|---|---|---|---|---|

| Product “A” | 2.0361 | 3 | RE = 6.11 | I |

| Product “B” | 4.073 | 5 | RE = 20.36 | II |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fargnoli, M.; Lombardi, M.; Puri, D.; Casorri, L.; Masciarelli, E.; Mandić-Rajčević, S.; Colosio, C. The Safe Use of Pesticides: A Risk Assessment Procedure for the Enhancement of Occupational Health and Safety (OHS) Management. Int. J. Environ. Res. Public Health 2019, 16, 310. https://doi.org/10.3390/ijerph16030310

Fargnoli M, Lombardi M, Puri D, Casorri L, Masciarelli E, Mandić-Rajčević S, Colosio C. The Safe Use of Pesticides: A Risk Assessment Procedure for the Enhancement of Occupational Health and Safety (OHS) Management. International Journal of Environmental Research and Public Health. 2019; 16(3):310. https://doi.org/10.3390/ijerph16030310

Chicago/Turabian StyleFargnoli, Mario, Mara Lombardi, Daniele Puri, Laura Casorri, Eva Masciarelli, Stefan Mandić-Rajčević, and Claudio Colosio. 2019. "The Safe Use of Pesticides: A Risk Assessment Procedure for the Enhancement of Occupational Health and Safety (OHS) Management" International Journal of Environmental Research and Public Health 16, no. 3: 310. https://doi.org/10.3390/ijerph16030310

APA StyleFargnoli, M., Lombardi, M., Puri, D., Casorri, L., Masciarelli, E., Mandić-Rajčević, S., & Colosio, C. (2019). The Safe Use of Pesticides: A Risk Assessment Procedure for the Enhancement of Occupational Health and Safety (OHS) Management. International Journal of Environmental Research and Public Health, 16(3), 310. https://doi.org/10.3390/ijerph16030310