Development of Closed-Form Equations for Estimating Mechanical Properties of Weld Metals according to Chemical Composition

Abstract

:1. Introduction

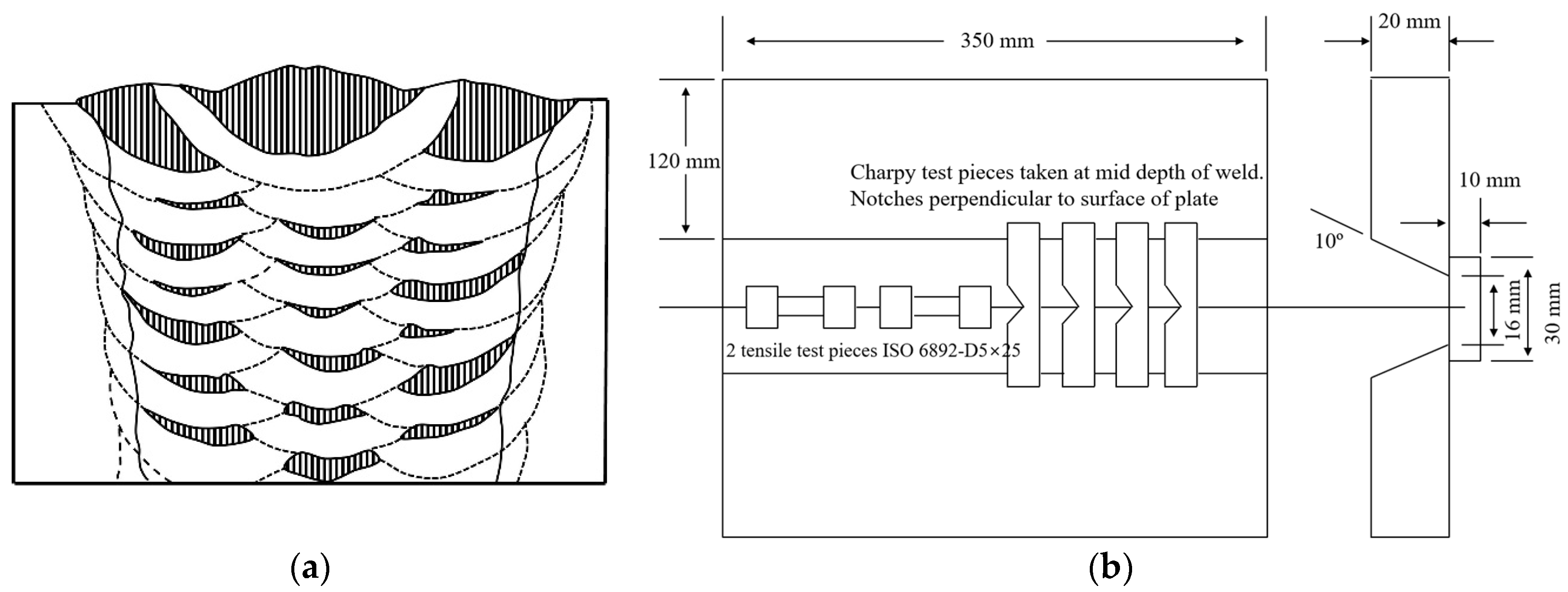

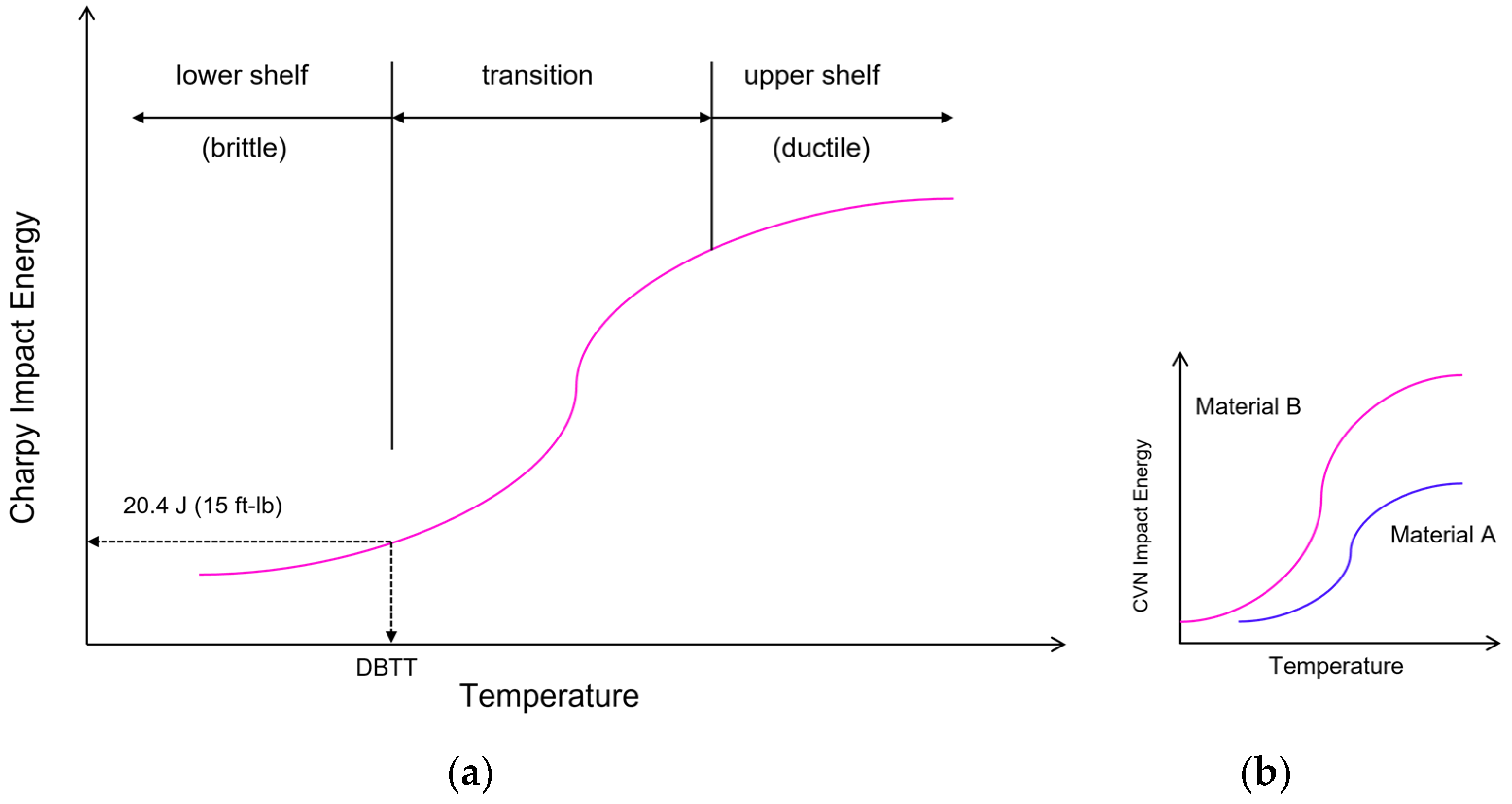

2. Data Collection and Augmentation

2.1. Data Collection

2.2. Data Augmentation

3. Development of Closed-Form Equations Using the ANN Model

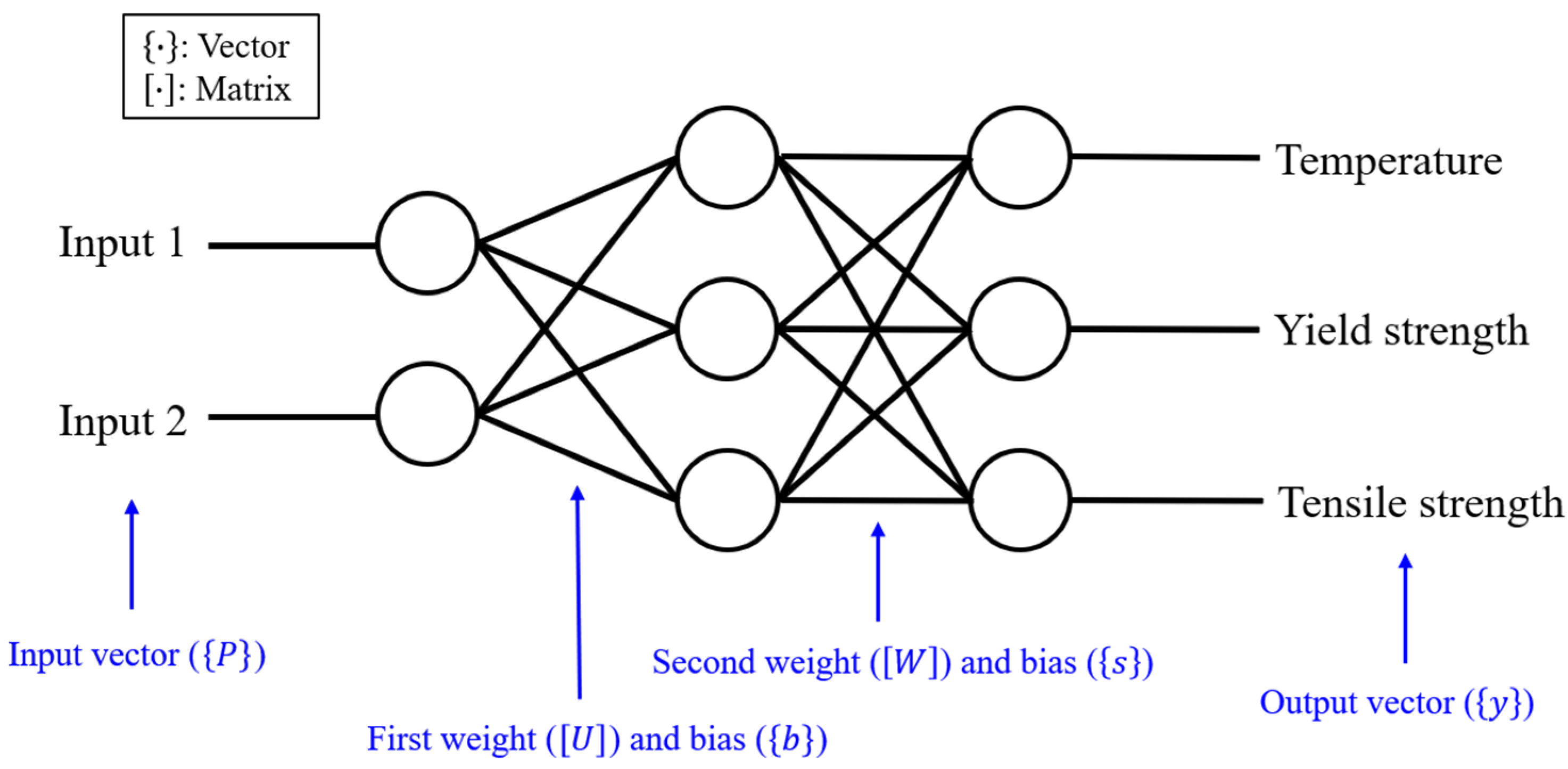

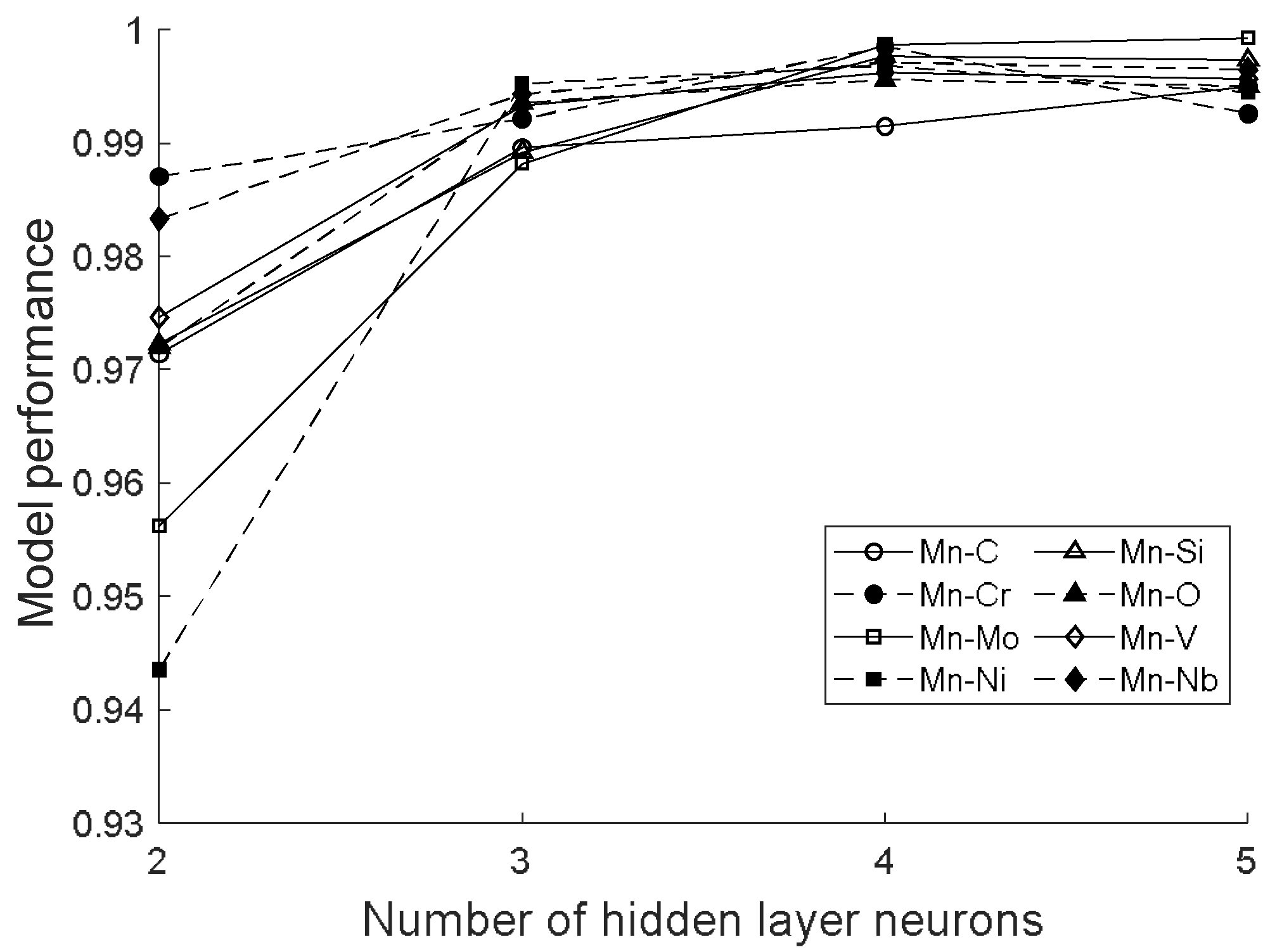

3.1. ANN Model

3.2. Closed-Form Equations

4. Model Performance Estimation and Discussion

5. Conclusions

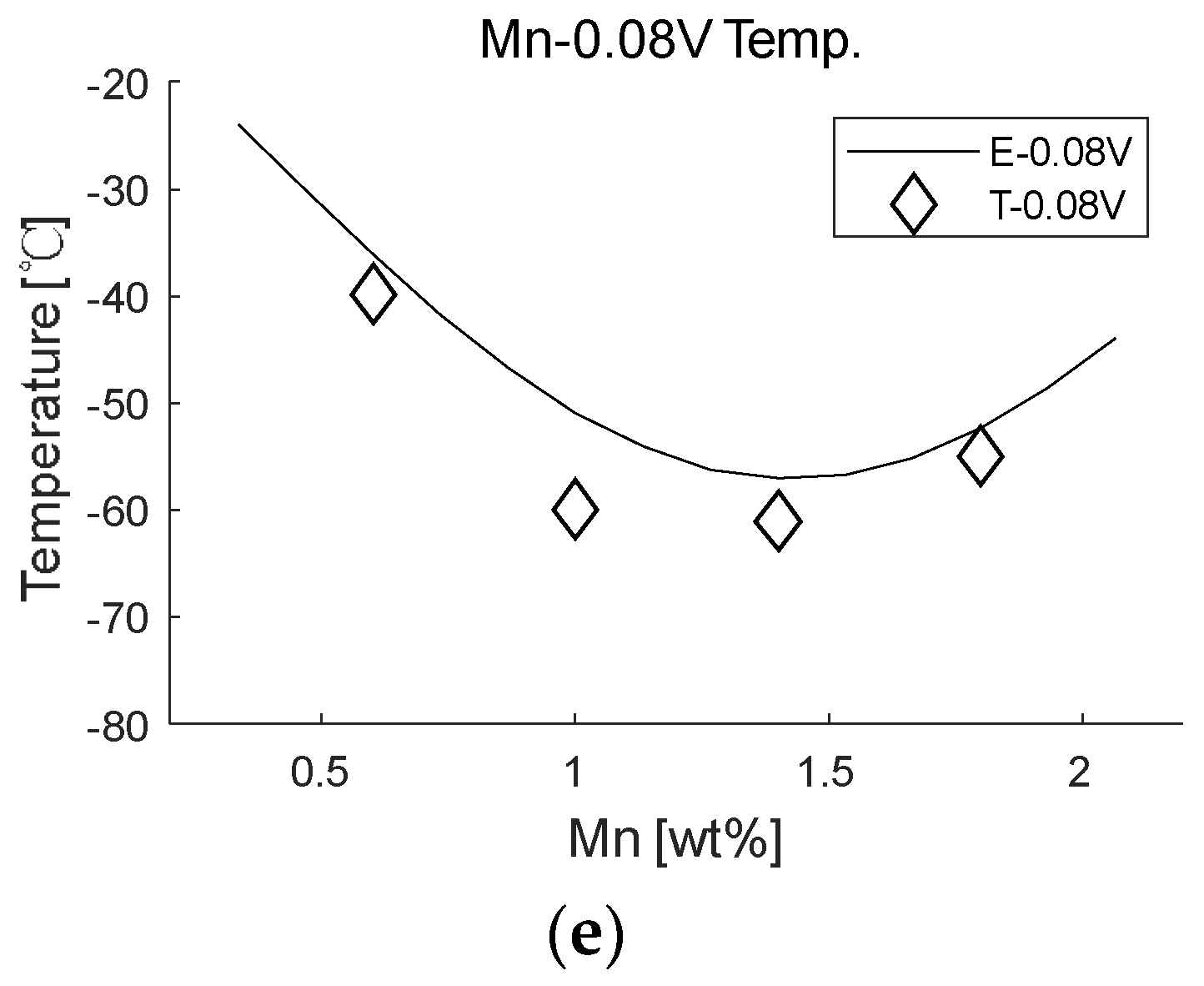

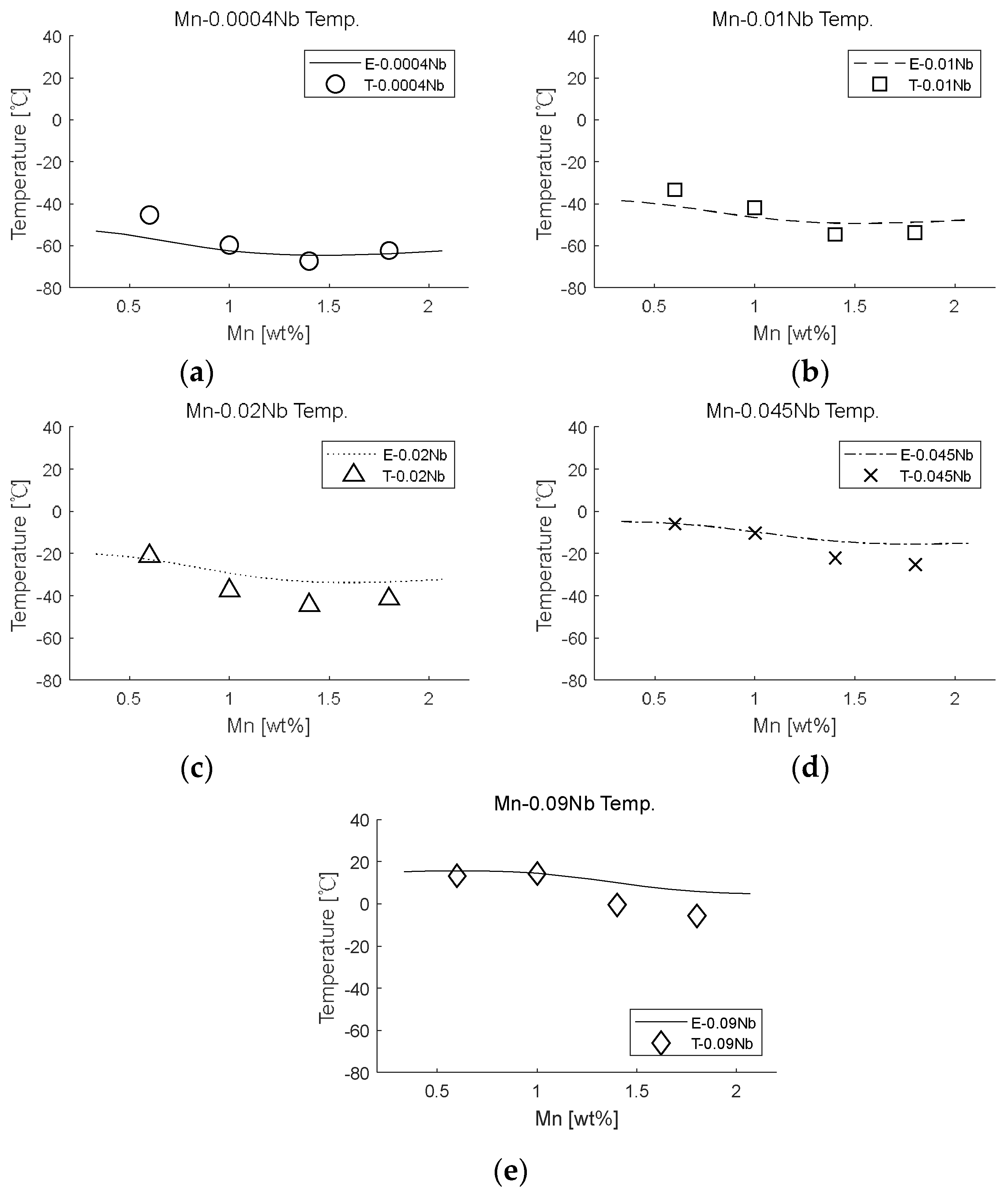

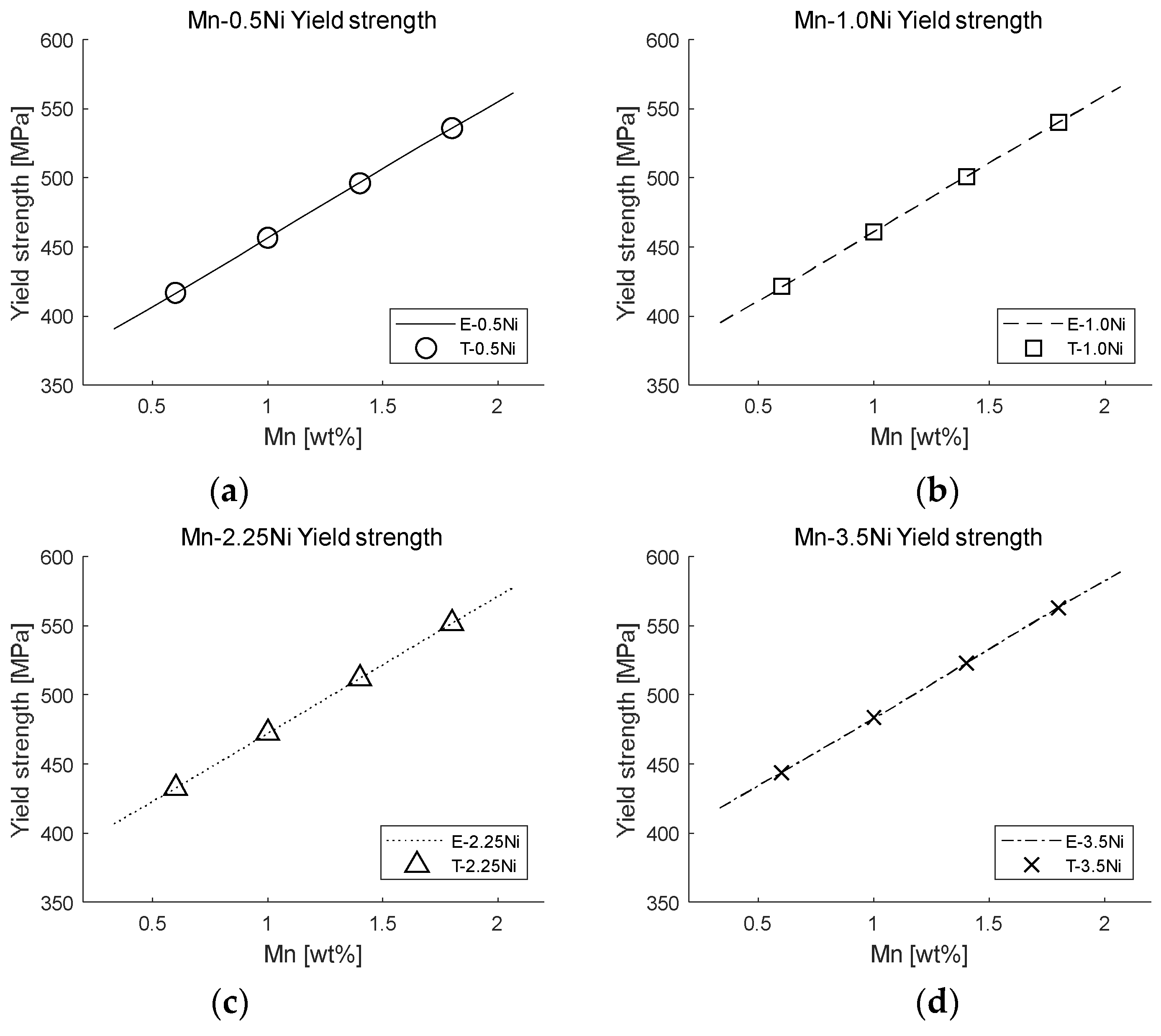

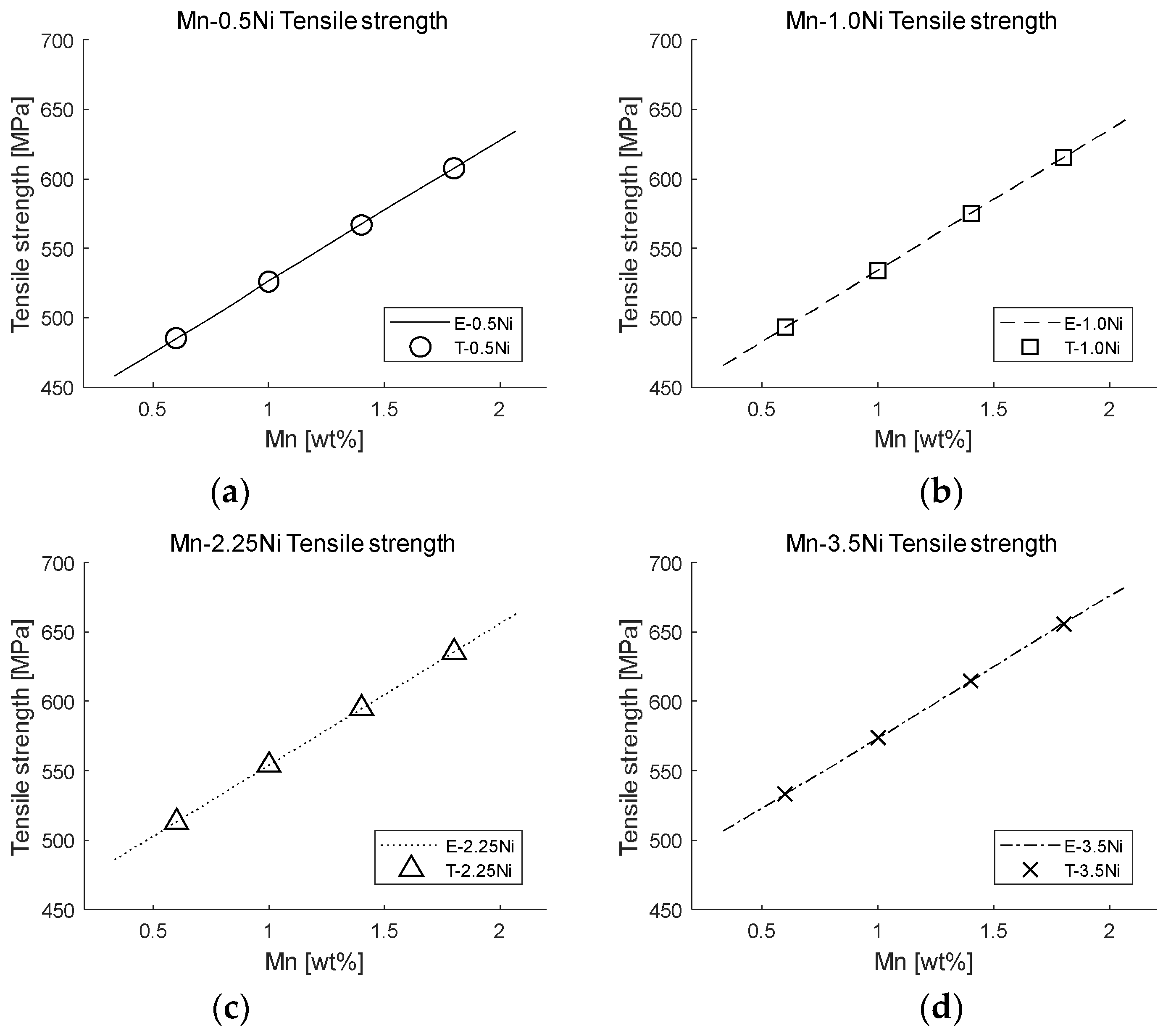

- By increasing the amount of data through data augmentation, the performance of the ANN model improved. Inaccurate regression that may occur due to the insufficient number of experimental results was prevented in advance, and efficient ANN model training was made. However, some cases of CVN temperature showed an estimation error owing to the large nonlinearity in the data used for the ANN training. Because each condition has a different tendency, accurate regression could not be made in this case with relatively large nonlinearity. For a better predictive model, securing more experimental results is essential. In contrast, the yield and tensile strengths showed high accuracy, as the data showed a linear relationship.

- The developed ANN models are presented in the form of vectors and matrices. Therefore, the three mechanical properties considered as targets in this study were calculated by inputting the content of each component through a simple matrix operation.

- However, because each ANN model developed in this study only considered changes in the content of two elements, there is a limitation in that an accurate prediction cannot be performed if any element with a content different from that of the specimen used for the ANN model is included. That is, the results of this study can be mainly used to predict the relative increase or decrease according to the change in the content of two elements, including Mn.

- Further studies are recommended to develop an ANN model based on data collected in a variety of ranges, including other factors. It will then be possible to efficiently estimate the exact mechanical properties with respect to the contents of chemical compositions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Evans, G.M.; Bailey, N. Metallurgy of Basic Weld Metal; Woodhead publishing: Sawston, UK, 1997. [Google Scholar]

- Fleck, N.A.; Grong, Ö.; Edwards, G.R.; Matlock, D.K. The role of filler metal wire and flux composition in submerged arc weld metal transformation kinetics. Weld. J. 1986, 65, 1135–1215. [Google Scholar]

- Shin, Y.T.; Kang, S.W.; Lee, H.W. Fracture characteristics of TMCP and QT steel weldments with respect to crack length. Mater. Sci. Eng. A 2006, 434, 365–371. [Google Scholar] [CrossRef]

- Glover, A.G.; McGrath, J.T.; Tinkler, M.J.; Weatherly, G.C. The influence of cooling rate and composition on weld meta microstructures in a C/Mn and a HSLA steel. Simulation 1977, 60, 80. [Google Scholar]

- Smith, N.J.; McGrath, J.T.; Gianetto, J.A.; Orr, R.F. Microstructure/mechanical property relationships of submerged arc welds in HSLA 80 steel. Weld. J. 1989, 68, 11. [Google Scholar]

- McGrath, J.T.; Gianetto, J.A.; Orr, R.F.; Letts, M.W. Factors Affecting the Notch Toughness Properties of High Strength HY80 Weldments. Can. Metall. Q. 1986, 25, 349–356. [Google Scholar] [CrossRef]

- Shao, L.; Ketkaew, J.; Gong, P.; Zhao, S.; Sohn, S.; Bordeenithikasem, P.; Datye, A.; Mota, R.M.O.; Liu, N.; Kube, S.A.; et al. Effect of chemical composition on the fracture toughness of bulk metallic glasses. Materialia 2020, 12, 100828. [Google Scholar] [CrossRef]

- Balaguru, V.; Balasubramanian, V.; Sivakumar, P. Effect of weld metal composition on impact toughness properties of shielded metal arc welded ultra-high hard armor steel joints. J. Mech. Behav. Mater. 2020, 29, 186–194. [Google Scholar] [CrossRef]

- Takashima, Y.; Minami, F. Prediction of Charpy absorbed energy of steel for welded structure in ductile-to-brittle fracture transition temperature range. Q. J. Jpn. Weld. Soc. 2020, 38, 103s–107s. [Google Scholar] [CrossRef]

- Jorge, J.C.F.; Souza, L.; Mendes, M.C.; Bott, I.S.; Araújo, L.S.; Santos, V.; Rebello, J.M.A.; Evans, G.M. Microstructure characterization and its relationship with impact toughness of C–Mn and high strength low alloy steel weld metals—A review. J. Mater. Res. Technol. 2021, 10, 471–501. [Google Scholar] [CrossRef]

- Khalaj, G.; Pouraliakbar, H.; Mamaghani, K.R.; Khalaj, M.J. Modeling the correlation between heat treatment, chemical composition and bainite fraction of pipeline steels by means of artificial neural networks. Neural Netw. World 2013, 23, 351. [Google Scholar] [CrossRef] [Green Version]

- Khalaj, G.; Nazari, A.; Pouraliakbar, H. Prediction of martensite fraction of microalloyed steel by artificial neural networks. Neural Netw. World 2013, 23, 117. [Google Scholar] [CrossRef] [Green Version]

- Pak, J.; Jang, J.; Bhadeshia, H.K.D.H.; Karlsson, L. Optimization of neural network for Charpy toughness of steel welds. Mater. Manuf. Process. 2008, 24, 16–21. [Google Scholar] [CrossRef]

- Jung, I.D.; Shin, D.S.; Kim, D.; Lee, J.; Lee, M.S.; Son, H.J.; Reddy, N.S.; Kim, M.; Moon, S.K.; Kim, K.T.; et al. Artificial intelligence for the prediction of tensile properties by using microstructural parameters in high strength steels. Materialia 2020, 11, 100699. [Google Scholar] [CrossRef]

- He, S.H.; He, B.B.; Zhu, K.Y.; Huang, M.X. On the correlation among dislocation density, lath thickness and yield stress of bainite. Acta Mater. 2017, 135, 382–389. [Google Scholar] [CrossRef]

- ISO 2560-2020; Covered Electrodes for Manual Metal Arc Welding of Non-Alloy and Fine Grain Steels—Classification. ISO: Geneva, Switzerland, 2020.

- Chao, Y.J.; Ward, J.D., Jr.; Sands, R.G. Charpy impact energy, fracture toughness and ductile–brittle transition temperature of dual-phase 590 Steel. Mater. Des. 2007, 28, 551–557. [Google Scholar] [CrossRef]

- Kim, J.H.; Kim, Y.; Lu, W. Prediction of ice resistance for ice-going ships in level ice using artificial neural network technique. Ocean Eng. 2020, 217, 108031. [Google Scholar] [CrossRef]

| Mn | C | Si | Cr | Ni | Mo | O | V | Nb |

|---|---|---|---|---|---|---|---|---|

| 0.6 | 0.04 | 0.20 | 0.25 | 0.50 | 0.0 | 0.03 | 0.0004 | 0.0004 |

| 0.06 | 0.40 | 0.50 | 1.0 | 0.25 | 0.037 | 0.02 | 0.01 | |

| 0.10 | 0.60 | 1.0 | 2.25 | 0.50 | 0.045 | 0.04 | 0.02 | |

| 0.15 | 0.90 | 2.3 | 3.5 | 1.1 | - | 0.06 | 0.045 | |

| - | - | - | - | - | - | 0.08 | 0.09 | |

| 1.0 | 0.04 | 0.20 | 0.25 | 0.50 | 0.0 | 0.03 | 0.0004 | 0.0004 |

| 0.06 | 0.40 | 0.50 | 1.0 | 0.25 | 0.037 | 0.02 | 0.01 | |

| 0.10 | 0.60 | 1.0 | 2.25 | 0.50 | 0.045 | 0.04 | 0.02 | |

| 0.15 | 0.90 | 2.3 | 3.5 | 1.1 | - | 0.06 | 0.045 | |

| - | - | - | - | - | - | 0.08 | 0.09 | |

| 0.04 | 0.20 | 0.25 | 0.50 | 0.0 | 0.03 | 0.0004 | 0.0004 | |

| 0.06 | 0.40 | 0.50 | 1.0 | 0.25 | 0.037 | 0.02 | 0.01 | |

| 1.4 | 0.10 | 0.60 | 1.0 | 2.25 | 0.50 | 0.045 | 0.04 | 0.02 |

| 0.15 | 0.90 | 2.3 | 3.5 | 1.1 | - | 0.06 | 0.045 | |

| - | - | - | - | - | - | 0.08 | 0.09 | |

| 0.04 | 0.20 | 0.25 | 0.50 | 0.0 | 0.03 | 0.0004 | 0.0004 | |

| 0.06 | 0.40 | 0.50 | 1.0 | 0.25 | 0.037 | 0.02 | 0.01 | |

| 1.8 | 0.10 | 0.60 | 1.0 | 2.25 | 0.50 | 0.045 | 0.04 | 0.02 |

| 0.15 | 0.90 | 2.3 | 3.5 | 1.1 | - | 0.06 | 0.045 | |

| - | - | - | - | - | - | 0.08 | 0.09 |

| C | Si | Cr | Ni | Mo | O | V | Nb | S | P | N | Cu | Ti | Al | B | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mn–C | - | 0.30 | 0.03 | 0.03 | 0.005 | 0.049 | 0.012 | 0.002 | 0.006 | 0.013 | 0.007 | 0.03 | 0.0055 | 0.0005 | 0.0002 |

| Mn–Si | 0.066 | - | 0.03 | 0.03 | 0.005 | 0.04 | 0.012 | 0.002 | 0.006 | 0.013 | 0.006 | 0.03 | 0.0055 | 0.0005 | 0.0002 |

| Mn–Cr | 0.046 | 0.32 | - | 0.03 | 0.005 | 0.04 | 0.012 | 0.002 | 0.006 | 0.013 | 0.006 | 0.03 | 0.0055 | 0.0005 | 0.0002 |

| Mn–Ni | 0.045 | 0.32 | 0.03 | - | 0.005 | 0.04 | 0.012 | 0.002 | 0.006 | 0.013 | 0.006 | 0.03 | 0.0055 | 0.0005 | 0.0002 |

| Mn–Mo | 0.043 | 0.33 | 0.03 | 0.03 | - | 0.04 | 0.012 | 0.002 | 0.006 | 0.013 | 0.006 | 0.03 | 0.0055 | 0.0005 | 0.0002 |

| Mn–O | 0.078 | 0.32 | 0.03 | 0.03 | 0.005 | - | 0.012 | 0.002 | 0.006 | 0.008 | 0.007 | 0.03 | 0.0005 | 0.0005 | 0.0002 |

| Mn–V | 0.076 | 0.31 | 0.03 | 0.03 | 0.005 | 0.042 | - | 0.0006 | 0.007 | 0.006 | 0.008 | 0.03 | 0.0032 | 0.0005 | 0.0002 |

| Mn–Nb | 0.076 | 0.32 | 0.03 | 0.03 | 0.005 | 0.042 | 0.0007 | - | 0.007 | 0.006 | 0.009 | 0.03 | 0.0036 | 0.0005 | 0.0002 |

| Mn–C | Mn–Si | Mn–Cr | Mn–Ni | Mn–Mo | Mn–O | Mn–V | Mn–Nb |

|---|---|---|---|---|---|---|---|

| 0.98959 | 0.98922 | 0.99215 | 0.99525 | 0.98821 | 0.99358 | 0.99334 | 0.99430 |

| Min. Value | Max. Value | Unit | ||

|---|---|---|---|---|

| Mn | 0.6 | 1.8 | wt% | |

| C | 0.04 | 0.15 | wt% | |

| Si | 0.2 | 0.9 | wt% | |

| Cr | 0.25 | 2.3 | wt% | |

| Ni | 0.5 | 3.5 | wt% | |

| Mo | 0 | 1.1 | wt% | |

| O | 0.03 | 0.045 | wt% | |

| V | 0.0004 | 0.08 | wt% | |

| Nb | 0.0004 | 0.09 | wt% | |

| Mn–C | Temp. | −64.91 | −16.29 | °C |

| YS | 389 | 626 | MPa | |

| TS | 435 | 711.67 | MPa | |

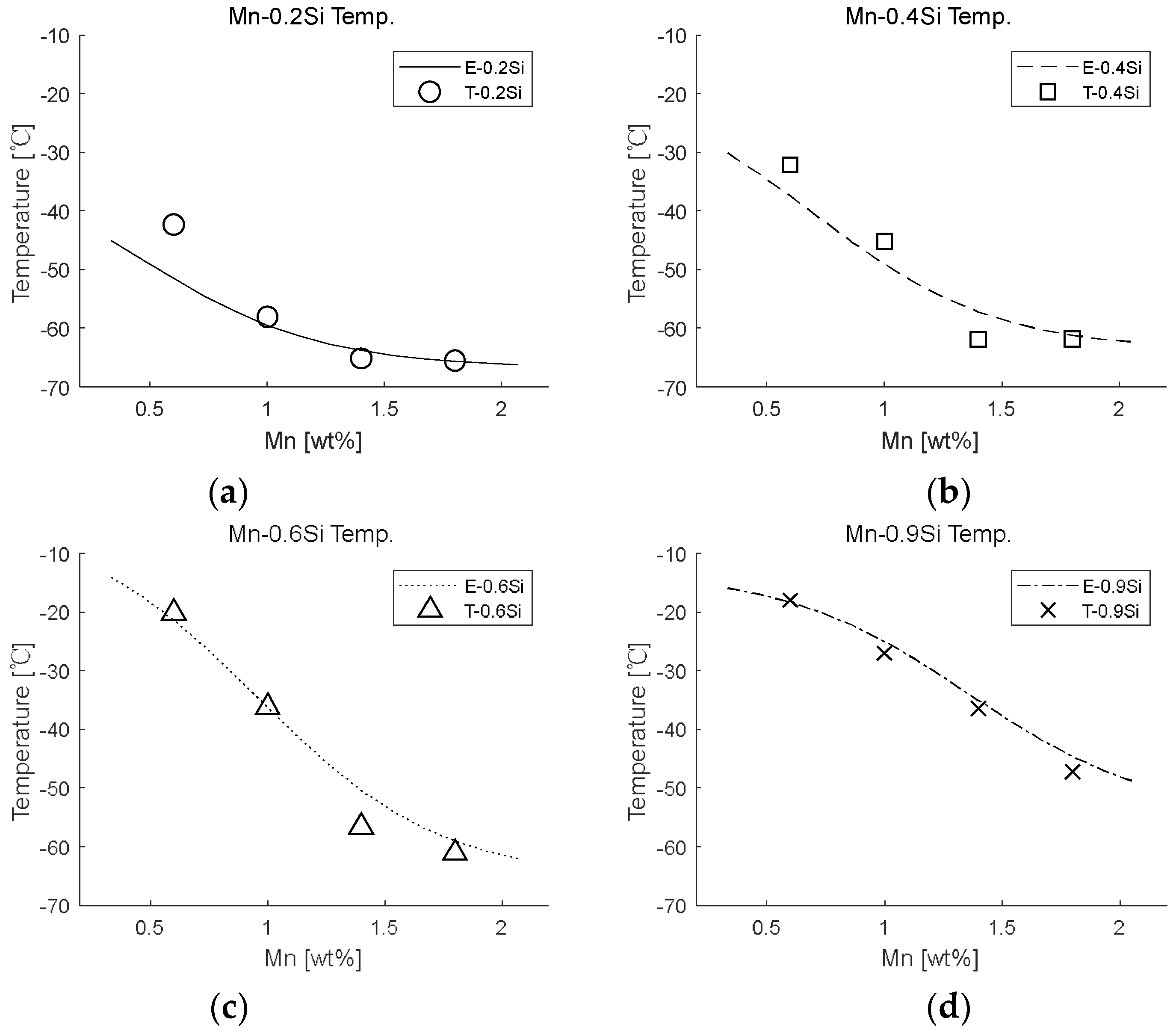

| Mn–Si | Temp. | −66.25 | −2.56 | °C |

| YS | 364 | 587 | MPa | |

| TS | 427 | 665 | MPa | |

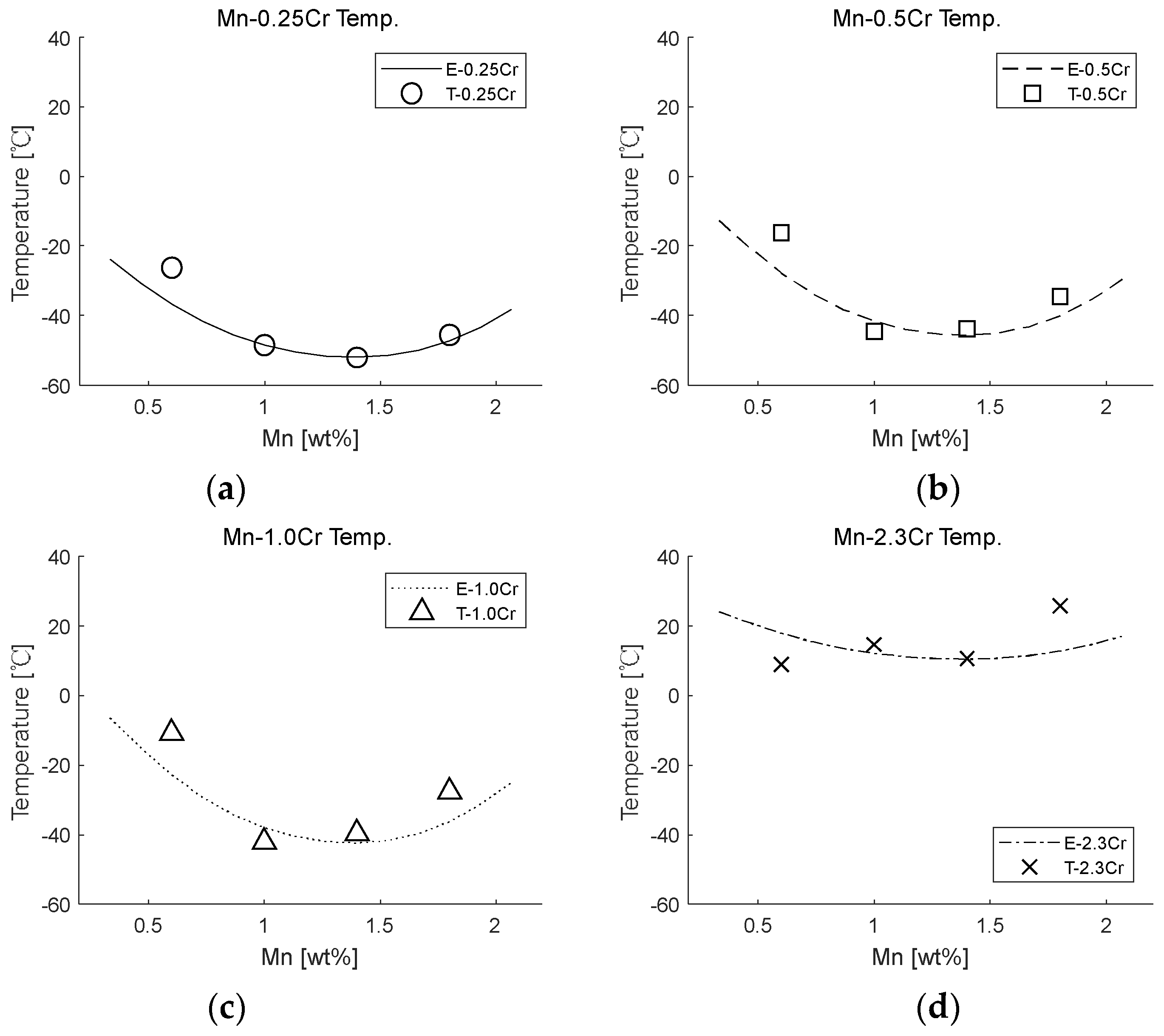

| Mn–Cr | Temp. | −53.31 | 33.19 | °C |

| YS | 416 | 743 | MPa | |

| TS | 482 | 797 | MPa | |

| Mn–Ni | Temp. | −62.62 | 69.39 | °C |

| YS | 391 | 589 | MPa | |

| TS | 458 | 683 | MPa | |

| Mn–Mo | Temp. | −54.93 | 16.16 | °C |

| YS | 372 | 736 | MPa | |

| TS | 430 | 796 | MPa | |

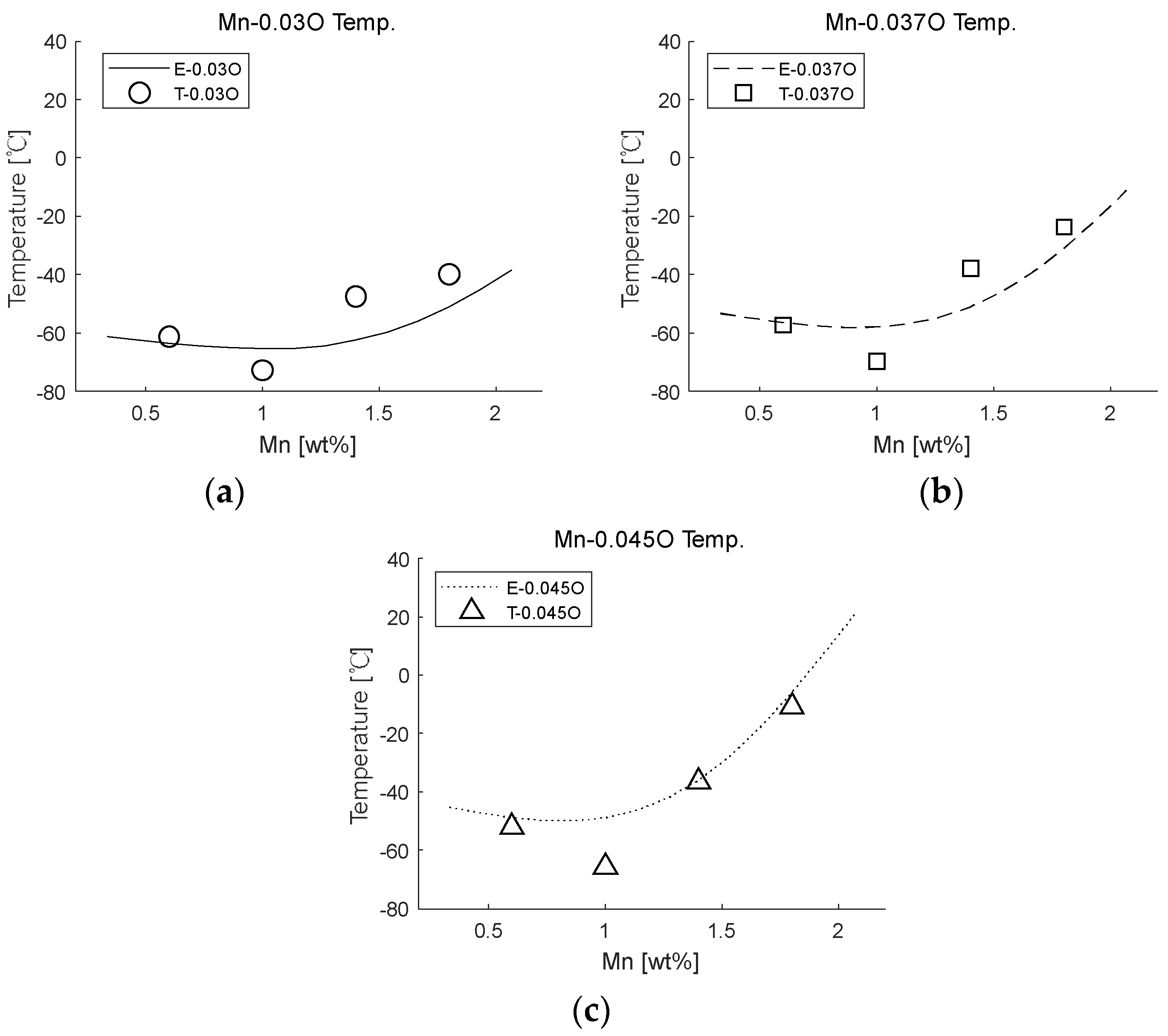

| Mn–O | Temp. | −65.47 | 25.86 | °C |

| YS | 378 | 468 | MPa | |

| TS | 467 | 560 | MPa | |

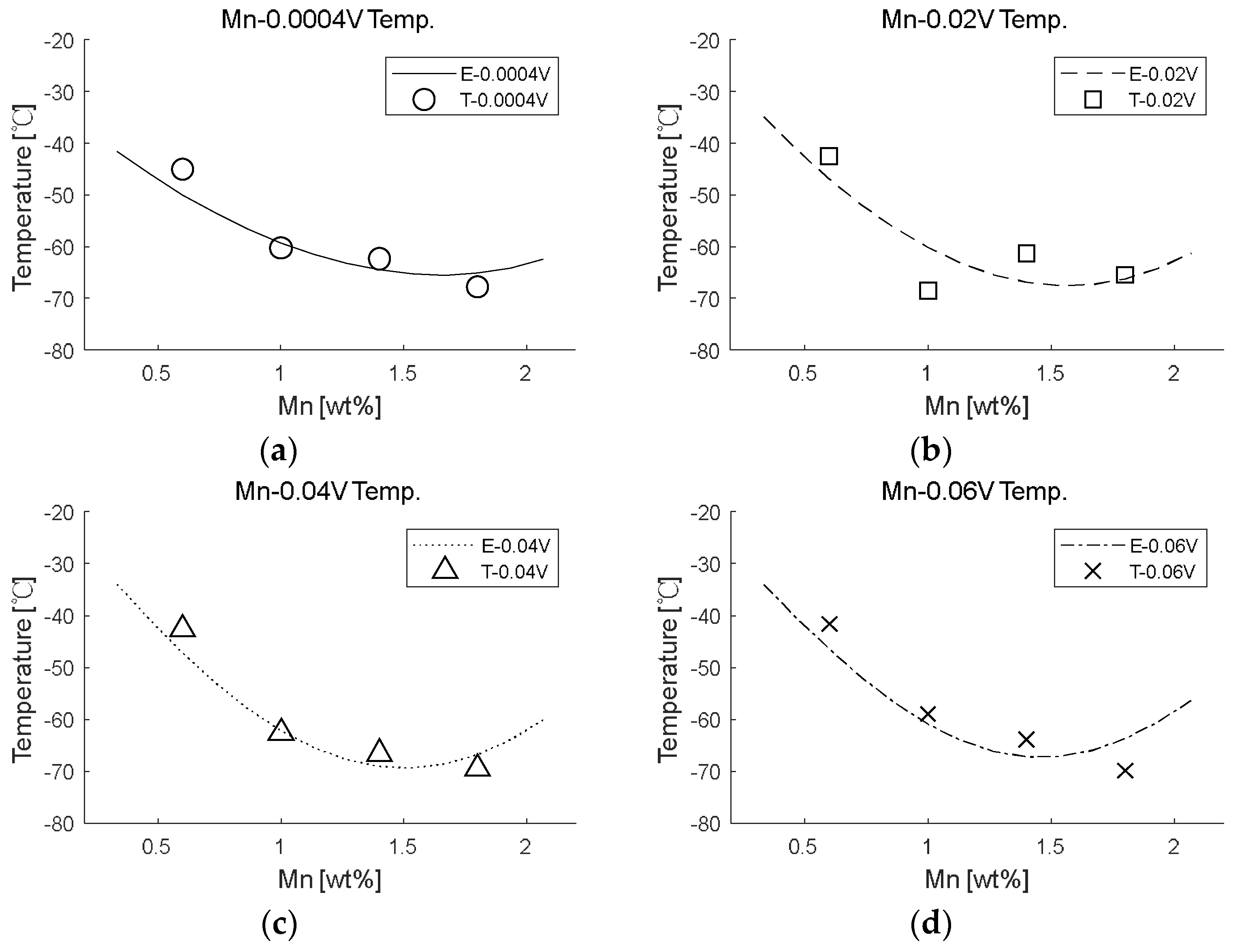

| Mn–V | Temp. | −69.74 | −21.27 | °C |

| YS | 366 | 648 | MPa | |

| TS | 459 | 685 | MPa | |

| Mn–Nb | Temp. | −66.45 | 15.50 | °C |

| YS | 384 | 682 | MPa | |

| TS | 475 | 729 | MPa | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.-H.; Jung, C.-J.; Park, Y.I.; Shin, Y.-T. Development of Closed-Form Equations for Estimating Mechanical Properties of Weld Metals according to Chemical Composition. Metals 2022, 12, 528. https://doi.org/10.3390/met12030528

Kim J-H, Jung C-J, Park YI, Shin Y-T. Development of Closed-Form Equations for Estimating Mechanical Properties of Weld Metals according to Chemical Composition. Metals. 2022; 12(3):528. https://doi.org/10.3390/met12030528

Chicago/Turabian StyleKim, Jeong-Hwan, Chang-Ju Jung, Young IL Park, and Yong-Taek Shin. 2022. "Development of Closed-Form Equations for Estimating Mechanical Properties of Weld Metals according to Chemical Composition" Metals 12, no. 3: 528. https://doi.org/10.3390/met12030528

APA StyleKim, J.-H., Jung, C.-J., Park, Y. I., & Shin, Y.-T. (2022). Development of Closed-Form Equations for Estimating Mechanical Properties of Weld Metals according to Chemical Composition. Metals, 12(3), 528. https://doi.org/10.3390/met12030528